Construction method of long spiral high-pressure mixing and spraying cement-soil continuous wall

A construction method and long-spiral technology, applied in water conservancy projects, artificial islands, sheet pile walls, etc., can solve the problems of stuck drilling, high cost, reduced construction efficiency, etc., and achieve the effect of high efficiency and poor waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

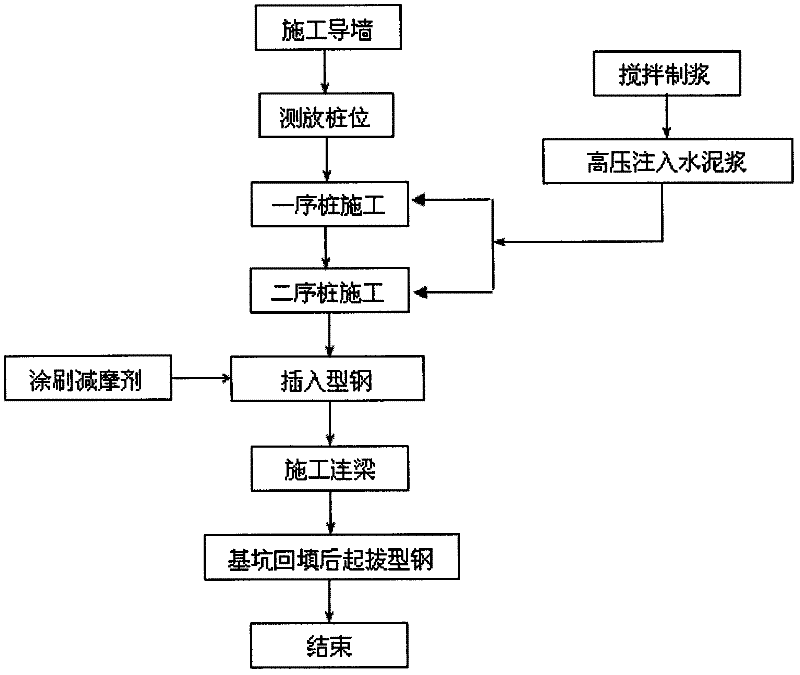

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be noted that, the embodiment of the construction method of the long spiral high-pressure sprayed cement-soil continuous wall according to the present invention is only an example, but the present invention is not limited to this specific embodiment.

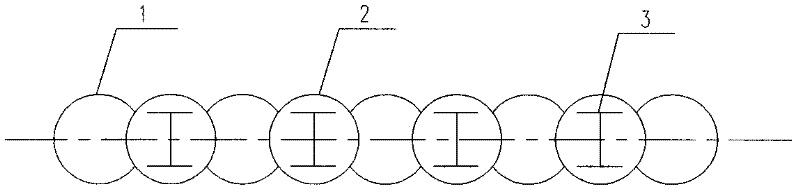

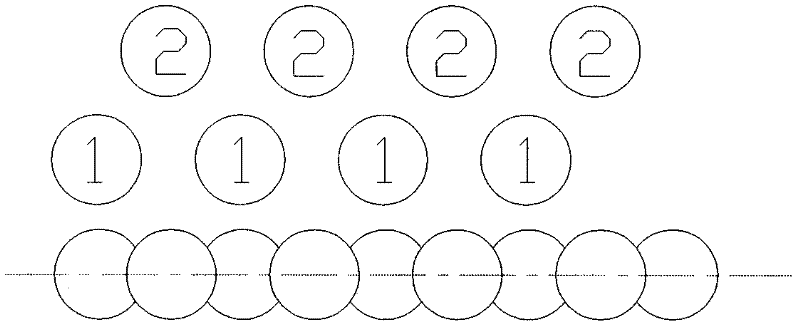

[0033] Next, refer to the attached Figure 1-3 Specific embodiments of the present invention will be described in detail.

[0034] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0035] Construction case: The foundation pit of a certain project is 7.0m deep, and its geological conditions are:

[0036] 1. Topography

[0037] The proposed site is located in the middle of the alluvial-diluvial fan of Wenyu Rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com