Patents

Literature

178 results about "Jet injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

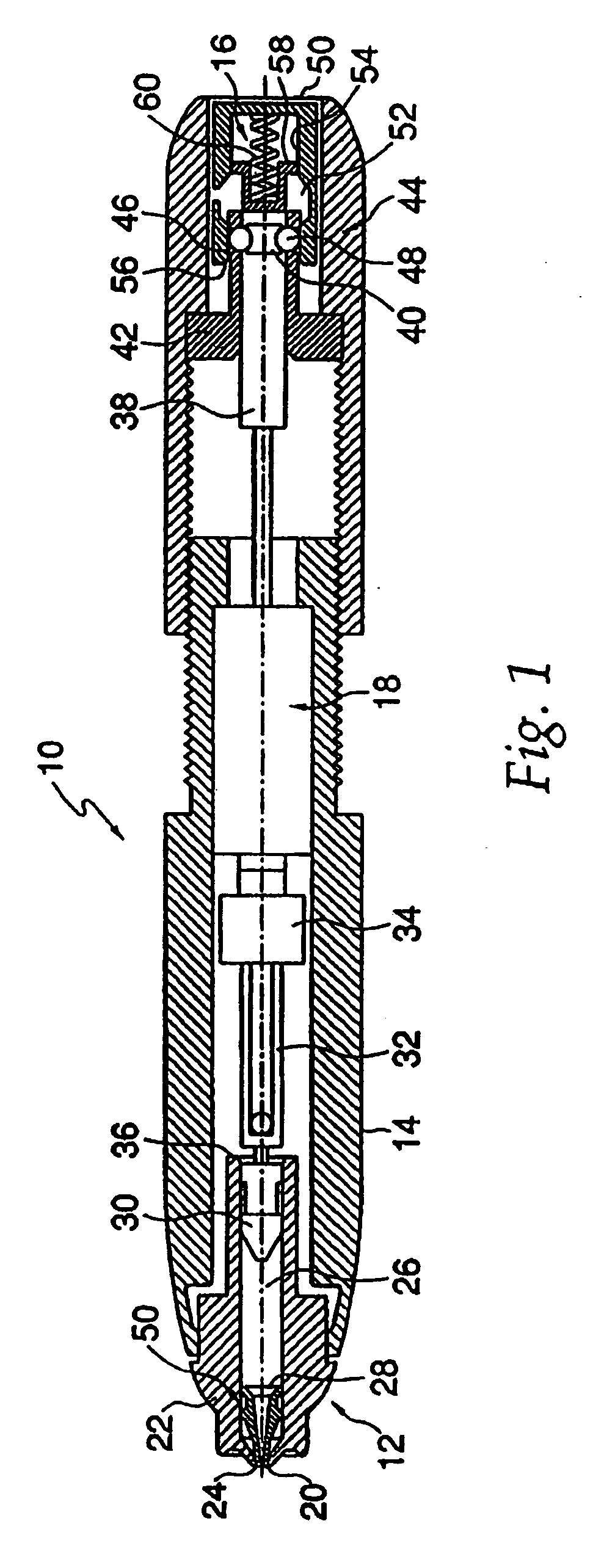

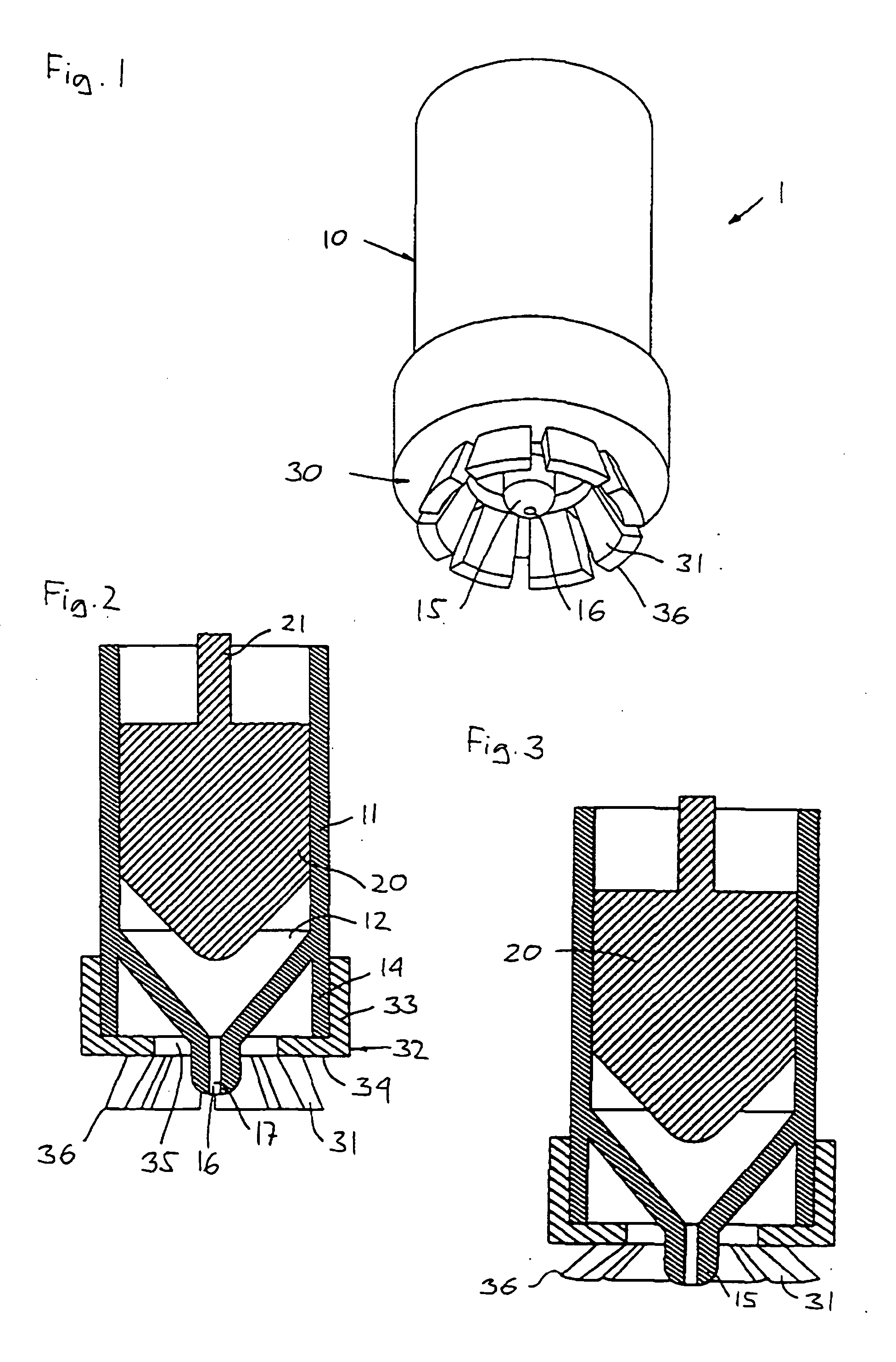

Hypodermic fluid dispenser

InactiveUS6056716AEfficient injectionEliminate the problemAmpoule syringesJet injection syringesHypodermoclysisJet flow

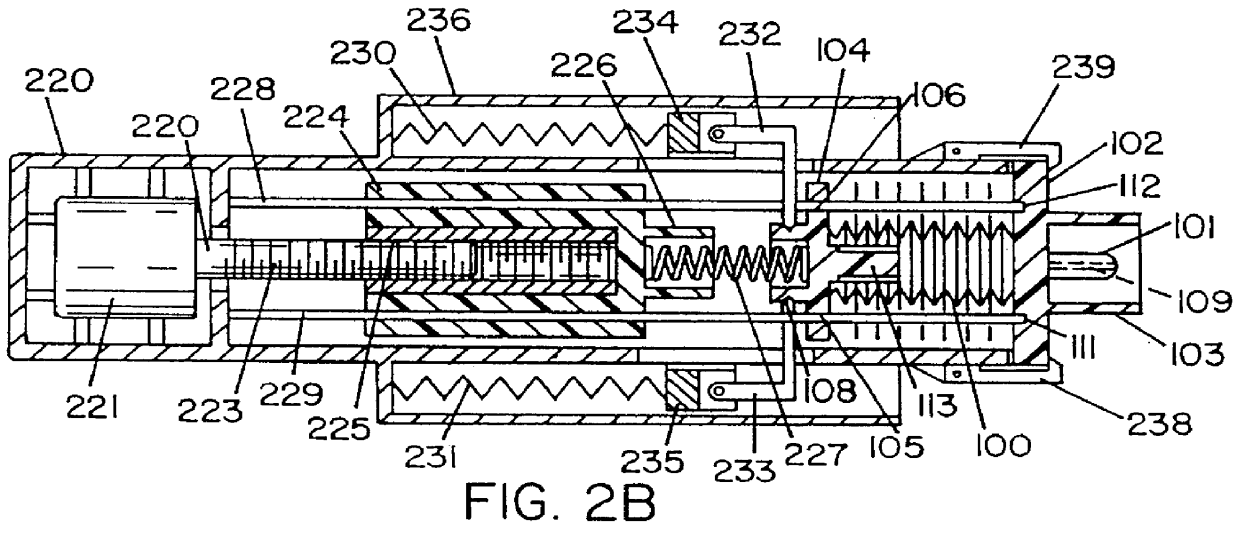

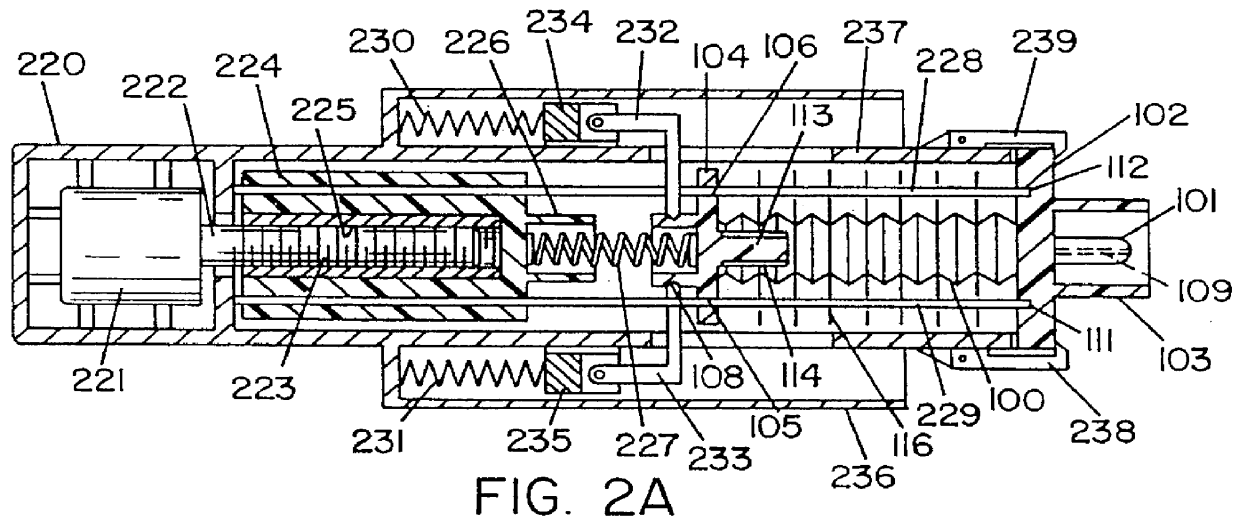

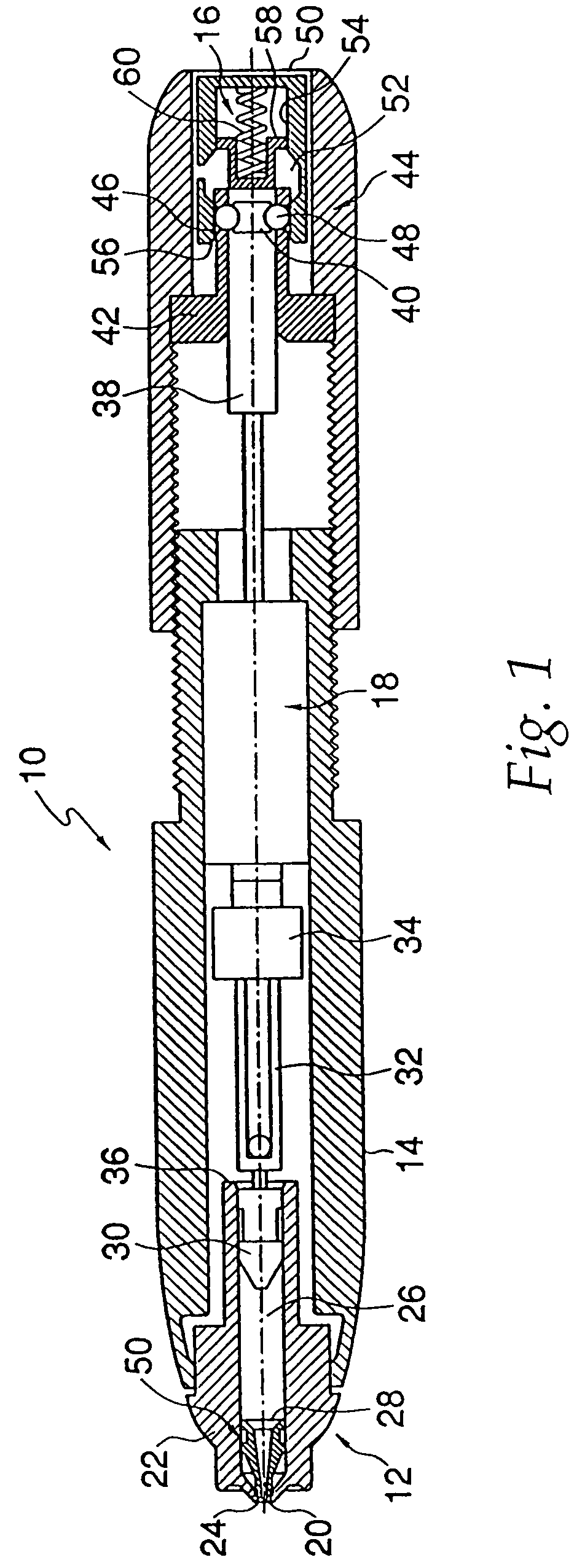

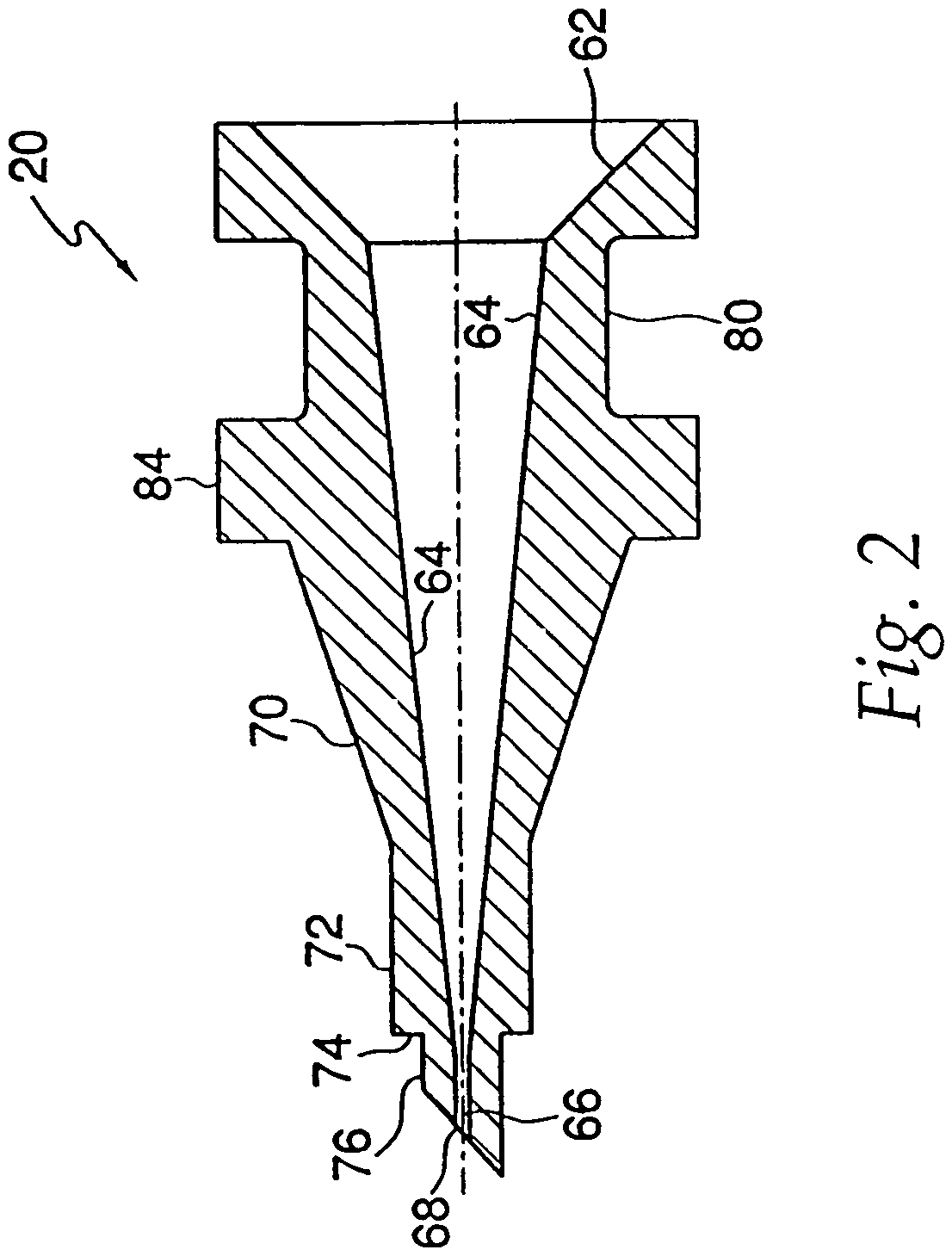

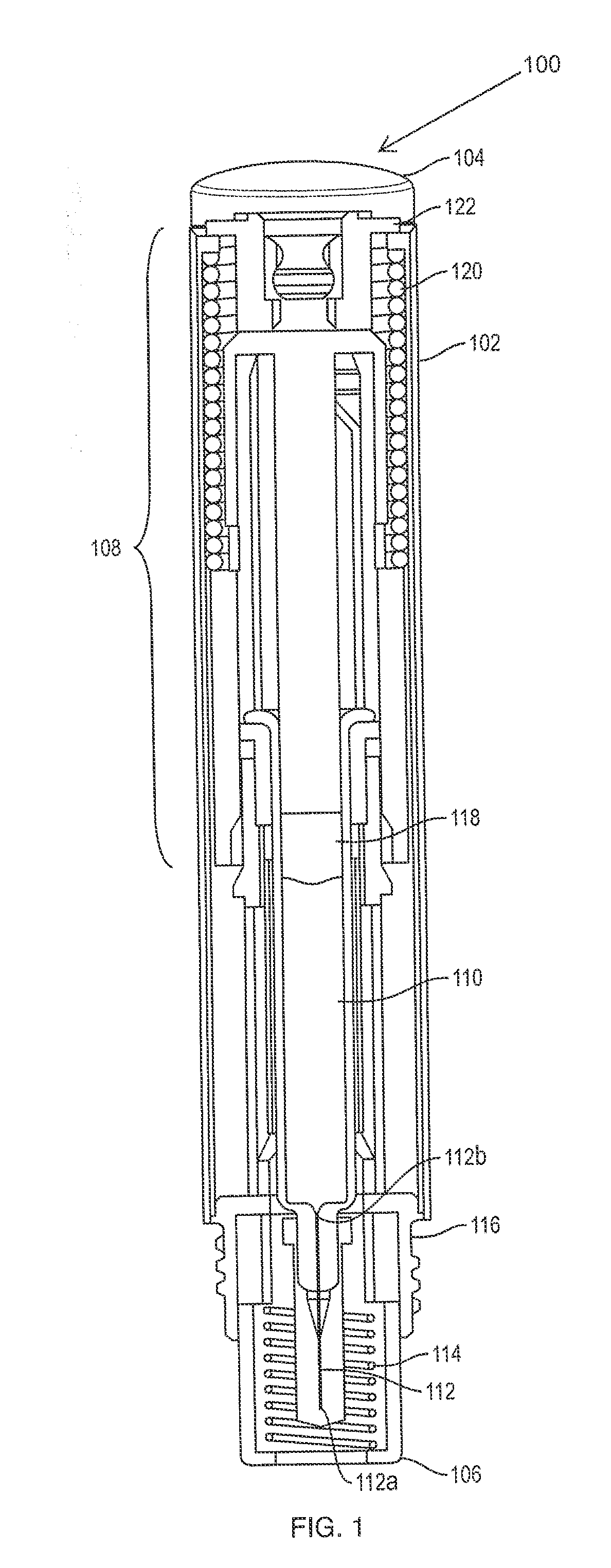

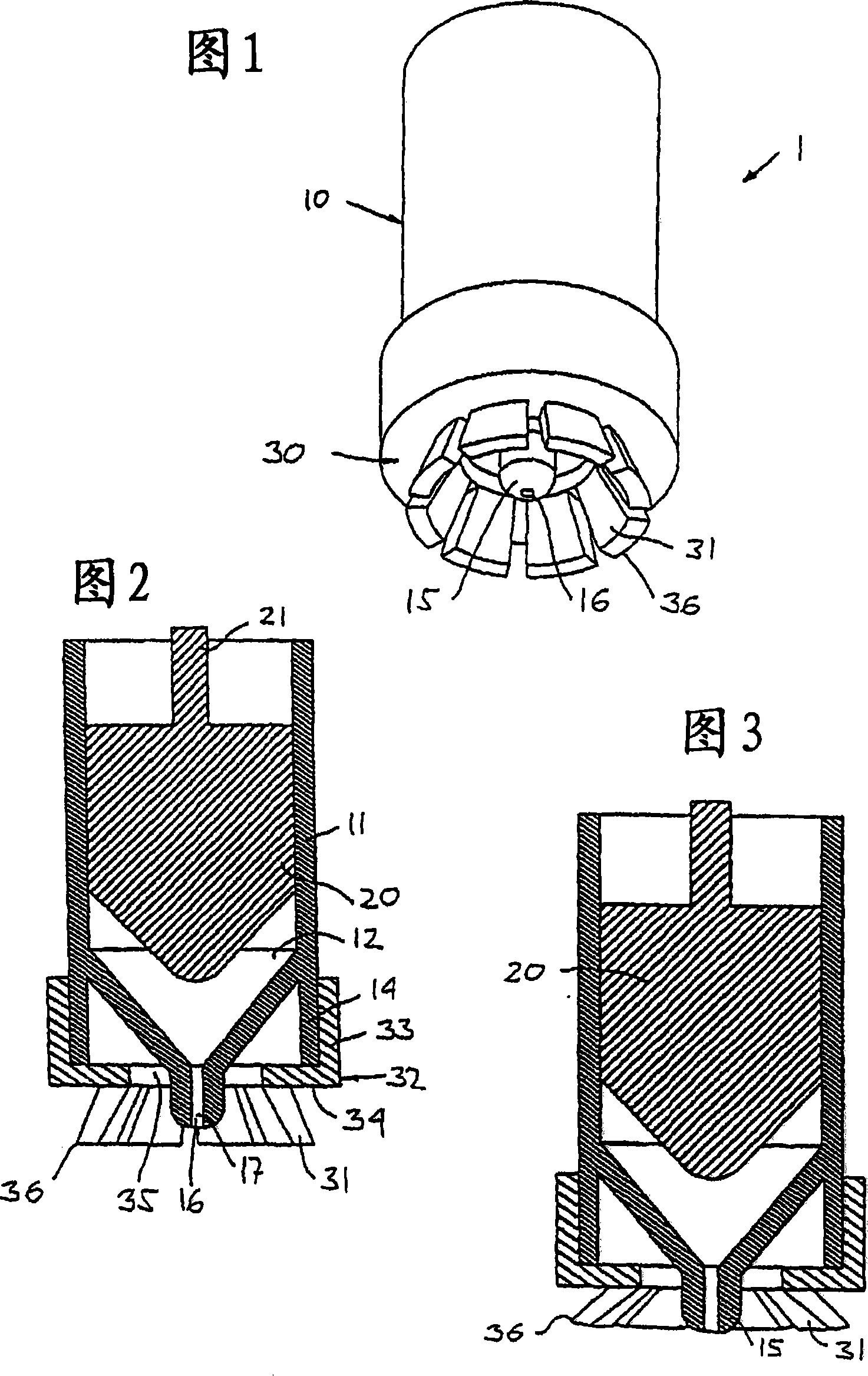

A jet injector system for injecting fluid into a body. The jet injection system includes capsules for holding the material to be injected, apparatus for applying force to the capsule(s) to eject the injection material(s) and a perforator for directing the jet stream for the respective materials into the body. A flyweight system is described for developing jet injection pressures, and latching devices control the flyweight system. An injector system for injecting more than one fluid is described.

