Patents

Literature

144results about How to "Avoid phase change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

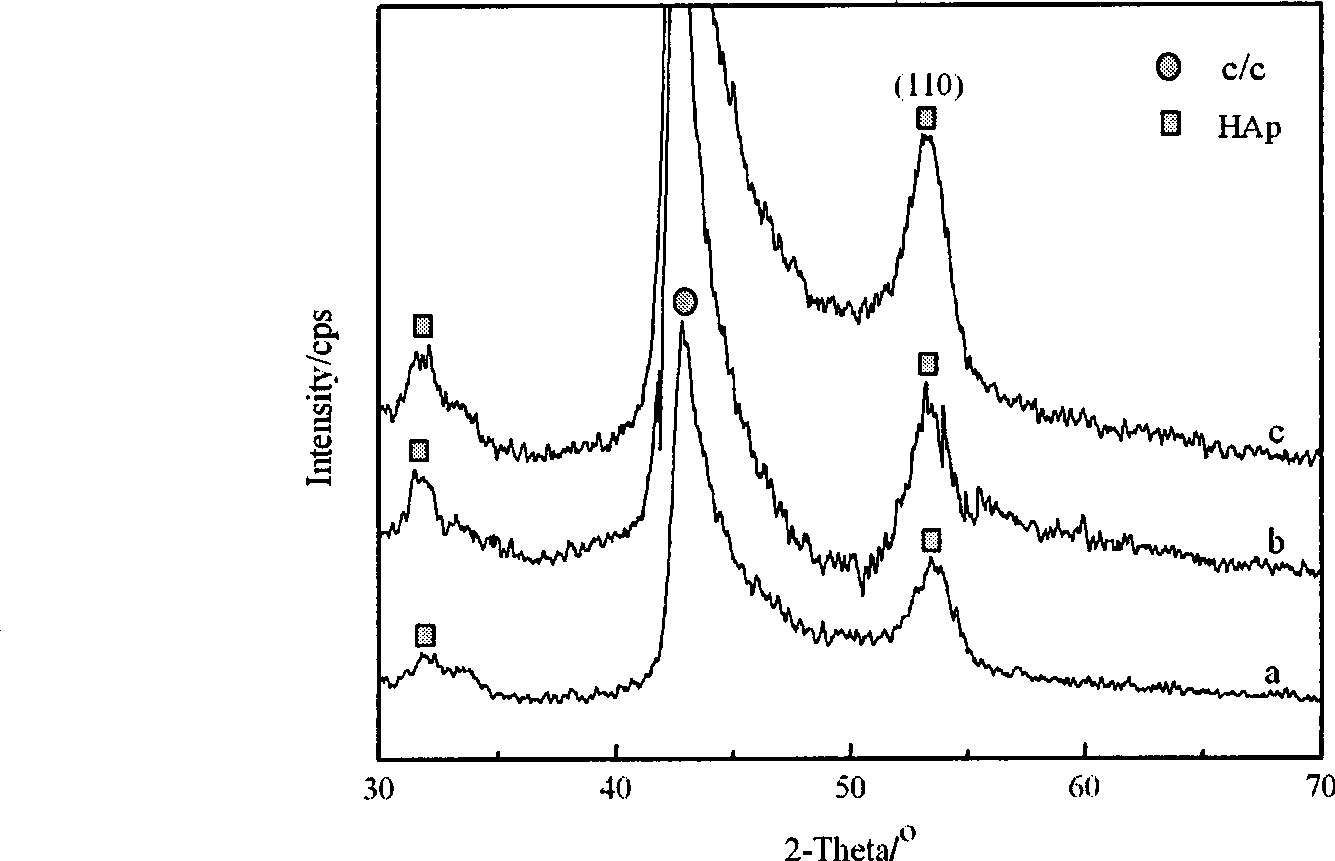

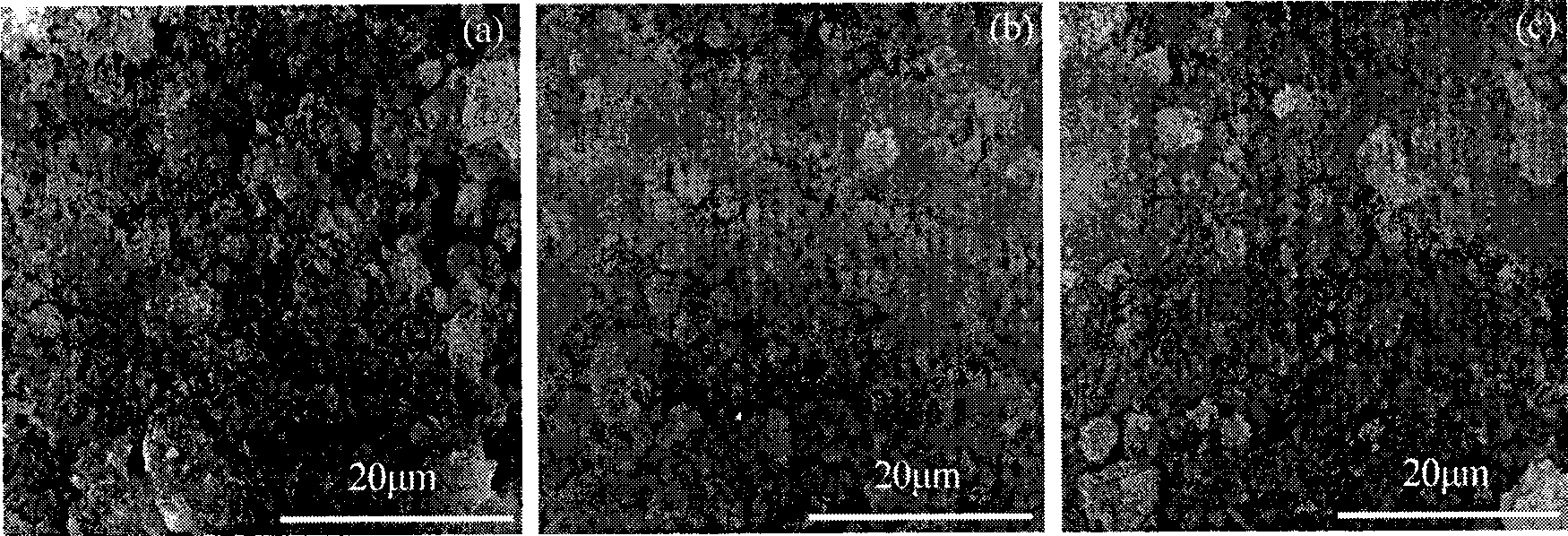

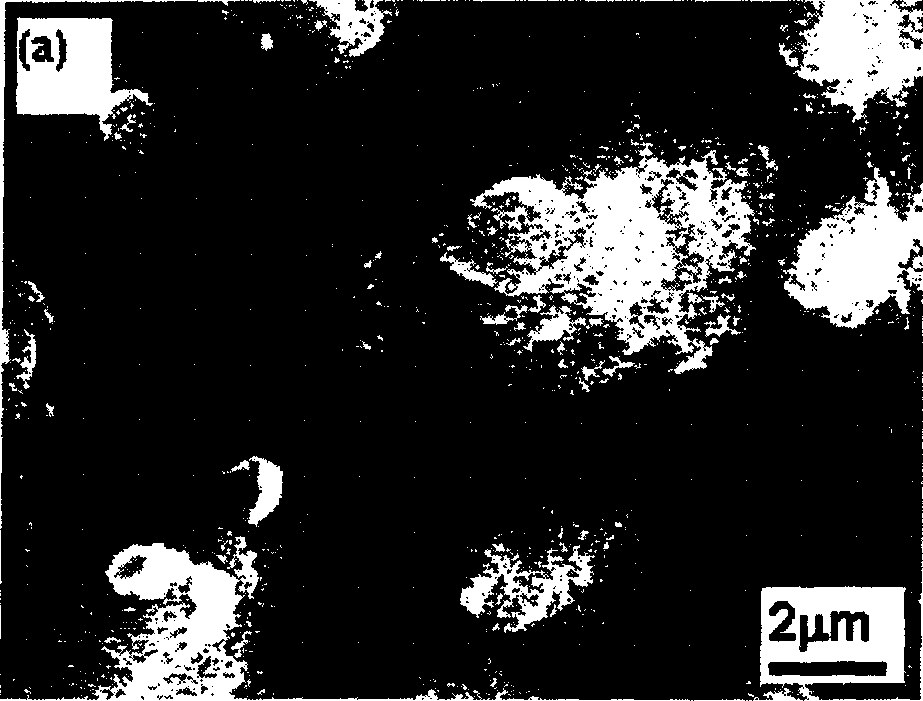

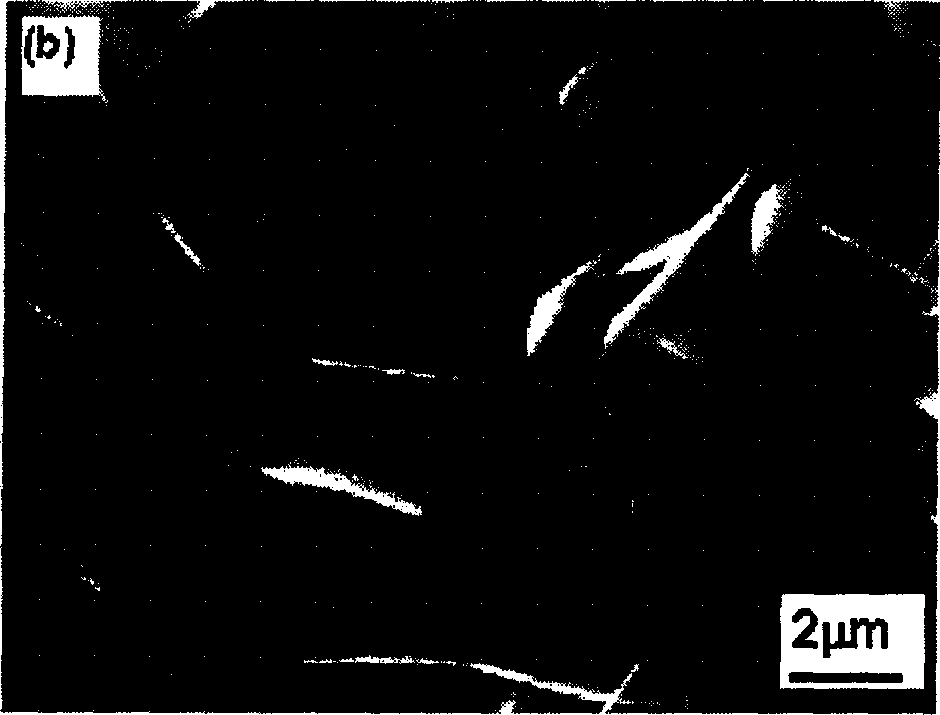

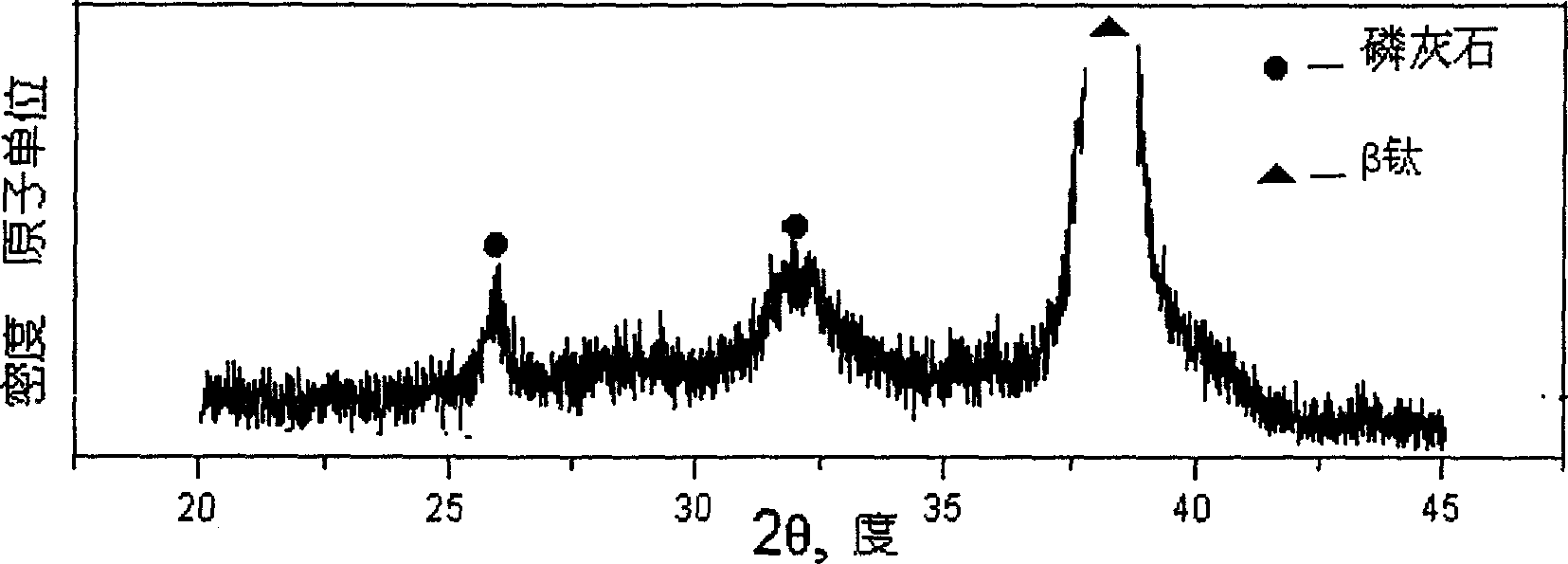

Preparation of nano-HAP coating/magnesium alloy composite biological material

InactiveCN101302638AHigh bonding strengthImprove biological activityElectrolytic inorganic material coatingProsthesisMagnesium phosphateBiocompatibility Testing

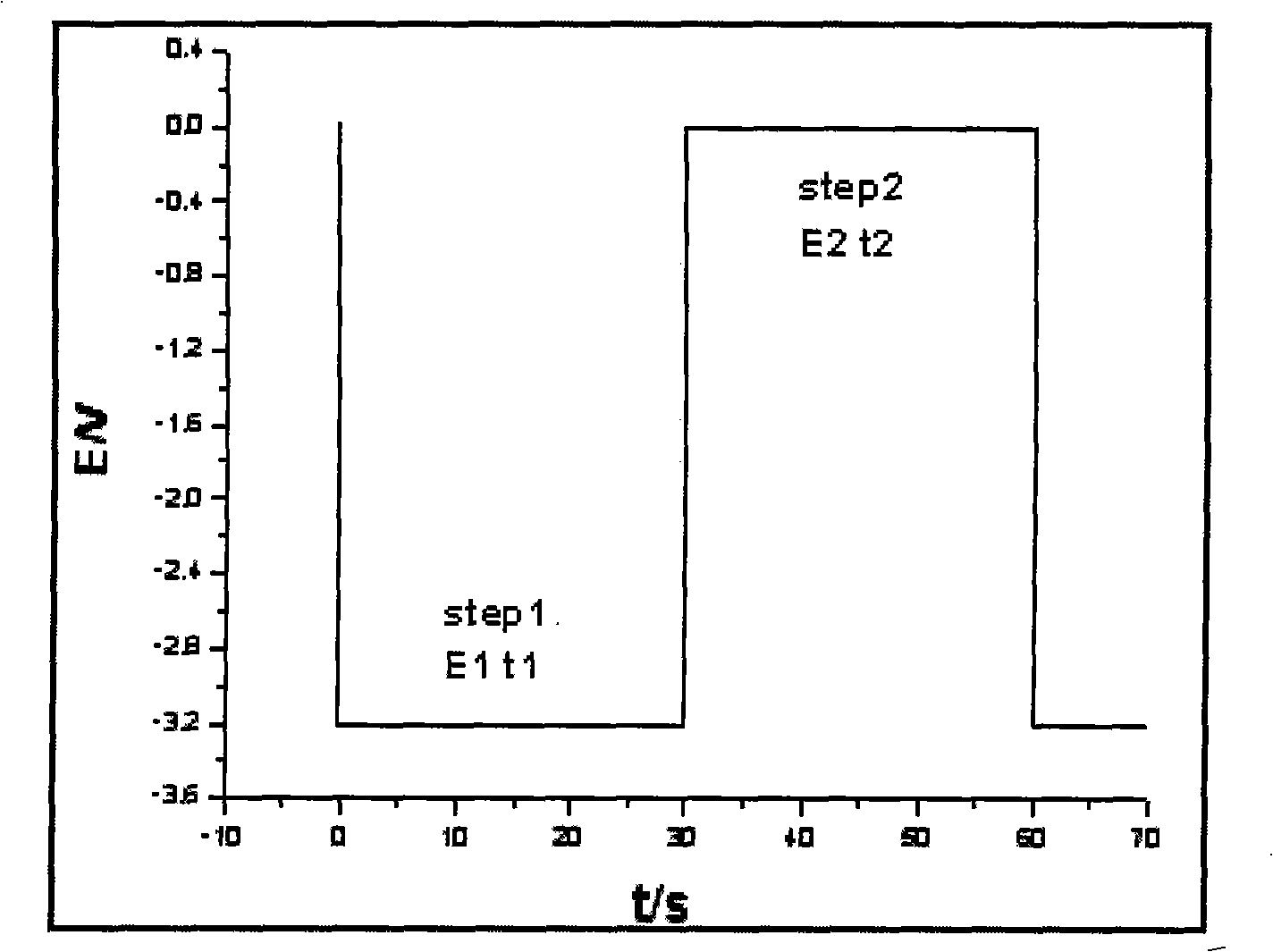

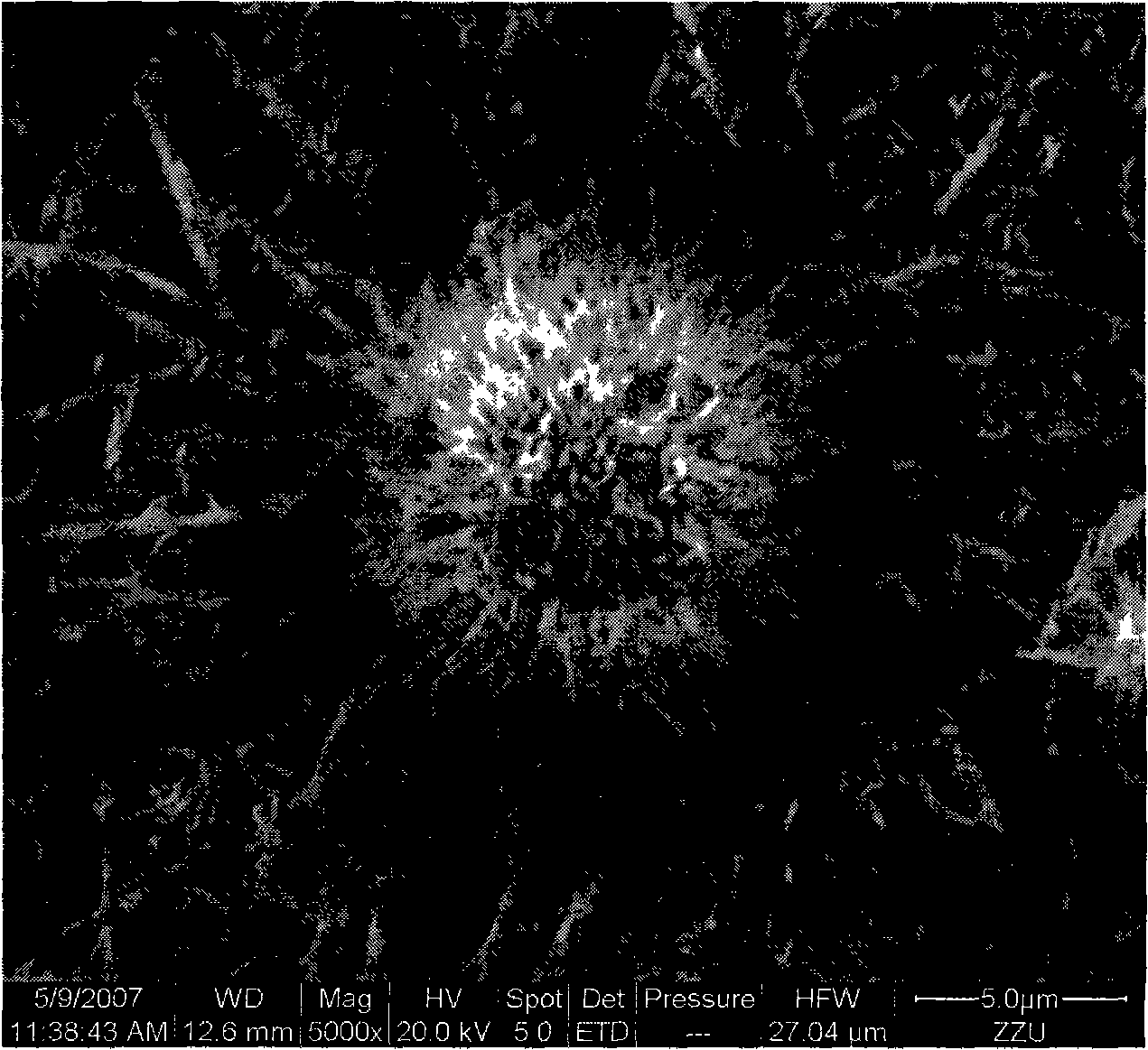

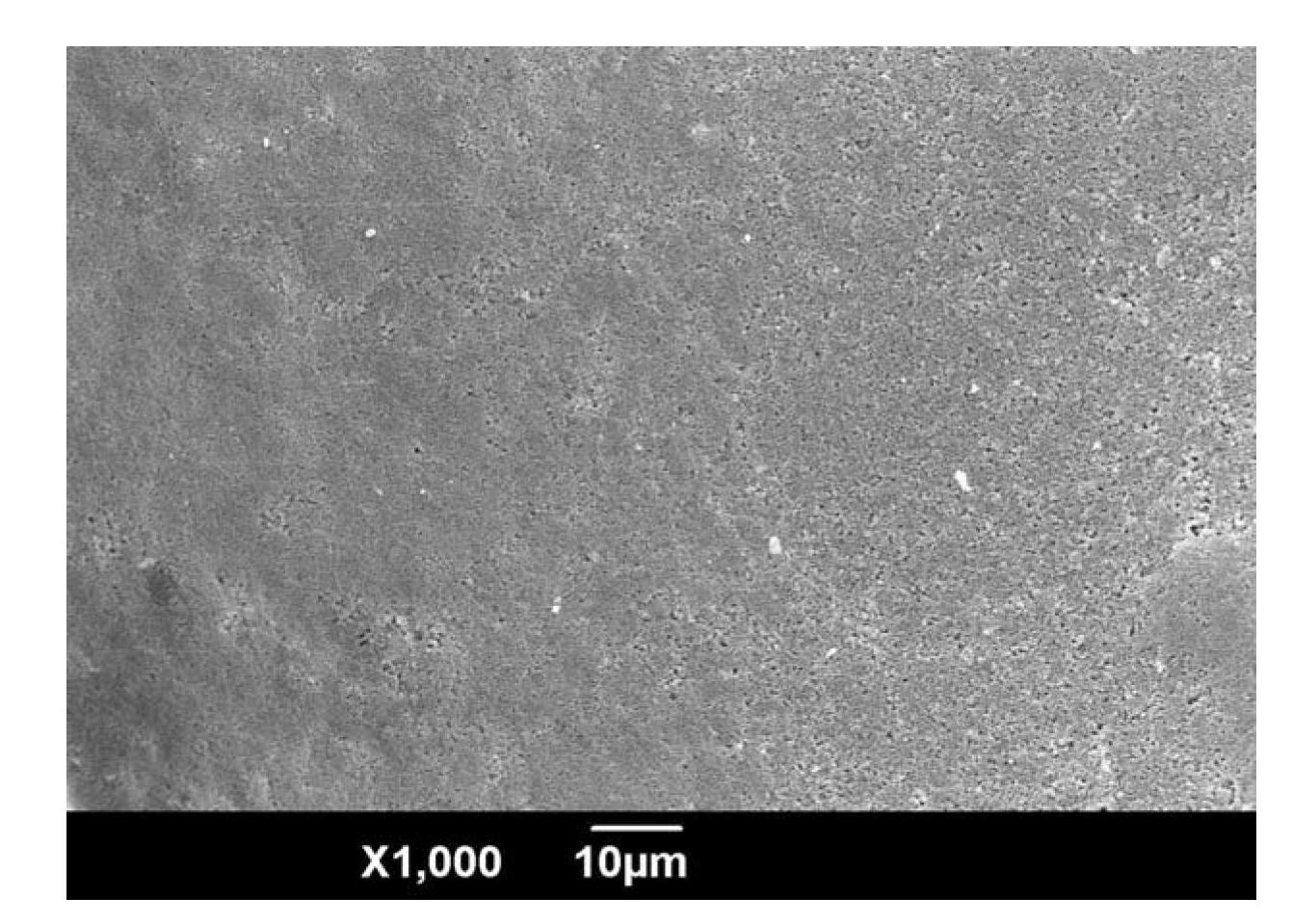

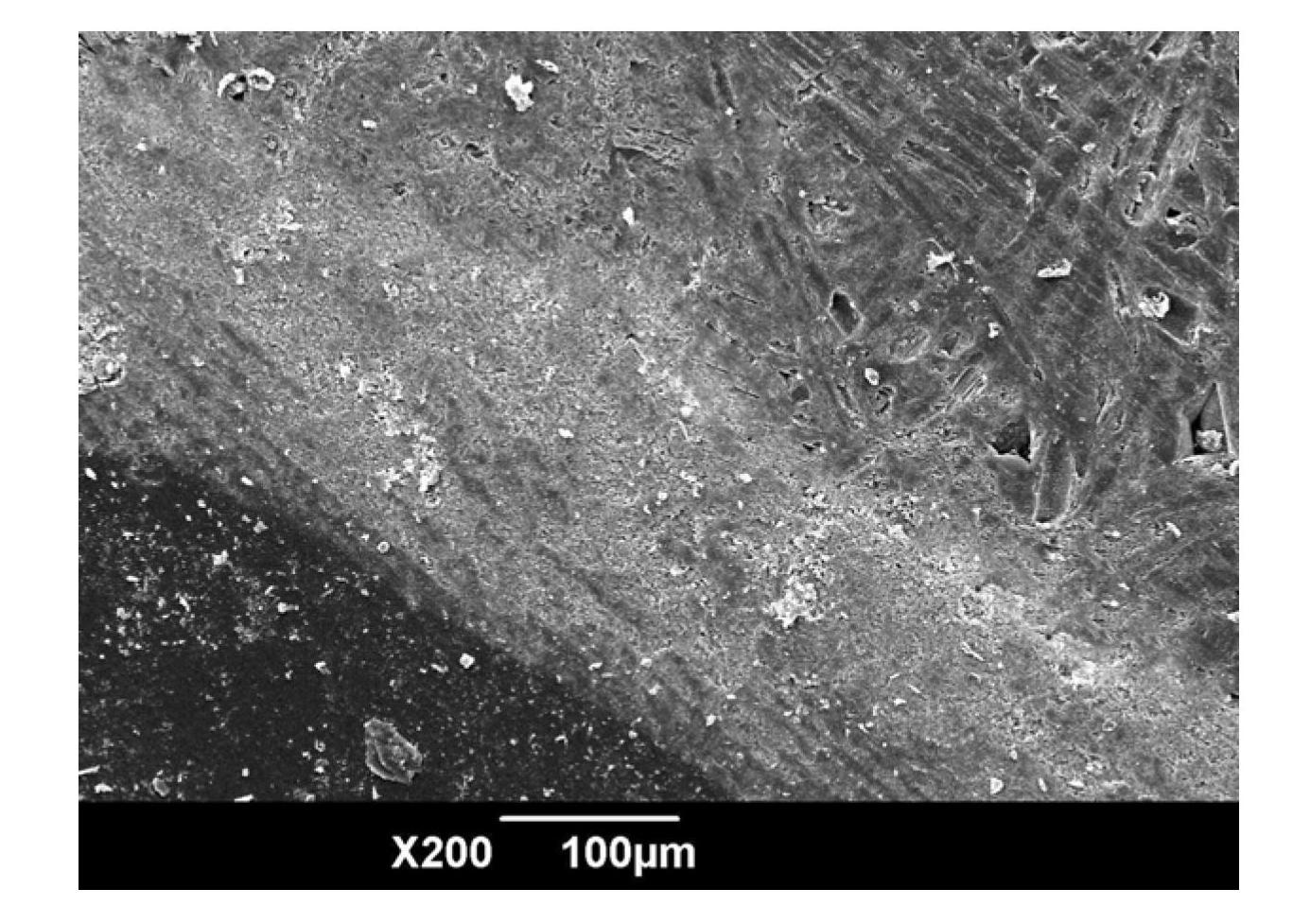

The invention provides a method for making a nano HAP coating / magnesium alloy composite biomaterial. The method is as follows: the method takes a magnesium alloy as a cathode and graphite as an anode; the magnesium alloy and the graphite are placed in electrolyte containing NH4H2PO4, NaHO3 and Ca(OH3)2.4H2O so as to carry out stepped electrodeposition at a temperature of between 60 and 95 DEG C and a voltage of between minus 5 V to minus 1 V and 0 V, thereby effectively improving the interface bonding between a coating and a matrix and reducing hydrogen evolution during electrodeposition; meanwhile, the increase of magnesium ions at an interface can realize in-situ doping of magnesium ions and hydroxyapatite so as to generate a magnesium phosphate transition layer on the surface of the magnesium alloy and to increase bonding strength; thus, a degradable nano acicular hydroxyapatite / magnesium alloy coating composite biomaterial with excellent mechanical property, biocompatibility and corrosion resistance can be obtained. Meanwhile, the method also has the advantages of low cost of raw materials and simple technological operation, etc.

