Liquid oxygen and methane engine adopting plug-in type valves and control method

A plug-in, engine technology, used in machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as complex engine structures, achieve good startup acceleration and shutdown deceleration, compact structure, and improve work reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

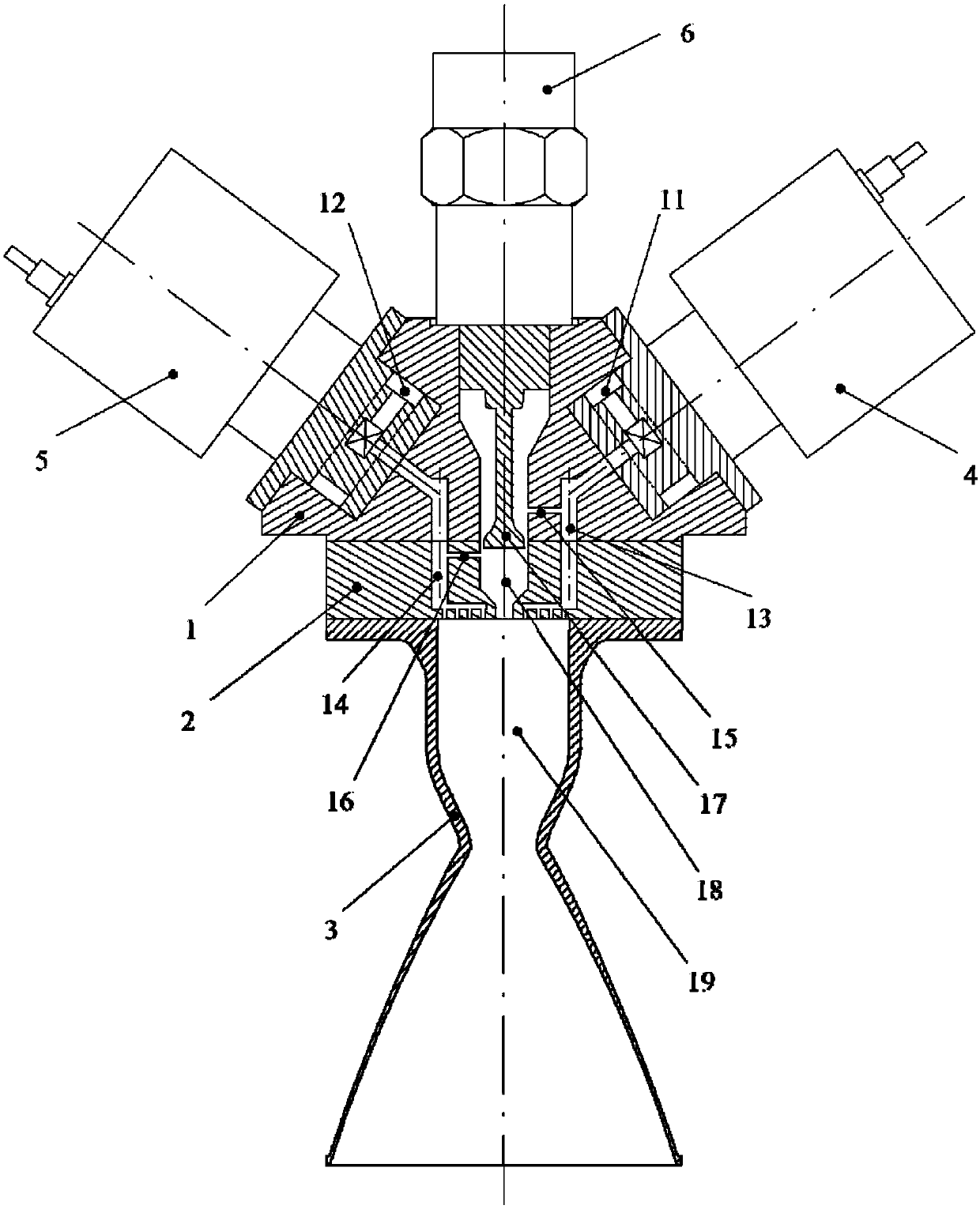

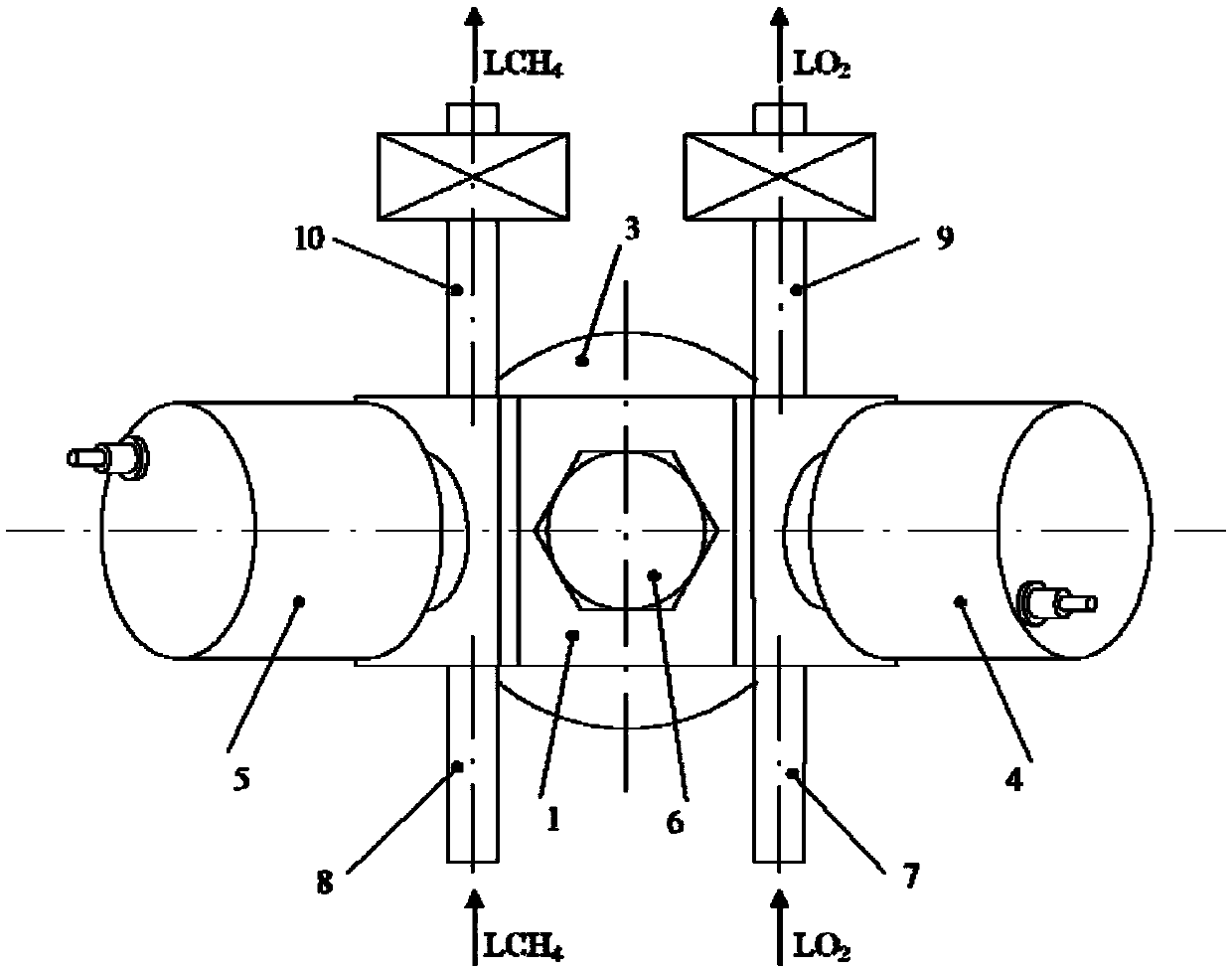

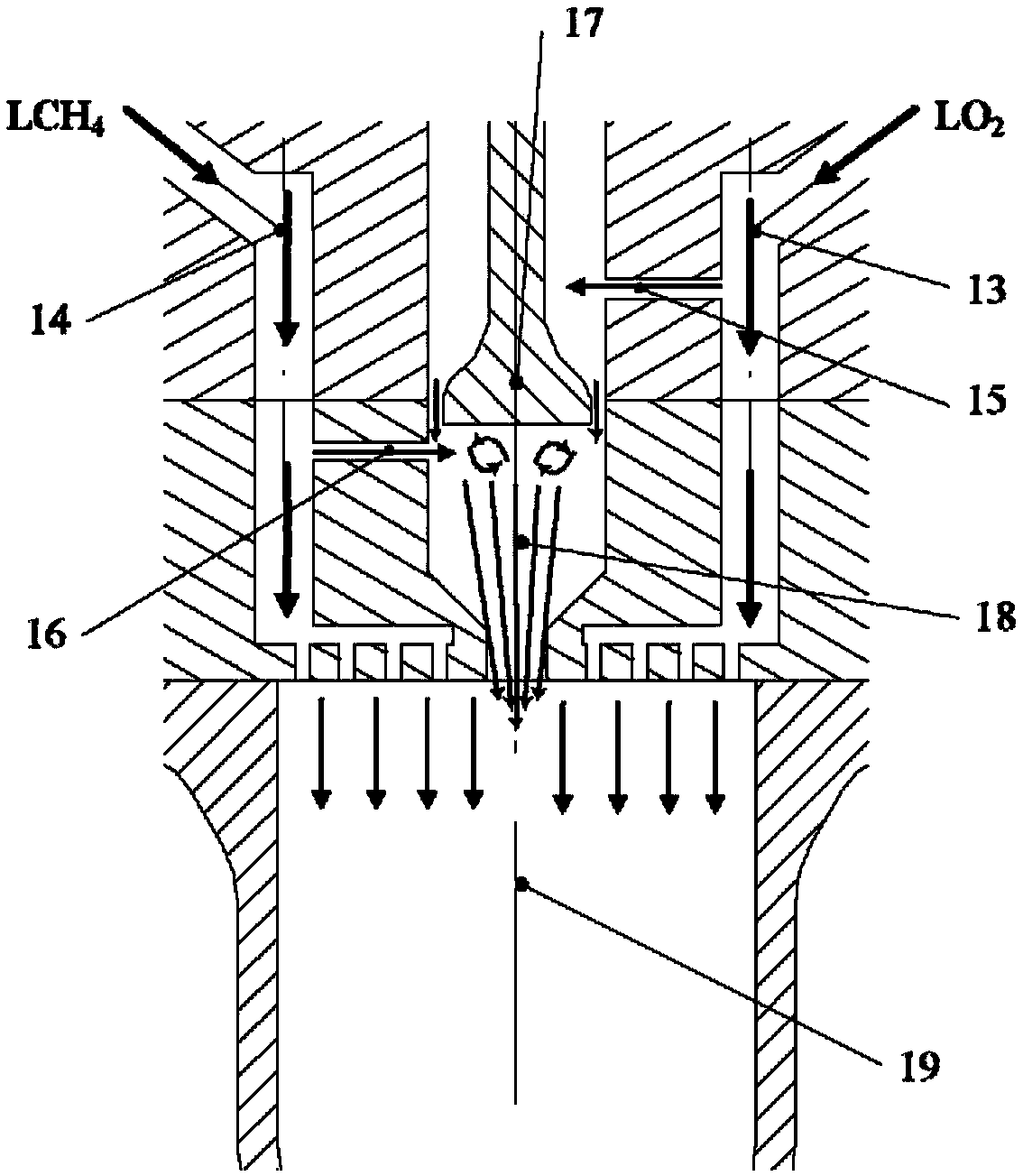

[0026] Figure 1 to Figure 4 They are respectively the structural schematic diagram and the working principle diagram of the liquid oxygen and methane engines using plug-in valves provided by Embodiment 1 of the present invention. Such as Figure 1 to Figure 4 As shown, the liquid oxygen and methane engine using plug-in valves provided by the present invention includes a head body 1, an injector 2, a thrust chamber 3, a liquid oxygen solenoid valve 4, a methane solenoid valve 5 and a spark plug 6. The injector 2 is installed on the lower end surface of the head body 1 by diffusion welding, the thrust chamber 3 is installed on the lower end surface of the injector 2 by screws, the liquid oxygen solenoid valve 4 and the methane electromagnetic valve The valve 5 is inserted into the left and right sides of the head body 1 through screws respectively, and the spark plug 6 is installed on the upper part of the head body 1 through threads.

[0027] Preferably, a liquid oxygen inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com