Owner:DANTONIO CONSULTANTS INT INC

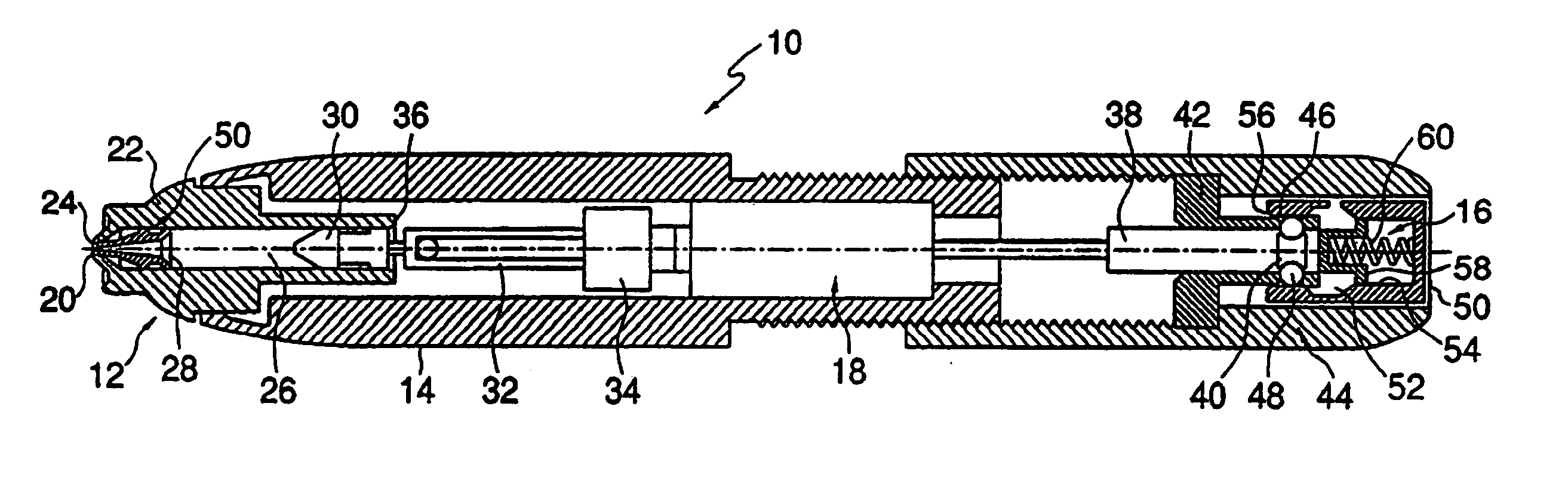

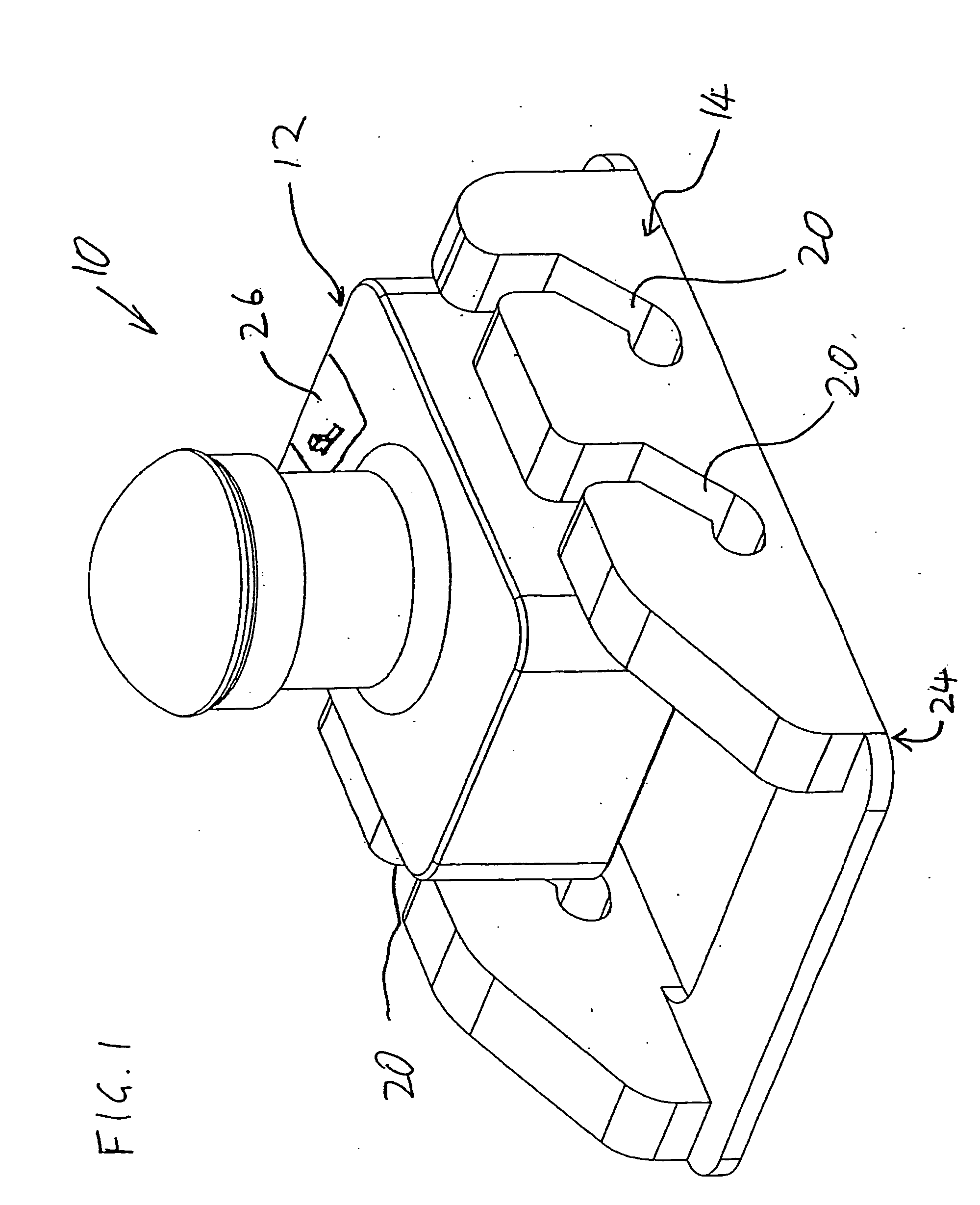

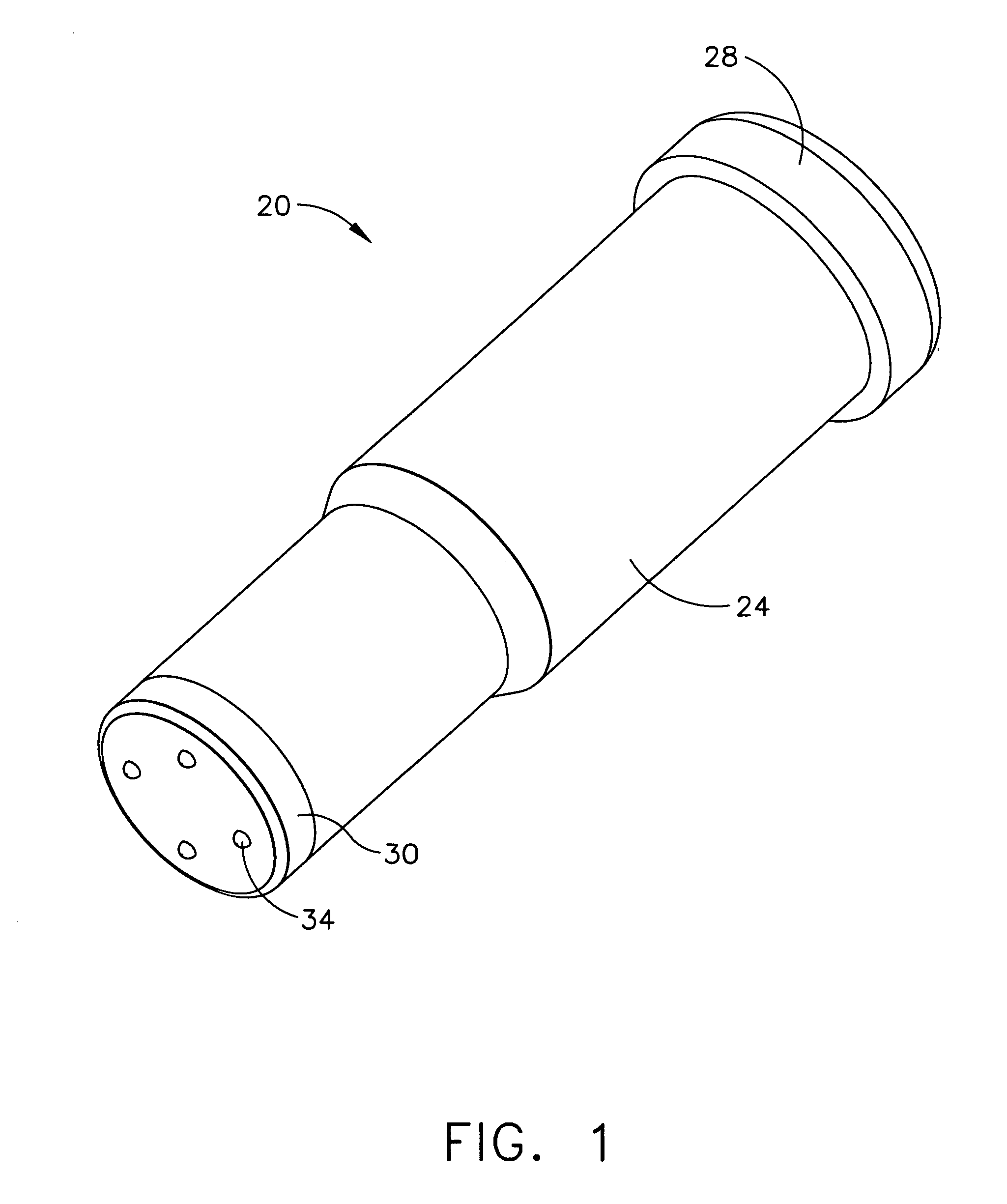

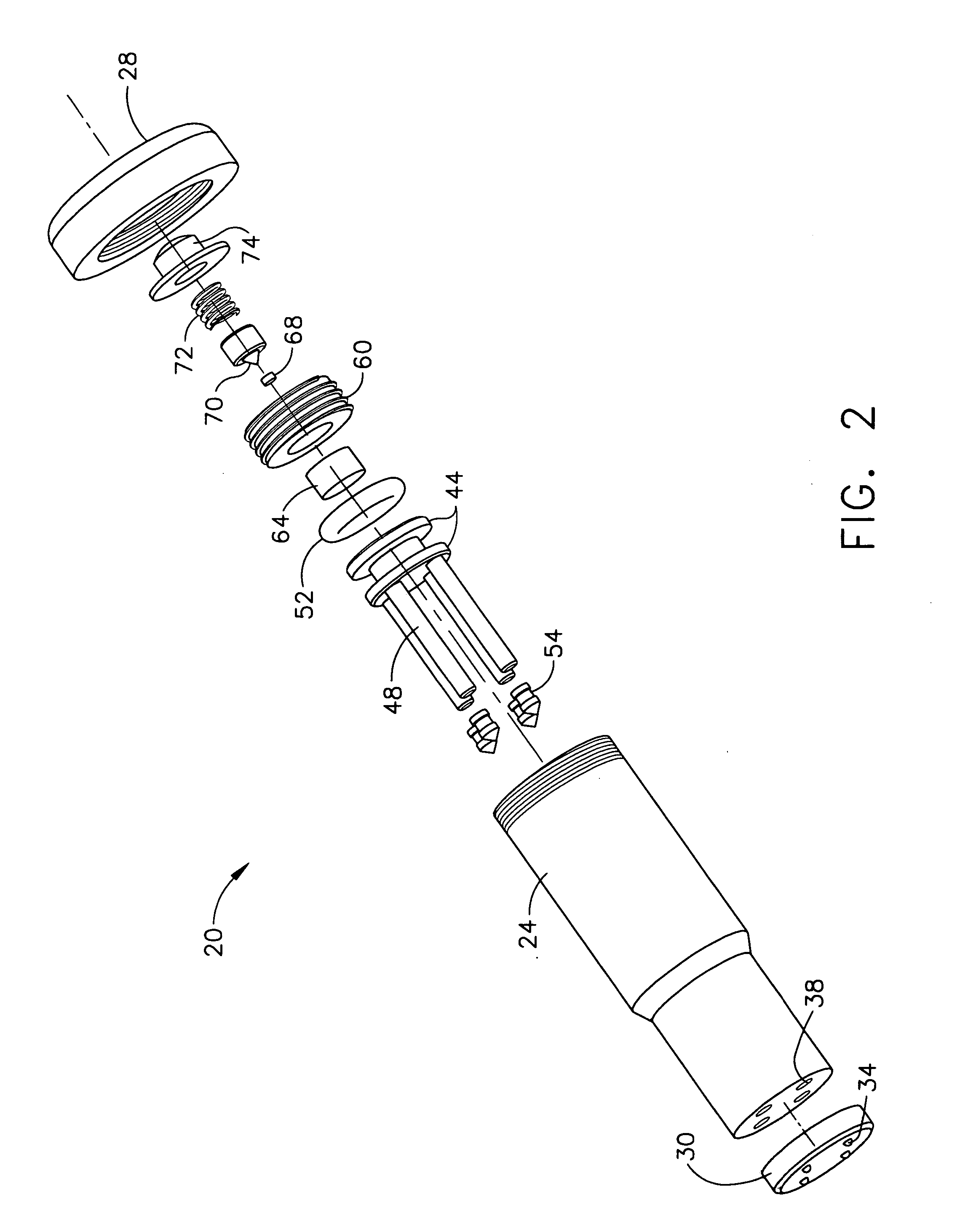

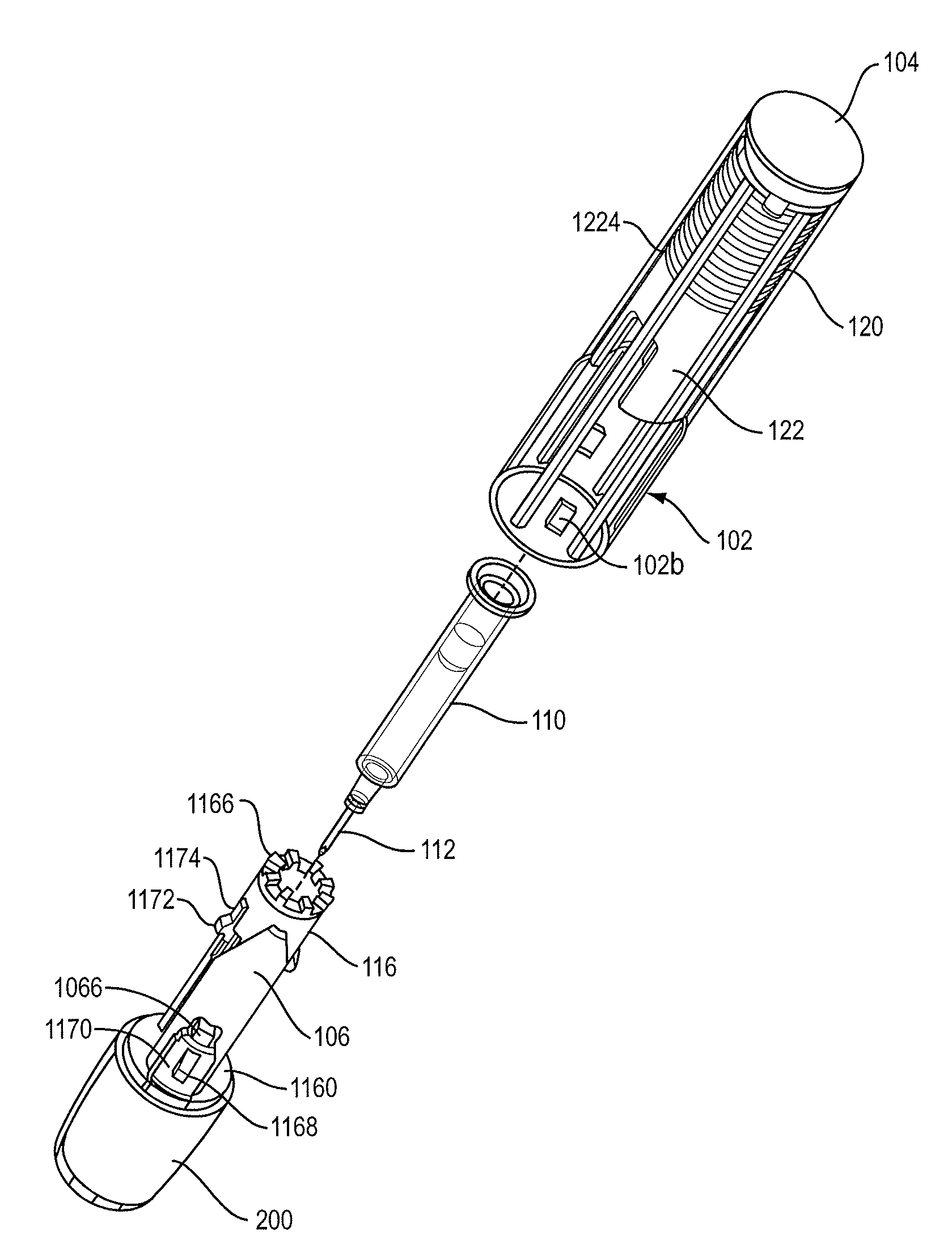

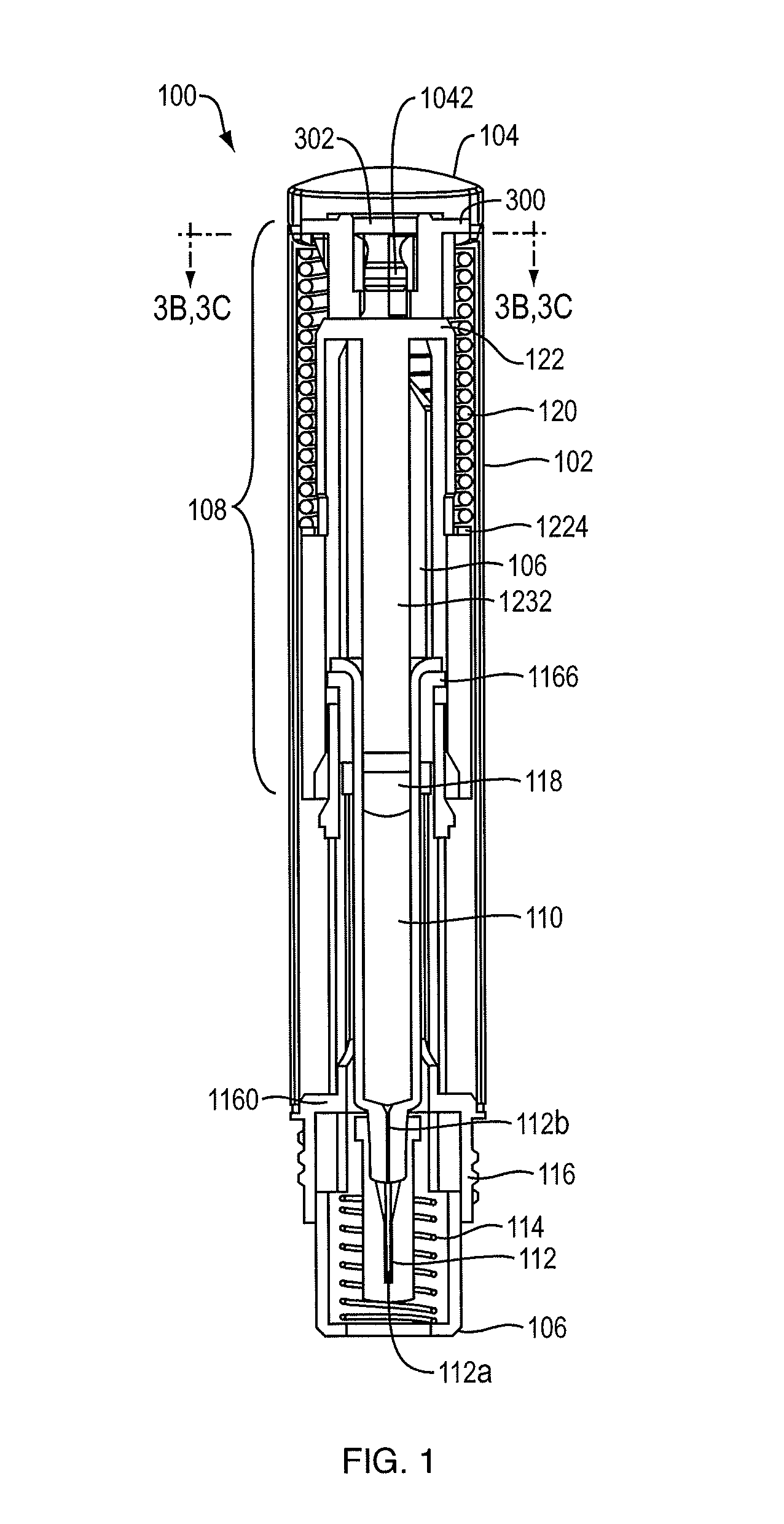

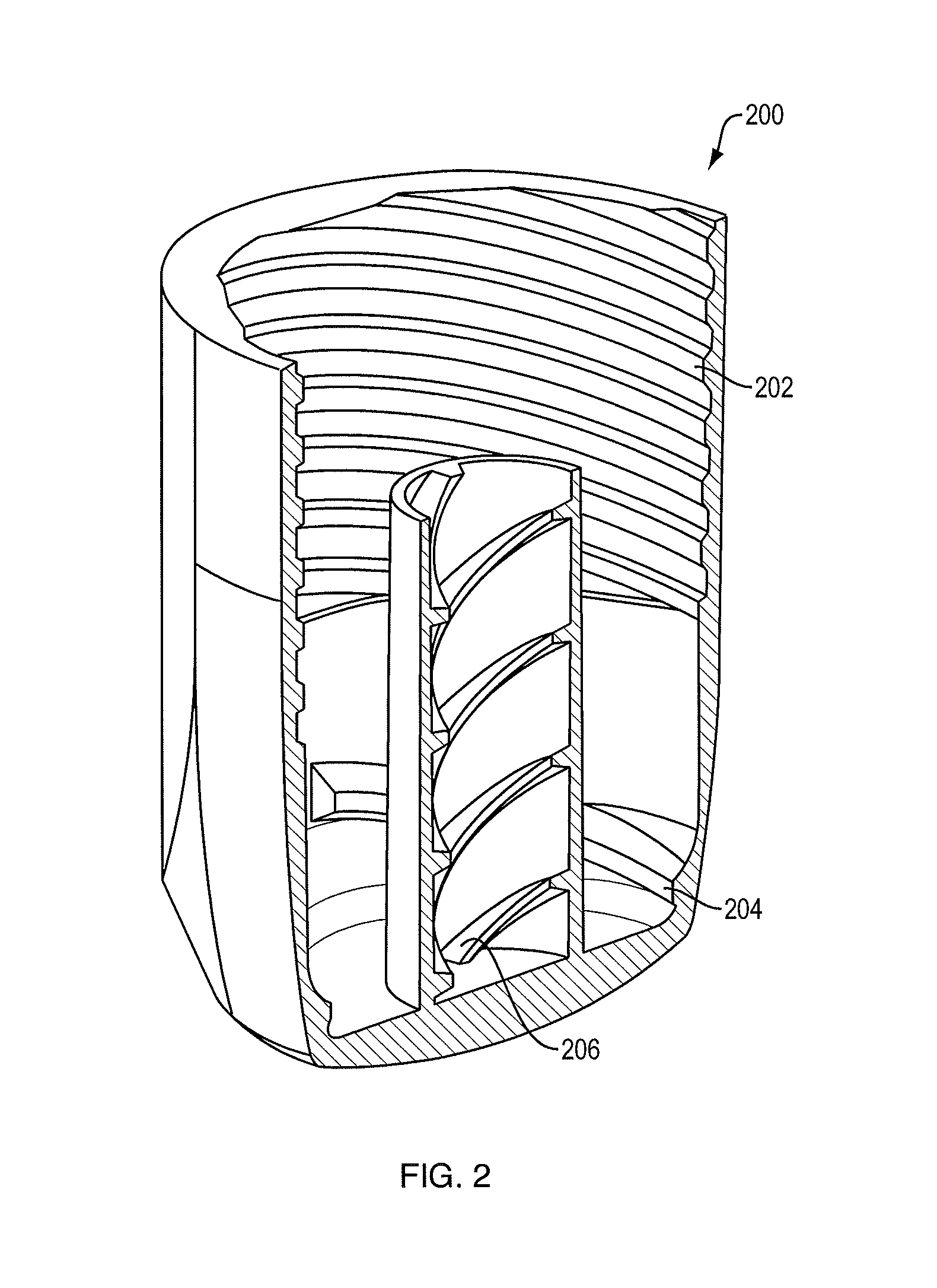

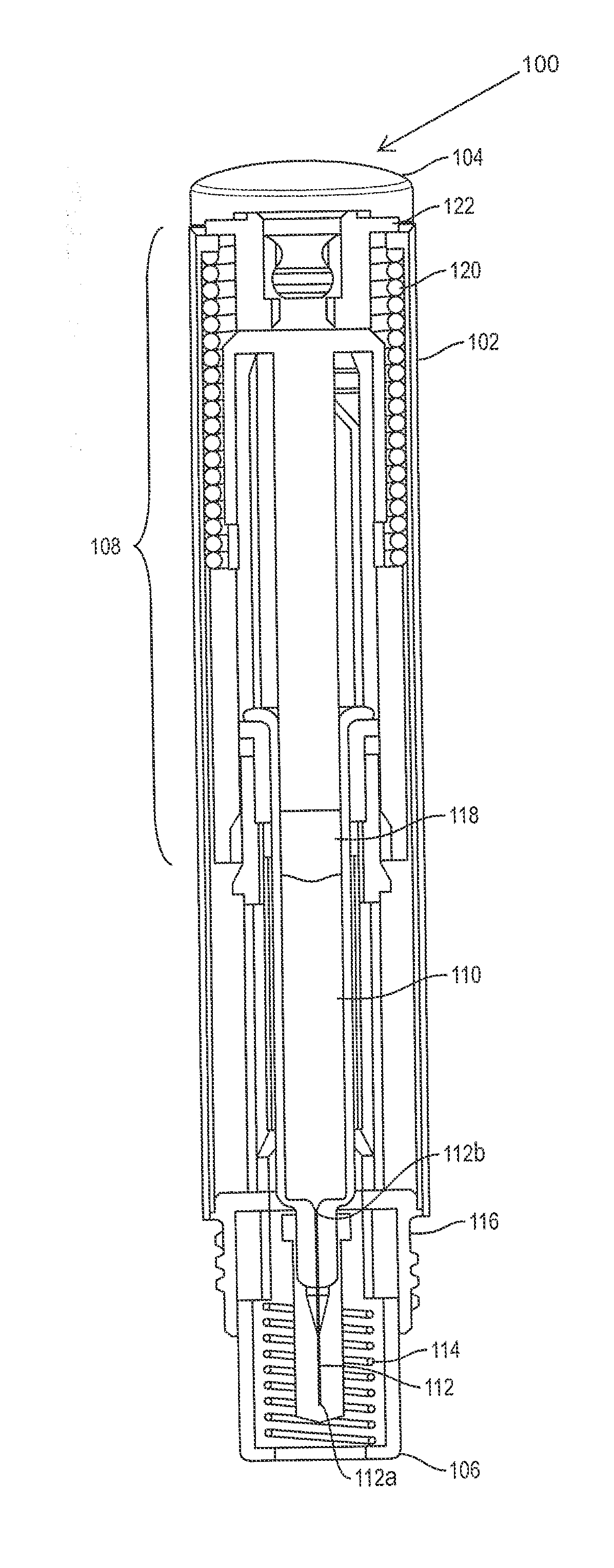

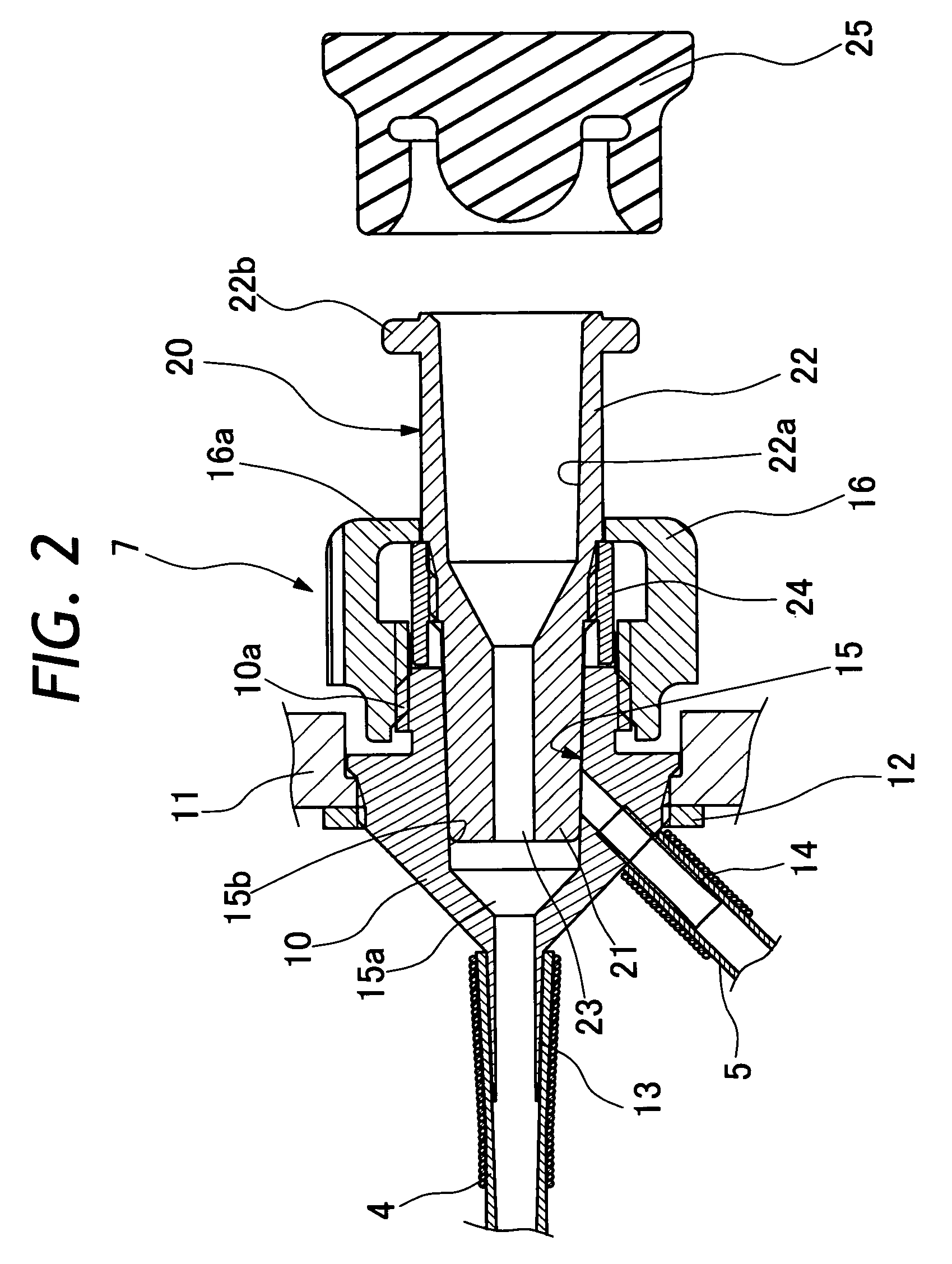

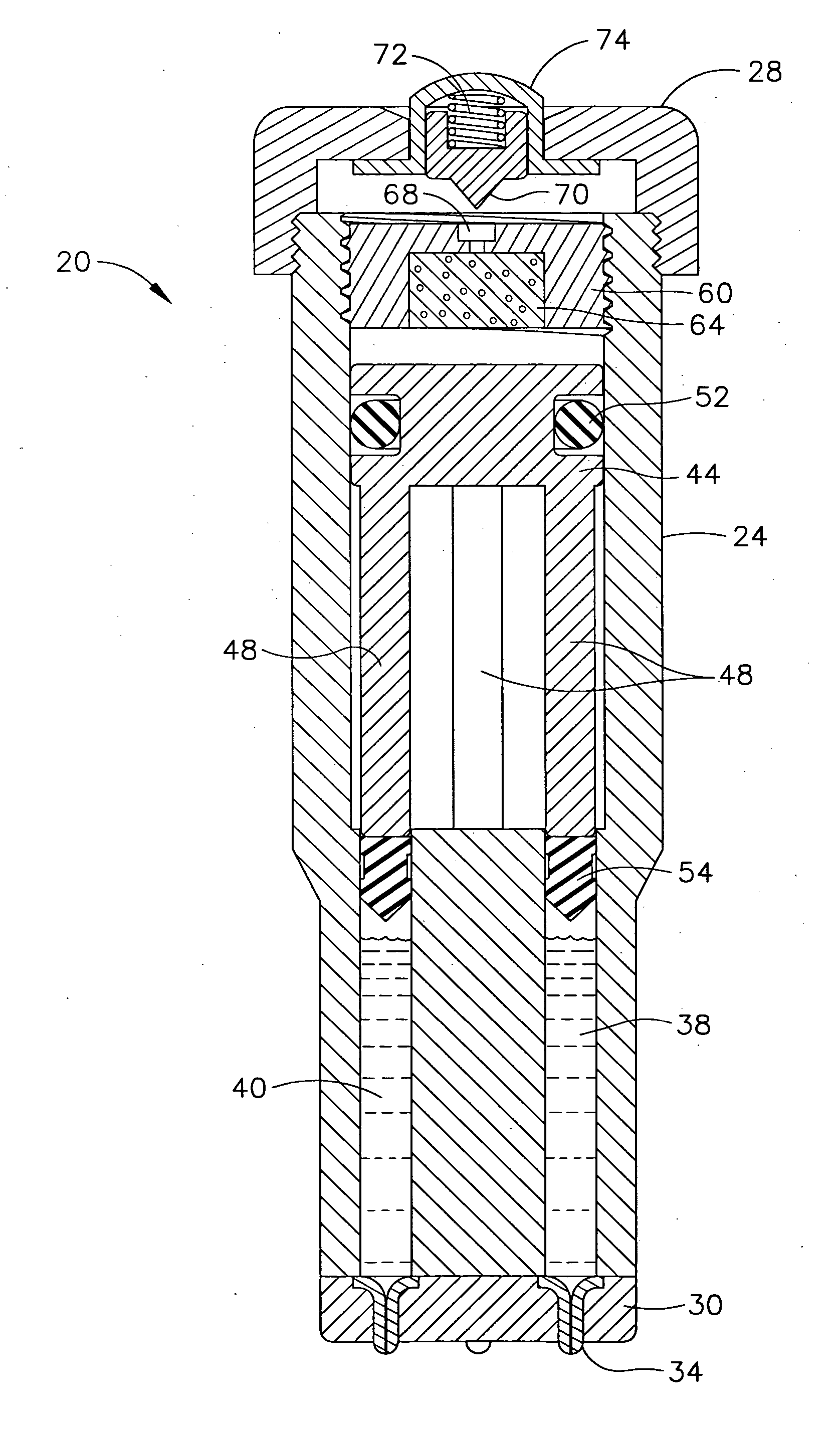

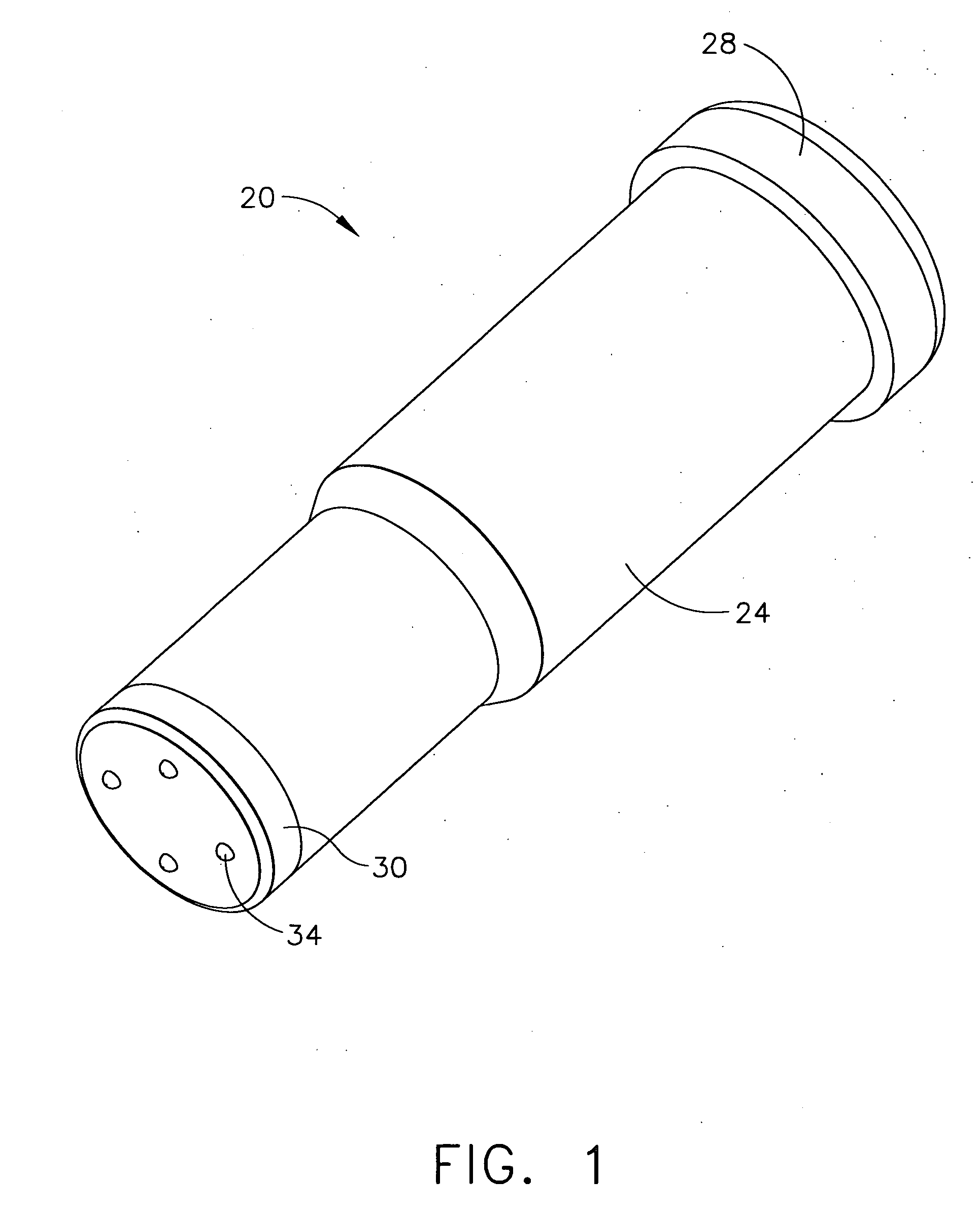

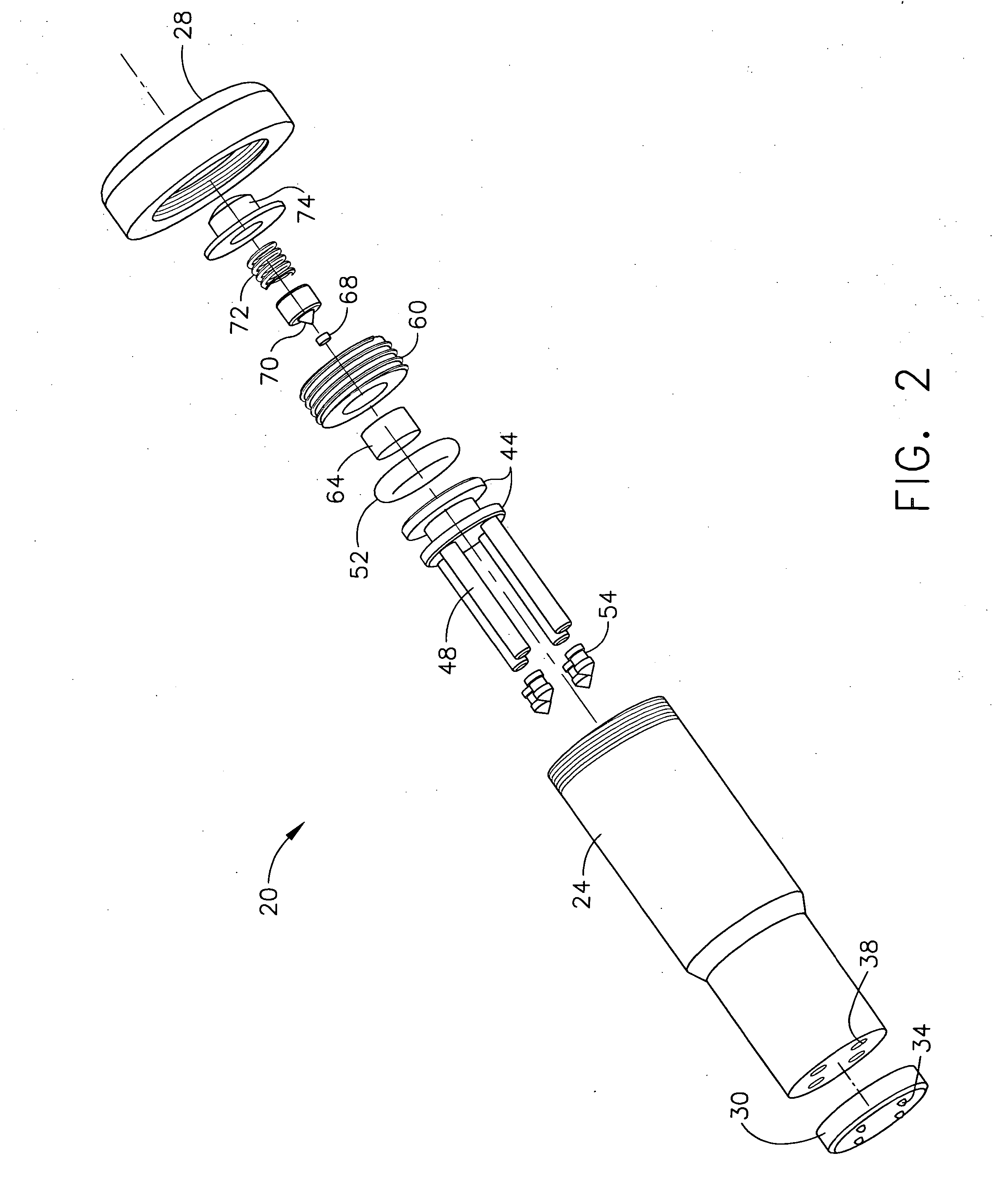

Needle assisted jet injector

InactiveUS7744582B2Prevent re-exposureAmpoule syringesJet injection syringesInjector nozzleJet injection

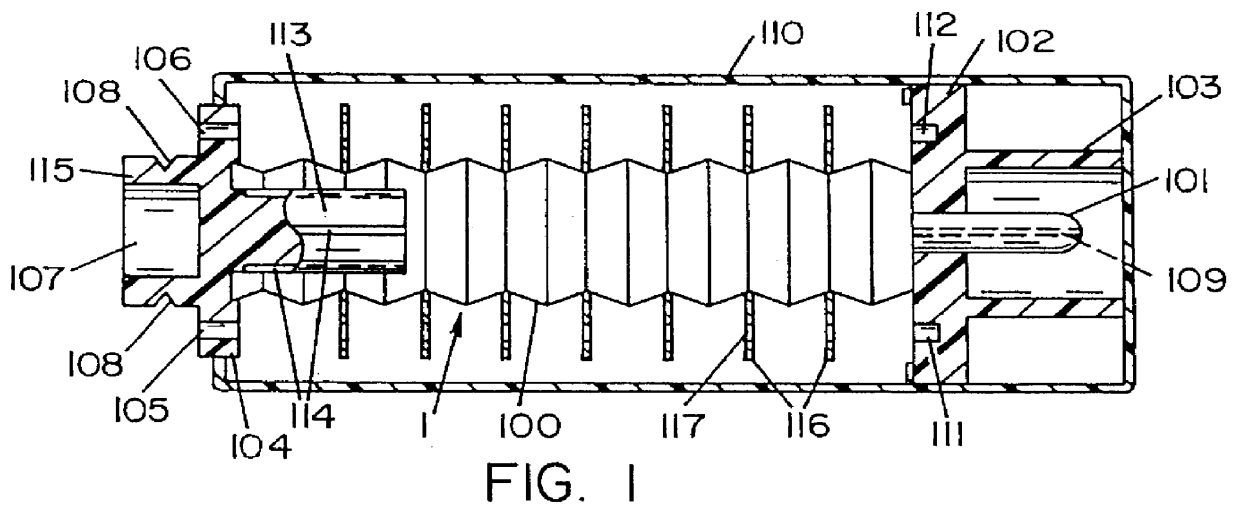

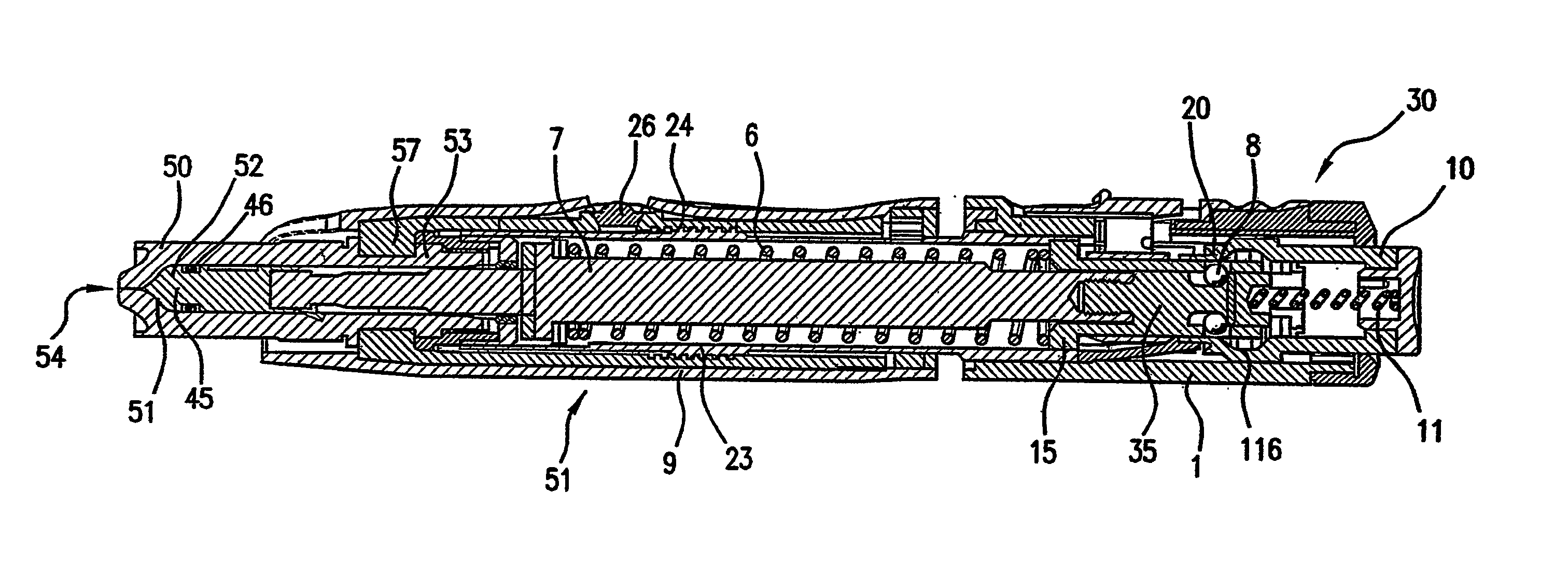

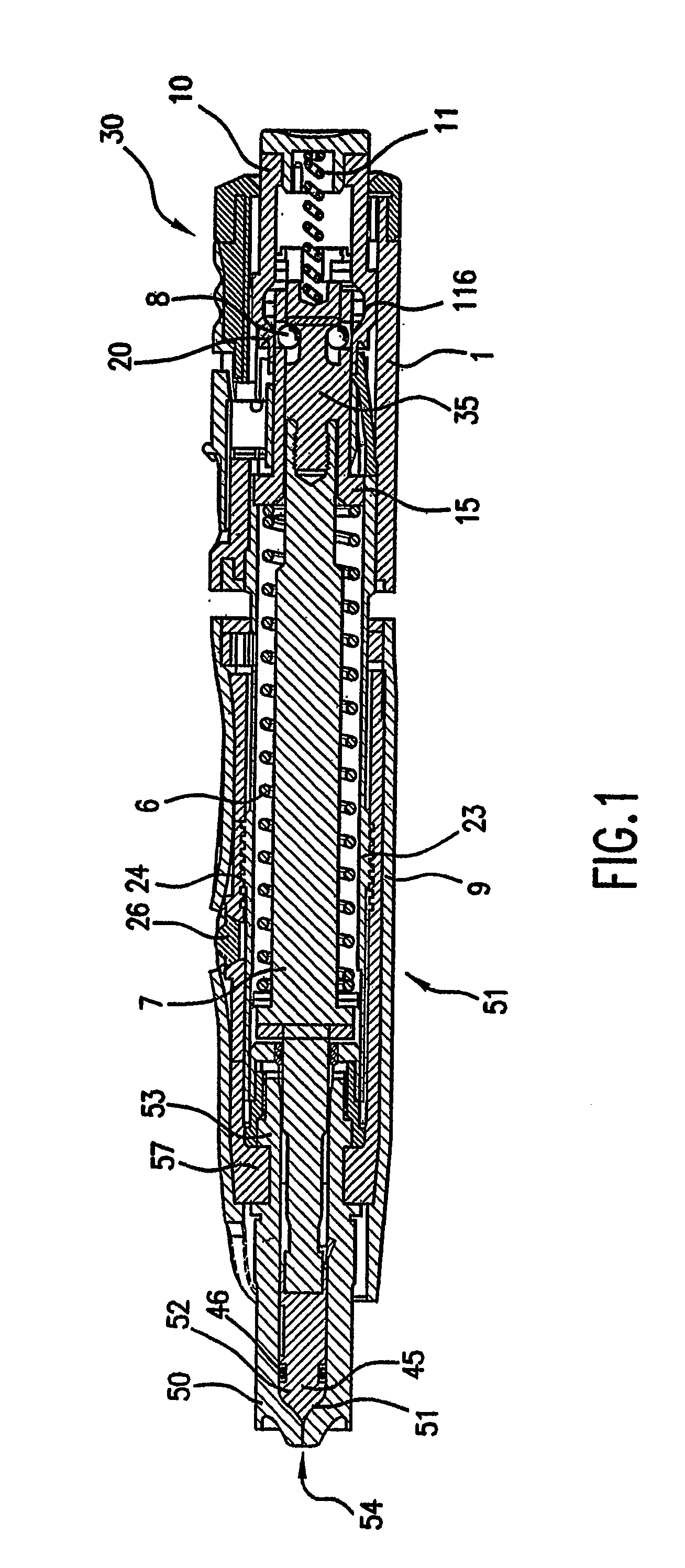

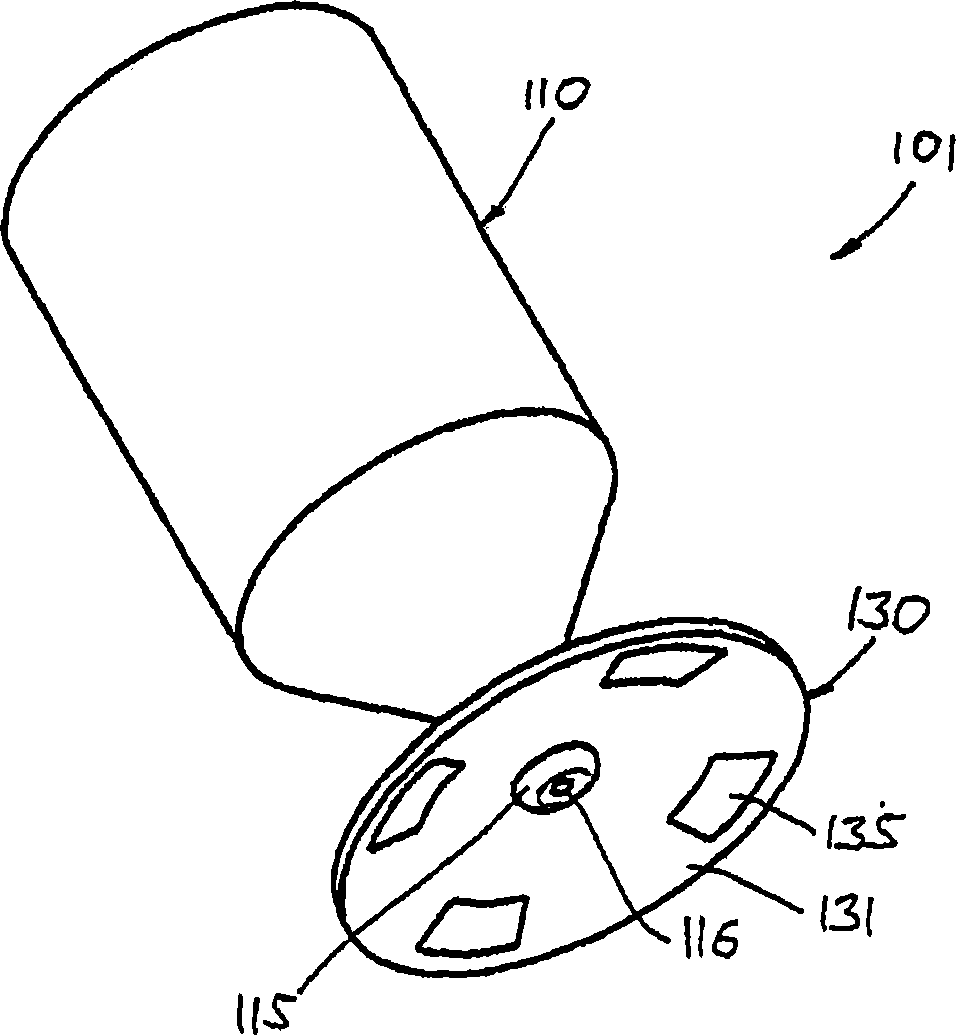

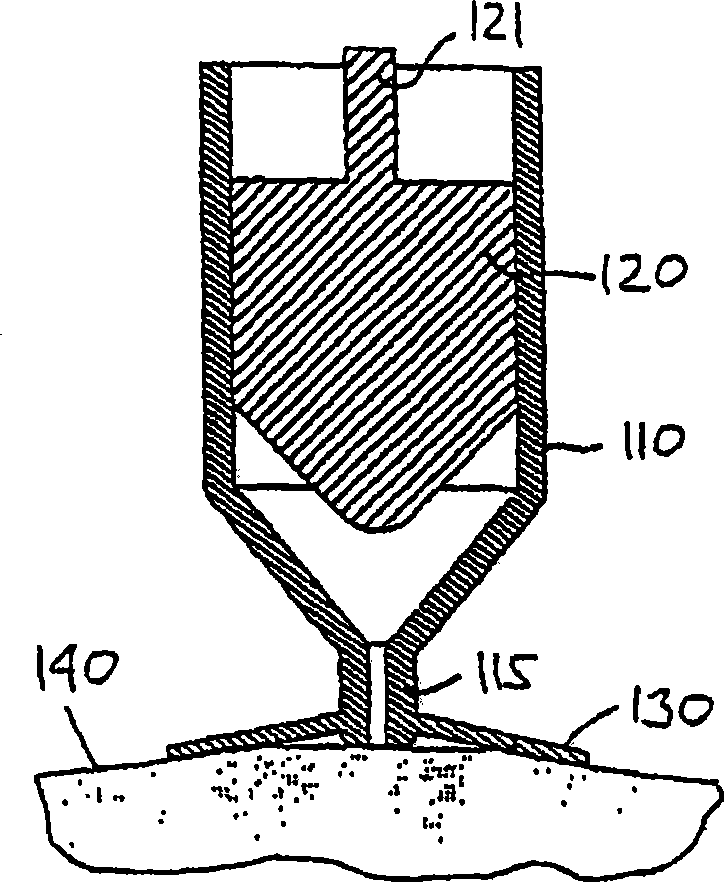

A needle assisted jet injector and method for jet injecting medicament are disclosed. In one embodiment of the injector, the needle is retractably located within an injector nozzle assembly. Upon activation of the force generating source, a portion of the needle extends past the nozzle assembly and penetrates the outer layer of skin to deliver the medicament via jet injection to a deeper region. After activation, the needle retracts back into the nozzle assembly. In another embodiment, the needle is fixed to the end of the nozzle assembly. In both embodiments, the length of the portion of the needle that penetrates the skin is less than 5 mm.

