Ultra-low carbon hot rolling weathering steel with yield strength larger than 550MPa

A yield strength, ultra-low carbon technology, applied in the field of low carbon and low alloy steel manufacturing, can solve the problems of not meeting the development needs of the weathering steel market, poor cold brittleness resistance, unfavorable welding performance, etc., to reduce the formation of carbide structures, The effect of improving welding performance and increasing phase deformation nucleus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

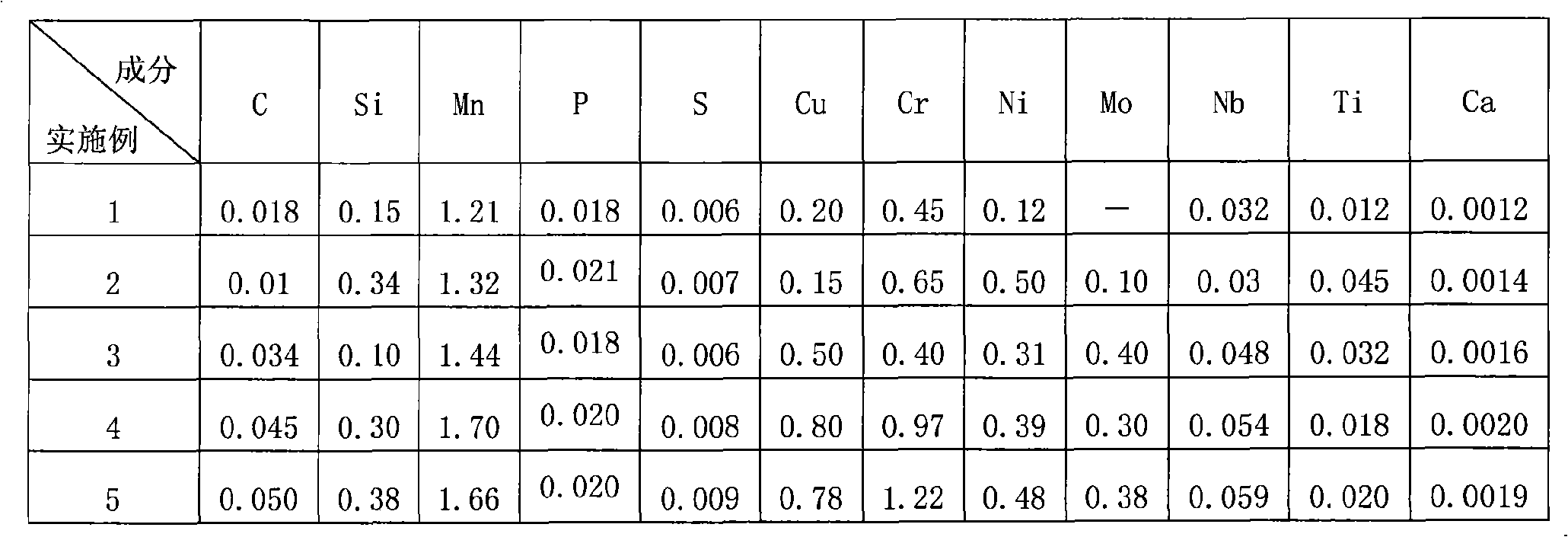

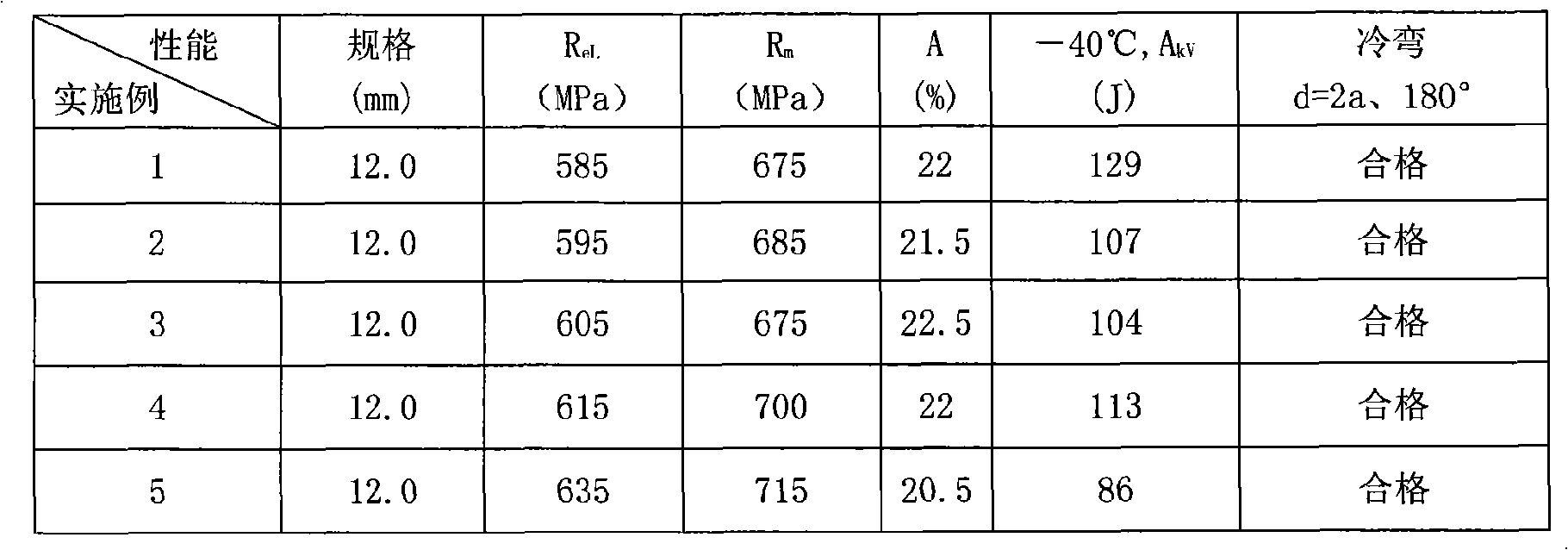

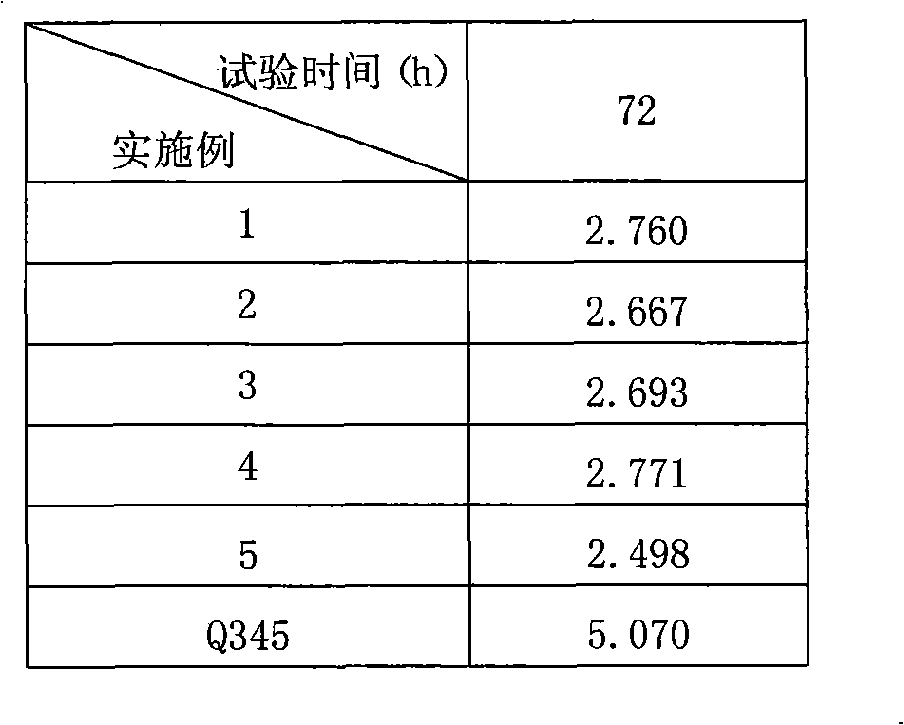

[0029] According to the above production process, steel 1 was produced, wherein the chemical composition of steel 1 is shown in 1 in Table 1, the mechanical properties of steel 1 are shown in 1 in Table 2, and the atmospheric corrosion resistance results of steel 1 are shown in 1 in Table 3.

Embodiment 2

[0031] According to the above production process, steel 2 is produced, wherein the chemical composition of steel 2 is shown in 2 in Table 1, the mechanical properties of steel 2 are shown in 2 in Table 2, and the atmospheric corrosion resistance results of steel 2 are shown in 2 in Table 3.

Embodiment 3

[0033] According to the above production process, steel 3 is produced, wherein the chemical composition of steel 3 is shown in 3 in Table 1, the mechanical properties of steel 3 are shown in 3 in Table 2, and the atmospheric corrosion resistance results of steel 3 are shown in 3 in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com