Production method of micro nanometer fiber non-woven fabric and device

A technology of micro-nano fibers and production methods, which is applied in the field of nonwovens, can solve problems such as complex production methods and equipment, high requirements for production conditions, and difficult industrial control. It is easy to promote industrialization, low implementation cost, and meets low-carbon requirements. The effect of production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

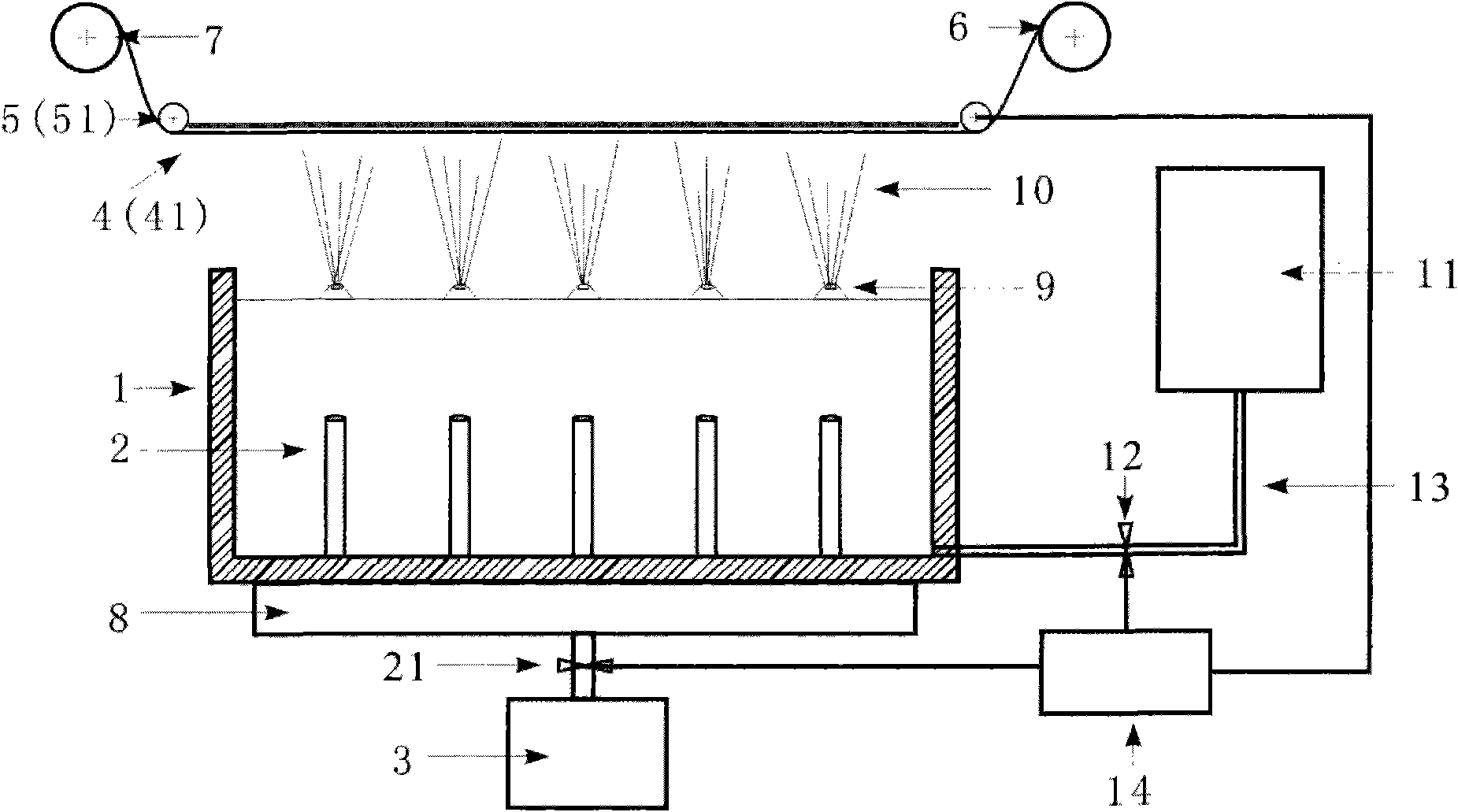

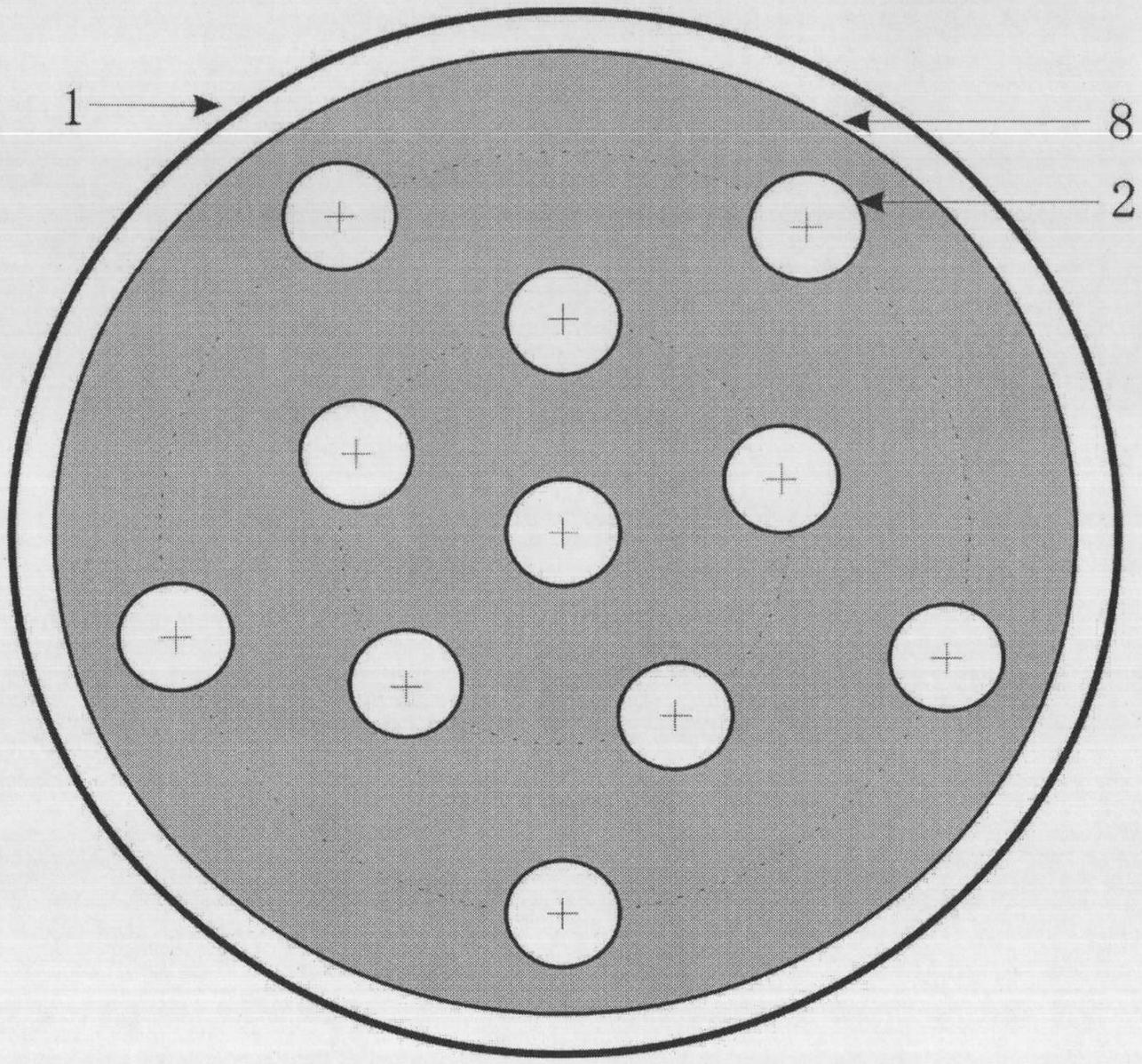

[0039] Design a kind of micro-nanofiber non-woven fabric production device (referring to figure 1 , 3 ), comprising a circular liquid storage tank 1, an air jet pipe 2, an air pump 3 and a plane non-woven fabric receiving net curtain 41 with openings on a diameter of 80mm. Wherein, the air jet pipe 2 is vertically installed at the bottom of the liquid storage tank 1, and the present embodiment adopts 11 air jet pipes 2, which are arranged in a staggered manner in concentric circles (see image 3 ); the air jet pipe 2 is at the bottom of the liquid storage tank 1, and communicates with the air flow distribution device 8, and the air flow distribution device 8 is installed on the bottom surface of the liquid storage tank 1, and is connected with the air pump 3 through the air guide pipe and the air supply valve 21, and The height of the jet pipe 2 in the liquid storage tank 1 can be adjusted; the side of the liquid storage tank 1 is connected to the liquid supply tank 11 throug...