Owner:ZHENGZHOU UNIV

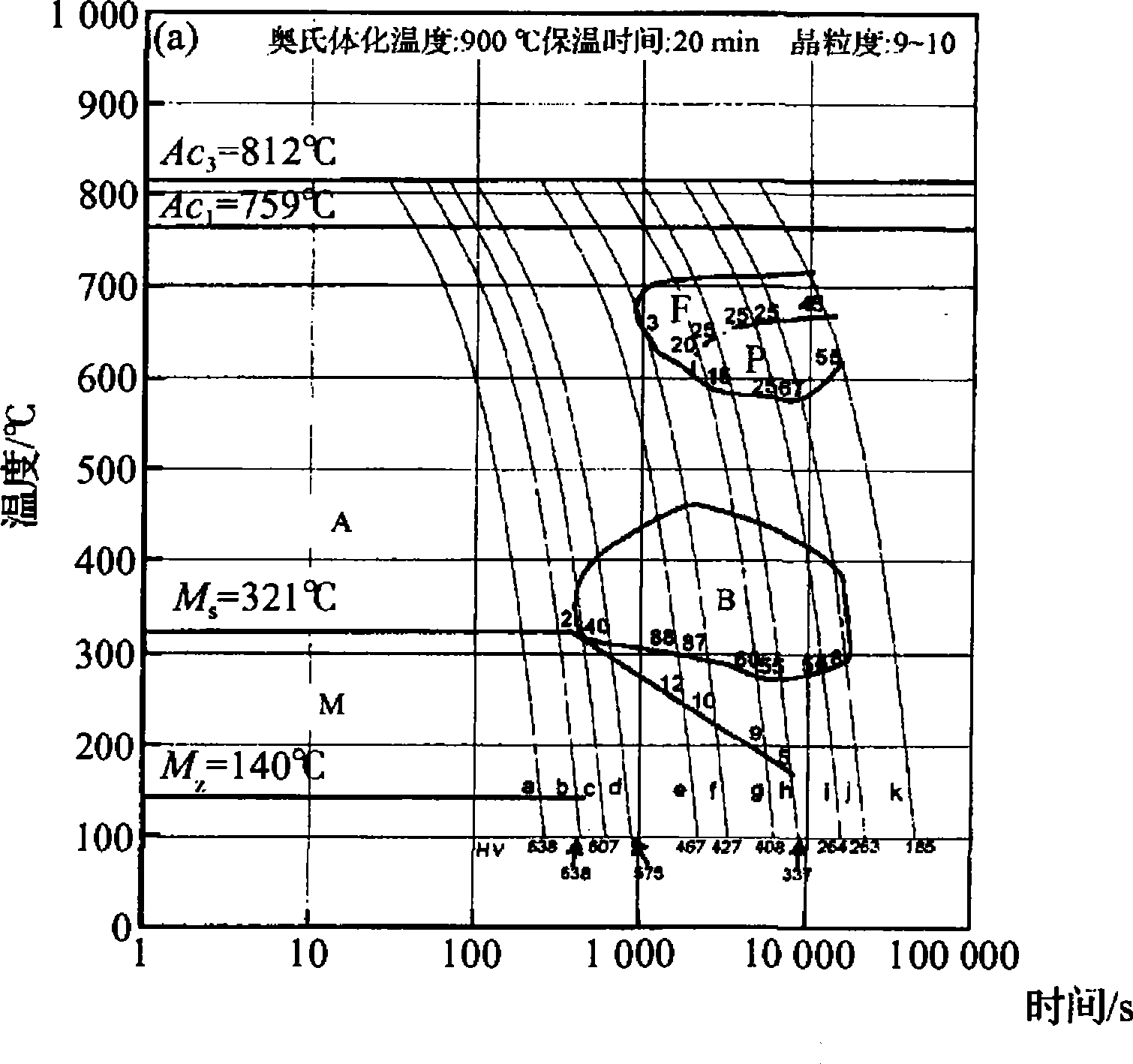

Tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel and production method thereof

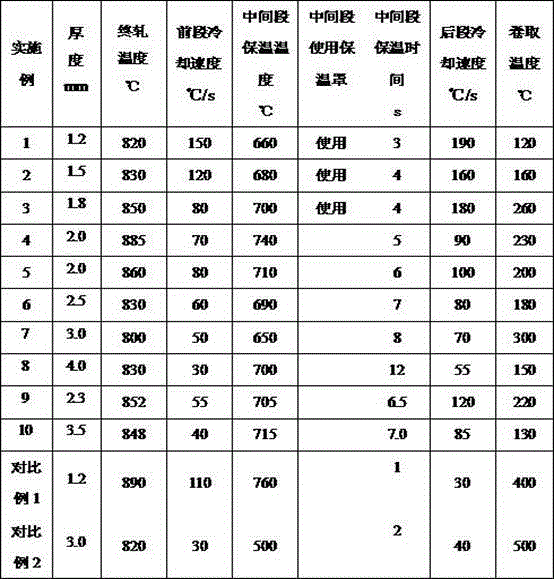

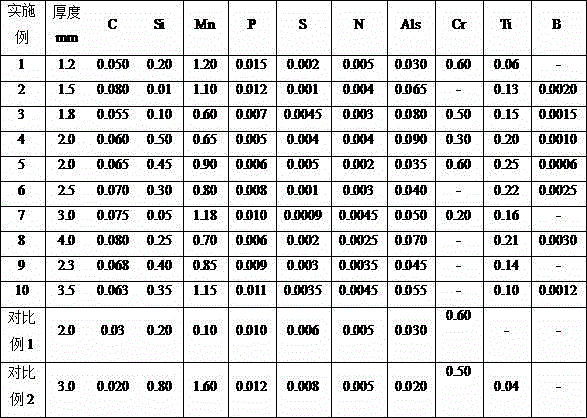

The invention provides tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel. The dual-phase steel comprises the following components in percentage by weight: 0.05-0.08 percent of C, not more than 0.5 percent of S, 0.6-1.2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.006 percent of N, 0.01-0.1 percent of Als, 0.05-0.25 percent of Ti, less than or equal to 0.6 percent of Cr or less than or equal to 0.003 percent of B or mixture of Cr and B. The production method by using CSP comprises the following steps: melting and continuously casting to form a slab; heating the continuous cast slab; rolling; carrying out laminar cooling; reeling; and naturally cooling to room temperature. The hot-rolled dual phase steel has the tensile strength of more than or equal to 780MPa, elongation of more than or equal to 15 percent and yield ratio of less than or equal to 0.70. An insulation cover additionally covers the intermediate insulation section, and the band steel cooling speed is reduced, so that generation of pearlite phase change can be effectively prevented. Production of hot-rolled dual phase steel with thickness of 1.2-4.0mm can be realized, the product has the advantages of uniform structure, small molding resilience and no cracking, existing equipment is utilized without adopting ultra fast cooling and other equipment, the production efficiency is high, and the investment is small.

Owner:武汉钢铁有限公司

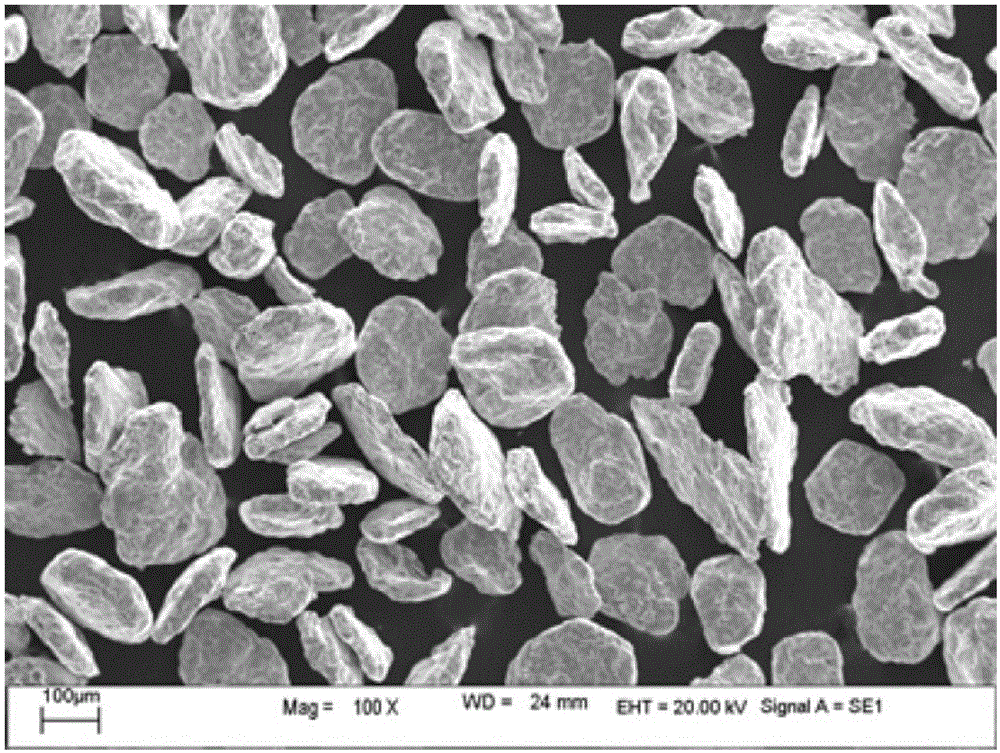

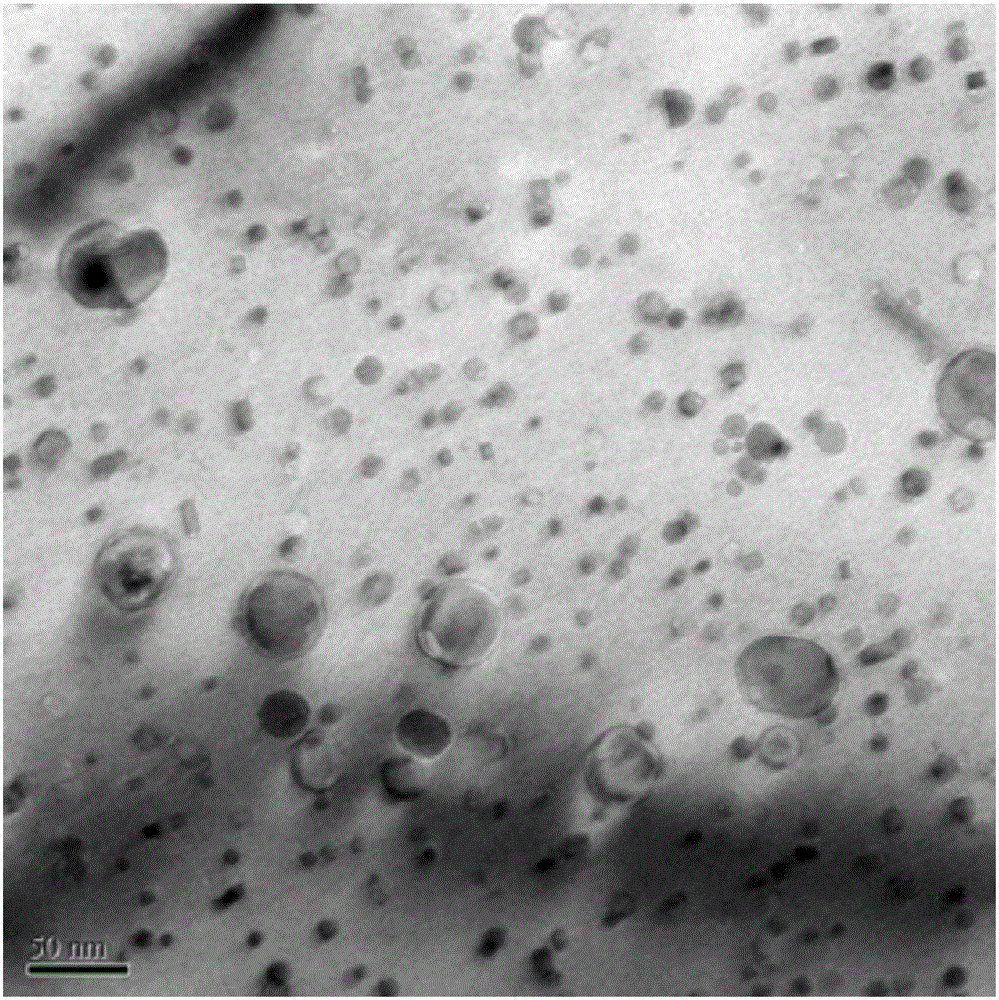

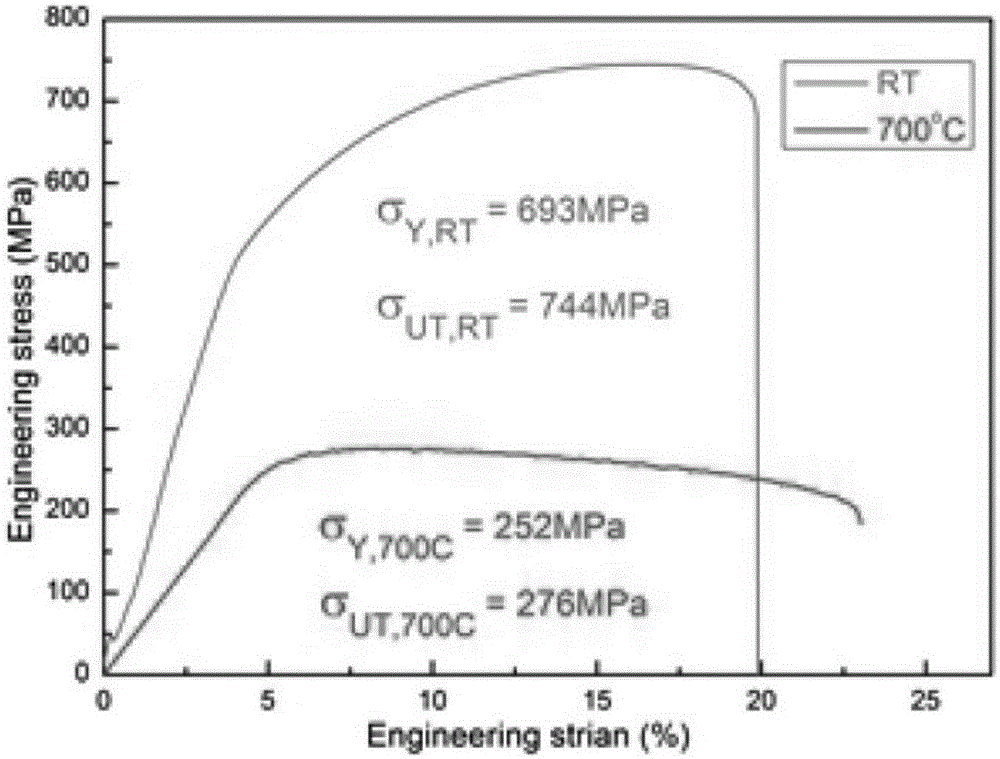

Oxide-dispersion-strengthening ferrite/martensitic steel and preparing method

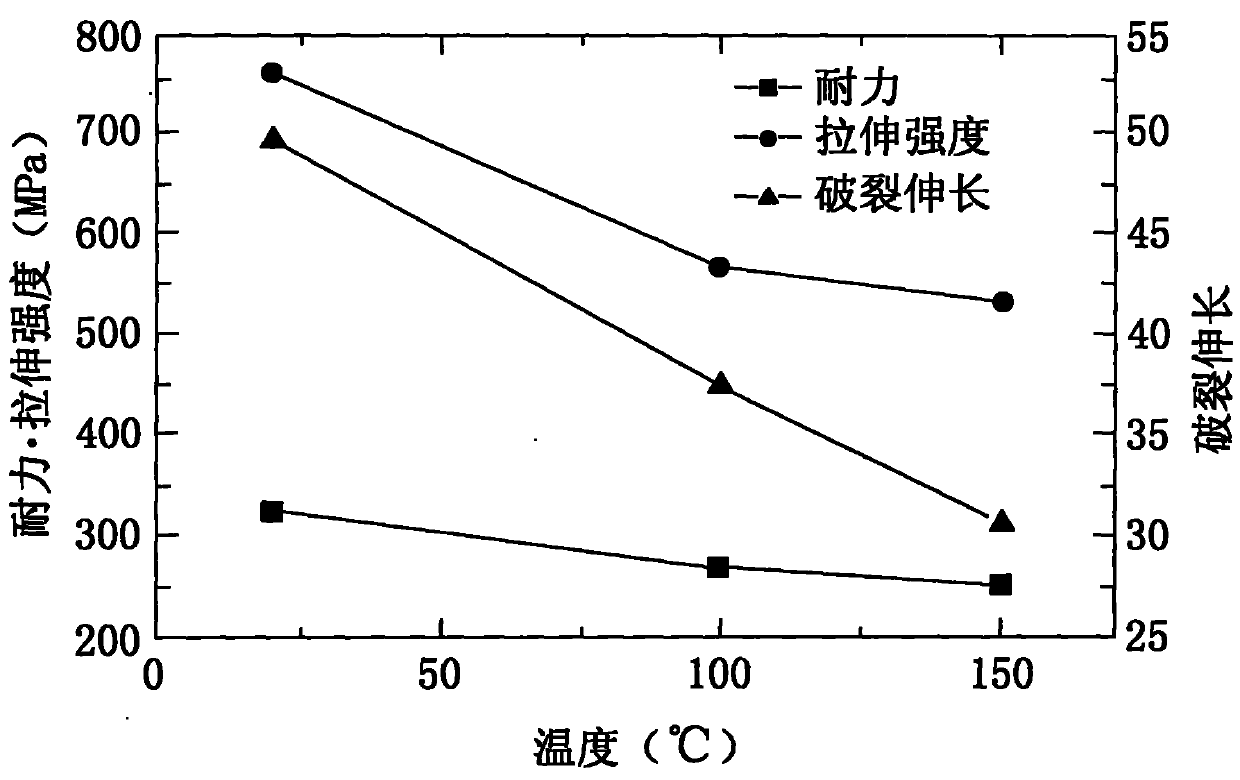

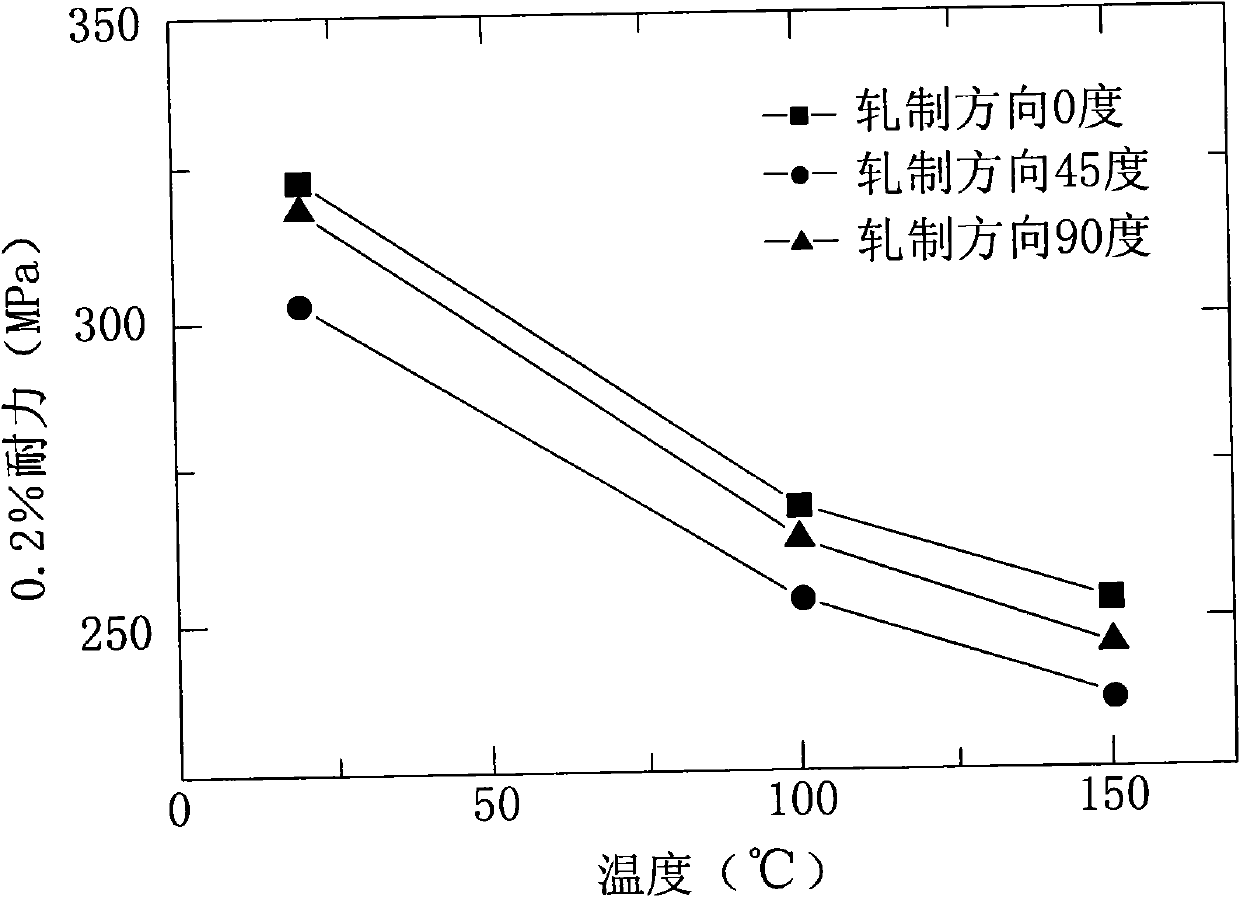

The invention relates to oxide-dispersion-strengthening ferrite / martensitic steel with the excellent high-temperature strength and the good oxidation resistance and a preparing method of the oxide-dispersion-strengthening ferrite / martensitic steel. The oxide-dispersion-strengthening ferrite / martensitic steel comprises 8% to 10% of Cr, 0.5% to 2% of W, 1.5% to 5.5% of Al, 0.1% to 0.4% of V, 0.1% to 0.5% of Mn, 0% to 1.0% of Zr, 0% to 1.0% of Hf and 0.25% to 0.5% of Y2O3. The content of C and the content of N are controlled to be lower than 0.1%, and at least one kind of the Hf and the Zr is contained; the oxygen content of atomized powder is controlled to be lower than 0.05 wt.%, the atomized powder with the particle size ranging from 50 meshes to 200 meshes is selected to be mechanically alloyed with Al powder, Zr powder, Hf powder and Y2O3 powder, and the size of obtained powder ranges from 90 micrometers to 200 micrometers; silicate glass is used for wrapping, compressing and molding, the pressure is started to be boosted to 120 MPa to 180 MPa at the temperature of 850 DEG C, a two-stage sintering manner in which the temperature ranging from 850 DEG C to 950 DEG C is kept for 1 hour and the temperature ranging from 1050 DEG C to 1150 DEG C is kept for 1 hour is adopted, the tensile strength of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 250 MPa to 320 MPa, and the ductility of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 18% to 32%; and the oxidation performance of the dispersion-strengthening steel is also greatly improved on the premise that the high-temperature strength and the high-temperature plasticity are guaranteed, and after 100-h oxidation is carried out at the temperature of 850 DEG C, the oxidation weight increase only ranges from 0.0327 mg / cm<3> to 0.098 mg / cm<3>.

