Flame stabilizer with jet injection

A technology of stable flame and deflector, applied in the direction of combustion method, combustion chamber, combustion equipment, etc., can solve the problems of restricting the thrust-to-weight ratio, and achieve the effect of good combustion scheme, weight reduction and length shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

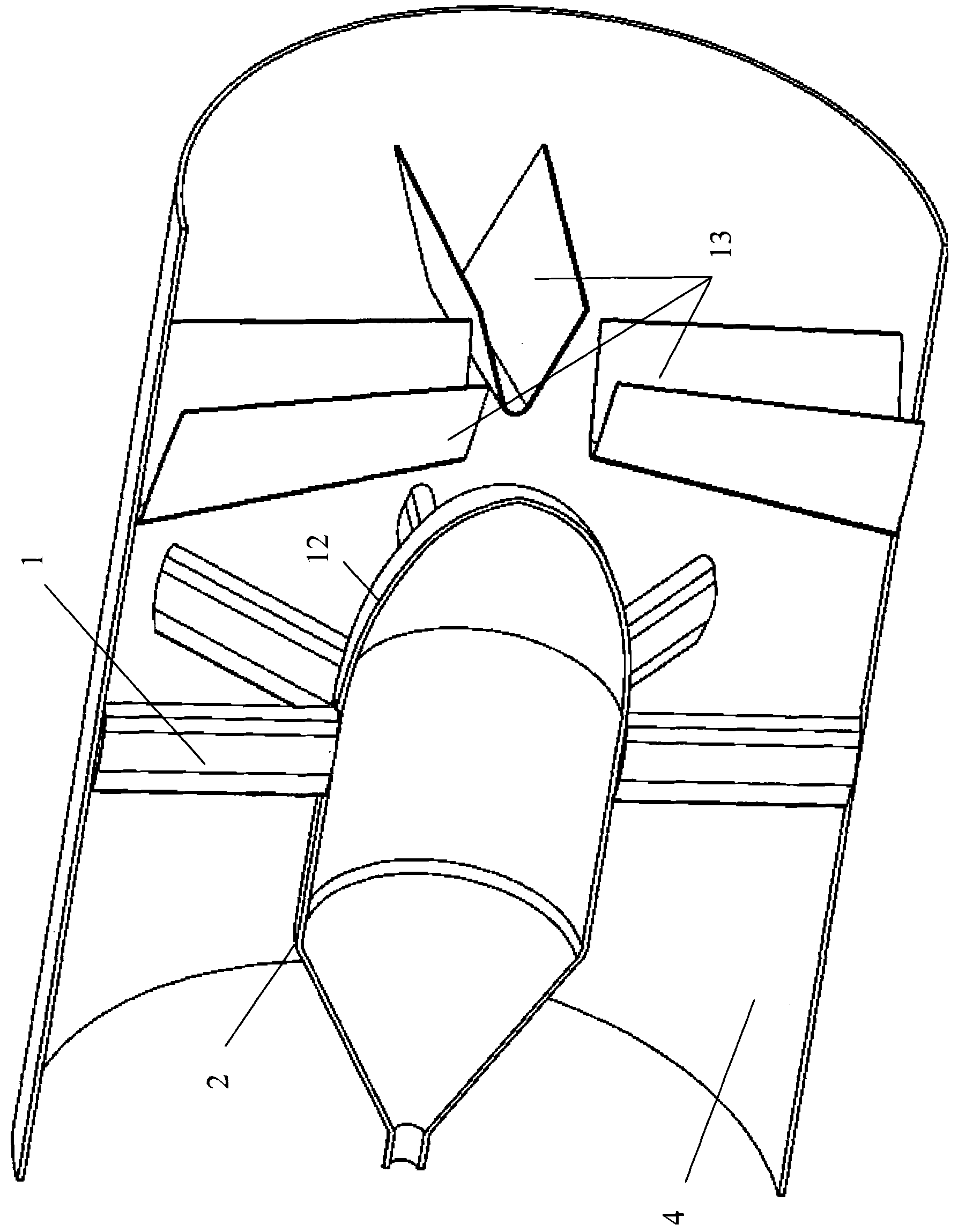

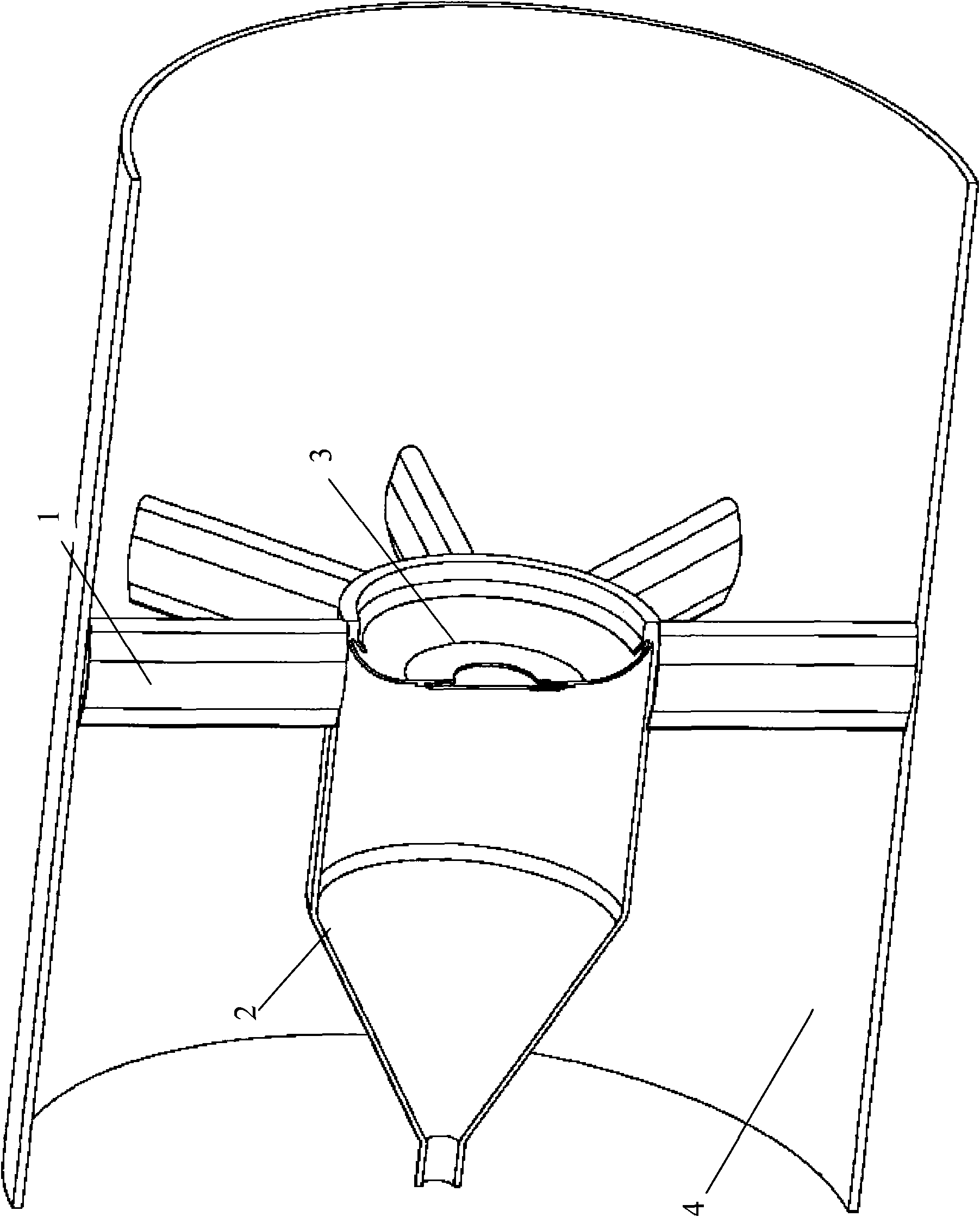

[0027] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

[0028] exist figure 2 In the shown embodiment of the present invention, the settings of the turbine rear frame support plate 1, the turbine rear frame inner wall 2, and the casing 4 are the same as those in the prior art, but no convex central cone and V-shaped groove flame stabilizer are provided. Instead, an inner concave curved wall 3 connected to the inner wall 2 of the turbine rear frame is provided, and the wall of the inner concave curved wall 3 is recessed in the upstream direction.