Owner:ANTARES PHARMA INC

Administration of insulin by jet injection

InactiveUS20060106362A1Easily employedHigh level of skillJet injection syringesMetabolism disorderInsulin dependentJet injection

The invention relates to a method for minimizing mean blood glucose levels in an insulin dependent patient by administering insulin to the patient in a sufficiently fast manner to provide a difference of 50% or less between high and low blood glucose levels. Advantageously, the insulin is administered to the patient by jet injection and the high and low blood glucose levels differ by an amount that is less than that which would be obtained after injection of insulin by a conventional needle syringe. The invention also relates to a method for reducing mean blood glucose levels in an insulin dependent patient that is receiving insulin through a conventional syringe and needle arrangement. This method provides for administration of the insulin to the patient by jet injection rather than by the syringe by substituting a jet injector for the syringe.

Owner:ANTARES PHARMA

Needle assisted jet injector

InactiveUS20050080377A1Prevent re-exposureAmpoule syringesJet injection syringesMedication injectionJet injection

Owner:ANTARES PHARMA INC

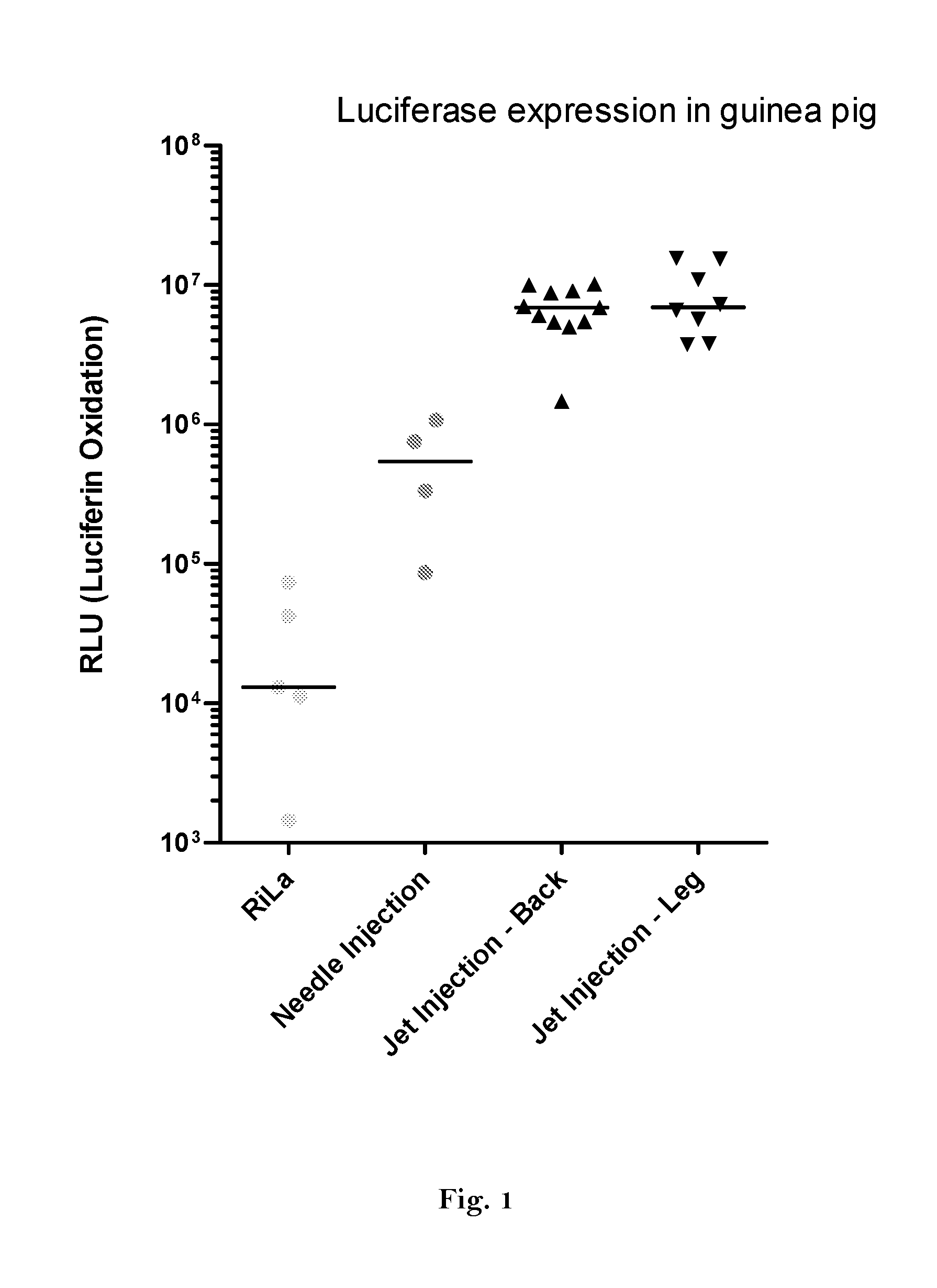

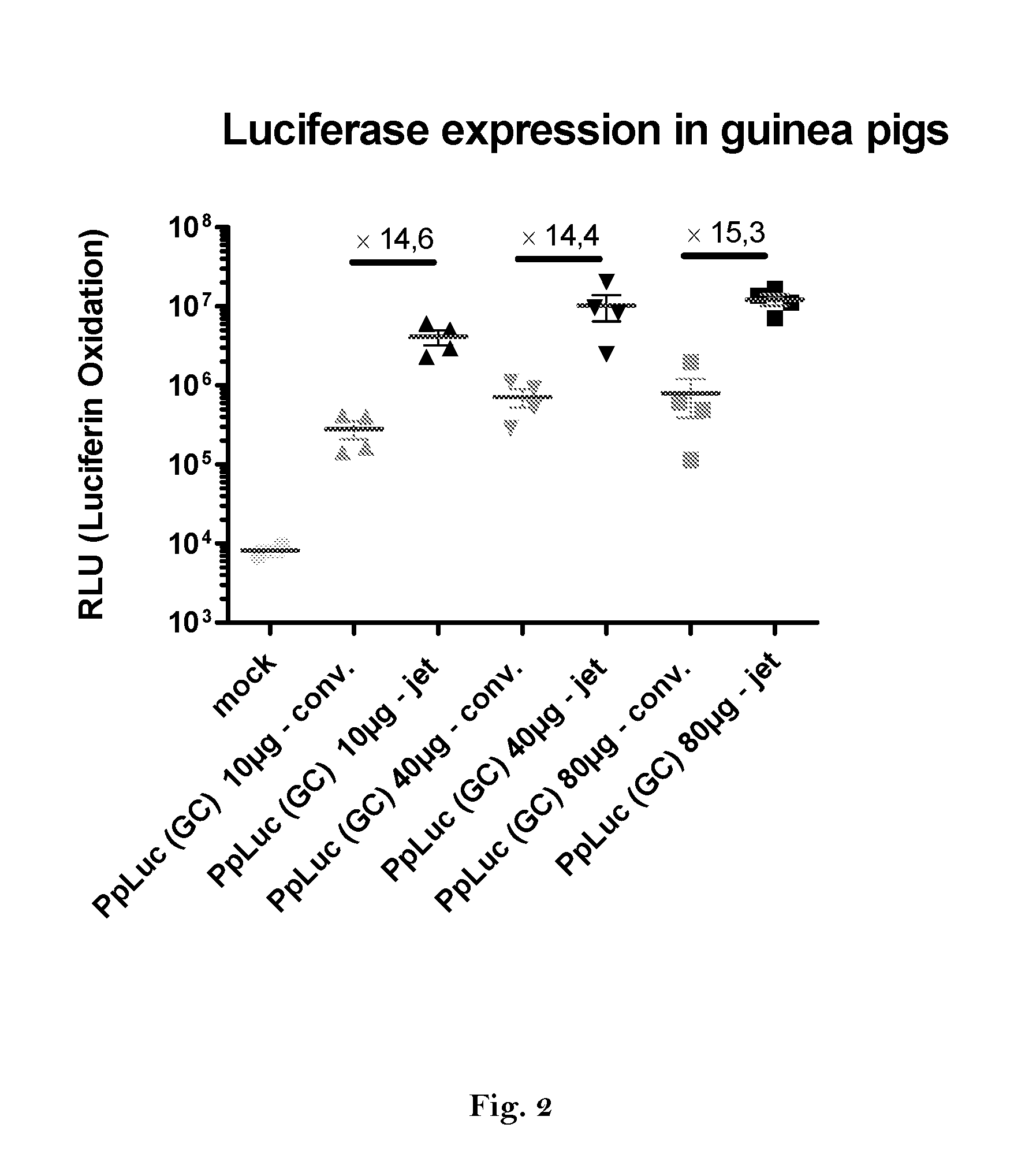

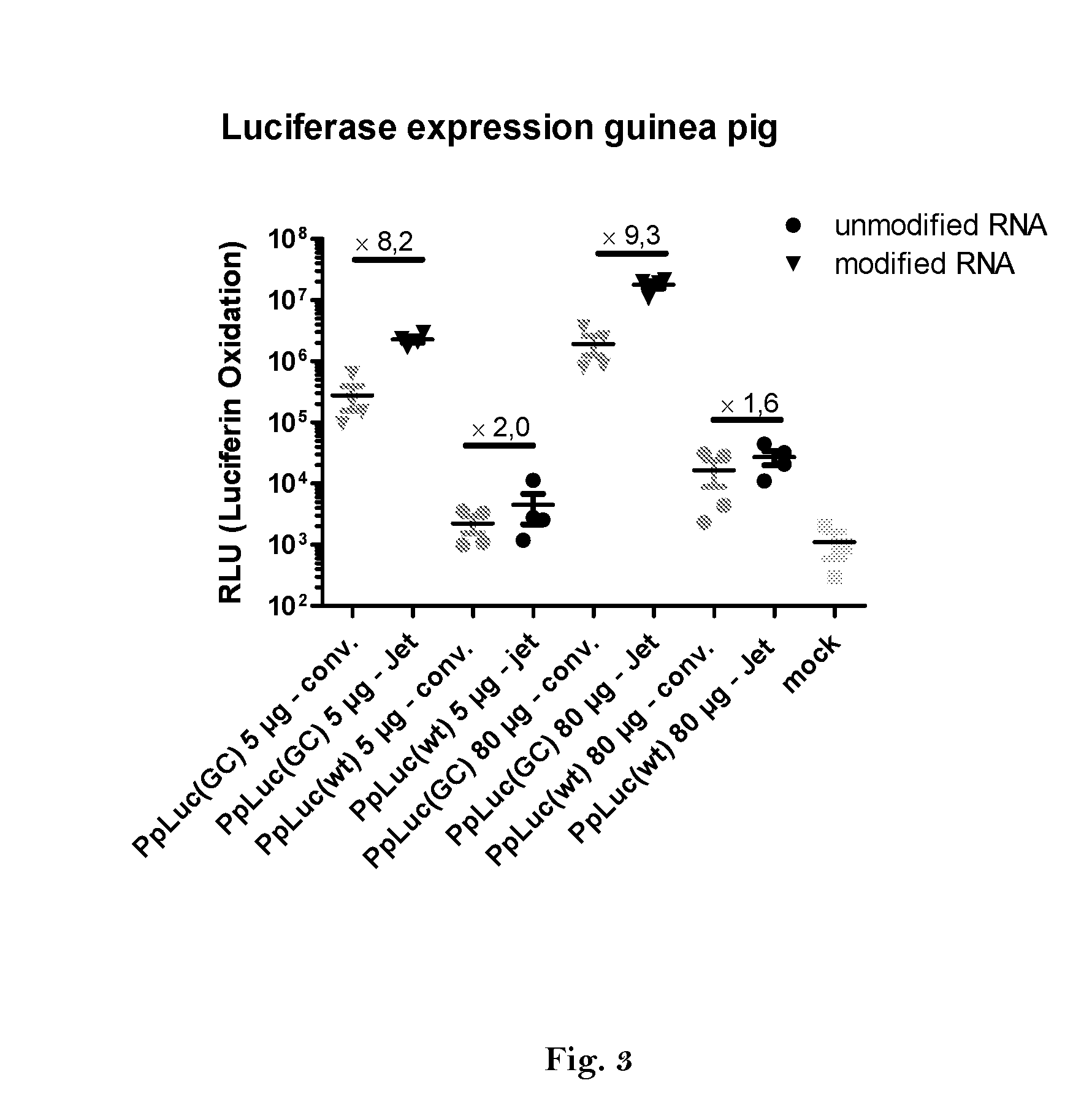

Method for increasing expression of rna-encoded proteins

ActiveUS20160166710A1High expressionImprove securitySsRNA viruses negative-sensePeptide/protein ingredientsOpen reading frameJet injection

The invention relates to an RNA comprising at least one open reading frame (ORF) and comprising at least one modification, which increases the expression of the encoded peptide or protein. Furthermore, the invention relates to the medical use of such a modified RNA administered to a subject by jet injection. The invention relates further to a pharmaceutical composition and to a kit of parts comprising said modified RNA for administration by jet injection, preferably for use in the field of gene therapy and / or genetic vaccination. Additionally, the invention relates to a method for enhancing the (localized) expression of RNA-encoded peptides or proteins in the dermis or muscle (of a mammal) comprising administering the modified RNA by jet injection. And finally, the invention relates to a method of treatment comprising administering the modified RNA by jet injection to a subject in need thereof.

Owner:CUREVAC SE

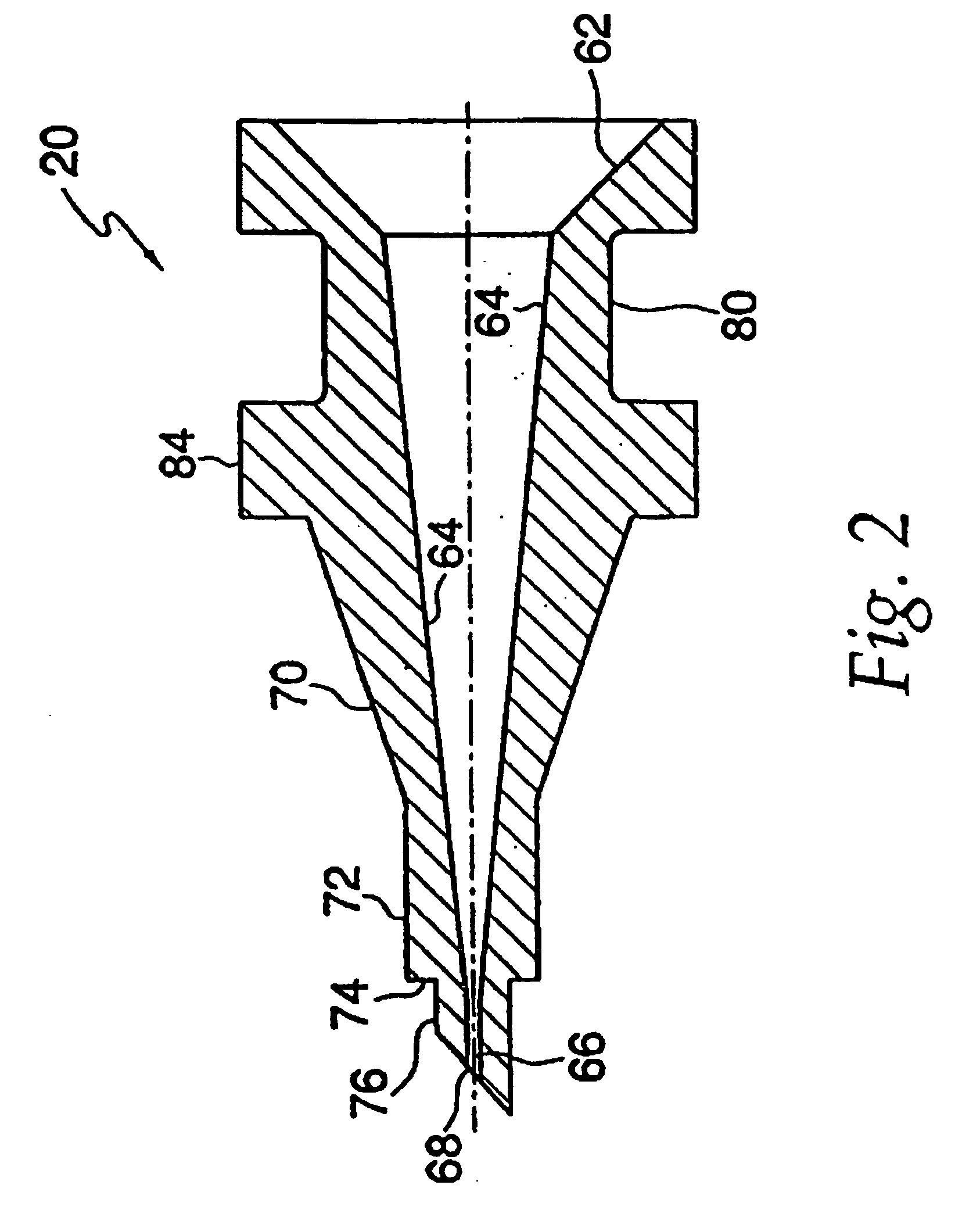

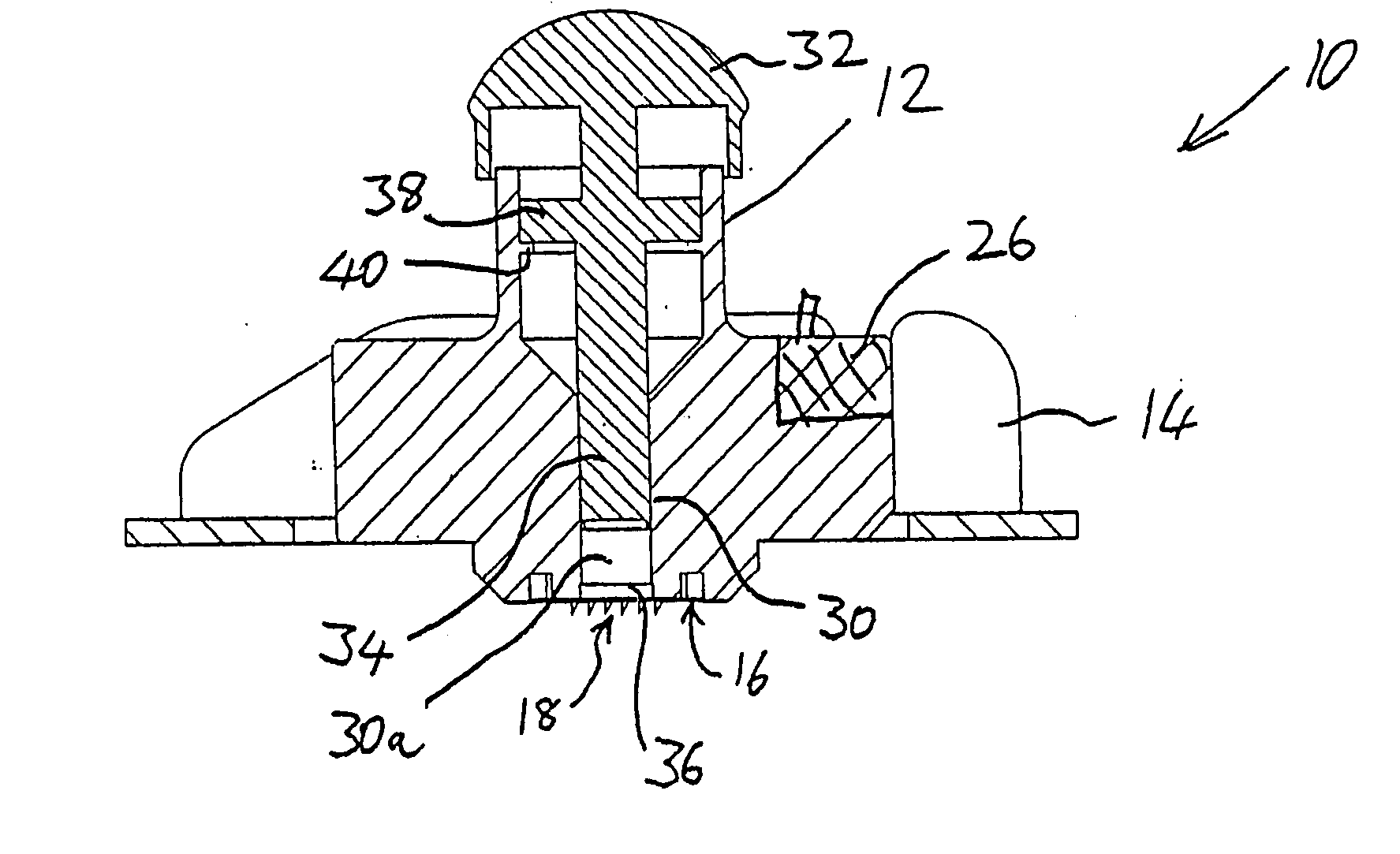

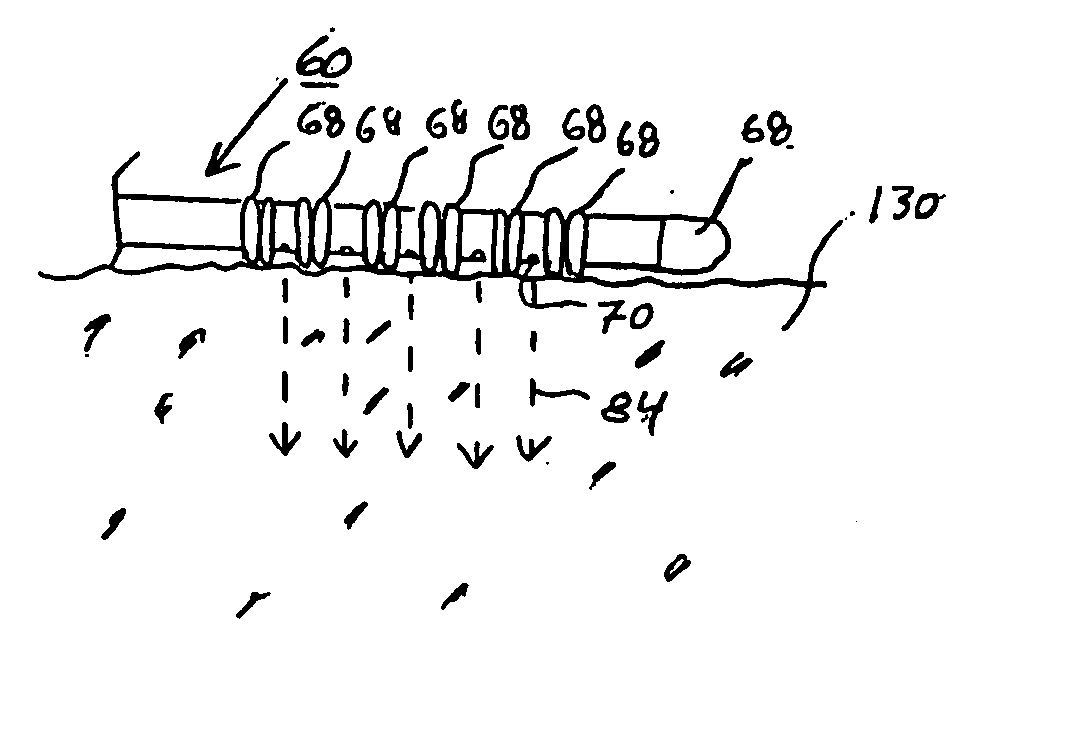

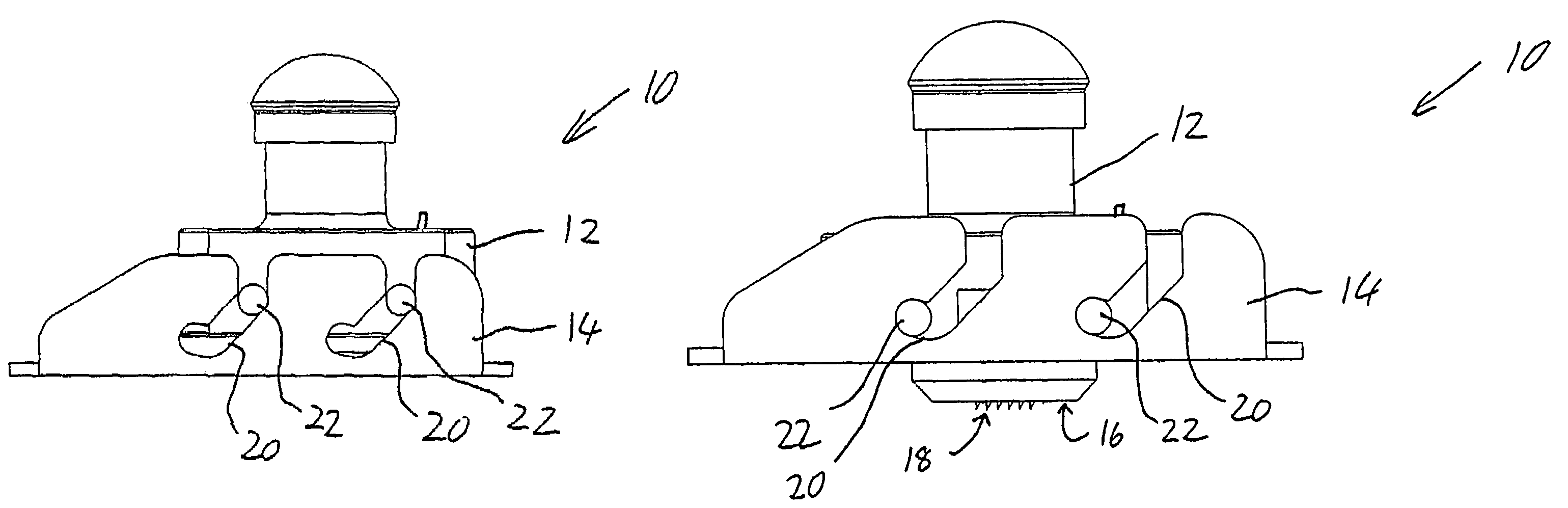

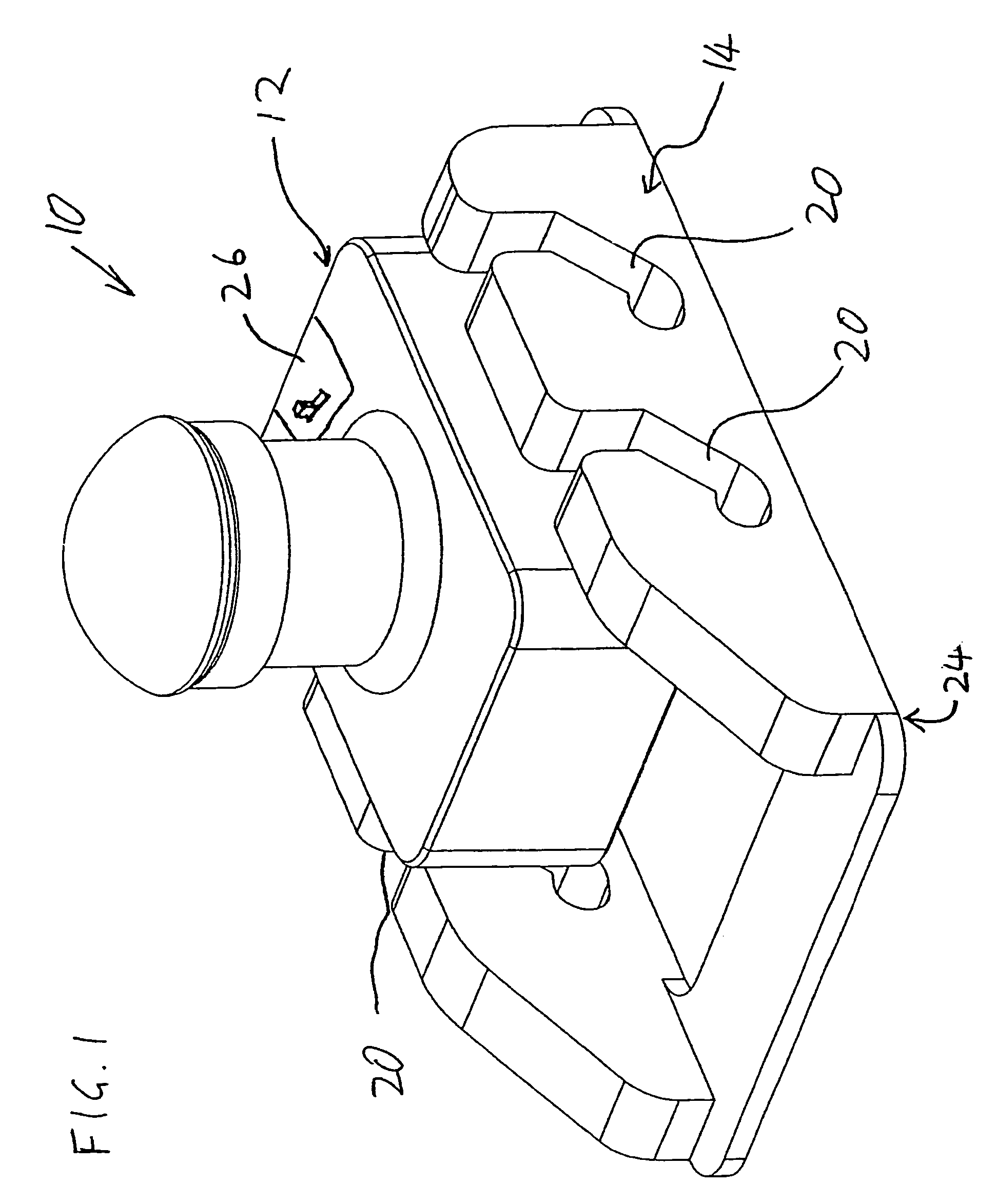

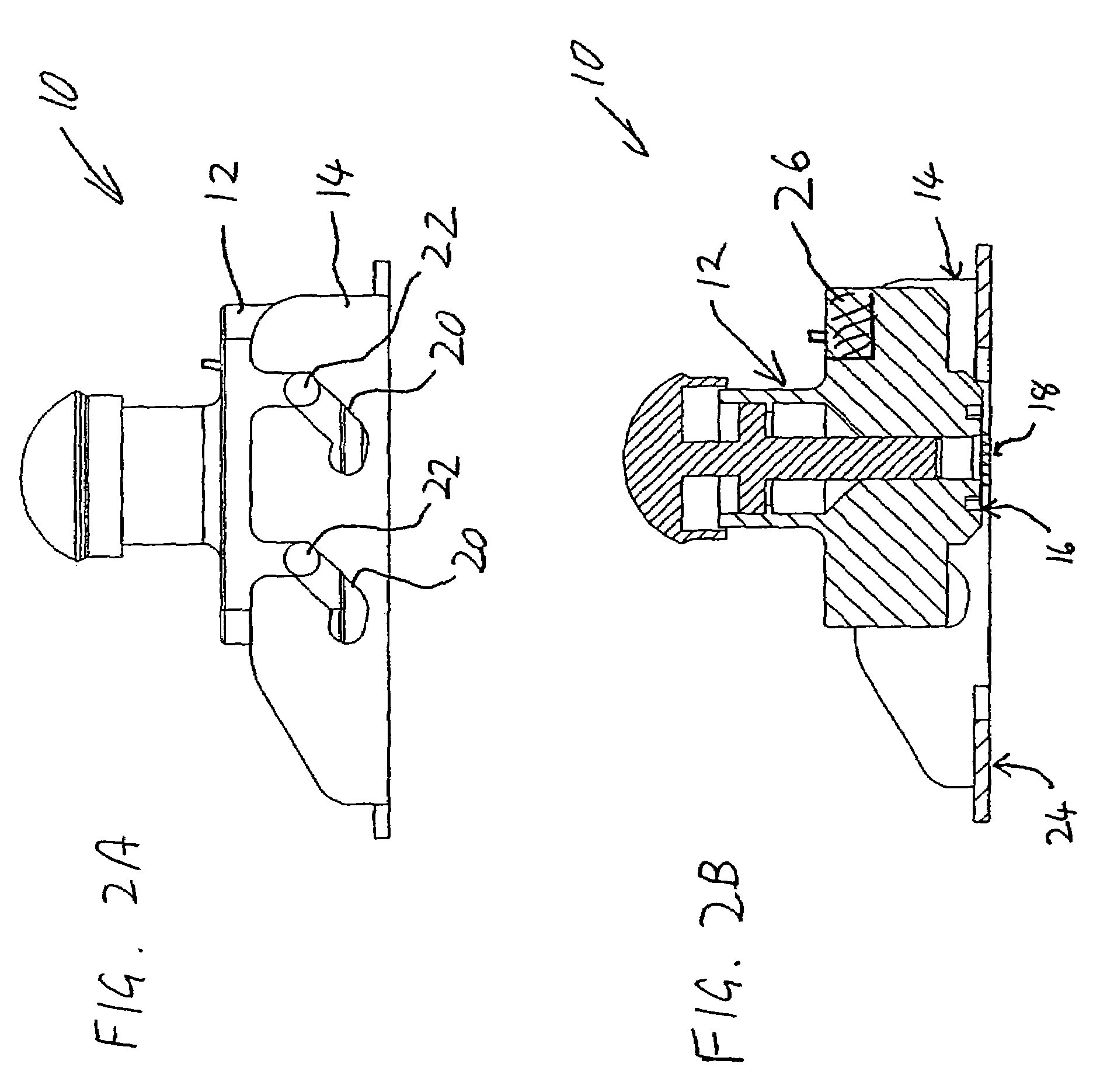

Devices and methods for transporting fluid across a biological barrier

A device (10) and method for tranporting fluids across biological barriers enhances penetration of a biological barrier by the use of directional insertion, preferably with asymmetric microneedles (18) and / or microneedles (18) with sharp edges. Additionally, or alternatively, adhesion followed by alteration of contact geometry is employed to stretch the biological barrier across the microneedles (18), thereby also enhancing penetration. Also disclosed is a device (10) and method which combine shallow penetration by hollow microneedles (18) with jet injection via the microneedles (18) to achieve a total liquid penetration depth greater than the mechanical penetration depth of the microneedles (18).