Owner:UNIV OF SCI & TECH BEIJING

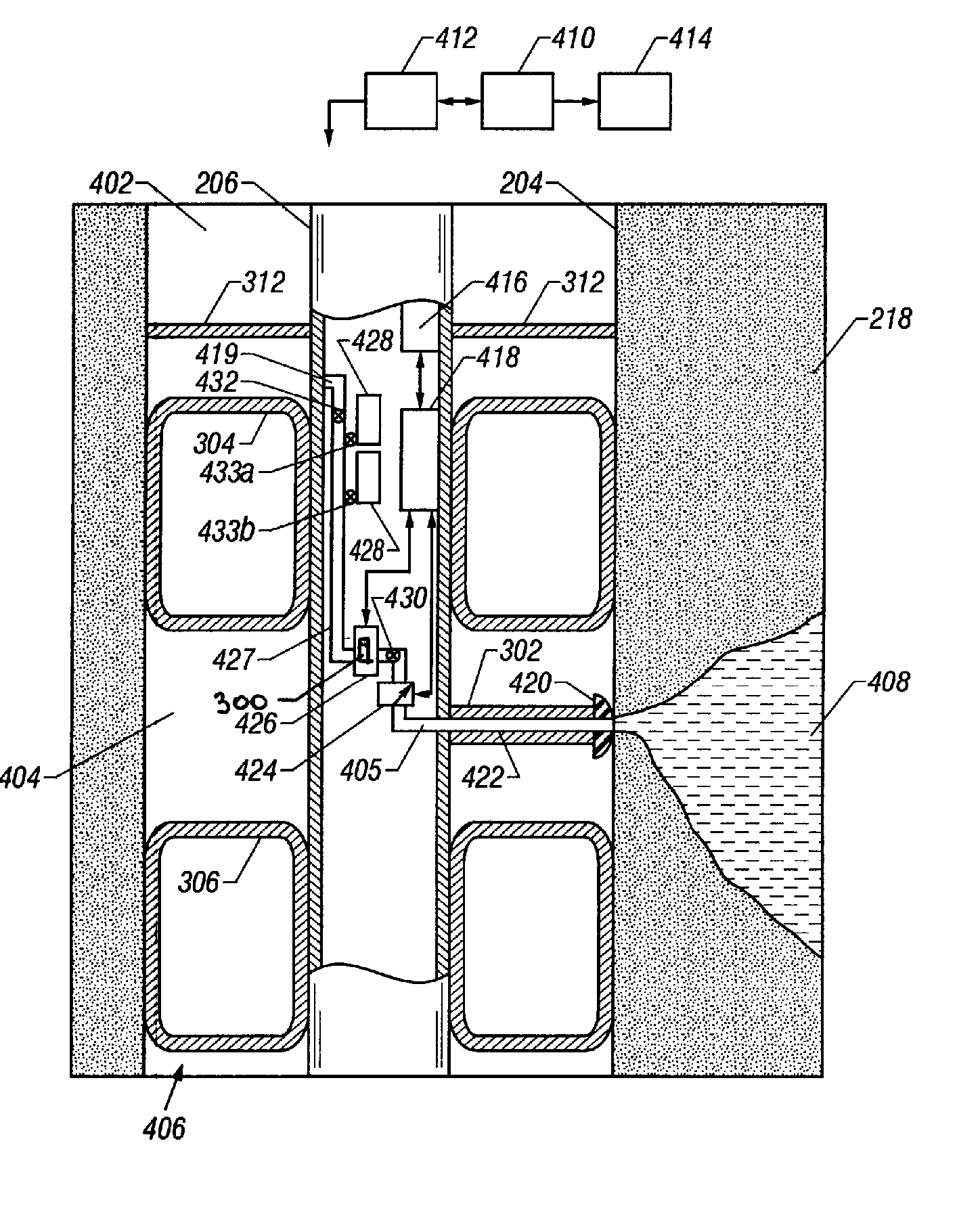

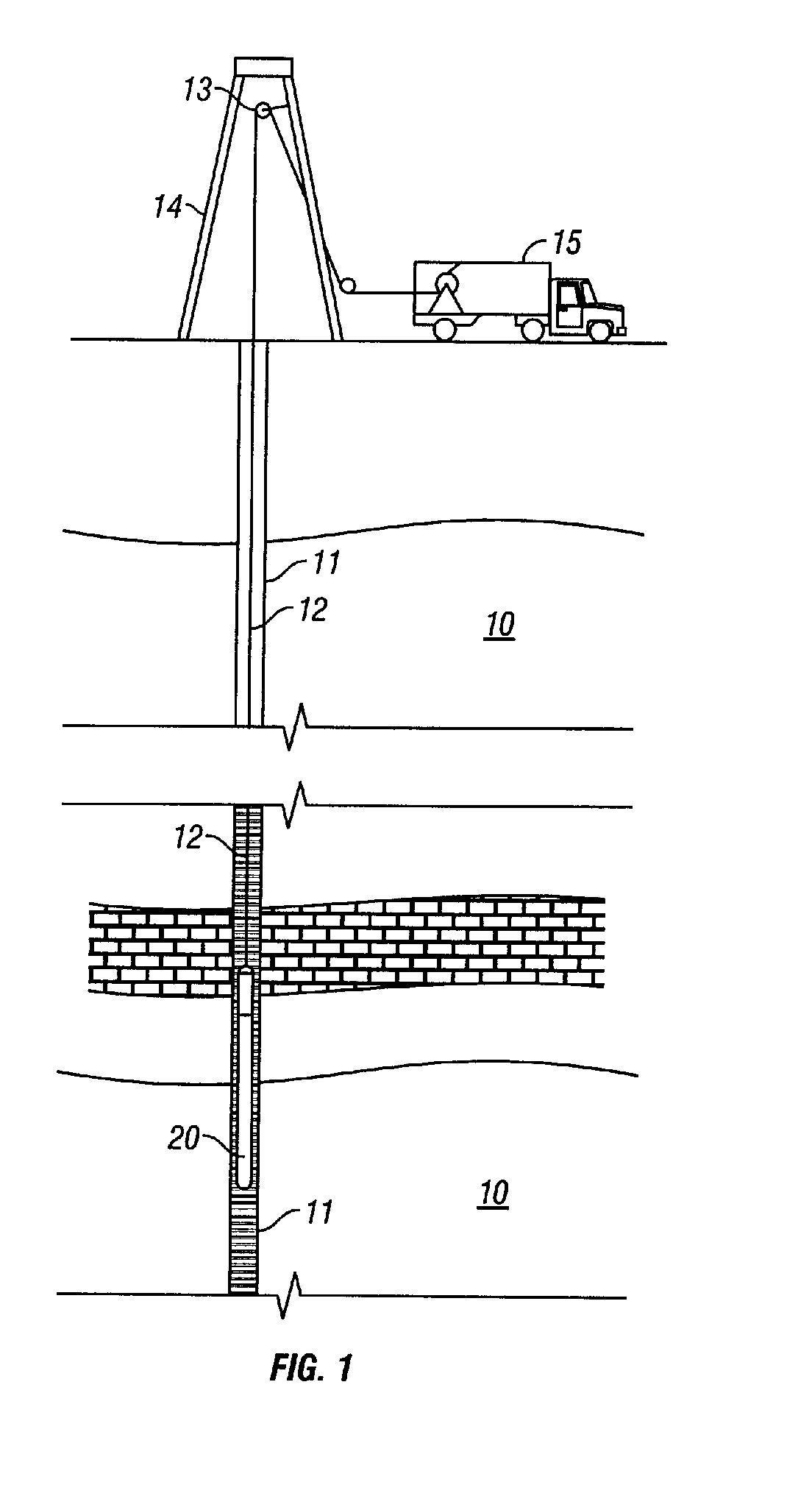

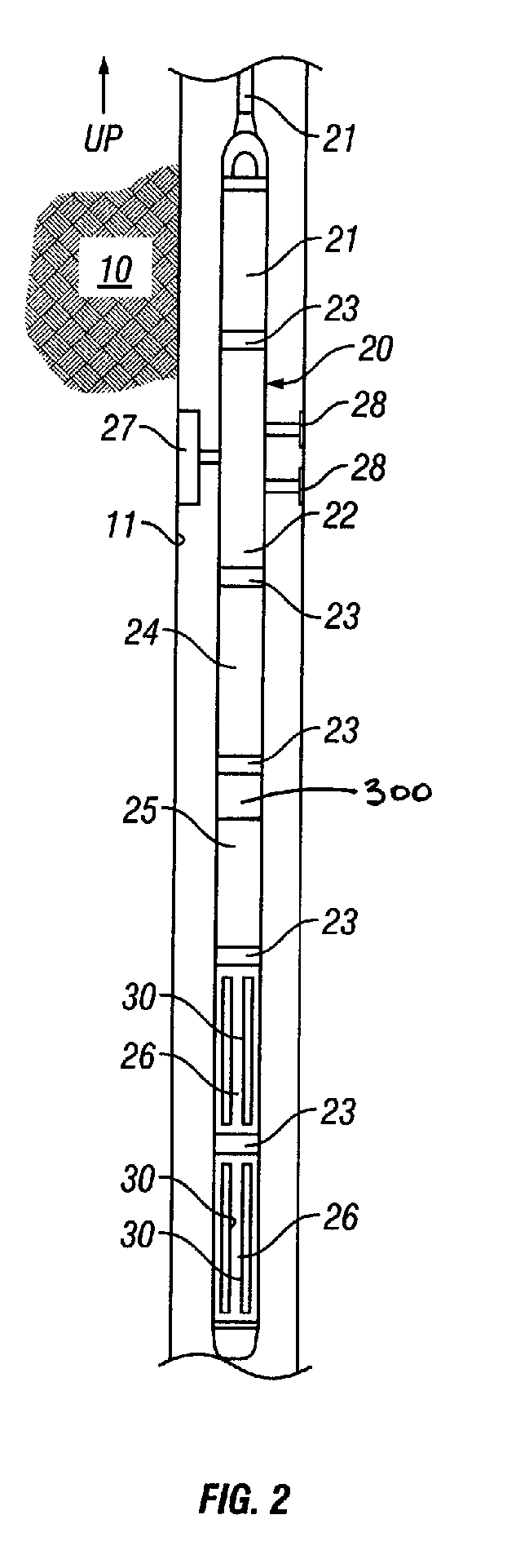

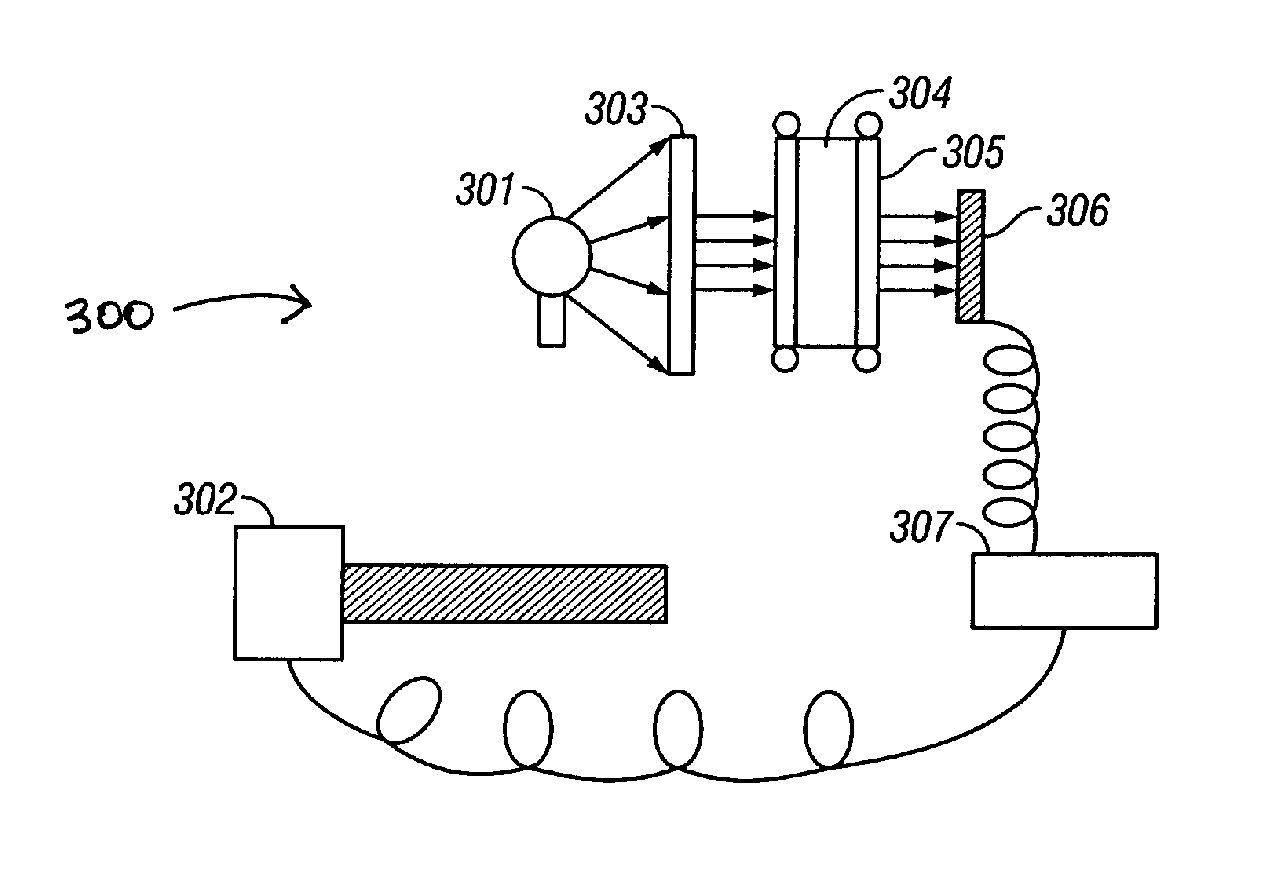

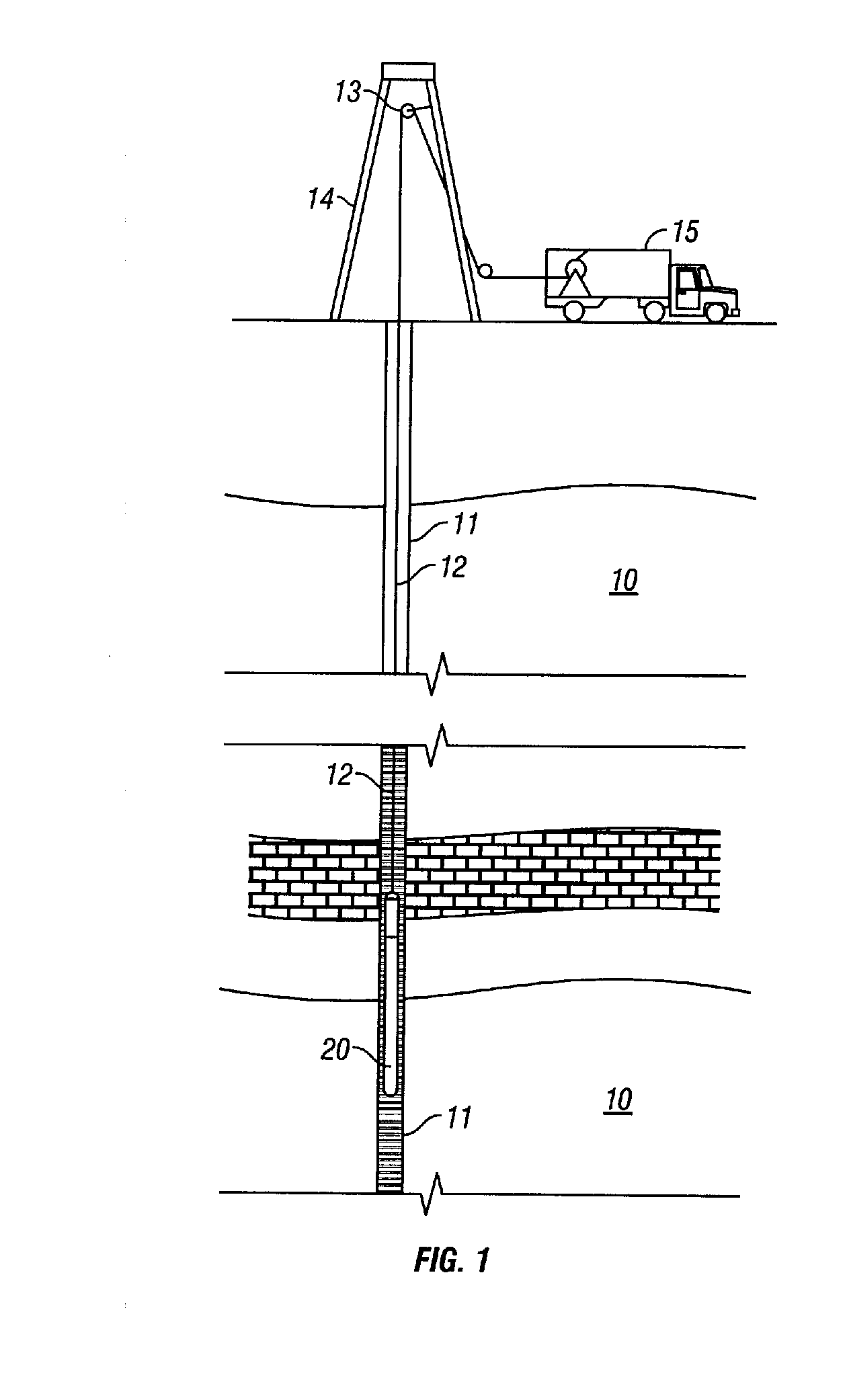

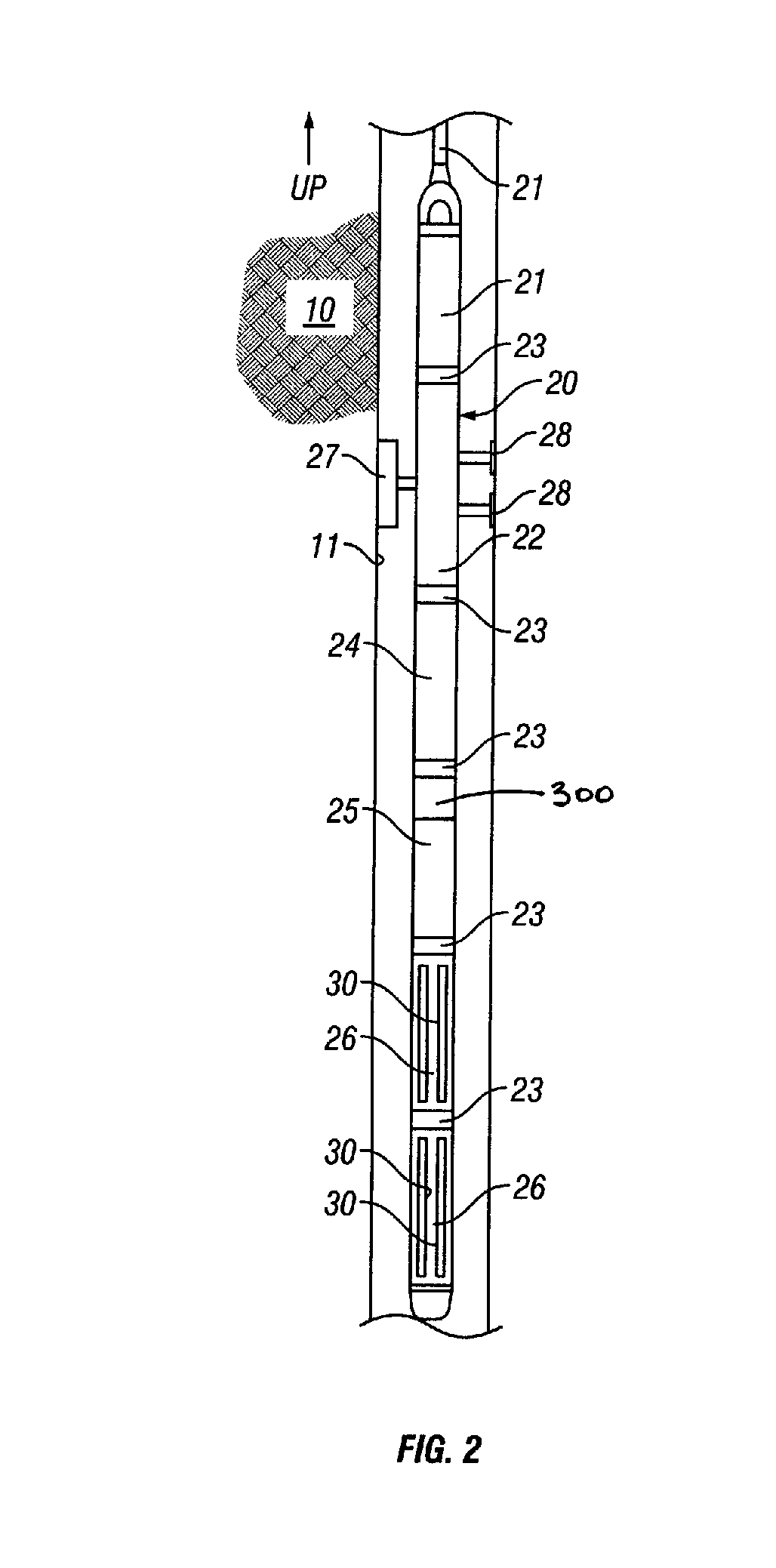

Method and apparatus for an optimal pumping rate based on a downhole dew point pressure determination

InactiveUS20070214877A1Reduce pressureLess-light energyBorehole/well accessoriesLight energyFormation fluid

Owner:BAKER HUGHES HLDG LLC

Method and apparatus for determining an optimal pumping rate based on a downhole dew point pressure determination

ActiveUS7222524B2Reduce pressureLess-light energyElectric/magnetic detection for well-loggingFluid pressure measurement by electric/magnetic elementsLight energyDew

Owner:BAKER HUGHES HLDG LLC

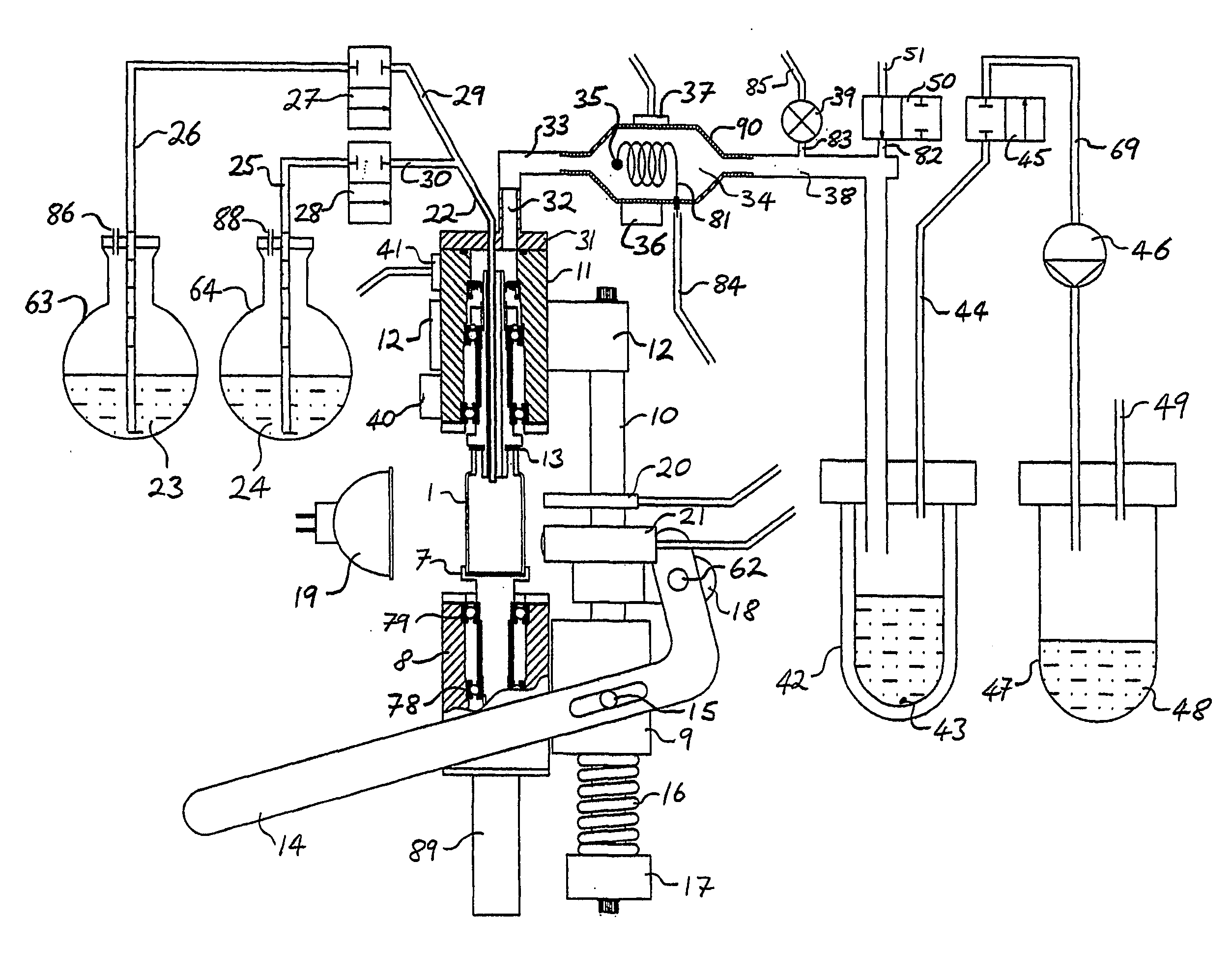

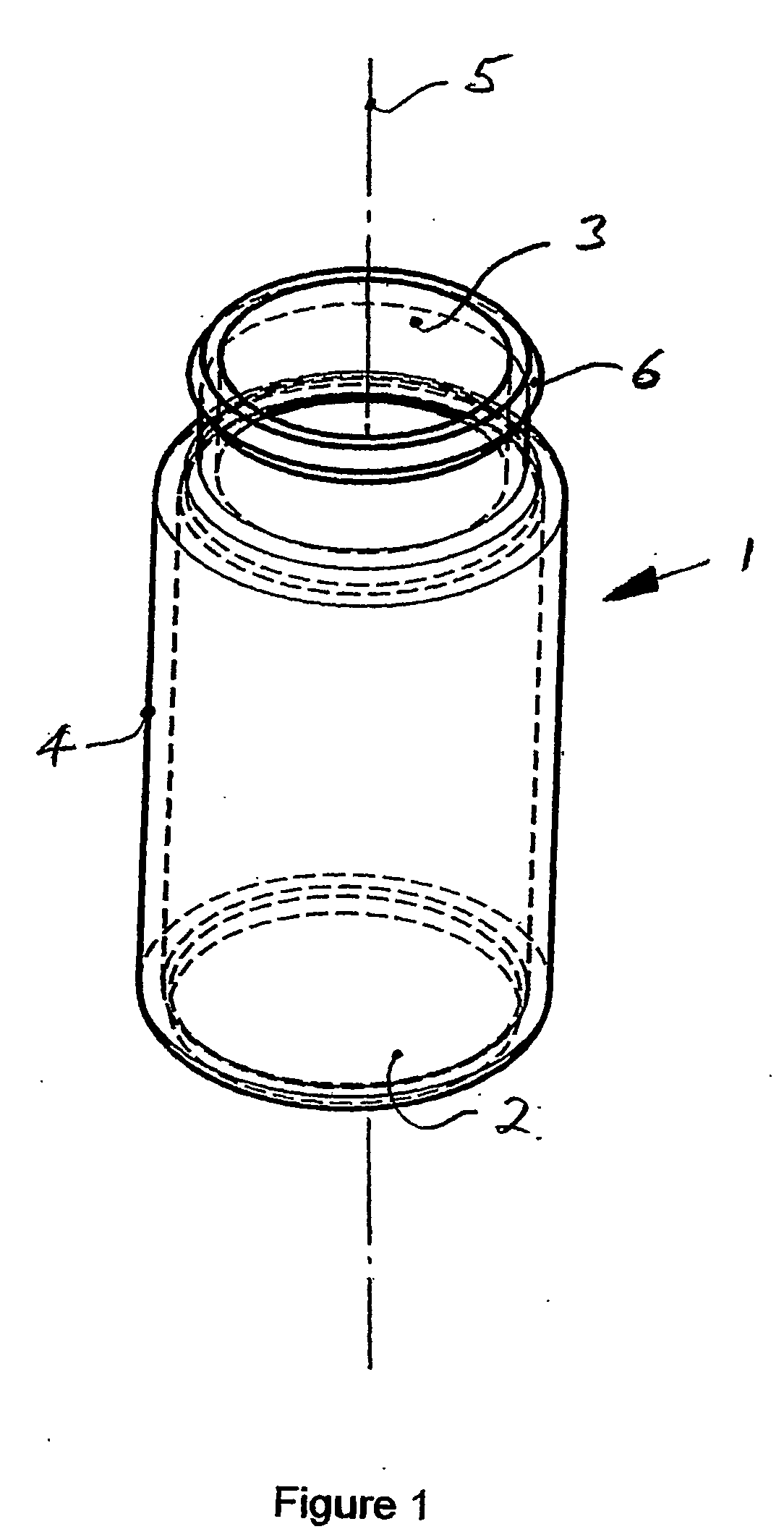

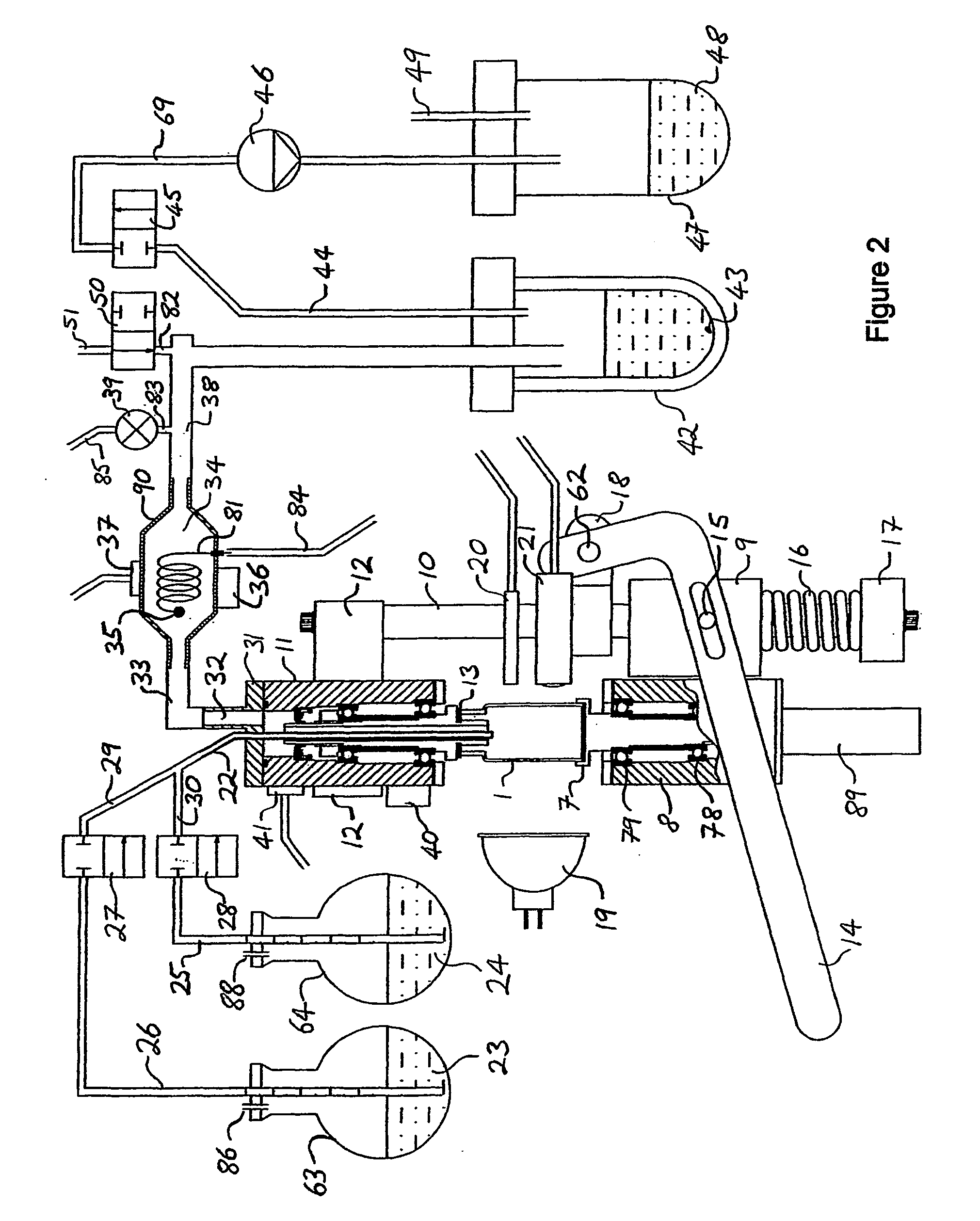

Solvent Evaporator

InactiveUS20080210384A1Reduces and eliminate disadvantageAvoid collisionPreparing sample for investigationEvaporationSolventSolvent evaporation

An apparatus for concentrating solutions in a vaporising receptacle (1) is provided wherein the receptacle (1) has a mouth (3), and the axis of the receptacle is perpendicular to the mouth. The apparatus comprises: support means (7) for supporting the vaporising receptacle with the mouth of the receptacle uppermost and the axis substantially vertical; rotation means (89) being operable to rotate the vaporising receptacle at high speed substantially about the axis; means (13) for sealing the vaporising receptacle to the apparatus; a vacuum pump (46) to reduce the pressure within the vaporising receptacle; means (22) for dispensing into the vaporising receptacle a solution to be concentrated; sensing means (21) to measure the temperature of the solution within the vaporising receptacle; heating means (19, 99) to apply heat to the solution within the vaporising receptacle; a control and regulating unit (75) for controlling or regulating at least one of said rotation means, said vacuum pump, said dispensing means, said sensing means and said heating means. The invention allows low pressure evaporation in regularly sized and shaped receptacles without bumping, and is also easy to use. A corresponding method is provided.

Owner:VAPORTEC

Active bio piezoelectric ceramic coating layer and method of preparing said coating layer on titanium base body surface

InactiveCN1785439AReduce bond strengthHigh bonding strengthAnodisationImpression capsPlasma electrolytic oxidationMicro arc oxidation

A coated active biologic piezoelectric layer on Ti substrate is prepared from fluorohydroxy apatite (FHA) and barium titanate (BT) through cleaning the surface of Ti substrate, microarc oxidizing to form a porous oxide film layer, and electrophoretic deposition to form a FHABT layer on the surface of Ti substrate. Its advantages are easy control to content of F, high implantation stability, binding power to interface, biocompatibility and bioactivity, and high effect to promote generation of biologic bone and taking part energy conversion in human body.

