Patents

Literature

61 results about "Jet injector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

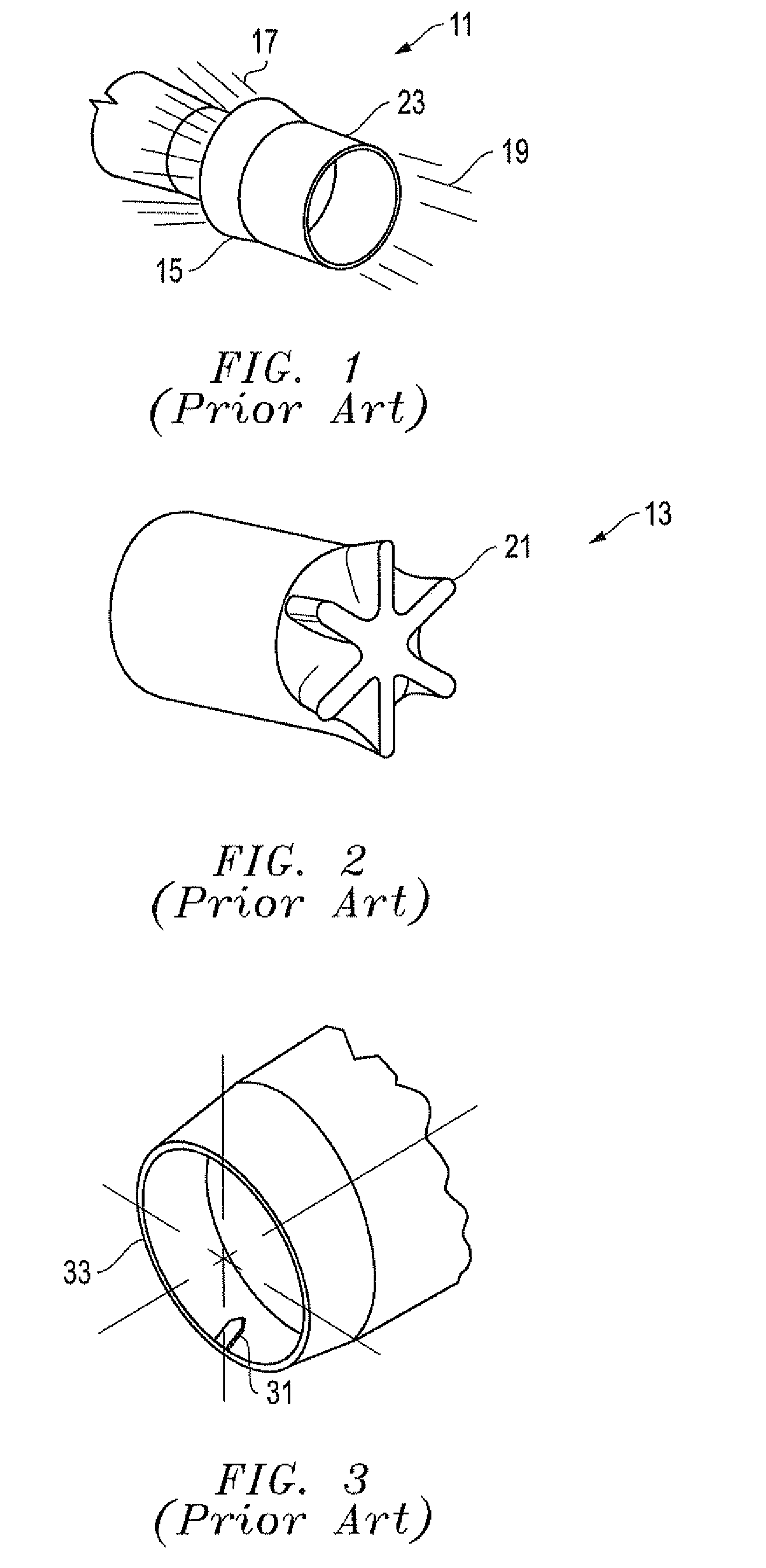

A jet injector is a type of medical injecting syringe device used for a method of drug delivery known as jet injection, in which a narrow, high-pressure stream of liquid penetrates without needle the outermost layer of the skin (stratum corneum) to deliver medication to targeted underlying tissues of the epidermis or dermis ("cutaneous" injection, also known as classical "intradermal" injection), fat ("subcutaneous" injection), or muscle ("intramuscular" injection).

Hypodermic fluid dispenser

InactiveUS6056716AEfficient injectionEliminate the problemAmpoule syringesJet injection syringesHypodermoclysisJet flow

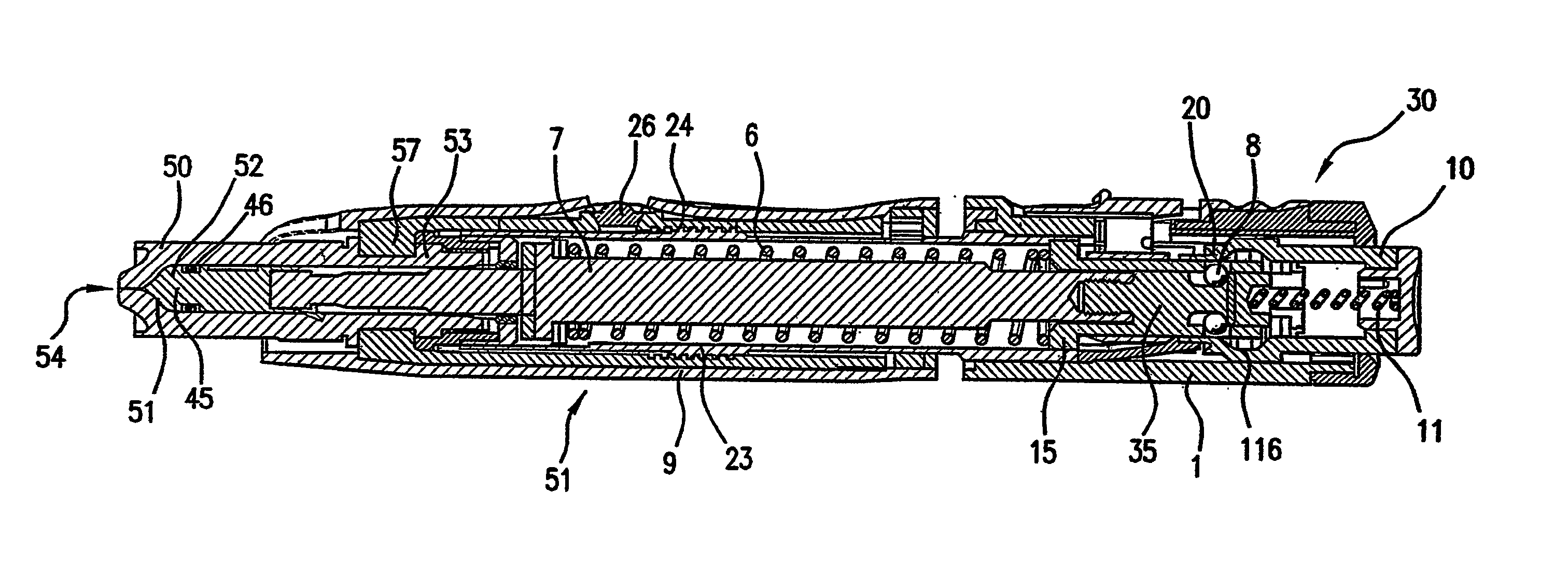

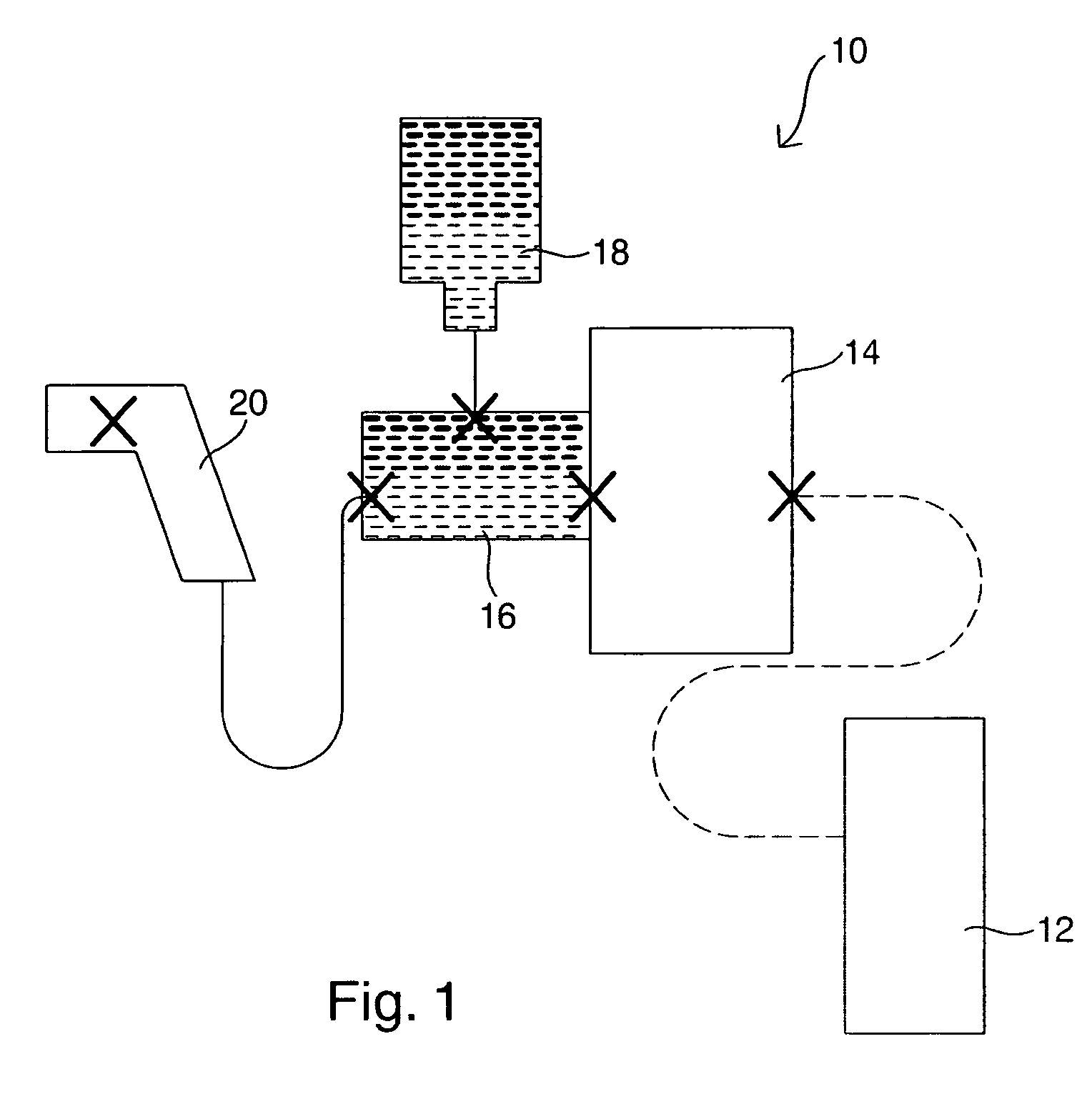

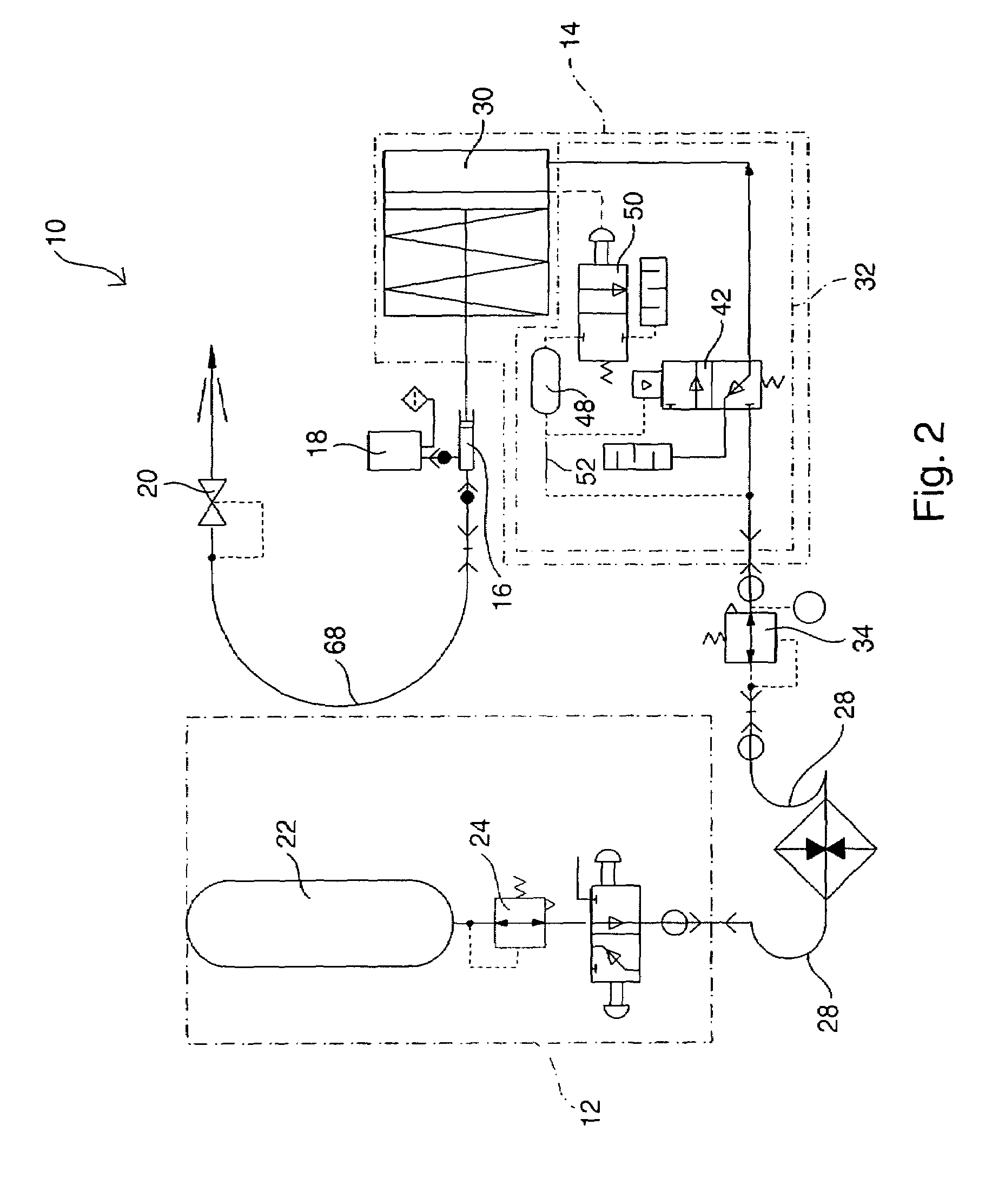

A jet injector system for injecting fluid into a body. The jet injection system includes capsules for holding the material to be injected, apparatus for applying force to the capsule(s) to eject the injection material(s) and a perforator for directing the jet stream for the respective materials into the body. A flyweight system is described for developing jet injection pressures, and latching devices control the flyweight system. An injector system for injecting more than one fluid is described.