Owner:NANOPASS TECH LTD

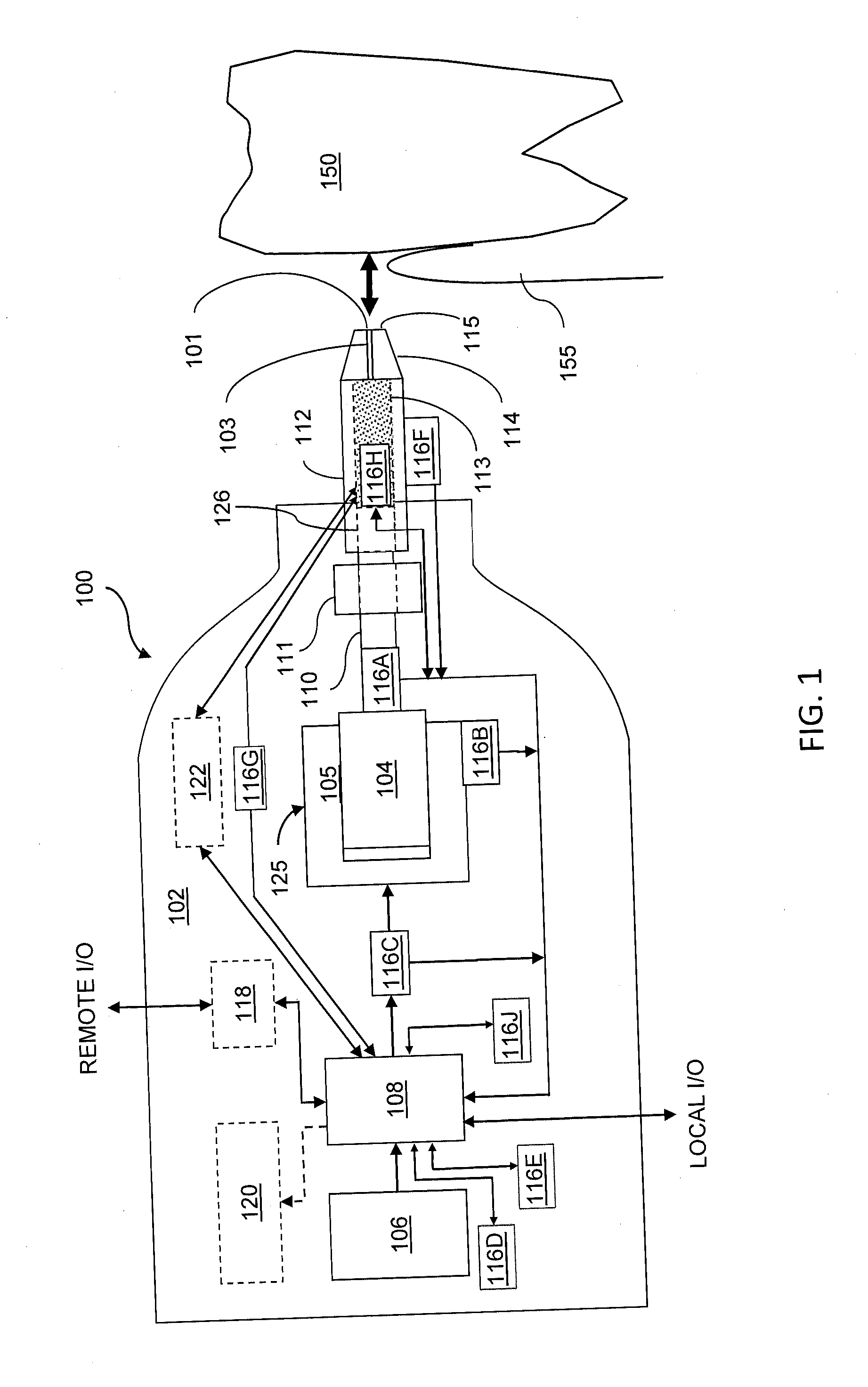

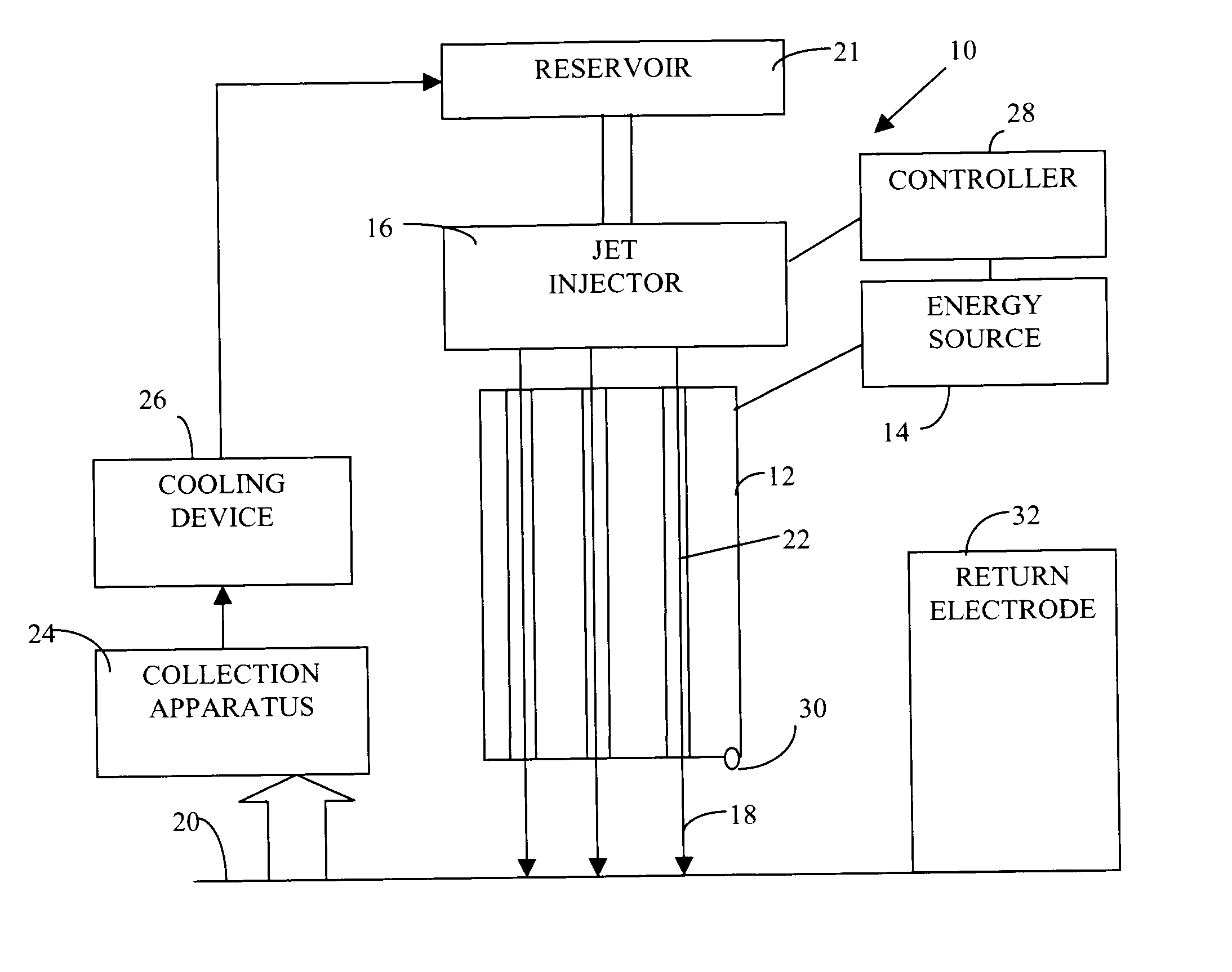

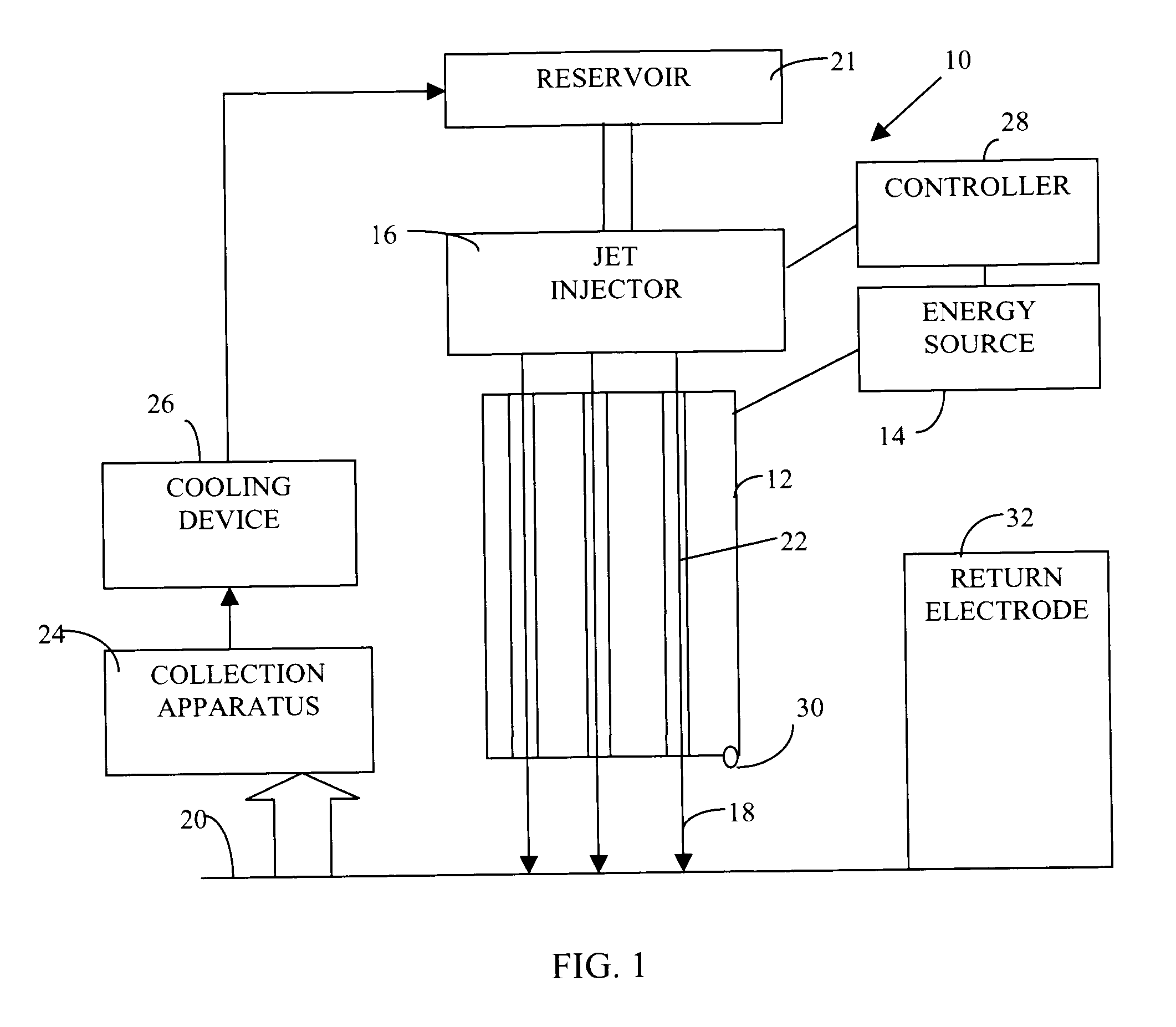

Systems and methods for RF ablation using jet injection of a conductive fluid

InactiveUS20050049583A1Reduce effective resistivityAccurate and deep lesionSurgical instruments for heatingRf ablationInjection site

A method of preparing and ablating heart tissue includes a pre-treatment step of delivering a jet of conductive fluid to a portion of heart tissue. The conductive fluid is delivered using an injection device such as a hand-held jet injector, probe, or catheter. After injecting the heart tissue with the conductive fluid, RF energy is delivered to the site of the injection to form a lesion. The method enables a physician to produce large and accurately placed lesions within the treated tissue.

Owner:SCI MED LIFE SYST

Needleless hypodermic jet injector apparatus and method

InactiveUS7347851B1Less painful experienceLess discomfortJet injection syringesAutomatic syringesLiquid jetJet flow

In the present invention, the impedance between patient's body and the jet injection drug delivery device is measured through the liquid jet during the drug delivery process. The liquid jet completes the electrical circuit formed by impedance monitor, drug delivery device, and the patient's body. When the jet pierces stratum corneum, the impedance in the circuit immediately decreases, thus an indicating the successful drug delivery. The impedance monitor then provides a signal, visible, audible, or electronic, indicating that the process of the drug delivery through skin was successful.

Owner:KRIKSUNOV LEO B

Devices and methods for transporting fluid across a biological barrier

A device (10) and method for transporting fluids across biological barriers enhances penetration of a biological barrier by the use of directional insertion, preferably with asymmetric microneedles (18) and / or microneedles (18) with sharp edges. Additionally, or alternatively, adhesion followed by alteration of contact geometry is employed to stretch the biological barrier across the microneedles (18), thereby also enhancing penetration. Also disclosed is a device (10) and method which combine shallow penetration by hollow microneedles (18) with jet injection via the microneedles (18) to achieve a total liquid penetration depth greater than the mechanical penetration depth of the microneedles (18).

Owner:NANOPASS TECH LTD

Needle-free jet injection drug delivery device

InactiveUS20070055200A1Faster in administeringImprove long-term stabilityJet injection syringesMedical devicesNeedle freeJet injection

A device for delivering a drug includes a housing; at least one nozzle at a portion of the housing; a source of drug in the housing; and an energy source for providing a pressure of up to about 2,000 psi for driving the drug through the at least one nozzle and out of the housing. The drug is delivered to tissue under microjet propulsion. The device is particularly useful for drug delivery applications such as transdermal and ocular by way of example.

Owner:ALZA CORP

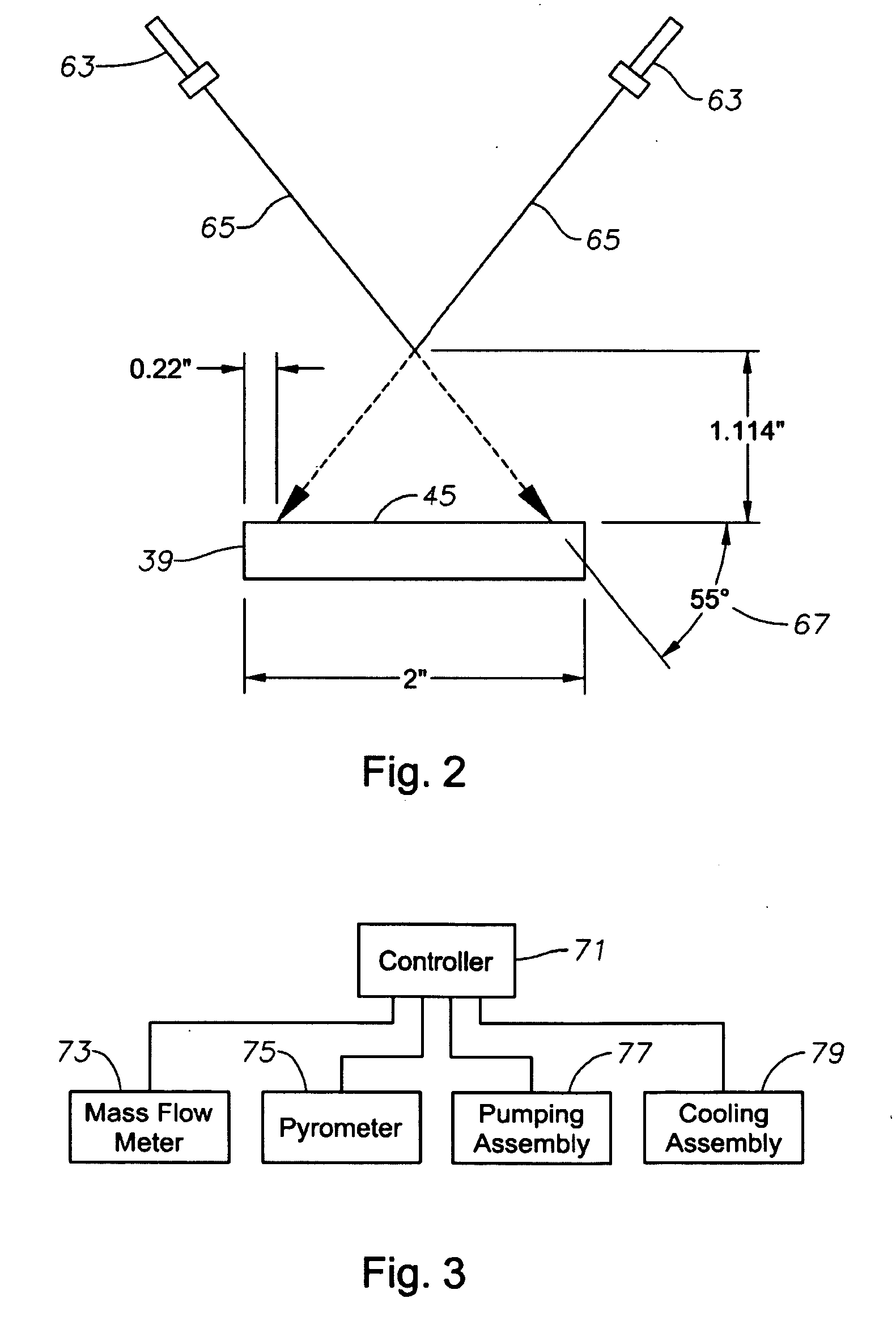

Apparatus and method for diamond film growth

ActiveUS20100189924A1Increase ratingsIncrease impingement rateElectric discharge tubesChemical vapor deposition coatingInjection portJet injection

An apparatus and methods for forming a diamond film, are provided. An example of an apparatus for forming a diamond film includes an electrodeless microwave plasma reactor having a microwave plasma chamber configured to contain a substrate and to contain a reactant gas excited by microwaves to generate a microwave plasma discharge. Gas injection ports extend through an outer wall of the plasma chamber at a location upstream of the plasma discharge and above the substrate. Gas jet injection nozzles interface with the gas injection ports and are configured to form a directed gas stream of reactant gas having sufficient kinetic energy to disturb a boundary layer above an operational surface of the substrate to establish a convective transfer of the film material to the operational surface of the substrate.

Owner:LOCKHEED MARTIN CORP

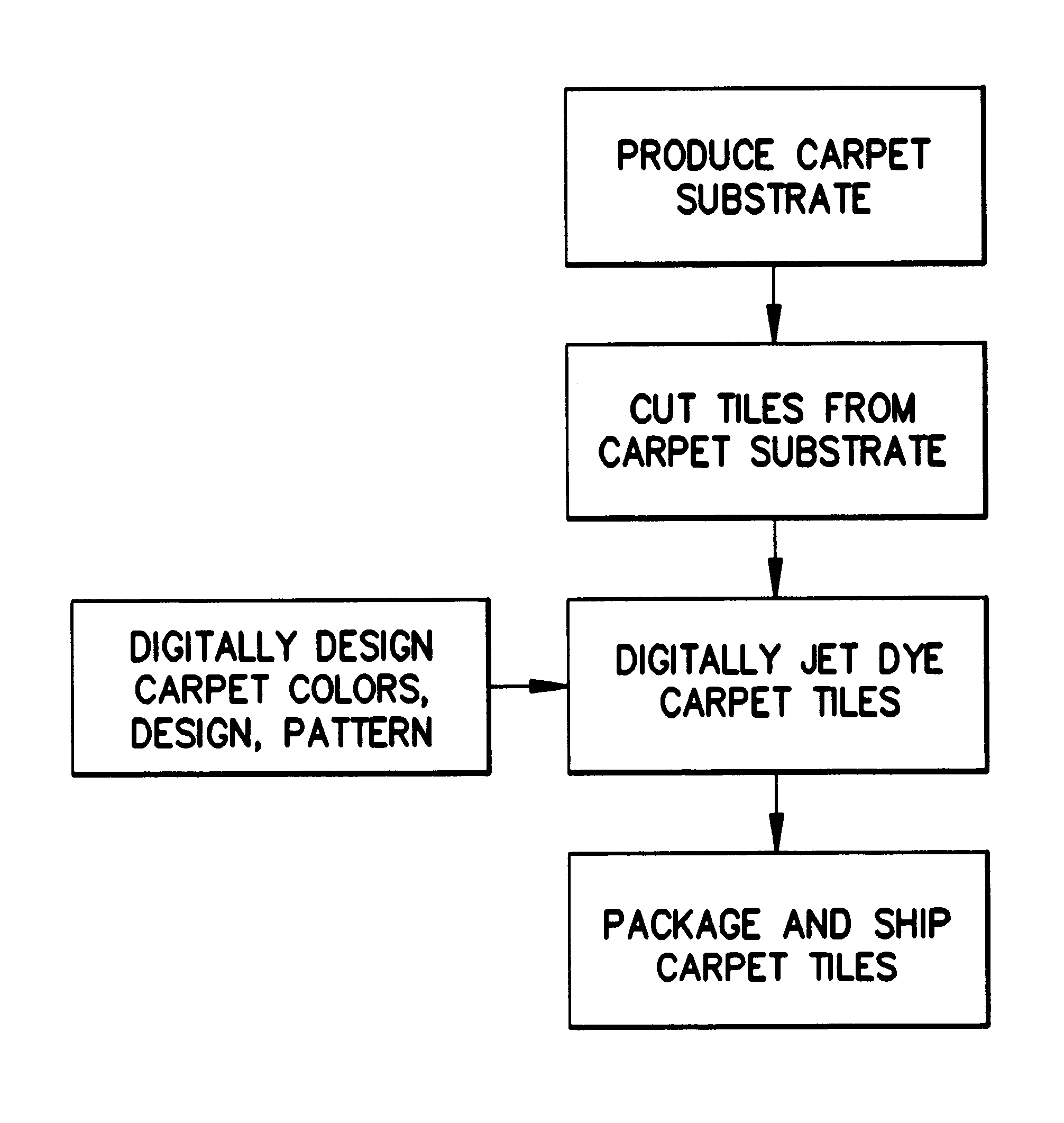

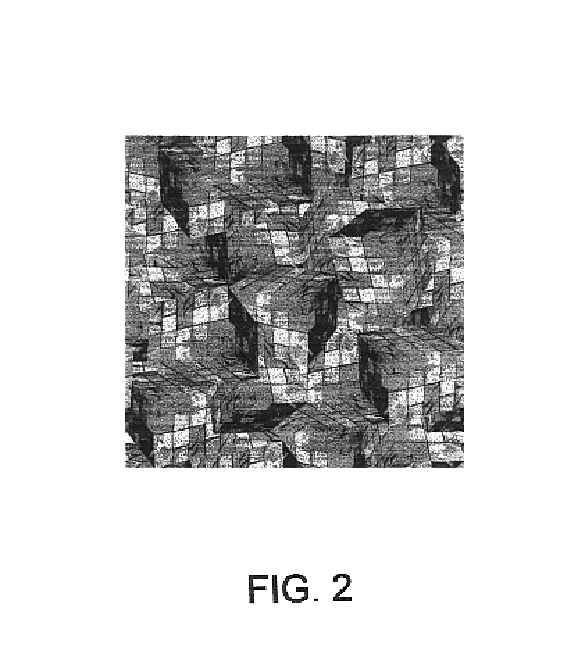

Method for producing digitally designed carpet

Exciting new optically engaging and controversial three dimensional simulating illusionary digital designs which generate emotional responses and photo-realism shock effects are produced by digitally creating a design or pattern and dying and / or printing the digitally created design using digitally controlled dying or printing equipment on flooring, such as, modular carpet tiles, area rugs, runners, rugs, carpets, floor mats, or the like. In accordance with the preferred embodiment of the present invention, a carpet tile substrate is cut into individual carpet tile blanks which are jet injection dyed with digitally created designs, colors, patterns, and / or the like which provide excellent seamability, look, feel, wear, and allow for true or accurate registration of three dimensional like, complex, complicated, intricate designs heretofore unknown in the carpet industry.

Owner:MILLIKEN & CO

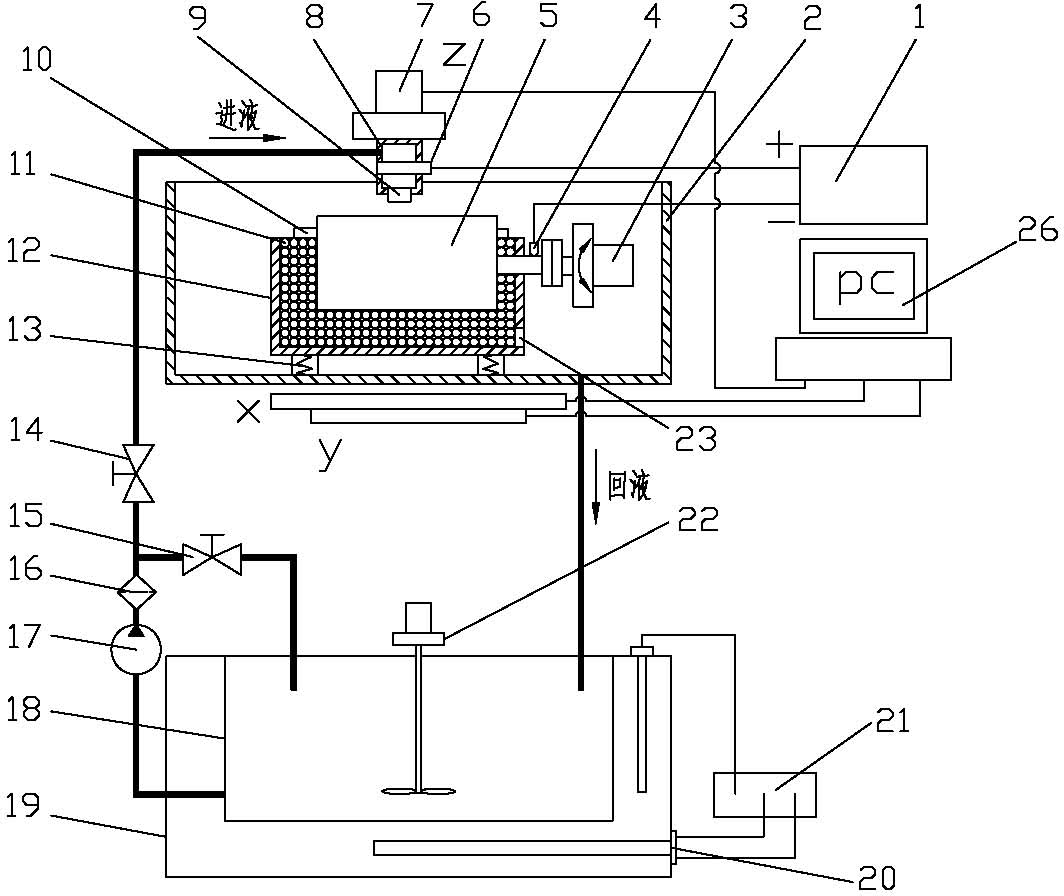

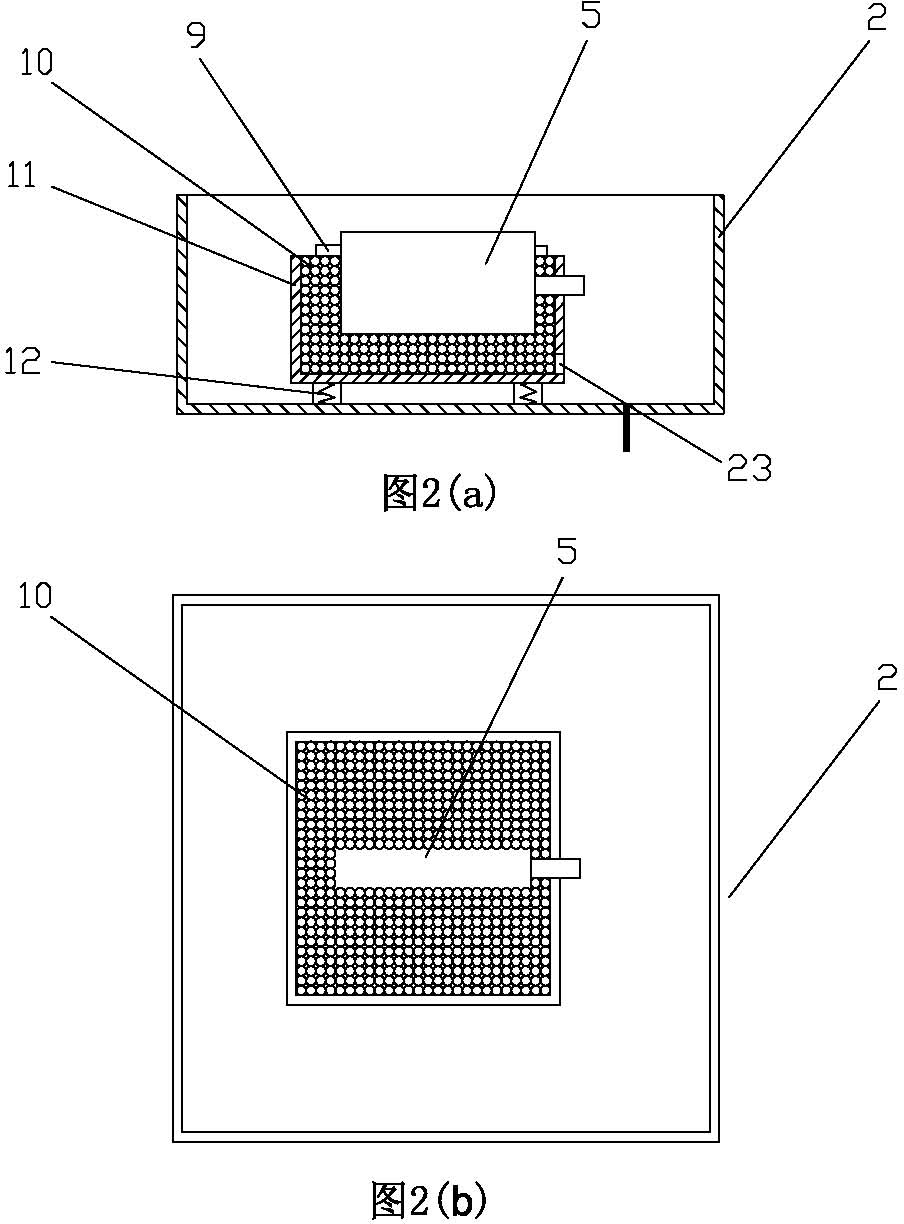

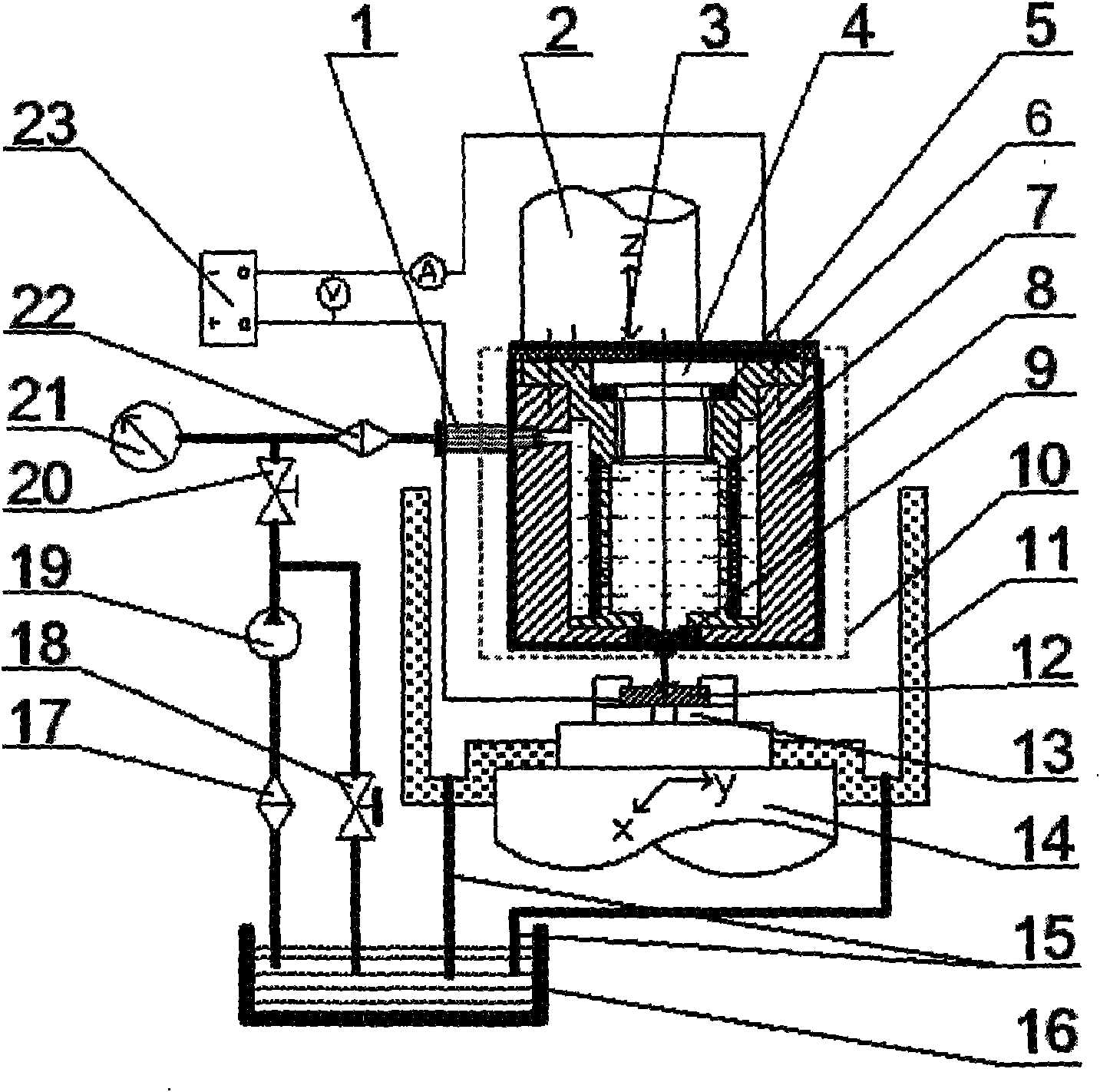

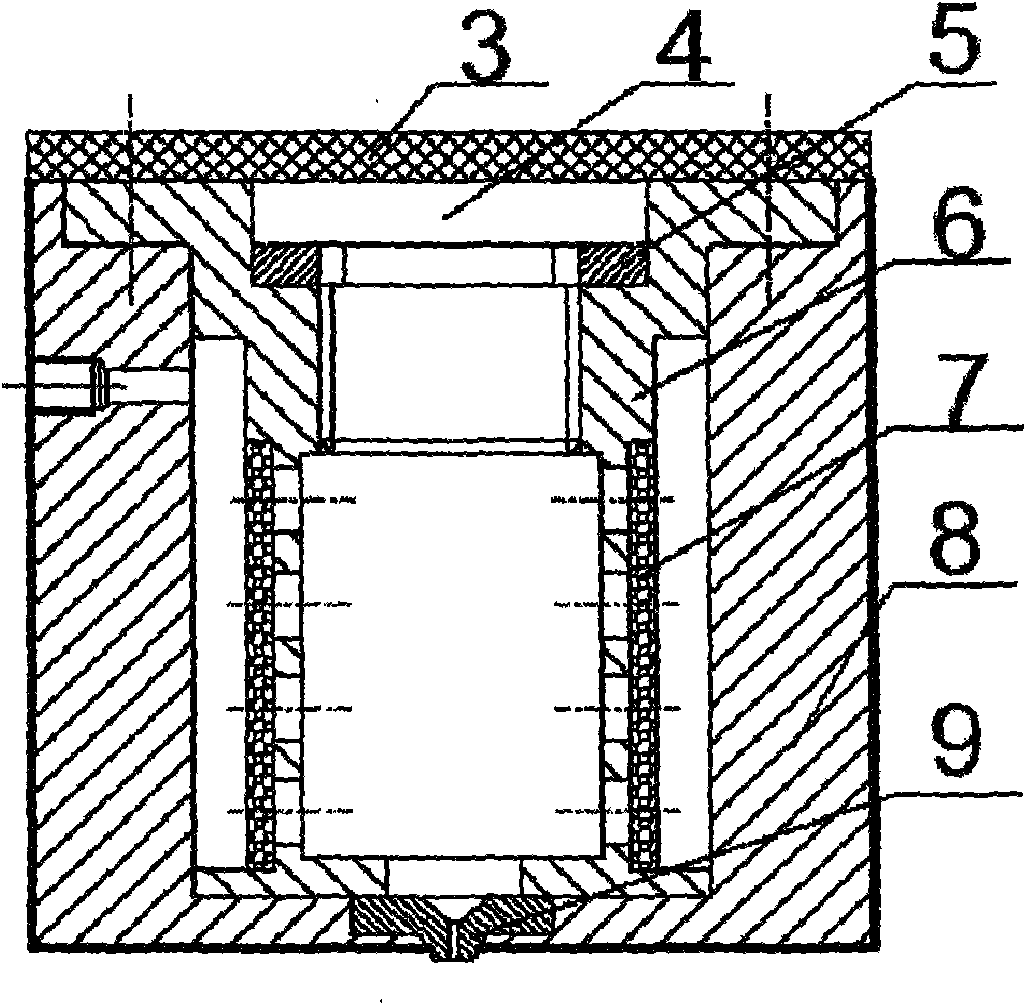

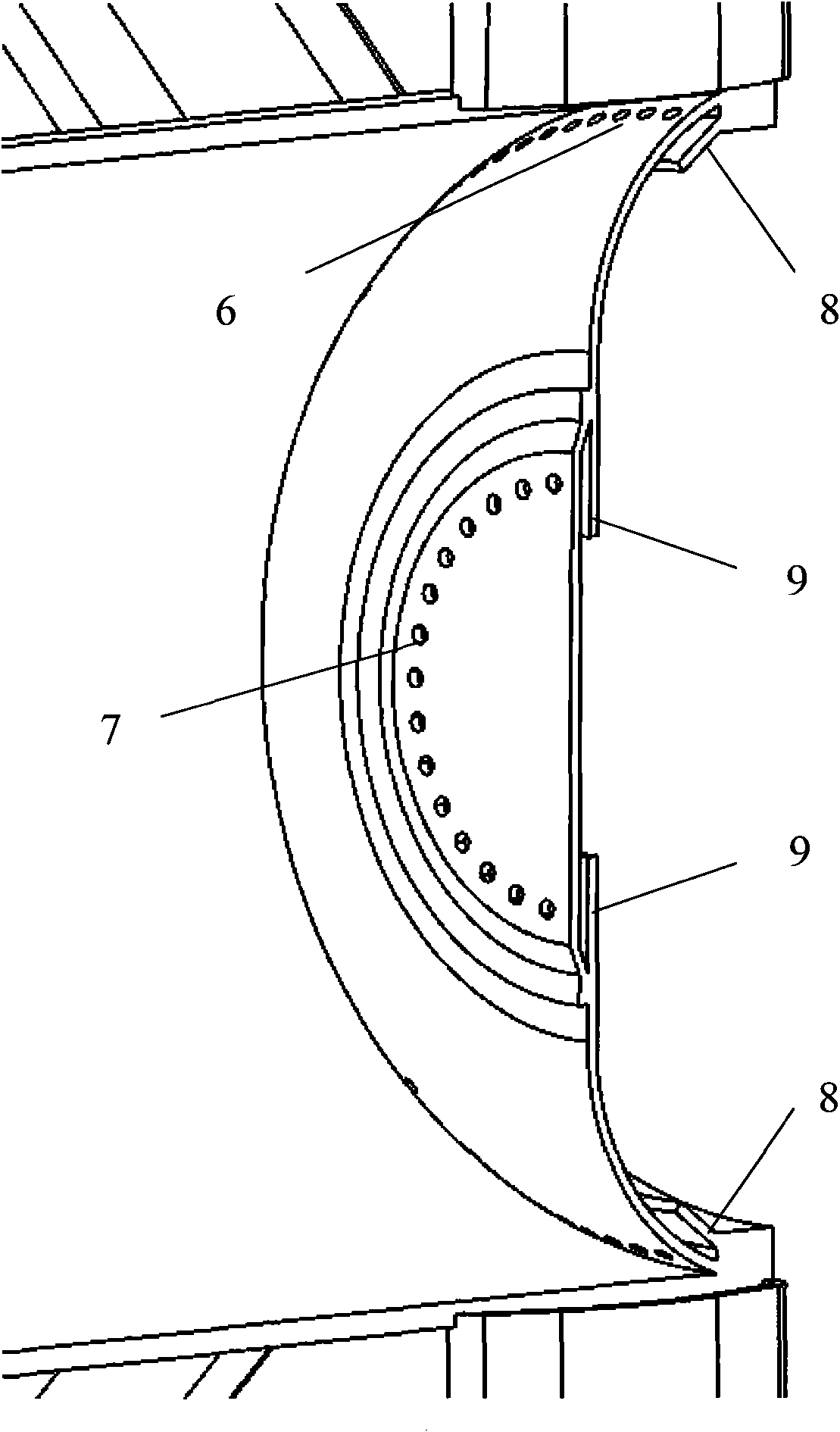

Method and device for processing revolving parts by high-speed jet injection electroforming