Owner:HARBIN ENG UNIV

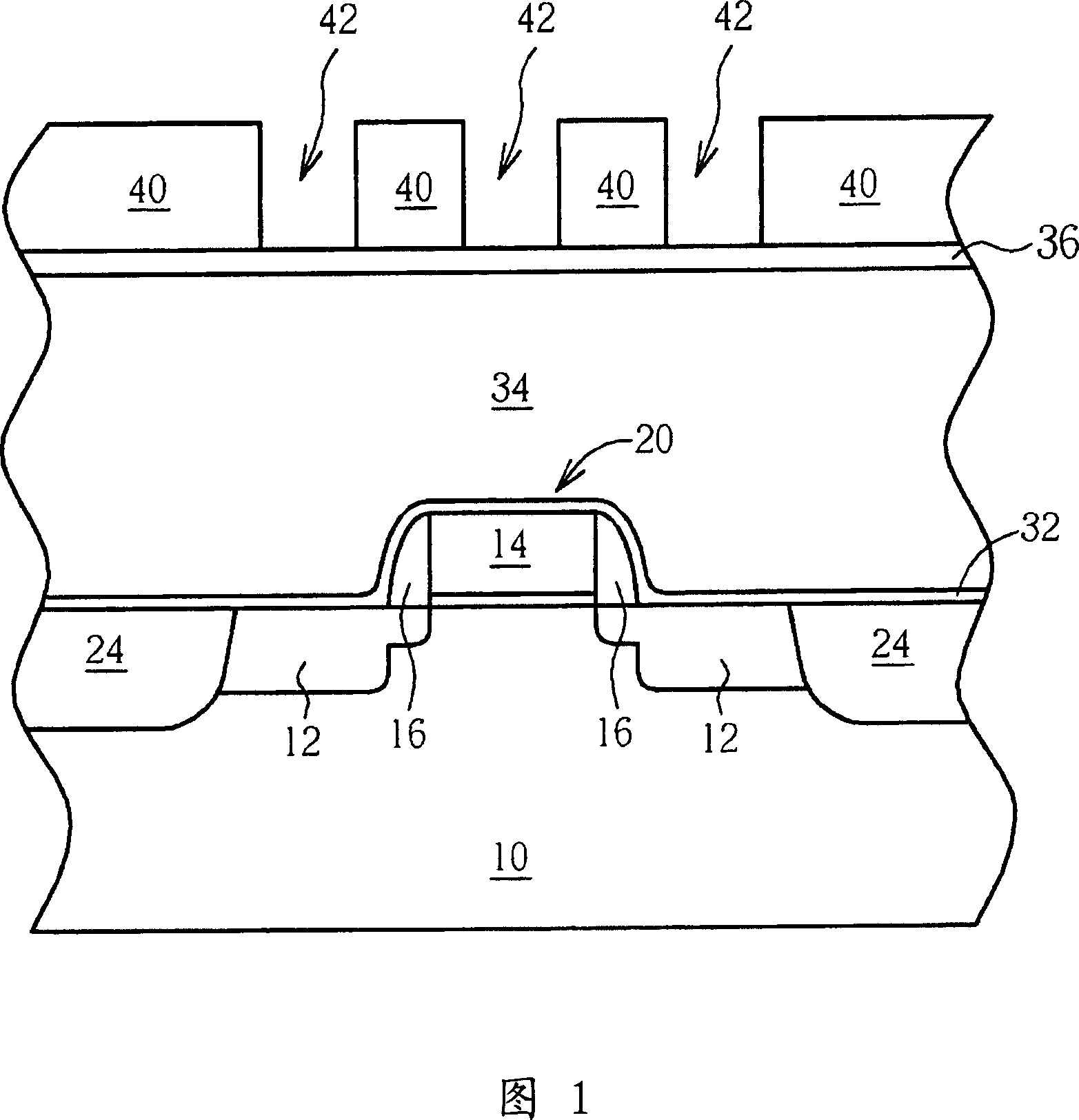

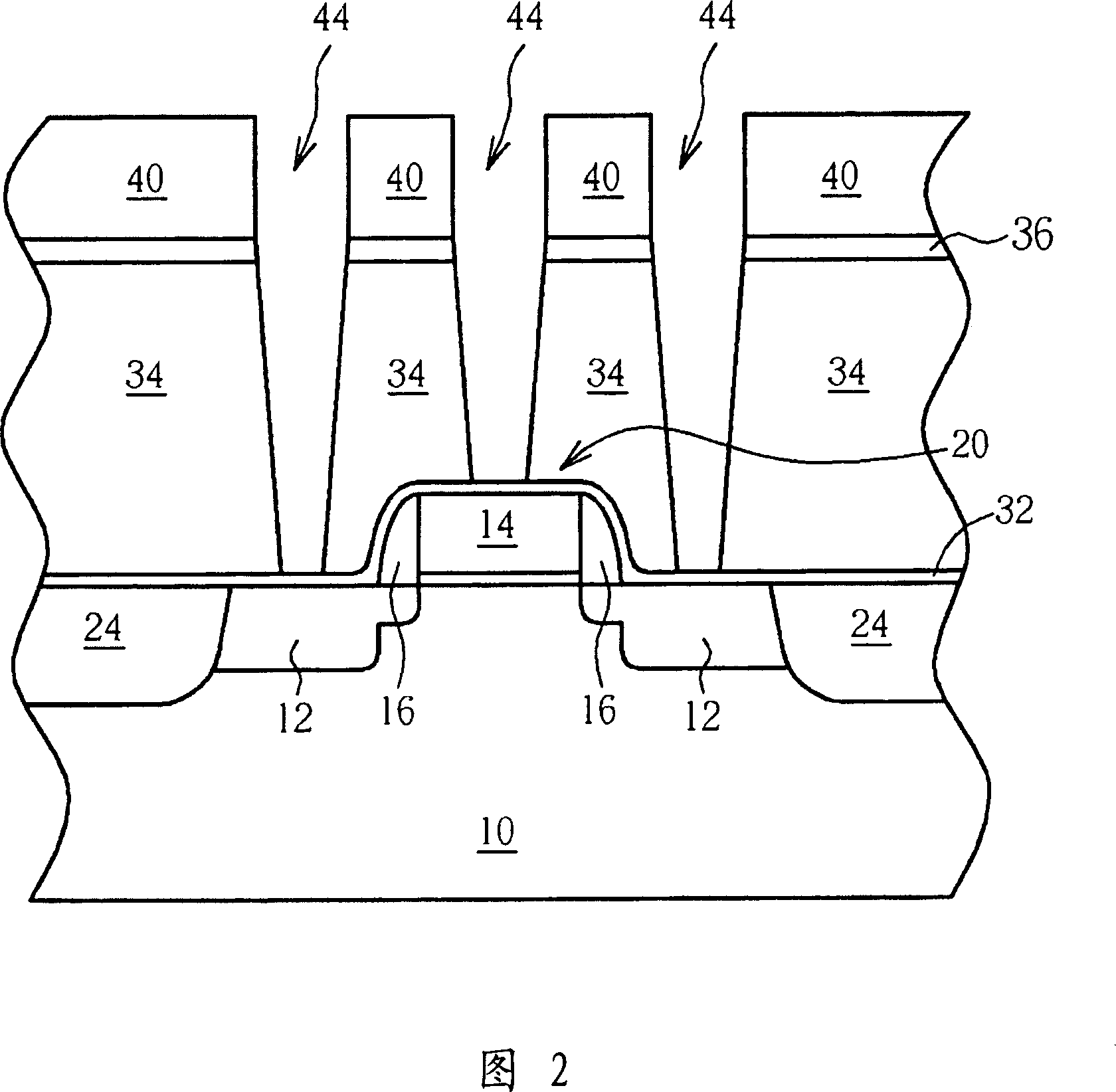

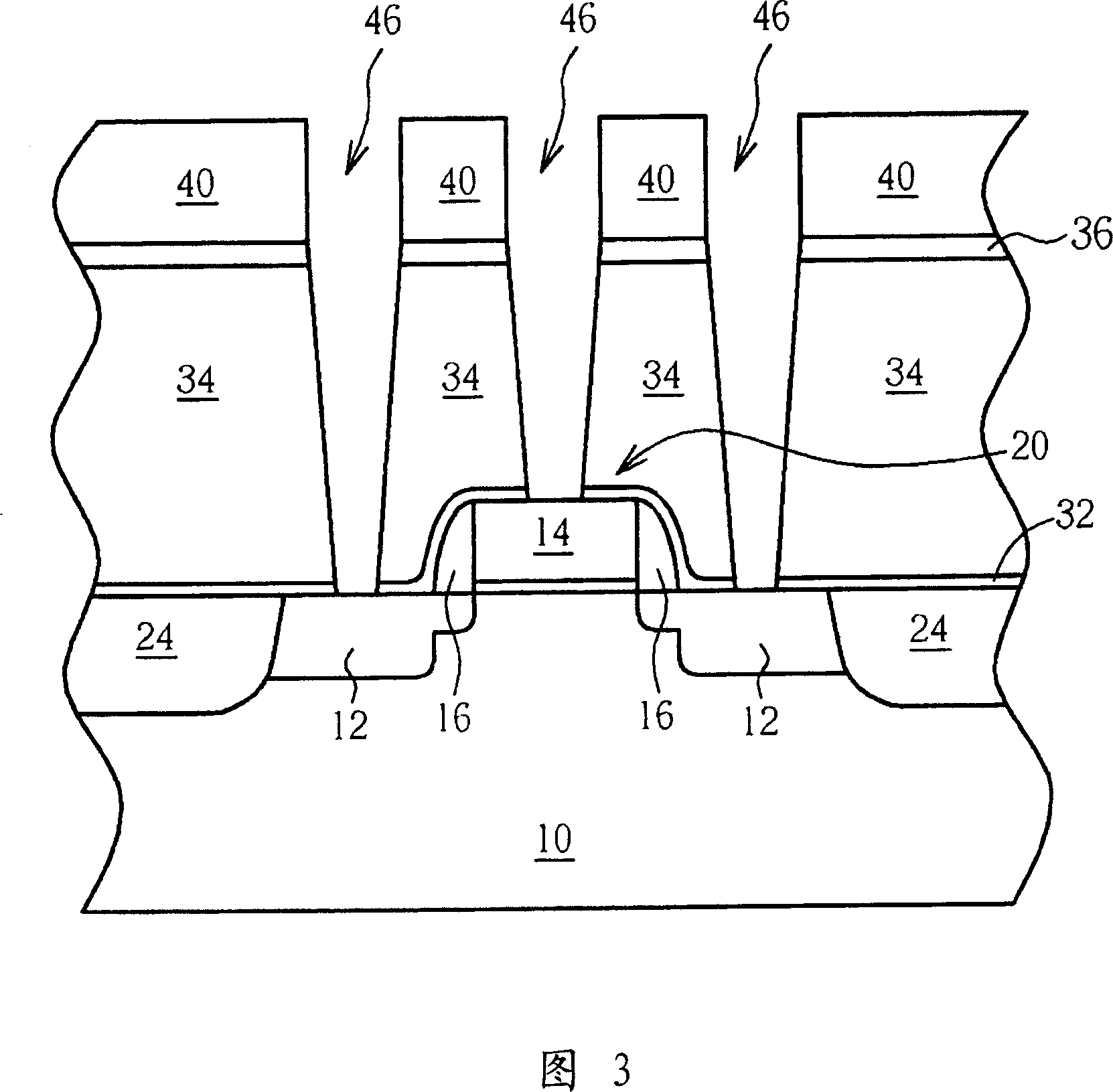

Manufacturing method and structure of metal interconnector

ActiveCN101000885AAvoid phase changeSemiconductor/solid-state device detailsSolid-state devicesInterconnectorDielectric layer

The invention relates to an inter-wire technology in metal and its structure, which provides a substrate with the first conductor. Firstly, it forms the first dielectric layer and the first pattern hard mask on the substrate. Then it etches the first hard mask to form the first shedding and the second conductor, and forms the second dielectric layer and the second hard mask on the firs hard mask. Finally, it takes the second hard mask as the etching mask and takes the first hard mask as the etching stop layer to form the second shedding and the third conductor.

Owner:UNITED MICROELECTRONICS CORP

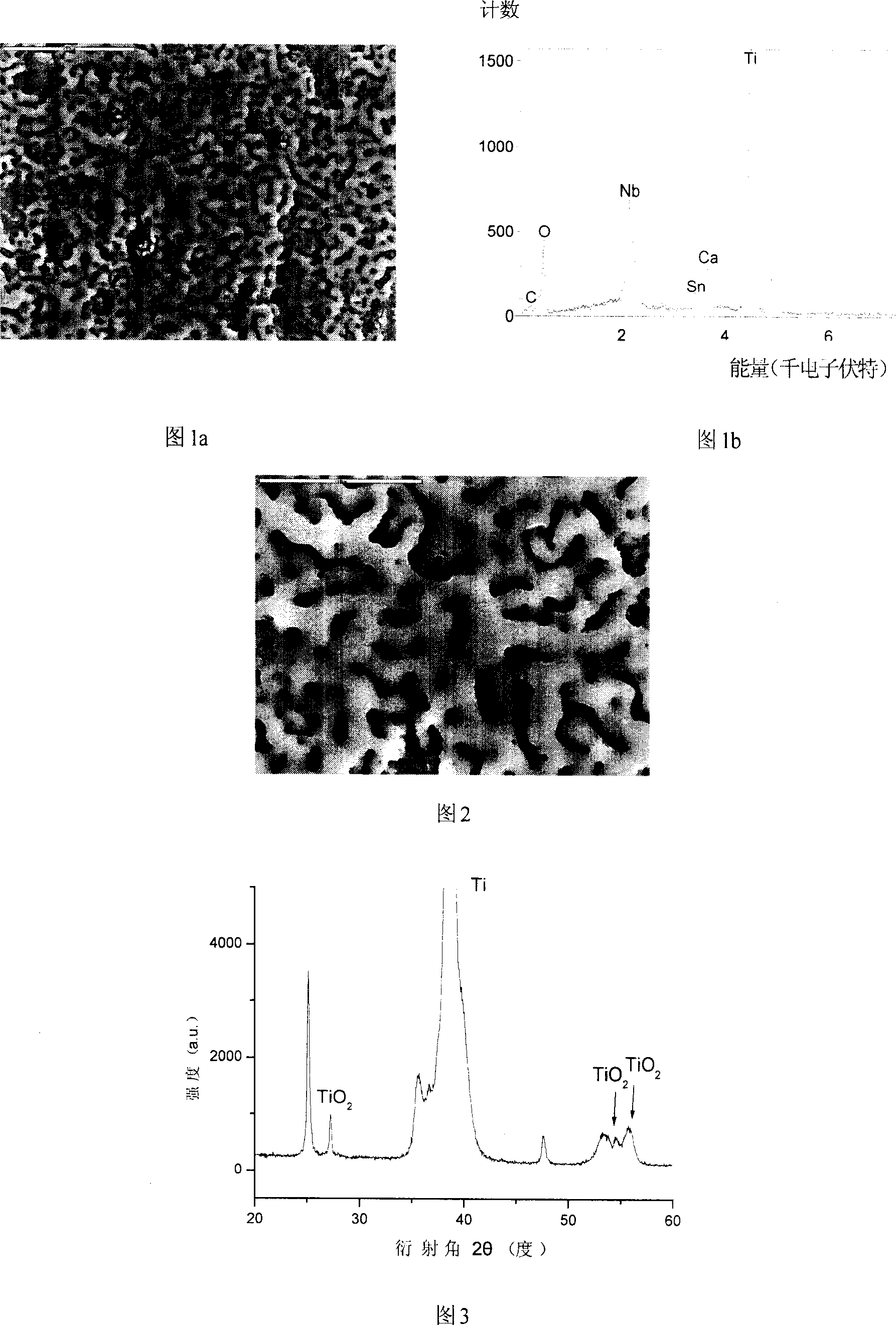

Bioactive coating on surface of Titanium or titanium alloy and its preparing method

InactiveCN1986003AGood biocompatibilityImprove biological activityCoatingsHigh cellBiocompatibility Testing

The present invention relates to bioactive coating on the surface of titanium or titanium alloy and its preparation process. The process includes the following steps: the first anode oxidation, alkali treatment and heat treatment of titanium or titanium alloy to form surface gradient coating in the thickness of 3 micron and comprising one inner thin and compact titania film and one outer porous titania film; introducing Ca element by means of the electrolyte solution into the coating to raise the biocompatibility; boiling in NaOH solution for 1-5 hr to form thin surface sodium titanate and calcium titanate layer; and final depositing a bone-like hydroxyapatite layer. The present invention raises the bioactivity of titanium or titanium alloy surface, and has high binding force of hydroxyapatite layer and high cell adhering capacity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for stimulation of liquid flow in a well

InactiveUS20050217851A1Easy to controlEfficient and effectiveSurveyCleaning apparatusWater qualityEngineering

An improved method of controlled energy delivery utilizing solid, liquid, and gaseous carbon dioxide (CO2) into a water well and the surrounding aquifer to remove deposited material which may cause loss of capacity in wells and a variety of water quality problems. After proper study and evaluation of problems associated with a well to be treated, adequate injection of the required amount of CO2 and energy is achieved by real-time monitoring during the injection and manipulating the phase changes in the CO2 that take place in the well and the aquifer.

Owner:SUBSURFACE TECH INC

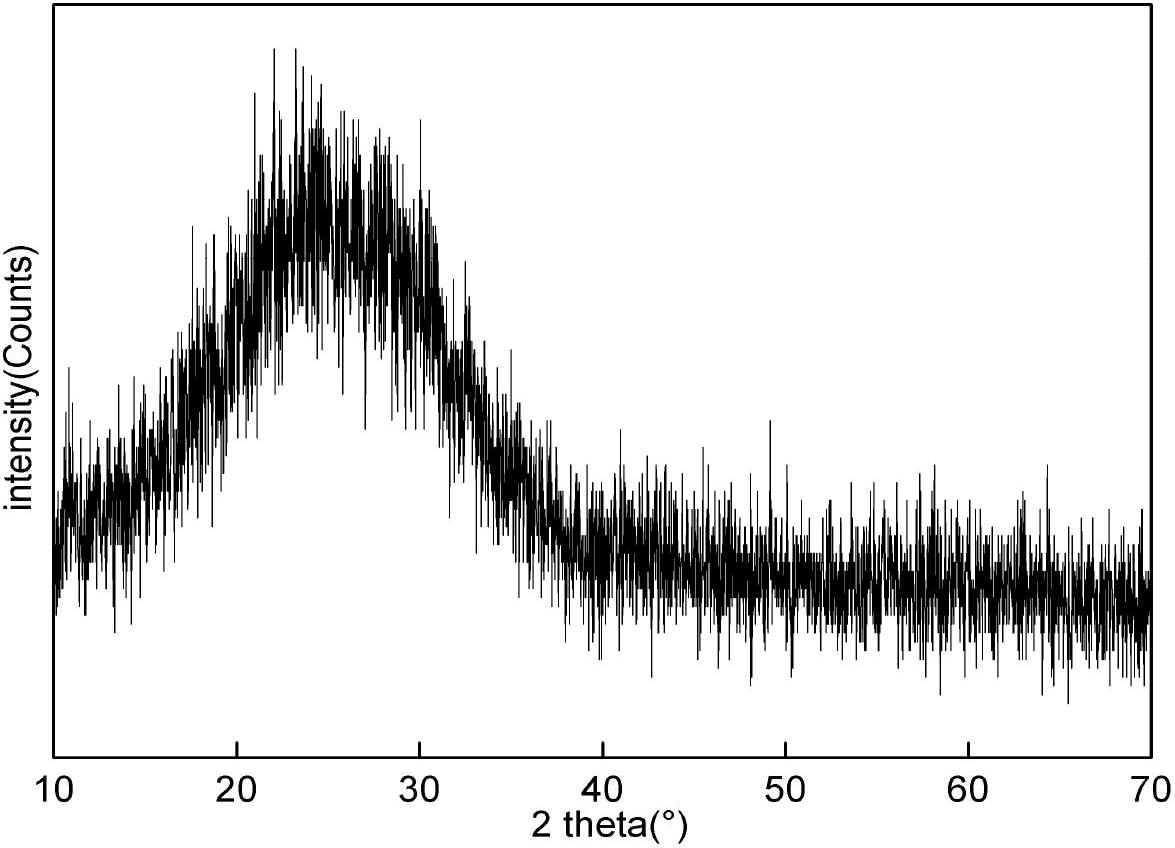

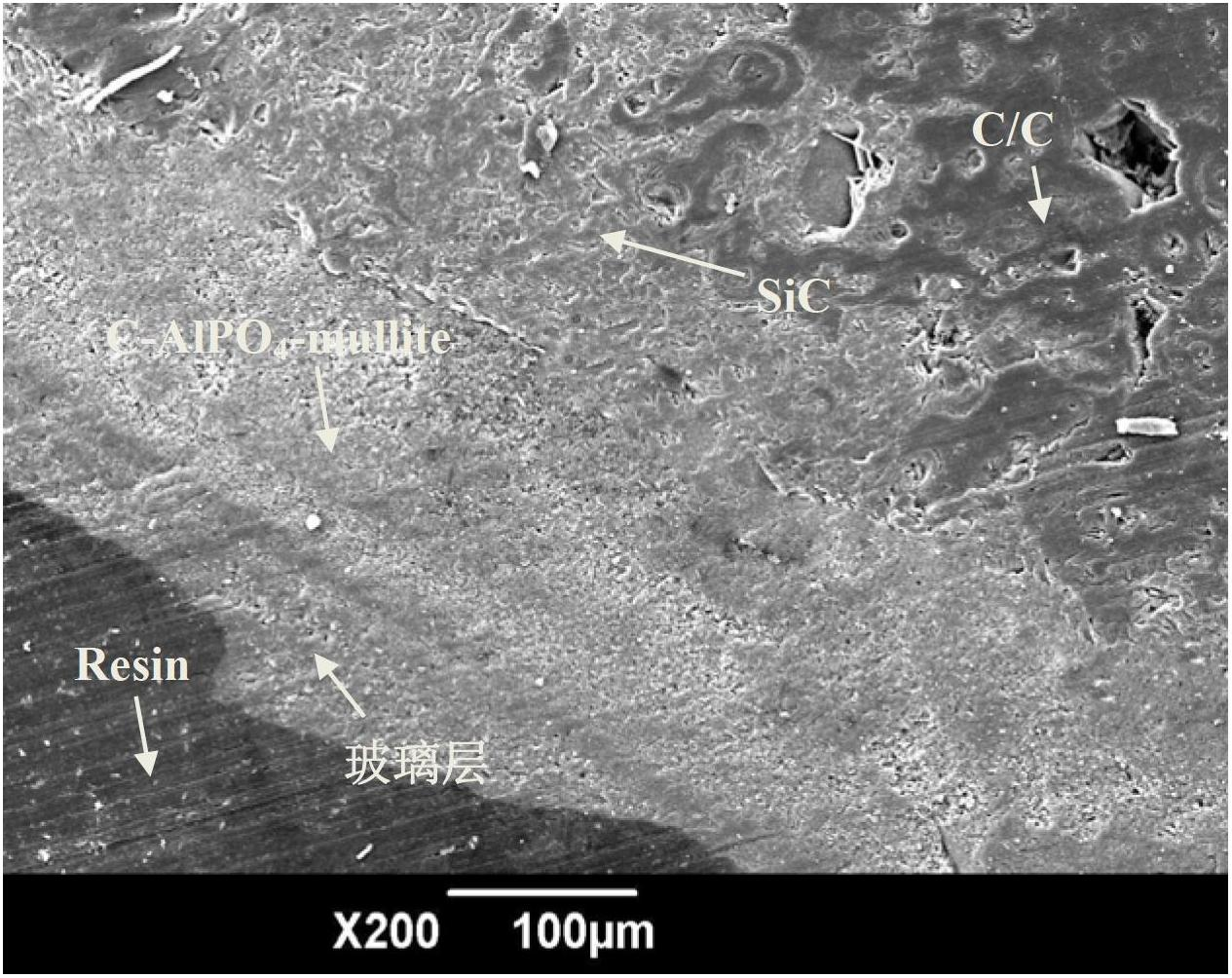

Preparation method of SiC/C-AlPO4-mullite antioxidation coating for C/C composite material

The invention relates to a preparation method of an SiC / C-AlPO4-mullite antioxidation coating for a C / C composite material, which comprises the following steps: mixing silicon powder and graphite powder to obtain powder A; mixing Al2O3 powder, WO3 powder and B2O3 powder to obtain powder B; mixing the powder A and the powder B to obtain embedded powder C; putting a sample in a graphite crucible, adding the embedded powder C, putting the graphite crucible in a vertical vacuum furnace, heating to react while introducing argon as a protective atmosphere, cooling to room temperature, and cleaning with anhydrous alcohol in ultrasonic waves to obtain a silicon carbide transition layer for the C / C composite material; adding the C-AlPO4 and the mullite powder into methanol, adding iodine to obtain a suspension, and putting the suspension in a hydrothermal kettle, wherein the cathode adopts the C / C composite material with the silicon carbide transition layer; and sealing the hydrothermal kettle, putting the hydrothermal kettle in an ultrasonic-microwave generator, depositing, taking out the sample, and drying to obtain the SiC / C-AlPO4-mullite antioxidation coating for the C / C composite material. The composite coating can protect the C / C composite material at 1500 DEG C in static air for 322 hours, and the oxidative weight loss is less than 2%.

Owner:深圳市贝尔新材料科技有限公司

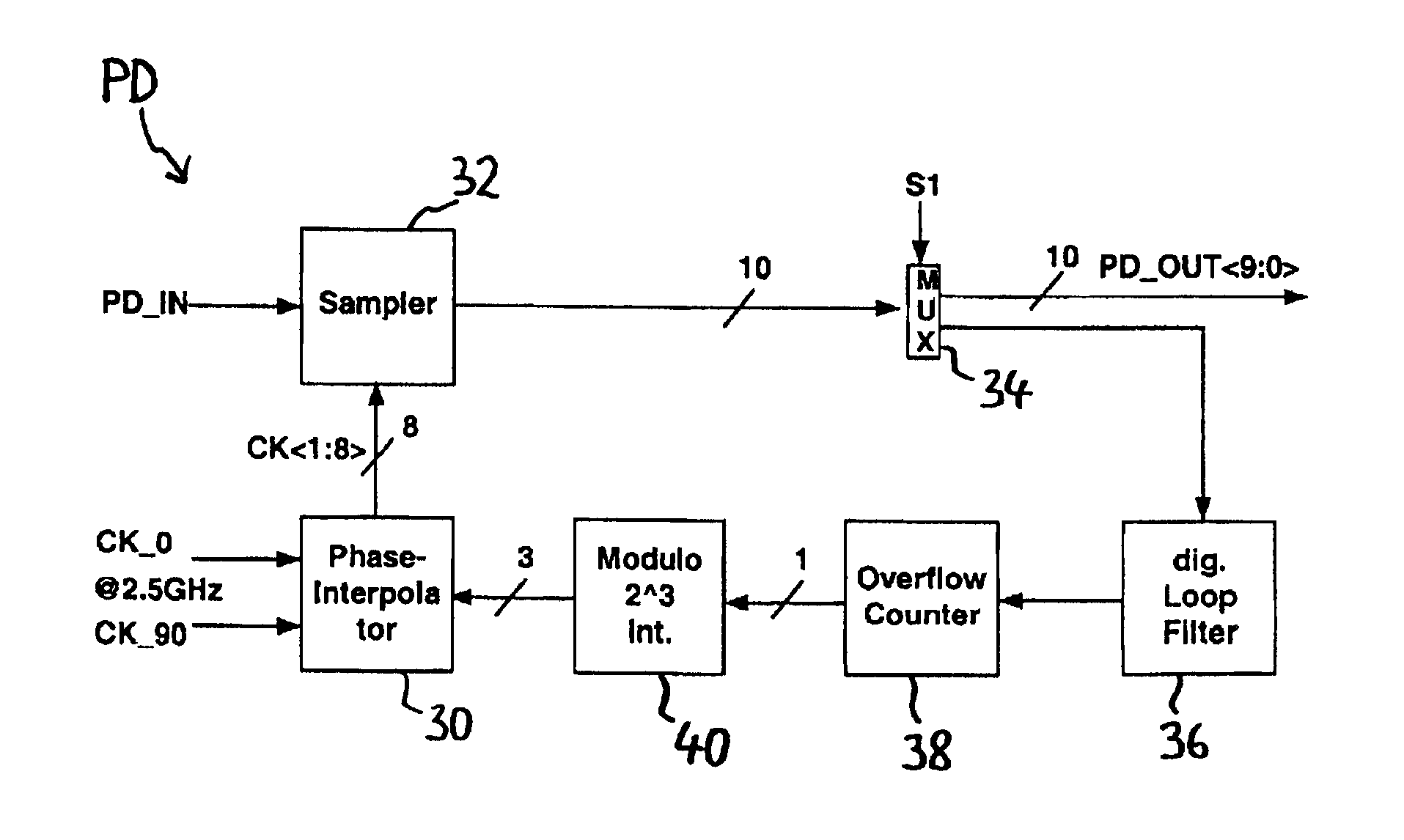

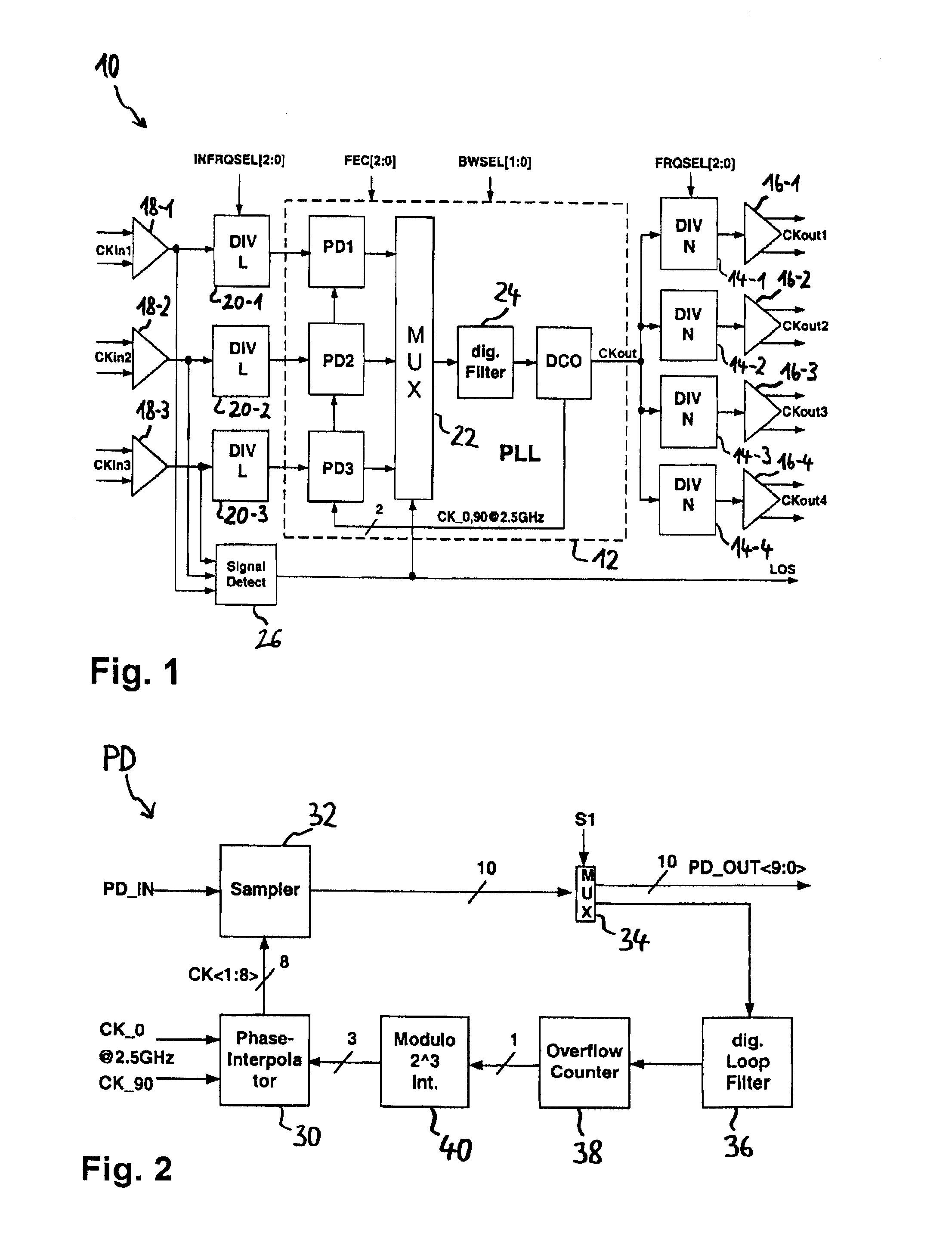

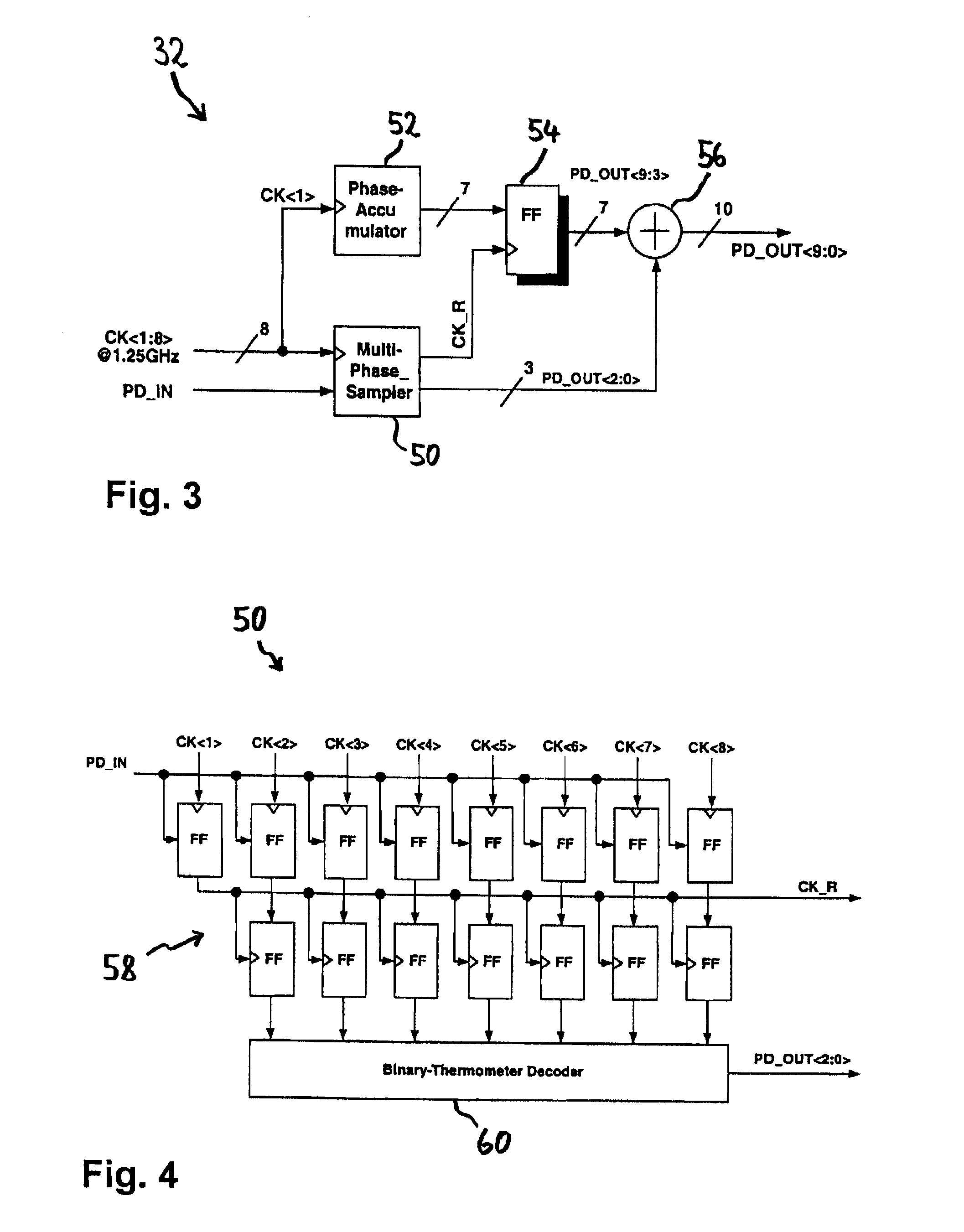

Switchable phase locked loop and method for the operation of a switchable phase locked loop