Owner:DANTONIO CONSULTANTS INT INC

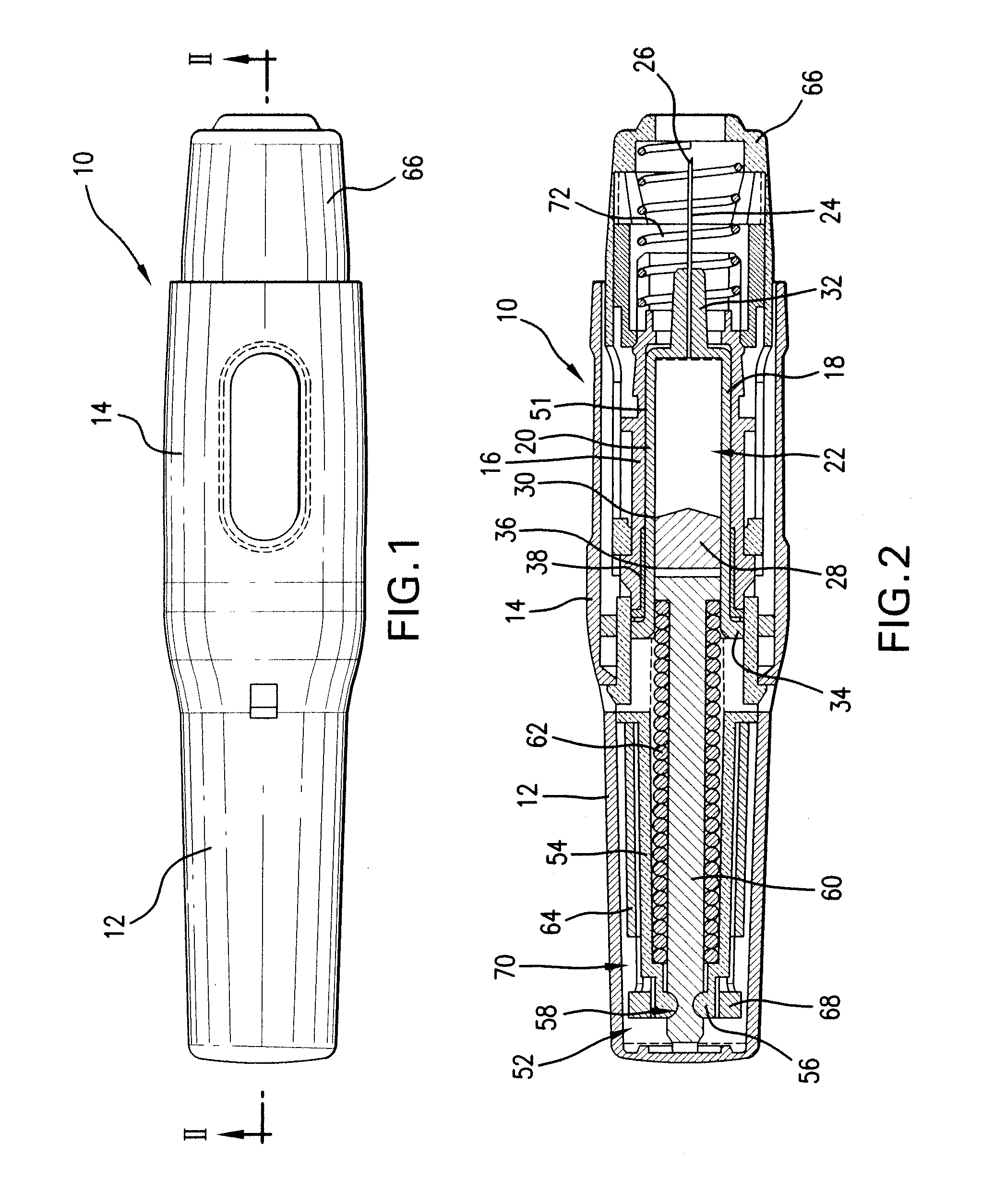

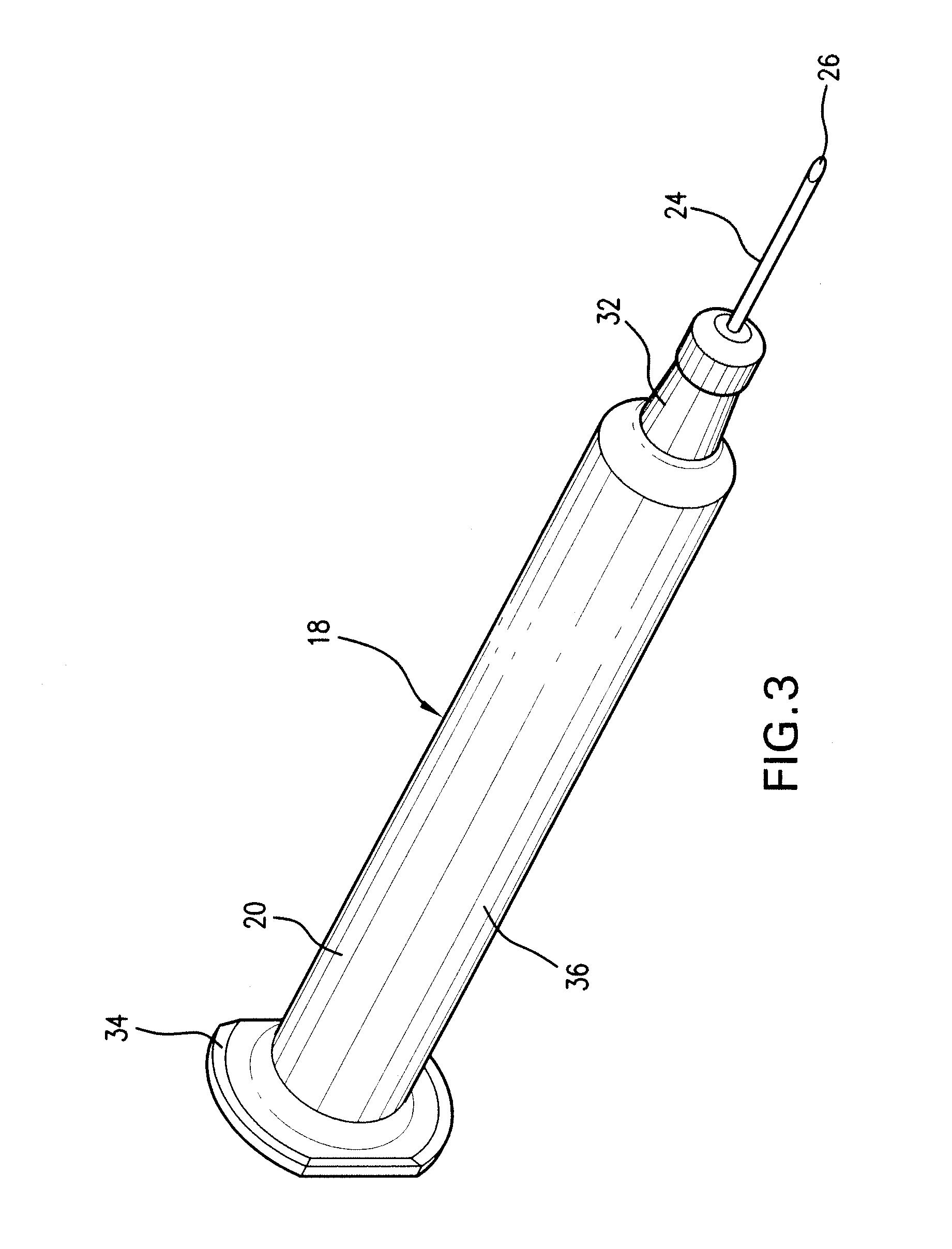

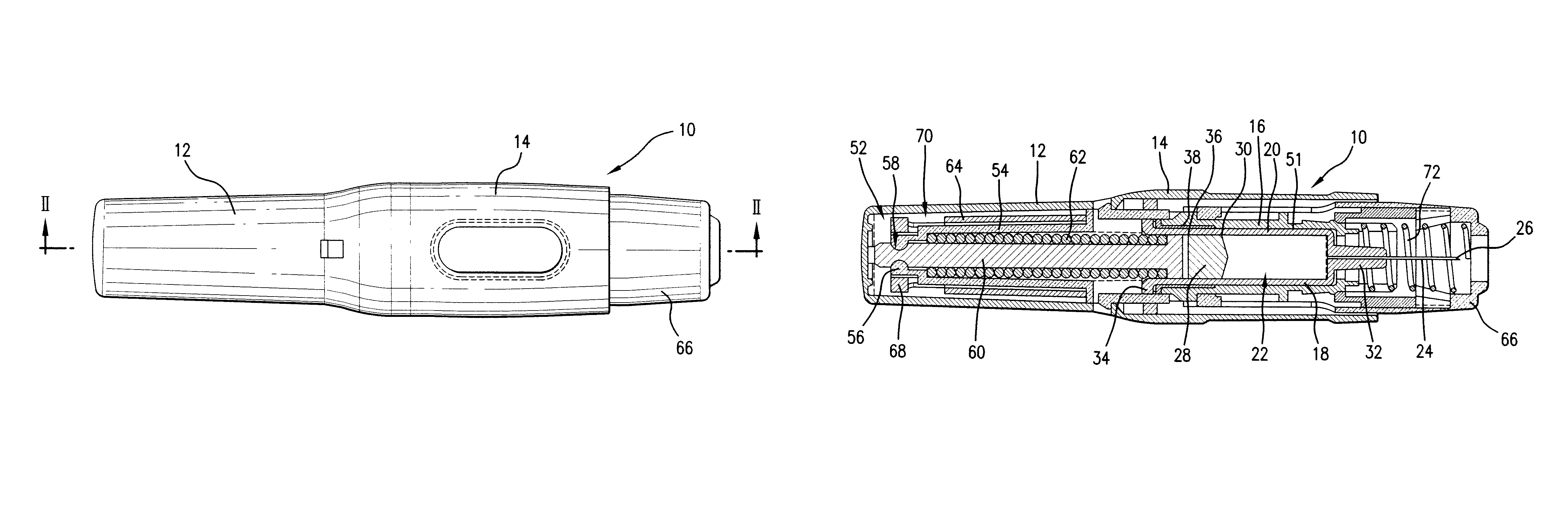

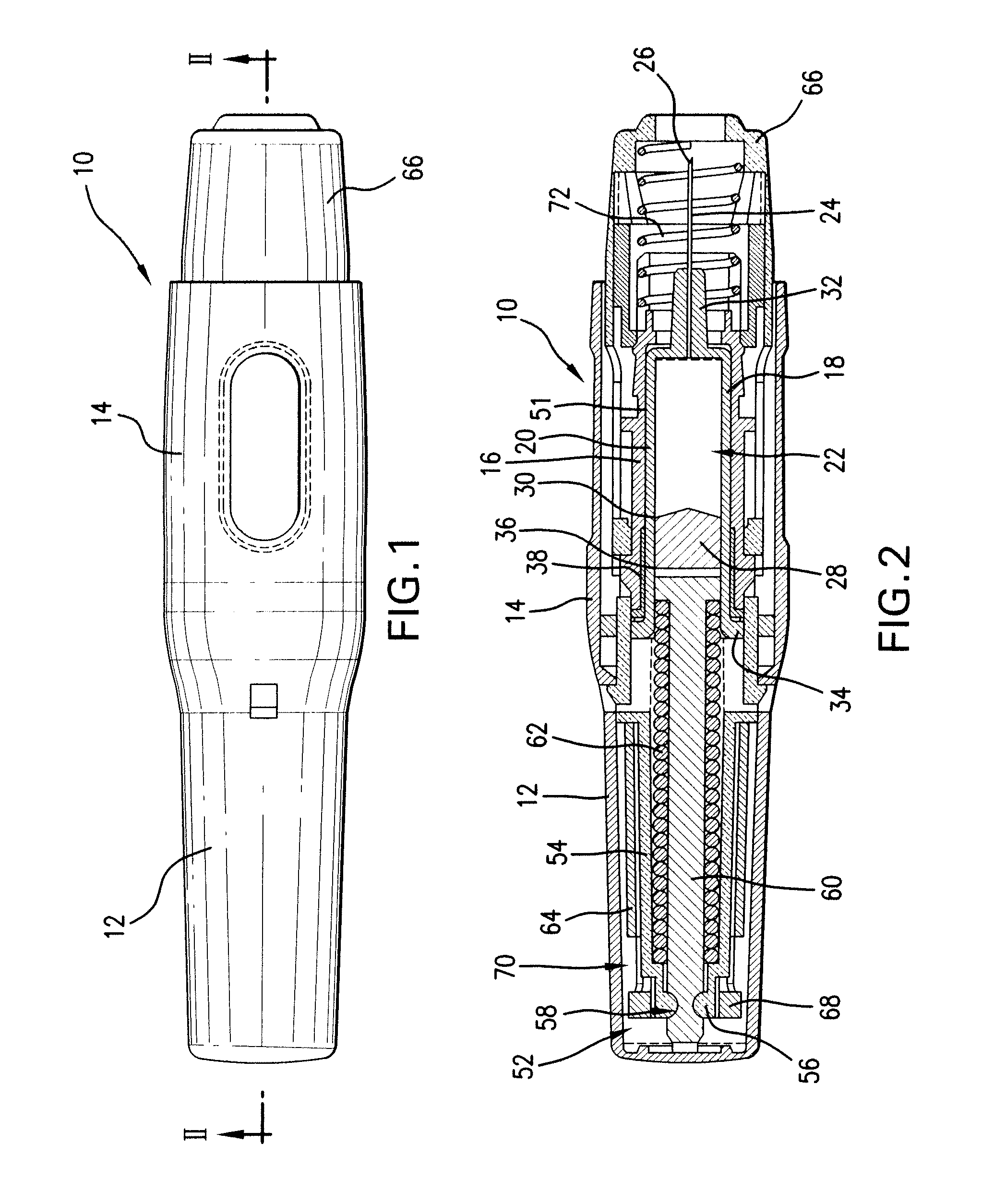

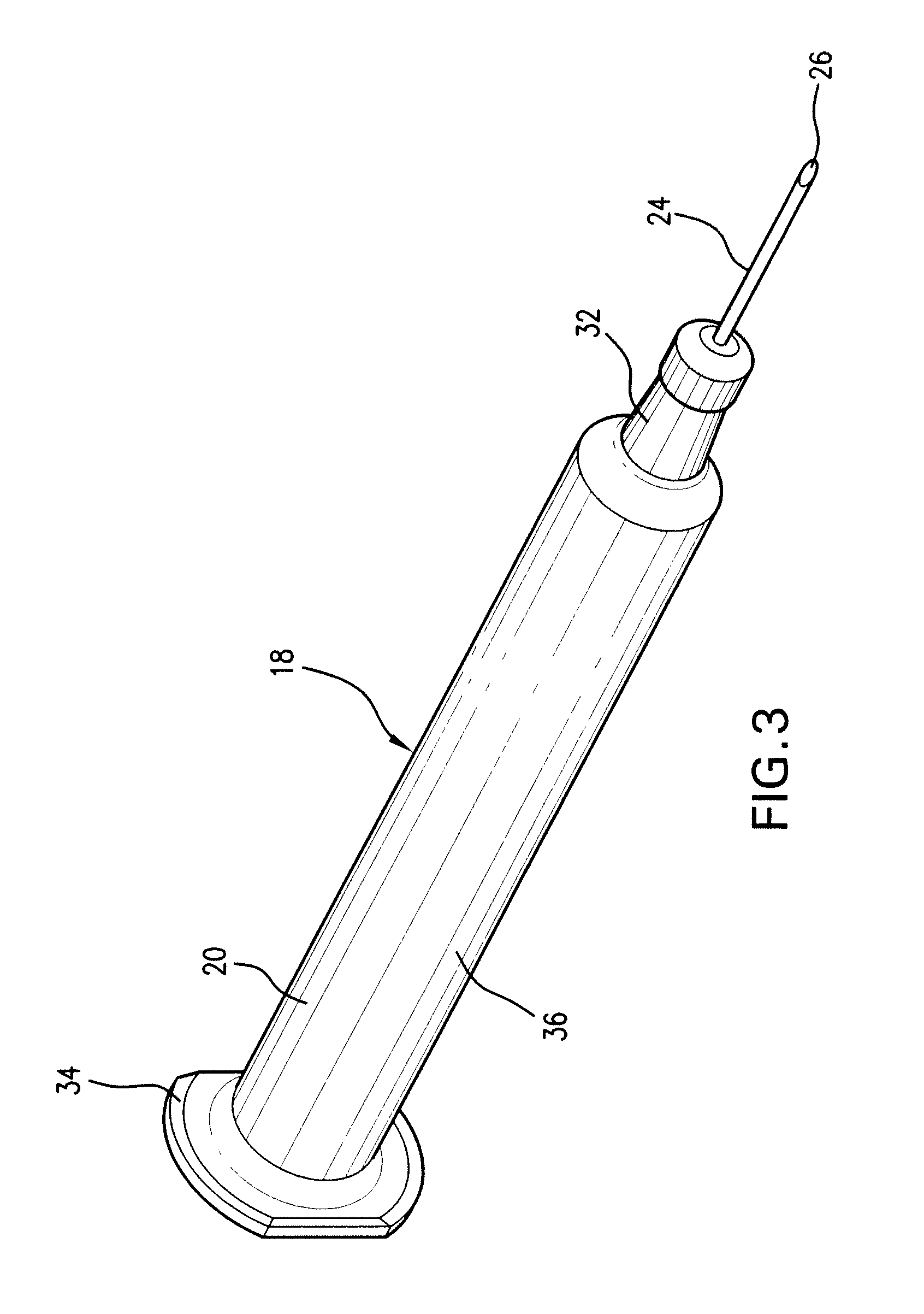

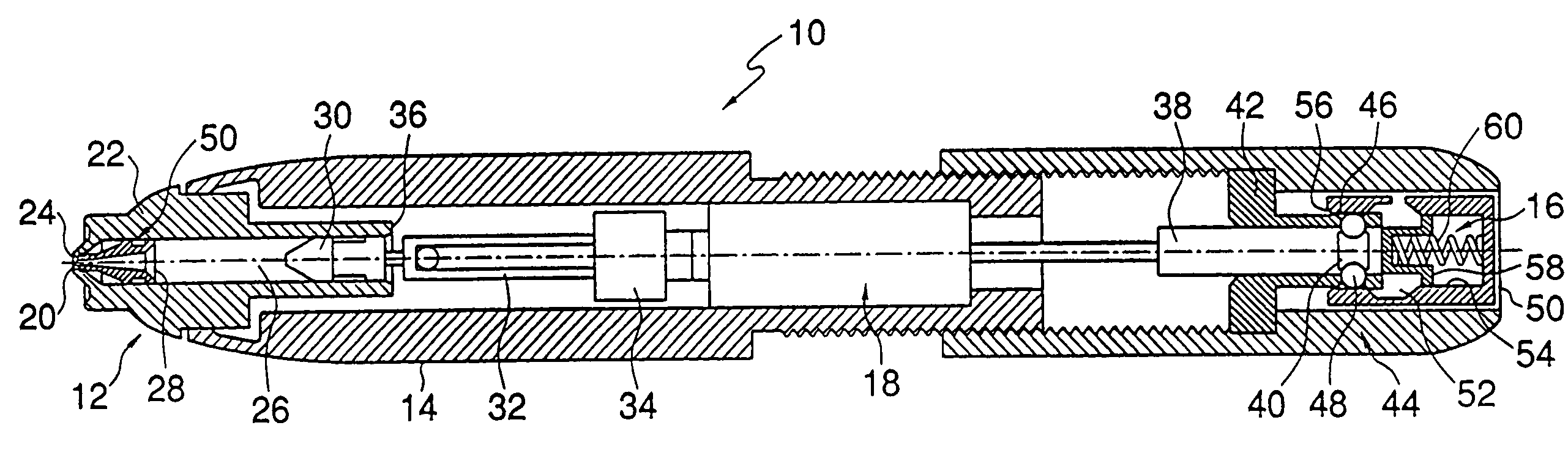

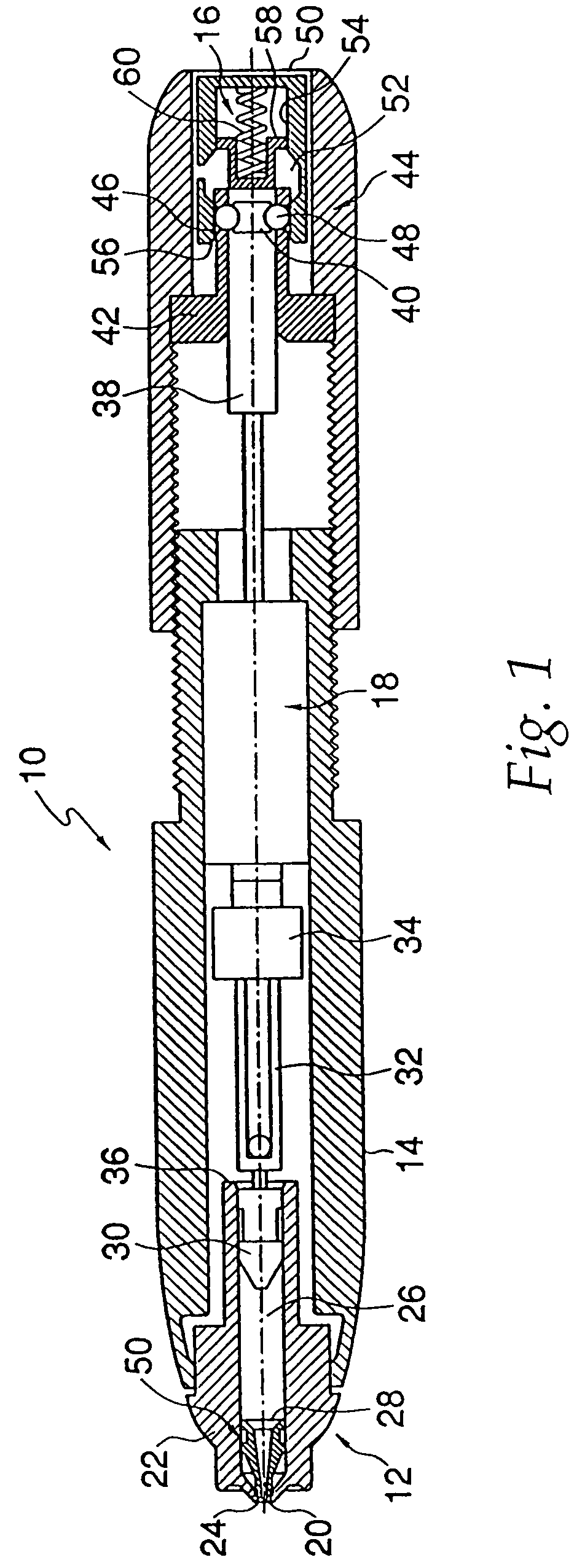

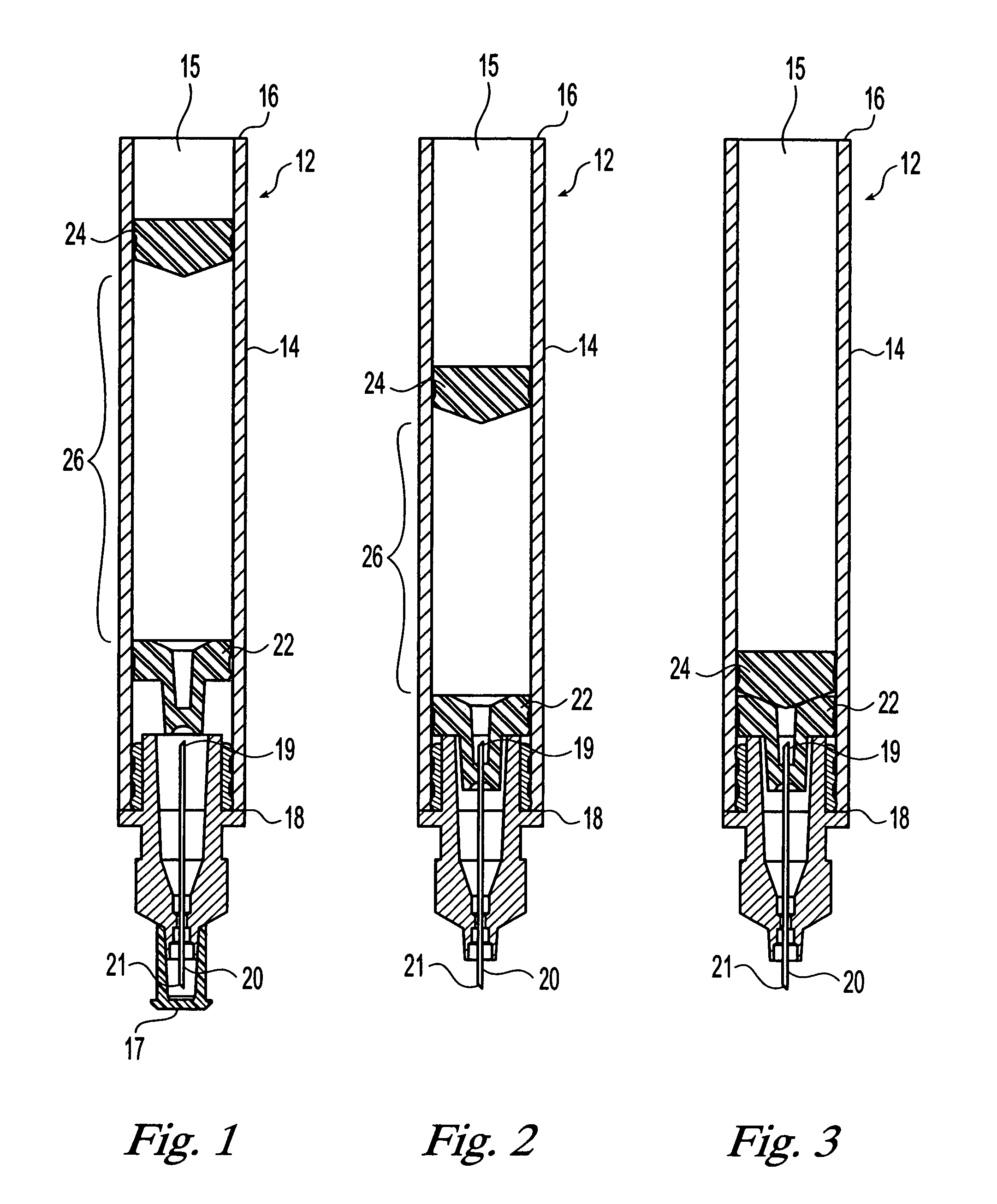

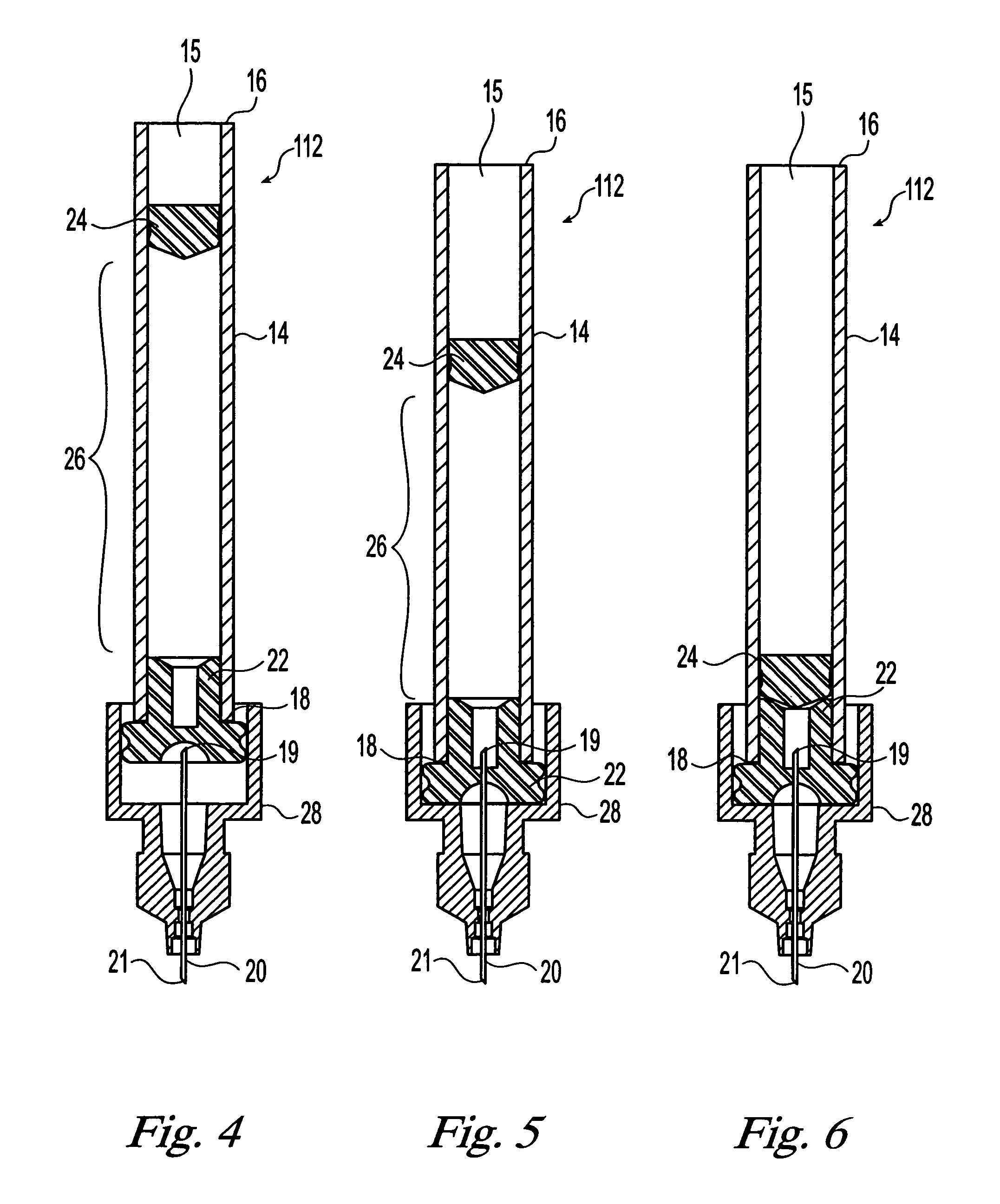

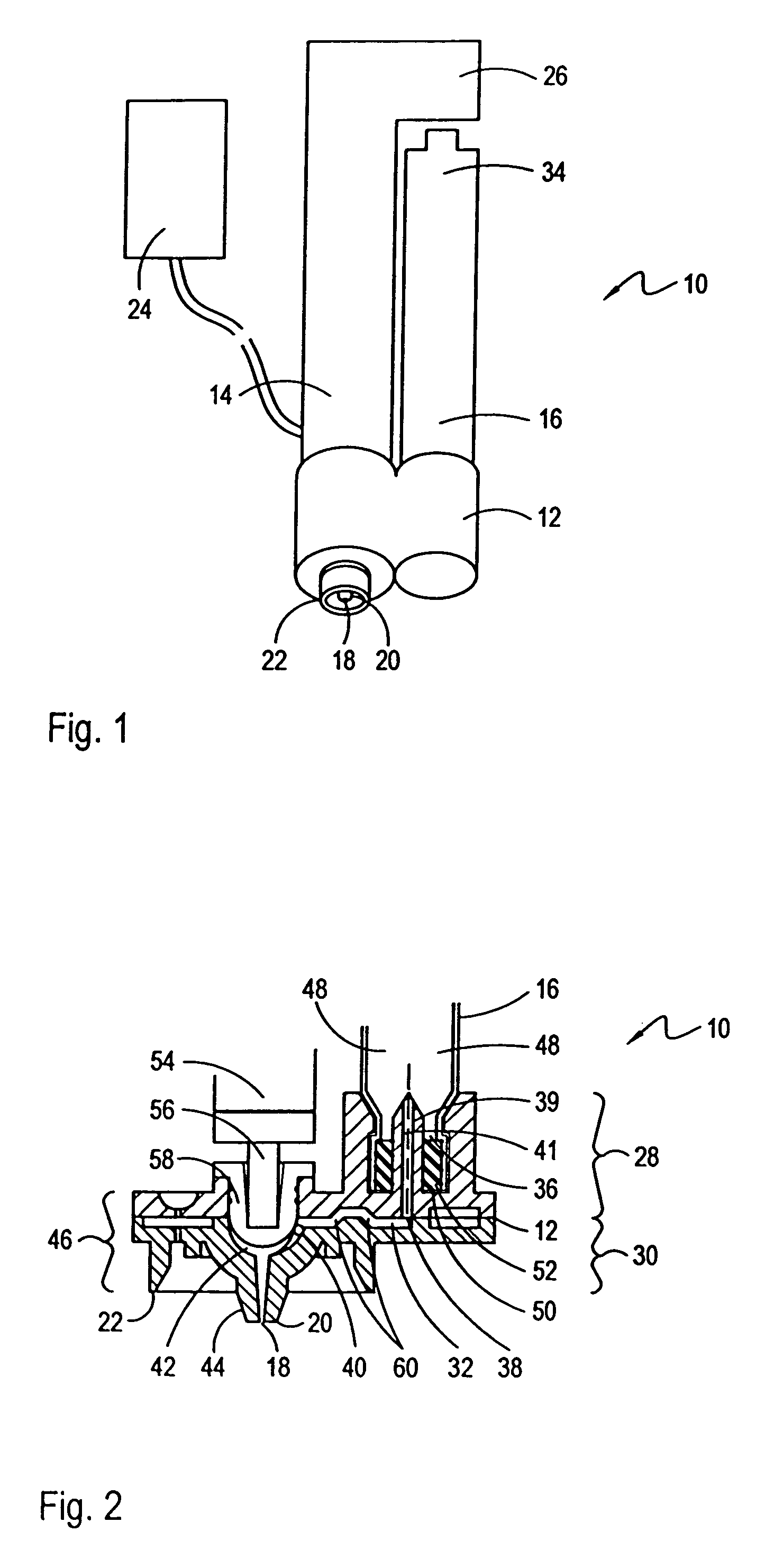

Prefilled syringe jet injector

ActiveUS20080154200A1Prevent backflowImprove distributionAmpoule syringesJet injection syringesEngineeringPrefilled Syringe