Embodiment 2

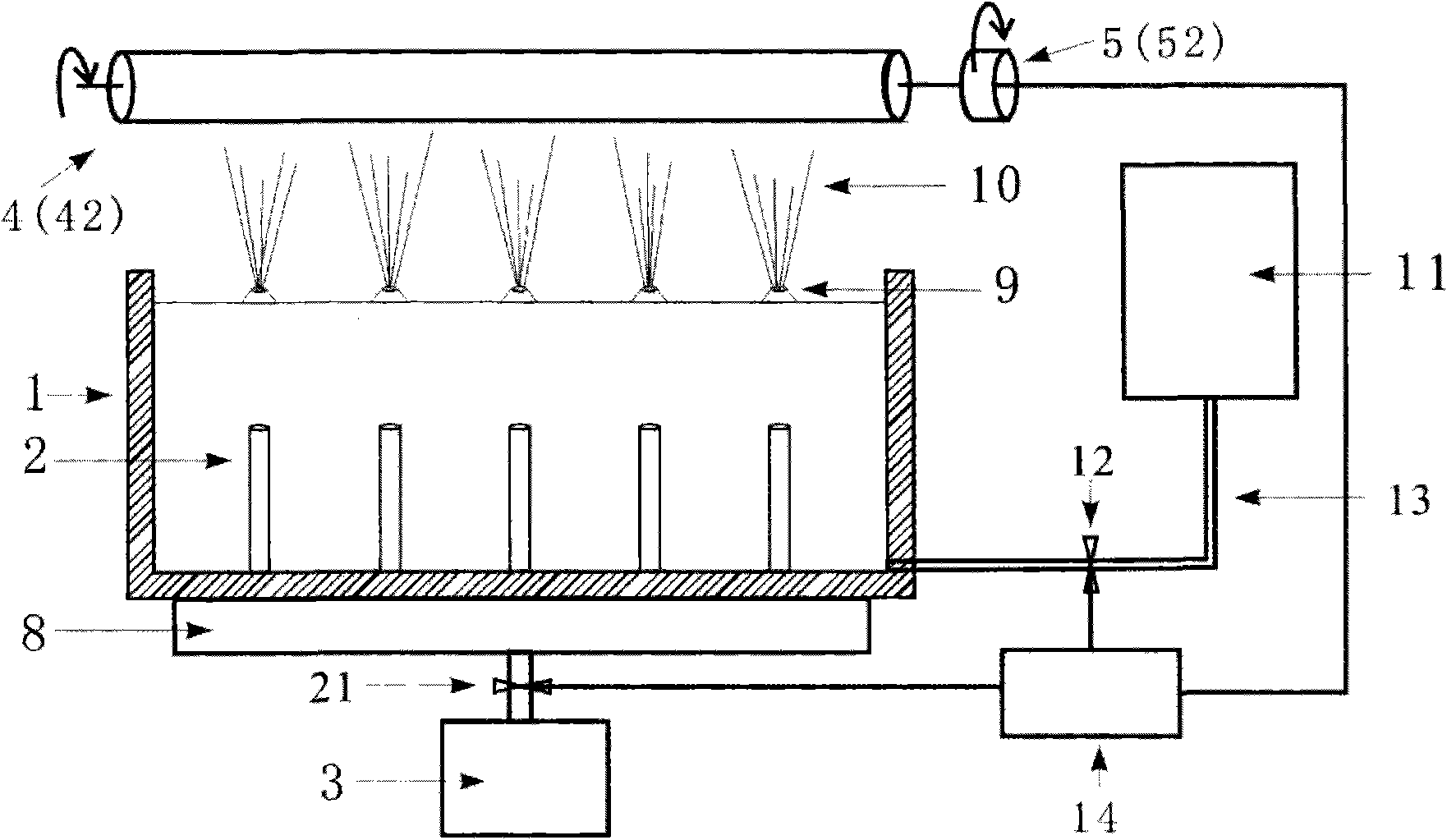

[0043] The micro-nanofiber non-woven production device of the present embodiment (see figure 2 , 4 ), including a rectangular liquid storage tank (length × width = 80mm × 60mm) 1 with an upward opening at the top, an air jet pipe 2, an air pump 3, a roller non-woven fabric receiving net curtain 42, a roller transmission device 52 and a control device 14, etc. . Present embodiment adopts 9 jet tubes 2, and arrange in parallel in the mode of matrix (referring to Figure 4); the air jet pipe 2 is installed at the bottom of the liquid storage tank 1, and communicates with the air flow distribution device 8, and the air flow distribution device 8 is installed on the bottom surface of the liquid storage tank 1, and is connected with the air pump 3 through the air guide pipe and the air supply valve 21, And the height of the jet pipe 2 in the liquid storage tank 1 can be adjusted; the side of the liquid storage tank 1 is connected with the liquid supply tank 11 through the liquid ...

Embodiment 3

[0047] This embodiment adopts the same device as Example 2.

[0048] Before spinning, first weigh 100 grams of polyvinyl alcohol (polymerization degree is 1750 ± 50) powder, and mix with solvent - distilled water with a mass ratio concentration of 12.5%, stir evenly in a water bath at 85 ° C, and let stand for 2 Hours, the polyvinyl alcohol / distilled water spinning solution is obtained; then the prepared polyvinyl alcohol spinning solution is packed into the liquid supply pool 11, and starts to supply the liquid in the liquid storage pool 1 until the liquid storage tank 1 The liquid level of the spinning solution is 2.5cm higher than the nozzle opening of the air jet tube 2; when spinning, first open the air pump 3, and slowly adjust the air supply valve 21 to increase the pressure and air flow until the liquid level of the polymer solution Generate bulge, suitably regulate air pressure again and be 1.2Mpa, make the liquid level of spinning liquid form the bulge 9 of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com