InactiveUS20070285177A1Avoid phase changeImprove accuracyPulse automatic controlSoftware engineeringMechanical engineering

The invention relates to a phase locked loop or “PLL” (12) and a method of operating a PLL (12), wherein a controllable oscillator (DCO) generates an output signal (CKout) and it is possible to switch between a first clock (CKin1 or CKin2) and a second clock (CKin2 or CKin1) for use as a PLL (12) input clock. In accordance with the invention, for the clock (CKin1 or CKin2) currently being used to generate the output signal (CKout) a phase difference is determined between this clock and a preset phase-shifted version (CK<1:8>) of the output signal (CKout) and is used to control the oscillator (DCO), whereas for the clock (CKin2 or CKin1) not currently being used to generate the output signal (CKout), the phase shift is adjusted. In this way, a phase difference between several clocks (CKin1, CKin2, CKin3) used as the input clock is effectively adjusted or else compensated before the switchover, so that any unwanted phase change in the PLL output signal resulting from the switchover can be avoided with a high degree of accuracy and hitless switching achieved.

Owner:NAT SEMICON GERMANY

Method for sealing aluminum alloy anodic oxide film pores through using silica sol

InactiveCN102732934AReduce pollutionAvoid phase changeSurface reaction electrolytic coatingElectrophoretic coatingsAnodic oxidationElectrophoretic deposition

A method for sealing aluminum alloy anodic oxide film pores through using a silica sol comprises the following steps: properly pre-treating aluminum or an aluminum alloy, and carrying out anodic oxidation treatment through a routine technology; and treating the aluminum or the aluminum alloy subjected to the anodic oxidation treatment through electrophoresis under different process conditions, carrying out electrophoretic deposition, drying, and sintering to seal the aluminum and aluminum alloy anodic oxide film pores and simultaneously generate a silicon oxide ceramic coating. The method using the electrophoretic deposition provided in the invention has the advantages of simple process, easy enforcement, and no need of high condition requirements, and the prepared ceramic coating has the advantages of compactness, good performances, and component uniformity. The method can be used for sealing the aluminum or aluminum alloy anodic oxide film pores, and the electrophoretic silica sol method applied to the anodic oxide film pores has the characteristics of cleanness, no pollution, and easy industrialization realization.

Owner:SHENYANG LIGONG UNIV

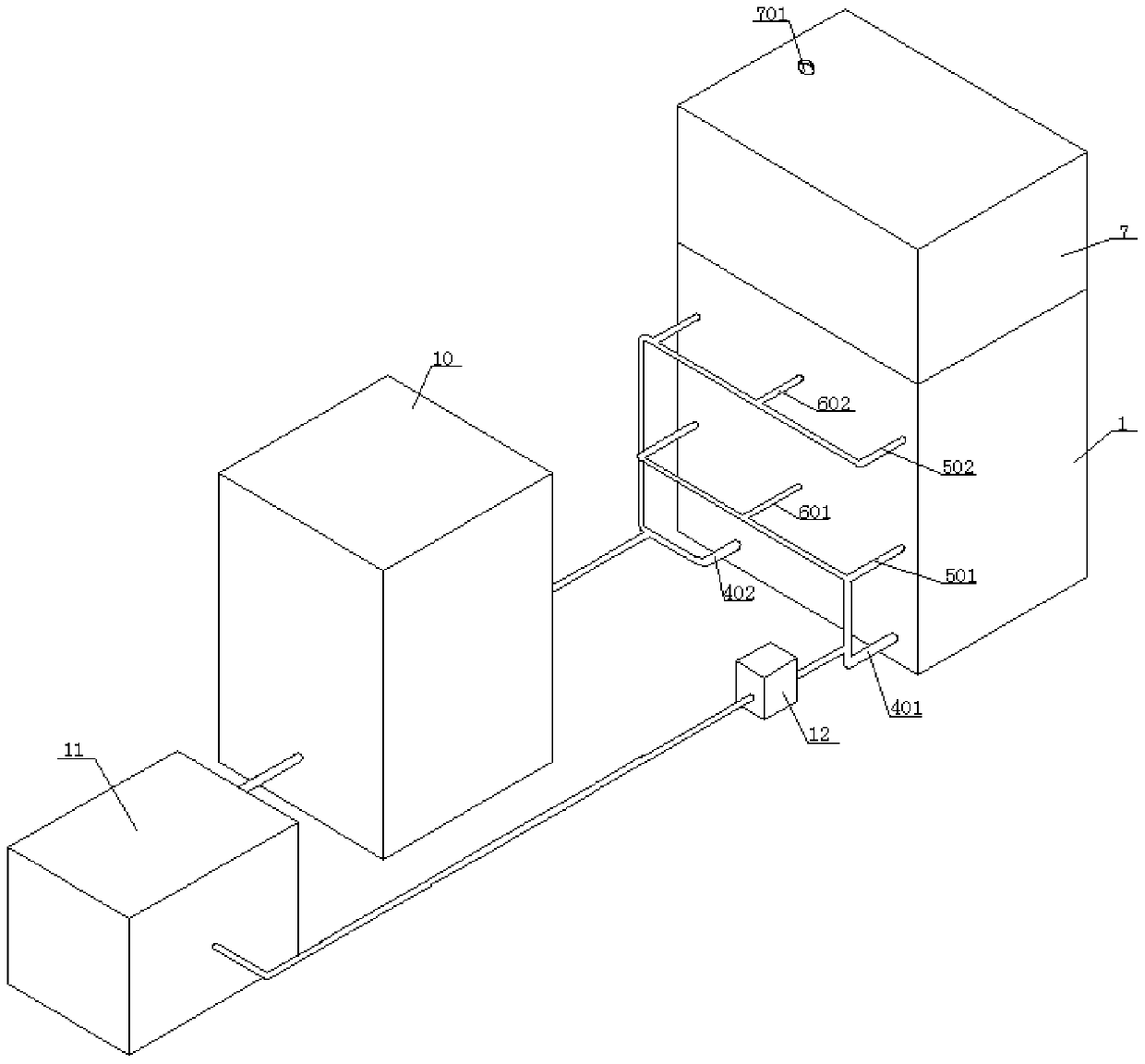

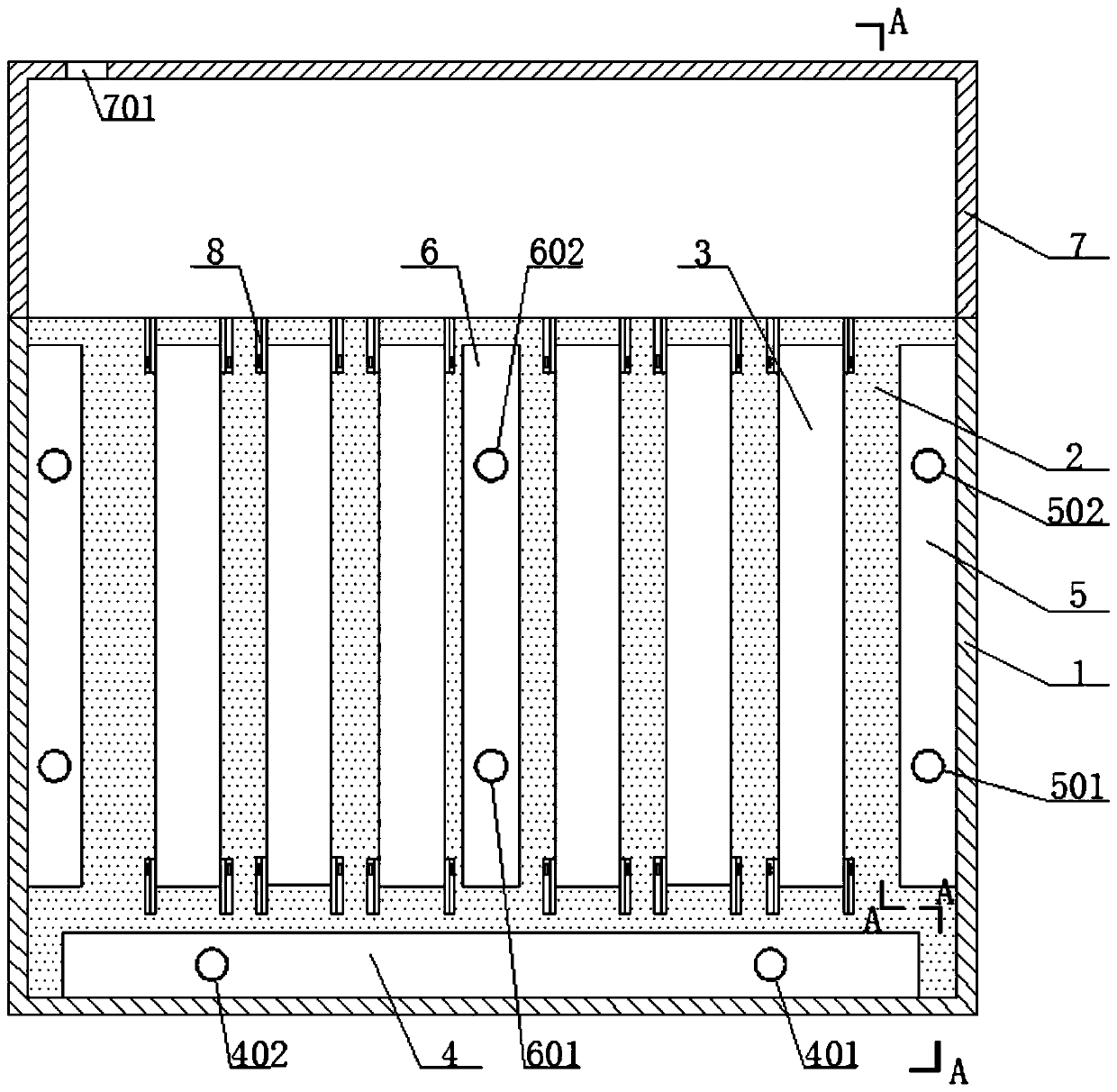

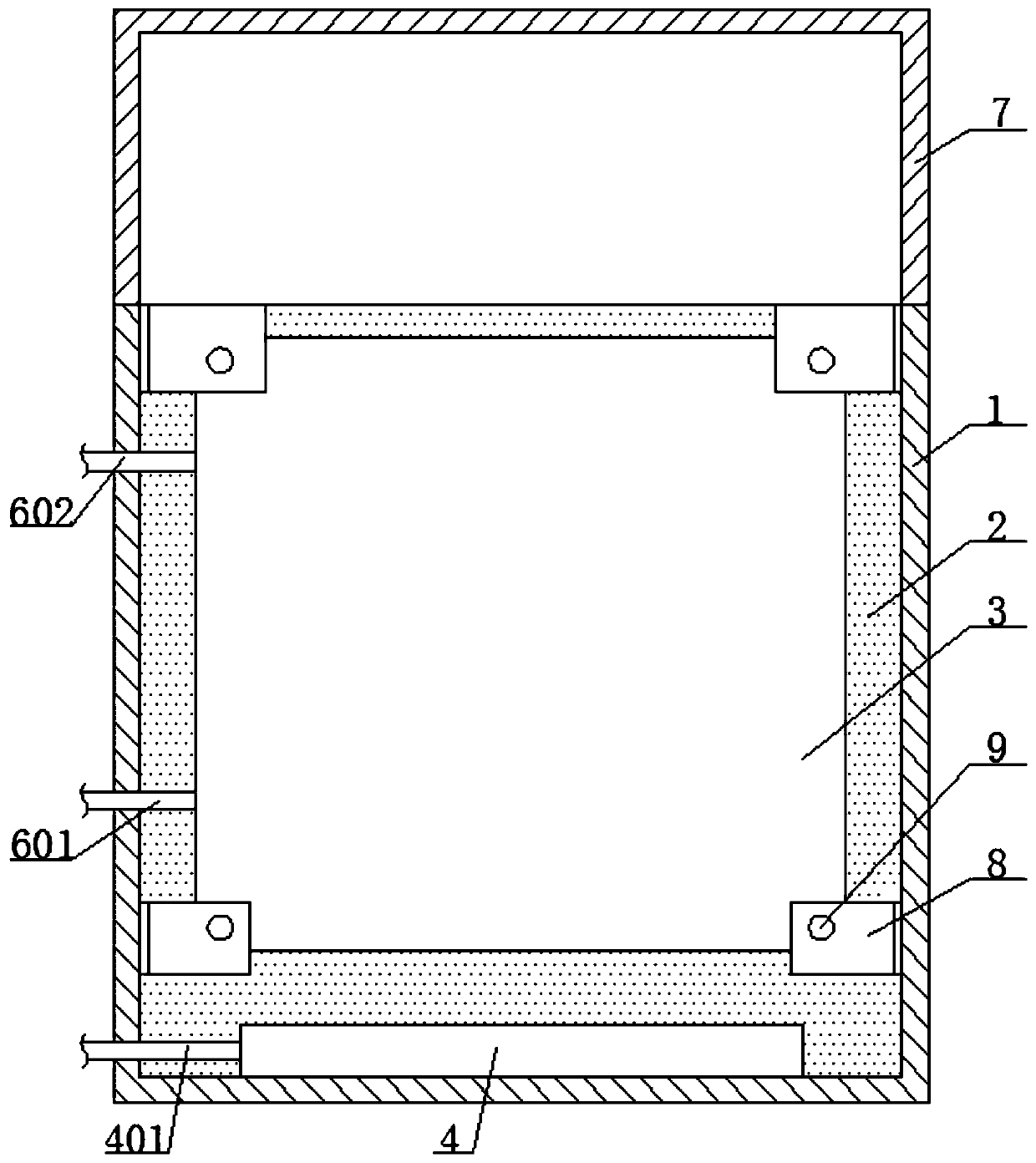

Data center liquid cooling system

PendingCN109952003ALow viscosityNo lossCooling/ventilation/heating modificationsData centerLiquid cooling system

The invention discloses a data center liquid cooling system and relates to the technical field of data center heat dissipation devices. The system comprises a box body, a server, a cold plate, a cooling device, a liquid storage tank and a refrigerant pump. The box body is filled with a single-phase refrigerant, the server is immersed in the single-phase refrigerant, the server is connected to thebox body, the cold plate is arranged in the box body and is connected to the box body, and the cold plate is sequentially connected to the cooling device, the liquid storage tank and the refrigerant pump to form a circulation loop. The invention realizes the combination of indirect contact liquid cooling, single-phase direct immersion liquid cooling and natural cooling, so that the single-phase refrigerant does not need to be circulated under the driving of a pump but is circulated by the change of temperature and density, although the refrigerant is circulated under the driving of the refrigerant pump, the refrigerant has a smaller viscosity than that of the single-phase refrigerant and is easy to flow, the loss of the refrigerant pump is not increased, so the pump loss caused by the single-phase refrigerant is reduced, the PUE of a data center is lowered, and the greenness of the data center is improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

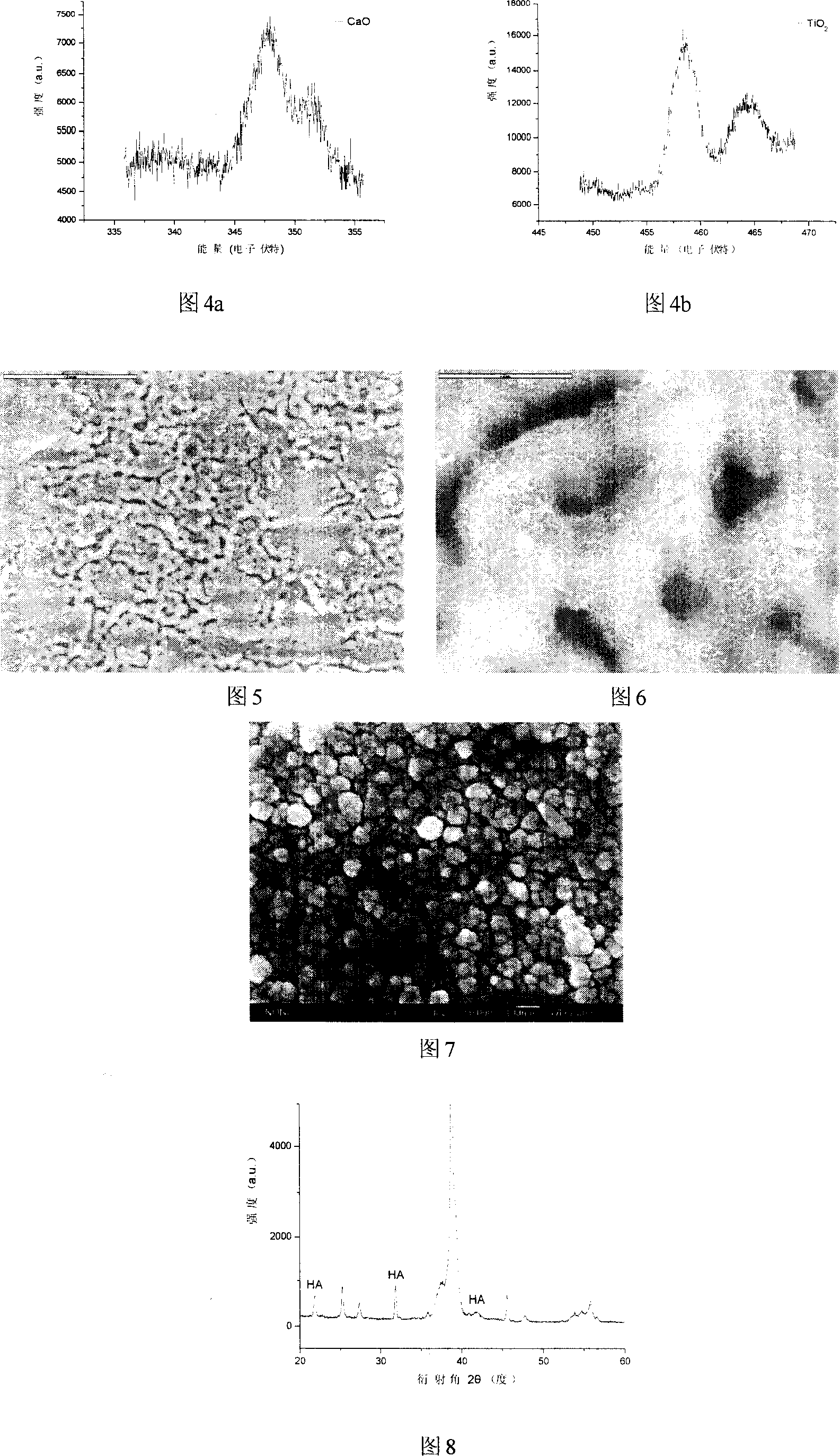

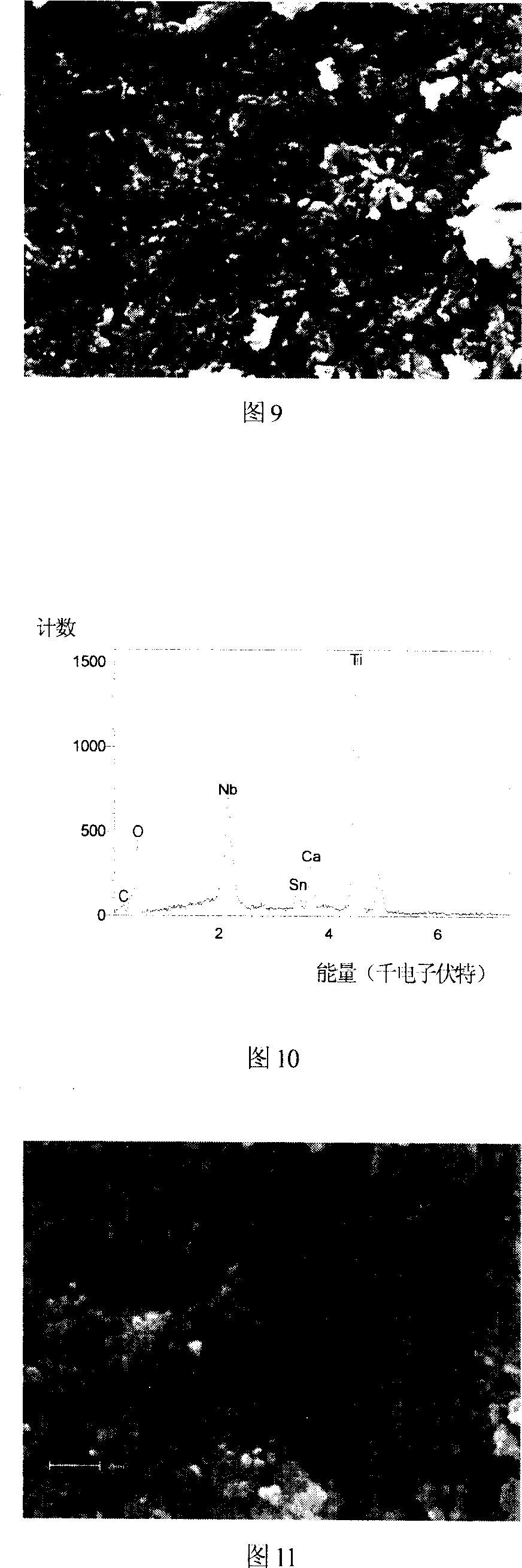

Preparation method of nano hydroxylapatite biology composite coating

InactiveCN101385873AAvoid phase changeAvoid decompositionCoatingsProsthesisDecompositionHydroxylapatite

The invention provides a preparation method of a nano-hydroxyapatite bio-composite coating. Ca(NO3)2.4H2O and (NH2) 2HPO4 are added with distilled water, dissolved, and then added with urea particles for sonochemical synthesis and dried to obtain nano-hydroxyapatite particles; the nano-hydroxyapatite particles and analytically pure chitosan are added into the isopropanol to obtain a suspending liquid; chitosan power is added into acetum, standing still to be defoamed; after being treated with ultrasonic cleaning in ethanol and dried, 2D C / C composite material is put into the defoamed chitosan solution; the surface of the 2D C / C composite material is modified by DC Electrodeposition; the suspending liquid is poured into a hydrothermal electrophoresis reaction kettle, and a C / C substrate with the surface modified is fixed at the anode of the hydrothermal electrophoresis reaction kettle and then immersed in the suspending liquid; the reaction kettle is then enclosed and electrified to ensure the deposition; after the obtained substances in the reaction kettle naturally cool down and are then dried, the composite coating is thus obtained. The preparation method of the coating needs no follow-up crystallized heating, thus avoiding phase change and decomposition of the bio-composite coating in the high-temperature heating.

Owner:SHAANXI UNIV OF SCI & TECH

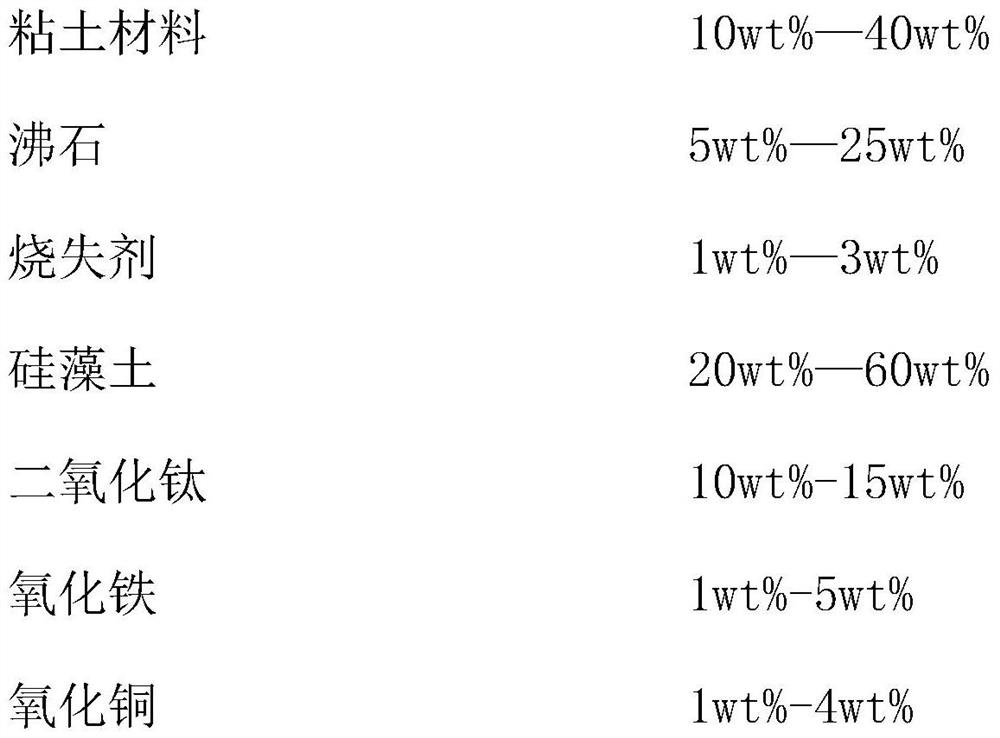

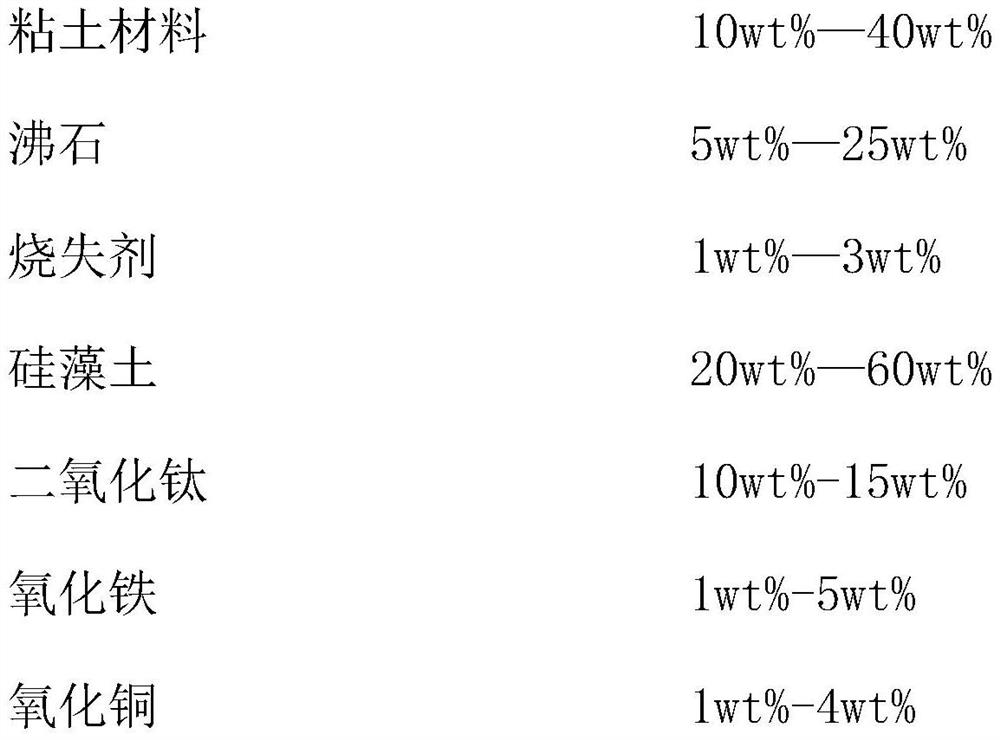

Catalyst capable of simultaneously removing CO, SO2 and NOx

InactiveCN111715234ALarge specific surface areaSimple preparation processGas treatmentHeterogenous catalyst chemical elementsPtru catalystFlue gas

The invention discloses a catalyst capable of simultaneously removing CO, SO2 and NOx and a preparation method of the catalyst. According to the catalyst capable of simultaneously removing CO, SO2 andNOx, cheap clay and fly ash are used as catalyst carriers; the invention comprises pre-oxidizing (acidifying) by using concentrated nitric acid, dissolving active ingredients of the low-temperature catalyst by using water, and then enabling metal oxide to be attached to the catalyst carrier capable of simultaneously removing CO, SO2 and NOx by using an equivalent impregnation method, so as to form the catalyst capable of removing CO and SO2 and NOx in low-temperature flue gas purification. The catalyst capable of removing CO, SO2 and NOx at the same time is simple in preparation process and low in cost, the technical effect of removing CO and SO2 and NOx at the same time can be achieved, the treatment cost and treatment difficulty of enterprises are reduced, and the invention has huge industrial application value.