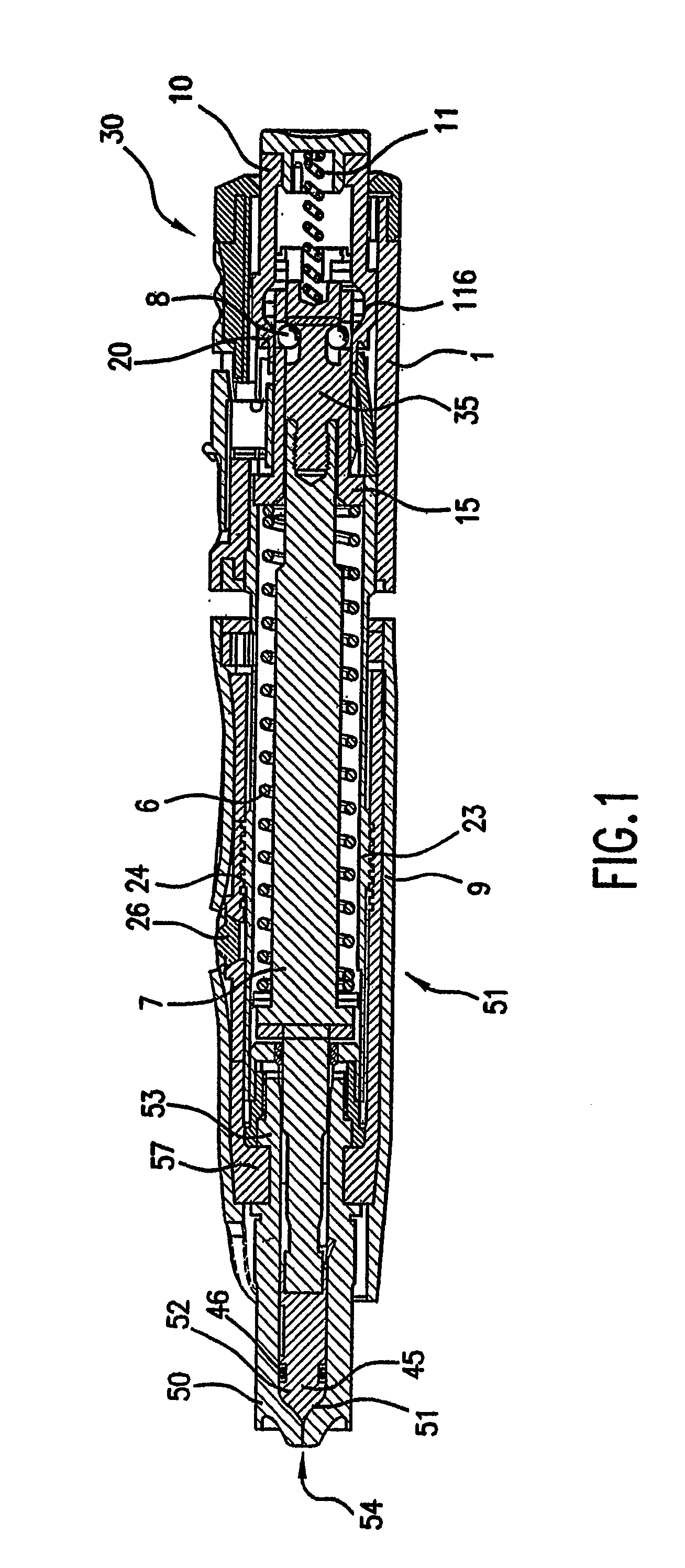

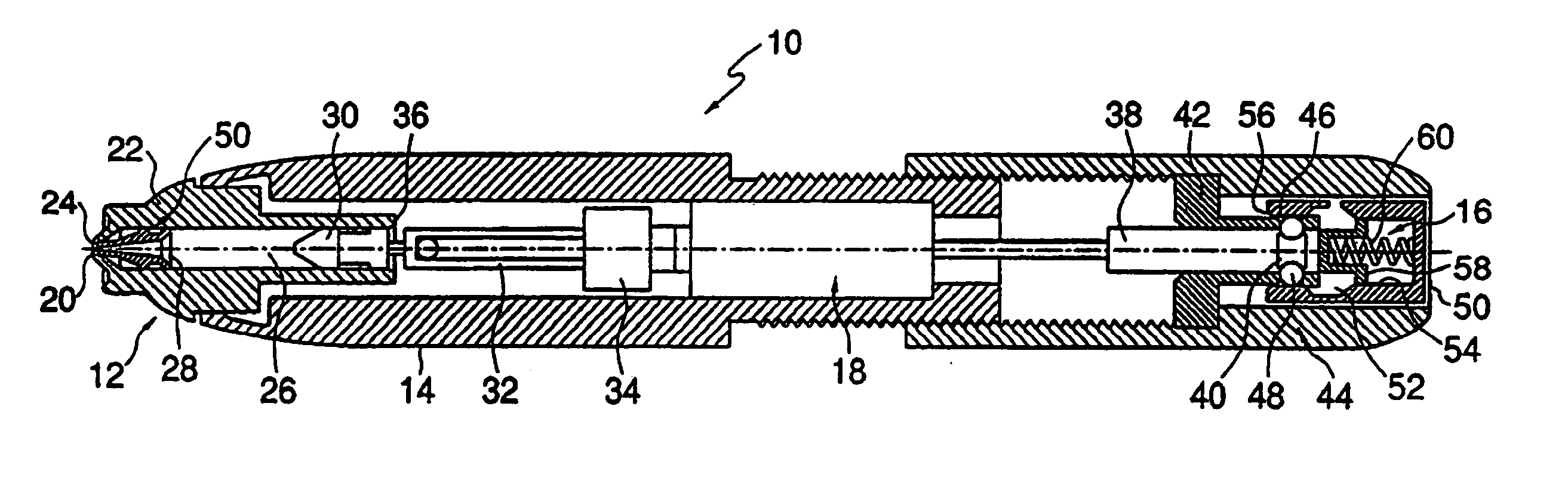

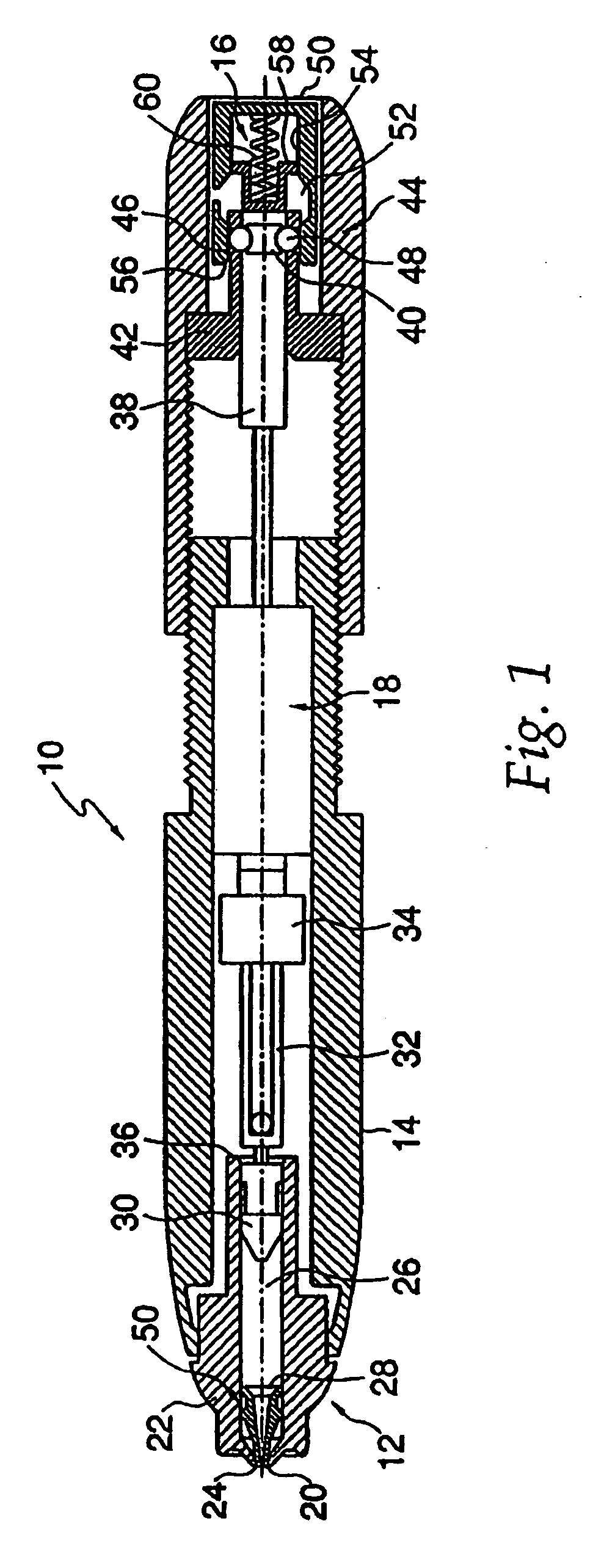

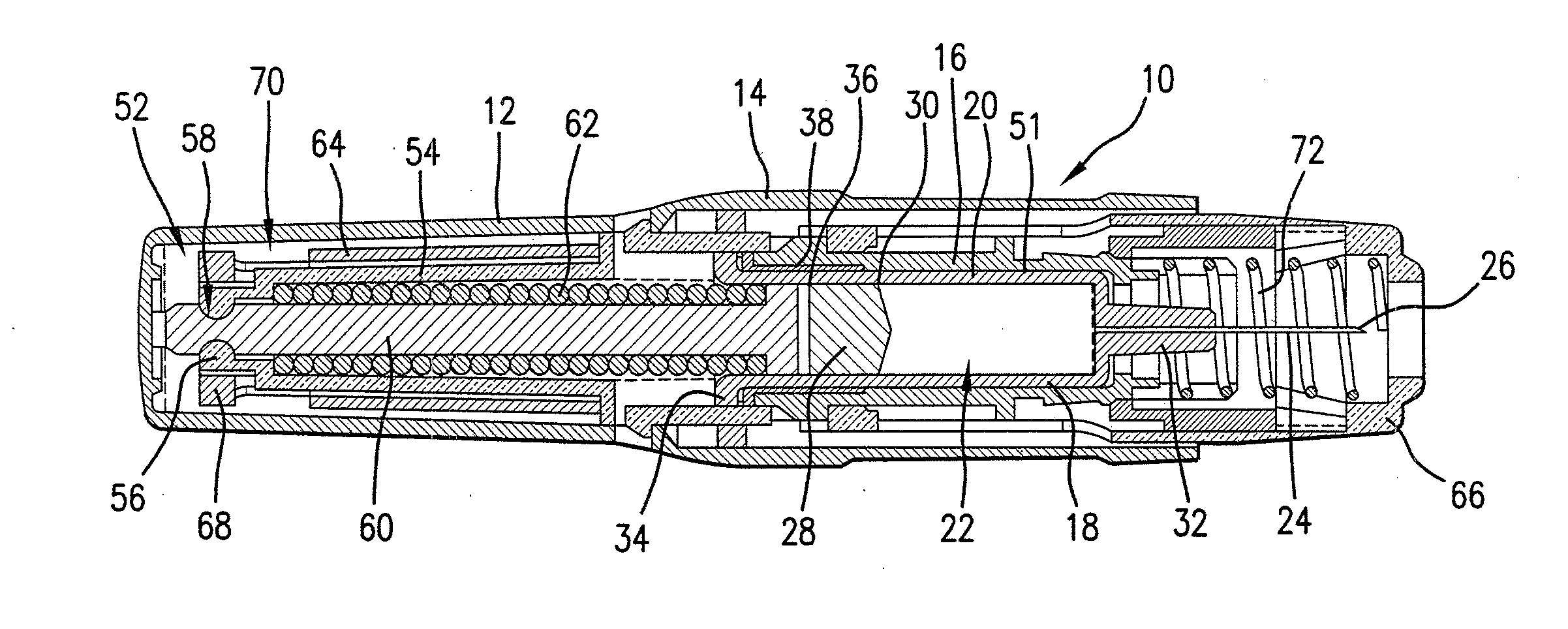

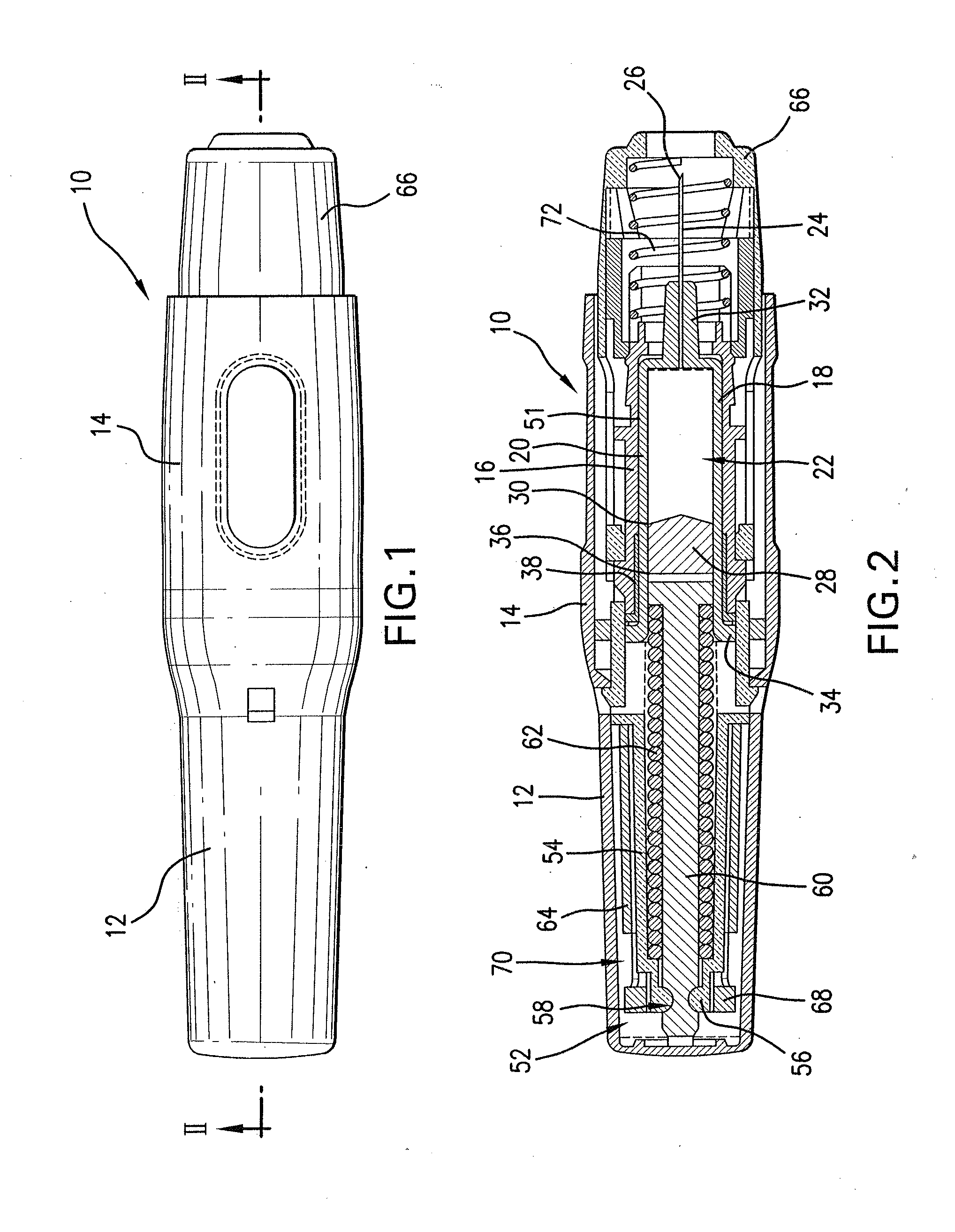

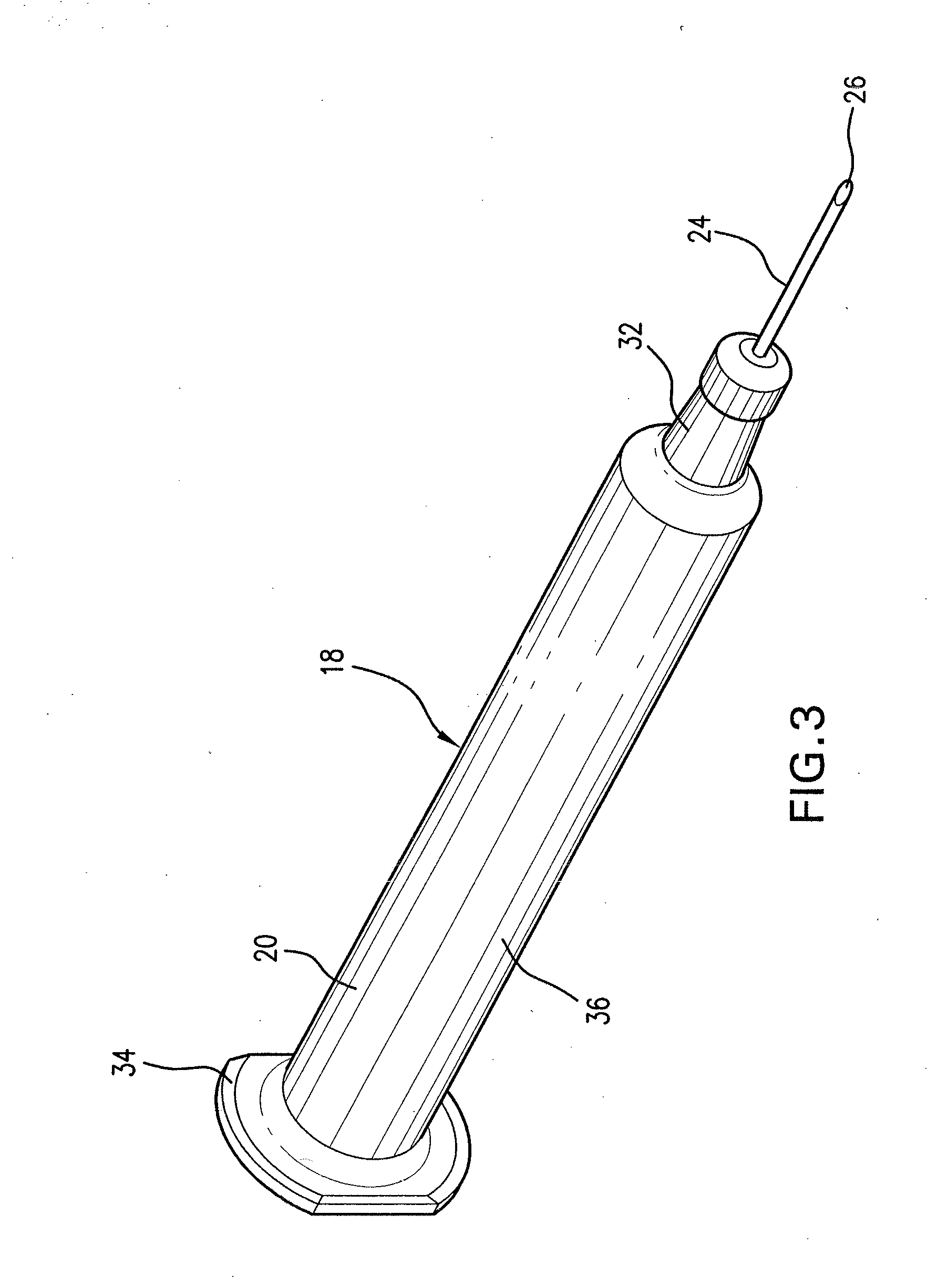

A jet injector that includes a prefilled syringe. The syringe includes a fluid chamber that contains a medicament. The syringe also has an injection-assisting needle, and a plunger is movable within the fluid chamber. A housing is configured for allowing insertion of the needle to a penetration depth. An energy source is configured for biasing the plunger to produce an injecting pressure in the medicament in the fluid chamber of between about 80 and 1000 p.s.i. to jet inject the medicament from the fluid chamber through the needle to an injection site.

Owner:ANTARES PHARMA INC

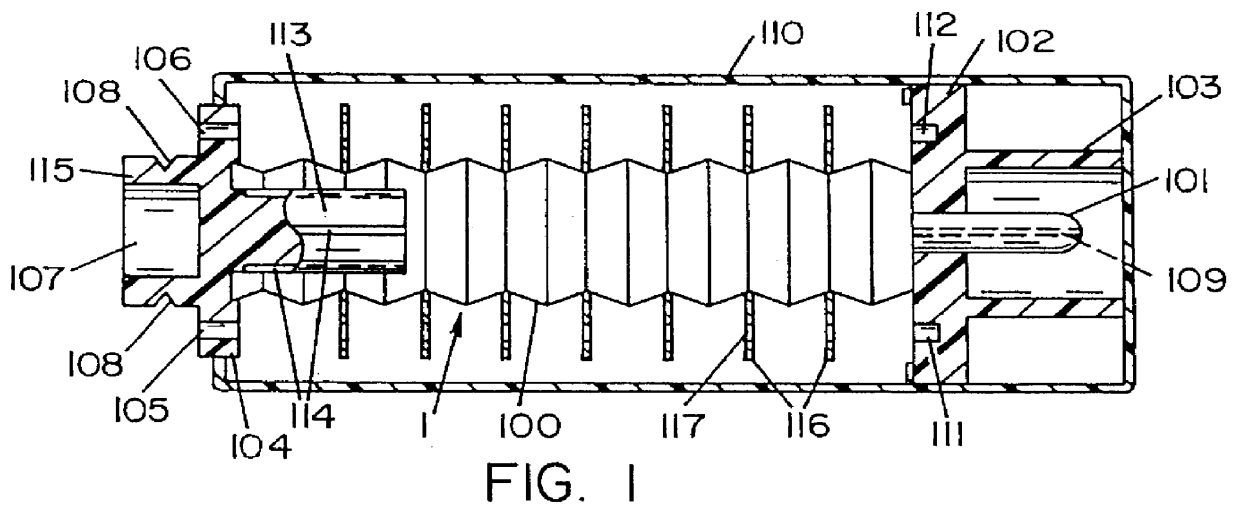

Prefilled syringe jet injector

ActiveUS8021335B2Prevent backflowImprove distributionAmpoule syringesJet injection syringesInjection pressureInjection site

A jet injector that includes a prefilled syringe. The syringe includes a fluid chamber that contains a medicament. The syringe also has an injection-assisting needle, and a plunger is movable within the fluid chamber. A housing is configured for allowing insertion of the needle to a penetration depth. An energy source is configured for biasing the plunger to produce an injecting pressure in the medicament in the fluid chamber of between about 80 and 1000 p.s.i. to jet inject the medicament from the fluid chamber through the needle to an injection site.

Owner:ANTARES PHARMA INC

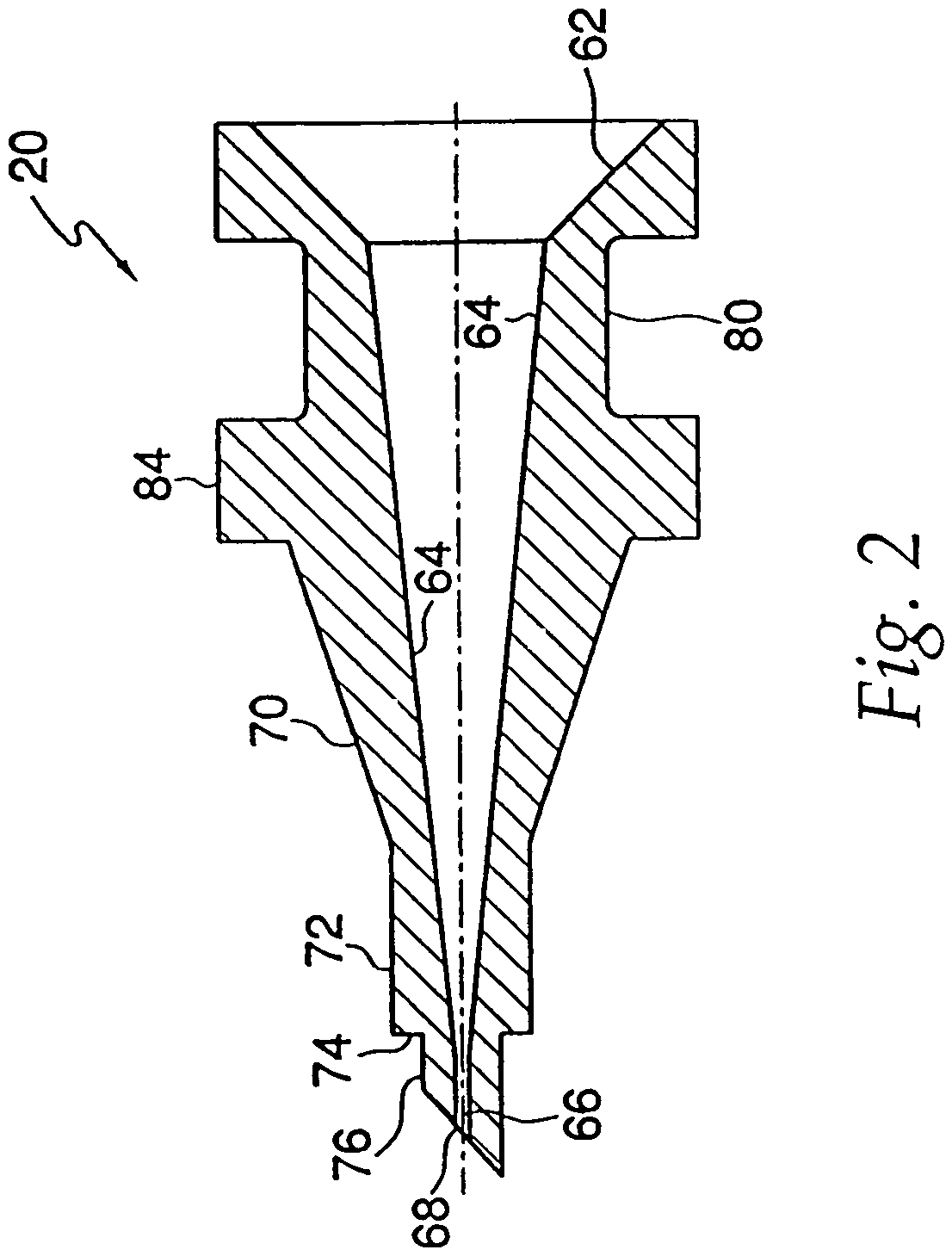

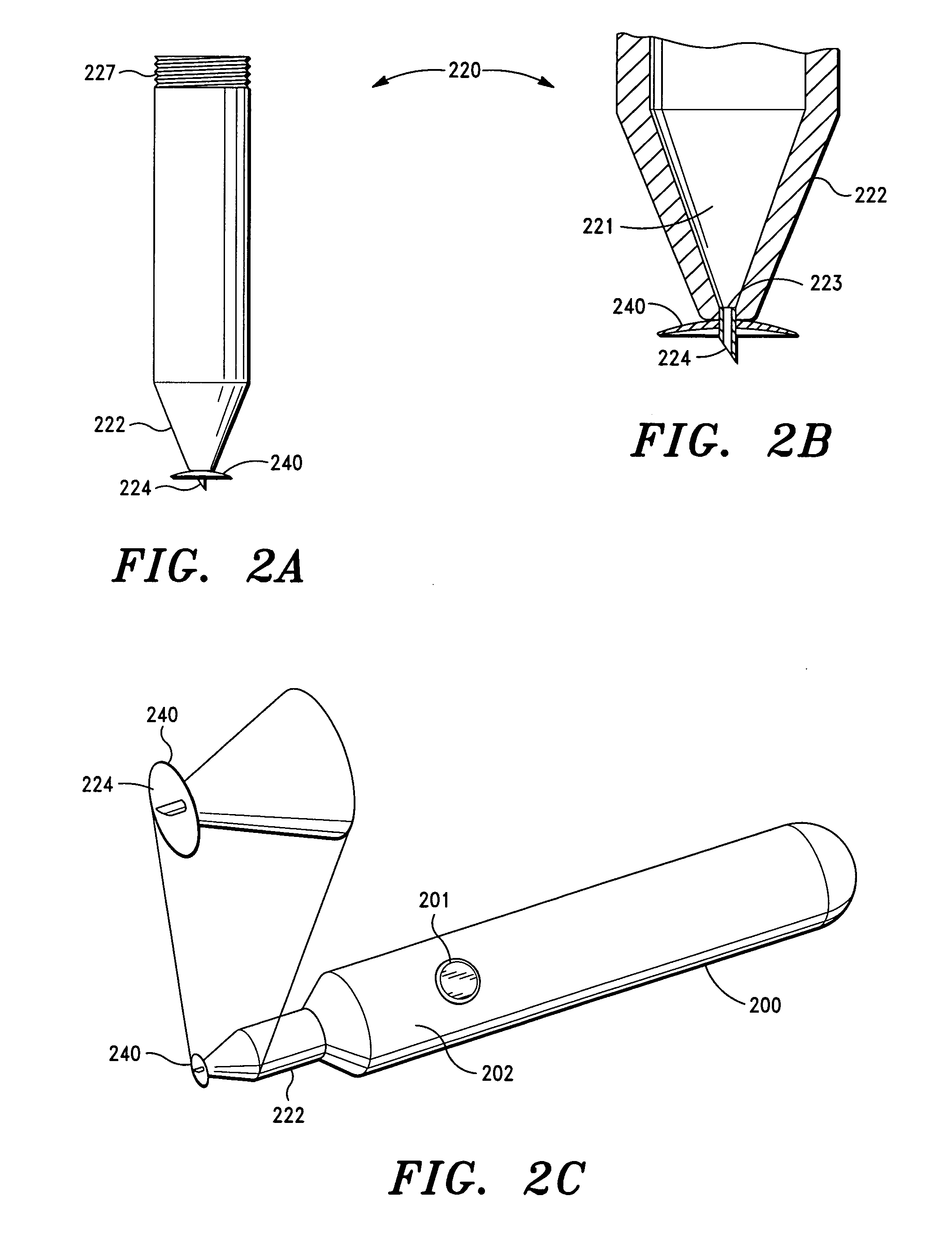

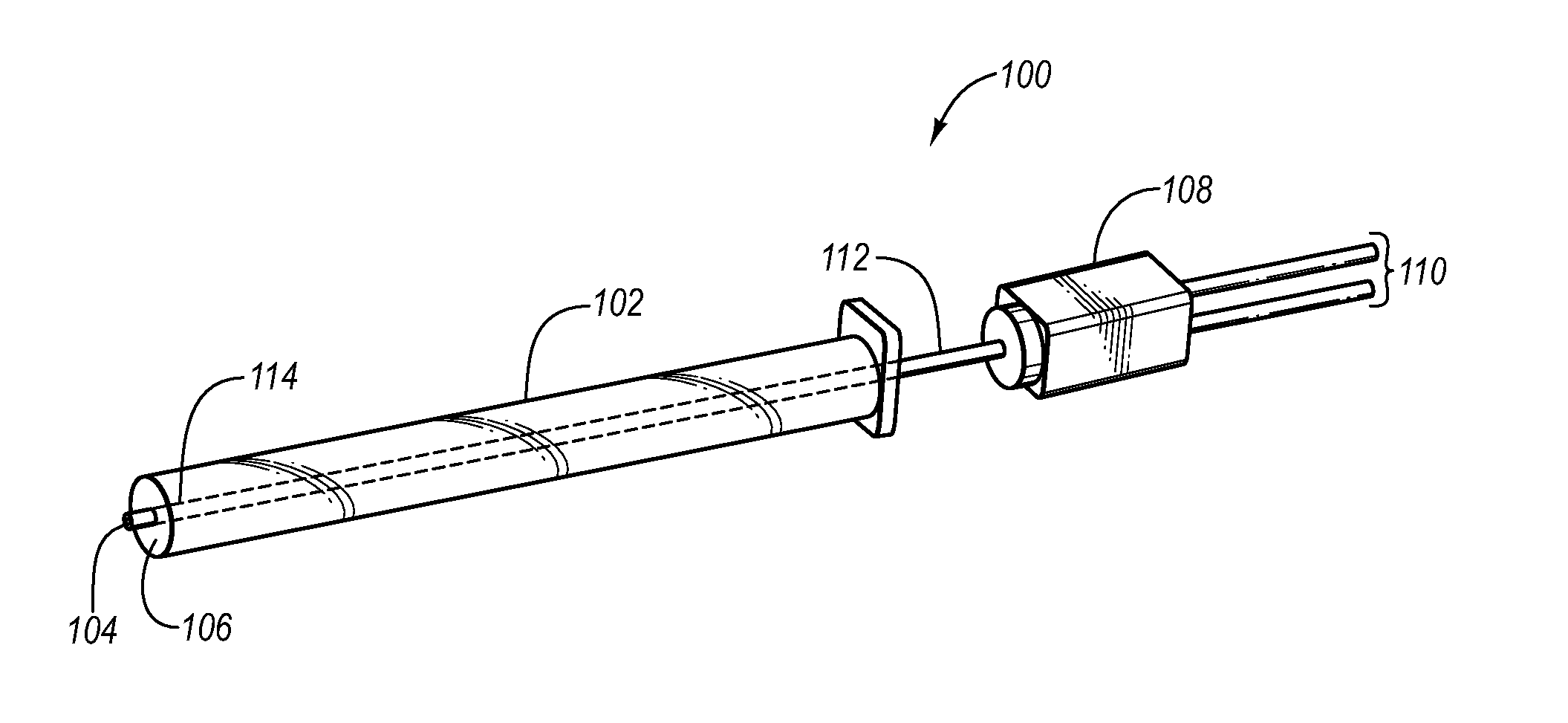

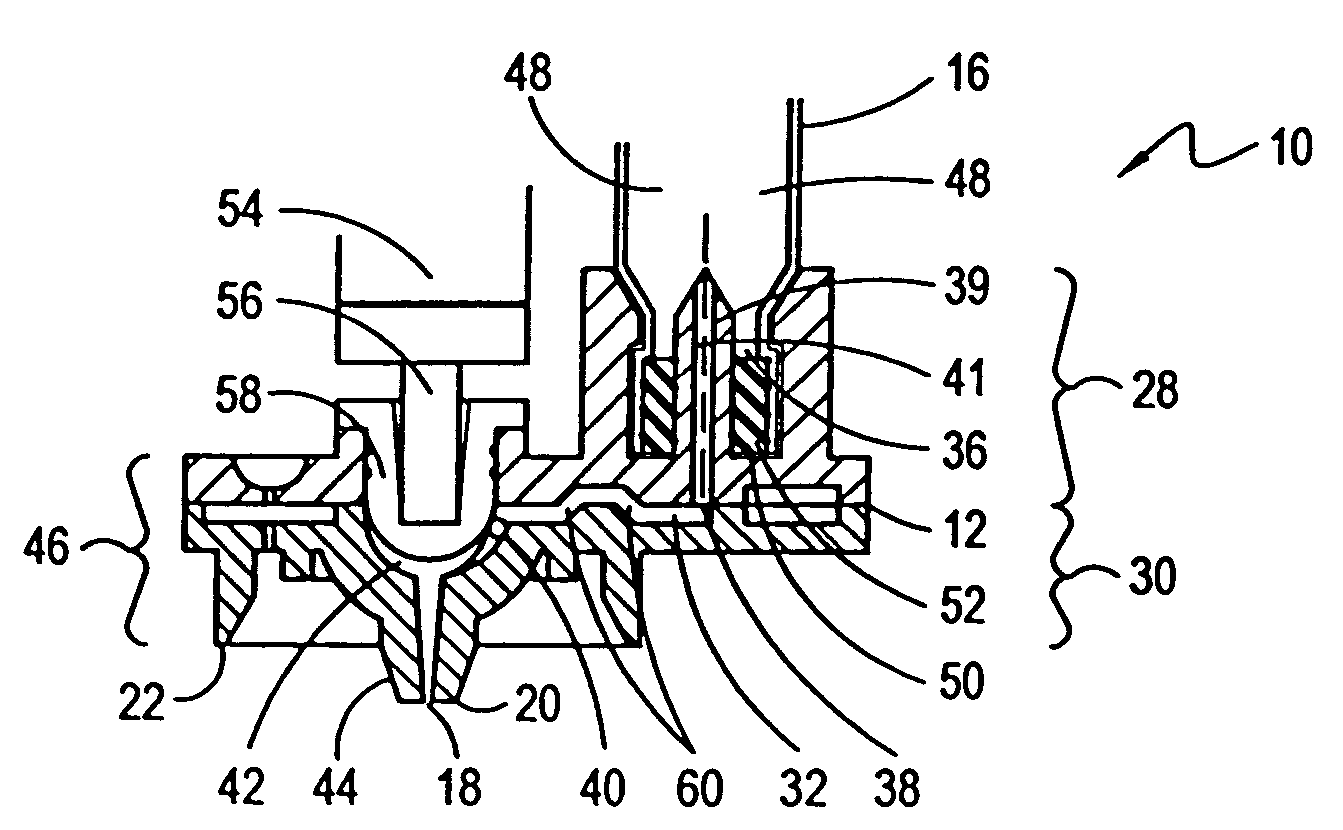

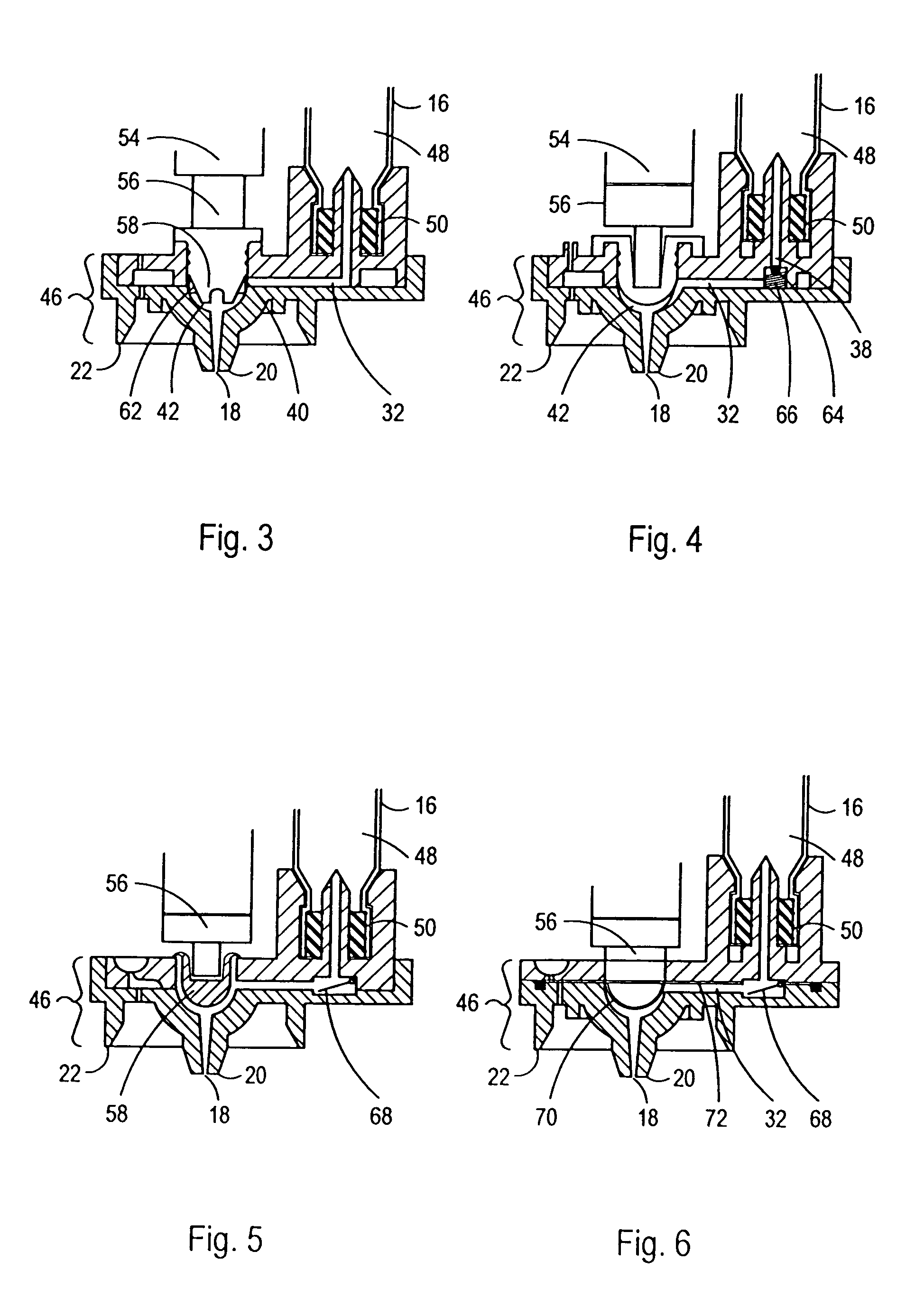

Needle assisted jet injector

InactiveUS7744582B2Prevent re-exposureAmpoule syringesJet injection syringesInjector nozzleJet injection