InactiveCN101994137AReduce thicknessOvercome timeElectroforming processesTemperature controlControl system

The invention provides a method and device for processing revolving parts by high-speed jet injection electroforming. The method is characterized in that an electroforming core mould is partially buried in an electroforming groove which is filled with hard particles or is in direct contact with a plated negative pole surface through a friction piece, so that the defects of accumulated tumors, burrs and the like on a deposition surface can be effectively removed by the friction of the hard particles or the friction piece on an electroforming layer; and a computer is used for controlling a jet nozzle to scan along with a certain track and cooperates with the rotary motion of the electroforming core mould at the same time, so that the exposed electroforming core mould surface is subjected to selective scanning electroforming so as to pile up the required parts layer by layer. The device of the invention mainly comprises a table movement mechanism, a negative pole rotation drive device, a control system, a temperature control device, an electroforming liquid circulating filter system and the like. The method and device for processing the revolving parts by high-speed jet injection electroforming of the invention are adopted, thus not only effectively removing the defects of hard spots, air holes, accumulated tumors and the like on the electroforming layer surface and manufacturing the electroforming layer with compact and even texture at higher deposition speed, but also abandoning the complicated negative pole female die of the traditional electroforming and rapidly and efficiently forming the revolving parts with different shapes and wall thicknesses by one step.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nozzle device with skin stretching means

InactiveUS20070021716A1Reduce the possibilityIncrease contactJet injection syringesAutomatic syringesSkin stretchingJet injection

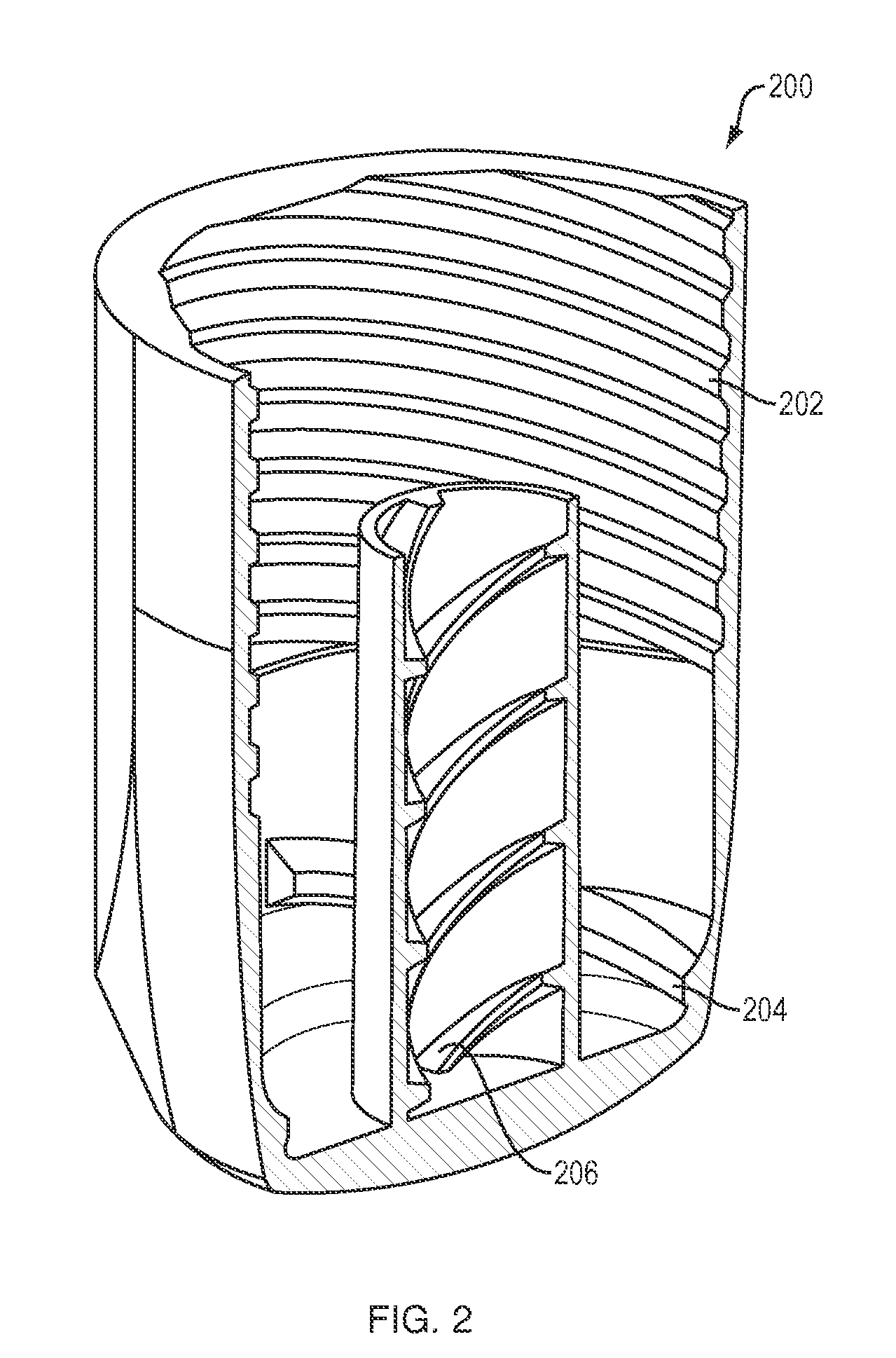

The invention relates to a nozzle device adapted for placement against a skin surface of a subject, the nozzle device providing a means for stretching the skin, the nozzle device being suitable for use in jet injection. More specifically, the skin stretching means is arranged circumferentially relative to a nozzle, the skin stretching means having an initial first configuration corresponding to an initial state in which the skin stretching means is adapted to be placed against a skin surface of the subject, the skin stretching means being moveable to a second configuration, wherein movement of the skin stretching means to the second configuration after the skin stretching means has been placed against the skin of the subject results in the skin being stretched relative to the outlet nozzle.

Owner:NOVO NORDISK AS

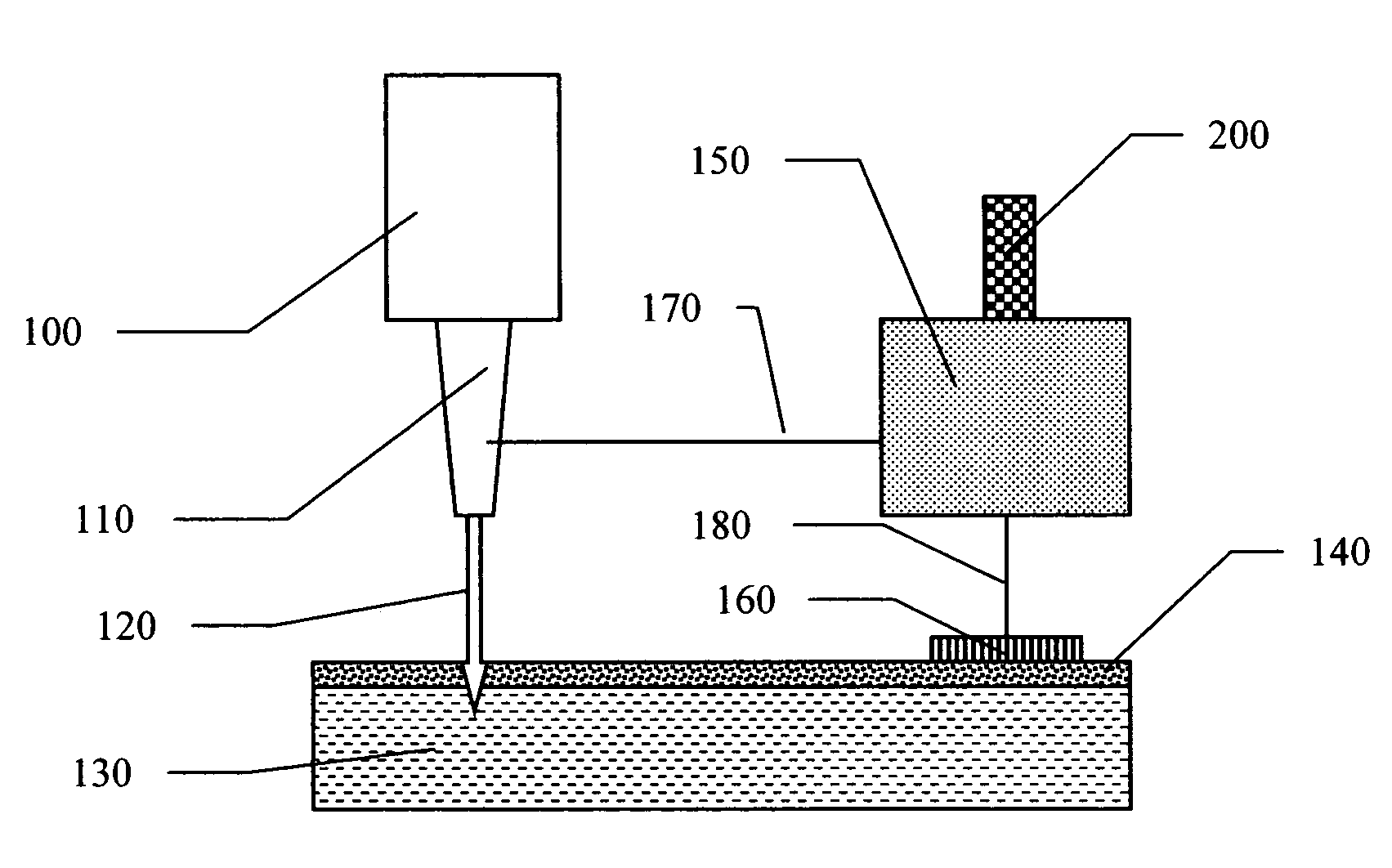

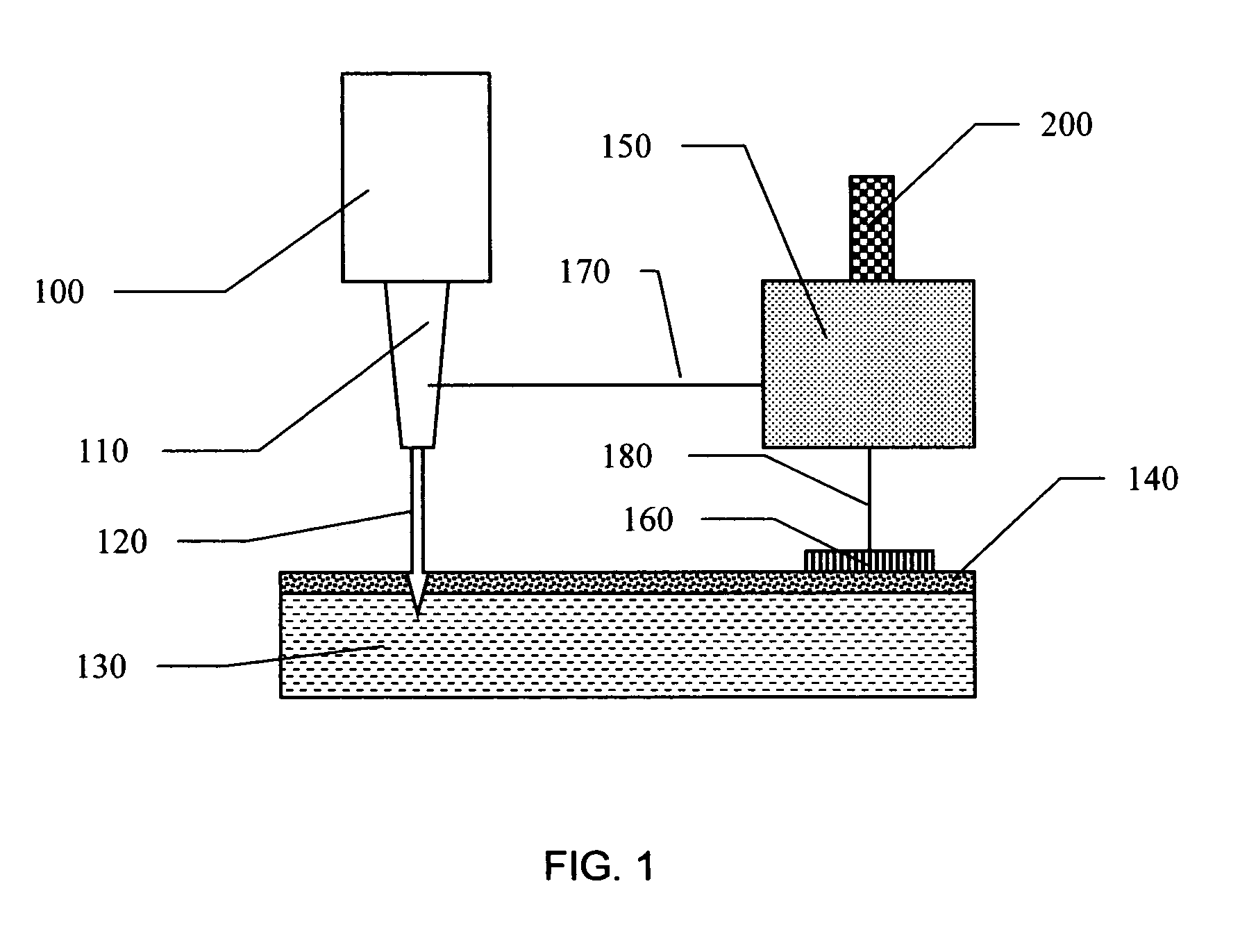

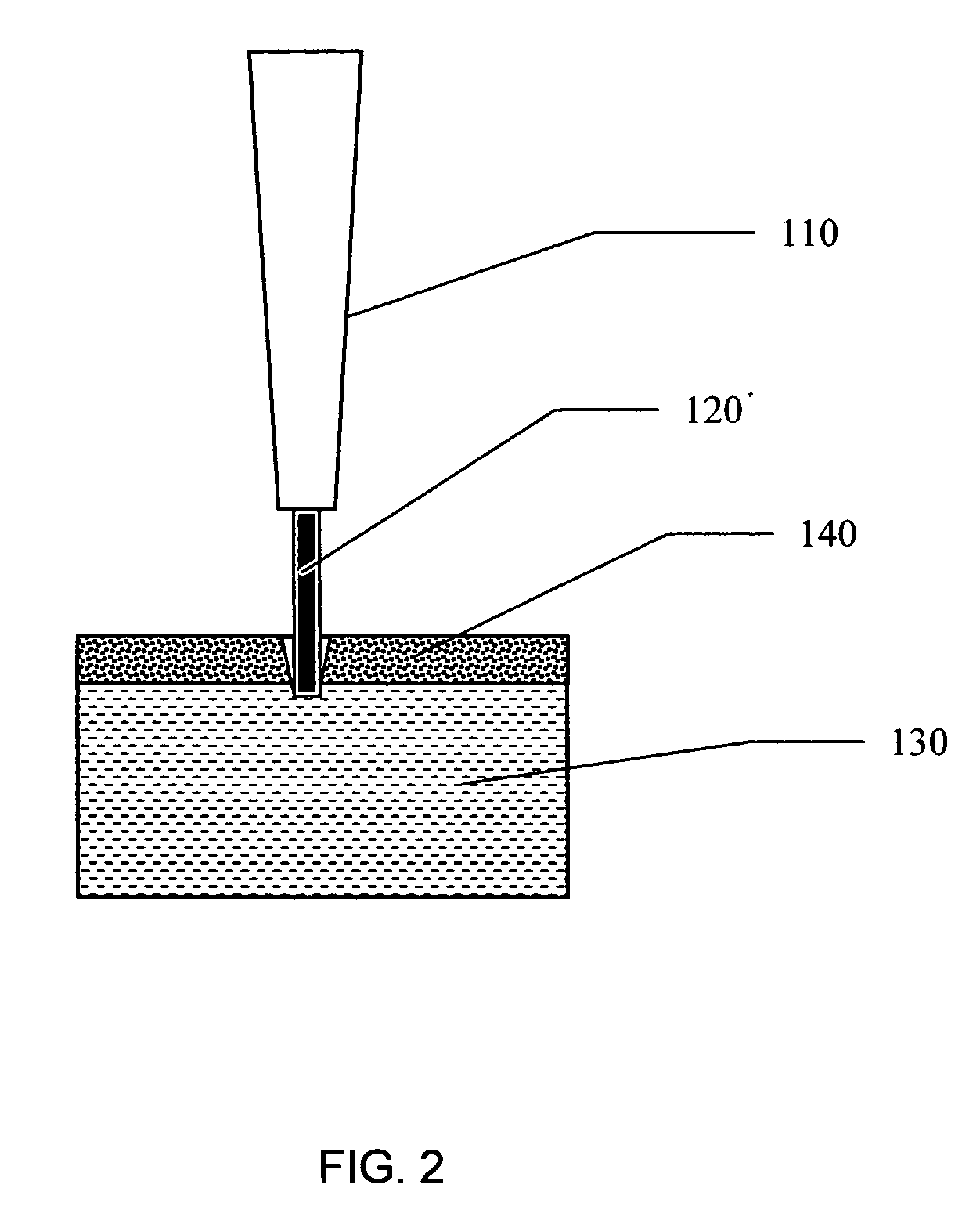

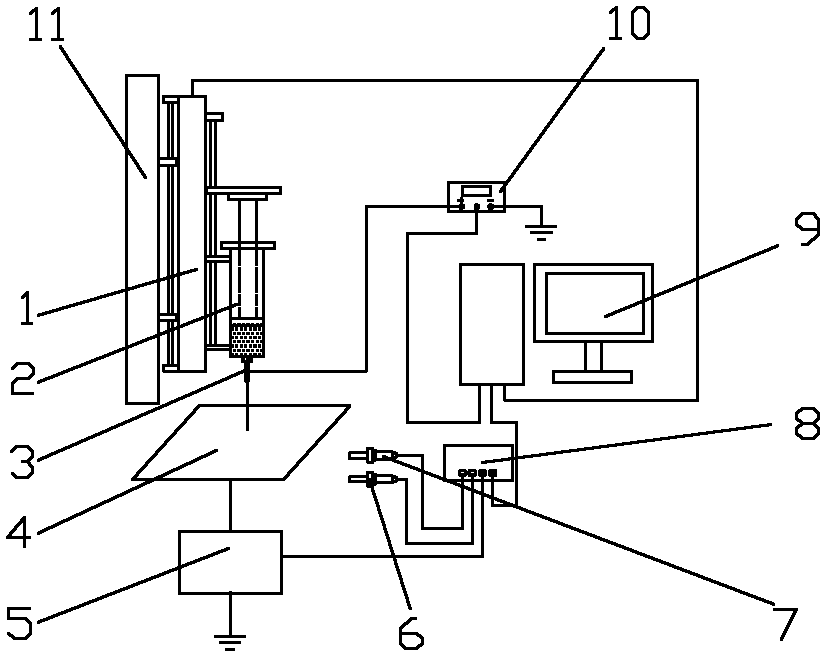

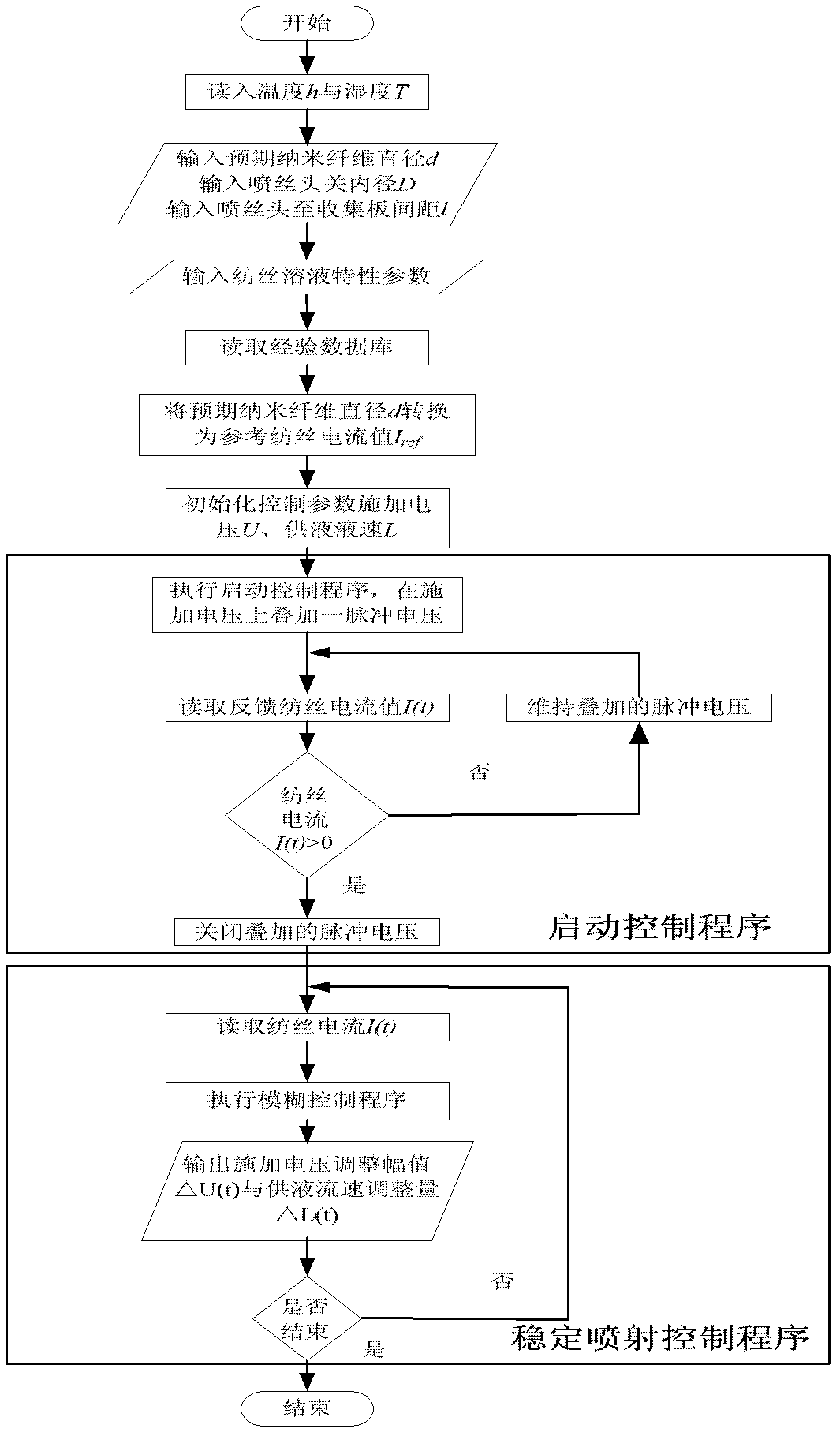

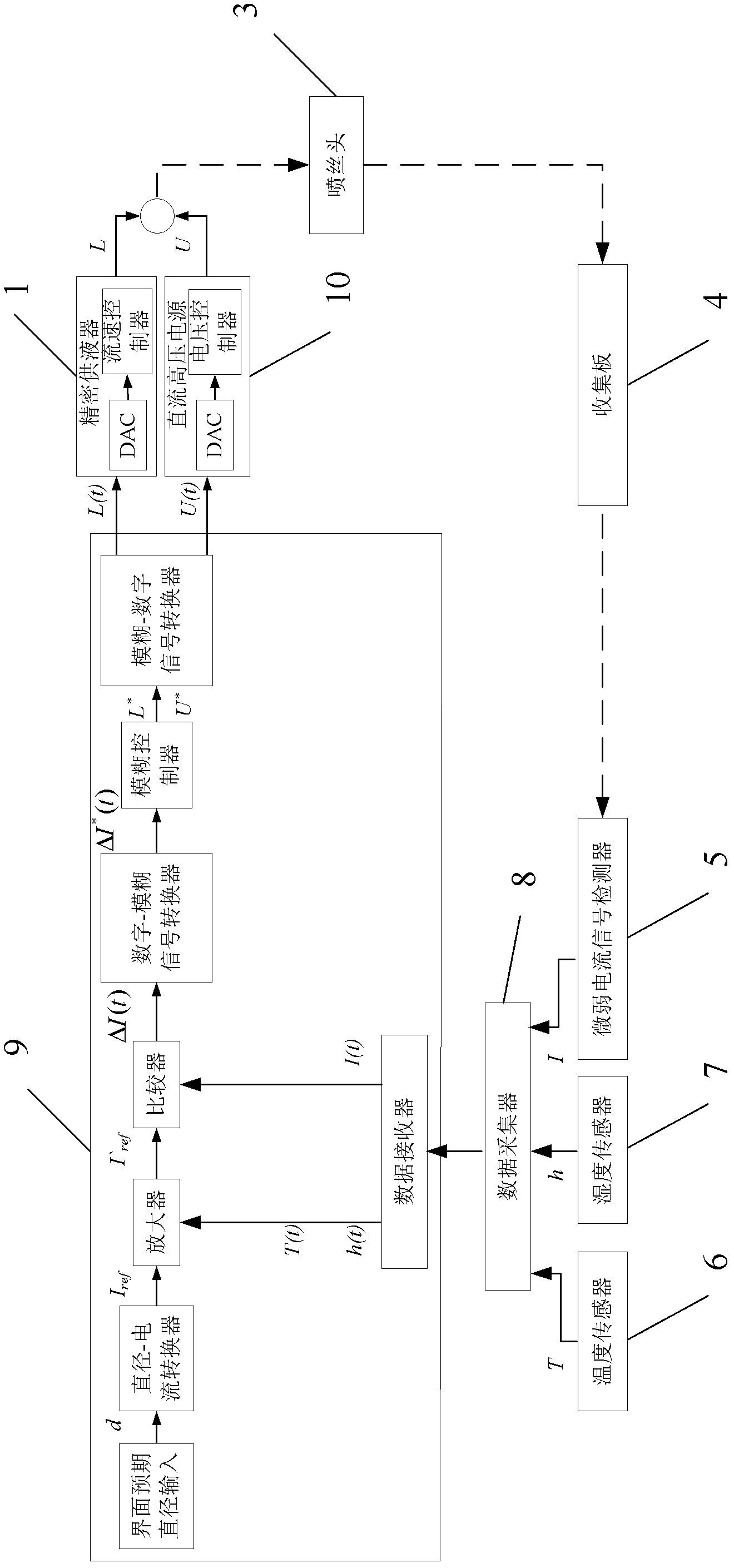

Electrospinning direct-writing closed-loop control system and control method

ActiveCN102582293ARealize controllable adjustmentImprove uniformityOther printing apparatusFiberLoop control

The invention relates to an electrospinning direct-writing closed-loop control system and a control method, which relate to electrospinning direct writing equipment. The invention provides the electrospinning direct-writing closed-loop control system which is capable of realizing the controllable adjustment of the electrospinning direct-writing nano fibre diameter and improves the jet injection stability of spinning and the uniformity of nano fibre diameter and the control method of the electrospinning direct-writing closed-loop control system. The system comprises a liquid storage tank, a liquid feeder, a spinning nozzle, a collecting plate, a weak current detector, a temperature sensor, a humidity sensor, a data collector, a control computer, a direct current high voltage power supply and an adjustable frame. The system establishes a fuzzy controller to obtain the jet injection state by detecting the spinning current, adjusts the applied voltage and the flow rate of the feeding liquid according to the change of the spinning current so as to avoid the influence of various interference factors and realize long time stable jet of the spinning jet flow. The set current of the fuzzy controller is adjusted to control the electrospinning direct-writing nano fibre diameter. The electrospinning direct-writing closed-loop control system is beneficial to improving the controllability of the electrospinning direct-writing nano fibre diameter and well promoting the industrialized application of the electrospinning direct-writing technology.