Owner:BEIJING ZHENJI ENVIRONMENTAL TECH

Method for producing alloy plastic die steel using direct hot delivery and hot charging technique

A method which adopts direct hot feeding and hot charging technique for manufacturing alloy plastic mold steel belongs to the technical field of medium steel plate. The technique comprises the steps of furnace revolving, LF desulfurizing, RH vacuum degassing, continuous casting, cutting, hot feeing, hot charging and heating. The continuous casting sheet billet with thickness of 200-380mm is hot fed and hot charged into a heating furnace after wire cutting without slowly cooling or annealing. The superheat degree of continuous casing pouring is controlled to 10-30 DEG C. The pulling rate is matched with superheat degree and is controlled to 0.7-1.0m / min. The plate bank is directly fed to a heating furnace through the hot feeding roller conveyor after linear fixed-length cutting. The plate blank can be executed with the hot charging technique after linear fixed-length cutting if surface checking or other production organization problem occurs. The plate blank is hotly charged into the heating furnace at a temperature which is larger than or equal to 550 DEG C after checking out of production line. When the plate blank is charged into the heating furnace, the temperature of heating furnace is between 500 and 700 DEG C, and the temperature of preheating section is between 450 and 600 DEG C. The method of the invention has the advantages of excellent heating quality of plate blank according to the technique, shorted production period, and reduced energy consumption of heating furnace.

Owner:SHOUGANG CORPORATION +1

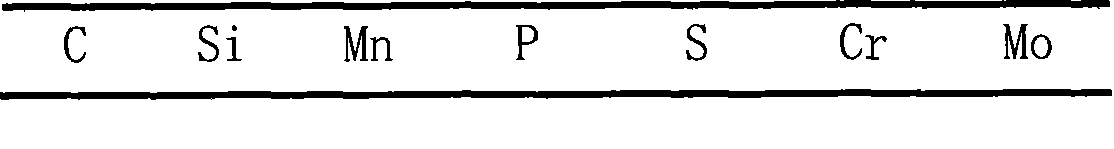

Pipeline pressure-stabilizing system and method used after liquefied petroleum gas out-conveying pipeline stops conveying

ActiveCN105864639AStable pressureEliminate Intensity EffectsPipeline systemsGround temperaturePressure stabilization

The invention discloses a pipeline pressure-stabilizing system and method used after a liquefied petroleum gas out-conveying pipeline stops conveying. The pipeline pressure-stabilizing system comprises a temperature sensor, a pressure sensor, a first-stage pressure-stabilizing device and a second-stage pressure-stabilizing device. The temperature sensor and the pressure sensor are arranged on a main pipeline short section, and the first-stage pressure-stabilizing device and the second-stage pressure-stabilizing device are connected with the main pipeline short section. The first-stage pressure-stabilizing device comprises a first block valve, a stop valve and a pressure buffering tank which are sequentially connected with the main pipeline short section. A second block valve is arranged between the first-stage pressure-stabilizing device and the second-stage pressure-stabilizing device. The second-stage pressure-stabilizing device comprises a third block valve, a pressure buffer, a pressure regulating device and a liquefied petroleum gas storage tank which are sequentially connected with the main pipeline short section. The temperature detection result obtained when conveying is stopped is compared with the ground temperature, the pressure change in the pipeline after a certain period is calculated, and the first-stage pressure-stabilizing device is used for carrying out pressure supplementation on the pipeline according to the analysis result, or the first-stage pressure-stabilizing device and the second-stage pressure-stabilizing device are used for releasing the pressure of the pipeline to achieve pressure stabilization of the pipeline after conveying is stopped, the system safety is guaranteed, and pigging and emptying of the whole line are avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

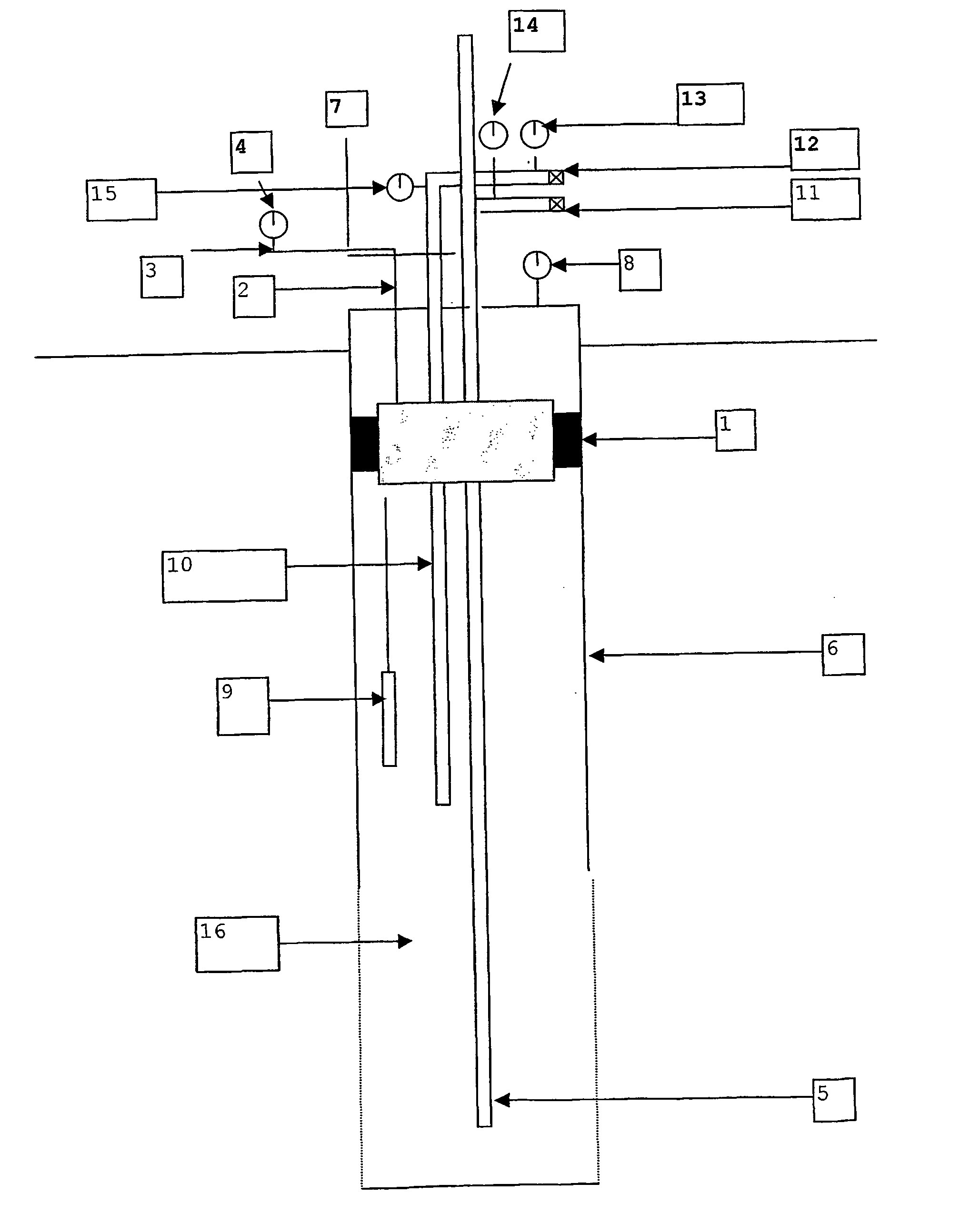

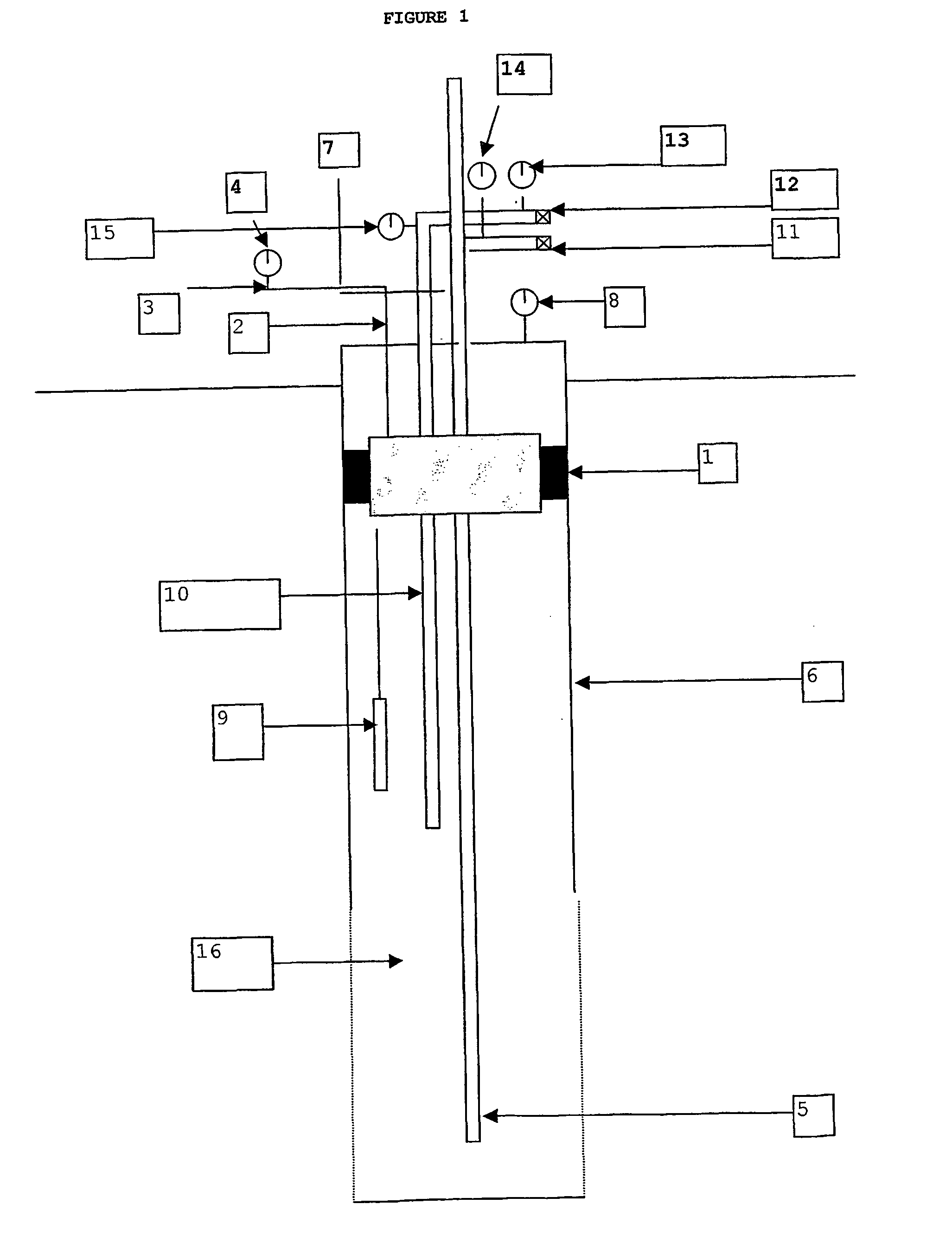

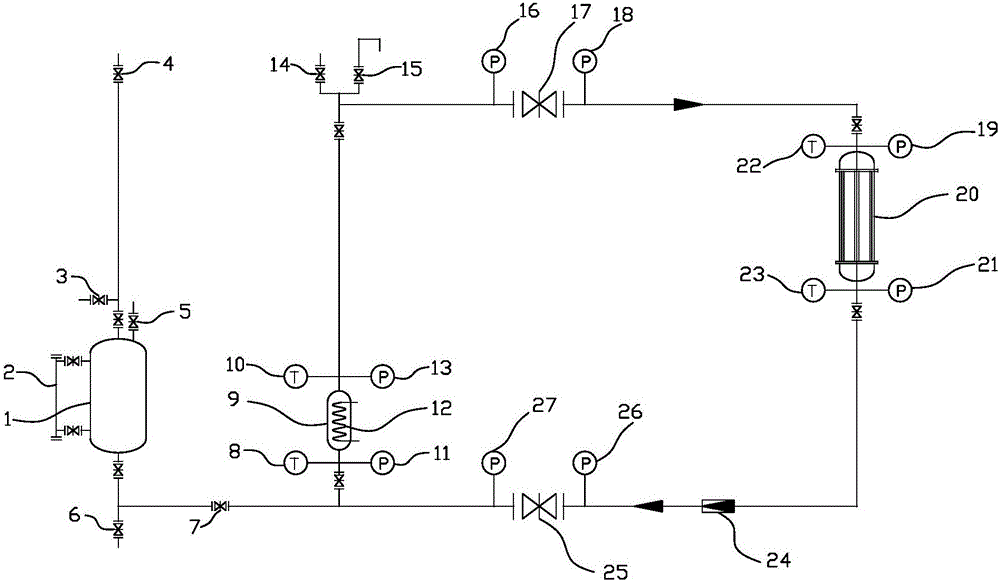

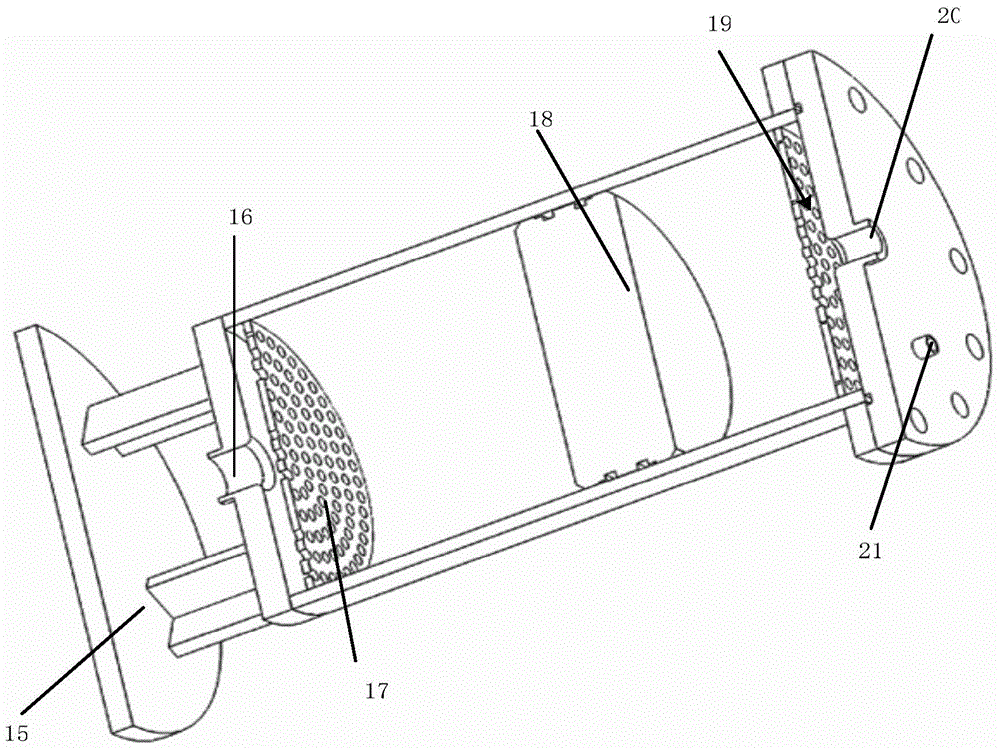

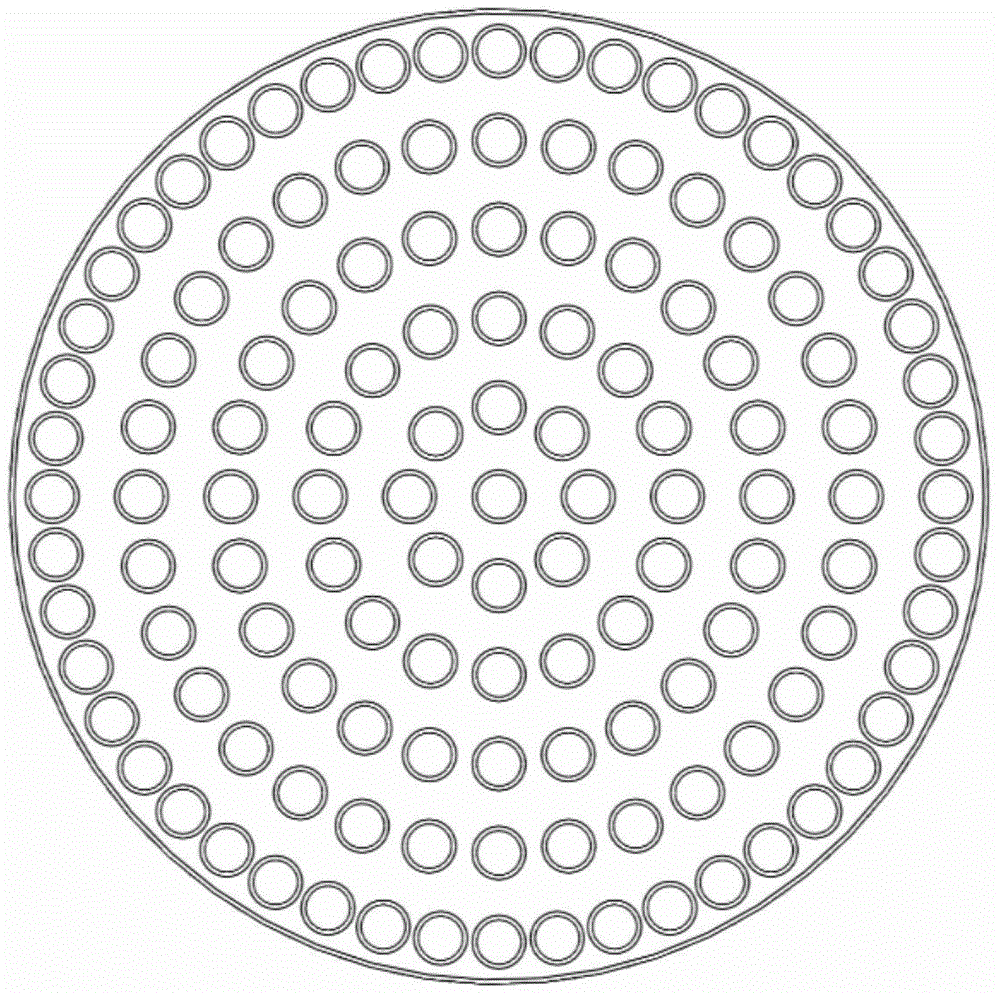

Passive residual heat removal circulating performance testing system and method

ActiveCN106024079AAvoid phase changeGuaranteed accuracyNuclear energy generationNuclear monitoringSteam pressureNuclear reactor

The invention mainly relates to a passive residual heat removal circulating performance testing system. The passive residual heat removal circulating performance testing system comprises a residual heat removal circulating simulation system and an oversaturated pressure system, wherein the residual heat removal circulating simulation system comprises an in-pile heat source simulation module and an out-pile heat dissipation module; the in-pile heat source simulation module and the out-pile heat dissipation module are communicated through a pipeline to from a circulating testing loop; and the oversaturated pressure system enables pressure in the testing system to exceed saturated steam pressure of circulating liquid at a testing temperature. The in-pile heat source simulation module is used for simulating a heat source in an actual nuclear reactor; the volume flow of circulating liquid in the circulating testing loop, temperatures of inlet and outlet ends of the in-pile heat source simulation module and temperatures of inlet and outlet ends of the out-pile heat dissipation module are monitored so that the performance of the residual heat removal circulating simulation system can be obtained; and performances of the residual heat removal circulating simulation system actually arranged in the nuclear reactor can be tested in an accident process according to a performance testing result.

Owner:HEFEI GENERAL MACHINERY RES INST

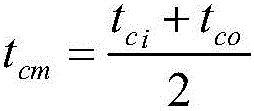

Preparation method of carbon/carbon material C-AlPO4-mullite-MoSi2 composite outer coating layer

The invention relates to a preparation method of a carbon / carbon material C-AlPO4-mullite-MoSi2 composite outer coating layer. The preparation method comprises the steps of: adding mullite powder, C-AlPO4 powder and MoSi2 powder into butanol to obtain suspension A, and adding elementary selenium into the suspension A to obtain solution B; and pouring the solution B into a device which uses a graphite electrode as an anode and a conductive substrate as a cathode for microwave ultrasonic cathode rotation hydrothermal electrophoretic arc-discharge deposition reaction, after the reaction is ended, naturally cooling to room temperature and drying to obtain the final product, i.e. a SiC-C / C test sample protected by the C-AlPO4-mullite-MoSi2 composite outer coating layer. The C-AlPO4-mullite-MoSi2 composite outer coating layer prepared by adopting the method has the advantages of uniform thickness and no surface crack. The preparation method of the C-AlPO4-mullite-MoSi2 composite outer coating layer has the advantages that the preparation period is short, the advantages of hydrothermal, electrophoretic, ultrasonic, microwave and arc-discharge processes are combined, the preparation steps are simple, the operation is convenient to conduct, the raw materials are easy to obtain and the preparation cost is lower.