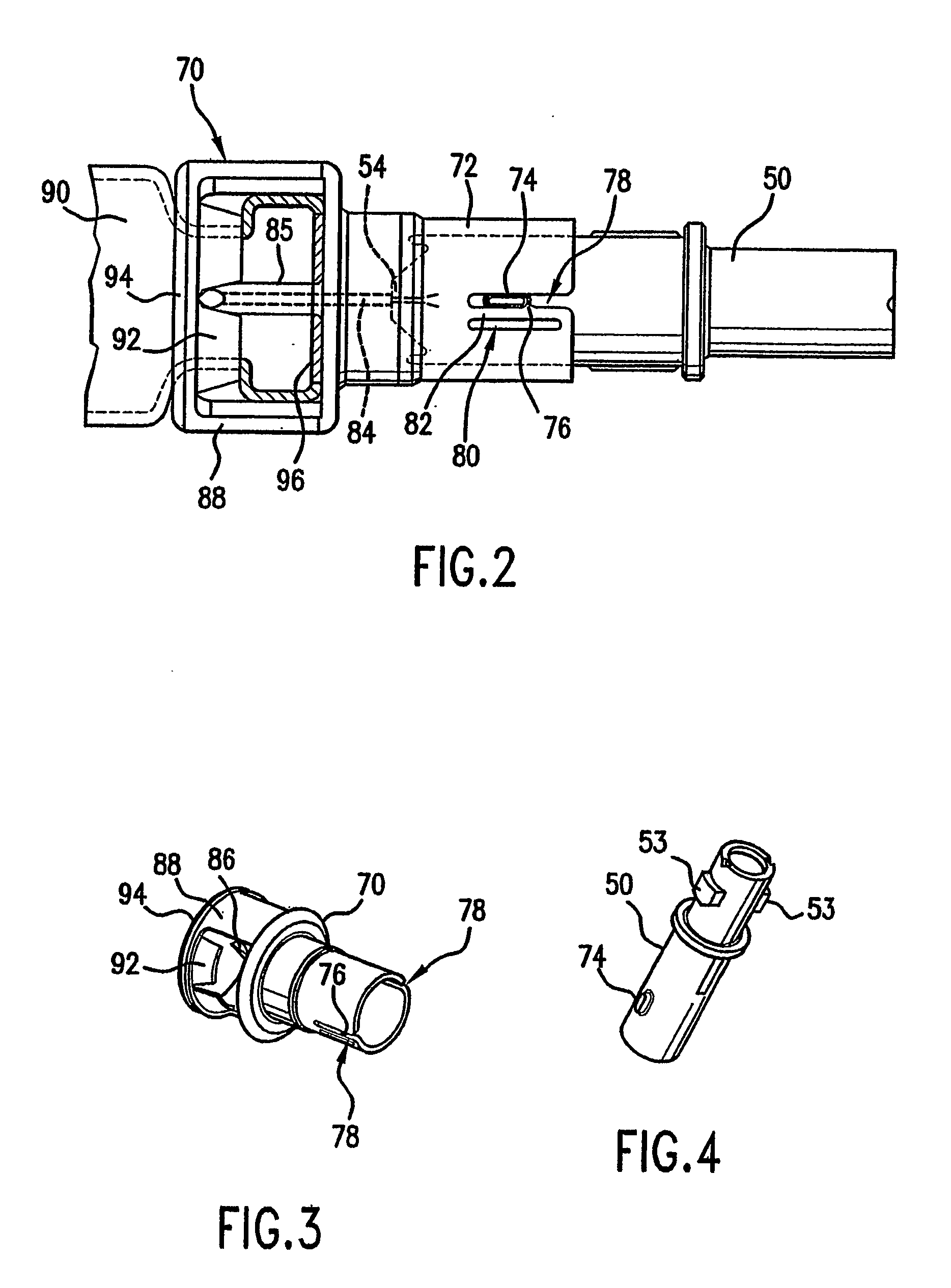

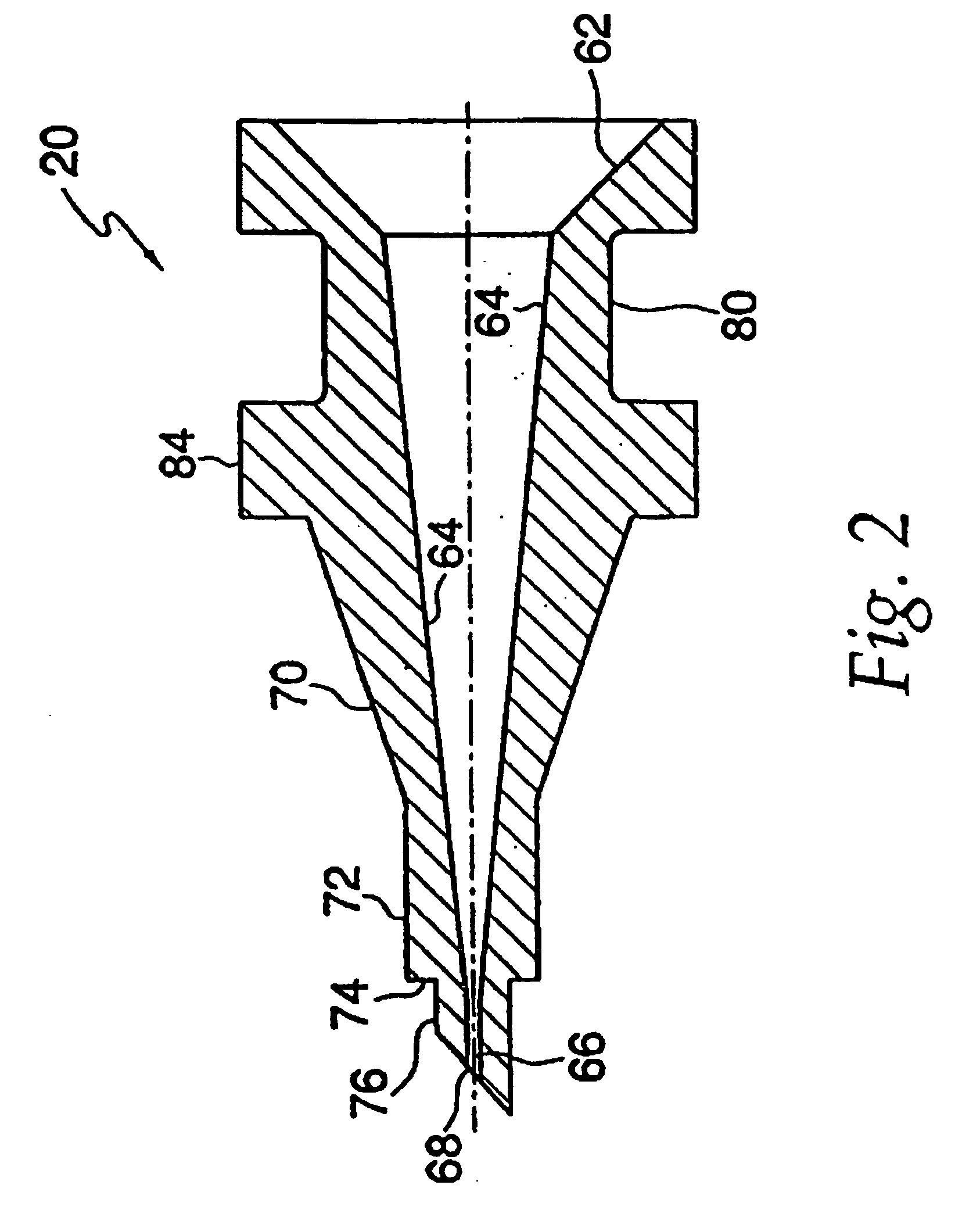

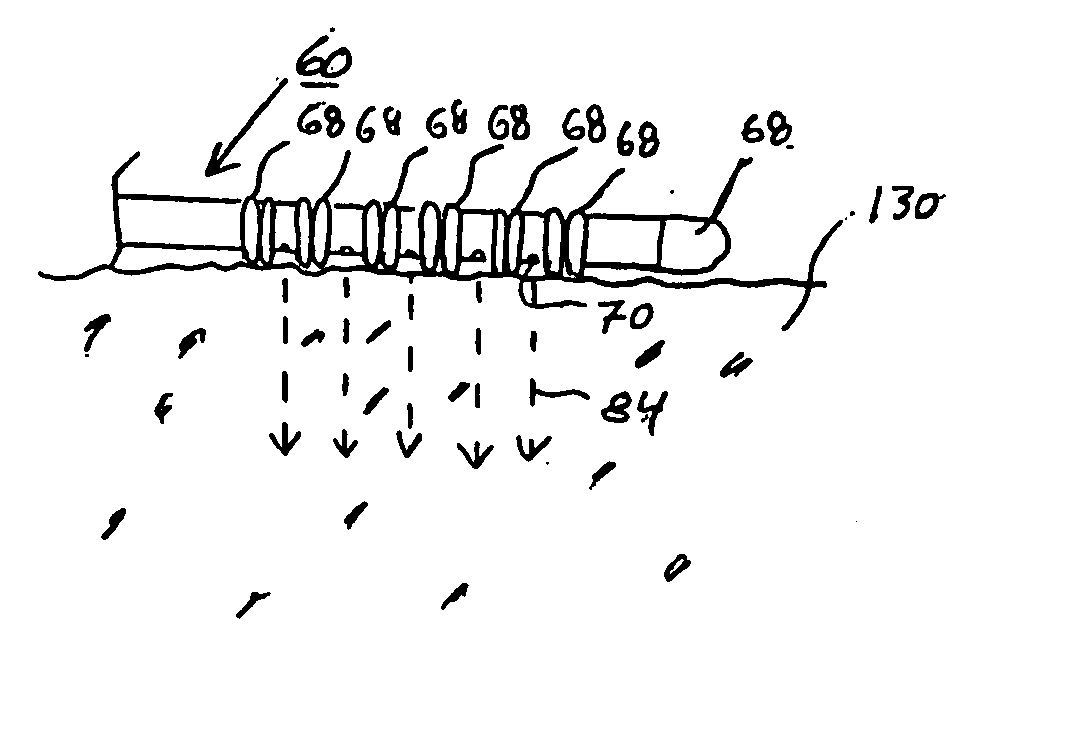

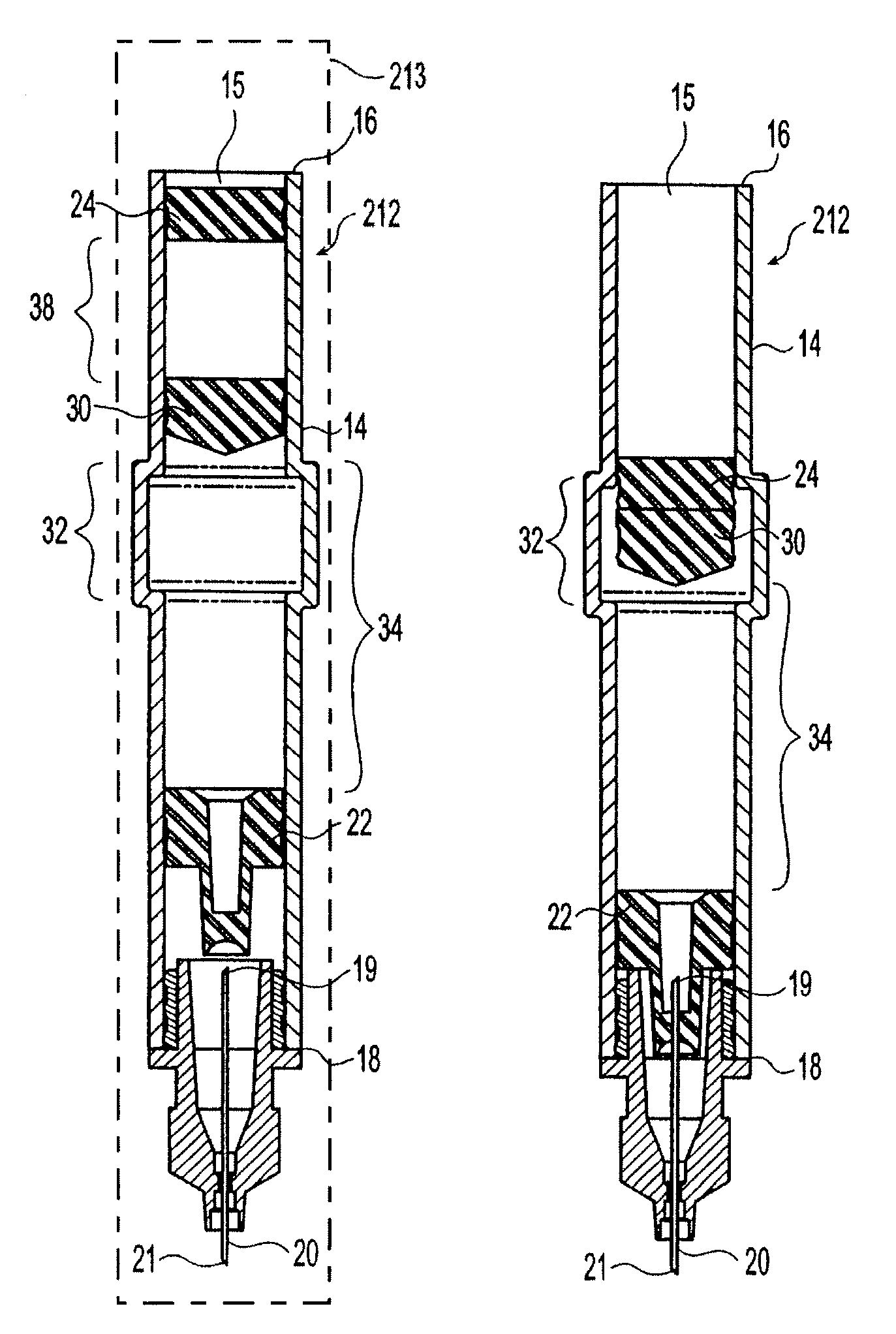

A needle assisted jet injector and method for jet injecting medicament are disclosed. In one embodiment of the injector, the needle is retractably located within an injector nozzle assembly. Upon activation of the force generating source, a portion of the needle extends past the nozzle assembly and penetrates the outer layer of skin to deliver the medicament via jet injection to a deeper region. After activation, the needle retracts back into the nozzle assembly. In another embodiment, the needle is fixed to the end of the nozzle assembly. In both embodiments, the length of the portion of the needle that penetrates the skin is less than 5 mm.

Owner:ANTARES PHARMA INC

Administration of insulin by jet injection

InactiveUS20060106362A1Easily employedHigh level of skillJet injection syringesMetabolism disorderInsulin dependentJet injection

The invention relates to a method for minimizing mean blood glucose levels in an insulin dependent patient by administering insulin to the patient in a sufficiently fast manner to provide a difference of 50% or less between high and low blood glucose levels. Advantageously, the insulin is administered to the patient by jet injection and the high and low blood glucose levels differ by an amount that is less than that which would be obtained after injection of insulin by a conventional needle syringe. The invention also relates to a method for reducing mean blood glucose levels in an insulin dependent patient that is receiving insulin through a conventional syringe and needle arrangement. This method provides for administration of the insulin to the patient by jet injection rather than by the syringe by substituting a jet injector for the syringe.

Owner:ANTARES PHARMA

Needle assisted jet injector

InactiveUS20050080377A1Prevent re-exposureAmpoule syringesJet injection syringesMedication injectionJet injection

Owner:ANTARES PHARMA INC

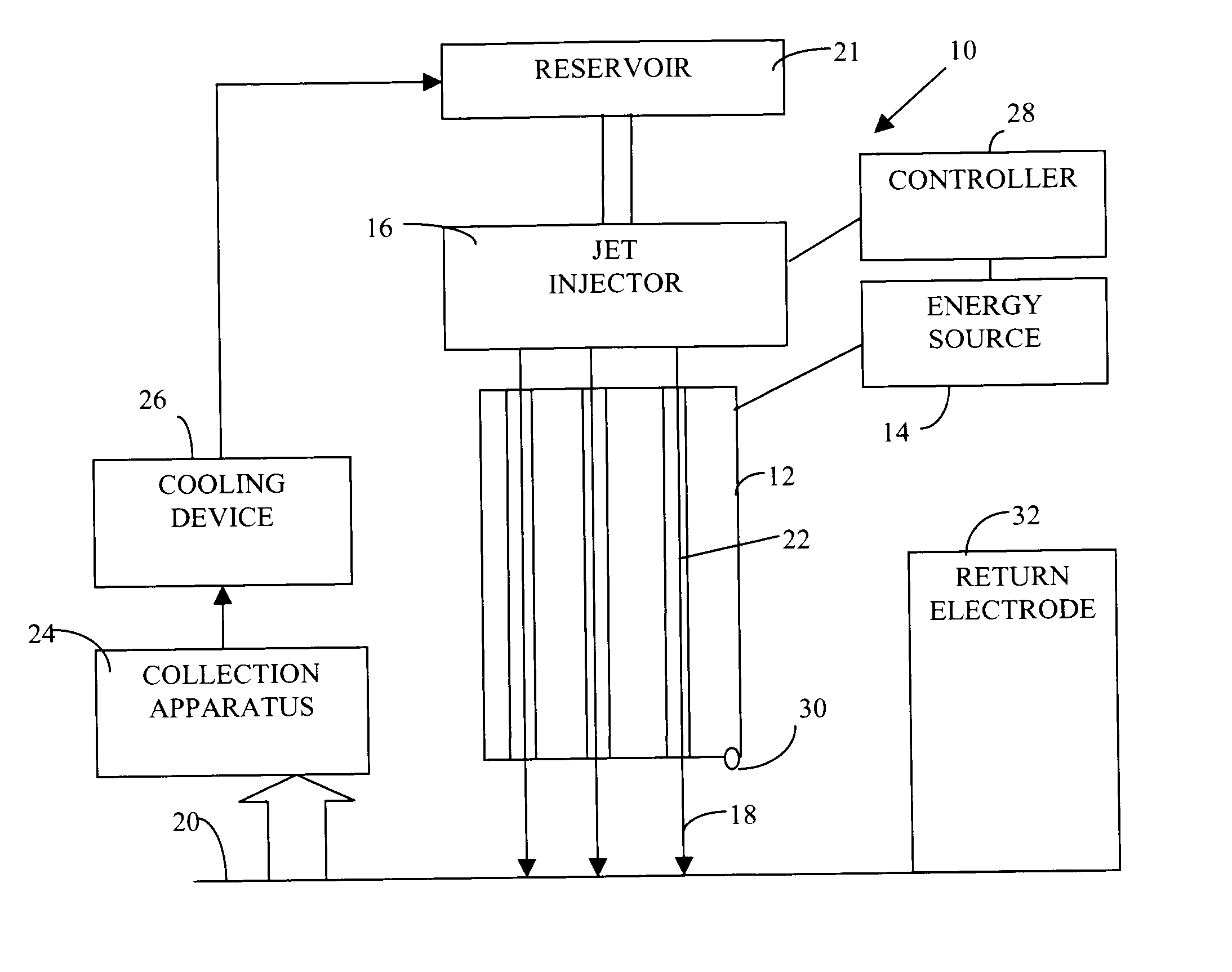

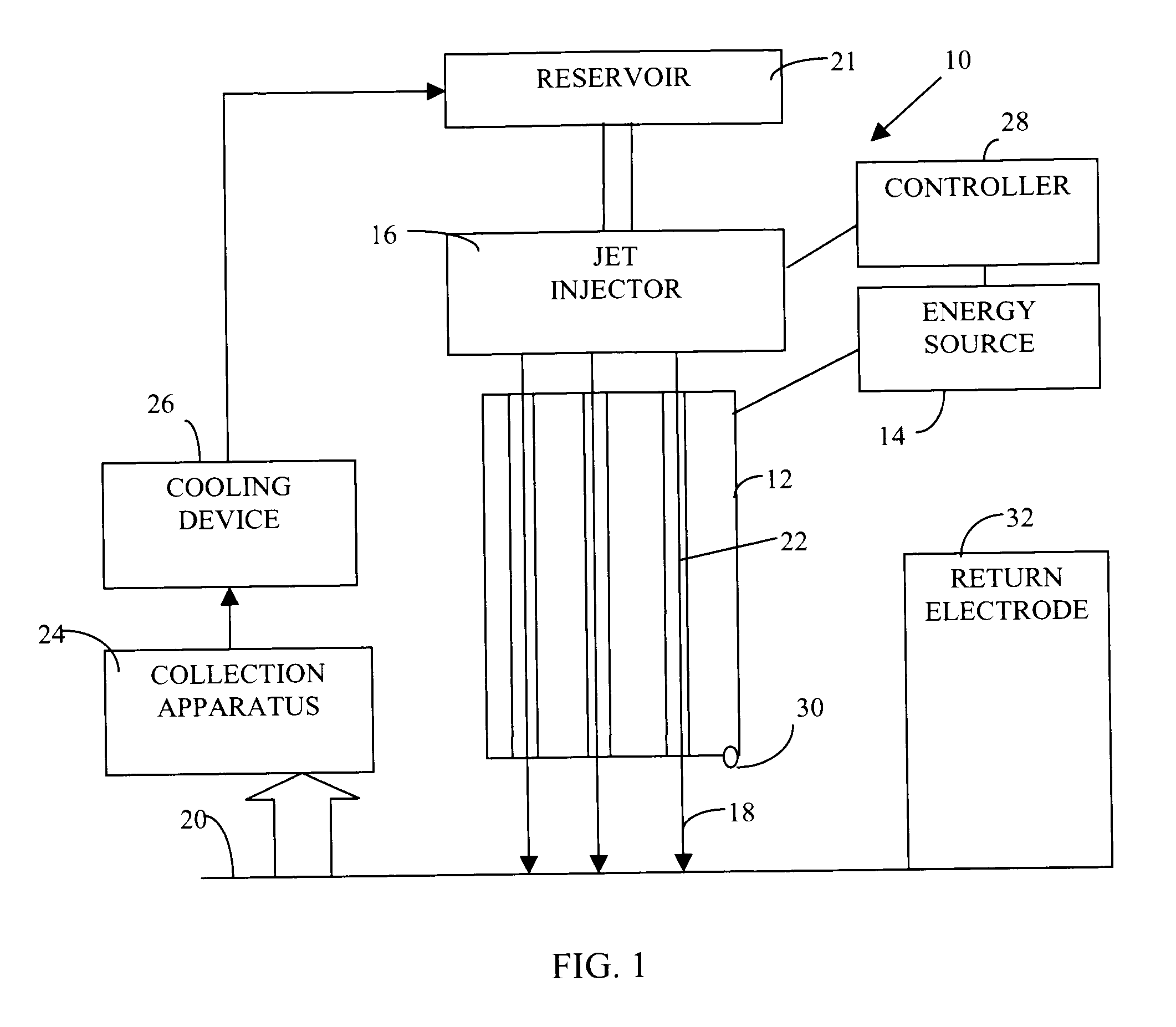

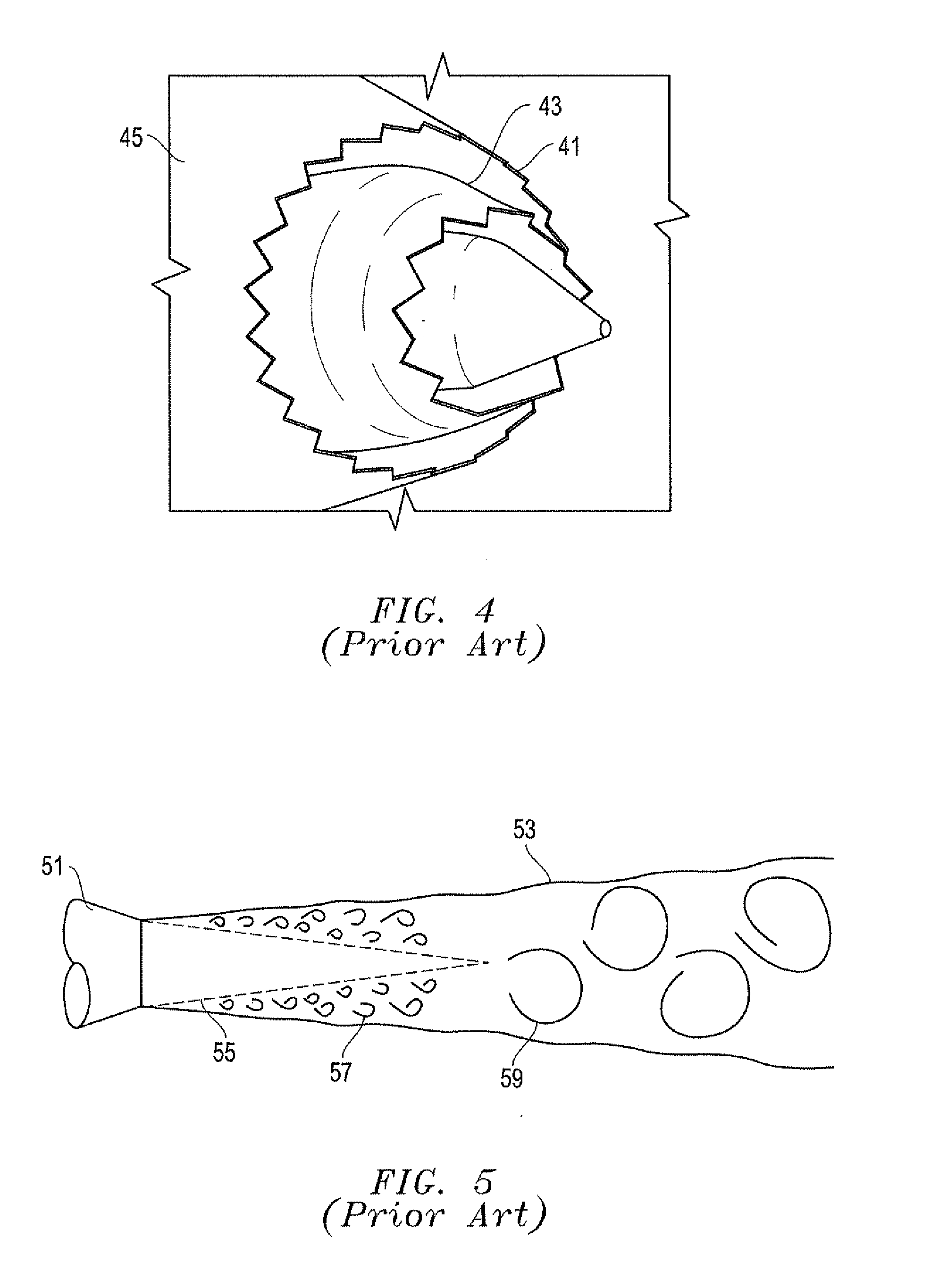

Systems and methods for RF ablation using jet injection of a conductive fluid

InactiveUS20050049583A1Reduce effective resistivityAccurate and deep lesionSurgical instruments for heatingRf ablationInjection site

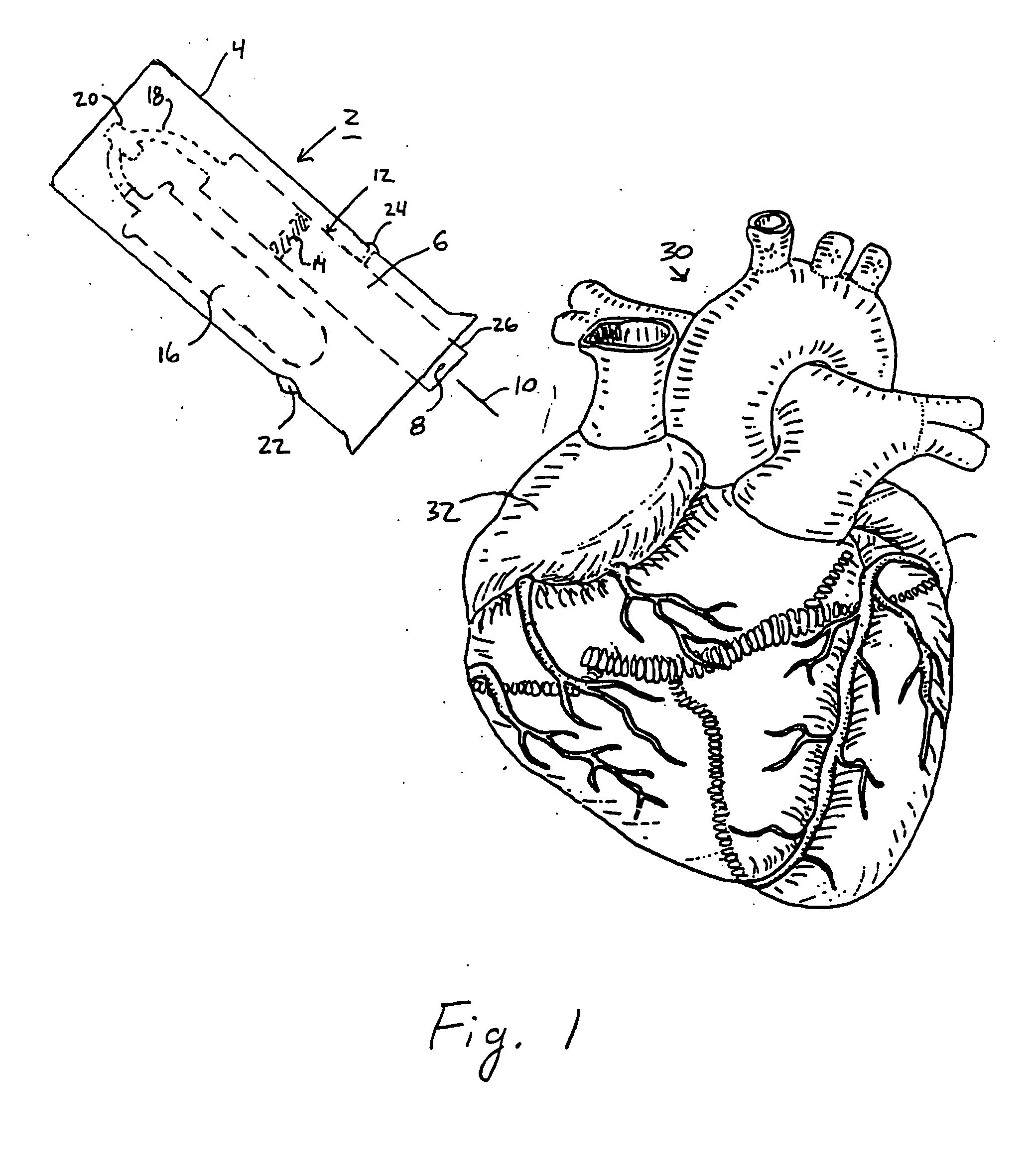

A method of preparing and ablating heart tissue includes a pre-treatment step of delivering a jet of conductive fluid to a portion of heart tissue. The conductive fluid is delivered using an injection device such as a hand-held jet injector, probe, or catheter. After injecting the heart tissue with the conductive fluid, RF energy is delivered to the site of the injection to form a lesion. The method enables a physician to produce large and accurately placed lesions within the treated tissue.