Owner:XIAMEN UNIV

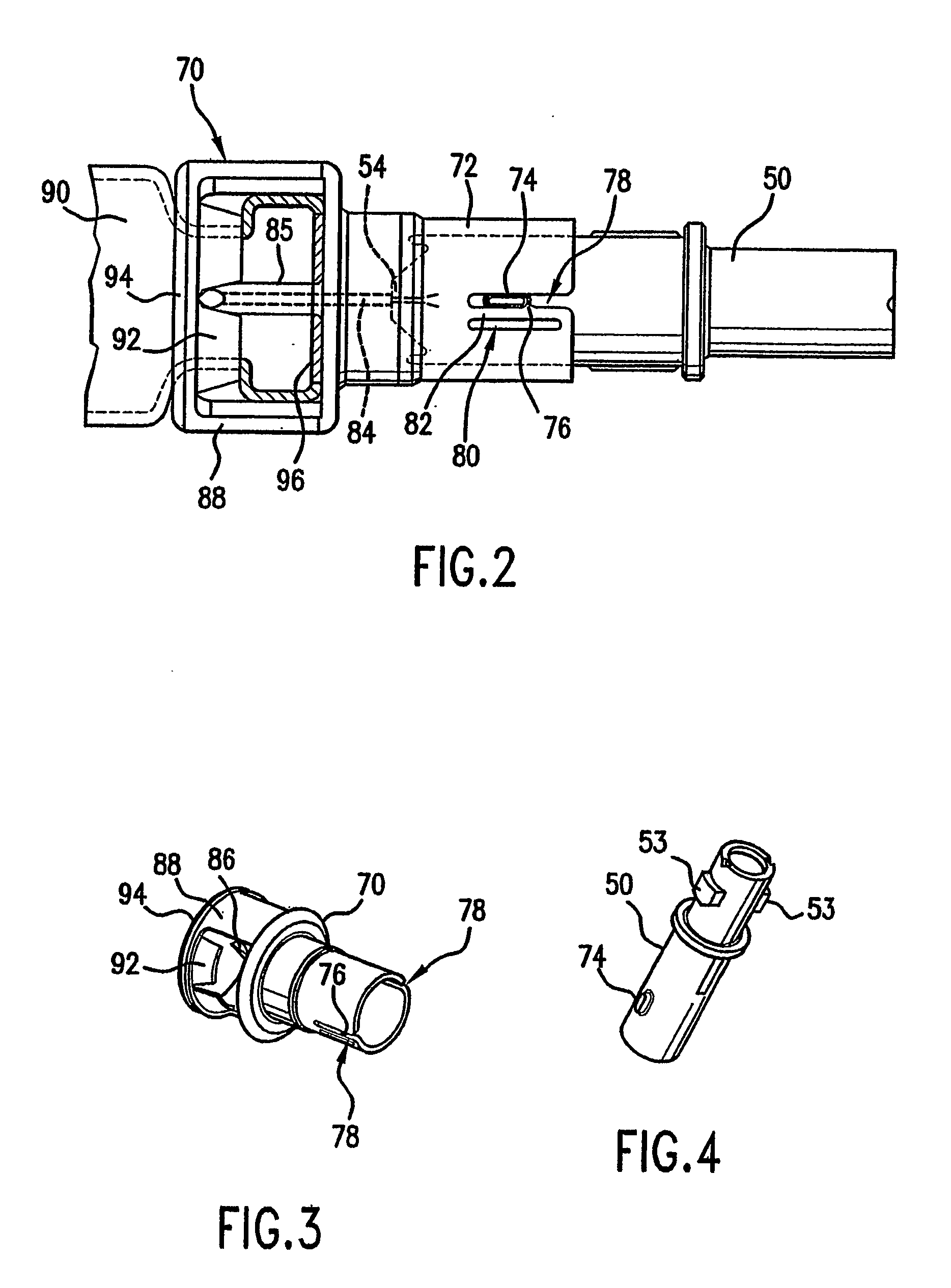

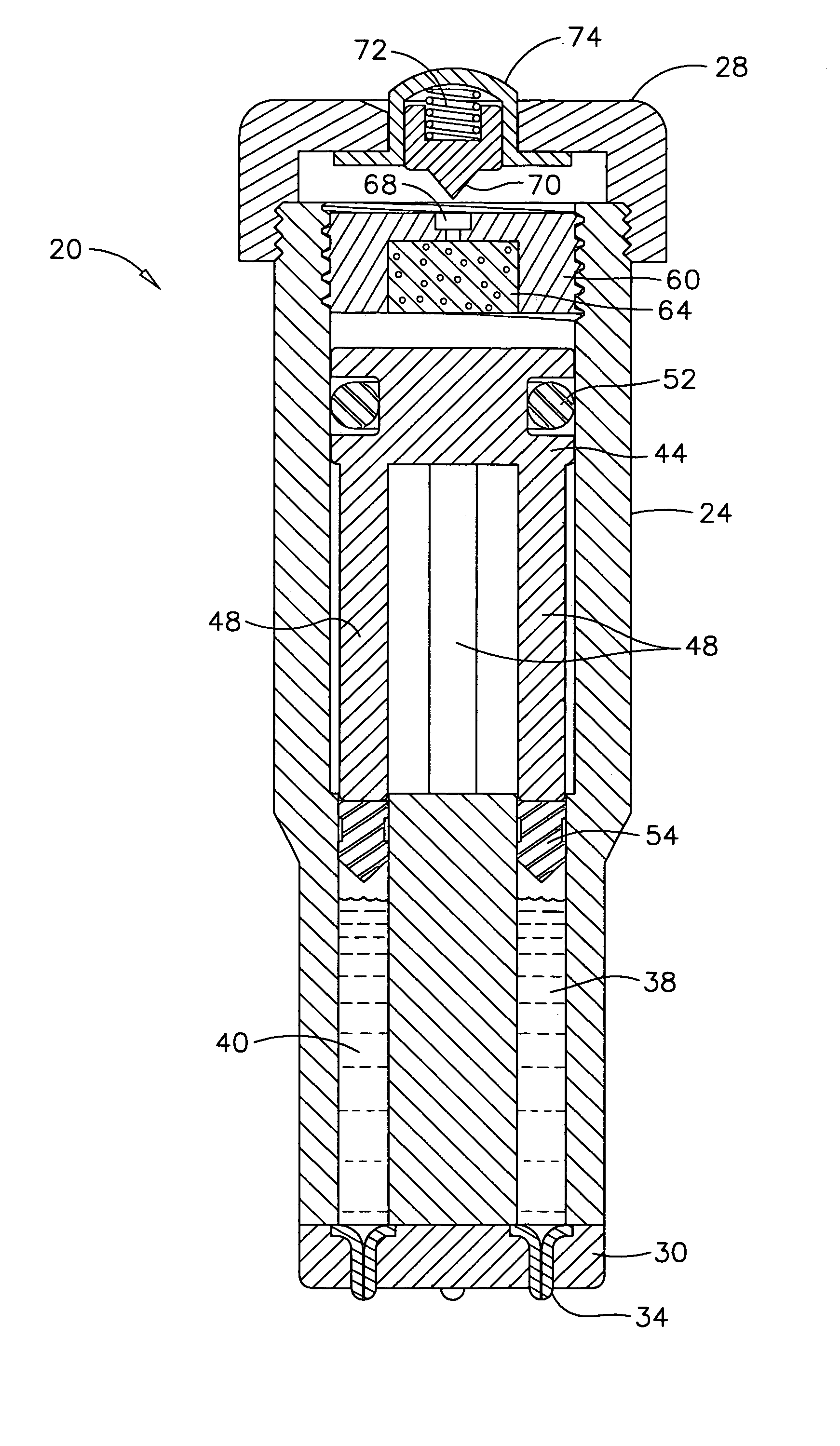

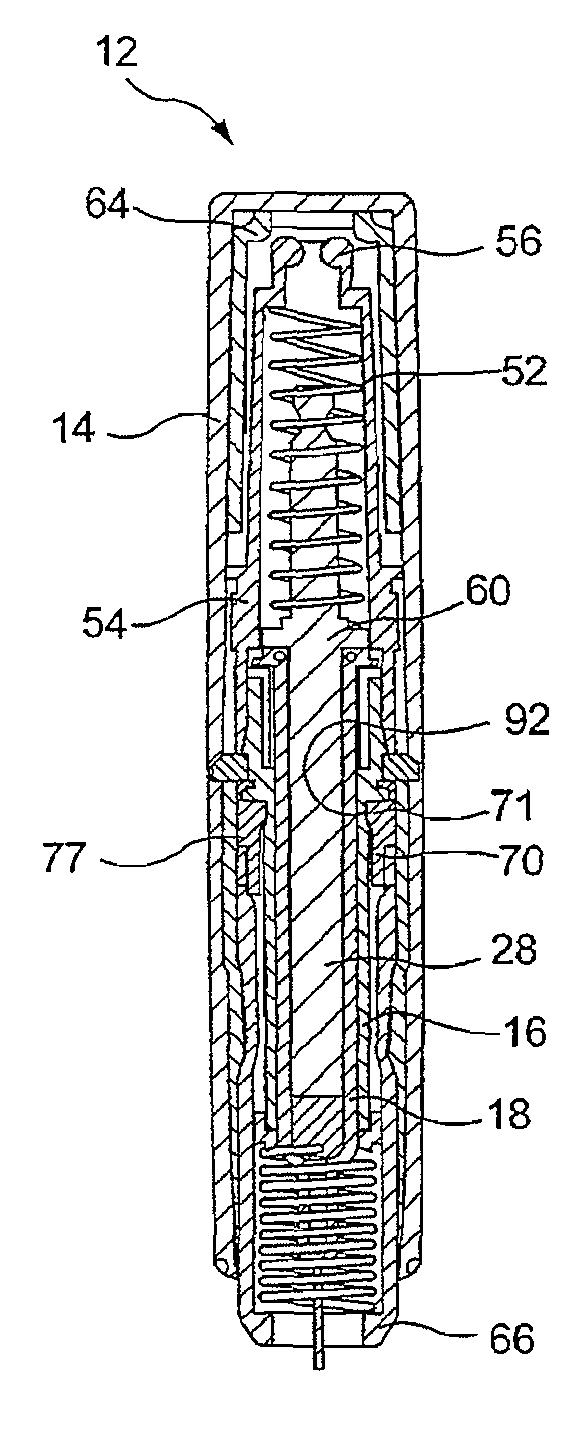

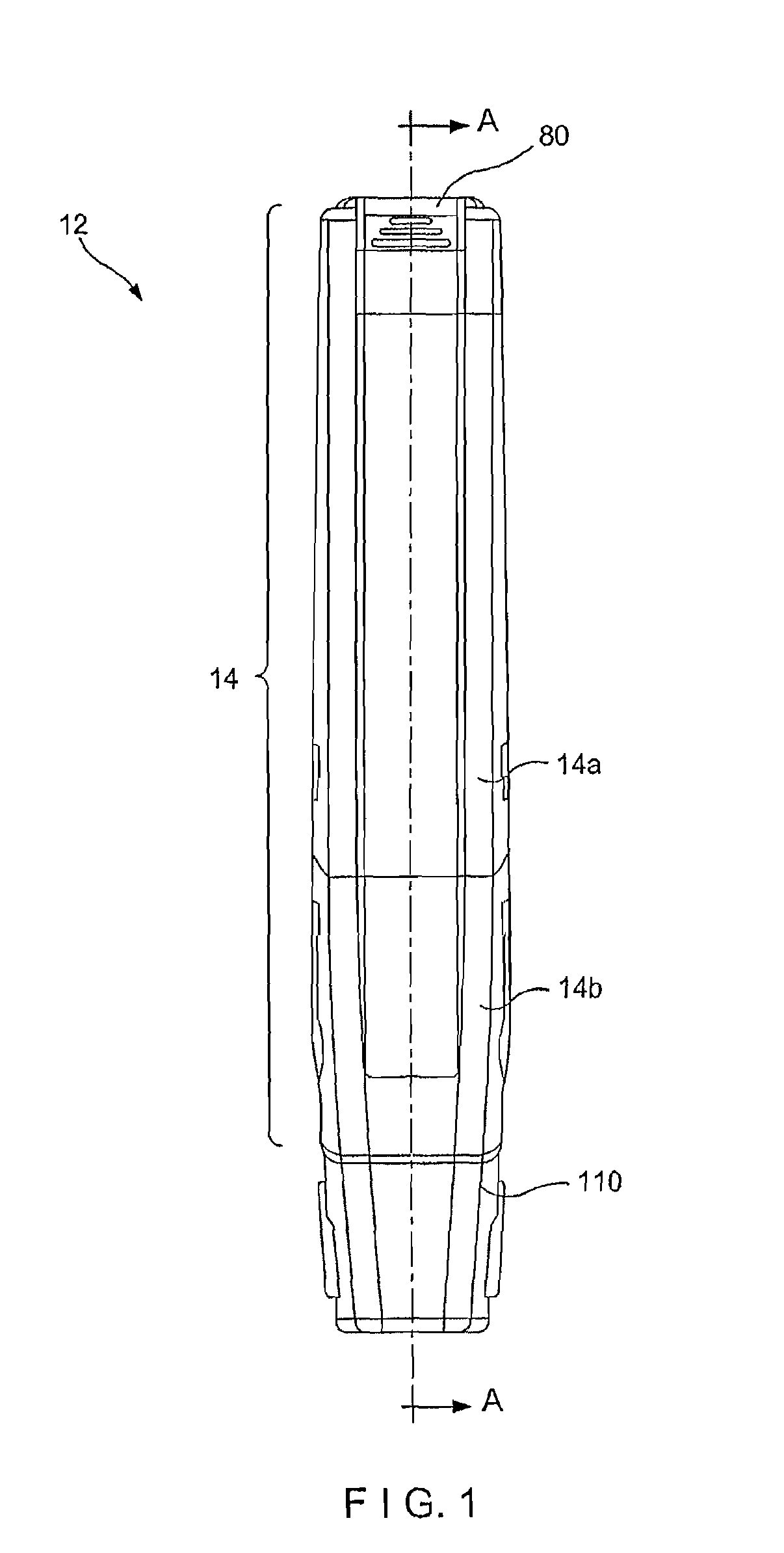

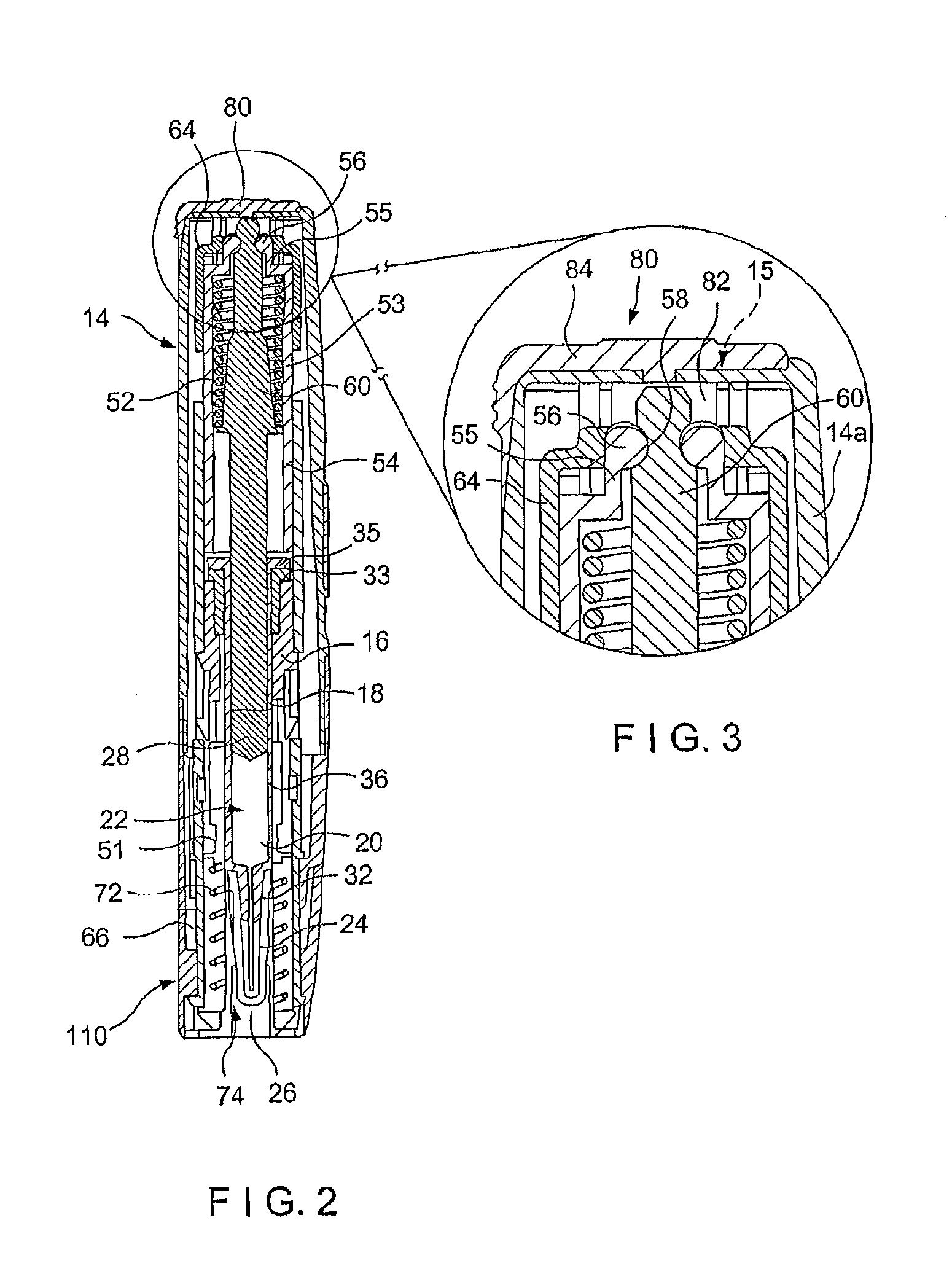

Needle assisted jet injection device having reduced trigger force

An injector includes a trigger mechanism including: a trigger member disposed about an axis having an aperture and a protrusion, and a ram assembly having a ram configured to pressurize a medicament container for expelling a medicament therefrom, the ram assembly further having a trigger engagement member configured to engage the aperture of the trigger member when the trigger member is in a pre-firing condition; an energy source associated with the ram for powering the ram to expel the medicament; and a user-operable firing-initiation member having an aperture engaged with the protrusion of the trigger member and operable for causing an axial translation of the trigger member in a proximal direction from the pre-firing condition to a firing condition in which the trigger engagement member is released from the retaining portion to allow the energy source to fire the ram.

Owner:ANTARES PHARMA

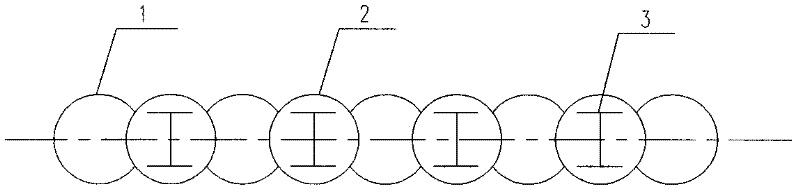

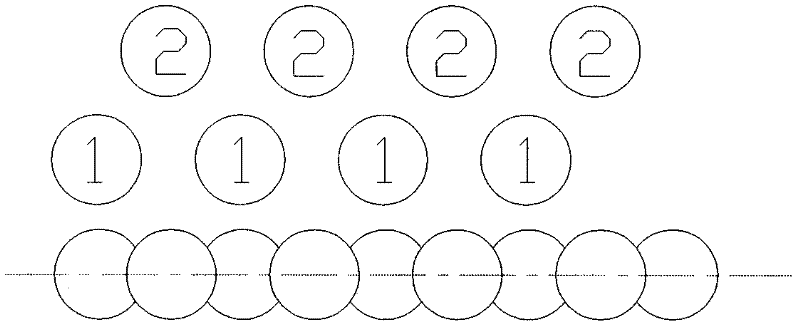

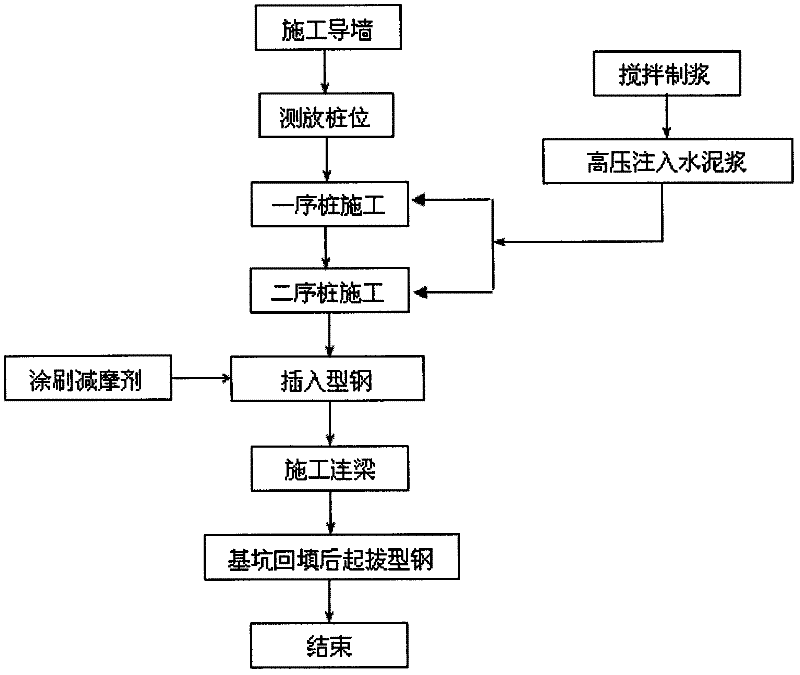

Construction method of long spiral high-pressure mixing and spraying cement-soil continuous wall

InactiveCN102296630AGood effectImprove efficacyArtificial islandsUnderwater structuresSupporting systemJet injection

The invention provides a construction method of a long spiral high-pressure spraying cement-soil continuous wall, which comprises the following steps: 1) making a guide wall or digging a guide ditch along the center line of the pile, and determining the pile position of the spraying pile; 2) injecting the long spiral high-pressure spraying The slurry stirring pile-forming device is aligned with the pile position as the drilling center, and drilled into the hole; 3) Start the grouting pump, and use the long spiral high-pressure jet grouting to stir the pile-forming device during the lifting or lowering process of high-pressure rotary spraying until it is formed. 4) insert section steel into the spigot pile; 5) repeat the steps 2), 3) and 4) until the continuous cement-soil continuous wall is formed; 6) construct the joint beam; 7) backfill the foundation pit, Pull out the section steel after finishing. Compared with the general slope protection pile support system, firstly, the section steel can be recycled, and secondly, cement soil is used instead of concrete, so it is relatively more economical and more efficient, and can achieve the two walls of the supporting wall and the curtain wall. The water stop effect is also better than the system composed of general slope protection piles + rotary grouting piles.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

Needle assisted jet injection device having reduced trigger force

An exemplary embodiment of an injector includes a trigger mechanism, an energy source, and a user-operable firing-initiation member. The trigger mechanism can include a floating trigger member having a retaining portion, a ram assembly having a ram configured to pressurize a medicament container for expelling a medicament therefrom, the ram assembly further having a floating trigger engagement member configured to engage the retaining portion of the floating trigger member when the floating trigger member is in a pre-firing condition. The energy source can be associated with the ram for powering the ram to expel the medicament, and the user-operable firing-initiation member can be operable for causing an axial rotation of the floating trigger member from the pre-firing condition to a firing condition in which the floating trigger engagement member is released from the retaining portion to allow the energy source to fire the ram.

Owner:ANTARES PHARMA INC

Endoscopic fluid supply conduit system

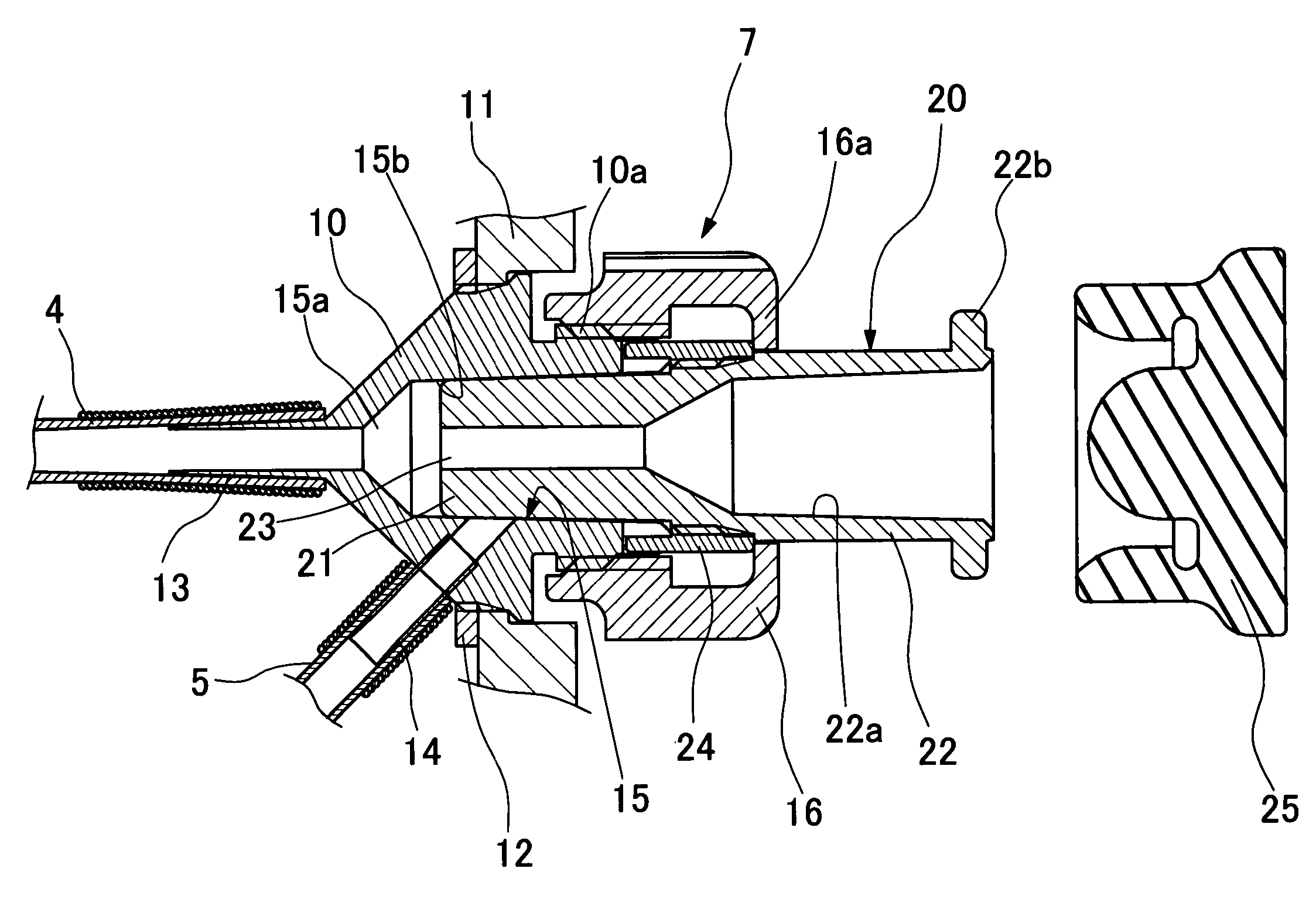

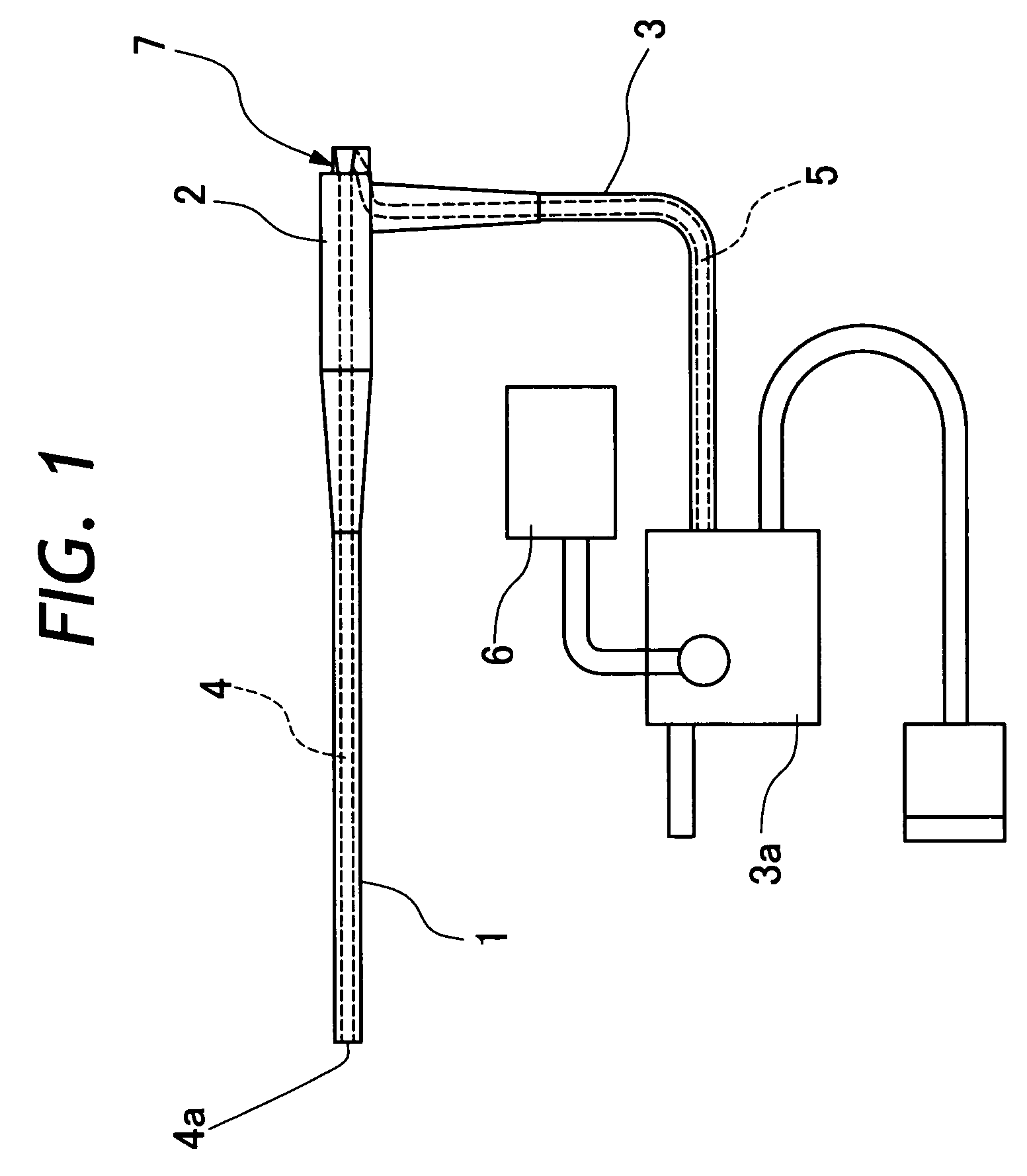

An endoscopic fluid supply conduit system for use with an endoscope having an insertion tube and a universal cable connected to and from a manipulating head assembly. A fluid conduit is provided internally of the insertion tube to supply a fluid from a fluid feed port on the manipulating head assembly toward a fluid jet injection port feed port which is provided on a rigid tip end section at the fore distal end of the insertion tube. In addition, a second fluid conduit is provided internally of the universal cable and toward the manipulating head assembly. A fluid supply channel selector is provided at the fluid feed port to which a fluid feed adaptor is to be disconnectibly connected. The fluid supply channel selector is adapted to block a fluid flow toward the second fluid conduit when a fluid is supplied to the first fluid conduit from the fluid feed port on the manipulating head assembly, and to bring the second fluid conduit into communication with the first fluid conduit when the fluid feed port on the manipulating head assembly is closed.

Owner:FUJI PHOTO OPTICAL CO LTD

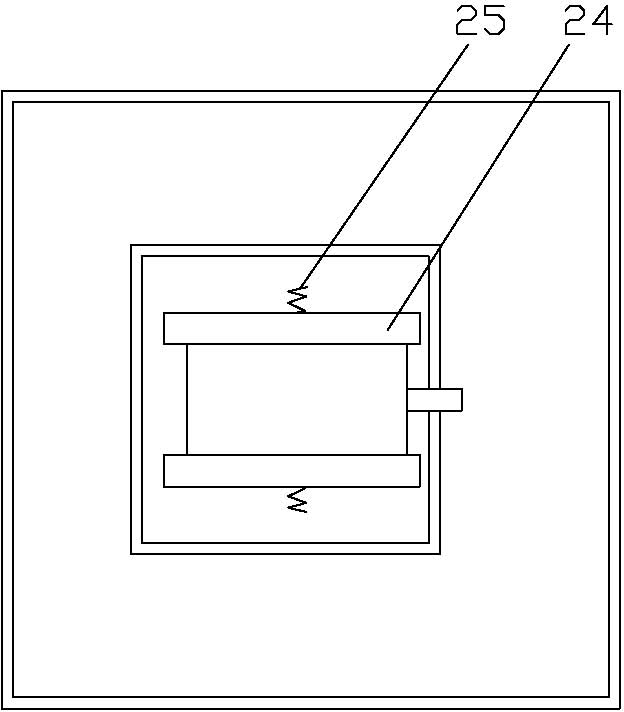

Microscale pulse electrolysis jet processing system and processing method thereof

InactiveCN101633065AEffective filteringEliminate pulsationMachining working media supply/regenerationNumerical controlElectrolysis

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

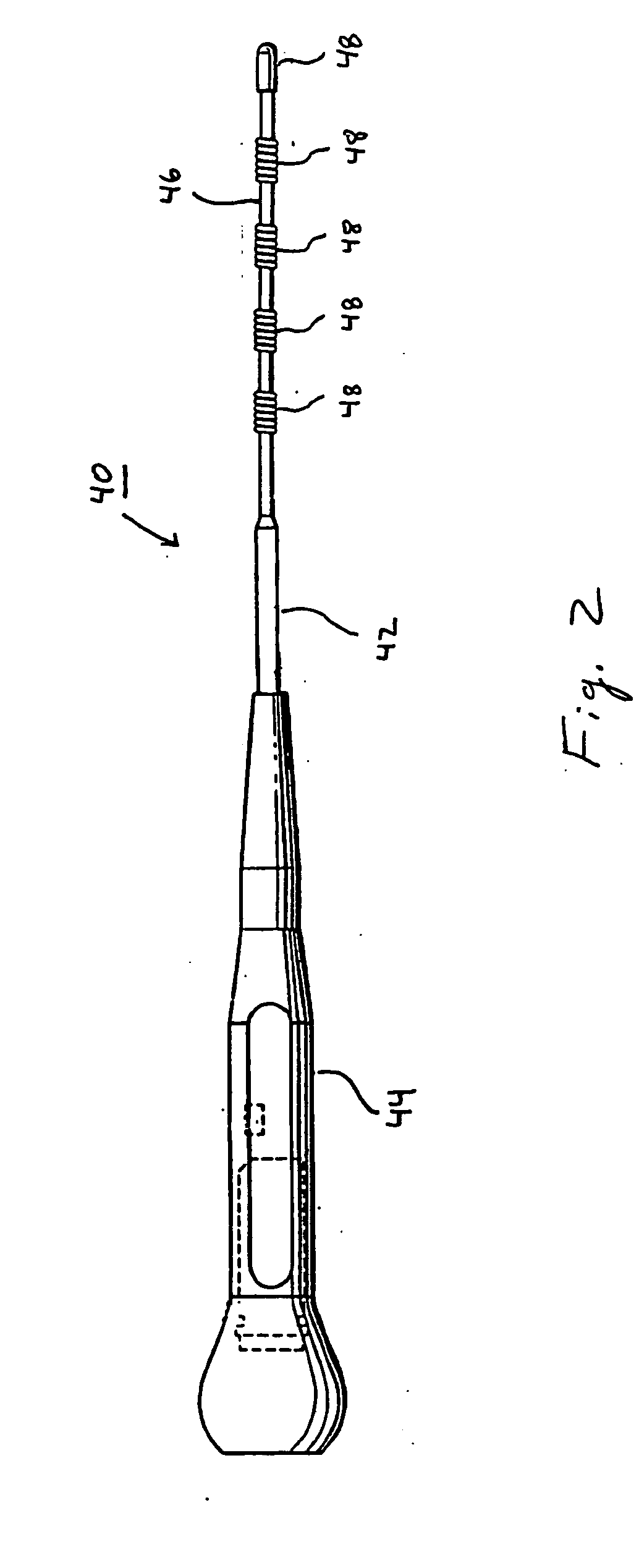

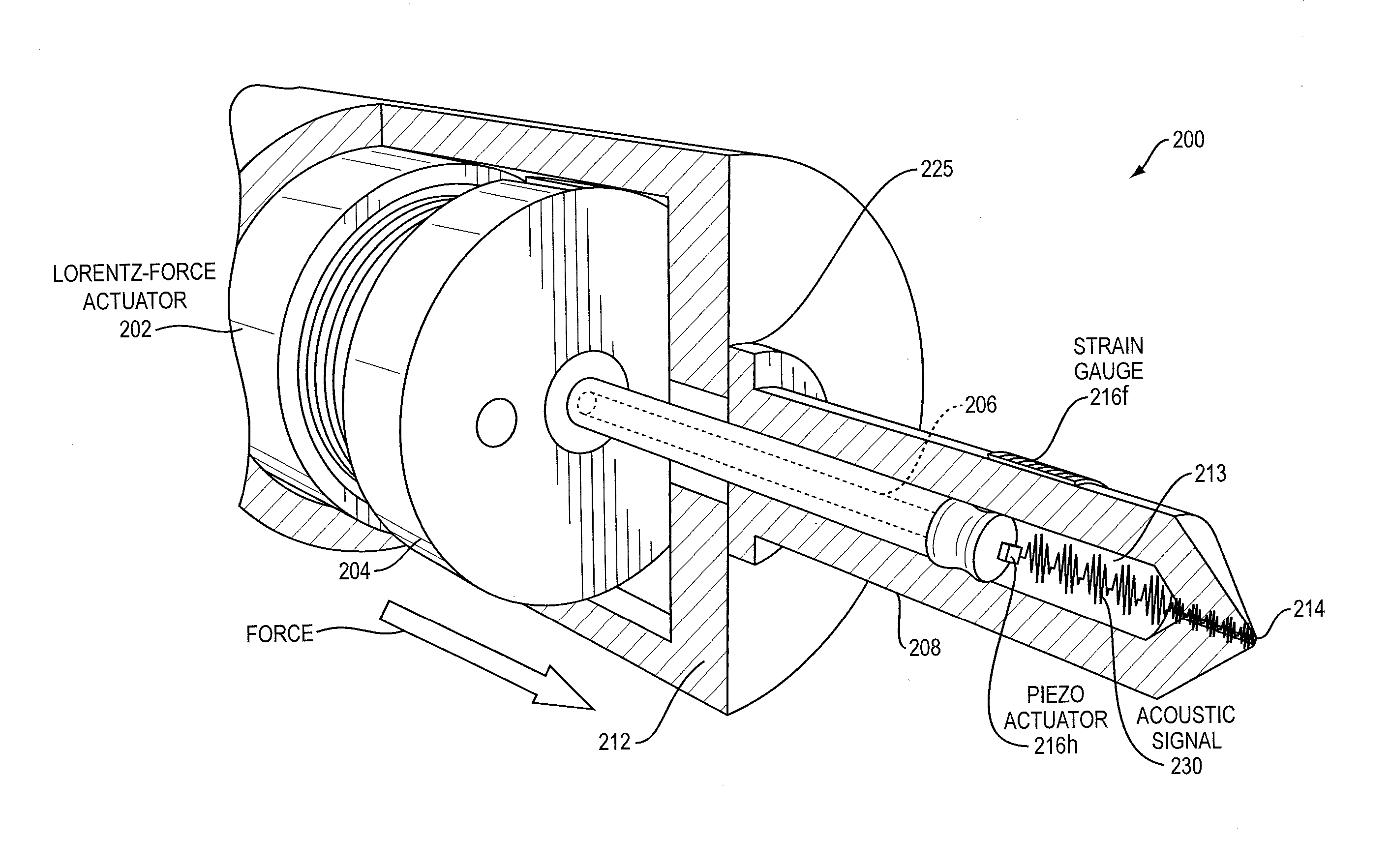

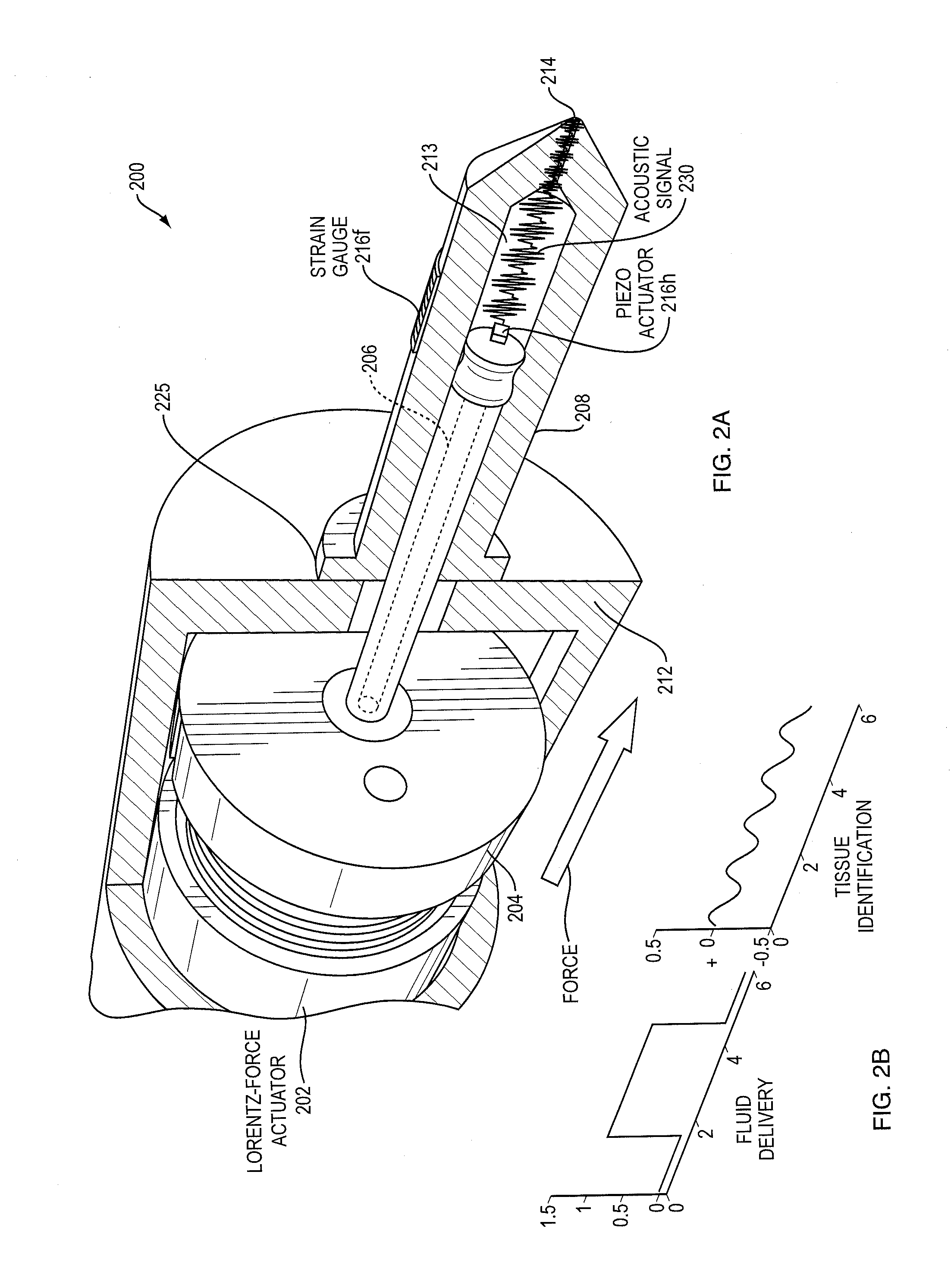

Jet Injector Use In Oral Evaluation

A tooth treatment device includes a detector that detects a marker of oral health and a fluid ejector that ejects fluid against teeth in response to the detected marker. The device can include a housing configured to be held on hand, the fluid ejector being positioned at an end of the housing. The fluid may include a liquid, a medicant, a cleansing solution, cleaning particles, or any combination thereof. The medicant can include any combination of a chelating agent, fluoride, a fluorescent dye, a bacterial specific probe, and a biochemical specific biomarker. Further, the device can include a servo controller controlling pressure of ejected fluid in response to the detected marker and a sensed surface condition, latter including for example, a mechanical property of tissue. The device may include a pressure sensor that senses pressure of the fluid in the ejector. Also included may be a distance sensor that senses distance of the ejector from a tissue surface. The surface condition may be sensed using the sensed pressure, sensed distance, or any combination thereof. In some embodiments, the fluid ejector comprises a stationary magnet assembly providing a magnetic field and a coil assembly, slidably disposed with respect to the magnet assembly, the coil assembly driving ejection of the fluid jet. A method of tooth treatment includes detecting a marker of oral health and controlling ejection of a fluid jet against the tooth responsive to the detected marker. In some embodiments, detecting the marker includes detecting plaque and the ejection is controlled to clean the plaque. Detecting the marker can include collecting a sample from an oral cavity.

