Tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel and production method thereof

A technology of hot-rolled dual-phase steel and tensile strength, applied in the field of hot-rolled dual-phase steel with a tensile strength ≥ 780MPa and its production field, can solve problems that have not yet been involved in the production method of dual-phase steel, and achieve the prevention of pearlite phase transformation, The effect of high production efficiency and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below:

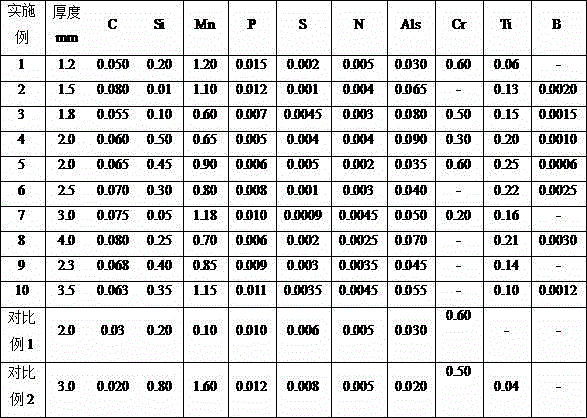

[0037] Table 1 is the value list of each embodiment of the present invention and comparative example;

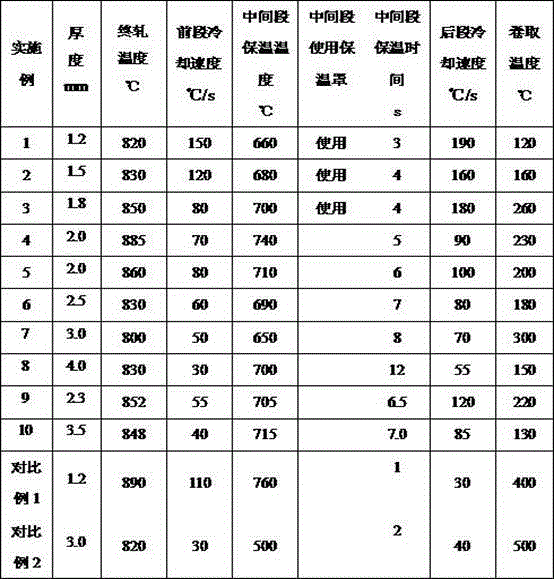

[0038] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0039] Table 3 is a list of performance monitoring conditions of each embodiment of the present invention and comparative examples.

[0040] Each embodiment of the present invention is produced according to the following steps with CSP:

[0041] 1) Smelting and continuous casting into billets: during this period, the molten steel is subjected to RH vacuum treatment;

[0042] 2) Heating the continuous casting slab: control the temperature of the casting slab into the furnace at 850~1050°C, and the temperature of the casting slab at 1100°C to 1250°C; the time of the casting slab in the furnace is 10~40 minutes;

[0043] 3) Carry out rolling, and control the final rolling temperature at 800~890°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com