Owner:SCI MED LIFE SYST

Needleless hypodermic jet injector apparatus and method

InactiveUS7347851B1Less painful experienceLess discomfortJet injection syringesAutomatic syringesLiquid jetJet flow

In the present invention, the impedance between patient's body and the jet injection drug delivery device is measured through the liquid jet during the drug delivery process. The liquid jet completes the electrical circuit formed by impedance monitor, drug delivery device, and the patient's body. When the jet pierces stratum corneum, the impedance in the circuit immediately decreases, thus an indicating the successful drug delivery. The impedance monitor then provides a signal, visible, audible, or electronic, indicating that the process of the drug delivery through skin was successful.

Owner:KRIKSUNOV LEO B

Prefilled syringe jet injector

ActiveUS20120004608A1Prevent backflowImprove distributionAmpoule syringesJet injection syringesEngineeringPrefilled Syringe

Owner:ANTARES PHARMA INC

Medicament cartridge and injection device

InactiveUS7503907B1Easy to punctureMinimized volumeAmpoule syringesInfusion needlesJet injectorBiomedical engineering

The present invention discloses a medicament cartridge for an injection device, such as a syringe or a jet injector. The medicament cartridge according to the present invention includes a tube having a lumen, a needle operatively associated with an end of the tube and having a piercing end extending into the lumen, a second stopper located within the lumen near the other end of the tube and moveable within the lumen, and a first stopper located within the lumen, covering the piercing end of the needle, and moveable within the lumen. Firing the injection device to commence an injection may move the second stopper toward the needle, which compresses medicament located in the lumen between the first stopper and the second stopper. The compression of the medicament moves the first stopper into contact with the piercing end of the needle so that the piercing end pierces the first stopper to thereby create a fluid pathway for the medicament through the needle. Other methods of piercing the first stopper are anticipated as a means of activating the injection device. The disclosed medicament cartridge can be safely and aseptically manufactured and filled during assembly and, once manufactured and filled, eliminates contact between the medicament and the needle during storage.

Owner:ANTARES PHARMA

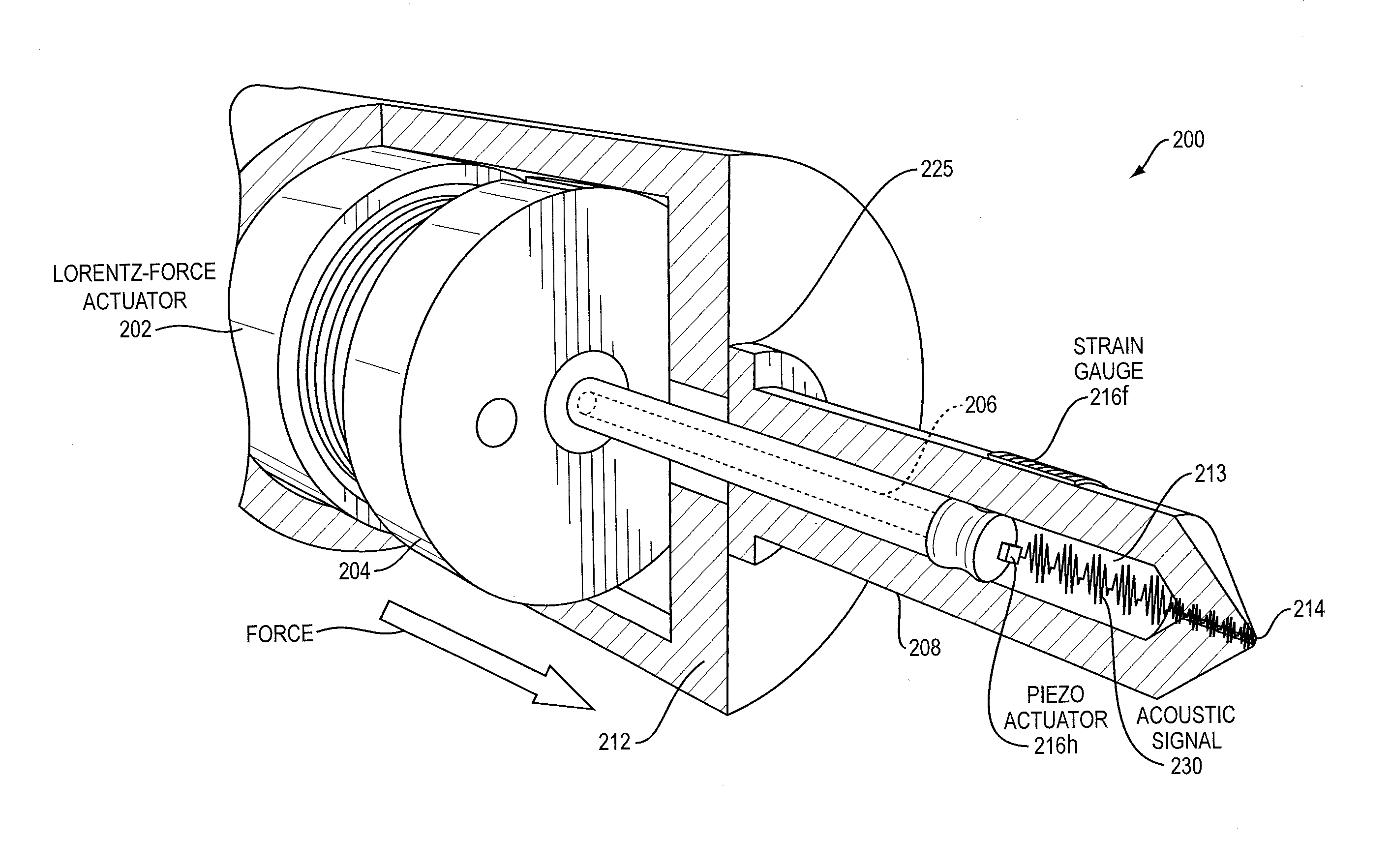

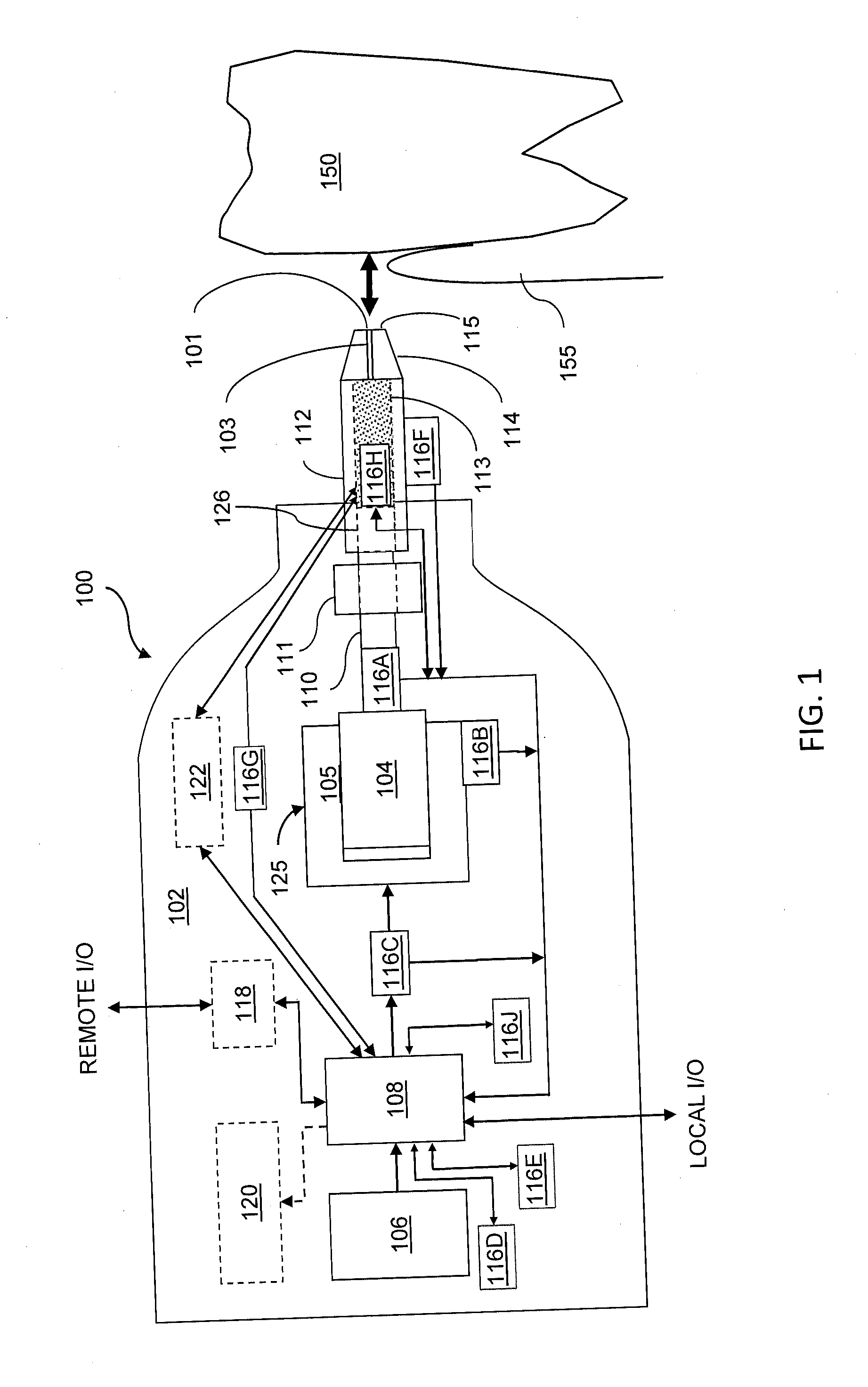

Jet Injector Use In Oral Evaluation

A tooth treatment device includes a detector that detects a marker of oral health and a fluid ejector that ejects fluid against teeth in response to the detected marker. The device can include a housing configured to be held on hand, the fluid ejector being positioned at an end of the housing. The fluid may include a liquid, a medicant, a cleansing solution, cleaning particles, or any combination thereof. The medicant can include any combination of a chelating agent, fluoride, a fluorescent dye, a bacterial specific probe, and a biochemical specific biomarker. Further, the device can include a servo controller controlling pressure of ejected fluid in response to the detected marker and a sensed surface condition, latter including for example, a mechanical property of tissue. The device may include a pressure sensor that senses pressure of the fluid in the ejector. Also included may be a distance sensor that senses distance of the ejector from a tissue surface. The surface condition may be sensed using the sensed pressure, sensed distance, or any combination thereof. In some embodiments, the fluid ejector comprises a stationary magnet assembly providing a magnetic field and a coil assembly, slidably disposed with respect to the magnet assembly, the coil assembly driving ejection of the fluid jet. A method of tooth treatment includes detecting a marker of oral health and controlling ejection of a fluid jet against the tooth responsive to the detected marker. In some embodiments, detecting the marker includes detecting plaque and the ejection is controlled to clean the plaque. Detecting the marker can include collecting a sample from an oral cavity.

Owner:MASSACHUSETTS INST OF TECH

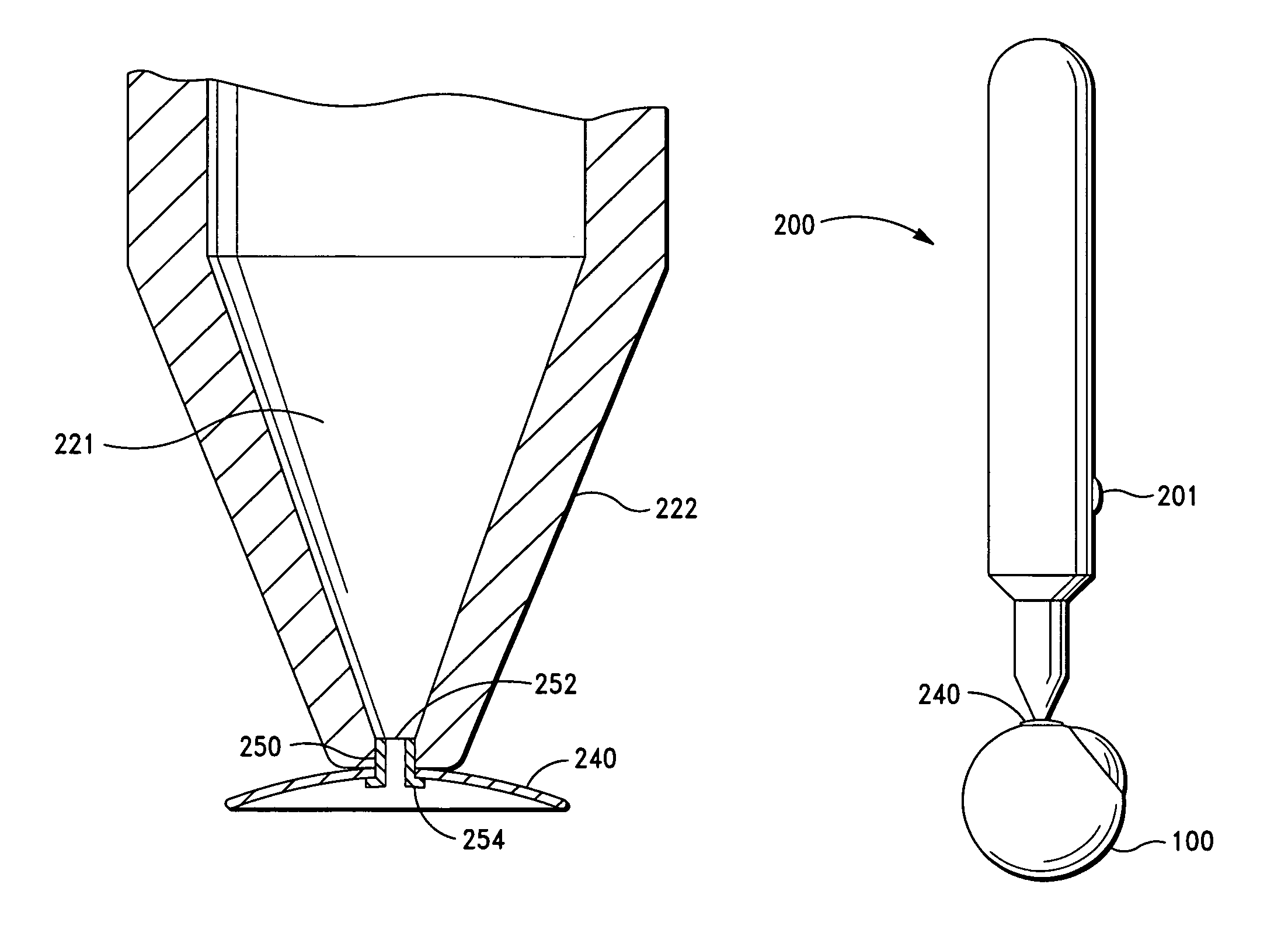

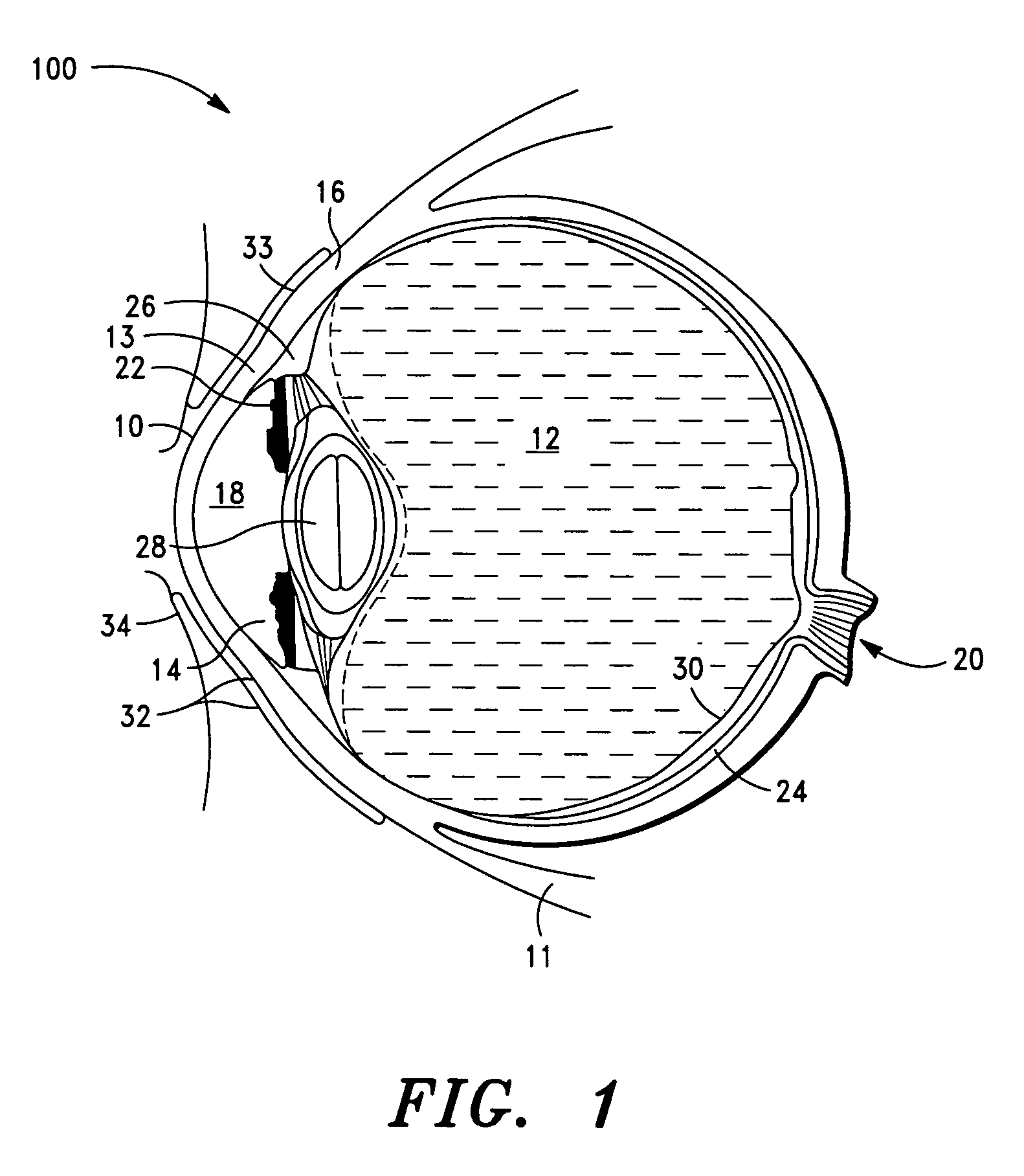

Subconjunctival agent delivery apparatus, system and method

A subconjunctival injection apparatus for administering a pharmacological agent formulation to a subconjunctival compartment of an eye, the apparatus including a jet injector having force generating means that is adapted to generate sufficient force to expel the pharmacological agent formulation from the jet injector and through the conjunctiva. In one embodiment of the invention, the jet injector comprises a needleless jet injector. In one embodiment, the needleless jet injector provides a delivery pressure in the range of approximately 100-1000 psi.

Owner:KMG PHARMA

Tissue ablation with jet injection of conductive fluid

InactiveUS20060271033A1Fluid jet surgical cuttersSurgical instruments for heatingJet injectionSkin surface

Ablation apparatus including an active electrode in electrical communication with an energy source, and a jet injector capable of propelling an electrically conducting fluid to a skin surface, the jet injector being positioned relative to the active electrode such that the electrically conducting fluid is in electrical communication with the active electrode.

Owner:EIN GAL MOXHE

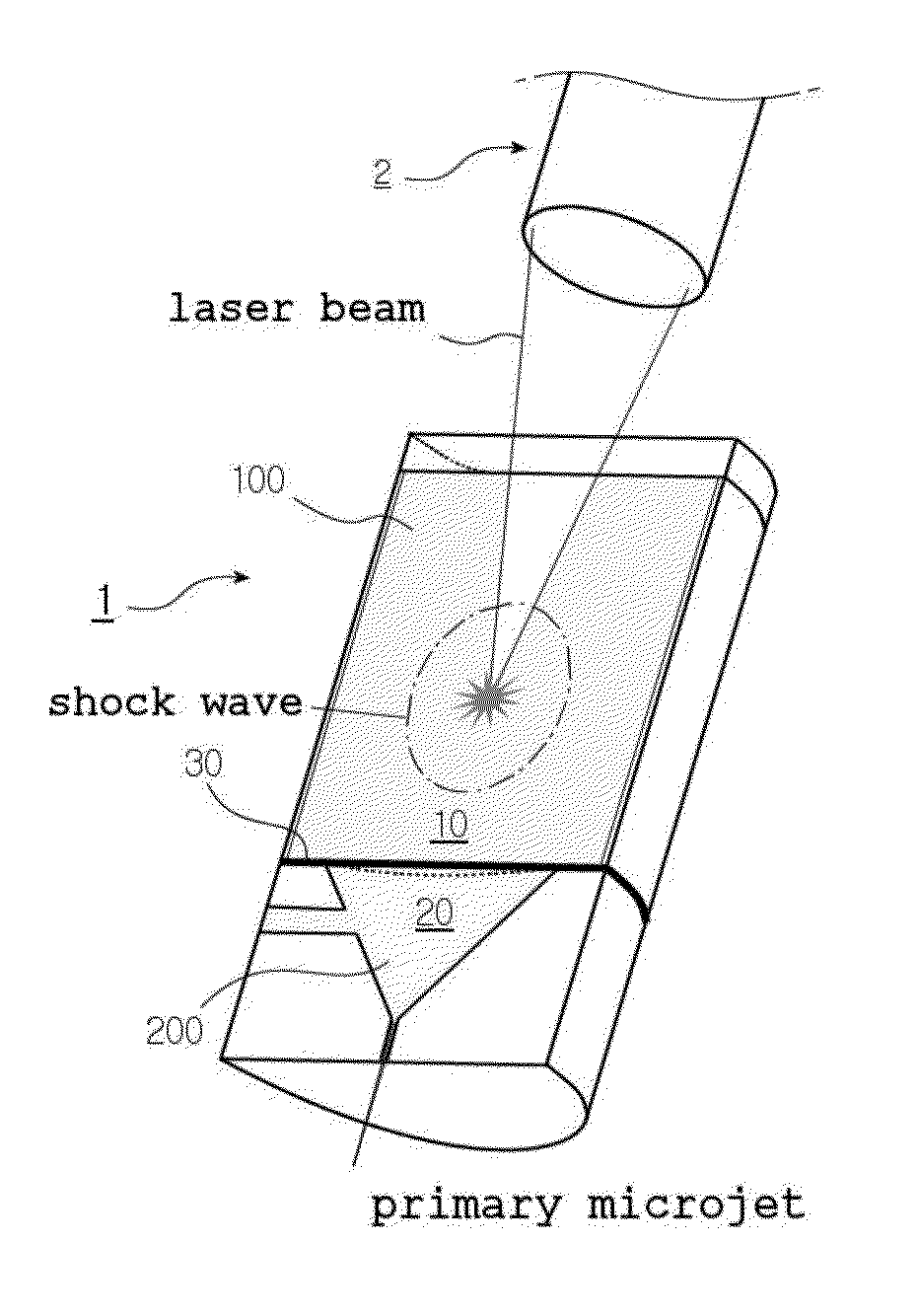

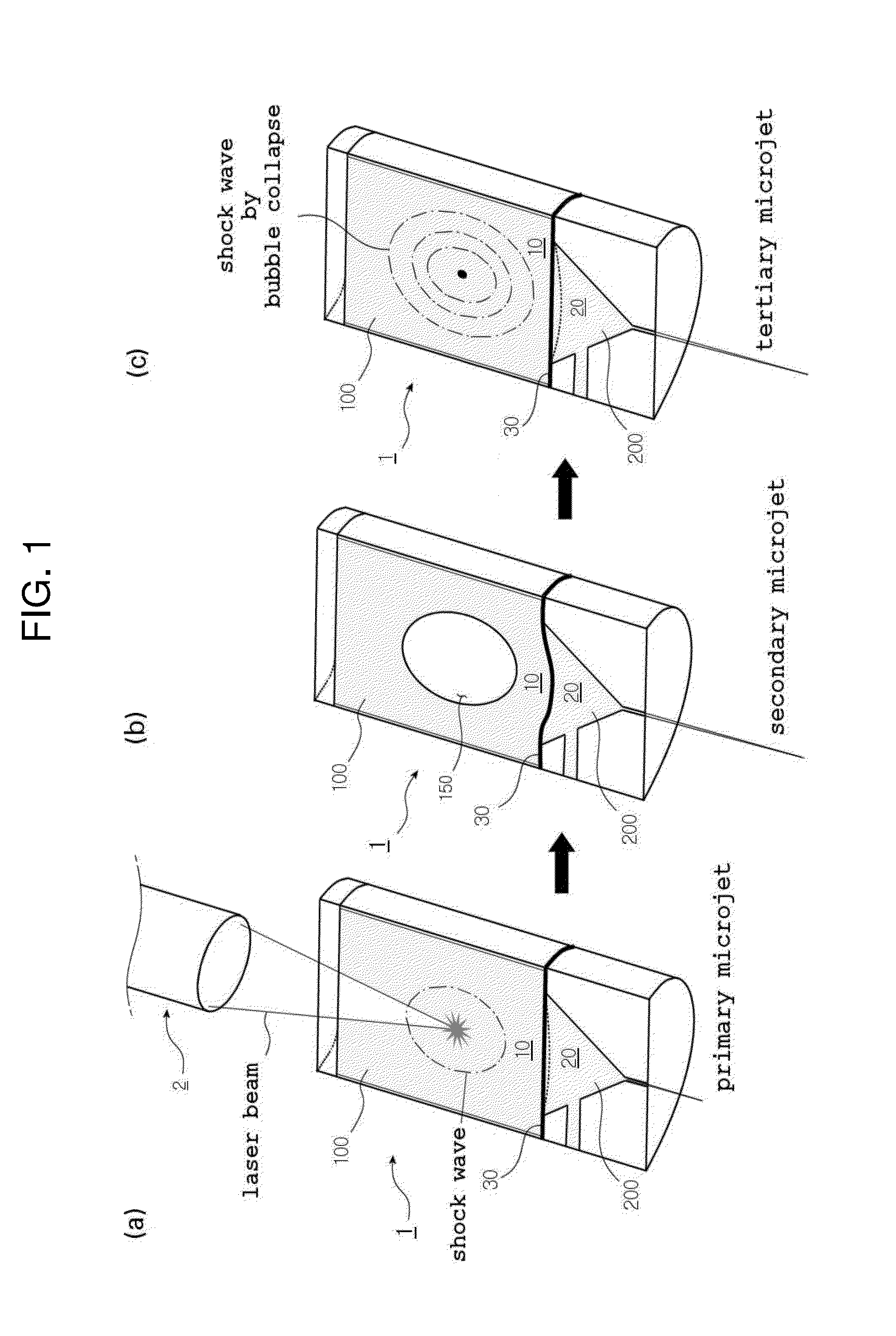

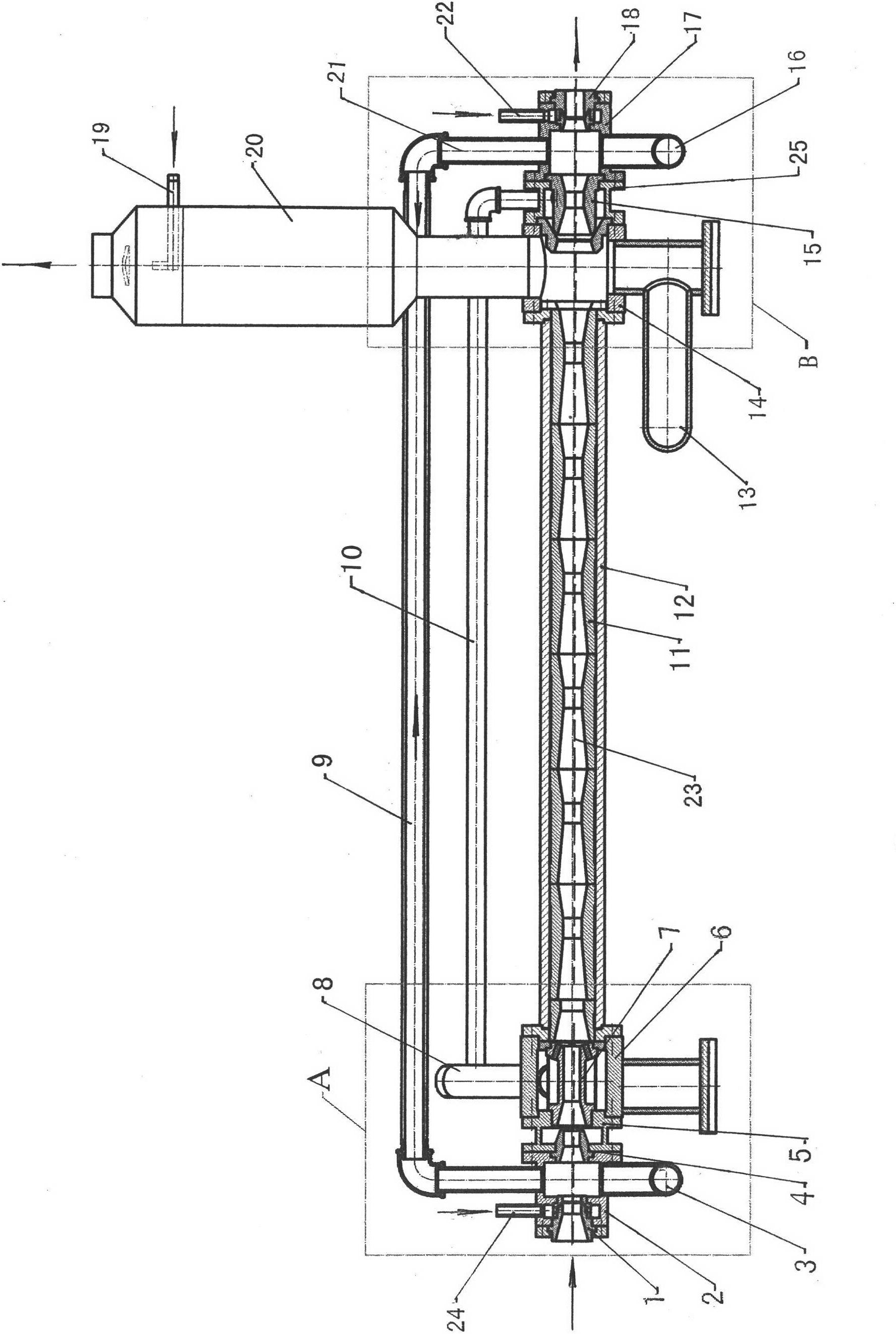

Microjet drug delivery system and microjet injector

InactiveUS20130066263A1Easy to installCompact structureJet injection syringesSurgical instrument detailsInterior spaceDrugs solution

The present invention relates to a microjet drug delivery system for microjet spraying a drug solution stored inside to inject the same into the bodily tissue of a person to be operated, and a microjet injector. The microjet injector comprises: a pressure chamber completely filled with the liquid for propelling pressure, having an accommodation space with one side opened; an elastic film, which is a film member made of an elastic material, arranged so as to form a closed space by closing the opened one side of the pressure chamber; a drug chamber for accommodating a drug solution in a predetermined inner space, provided adjacent to the pressure chamber with interposing the elastic film therebetween; and a microjet nozzle communicating with the inner space of the pressure chamber so as to be formed as a channel for allowing the drug solution stored inside the pressure chamber to be microjet sprayed to the outside. The microjet drug delivery system provided by the present invention comprises: the microjet injector; an energy focusing device for generating bubbles in the liquid for propelling pressure stored in the pressure chamber by applying a concentrated energy to the liquid for propelling pressure; and a connecting adaptor for selectively detachably coupling the microjet injector to the energy focusing device.