Owner:MASSACHUSETTS INST OF TECH

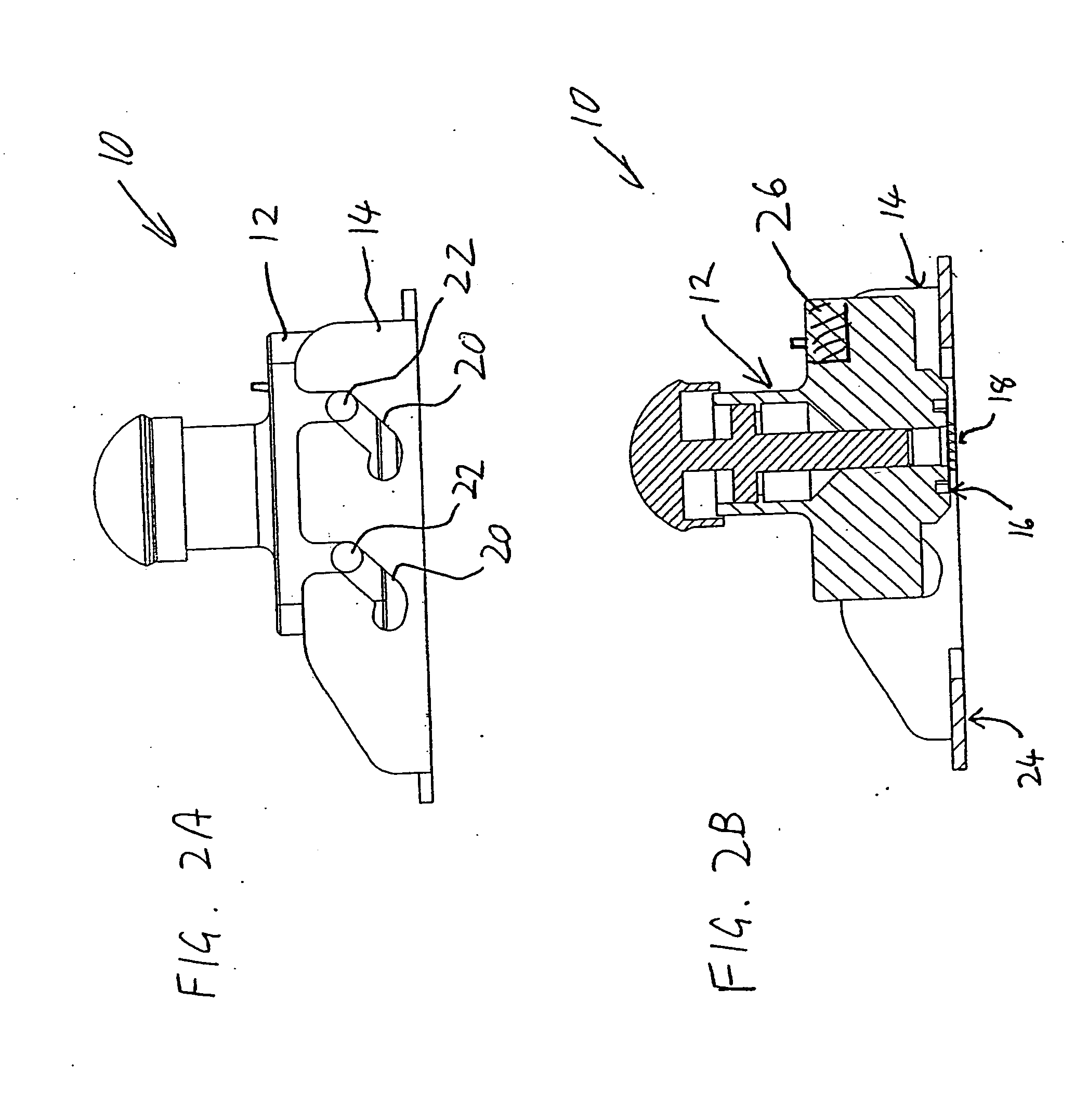

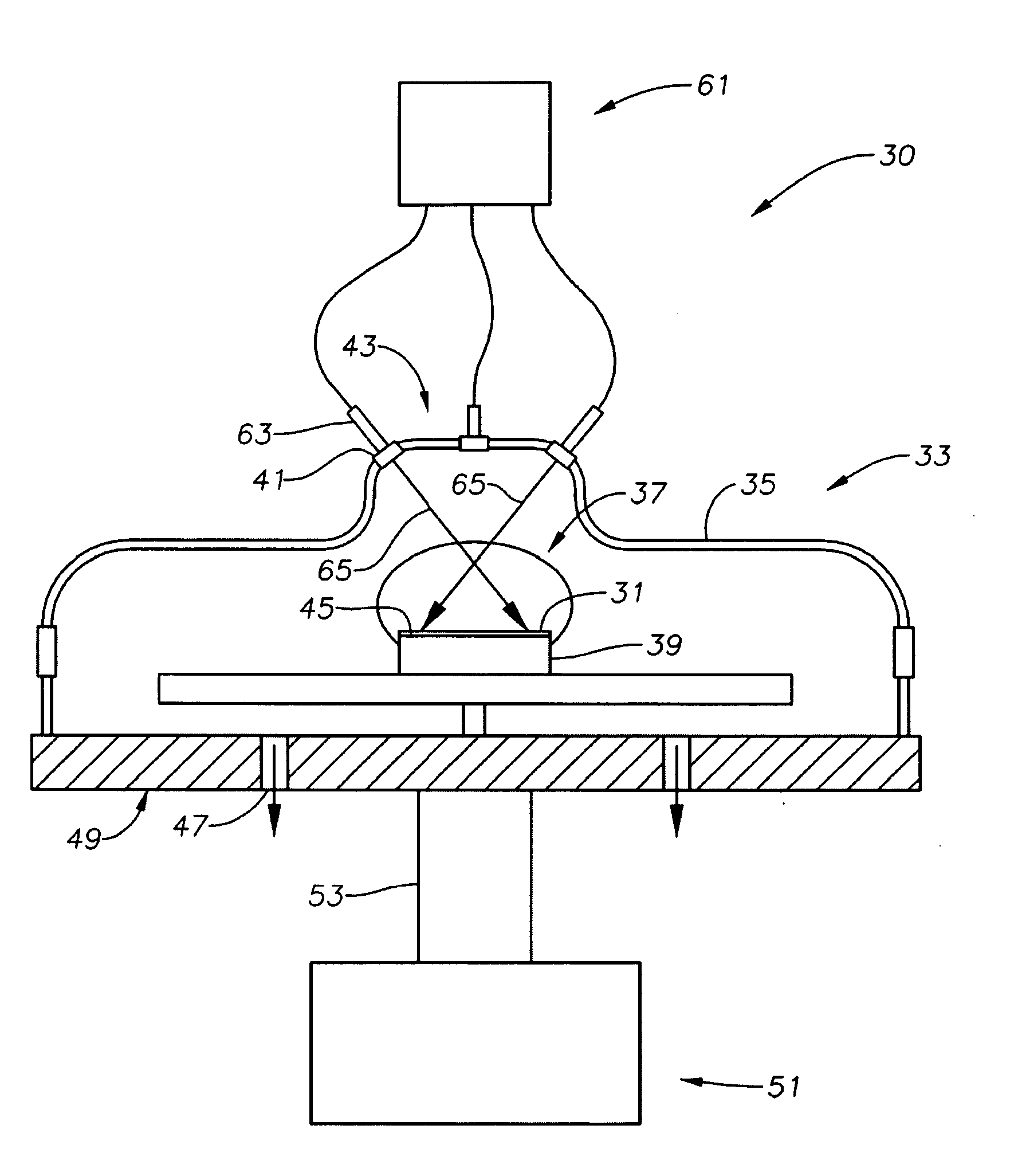

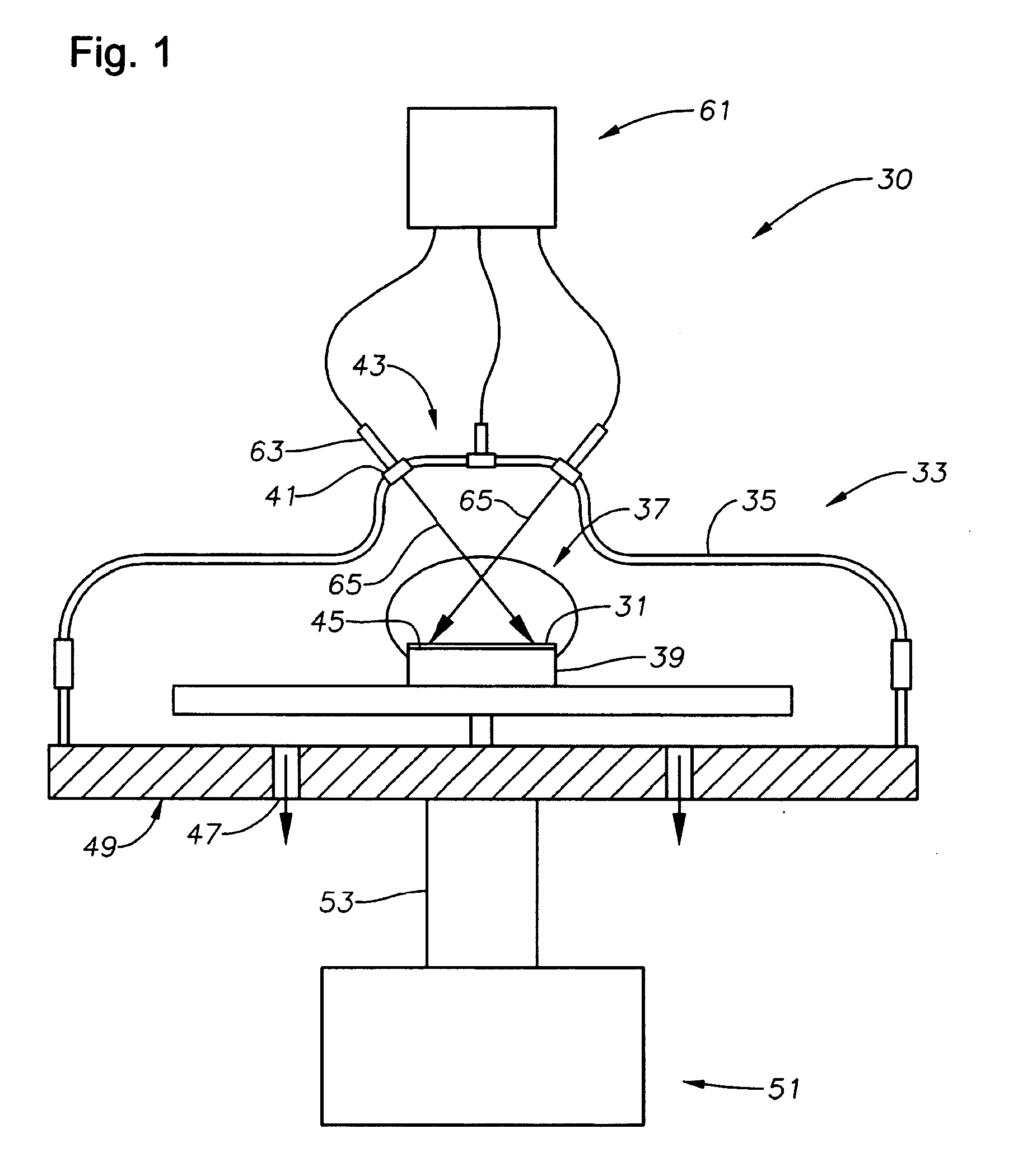

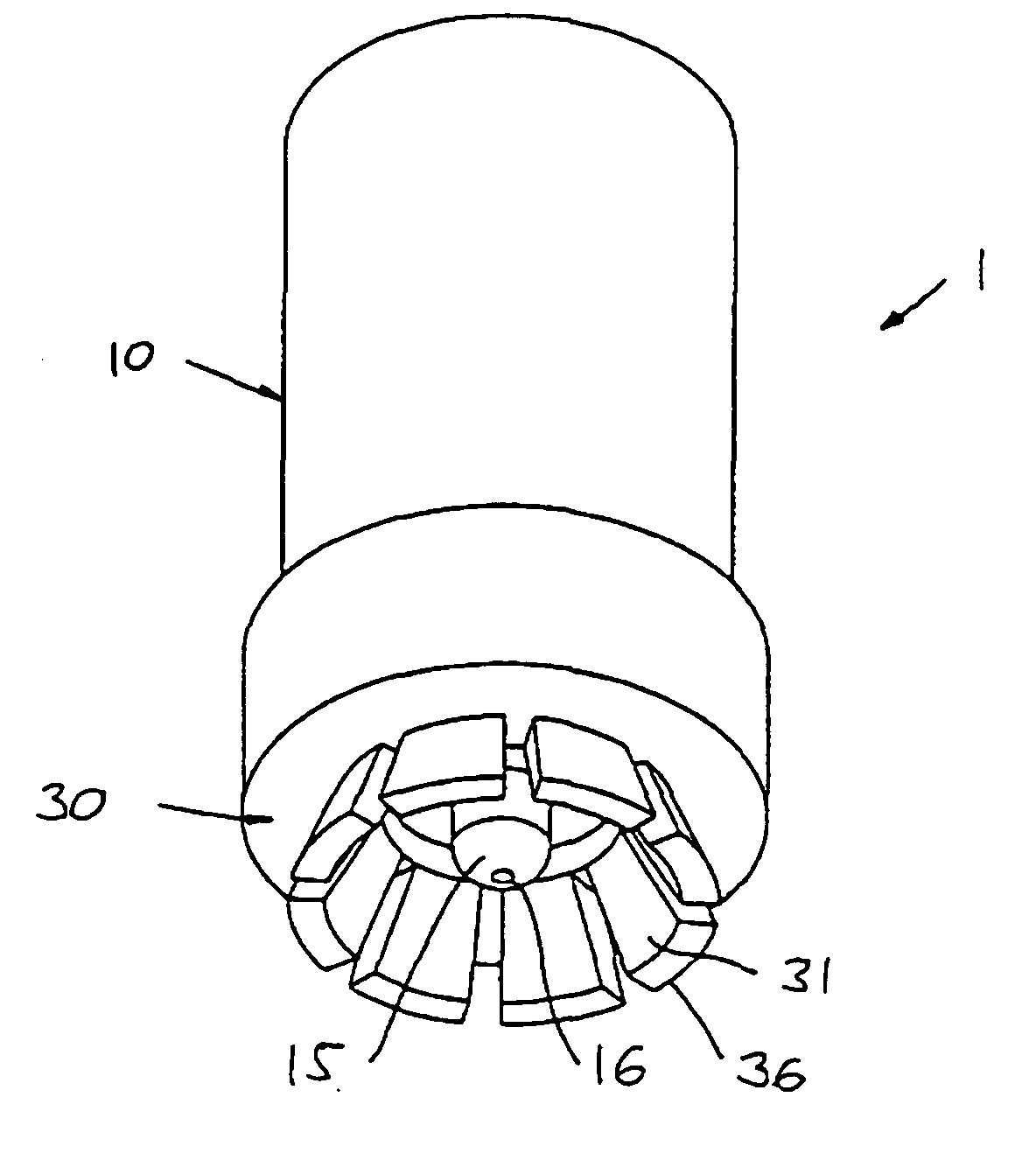

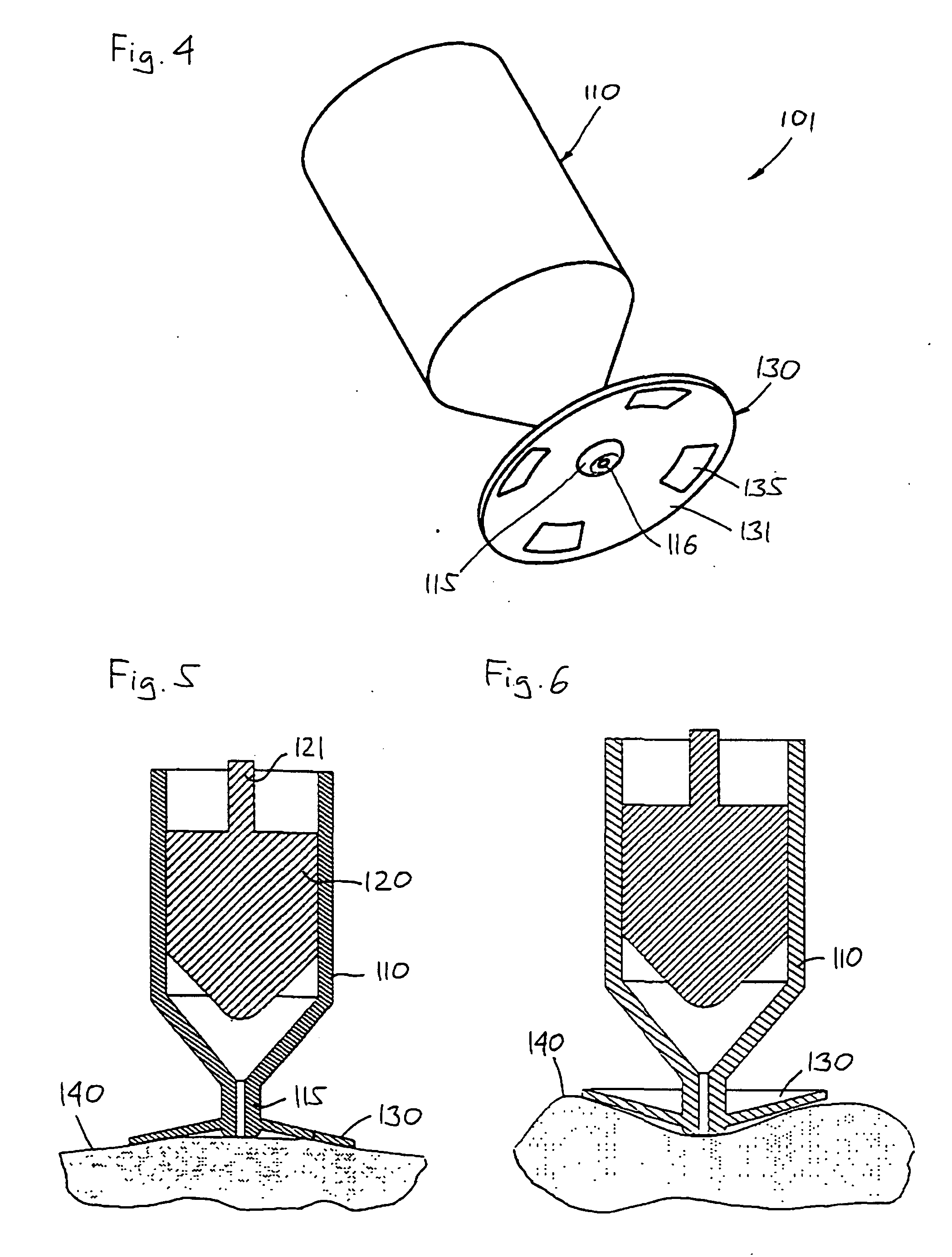

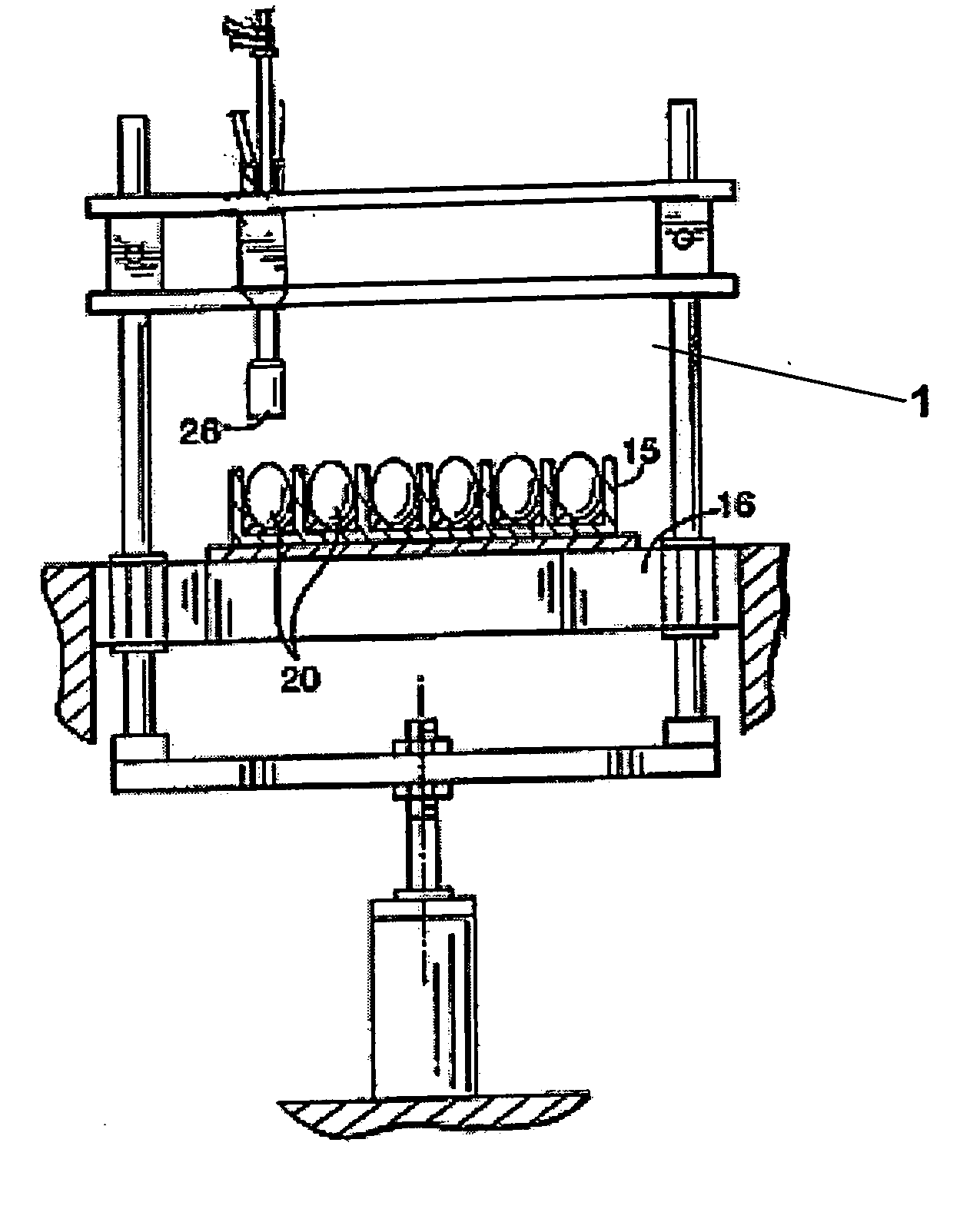

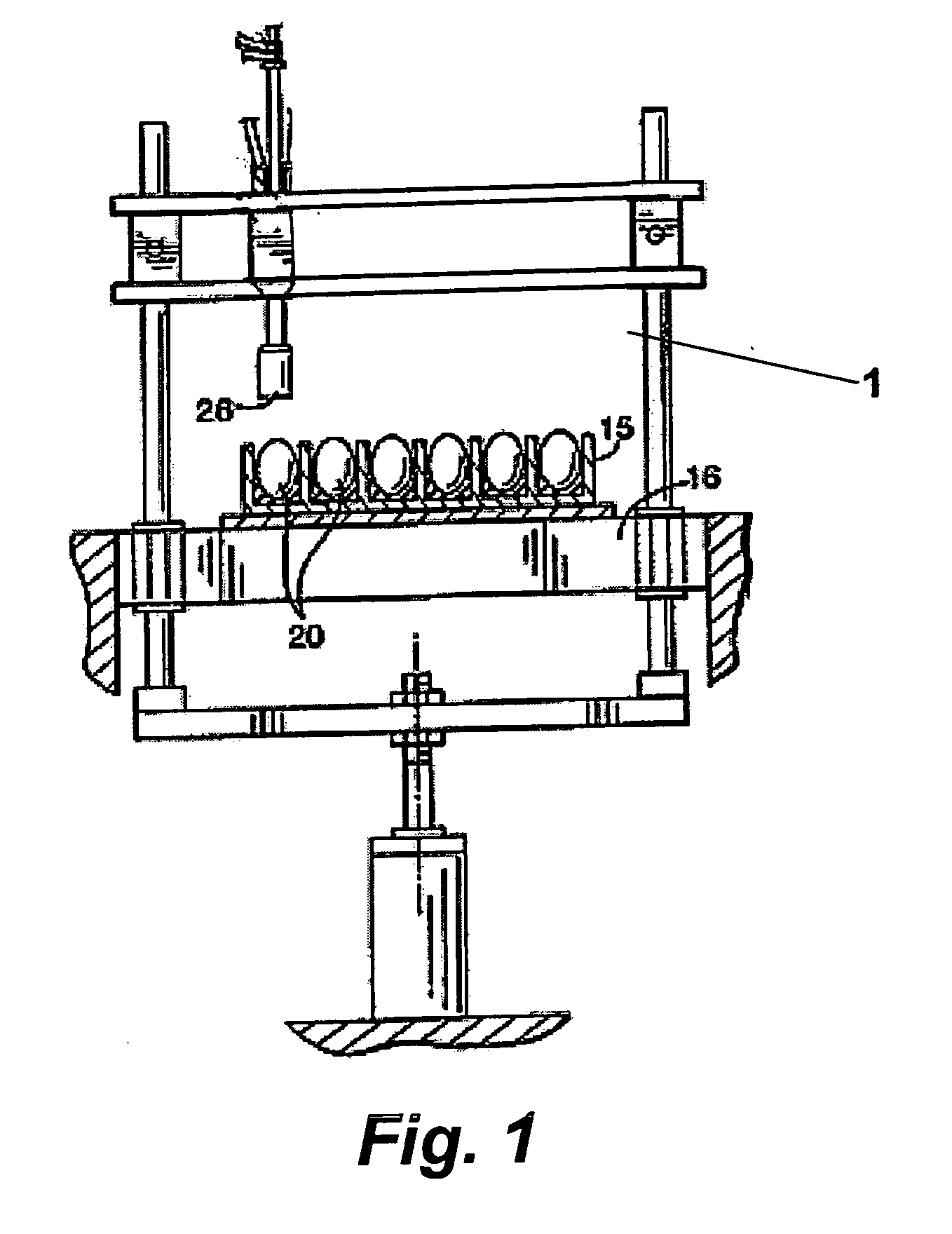

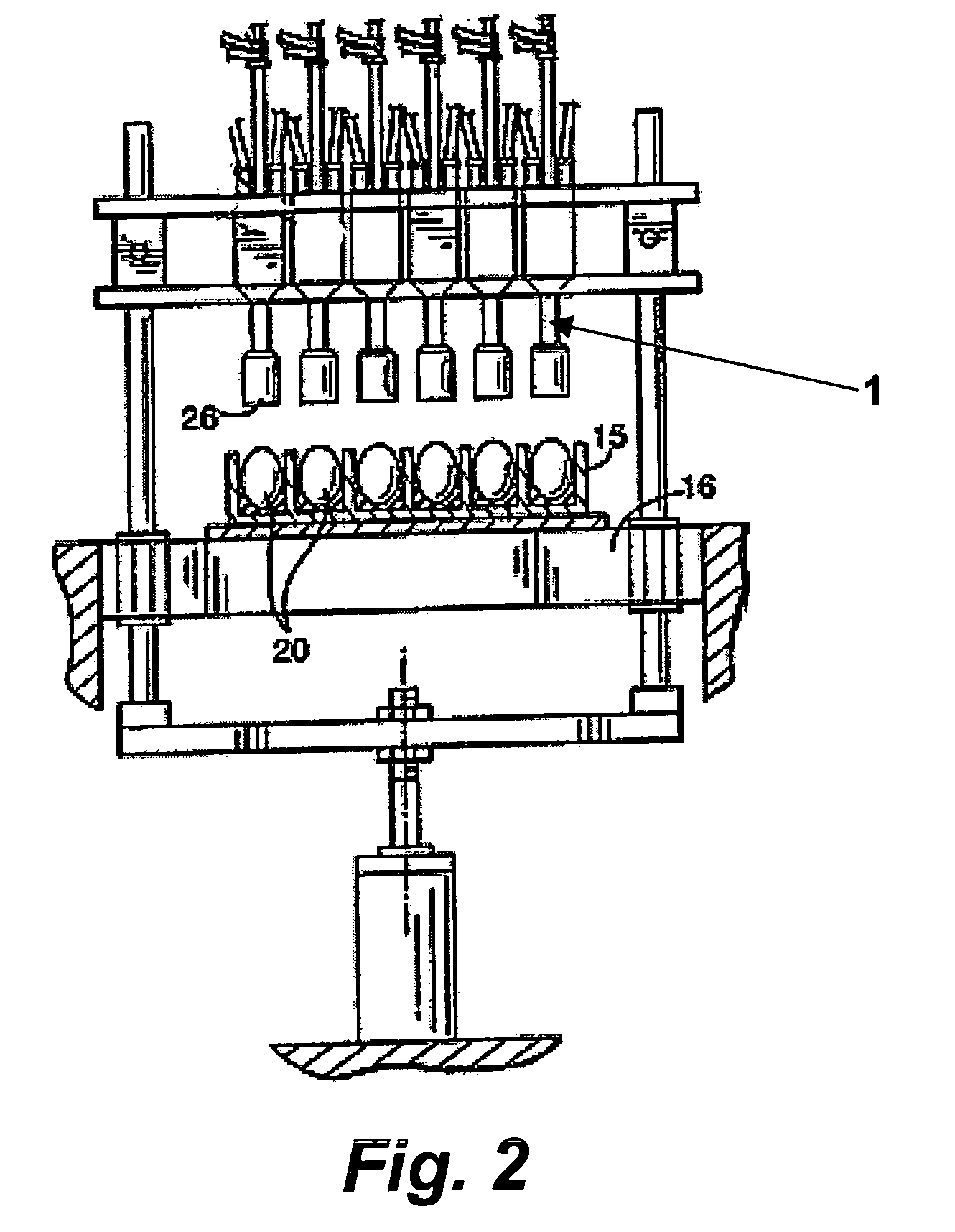

Methods and apparatus for automatic jet injection of bird eggs

An in ovo jet injection apparatus and related methods for treating live eggs. The jet injection apparatus includes one or more jet injection delivery devices configured to deliver one or more treatment substances to predetermined areas of eggs using a high pressure stream of the treatment substance(s). Multiple treatment substances can be delivered so that they are spatially and / or temporally separate. The devices and methods of the invention enable the effective use of a plurality of treatment substances, including those that are effective when used alone but can be noxious if mixed. The methods and apparatus for the jet injection of substances into embryonic chicks reduce the risk of mechanical injury to the developing birds that would be caused by injection needles. The methods and apparatus of the invention can also reduce the introduction of an infection into the chicks.

Owner:MERIAL INC

Needle assisted jet injection administration of testosterone compositions

ActiveUS20130303985A1Minimize leak-backOrganic active ingredientsJet injection syringesJet injectionTestosterone

Owner:ANTARES PHARMA

Method for making a needle-free jet injection drug delivery device

InactiveUS20070052139A1Faster in administeringImprove long-term stabilityJet injection syringesMedical devicesNeedle freeDrug reservoir

A method for making a jet injection drug delivery device wherein the drug delivery device has at least one drug reservoir and at least one injection nozzle includes the steps of: identifying a drug desired to be delivered; identifying a volume of the drug desired to be delivered; establishing a reservoir diameter for the at least one drug reservoir; establishing a nozzle diameter for the at least one injection nozzle; identifying a tissue model for delivery of the drug; identifying a penetration depth in the tissue model for the delivery of the drug; and injecting the drug into the tissue model under variable pressure until the desired penetration depth is achieved. The method also includes identifying an optimal pressure range for the drug delivery device that achieves the desired penetration depth.