[0029] according to figure 2 In one embodiment of the present invention shown, the concave curved wall 3 is arranged near the position of the support plate 1 of the rear frame of the turbine along the axial direction of the combustion chamber.

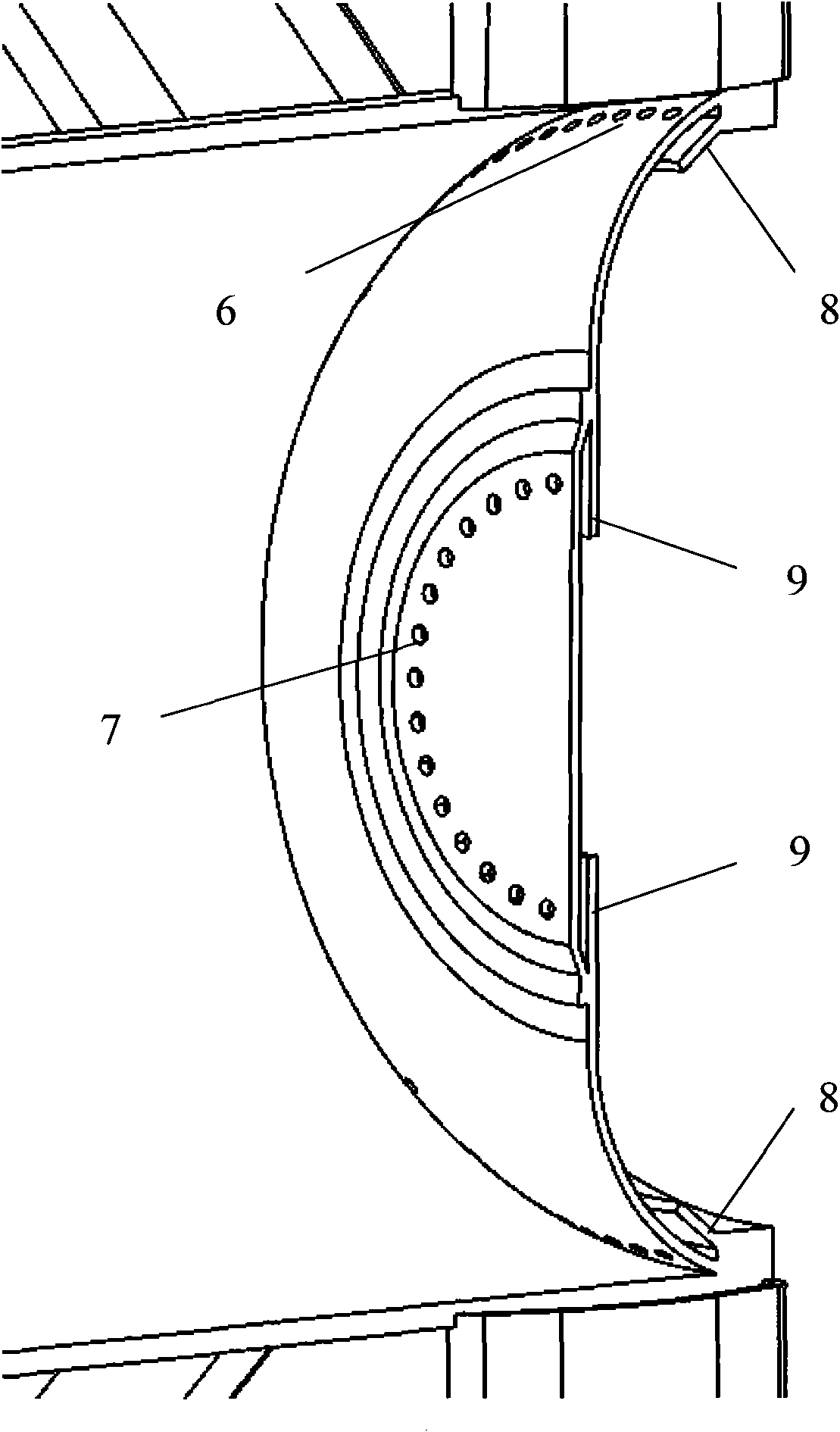

[0030] Figure 4 is indicated in figure 2 The airflow and vortex distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com