Owner:SEOUL NAT UNIV R&DB FOUND

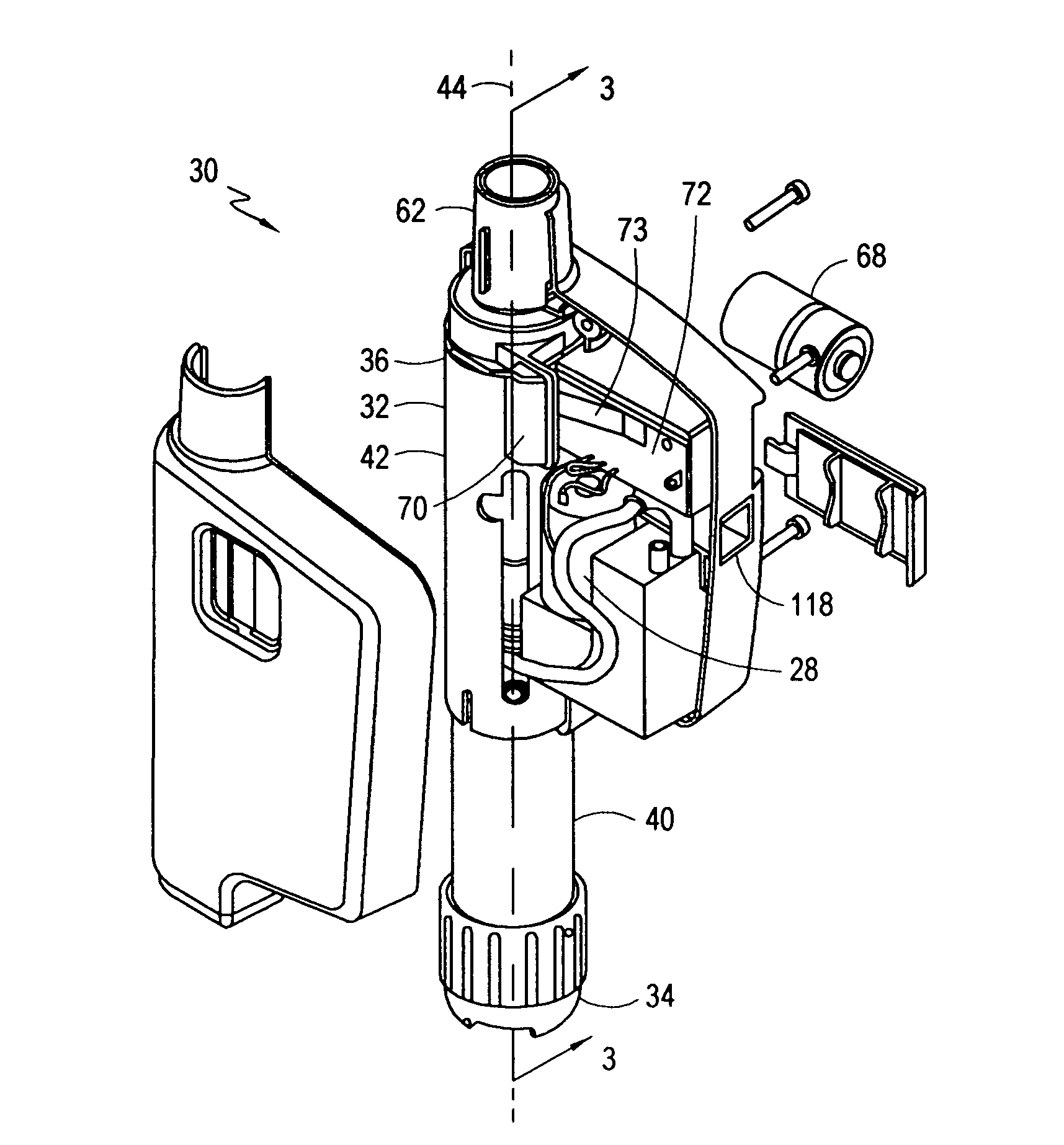

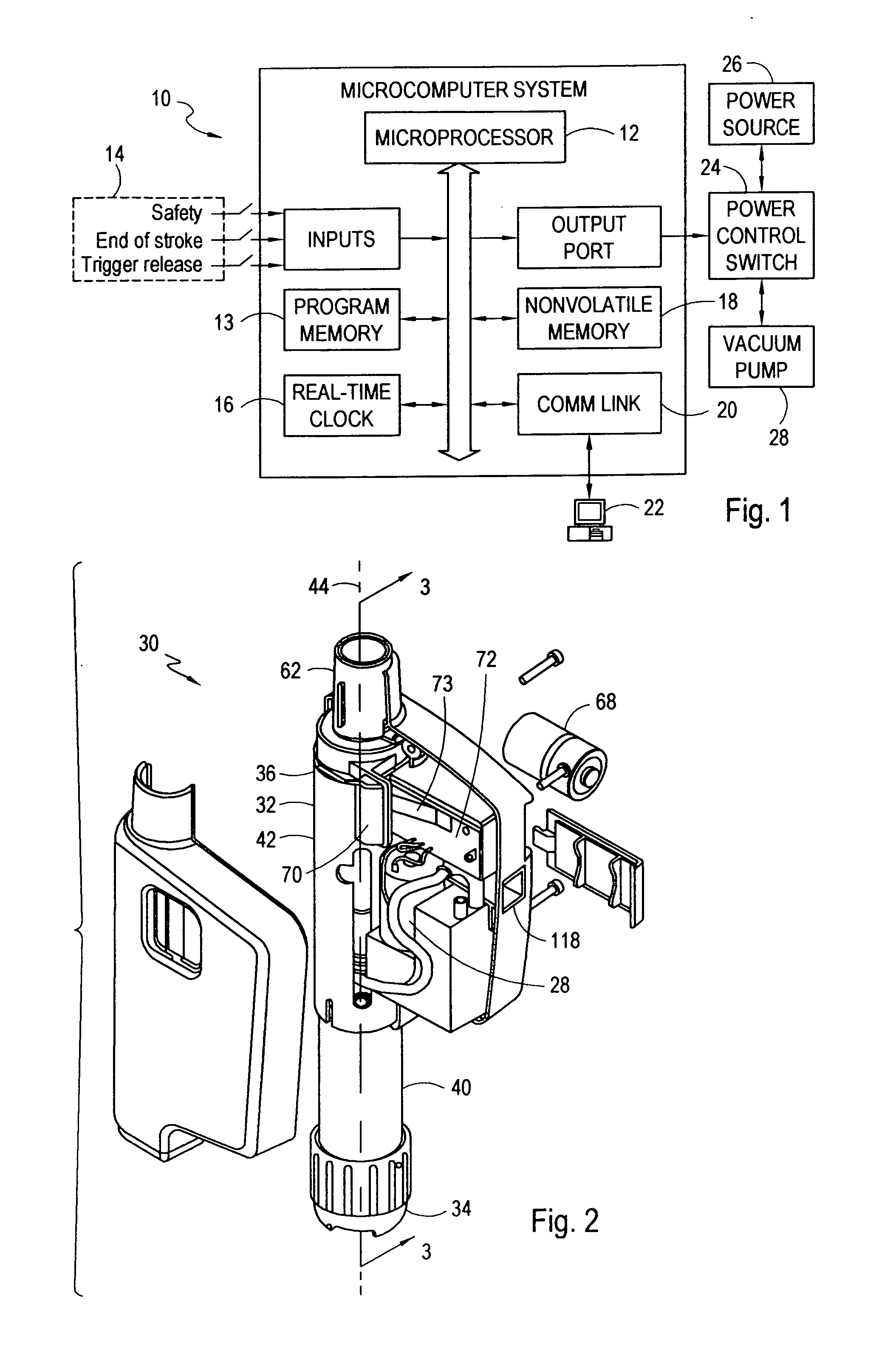

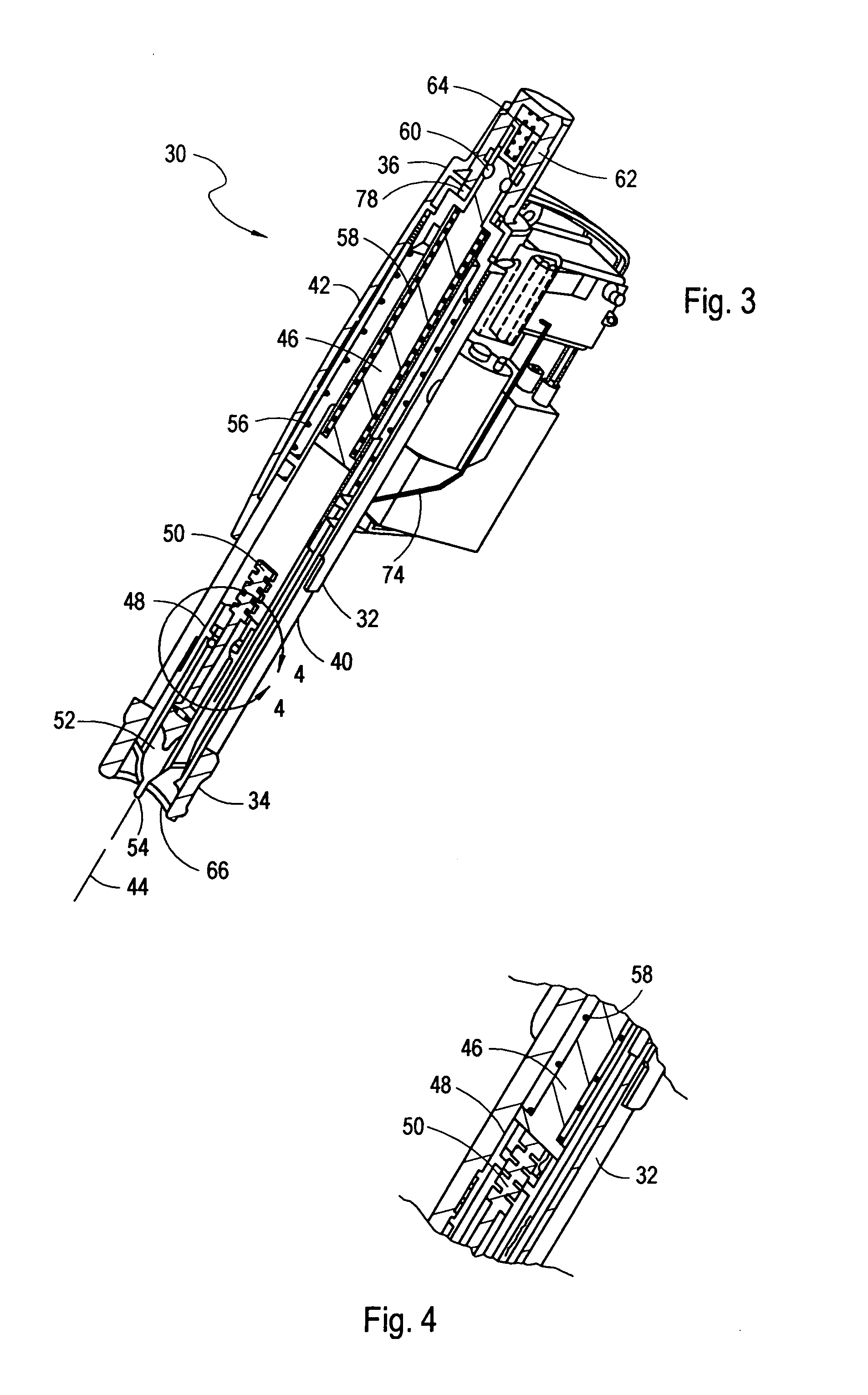

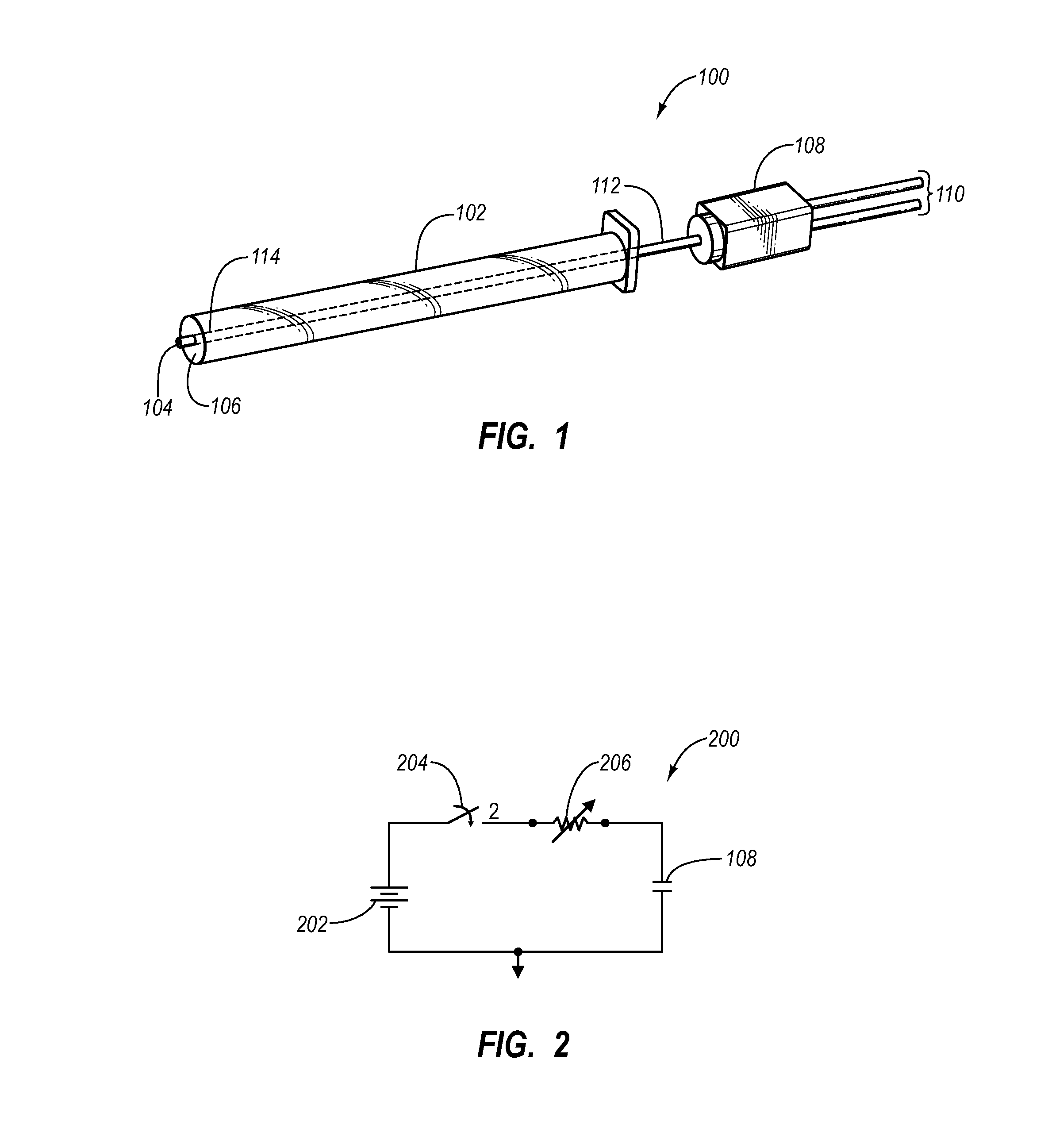

Jet injector with data logging system for use in compliance and dose monitoring programs

An integral data logging system for a jet injector includes at least one electrical switch that changes state (e.g. from OFF to ON) during an injection procedure. The switch(es) are connected to an electrical circuit having a microprocessor, a clock and an electronic memory. When a switch changes state, this information along with the applicable date and time is recorded in the electronic memory. A communications link is provided to upload the stored data to a remote computer for subsequent manipulation and analysis to determine compliance with a prescribed dosing regimen. In one implementation, the injection duration is logged by using a trigger release switch and an end-of-stroke switch. The end-of-stroke switch is configured to change state after the drive bar of the injector transits through the injector tube. The injection duration is indicative of dose amount and can be used to distinguish between valid and invalid injections.

Owner:NOVO NORDISK AS

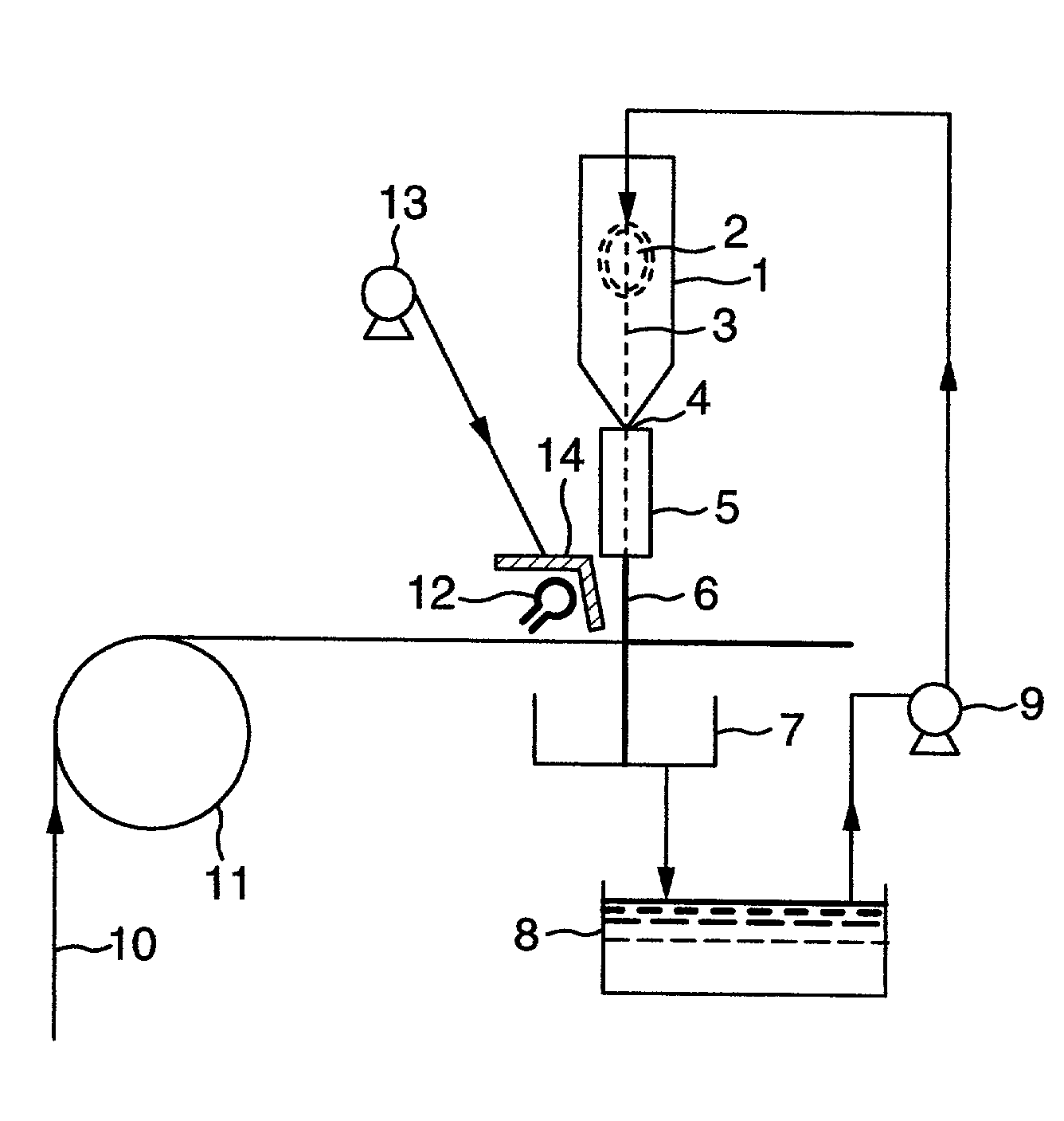

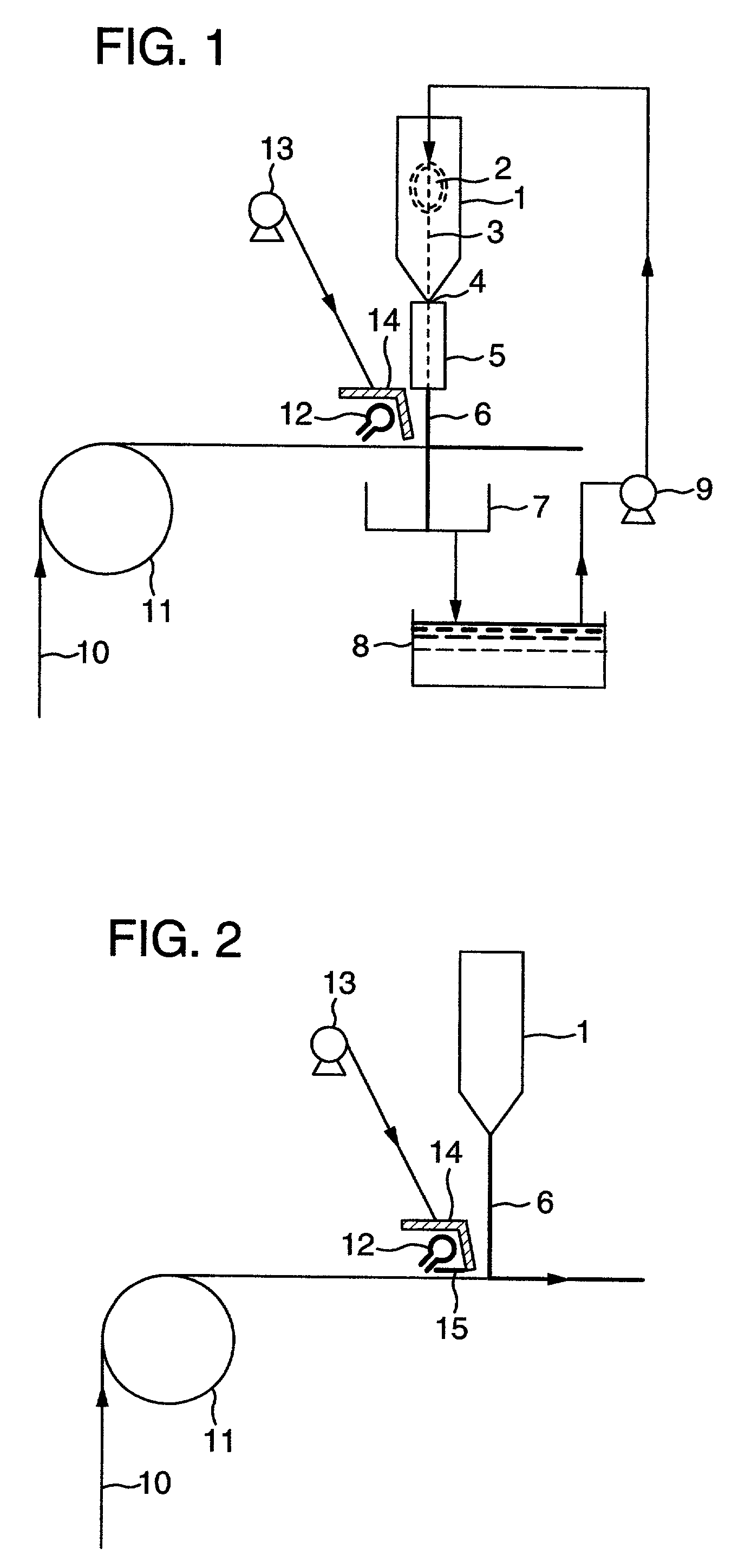

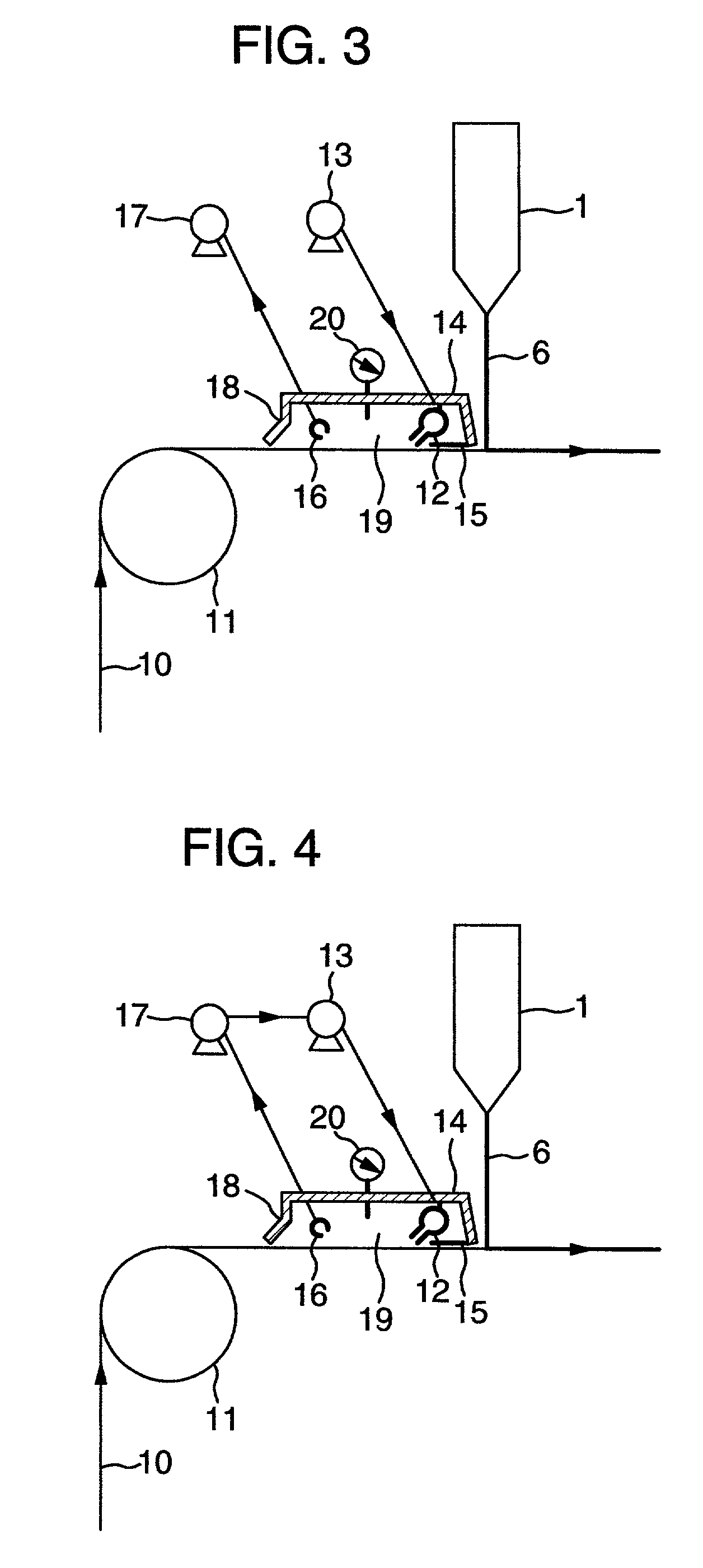

Curtain coating apparatus and curtain coating process

A curtain coating apparatus for applying a coating solution to a continuously moving web, which comprises an air jet injector for injecting air in the upstream direction of a web, provided at a position upstream of a contact point of a curtain film with the web and a shielding member shutting off entrained air generated by movement of the web, provided between the contact point and the air jet injector, thereby diminating an influence of turbulent air flow and preventing the curtain film from suction toward the air jet injector, or which further comprises a control member connected to the shielding member, the control member being provided at a position near and in parallel to the web, or which further comprises a control member and a partition wall member, both being integrated with the shielding member to form a closed space, the air jet injector and an air suction means being provided in the closed space, thereby making the closed space a subatmospheric pressure zone, can produce coated products of good quality by eliminating entrained air around a web at a high speed coating to stabilize the curtain film.