Owner:ALZA CORP

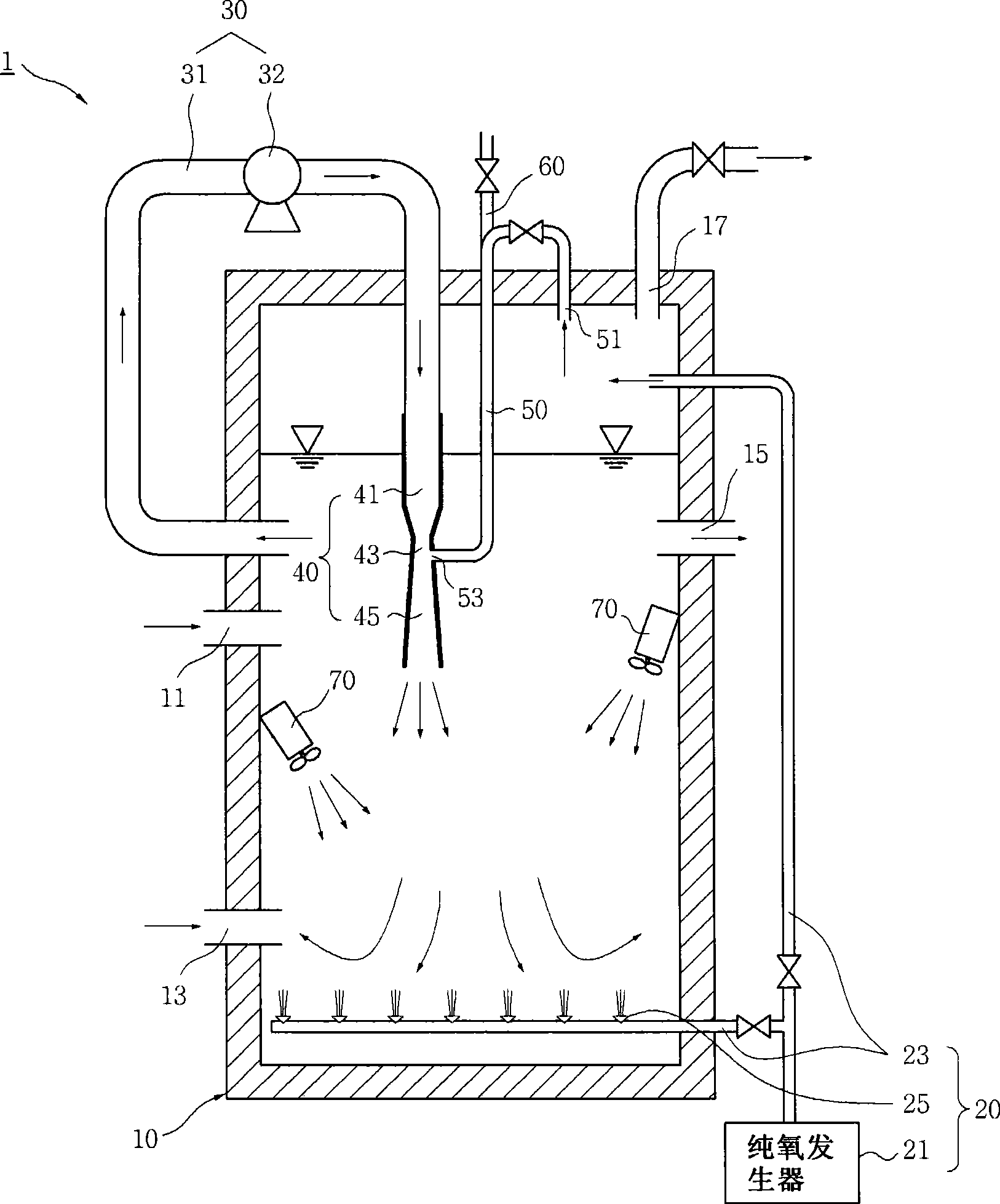

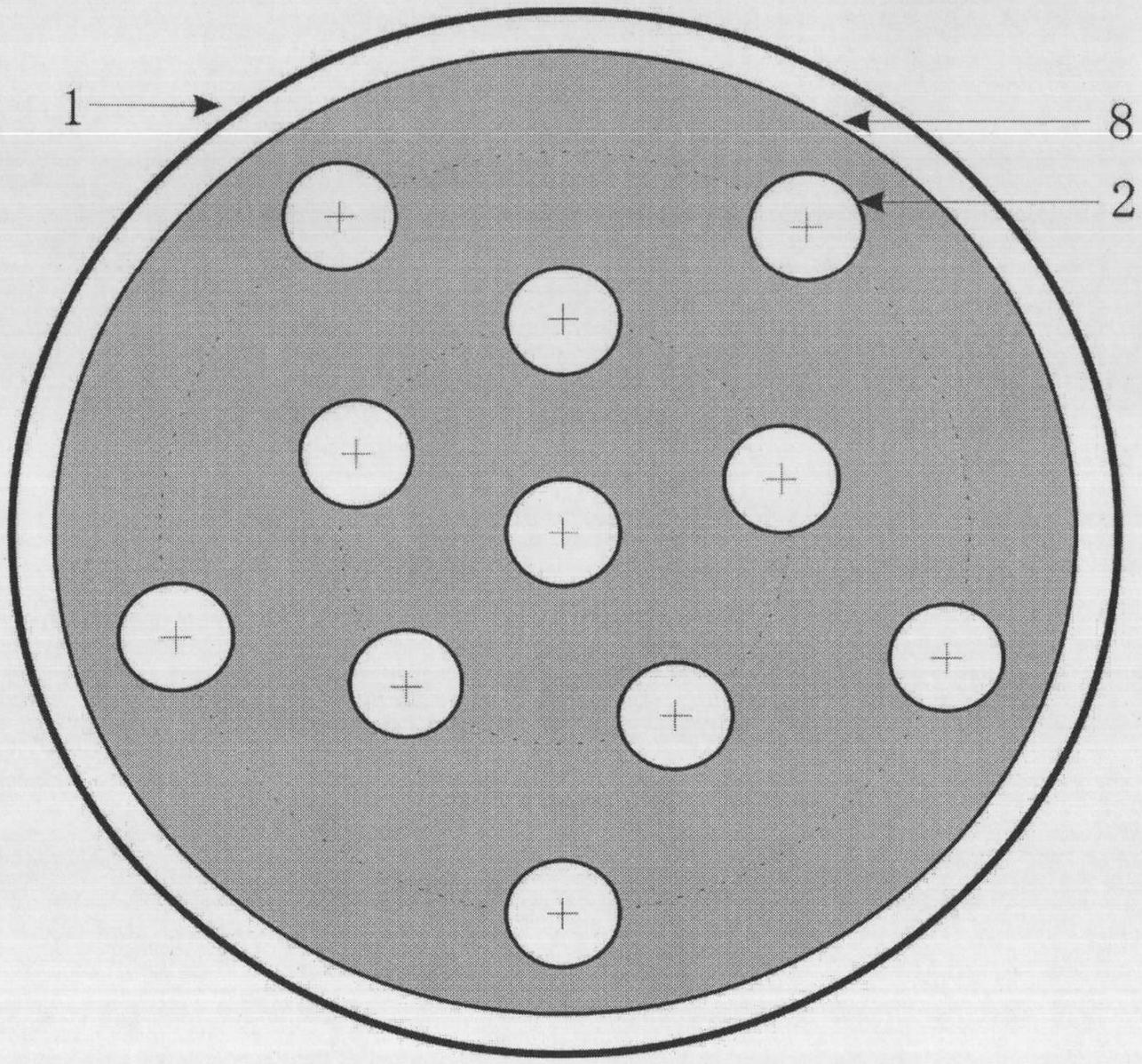

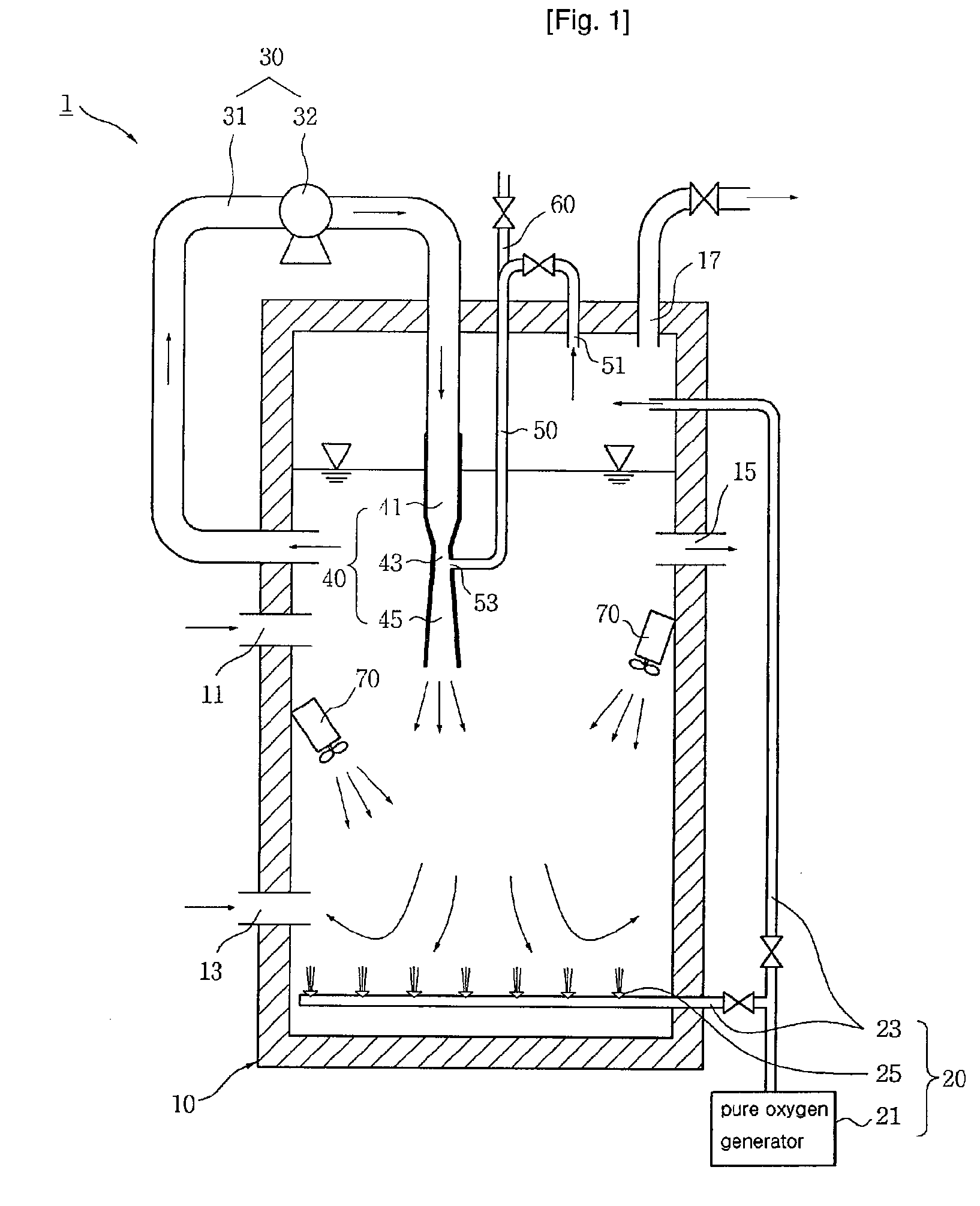

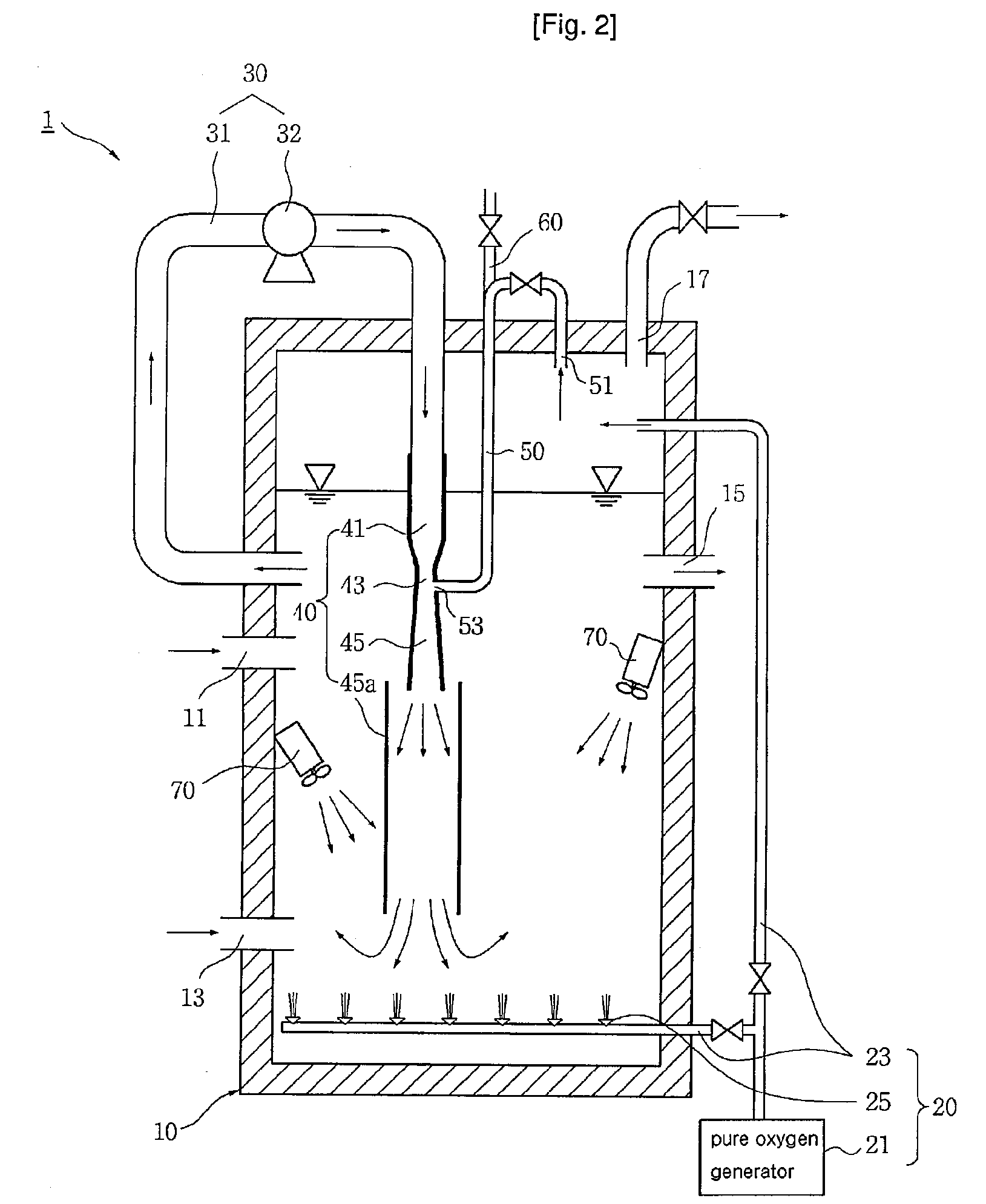

Pure oxygen aeration system for wastewater treatment

InactiveCN101395091AImprove efficiencyCost efficientTreatment using aerobic processesFlow mixersActivated sludgeAeration system

Owner:李载宪

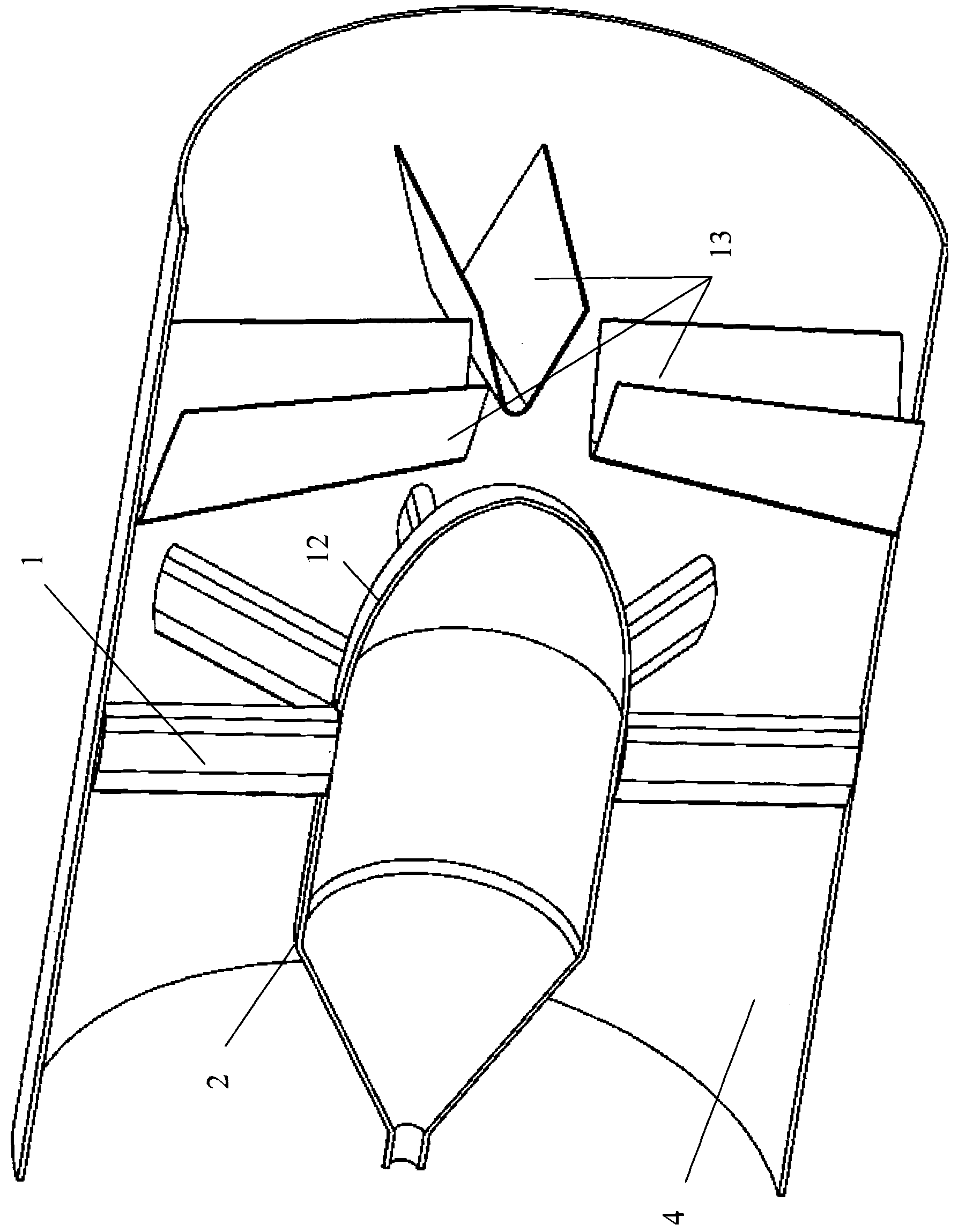

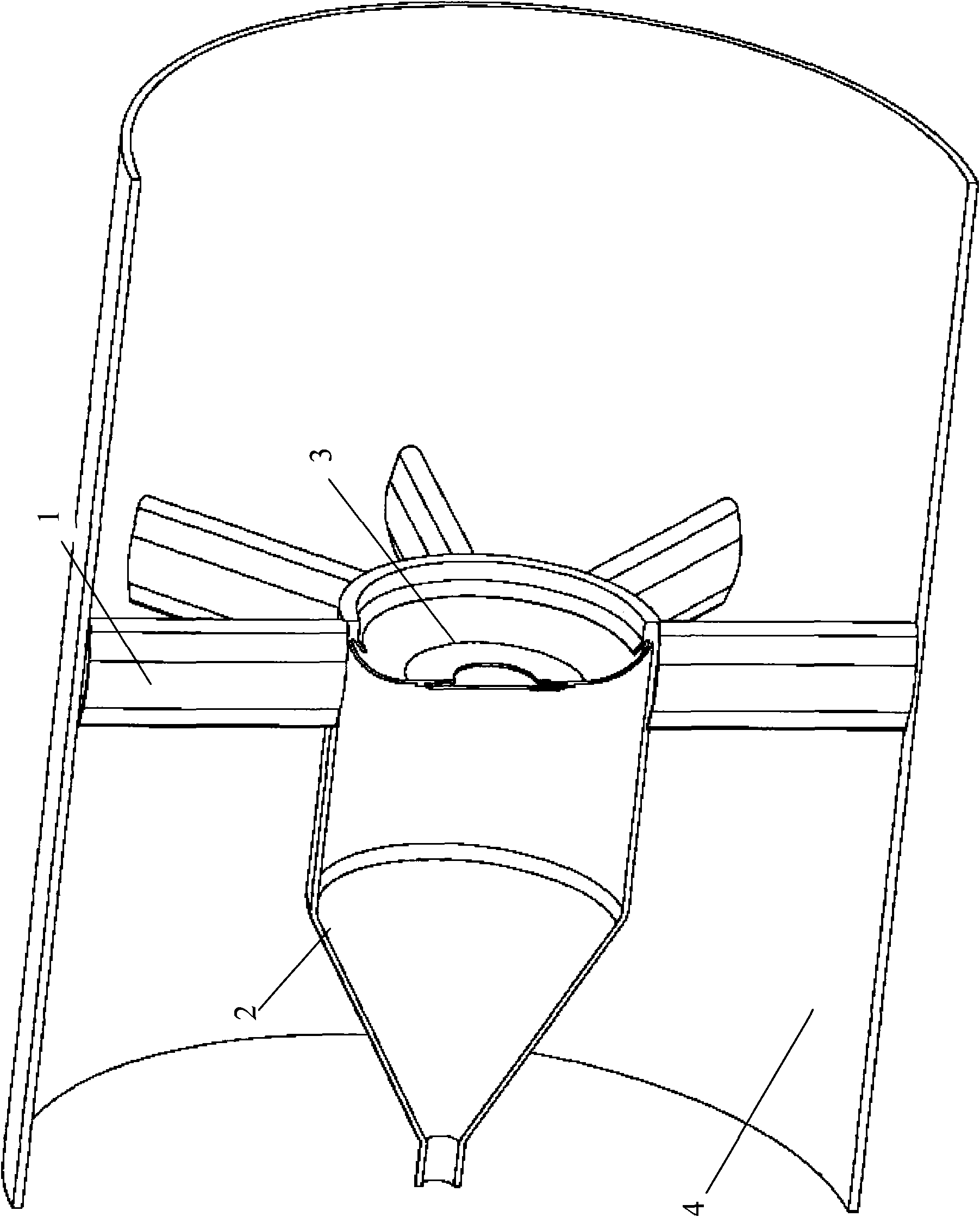

Flame stabilizer with jet injection

InactiveCN101776283AReduce weightGood Burn ProgramContinuous combustion chamberCombustion chamberJet injection

The invention provides a flame stabilizer for an after-combustion chamber of a gas turbine engine. In the device, which is characterized in that turbine rear frames are integrated, a radial flame stabilizer and a center cone in the prior art are omitted, and the an upstream concave structure and the a jet injection gas flow are used for forming a vortex system to form a necessary backflow region for flame stabilization, thereby reducing the amount of parts, shortening the total length of the combustion chamber, lightening the structural weight, reducing the resistance loss, and enabling the thrust-weight ratio of the engine to have great expansion lifting space.

Owner:BEIHANG UNIV

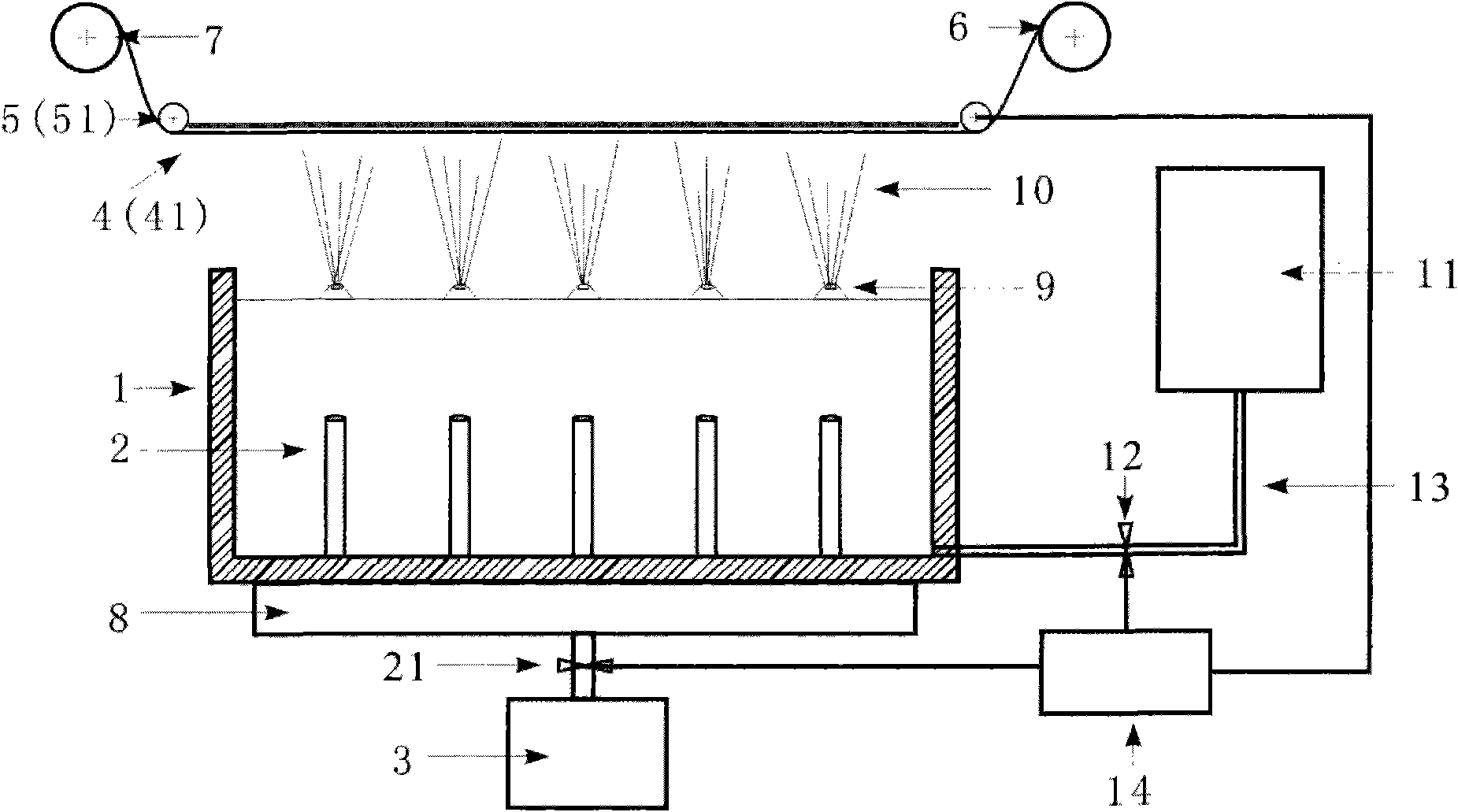

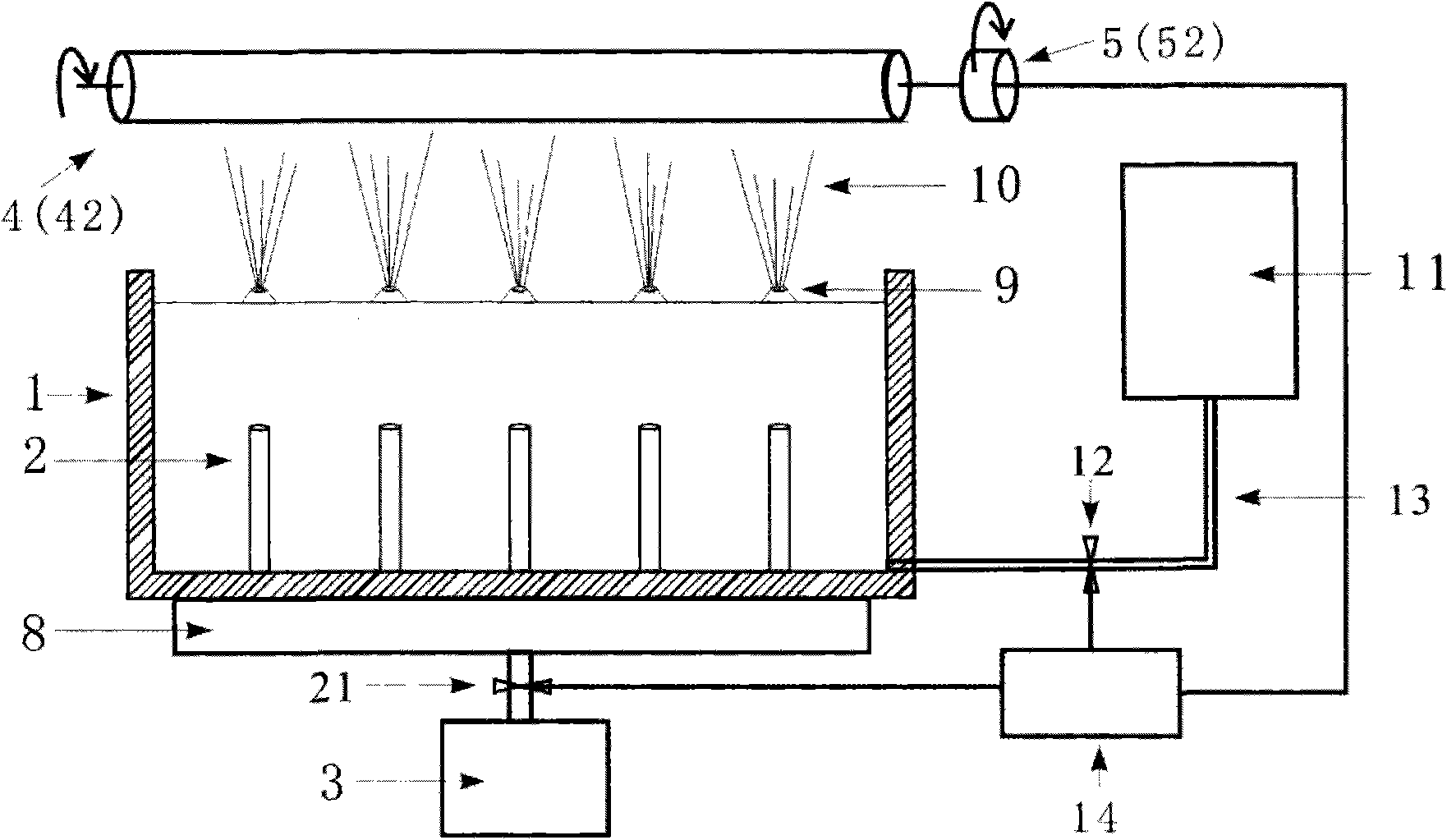

Production method of micro nanometer fiber non-woven fabric and device

InactiveCN101775706AAvoid cloggingAvoid cleaningArtificial thread manufacturing machinesNon-woven fabricsJet injectionLiquid storage tank

The invention discloses a production method of a micro nanometer fiber non-woven fabric and a device. The production method comprises the following steps: (1) polymer solution is prepared: (2) fiber is formed by micro nanometer jet injection: air pressure is supplied by an air pump, so the air stream is vertically sprayed out from a nozzle below the polymer solution liquid surface of a liquid storage tank, a crater-shaped projection is produced on the liquid surface of the polymer solution, the micro nanometer jet flow is sprayed out form the projection under the effect of the cutting force of the air stream and flies to a receiving device, during the injection process, good solvent in the micro nanometer jet flow is volatilized, and at the same time, the jet flow is drawn and refined to micro nanometer fiber under the effect of the air stream force; (3) and the non-woven fabric is formed. The production device is designed according to the production method and mainly comprises a spinning system, a liquid supply system, a transmission system and a control system.

Owner:TIANJIN POLYTECHNIC UNIV

Nozzle device with skin stretching means

Owner:NOVO NORDISK AS

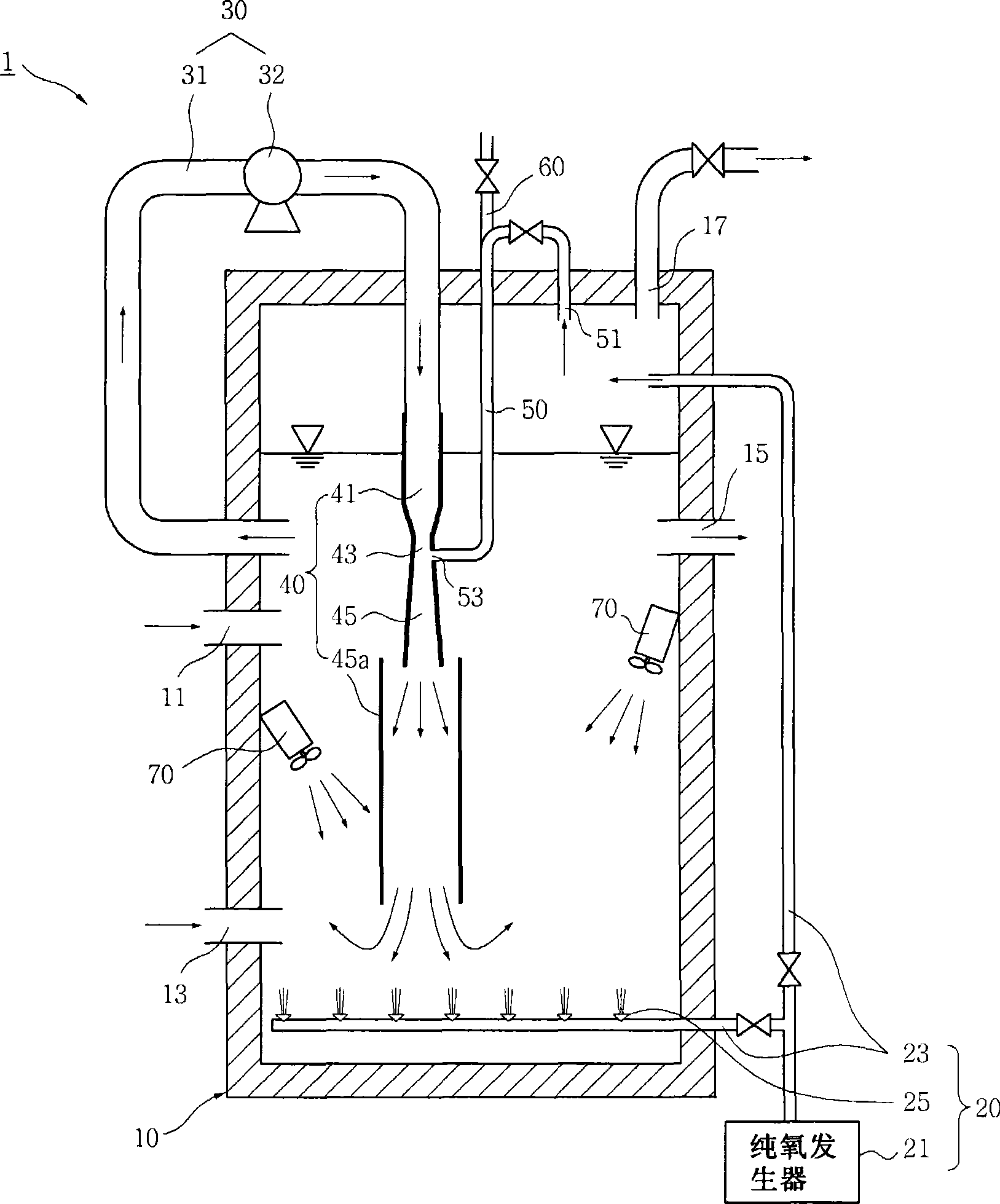

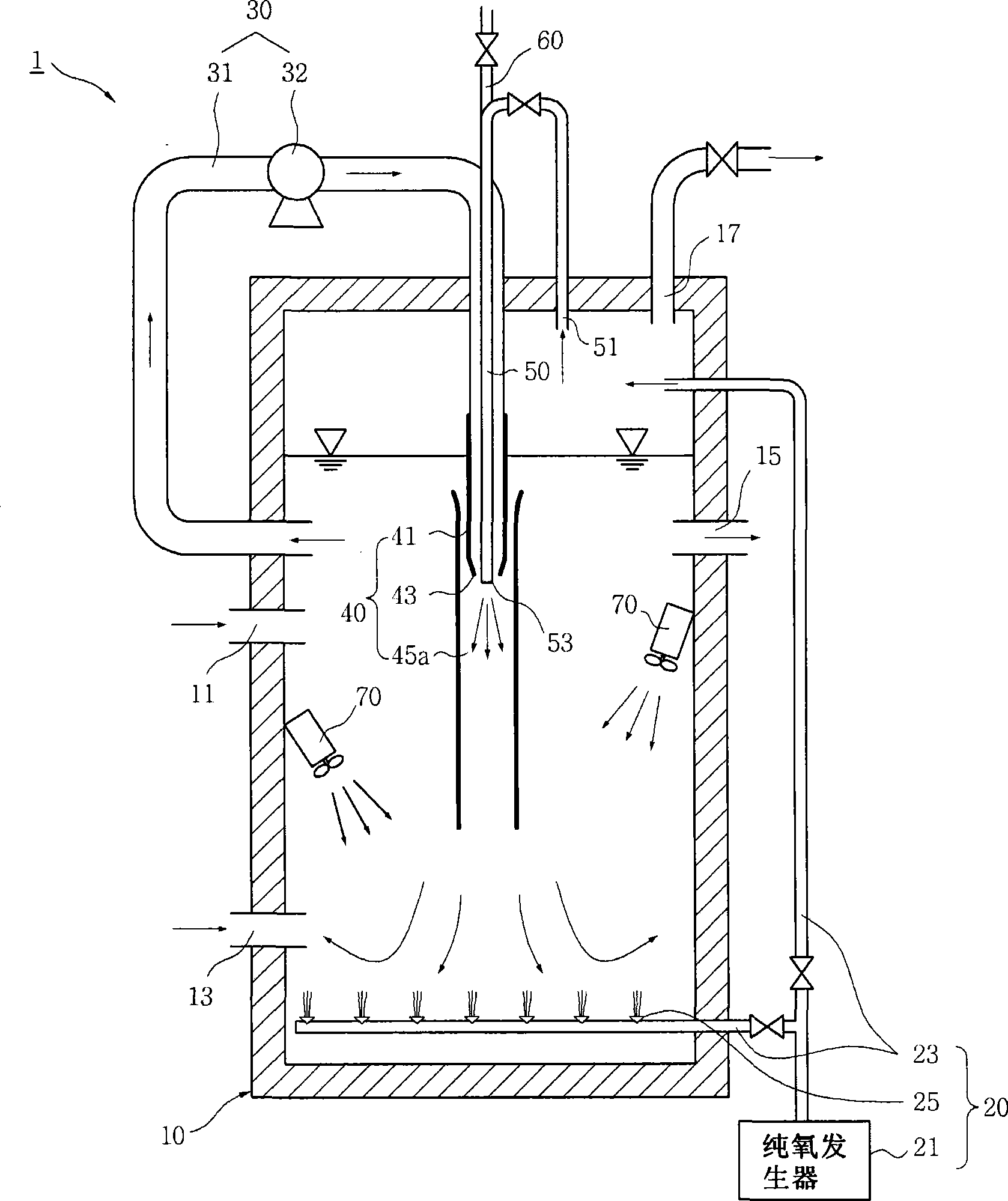

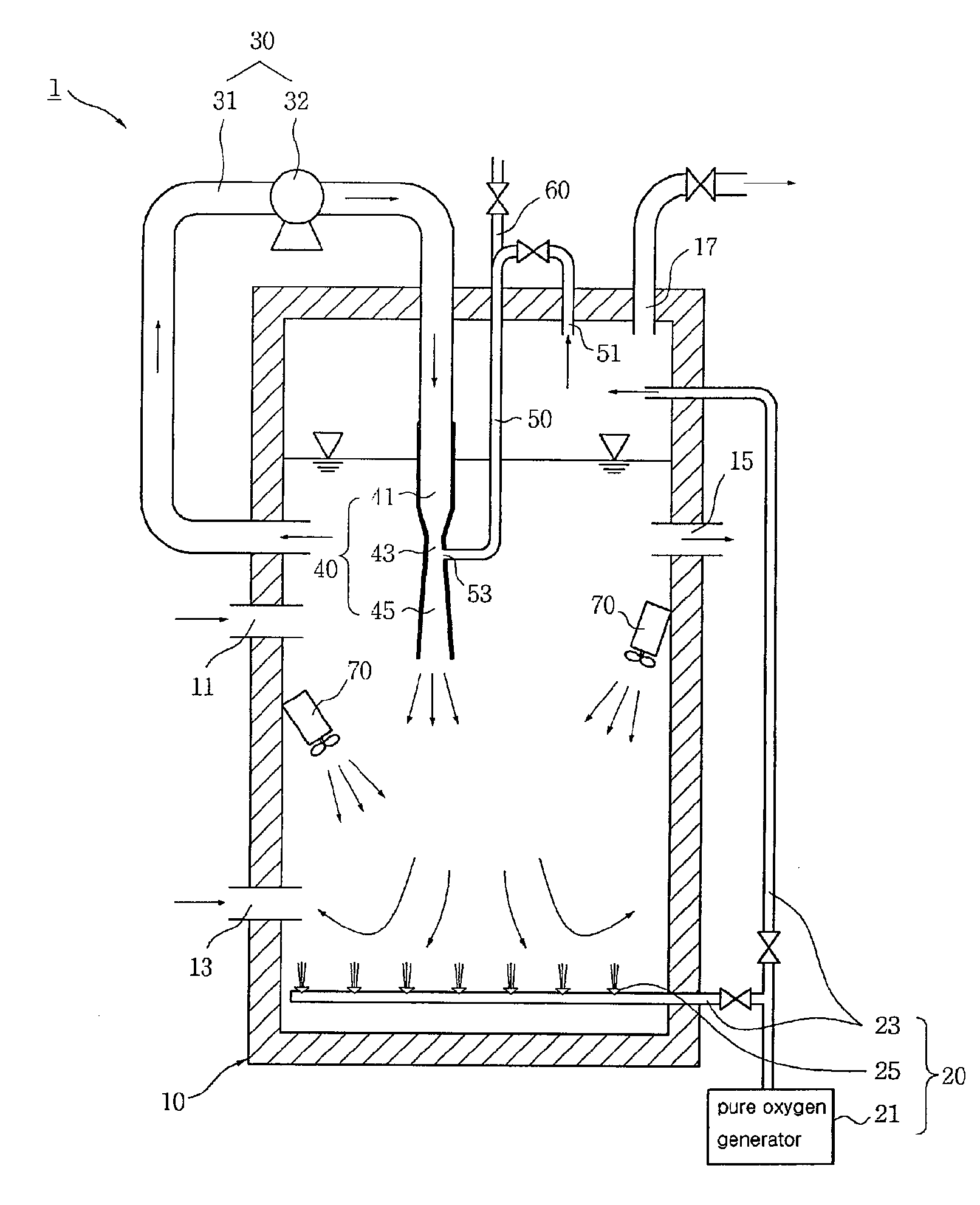

Pure Oxygen Aeration System for Wastewater Treatment

InactiveUS20090008311A1Disadvantageous effectShort retention timeTreatment using aerobic processesFlow mixersActivated sludgeAeration system

Disclosed is a pure oxygen aeration system for wastewater treatment, which biologically treats wastewater using microbes of activated sludge in an aeration tank. The pure oxygen aeration system comprises a pure oxygen supply device including a pure oxygen generator and at least one oxygen supply pipe extending from the pure oxygen generator and directed toward the internal space of the aeration tank, a high-speed jet injection device installed in the aeration tank, a mixed liquor circulation device for circulating and introducing the mixed liquor in which microbes of activated sludge, wastewater and pure oxygen are mixed, into the aeration tank through the high-speed jet injection device, and an oxygen suction pipe for sucking in the oxygen remaining in the headspace of the aeration tank and reintroducing the sucked oxygen into the water in the aeration tank. The present invention provides a pure oxygen aeration system for wastewater treatment which is economical, increases an oxygen utilization efficiency, secures easily the required land, saves the expense and can maintain an optimum level of dissolved oxygen and discharge smoothly and rapidly harmful gases.

Owner:LEE JAI HUN

Tissue ablation with jet injection of conductive fluid

InactiveUS20060271033A1Fluid jet surgical cuttersSurgical instruments for heatingJet injectionSkin surface

Ablation apparatus including an active electrode in electrical communication with an energy source, and a jet injector capable of propelling an electrically conducting fluid to a skin surface, the jet injector being positioned relative to the active electrode such that the electrically conducting fluid is in electrical communication with the active electrode.

Owner:EIN GAL MOXHE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com