Stroke processing method of ultrathin cylinder stainless steel tube film for printer and duplicator

A technology of stainless steel pipe and processing method, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., and can solve the problems of stainless steel processing rate reduction, high hardness, poor plasticity, and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

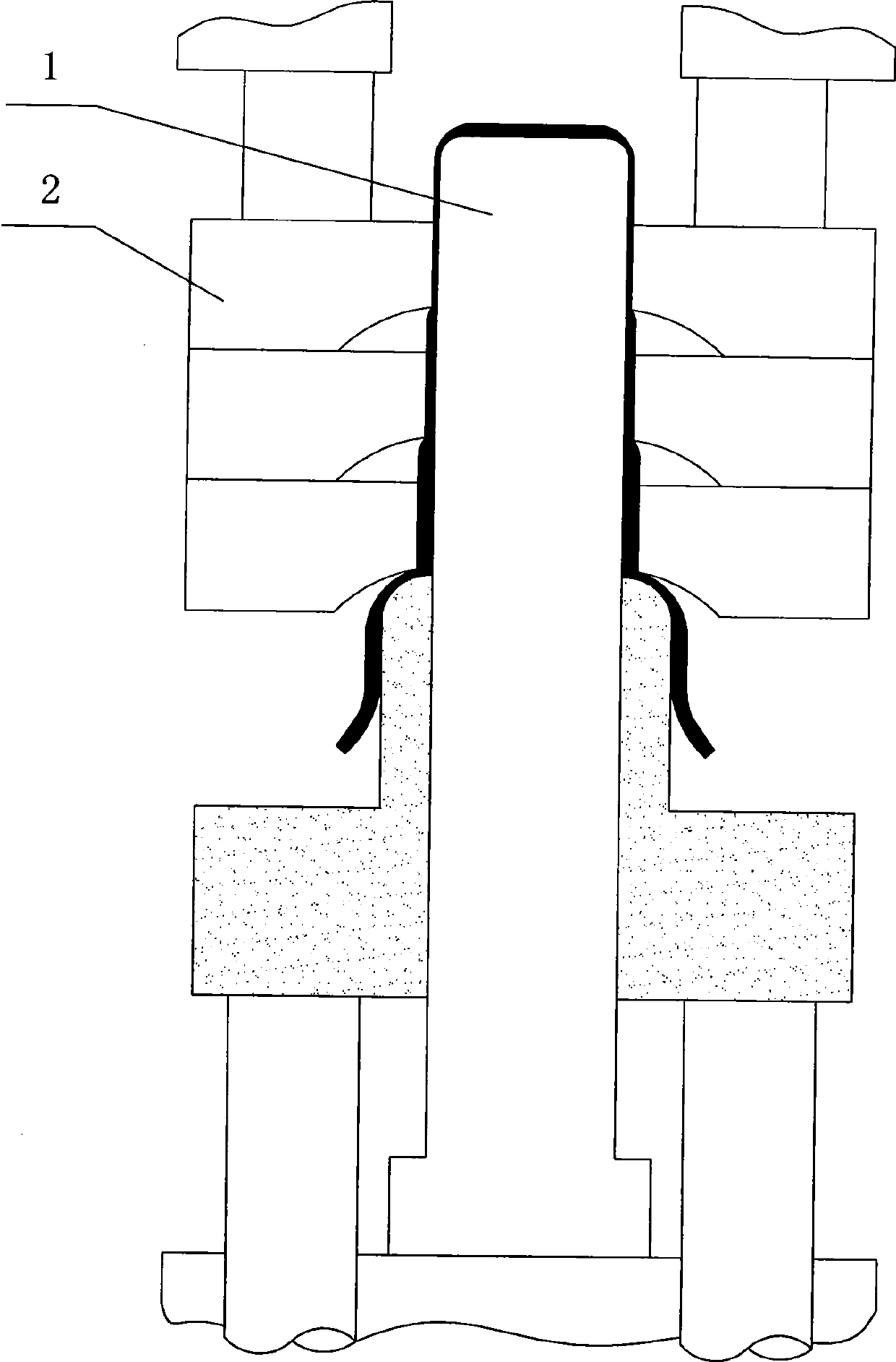

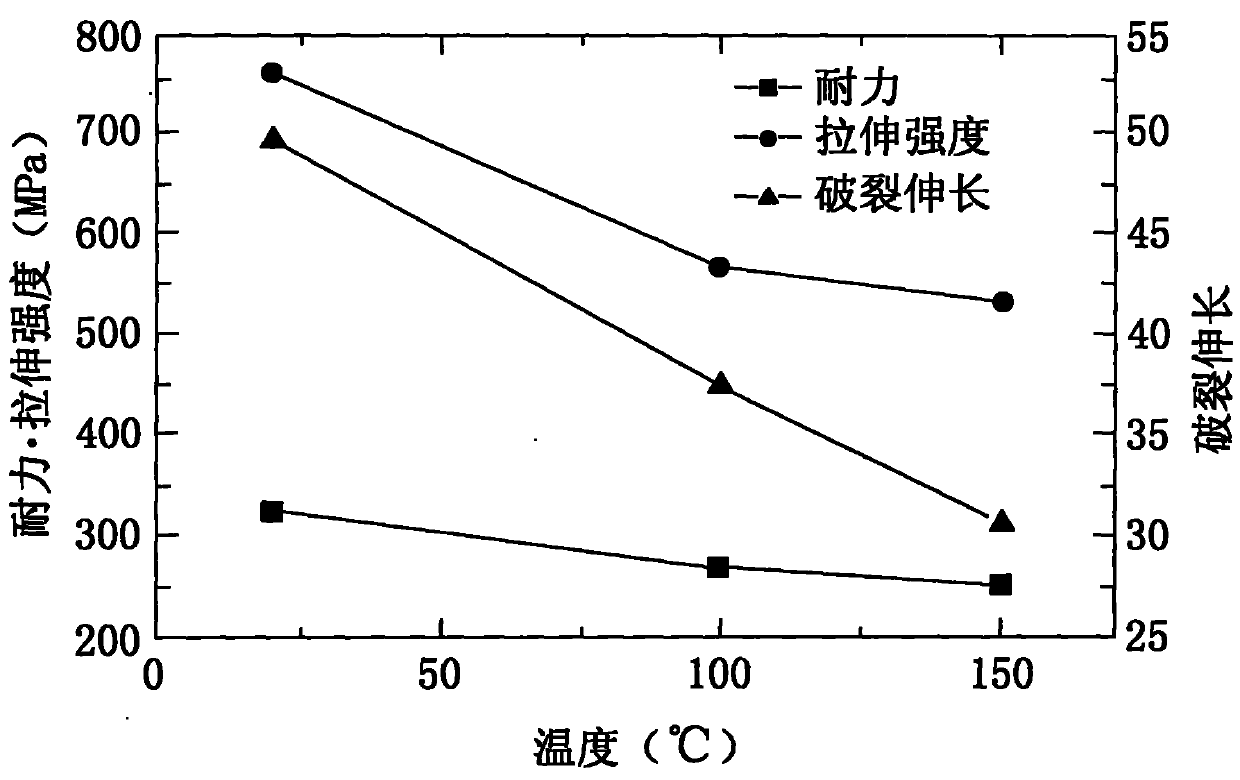

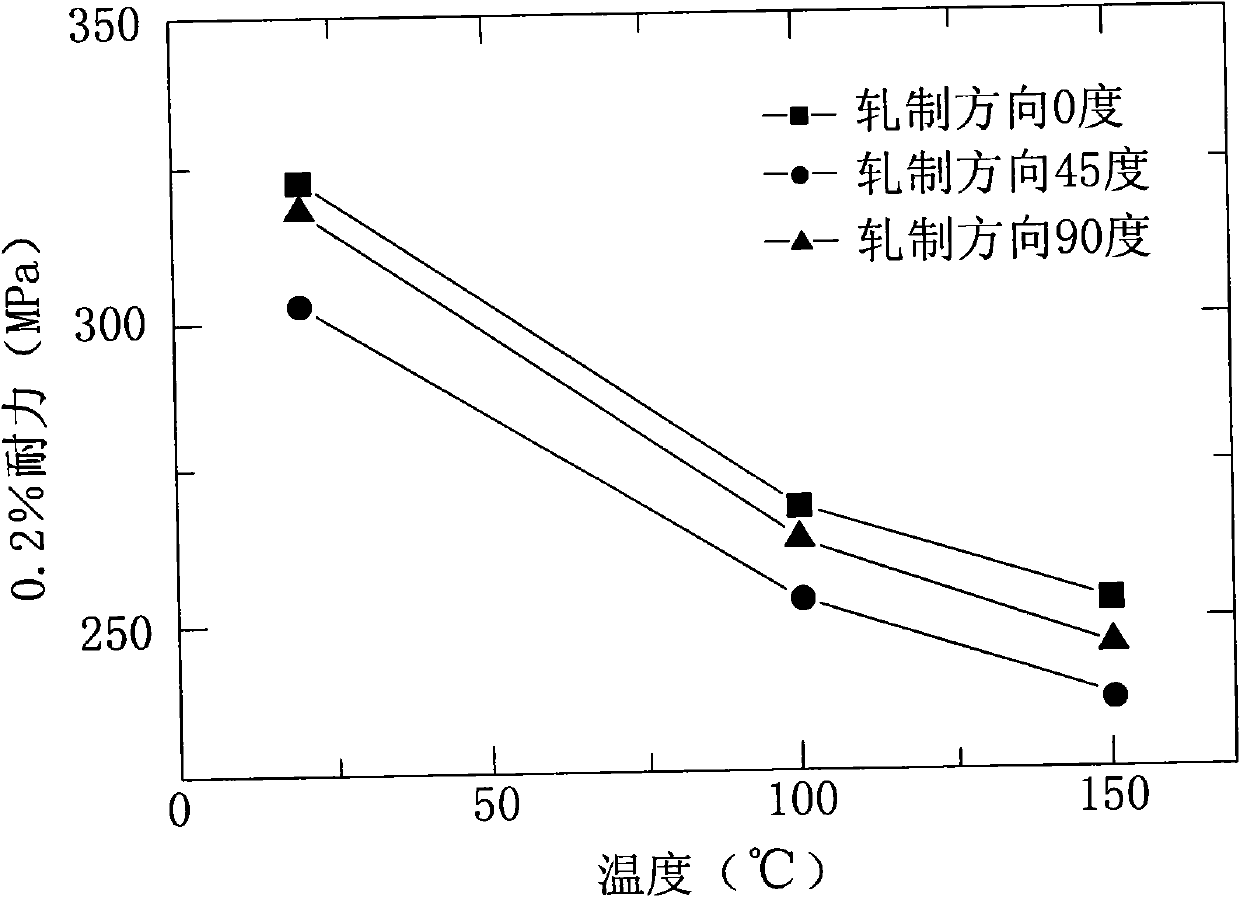

[0027] The processing method of the ultra-thin cylindrical stainless steel tube film for printers and copiers in this embodiment comprises the steps of: a. preparing a mold with continuous multi-stage processing; b. performing differential temperature primary stretching on the plate to prepare a Cylinder of the cap; c. Apply lubricant to the inner and outer walls of the above-mentioned cylinder, install the cylinder on the punch of the mold, drive the punch to press into the die once, and cool the punch at the same time, and process the punch for each level for heating. d. Pull out the punch to demould, cut off the two ends of the pipe fittings processed by differential temperature, and keep the middle pipe body, so as to obtain the required ultra-thin cylindrical stainless steel pipe film.

[0028] The processing speed at which the punch is pressed into the die is 10-1000mm / sec. When processing stainless steel cylinders with a thickness of less than 0.1mm, the processing spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com