Owner:MITSUBISHI PAPER MILLS LTD

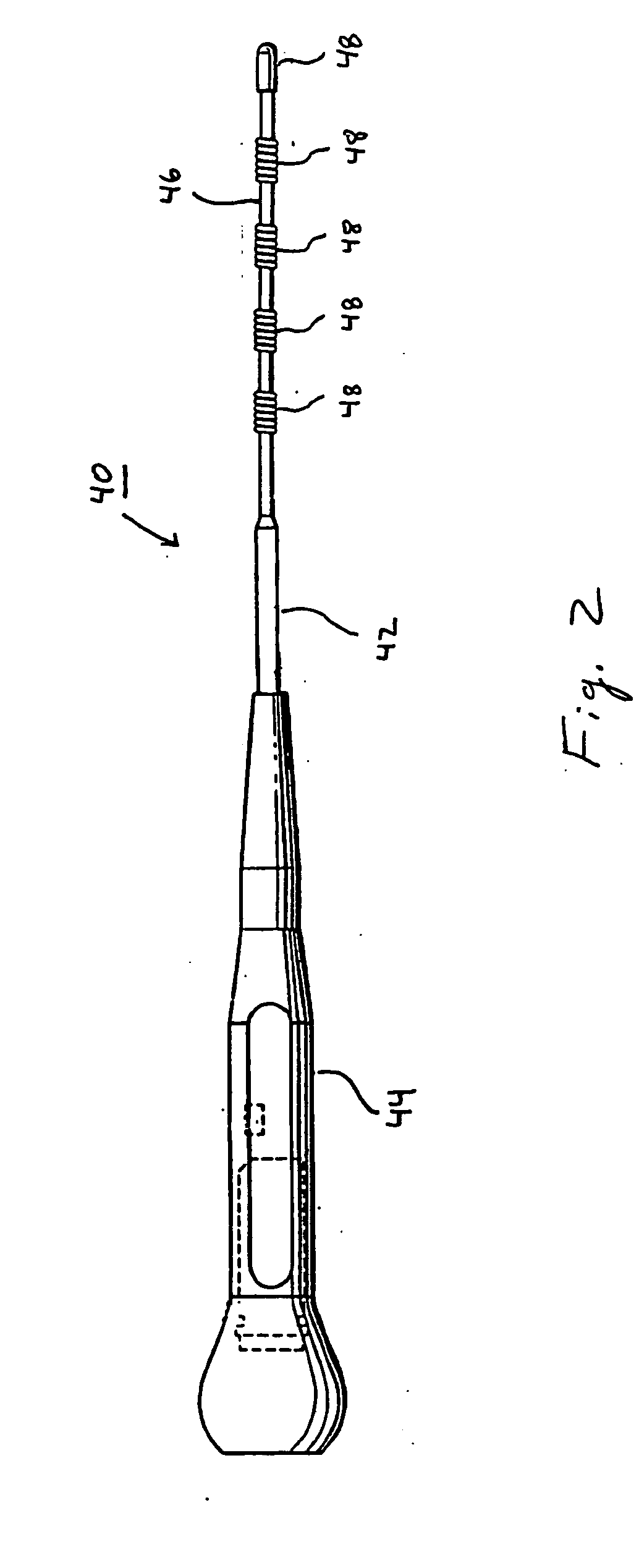

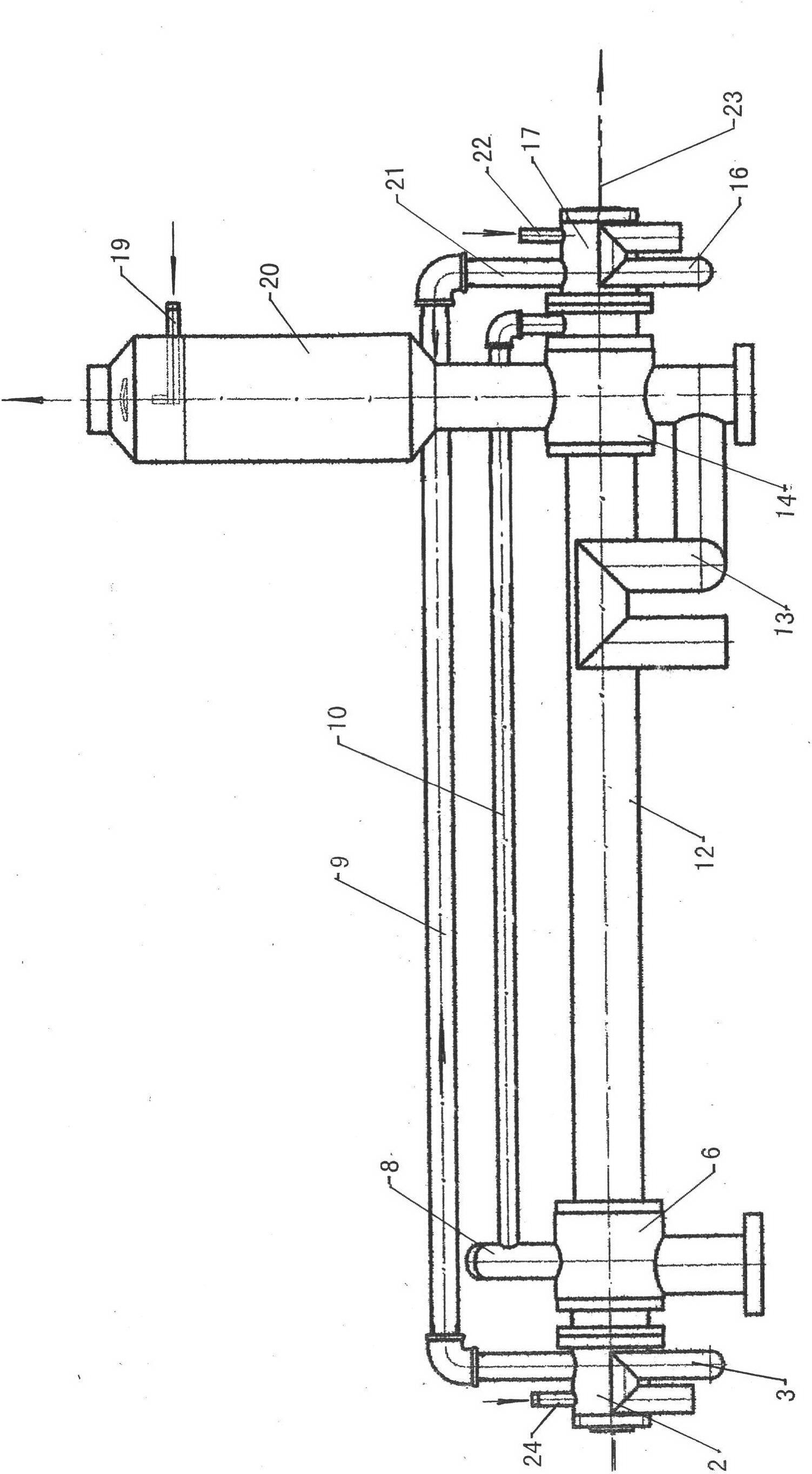

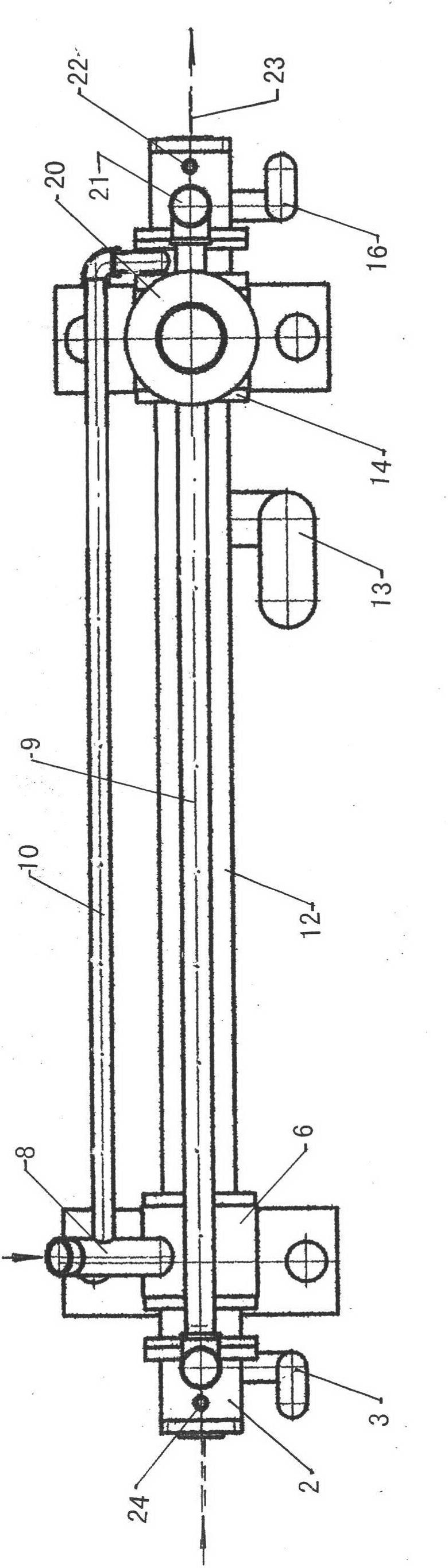

Jet injector with hand piece

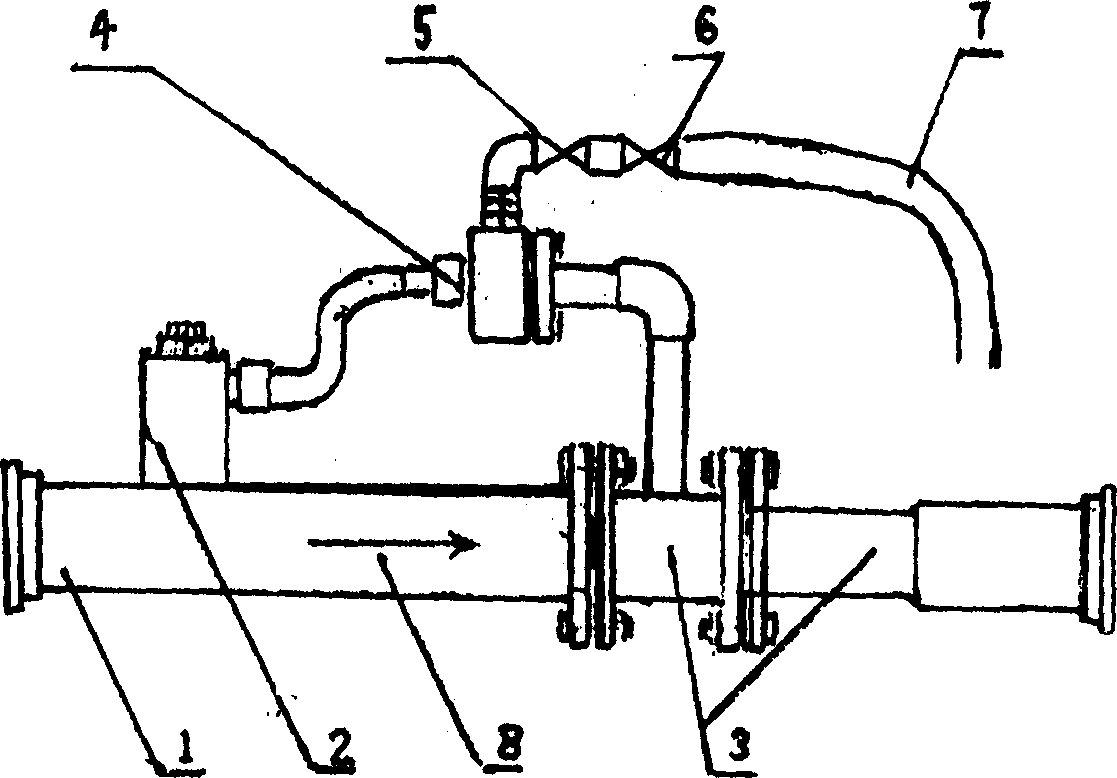

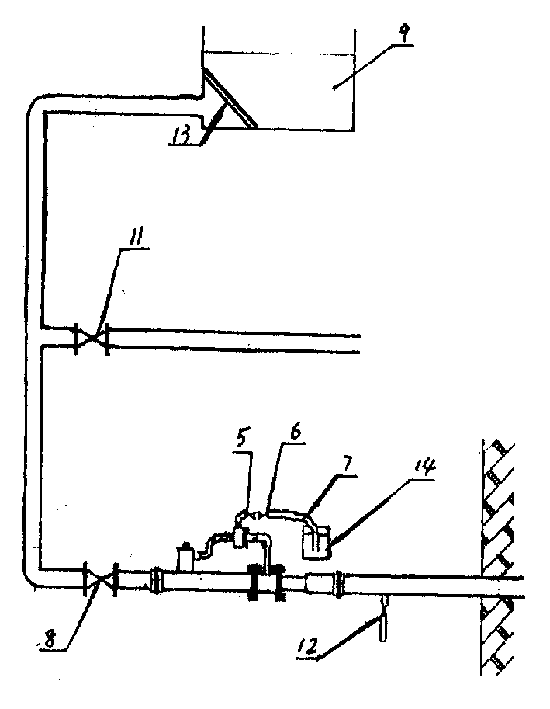

InactiveUS7029457B2Avoid less flexibilityEasy to controlJet injection syringesAutomatic syringesEngineeringHigh pressure

The present invention relates to a jet injector system with a hand piece. The present invention generally comprises a power unit, a medicine unit, an energy unit, a supply bottle, and a hand piece. The hand piece and power unit may be separate components connected to each other by a high pressure hose, which gives the user more flexibility. A valve assembly having a ball lock assembly and a needle assembly controls the release of medication from the high pressure hose into the hand piece and out a nozzle into the subject.

Owner:PULSE NEEDLEFREE SYST

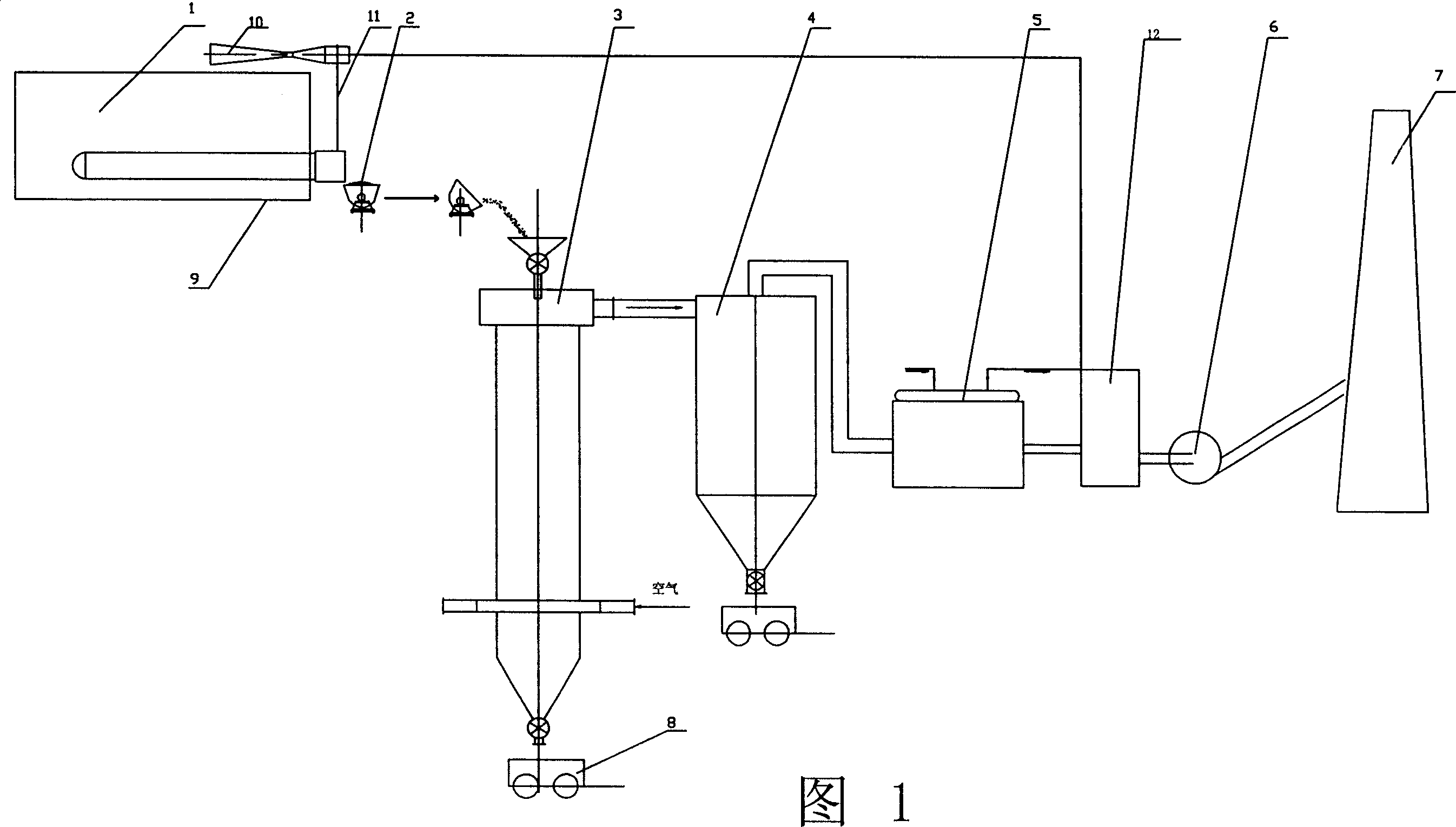

System for vacuum pumping by steam produed by reduction dregs afterheat

InactiveCN1912519AUnique structureReasonable structureJet pumpsIncreasing energy efficiencyVacuum pumpingSlag

A system using residual heat of reduced slag to create vacuum comprises reduction furnace, fluidized bed, dust remover, residual heat boiler, draught fan and chimney. It is featured as setting jet injector being connected to air outlet of residual heat boiler on top of reduction furnace, utilizing residual heat generated by Mg reduced slag to produce steam through said system fir making reduction furnace be vacuumed.

Owner:宁夏华源冶金实业有限公司

Steam-free passing water cooler

ActiveCN102671977AEnsure personal safetyImprove on-site operating conditionsWork treatment devicesMetal rolling arrangementsEngineeringJet injector

The invention discloses a steam-free passing water cooler. Two heads of a venture sleeved in an outer sleeve pipe are communicated with cooling water nozzles and the inner chamber of a main steam / water separation box, two ends of a center hole of a front steam / water separation box are respectively provided with a positive puffing split-jet injector and a transition catheter, two head of a front air / water delivery pipe are respectively communicated with the front steam / water separation box and the inner chamber of a steam condenser, a backwater balance box is sleeved with a nozzle box, and the plurality of cooling water nozzles are arranged on the nozzle box. The upper side wall of the main steam / water separation box is provided with the steam condenser, the cooling water nozzles are communicated with the inner chamber of the steam condenser, a main drainage pipeline is communicated with the lower side of the main steam / water separation box, a negative puffing water ring split-jet injector extends into the inner chamber of the main steam / water separation box, a negative puffing water pipe on a negative puffing water box is communicated with a cooling water inlet pipe, a back air / steam delivery pipe on a back steam / water separation box communicated with the negative puffing water box is communicated with the steam condenser, and a negative puffing split-jet injector is sleeved at the center of the back steam / water separation box. The condensed steam can be collected, and the service life of equipment can be prolonged.