Owner:XINING GONGJIN NEW MATERIAL TECHNOLOGY CO LTD

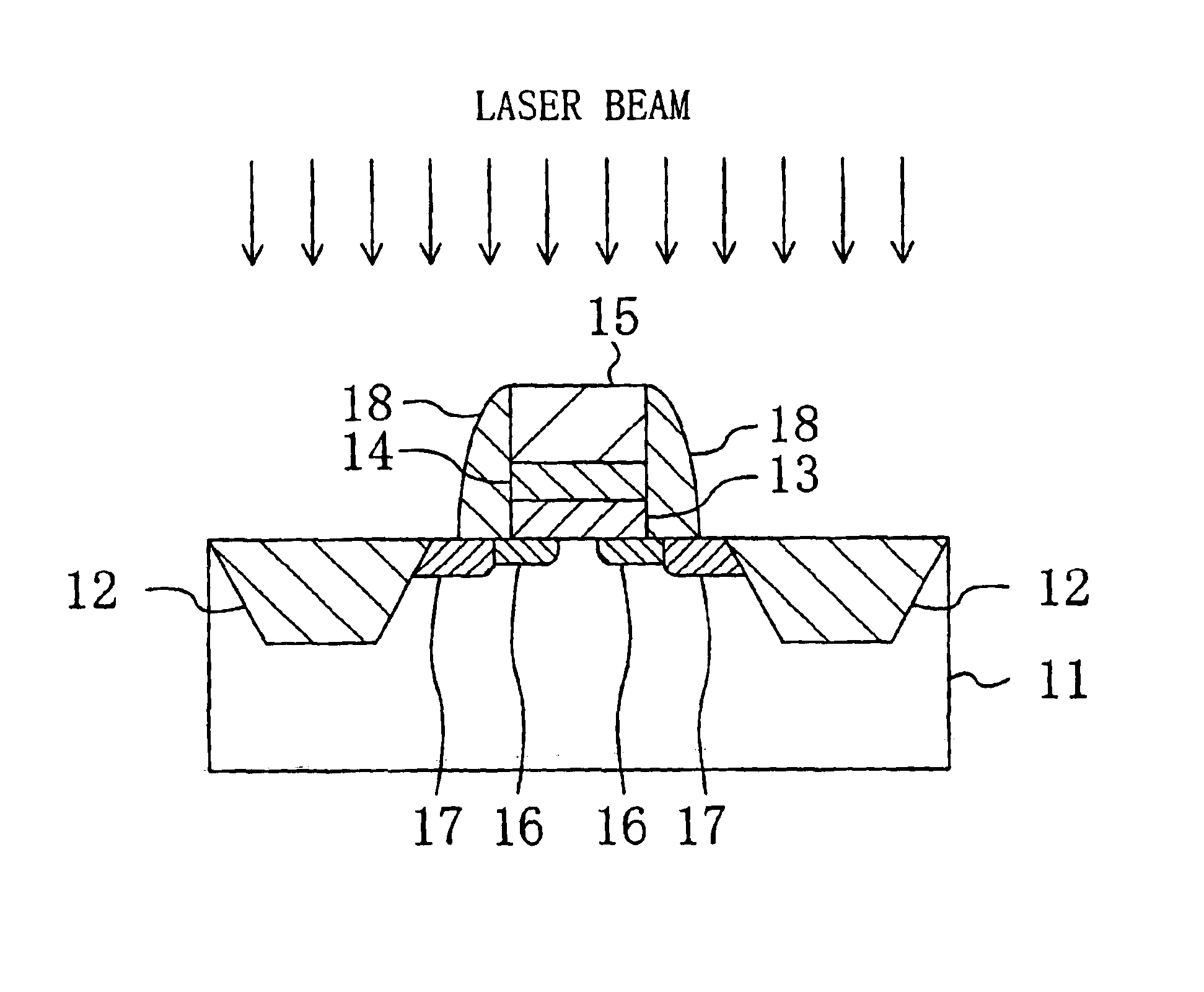

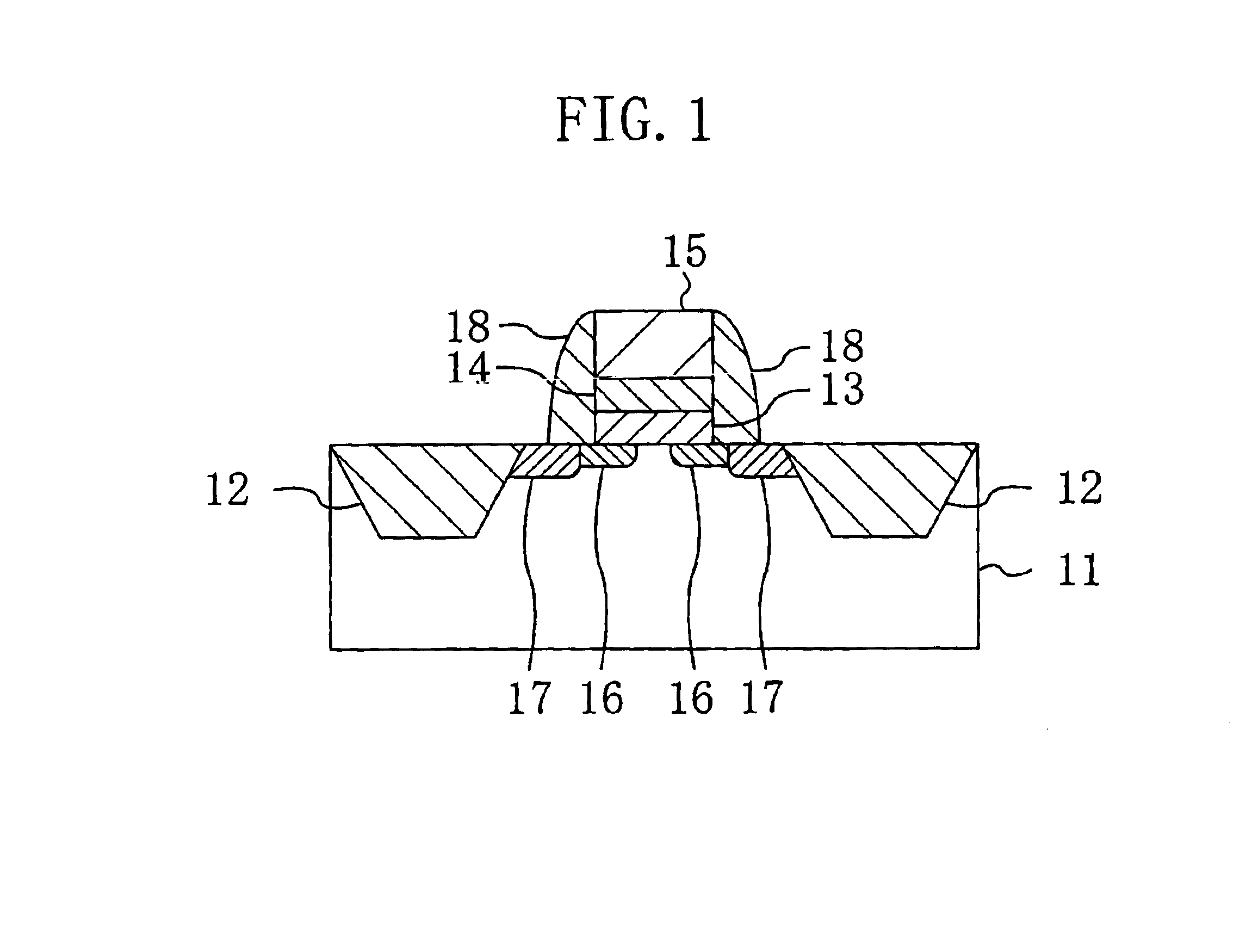

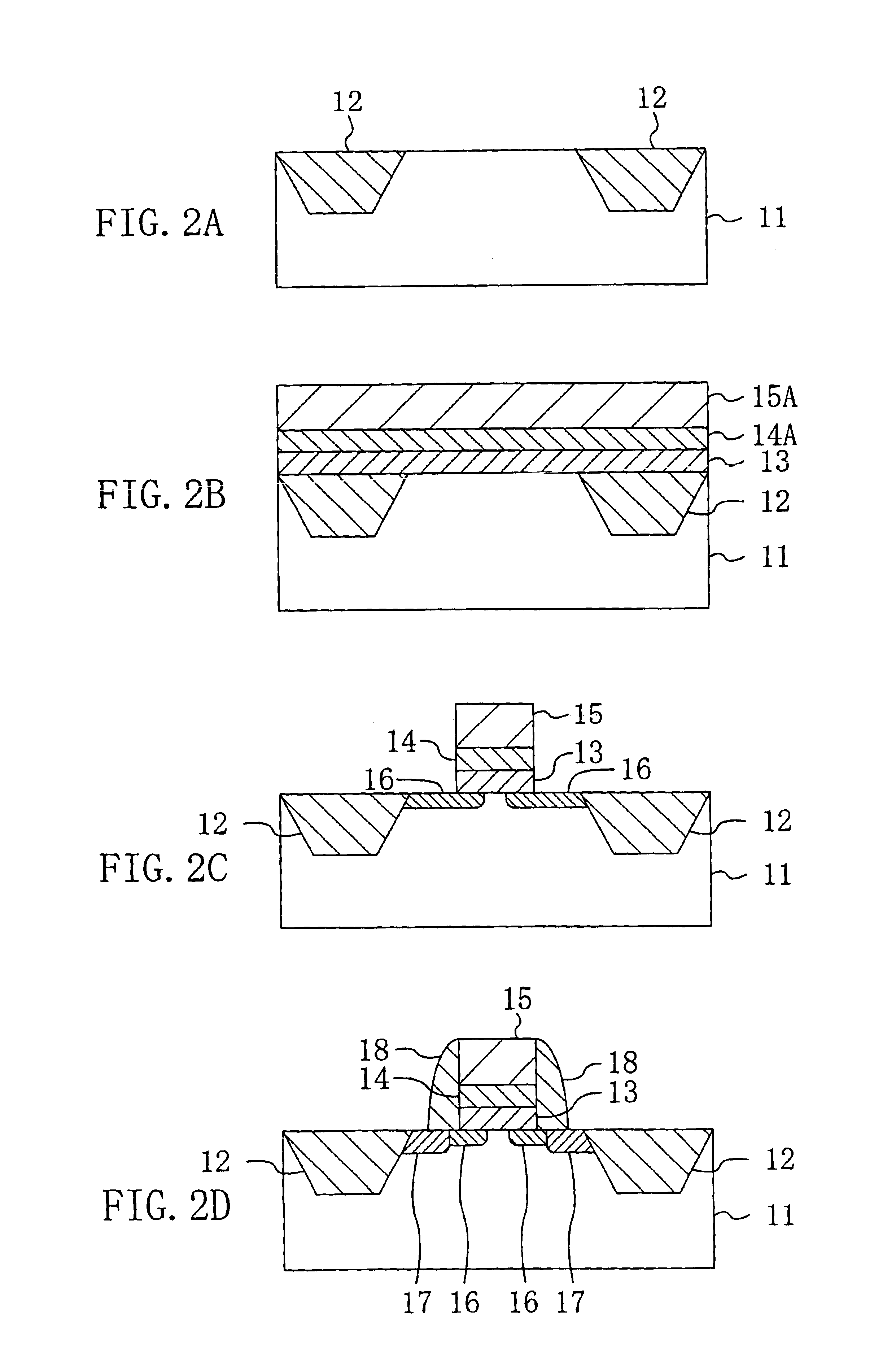

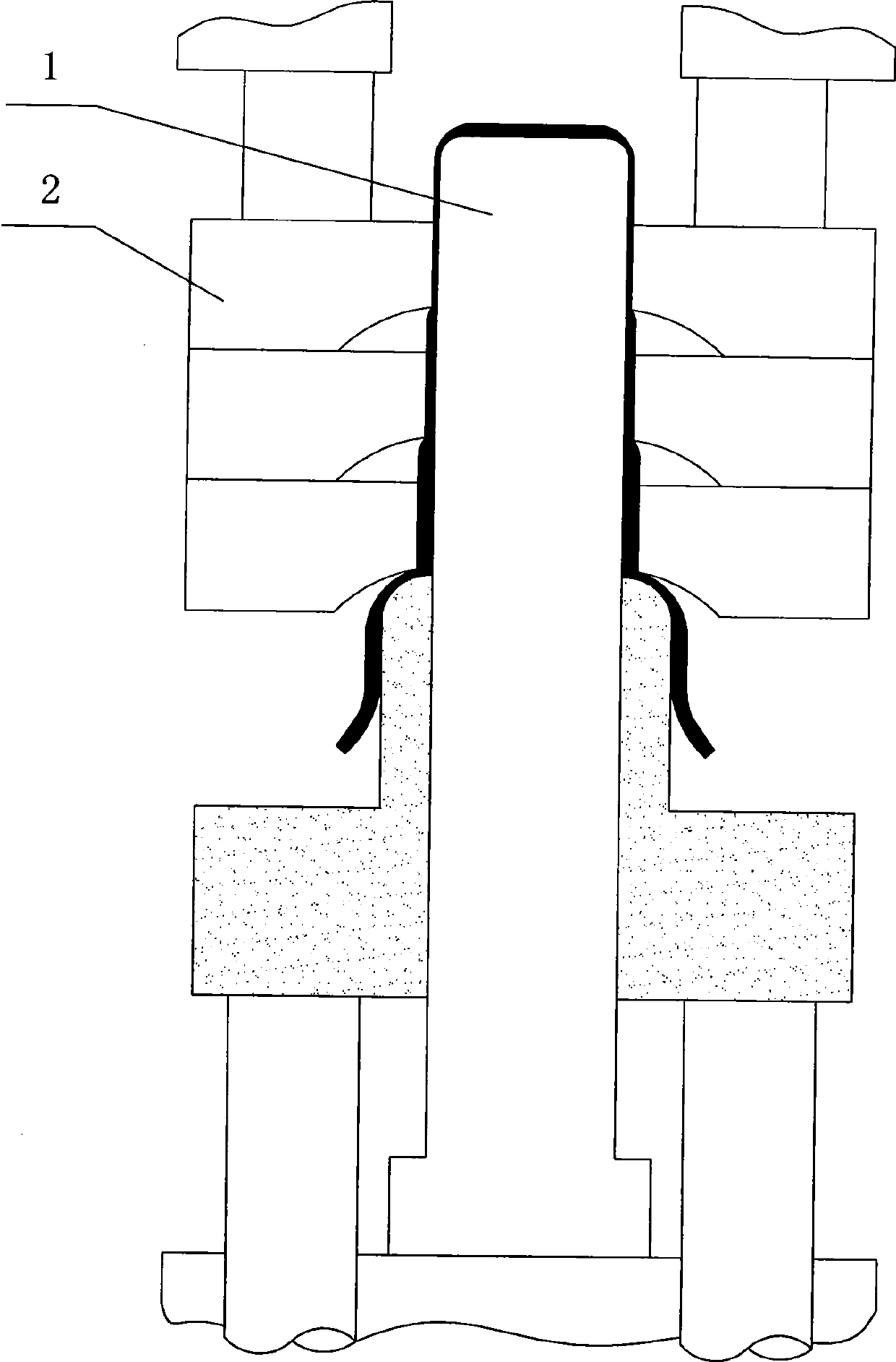

Method for fabricating semiconductor device

ActiveUS7094639B2Shallow junctionLower resistanceTransistorSemiconductor/solid-state device manufacturingSilicon oxidePeak value

An underlying insulting film of silicon oxide, a gate insulating film of hafnium oxide, a gate electrode of polysilicon, and side walls of silicon oxide are formed above an element formation region of a semiconductor substrate. In the upper portion of the element formation region of the semiconductor substrate, source and drain areas and extension areas are formed by implantations of respective types. Thereafter, the scan speed of the semiconductor substrate and the pulse interval and the peak power of laser beam are adjusted to irradiate only the vicinity of the surface of the semiconductor substrate with laser beam for 0.1 second so that the vicinity of the surface of the semiconductor substrate has a temperature of 1150 to 1250° C. Thus, heat treatments for the gate insulating film and the source and drain areas are performed.

Owner:TAIWAN SEMICON MFG CO LTD

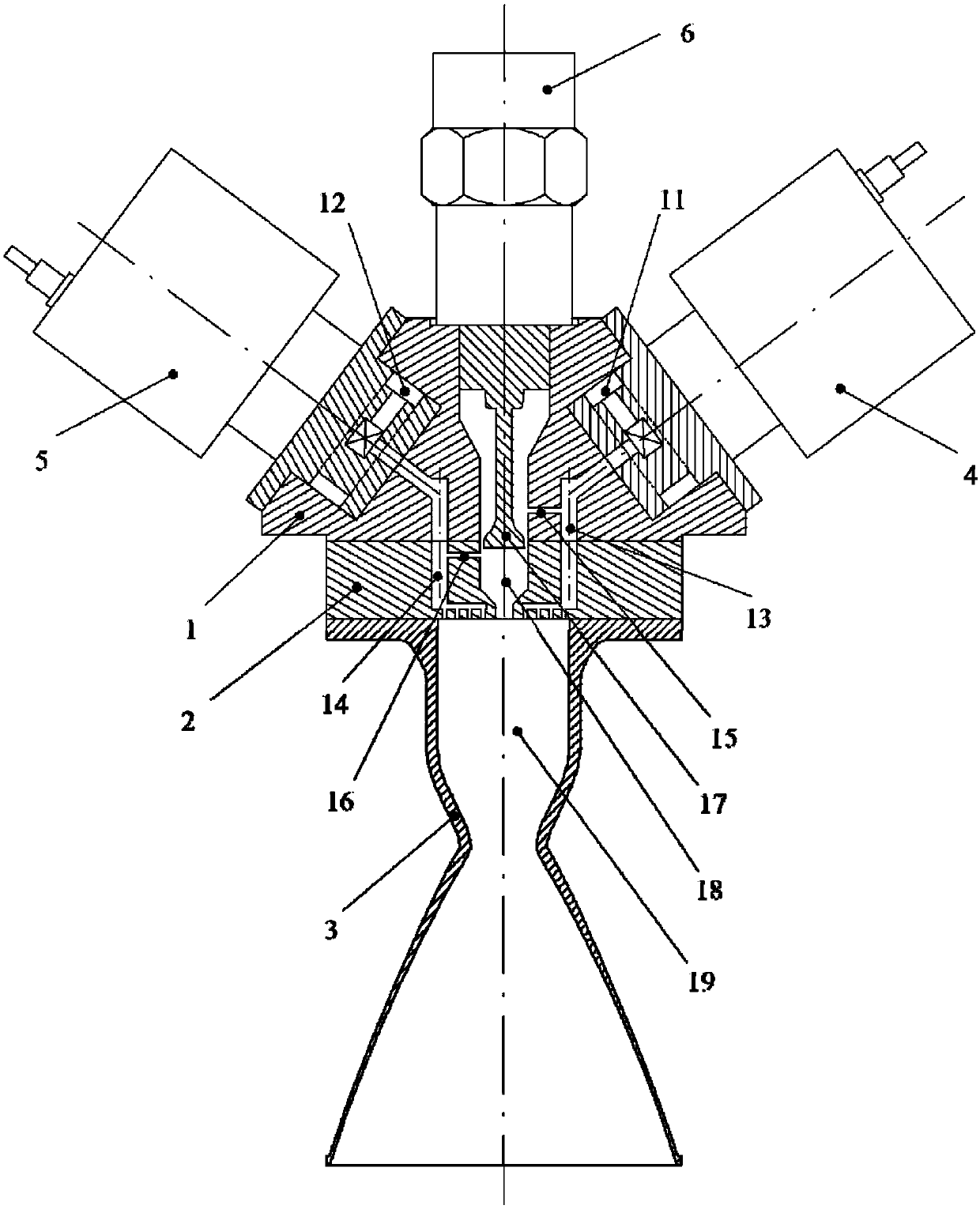

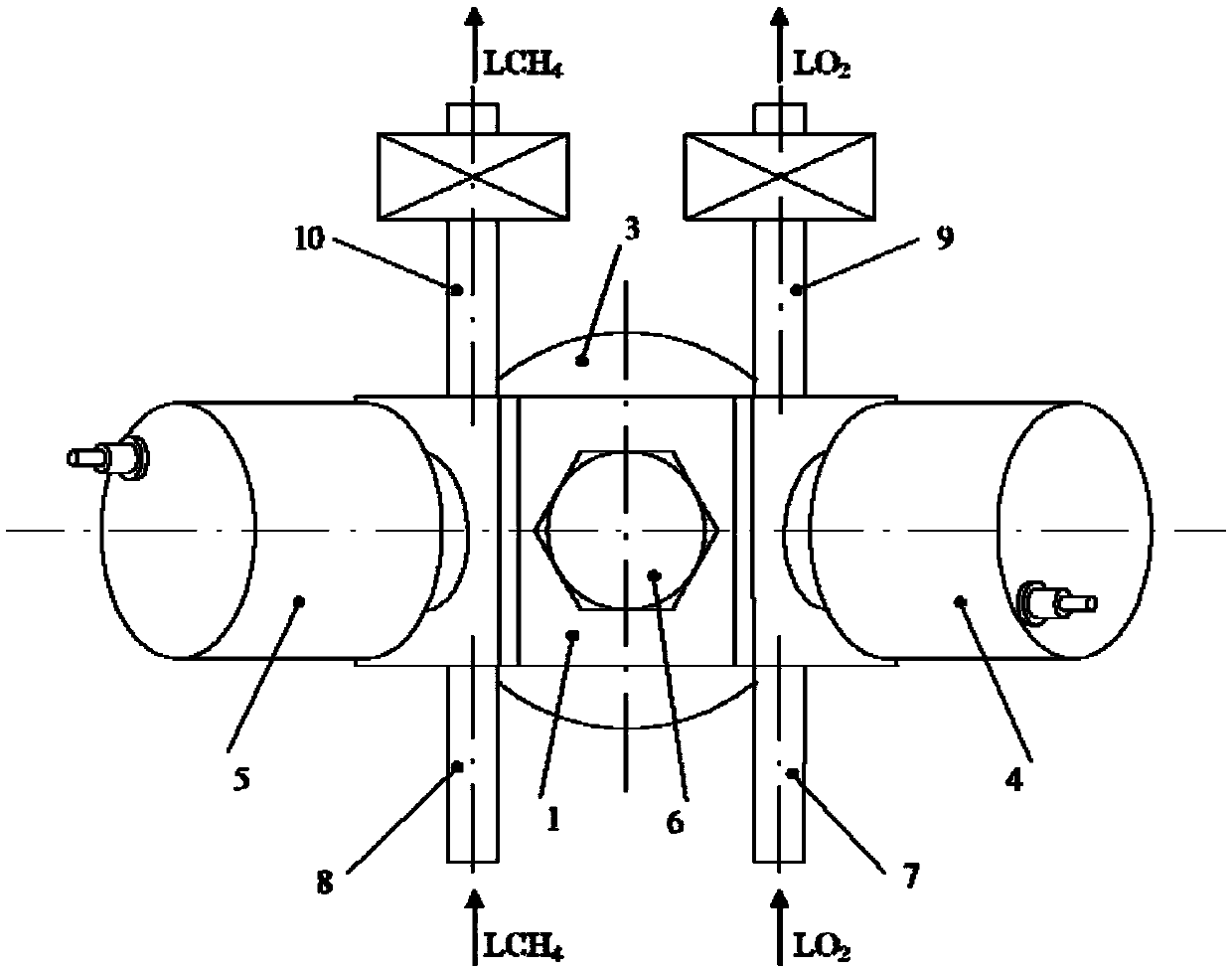

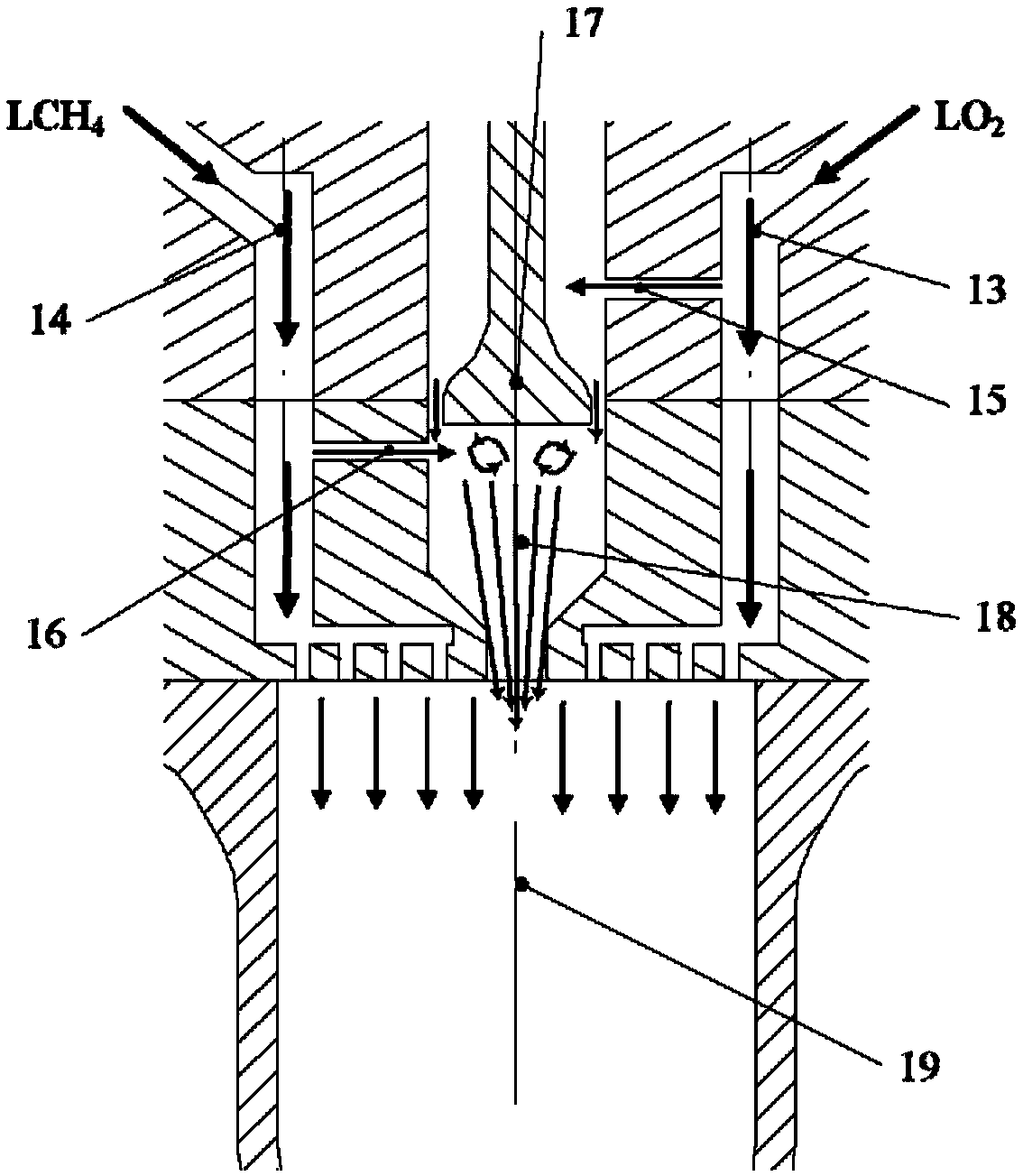

Liquid oxygen and methane engine adopting plug-in type valves and control method

ActiveCN109595097AAvoid phase changeHigh working reliabilityRocket engine plantsJet injectionAttitude control

The invention provides a liquid oxygen and methane engine adopting plug-in type valves and a control method. The liquid oxygen and methane engine comprises a head portion body, a jet injection device,a thrust chamber, a liquid oxygen electromagnetic valve, a methane electromagnetic valve and an ignition plug, wherein the jet injection device is installed to the lower end face of the head portionbody by diffusion welding, the thrust chamber is installed to the lower end face of the jet injection device through bolts, the liquid oxygen electromagnetic valve and the methane electromagnetic valve are installed to the left side face and the right side face of the head portion body in a plug-in type manner through the bolts correspondingly, and the ignition plug is installed to the upper portion of the head portion body through screw threads. By means of the liquid oxygen and methane engine, the problems existing in the prior art that a low-temperature attitude control engine is difficultto precool, and a low-temperature propulsive agent is prone to generating phase change inside the head portion of the engine can be solved, meanwhile, the liquid oxygen and methane engine has the advantages of being compact in structure, easy to operate and control and fast in response speed, and the use requirements for an attitude control power system can be met.

Owner:SHANGHAI INST OF SPACE PROPULSION

Surface treatment for improving bioactivity and wear-resistant ability of titanium alloy surfaces

InactiveCN1712076AHigh surface hardnessImprove surface activityCoatingsWear resistantHydroxyapatite crystal

A surface treating method for increasing the surficial bioactivity and antiwear power of Ti alloy features that a gradient coated layer composed of internal oxidized layer (0.5-5 microns in thickness) and external hydroxyapatite layer (0.1-10 microns in thickness) is prepared on the surface of Ti alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

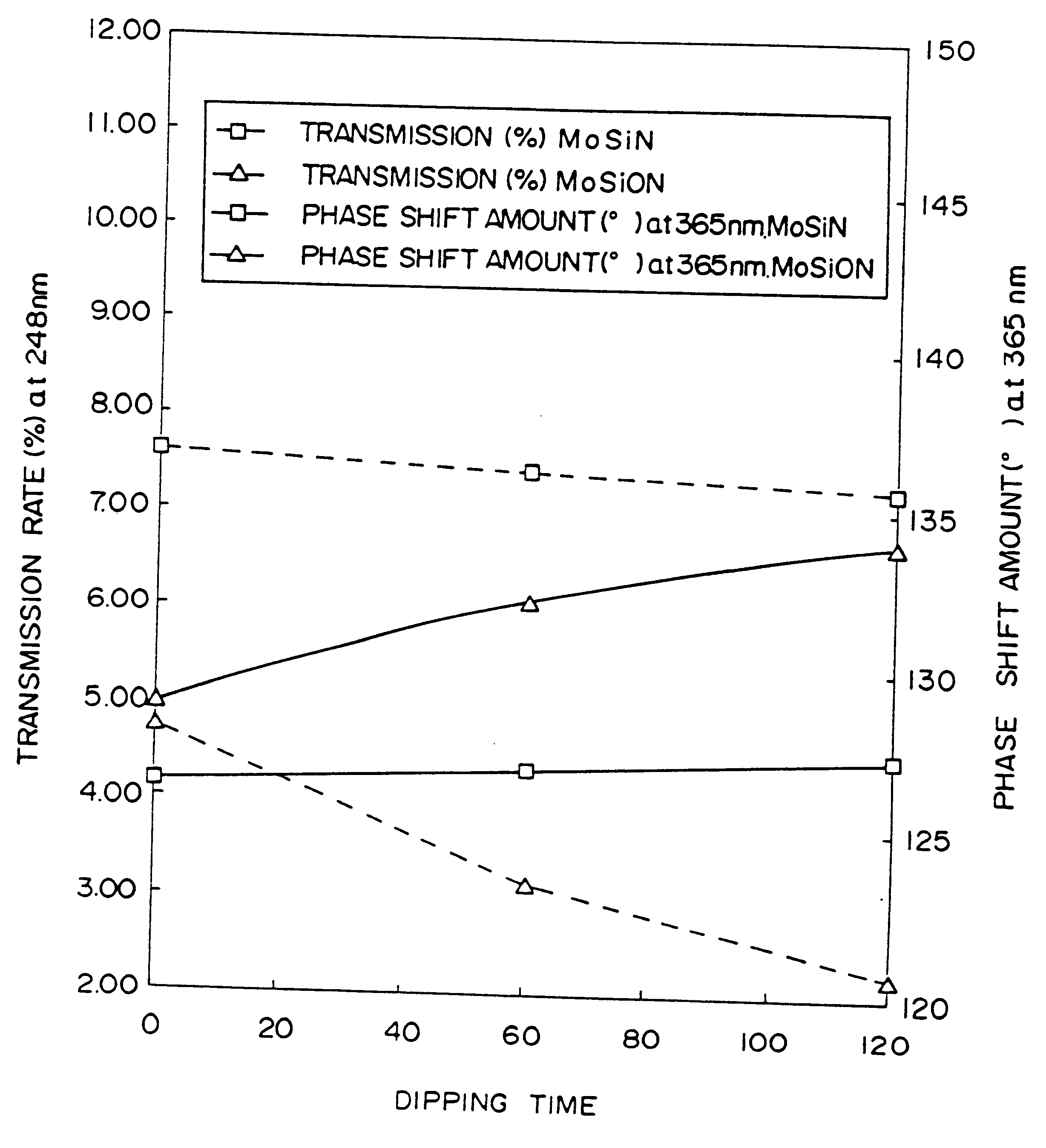

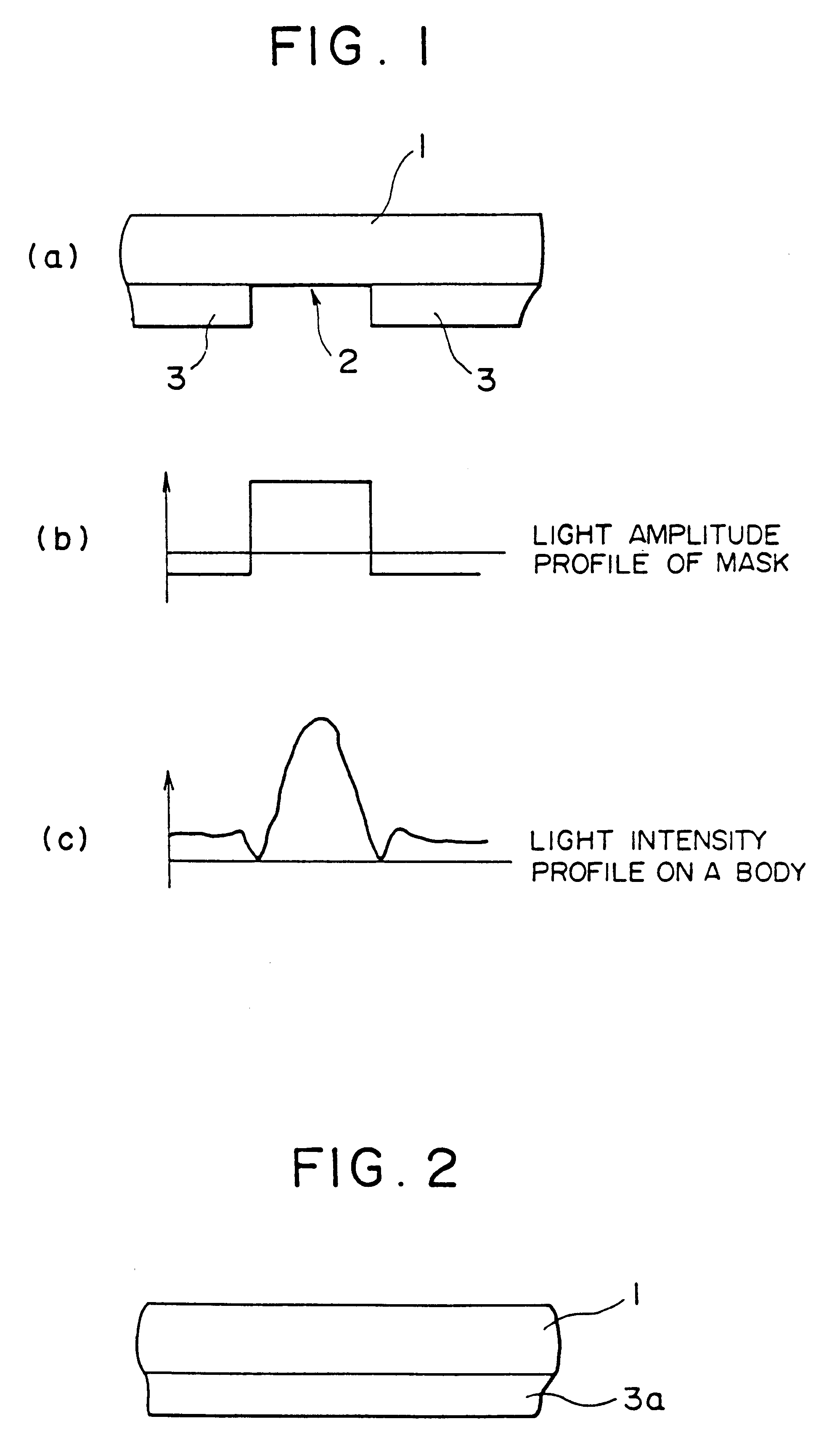

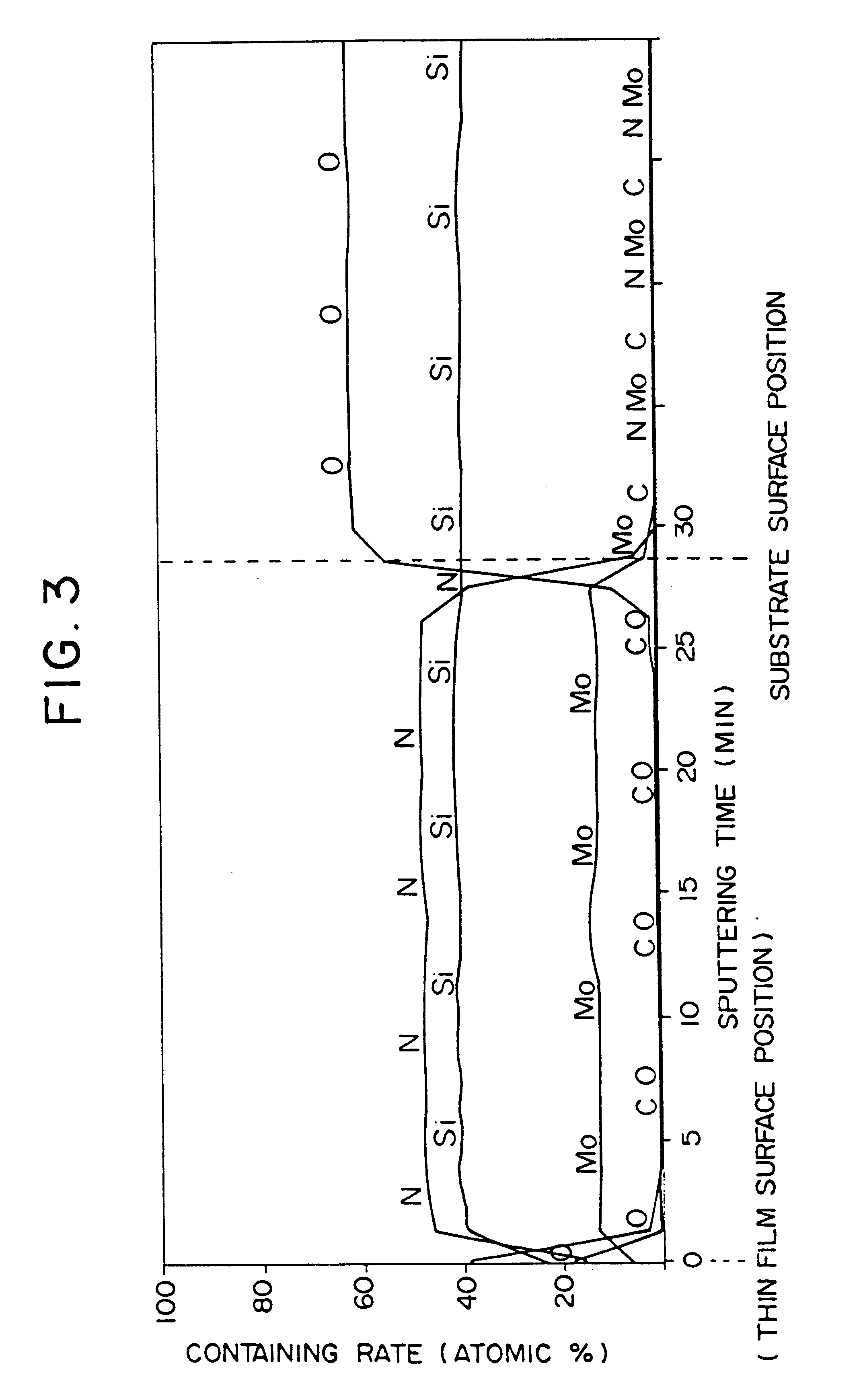

Phase shift mask and phase shift mask blank

InactiveUS6242138B1Improve featuresImprove film propertiesSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentOptical propertyPhase shifted

A half tone type phase shift mask as well as a phase shift mask blank for the mask is formed with a thin film light translucent portion made of essentially, nitrogen, metal, and silicon. The containing rate of each element and ratio in the thin film is specified in a certain range to improve film characteristics, such as acid resistance, photo resistance, conductivity, refractive index rate (film thickness), light transmission rate, etching selectivity, etc. of the light translucent portion. The phase shift mask satisfies optical characteristics (i.e., light transmitting rate and phase shift amount) with high precision, as well as reduces defects in the thin film.

