Pure oxygen aeration system for wastewater treatment

A pure oxygen aeration and pure oxygen technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of oxygen use efficiency reduction, dissolved oxygen level in difficult aeration tanks, damage to microorganisms, pH value reduction and other issues, to achieve high oxygen use efficiency and cost efficiency, fast and smooth emptying, low land occupation and equipment installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] [0059] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

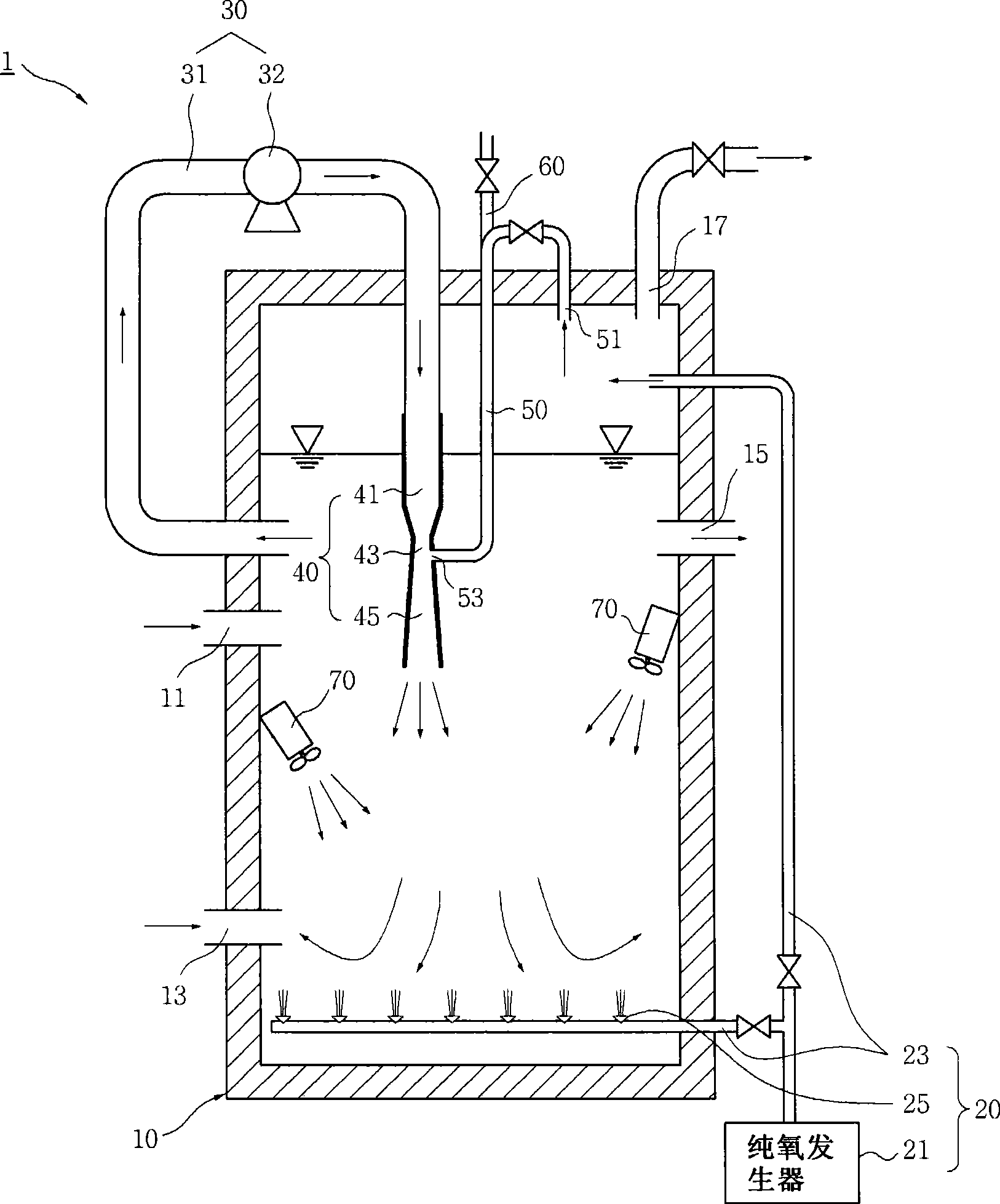

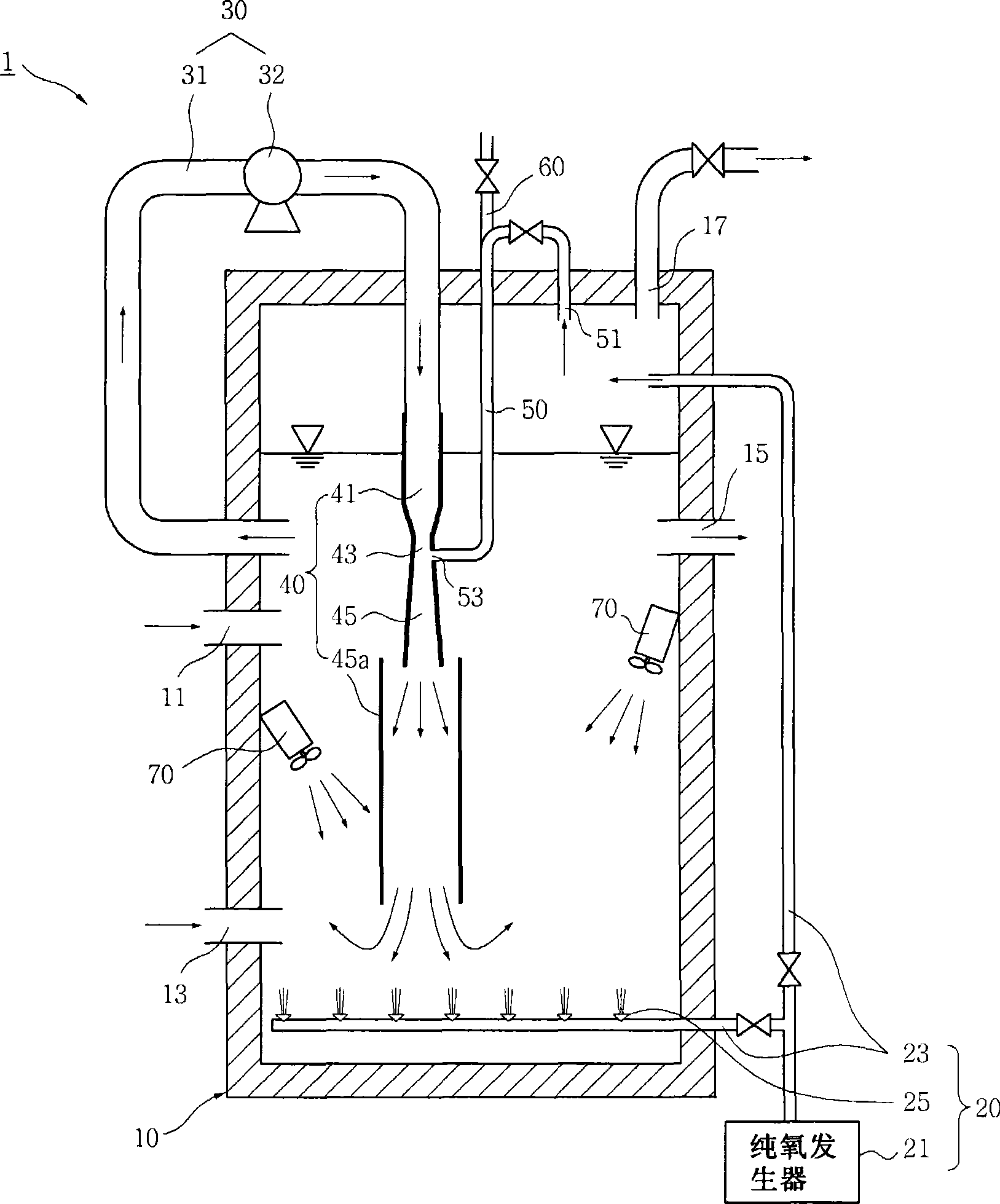

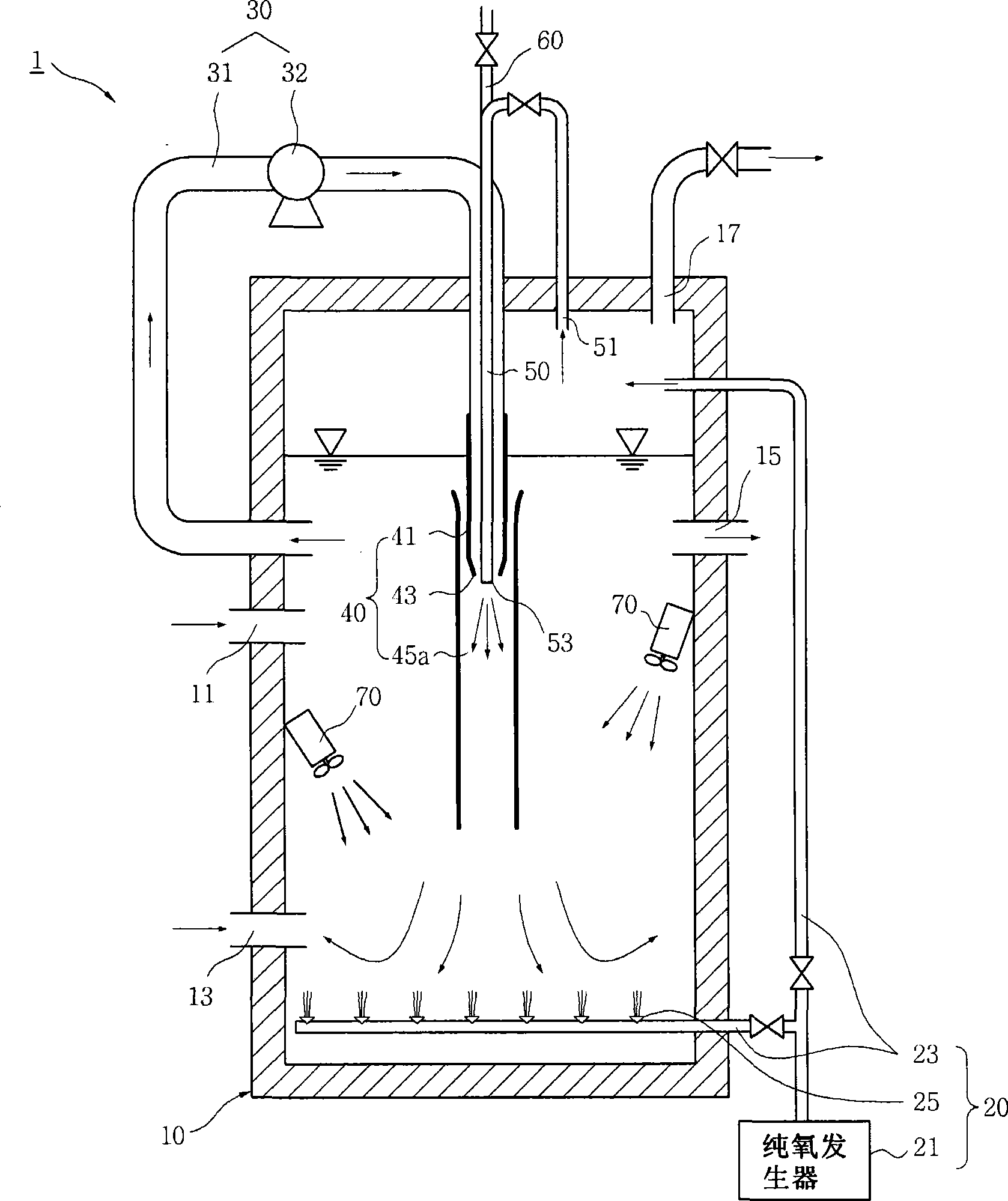

[0063] 【0060】 figure 1 is a cross-sectional view showing a pure oxygen aeration system for wastewater treatment according to a first embodiment of the present invention. like figure 1 As shown, the pure oxygen aeration system 1 includes an aeration tank 10 for providing a space for performing aeration, a pure oxygen supply device 20 for supplying pure oxygen to the aeration tank 10, and a pure oxygen supply device 20 for circulating in the aeration tank 10 A mixed solution circulation device 30 for mixed solution, a high-speed jet jet spray device 40 for rapidly spraying the mixed solution circulated through the mixed solution circulation device 30 to the lower part of the aeration tank 10 , and a top of the aeration tank 10 for sucking The oxygen in the space (hereinafter, referred to as "head space oxygen") and the head space oxygen are re-injected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com