Production method of low-temperature steel plate capable of being welded by high heat input

A large heat input welding and production method technology, applied in the direction of improving process efficiency, etc., can solve the problems of deterioration of toughness, lack of research on the order and influence of alloy addition, and achieve the effect of improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

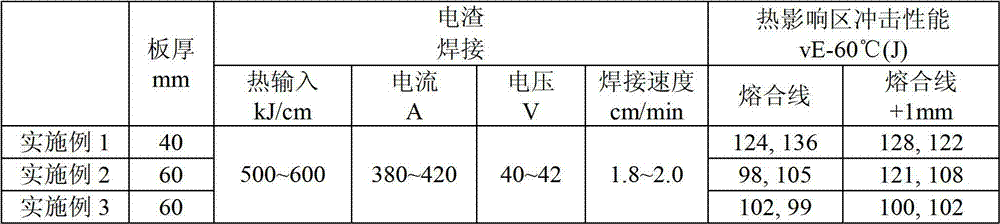

Embodiment 1

[0022] The molten steel smelting process is as follows:

[0023] Hot metal pretreatment→180t combined blowing converter smelting→LF refining→RH refining→wire feeding→continuous casting. During the converter smelting process, the ratio of the amount of molten iron for furnace charging to clean steel scrap is 7.5, the temperature of molten iron is 1400°C, S≤0.003% by weight, the basicity of slag is 3.5, and the ratio of MgO is 9.0%; Ferromanganese, ferrosilicon, lime. White slag is produced during the LF refining process. At the same time, the molten steel is oxygenated, ferroboron is added, diffusion deoxidized, and molten steel samples are taken for composition fine-tuning. In the RH vacuum treatment stage, measure oxygen and control the oxygen content at 10-100ppm before adding ferrotitanium. After the net circulation, the temperature of the molten steel is 1570-1600°C and the oxygen content is 20-80ppm. Feed 400 meters of magnesium alloy cored wire into the water, the diam...

Embodiment 2

[0031] The molten steel smelting process is as follows:

[0032]Hot metal pretreatment→180t combined blowing converter smelting→LF refining→RH refining→wire feeding→continuous casting. During the converter smelting process, the ratio of the amount of molten iron used for charging to clean steel scrap is 7, the temperature of molten iron is 1450°C, S≤0.003% by weight, the basicity of slag is 3.5, and the ratio of MgO is 9.0%; Ferromanganese, ferrosilicon, lime. During the LF refining process, white slag is produced, and ferroboron is added. At the same time, the molten steel is subjected to constant oxygen, diffusion deoxidation, and liquid steel samples are taken to fine-tune the composition. The tapping temperature is controlled at 1620-1640°C. In the stage of RH vacuum treatment, when the oxygen content of the molten steel meets the requirements of 10-100ppm, add ferrotitanium, and then measure the oxygen. Feed 350 meters of magnesium alloy cored wire with a diameter of 14...

Embodiment 3

[0040] The molten steel smelting process is as follows:

[0041] Hot metal pretreatment→180t combined blowing converter smelting→LF refining→RH refining→wire feeding→continuous casting. During the converter smelting process, the ratio of the amount of molten iron used for charging to clean steel scrap is 8, the temperature of the molten iron is 1430°C, S≤0.003% by weight, and the basicity of the slag is 3.5; ferromanganese and ferrosilicon are added sequentially when tapping about 35 tons of steel ,lime. White slag is produced during the LF refining process. At the same time, oxygen is fixed for molten steel, ferroboron is added, and the composition is fine-tuned. The tapping temperature is controlled at 1620-1640 °C. In the RH vacuum stage, when the oxygen content of the molten steel meets the requirements of 10-100ppm, add ferrotitanium, and then measure the oxygen. After the oxygen content of the molten steel meets 20-80ppm, feed it into the molten steel for 380 meters at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com