Production method for extra-thick ultrahigh-strength SX690DZ35 steel plate

A SX690DZ35, ultra-high-strength technology, applied in the field of thick plate production, can solve the problems of poor welding performance, poor Z-direction performance, restricting application, etc., to improve welding performance, ensure mechanical properties, and reduce the requirements of controlled cooling and heat treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

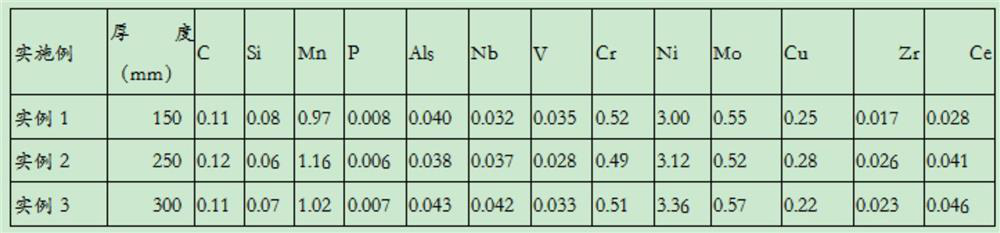

[0029] Through converter smelting, LF refining, VD vacuum degassing, die casting, ingot heating, rolling, controlled cooling, stack cooling, tempering and other processes, the 100mm-350mm extra-thick and ultra-high-strength SX690DZ35 with the chemical composition described in Table 1 below is obtained Steel plate, wherein the process parameters and mechanical properties are shown in Tables 1 and 2 below.

[0030] Table 1 is the chemical composition (Wt, %) of 100mm ~ 350mm extra-thick ultra-high strength SX690DZ35 steel plate

[0031]

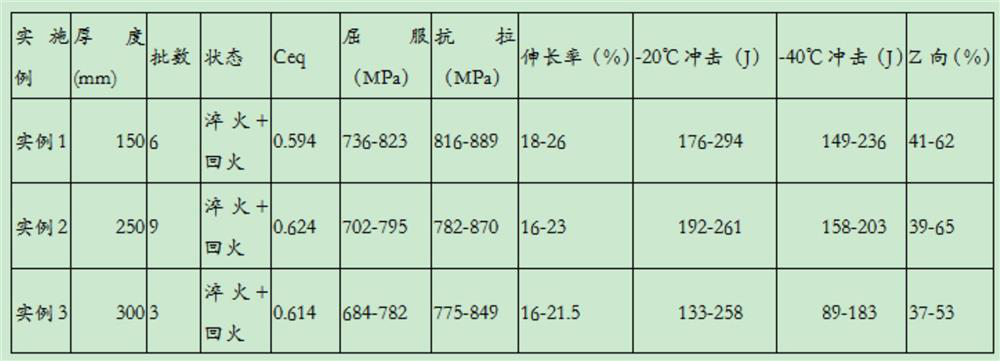

[0032] Table 2 shows the mechanical and mechanical properties of 100mm ~ 350mm extra-thick ultra-high strength SX690DZ35 steel plate

[0033]

[0034] This time, 6 batches, 9 batches and 3 batches of 150mm, 250mm, and 300mm ultra-thick ultra-high-strength SX690DZ35 steel plates were trial-produced respectively. Through reasonable chemical composition design and production process control, the yield strength of the steel plate was 684-823M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com