Owner:HOYA CORP

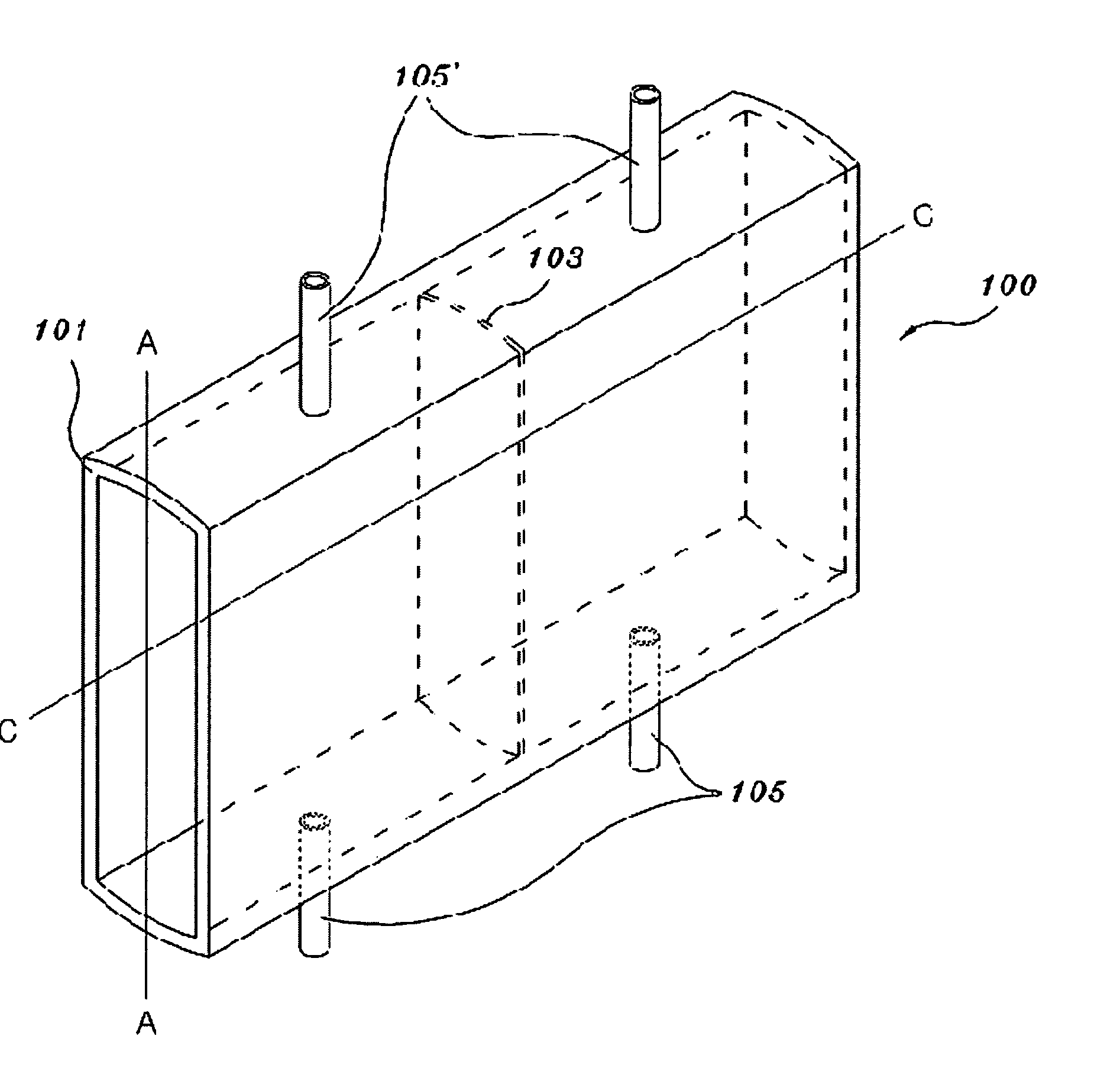

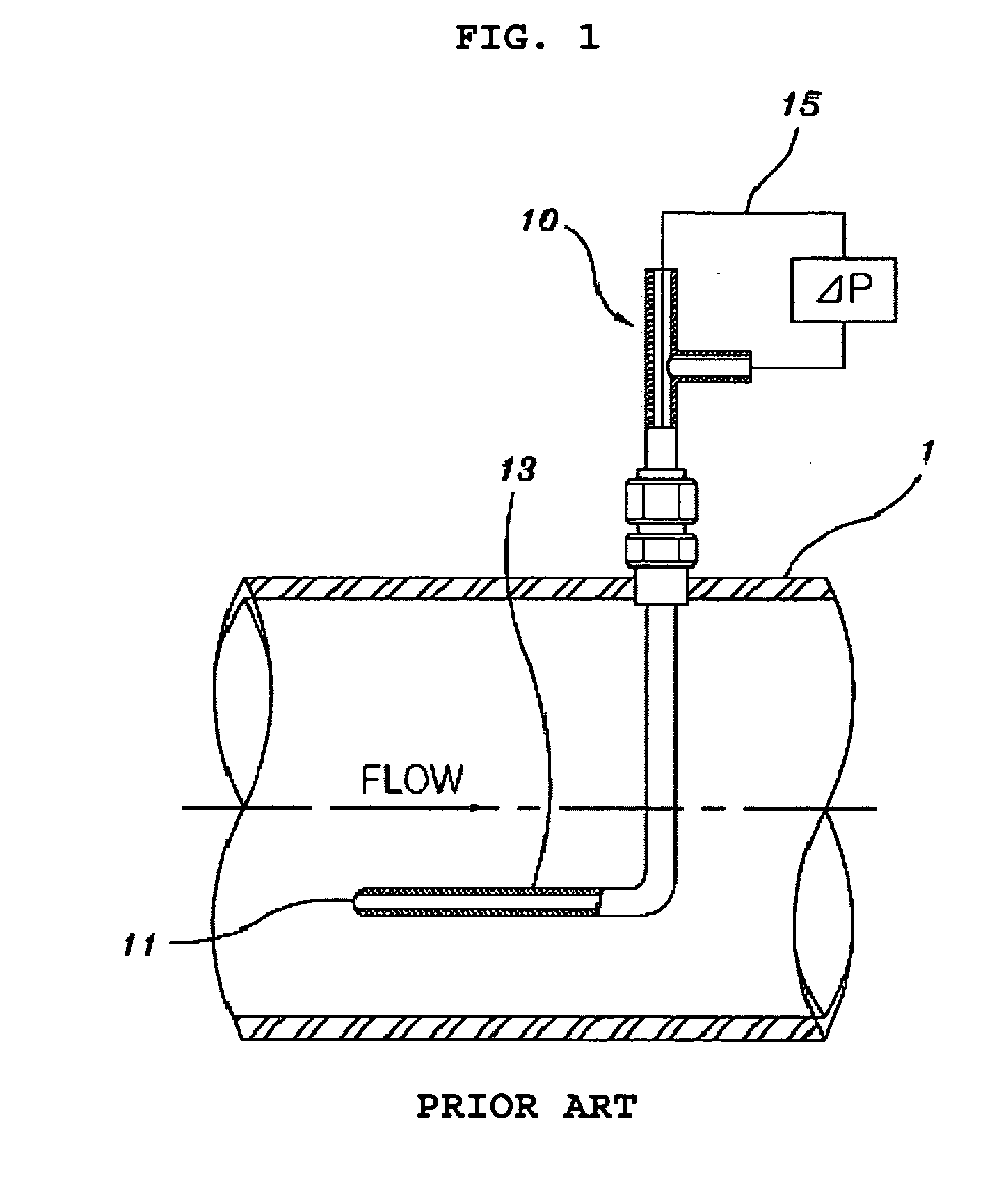

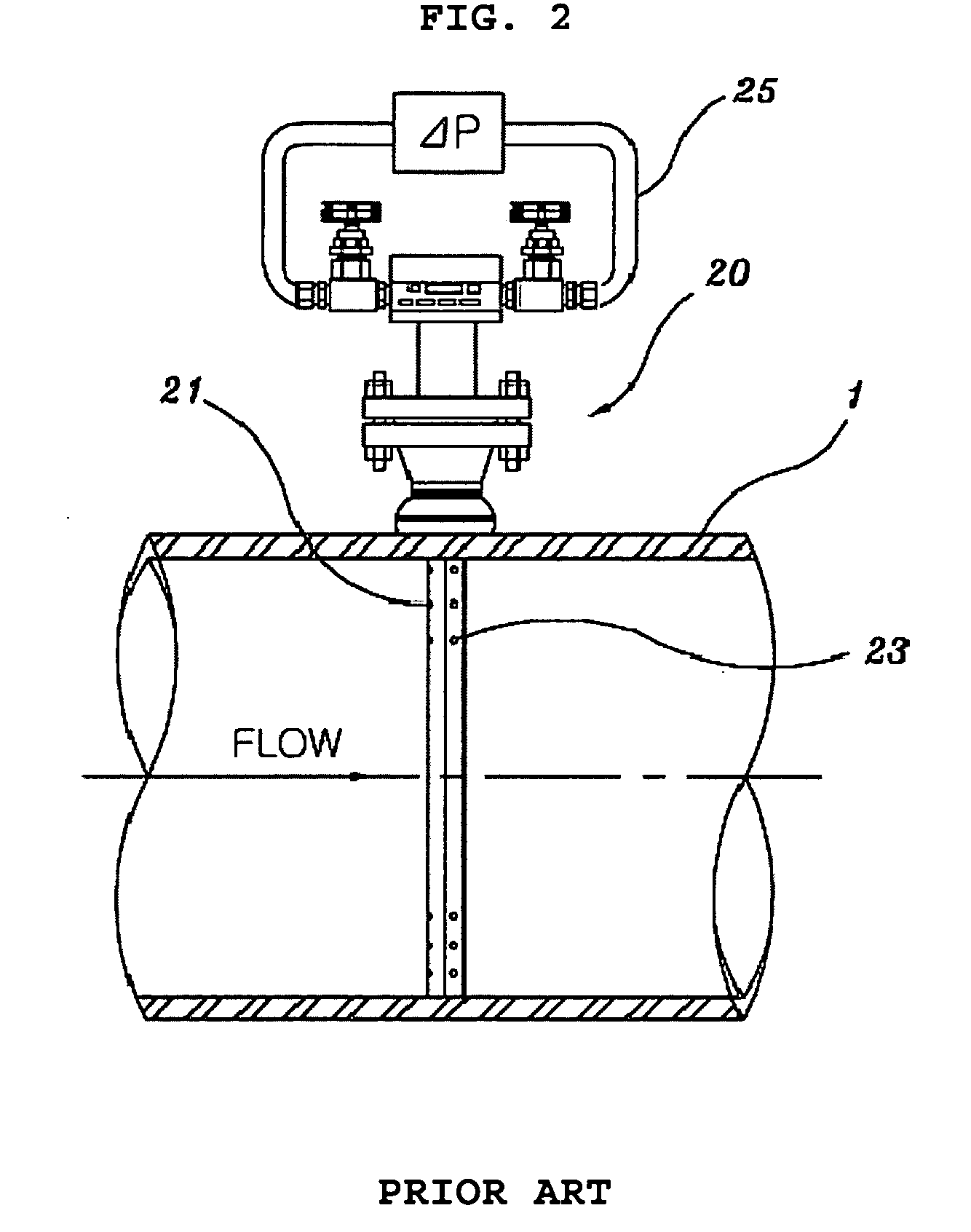

Average bidirectional flow tube

ActiveUS20050229717A1Easy to measureReduce back pressureVolume/mass flow by differential pressureLow speedStream flow

An average bidirectional flow tube, including a body having two side plates and upper and lower plates, a partition plate installed to be perpendicular to the side plates of the body so that front and rear ends of the tube are separated from each other, and two pairs of pressure impulse lines installed at front and rear positions of the partition plate. The upper and lower plates of the body each have a curvature to be in contact with an inner surface of a pipe in which the average bidirectional flow tube is installed, and each of the pressure impulse lines is installed to communicate with an interior of the pipe. Although a two-phase flow occurs in the pipe or the flow of the fluid flowing in the pipe is changed, an average flow rate of a fluid can be measured. Particularly, it is easy to measure an average flow rate of the fluid when the fluid flows at a low speed. Further, even when sudden pressure reduction occurs in the pipe, an additional cooling device is not required. When a two-phase flow occurs in the pipe, the fluid suffers a phase change due to the sudden pressure reduction of the pipe, or a stratified flow occurs due to the two-phase flow in a horizontal pipe, it is unnecessary to displace the average bidirectional flow tube.

Owner:KOREA ATOMIC ENERGY RES INST +1

Stroke processing method of ultrathin cylinder stainless steel tube film for printer and duplicator

InactiveCN101767139AAvoid phase changeImprove plasticityShaping toolsMartensite transformationPunching

The invention discloses a stroke processing method of an ultrathin cylinder stainless steel tube film for a printer and a duplicator, comprising the following steps of: a. preparing a mould with continuous multistage stroke processing; b. primarily stretching a plate to prepare a cylinder with marginal ridge; c. coating lubricating agents on the inner wall and the outer wall of the cylinder, mounting the cylinder on a punching head of the mould, driving the punching head to press into the mould once, simultaneously cooling the punching head and heating a punching die of each stage through stroke processing; and d. drawing out the punching head for demoulding, cutting off two ends of a pipe fitting subjected to the differential temperature stroke processing and reserving the pipe body at the middle to obtain the required ultrathin cylinder stainless steel tube film. With the technical scheme, by cooling the punching head, heating the punching die of each stage through stroke processing and carrying out multistage stroke processing by one-time differential temperature, the invention avoids the martensite phase transformation and improves the plasticity of stainless steel materials. In addition, by using the process method, the production can be finished by only three working procedures of primary stretching, annealing and multistage stroke processing and re-stretching, so that the production efficiency is improved.

Owner:刘江

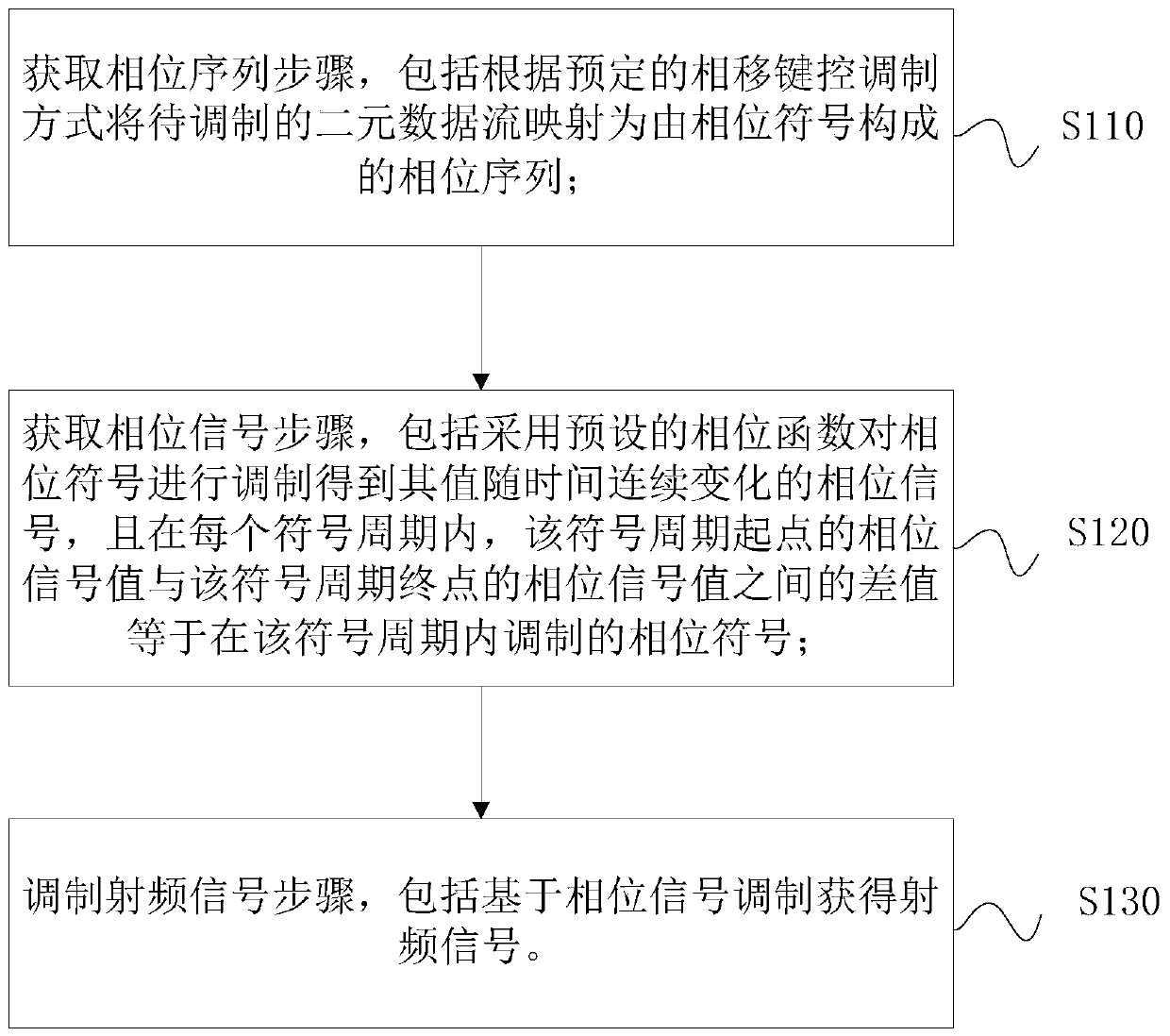

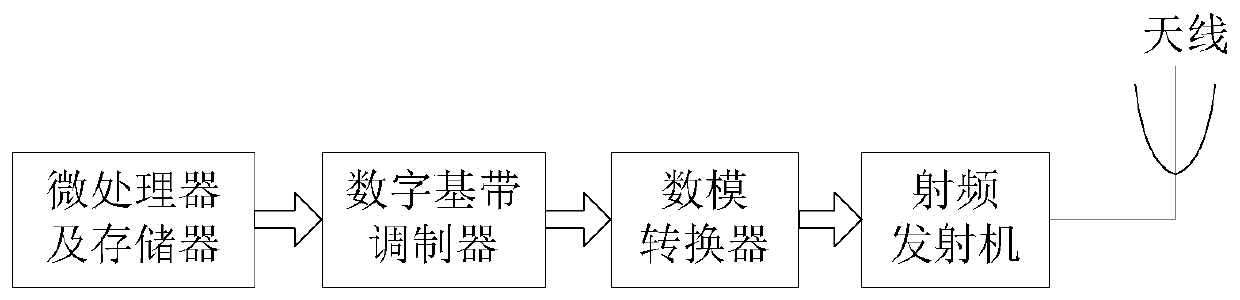

Phase shift keying modulation and demodulation method and equipment

ActiveCN111245757AReduce complexityHigh Power Amplification EfficiencyPhase-modulated carrier systemsModem deviceFrequency spectrum

The embodiment of the invention provides a phase shift keying modulation method and a corresponding modem thereof. The method adopts a technology of continuously changing the phase to avoid phase mutation so as to reduce the out-of-band frequency spectrum and improve the frequency spectrum efficiency; and meanwhile, the characteristic of a constant envelope is maintained so as to improve the efficiency of radiofrequency signal power amplification. The corresponding modem modulates the signal by adopting the phase shift keying modulation method, and the corresponding modem modulates the signalby adopting the phase shift keying modulation method.

Owner:NANJING ZGMICRO CO LTD

Hard-face overlaying welding material and use thereof

ActiveCN101439445AAvoid phase changeUniform tissueFurnace typesHeat treatment process controlChemical compositionWear resistant

The invention discloses an overlaying welding alloy material which can resist abrasion and corrosion and can be moulded without crack, and usage thereof. Counted by weight percentage, the welding alloy material comprises the components as follows: 0.4-0.6 percent of C, 0.6-1.0 percent of Si, 1.5-1.8 percent of Mn, 0.8-1.2 percent of Mo, 14-16 percent of Cr, 0.6-1.0 percent of W, 0.3-0.5 percent of Nb, 0.05-0.1 percent of V, 0.05-0.1 percent of rare earth, not more than 0.035 percent of S, not more than 0.035 percent of P and the balance of Fe, wherein, the amount of the components is 100%. The welding process matching the material comprises that the heating temperature is 180-230 DEG C; the interlayer temperature is 250-300 DEG C and the backfiring temperature is 550-650 DEG C. The invention is simple in process and adds no cost. The alloy is overlaying welded on the surface of a work piece so that the anti-abrasion capability thereof is the same as the capability of high-chromium cast iron welding material. Meanwhile, no crack forms in the moulding process, thereby enhancing the anticorrosion capability; therefore, the comprehensive performance of the material is better than that of high-chromium cast iron, so as to prolong service life of the work piece. Take for instance, the comprehensive performance of a rotor of an internal mixer is more than 1.5 times of an original one. Meanwhile, the surface is moulded without crack so that the material can also be used as hard alloy of the transition layer during manufacturing process of a super wear-resistant piece.

Owner:YIYANG RUBBER PLASTICS MACHINERY GROUP

Preparation method of C-AlPO4-mullite/glass layer gradient composite antioxidation coating

The invention relates to a preparation method of a C-AlPO4-mullite / glass layer gradient composite antioxidation coating, which comprises the following steps: mixing SiO2, B2O3, Al2O3 and MgO to obtain powder A; calcining the powder A, and grinding to obtain glass powder B; adding the mullite powder and the C-AlPO4 powder into isopropanol to obtain a suspension C; adding a simple substance iodine into the suspension C to obtain a solution D; pouring the solution D into a device which uses a graphite electrode as the anode and a conductive base as the cathode, clamping a C / C composite material sample with an SiC internal coating onto the cathode in the device, and carrying out electrophoretic arc discharge deposition to obtain a sample E; adding the glass powder B into ethanol to obtain a slurry, repeatedly brushing the slurry on the surface of the sample E, and drying to obtain a sample F; and putting the sample F in a crucible, putting the crucible in a vertical vacuum furnace, heating to react while introducing argon as a protective atmosphere, and opening the furnace and the crucible to obtain the C-AlPO4-mullite / glass layer gradient composite antioxidation coating. The composite coating prepared by the method provided by the invention can protect a C / C composite material at 1500 DEG C in static air for 700 hours, and the oxidative weight loss is less than 0.8%.

Owner:吴文婕

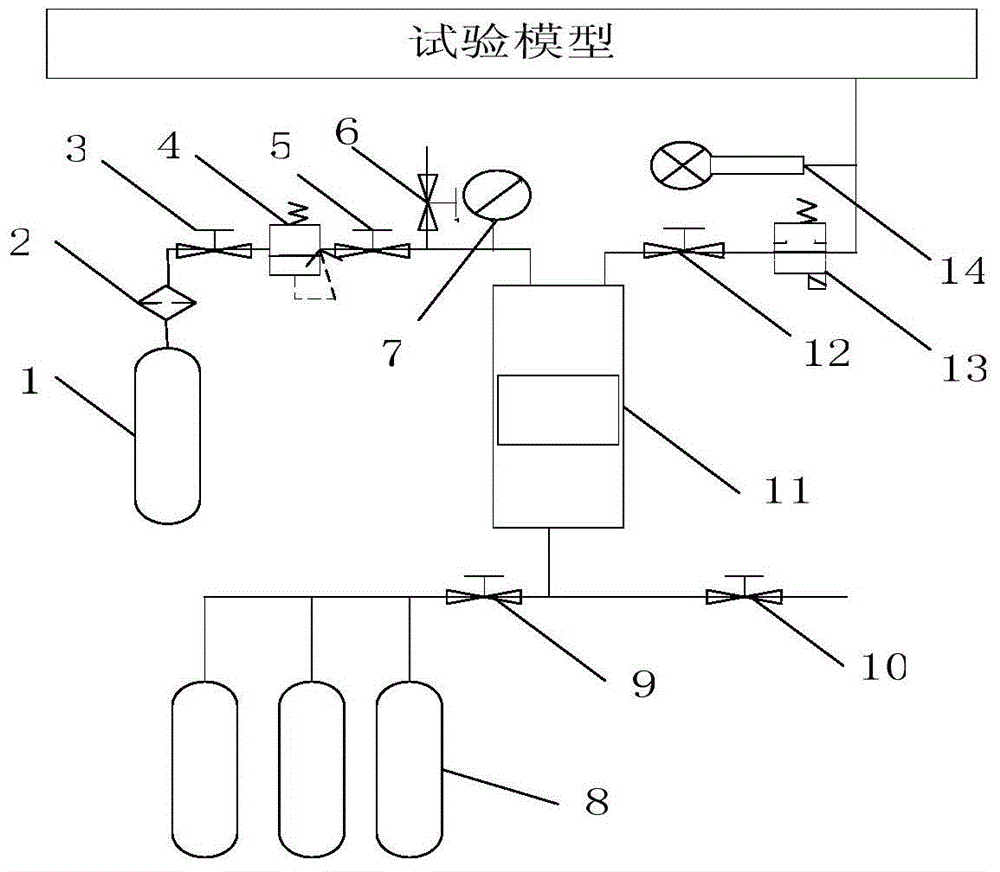

Ethylene supply device and flow measuring method thereof

InactiveCN104654007AConstant pressureStable supplyVolume/mass flow by differential pressureContainer discharging methodsPistonPiston cylinder

The invention discloses an ethylene supply device and a flow measuring method thereof. An ethylene gas cylinder is connected with a piston cylinder through a pipeline, the piston cylinder is connected with a test model through a pipeline, a compensation gas source is connected with the piston cylinder through a pipeline, wherein the ethylene gas cylinder is used for filling an ethylene gas into the piston cylinder, and connected to the test model through the pipeline; the compensation gas source is used for compensating compensation gas with stable pressure into the piston cylinder, wherein the compensation gas pushes a piston with stable pressure, so that the piston extrudes the ethylene gas with stable pressure to realize stable and quick supply of the ethylene. Meanwhile, the ethylene supply device precisely controls pressure of the ethylene gas which enters the piston cylinder through a solenoid valve, so that the working pressure is lower than a liquidation pressure point at a local temperature all the time, an ethylene phase change problem in a working process is avoided, the mass of the ethylene gas fed into a fuel cylinder is obtained by measuring the pressure and the volume of the ethylene gas in the piston cylinder, and the flow of the ethylene is accurately calculated and obtained by measuring ethylene outflow time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com