High-strength corrosion-resistant cold-resistant hot rolled steel coil as well as production method and application thereof

A technology of hot-rolled steel coils and production methods, applied in the field of hot-rolled steel coils, can solve problems such as cold resistance and corrosion resistance that cannot meet environmental requirements, and poor deformation performance of solar brackets, so as to avoid deformation, improve welding performance, and improve shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

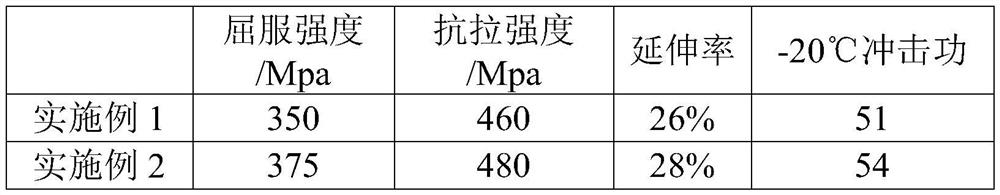

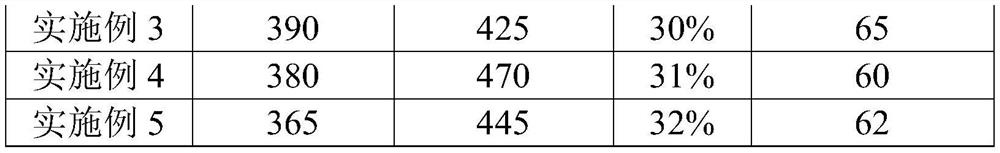

Examples

Embodiment 1

[0031] This embodiment provides a high-strength, corrosion-resistant and cold-resistant hot-rolled steel coil, which includes the following components in terms of weight percentage: C: 0.15%, Si: 0.1%, Mn: 0.025%, P: 0.020%, S: 0.010%, ALs: 0.02%, Ti: 0.025%, Cu: 0.1%, Cr: 0.3%, V: 0.01%, and the rest are iron and unavoidable impurities.

[0032] The production method of the above-mentioned high-strength corrosion-resistant and cold-resistant hot-rolled steel coil comprises the following steps:

[0033] 150-ton converter vanadium extraction, 150-ton converter smelting, LF refining, and continuous casting to obtain a slab with a thickness of 200mm;

[0034] Place the slab in a heating furnace for heating, the heating time is 120min, and the heating temperature is 1200°C;

[0035] After the slab is released from the heating furnace, it is descaled by high-pressure water with a pressure of 20MPa;

[0036] Then the above-mentioned slab is rolled through the rough rolling mill fo...

Embodiment 2

[0039] This embodiment provides a high-strength, corrosion-resistant and cold-resistant hot-rolled steel coil, which includes the following components in terms of weight percentage: C: 0.20%, Si: 0.08%, Mn: 0.055%, P: 0.018%, S: 0.008%, ALs: 0.06%, Ti: 0.050%, Cu: 0.2%, Cr: 0.6%, V: 0.03%, and the rest are iron and unavoidable impurities.

[0040] The production method of the above-mentioned high-strength corrosion-resistant and cold-resistant hot-rolled steel coil comprises the following steps:

[0041] 150-ton converter vanadium extraction, 150-ton converter smelting, LF refining, and continuous casting to obtain a slab with a thickness of 200mm;

[0042] Place the slab in a heating furnace for heating, the heating time is 200min, and the heating temperature is 1260°C;

[0043] After the slab is released from the heating furnace, it is descaled by high-pressure water with a pressure of 20MPa;

[0044] Then the above-mentioned slab is rolled through 5 passes of the rough ro...

Embodiment 3

[0047] This embodiment provides a high-strength corrosion-resistant and cold-resistant hot-rolled steel coil, which includes the following components in terms of weight percentage: C: 0.18%, Si: 0.05%, Mn: 0.040%, P: 0.015%, S: 0.007%, ALs: 0.05%, Ti: 0.040%, Cu: 0.2%, Cr: 0.5%, V: 0.02%, and the rest are iron and unavoidable impurities.

[0048] The production method of the above-mentioned high-strength corrosion-resistant and cold-resistant hot-rolled steel coil comprises the following steps:

[0049] 150-ton converter vanadium extraction, 150-ton converter smelting, LF refining, and continuous casting to obtain a slab with a thickness of 200mm;

[0050] Place the slab in a heating furnace for heating, the heating time is 130min, and the heating temperature is 1240°C;

[0051] After the slab is released from the heating furnace, it is descaled by high-pressure water with a pressure of 20MPa;

[0052] Then the above-mentioned slab is rolled through the rough rolling mill for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com