Owner:湖南天益高技术材料制造有限公司

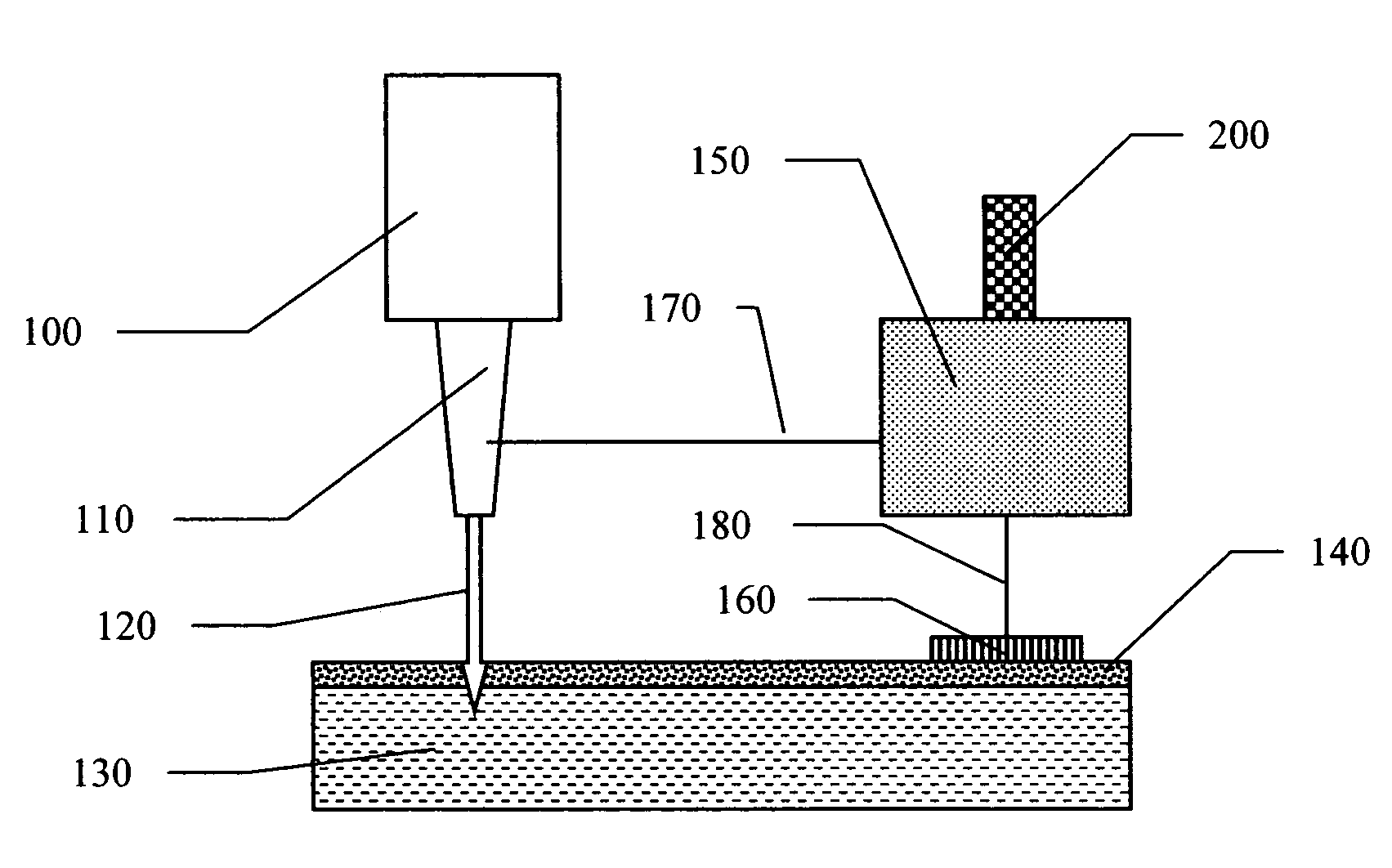

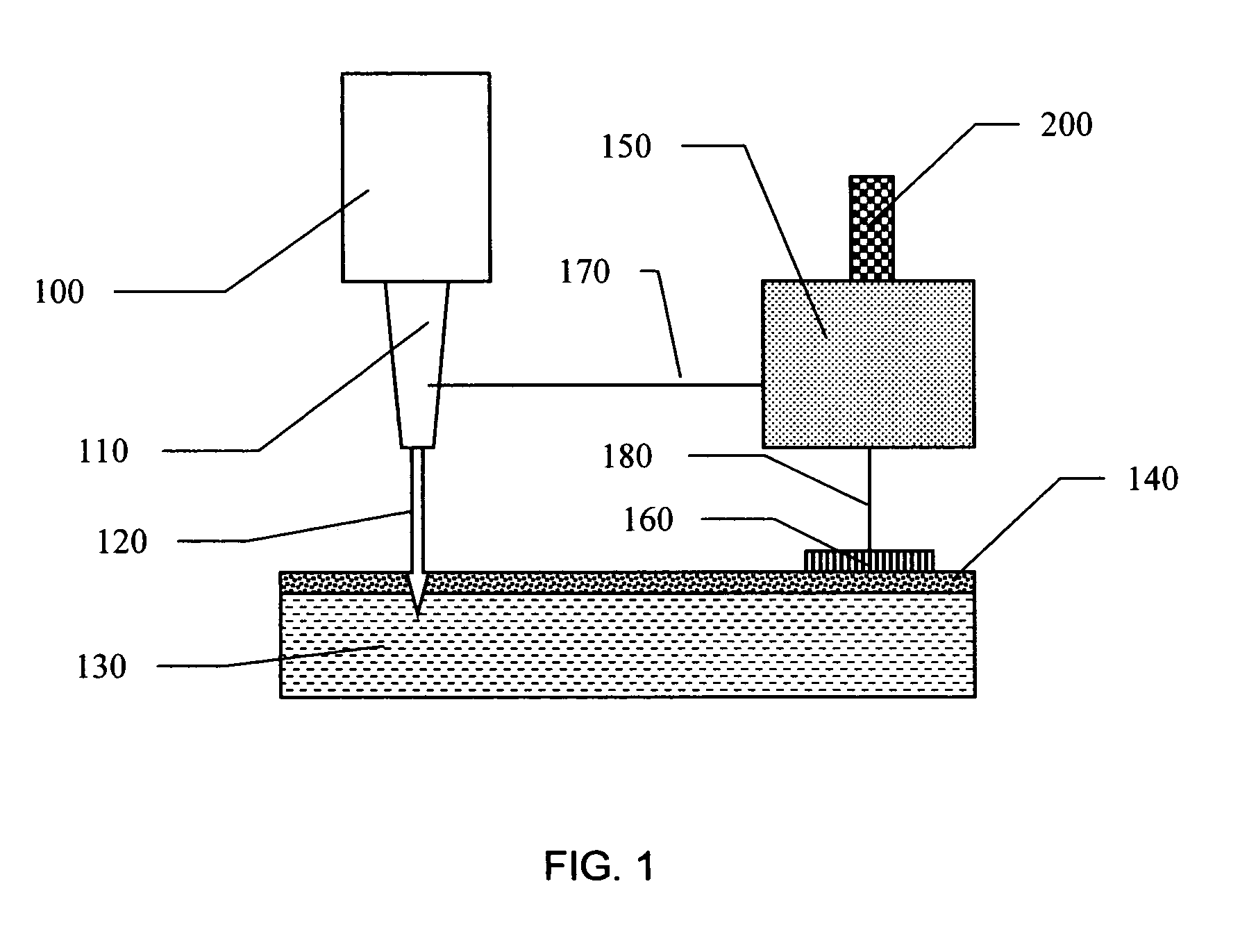

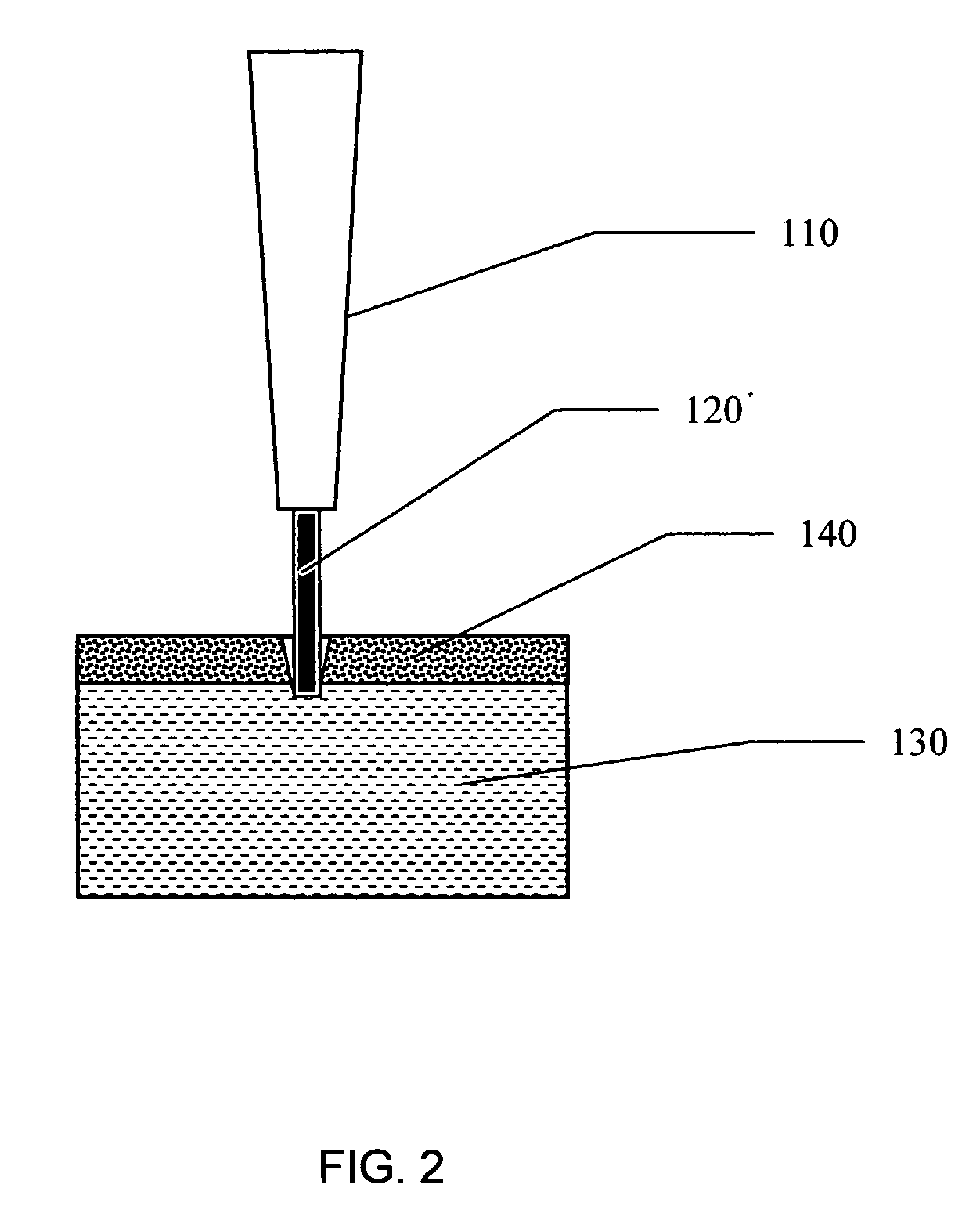

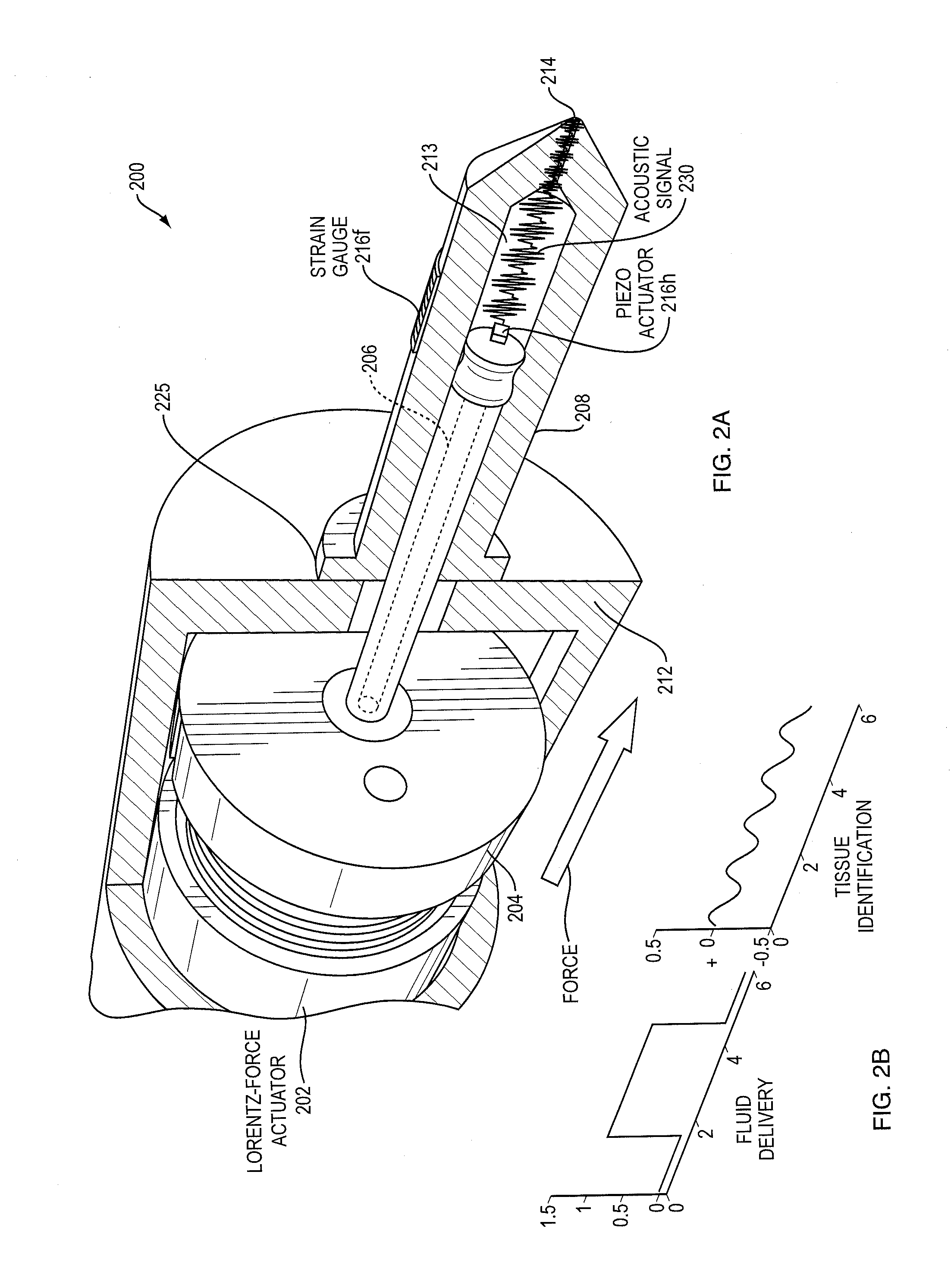

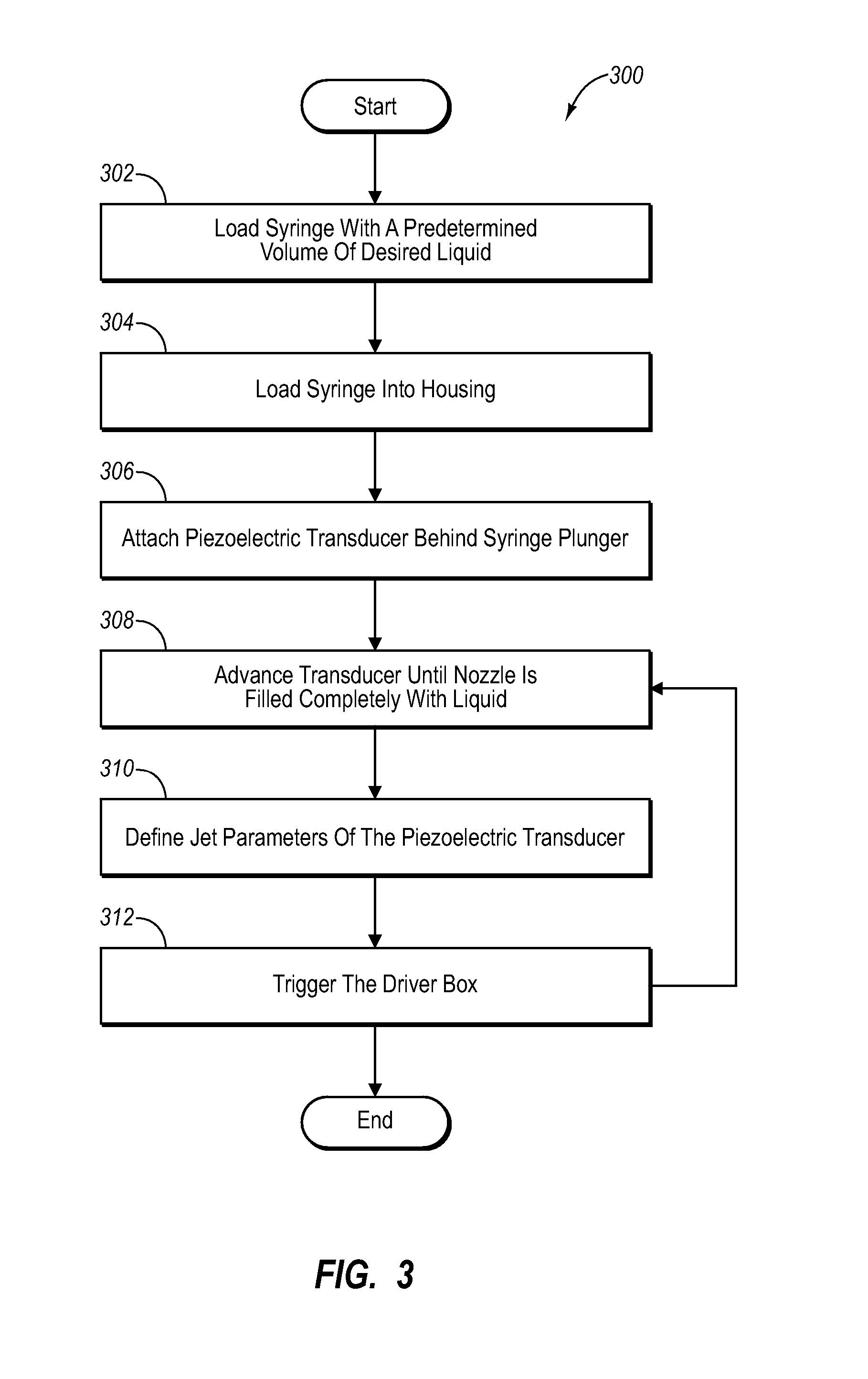

High-speed jet devices for drug delivery

A method and apparatus for performing jet injections using piezoelectric technology. A jet injector apparatus includes a reservoir having a variable capacity for holding a liquid to be delivered to a biological tissue via a jet injection. A nozzle is disposed at a first end of the reservoir with at least one opening for allowing the liquid to be expelled from the reservoir. The capacity of the reservoir may be altered by the actuation of a piezoelectric transducer located at a second end of the reservoir

Owner:CORIUM INT +1

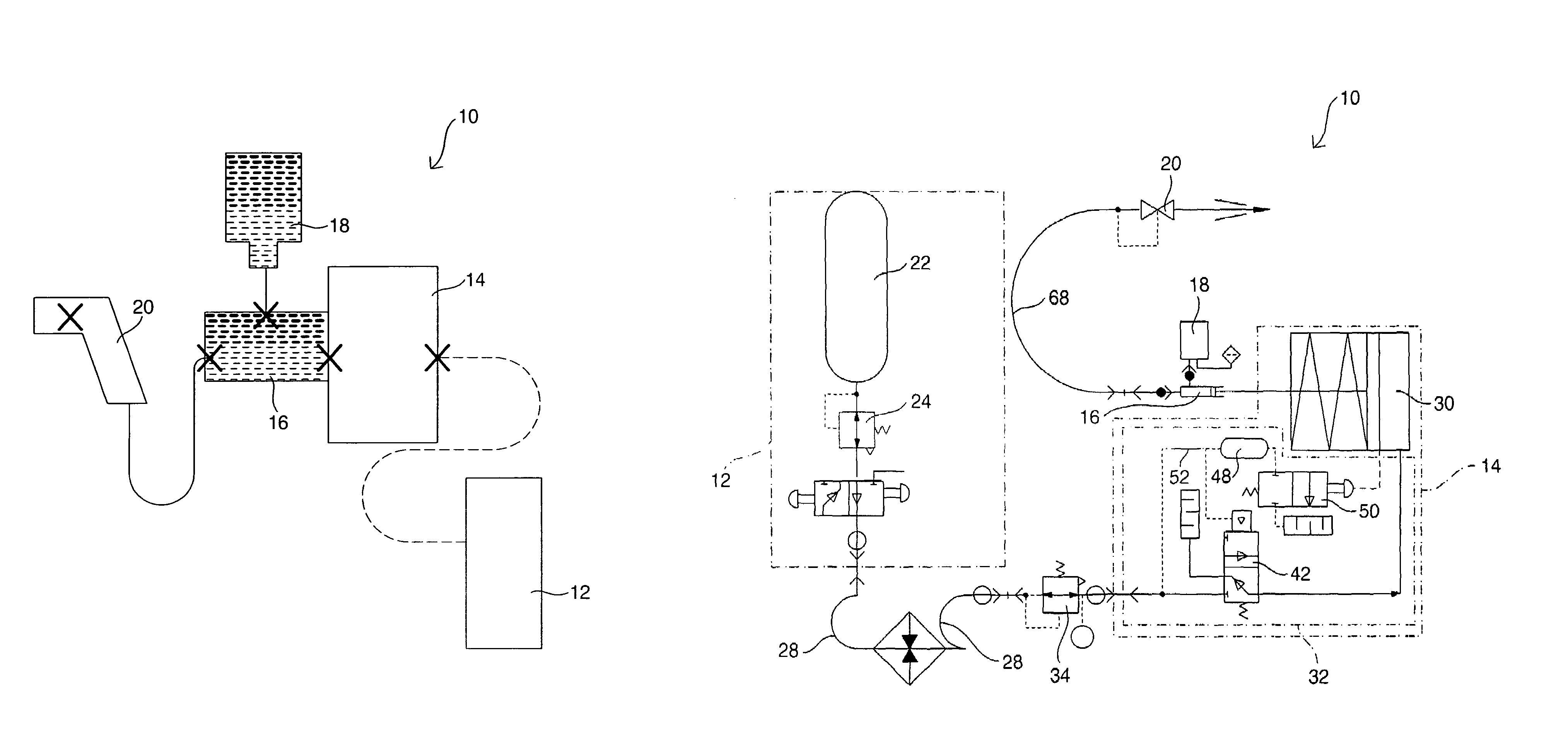

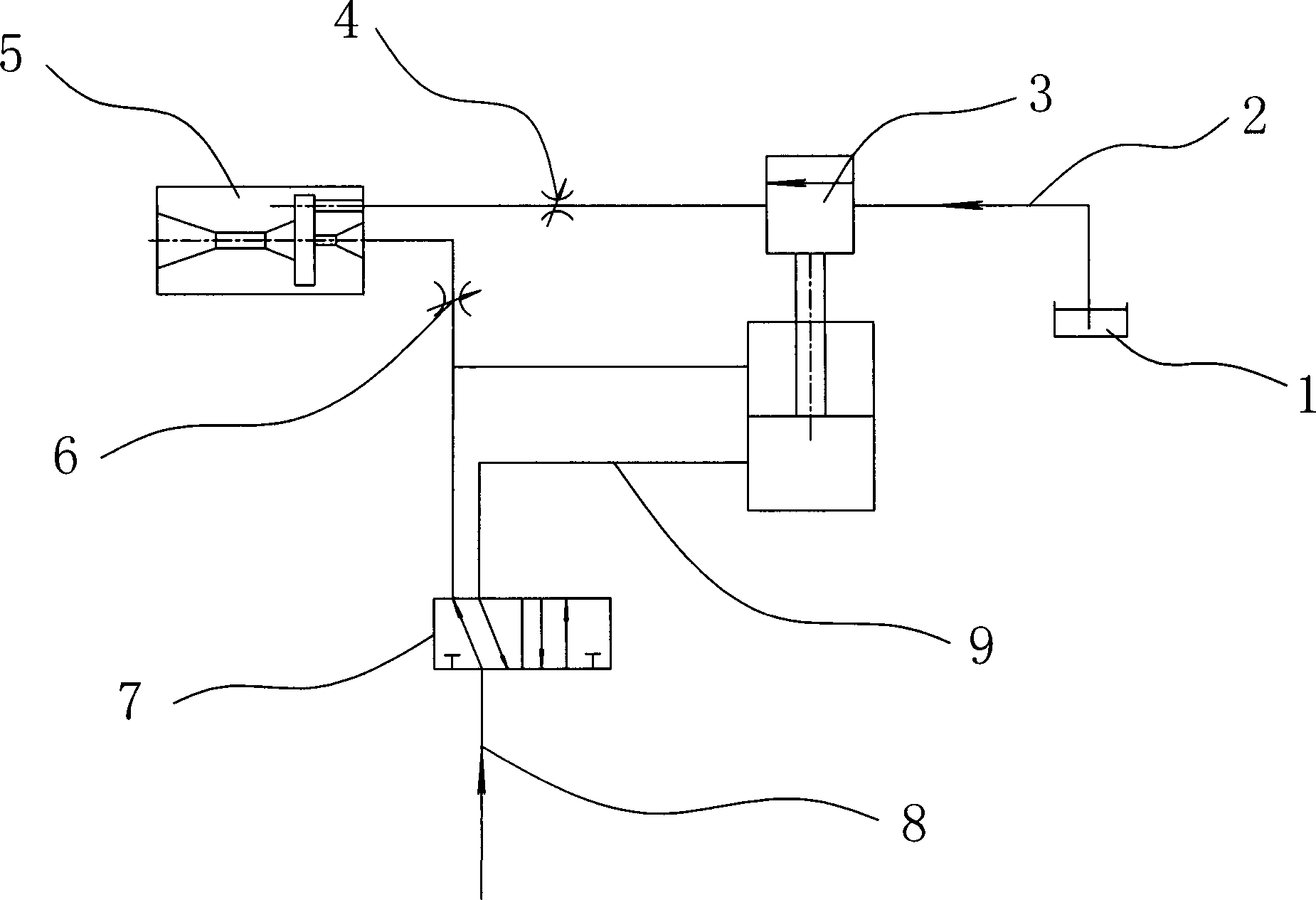

Near-dry cutting supersonic jet apparatus and control method thereof

InactiveCN103551915AReduce the temperatureNo refluxServomotor componentsMetal working apparatusSolenoid valveSpray nozzle

The invention provides a near-dry cutting supersonic jet apparatus and a control method thereof. The near-dry cutting supersonic jet apparatus comprises a control circuit board, a supersonic jet injector, a nozzle, a cutting fluid delivery pipe, a compressed air delivery pipe and an adjusting block. The supersonic jet injector is mounted on the nozzle, the adjusting block comprises a pneumatic cutting fluid one-way stop valve, a cutting fluid adjusting valve and a compressed air adjusting valve, the cutting fluid delivery pipe is connected with a cutting fluid storage tank and the supersonic jet injector, the pneumatic cutting fluid one-way stop valve and the cutting fluid adjusting valve are sequentially arranged on the cutting fluid delivery pipe from the cutting fluid storage tank to the supersonic jet injector, the compressed air delivery pipe is connected with a compressed air source and the supersonic jet injector, a control solenoid valve and the compressed air adjusting valve are sequentially arranged on the compressed air delivery pipe from the compressed air source to the supersonic jet injector, and the control solenoid valve is connected with the pneumatic cutting fluid one-way stop valve through a connecting pipe.

Owner:陈建军 +1

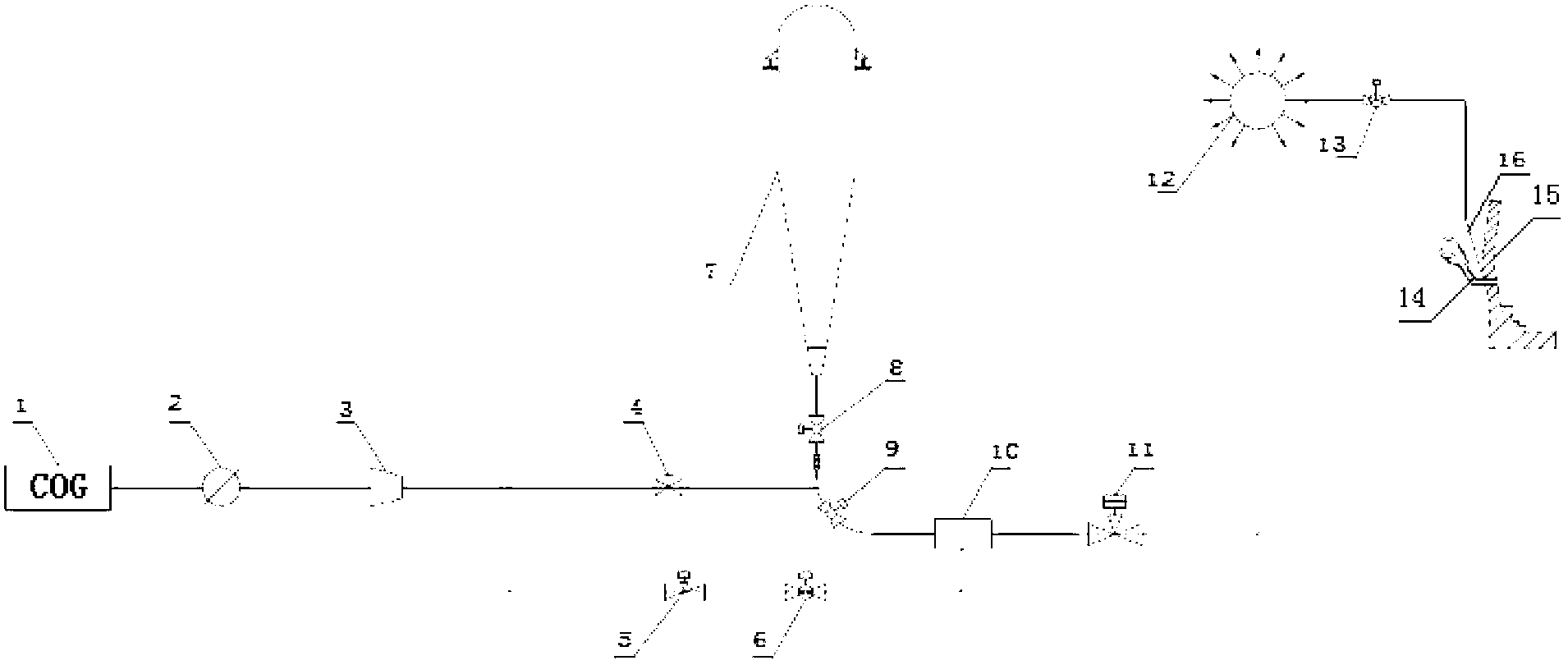

Blast furnace coal injection method adopting coke oven coal gas as coal injection conveying carrier

InactiveCN102936633AHigh calorific valueNo pollution in the processBlast furnace detailsChemical reactionGas compressor

The present invention discloses a blast furnace coal injection method adopting a coke oven coal gas as a coal injection conveying carrier. The method comprises the following steps that: coke oven coal gas adopted as a coal powder injection carrier is subjected to a dehydration treatment, and then is conveyed to a coal gas compressor to carry out pressurization; with the coke oven coal gas pressurized by the coal gas compressor, coal powder in an injection tank is injected to a coal powder distributor; and the coke oven coal gas and the coal powder distributed to various air ports of a blast furnace through the coal powder distributor are injected into the blast furnace through a coal powder jet injector. According to the present invention, the coke oven coal gas enters the blast furnace to participate in the chemical reaction so as to reduce iron ore and provide a coke ratio reduction effect; hydrogen in the coke oven coal gas is changed into water vapor after the reaction, such that no environmental pollution is generated, and carbon emission is reduced; nitrogen content in the coke oven coal gas is low, such that a heat value of the blast furnace coal gas after the reaction is increased; and the coke oven coal gas is mainly subjected to a heat emission reaction in the blast furnace, such that theoretical combustion temperature increase and coal injection increase are easily achieved.

Owner:WISDRI ENG & RES INC LTD

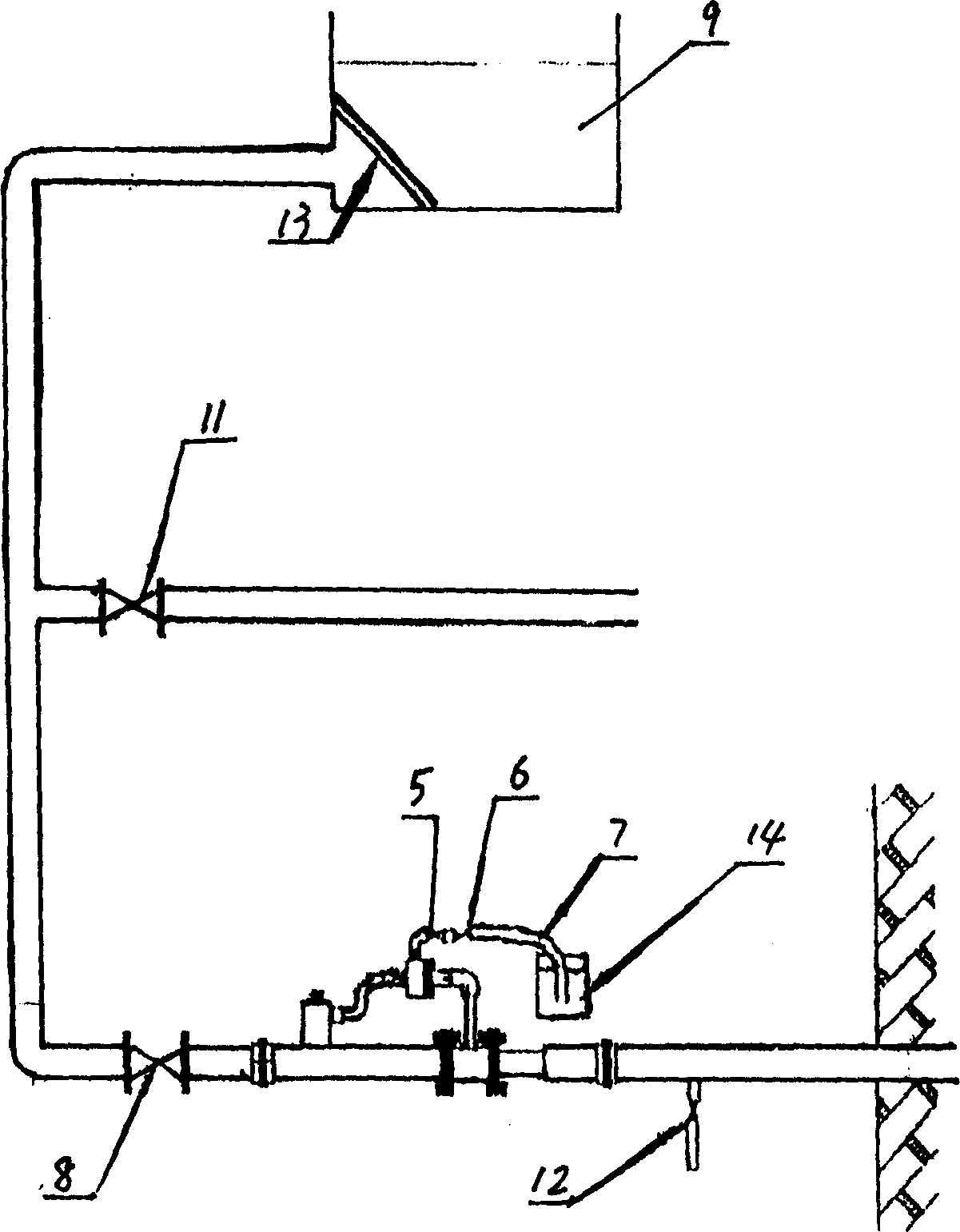

Automatic quantification charging technology and apparatus using dytory method to prevent spontaneous combustion of coal

InactiveCN1525044AReduce failureEasy maintenanceDust removalFire preventionSpontaneous combustionEngineering

The invention discloses an automatic quantitative feeding technique and device to prevent and cure spontaneous combustion by colloidal slurry. In the ground pulping station, it proportionally mixes water, yellow mud and water glass to feed them by pipeline to underground slip casting site, then adopts two-stage jet injector in series with the slip casting pipeline, connects a drawing tubule onto the first-stage jet injector, uses the negative pressure in the jet injector to draw coagulation accelerator by the drawing tubule into the serum in the pump, then feeds the mixed serum by the second-stage jet injector to the slip casting site, and regulates the opening size of the drawing tubule to regulate the drawing quantity. It has advantages of simple structure, convenient operation and energy saving.

Owner:SHANGHAI DATUN ENERGY

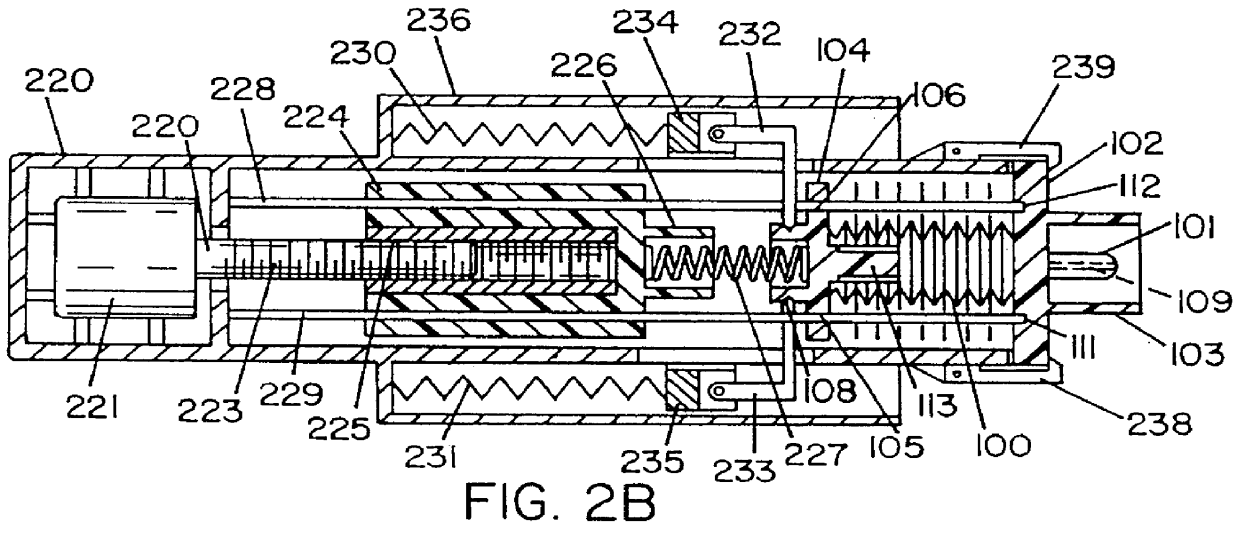

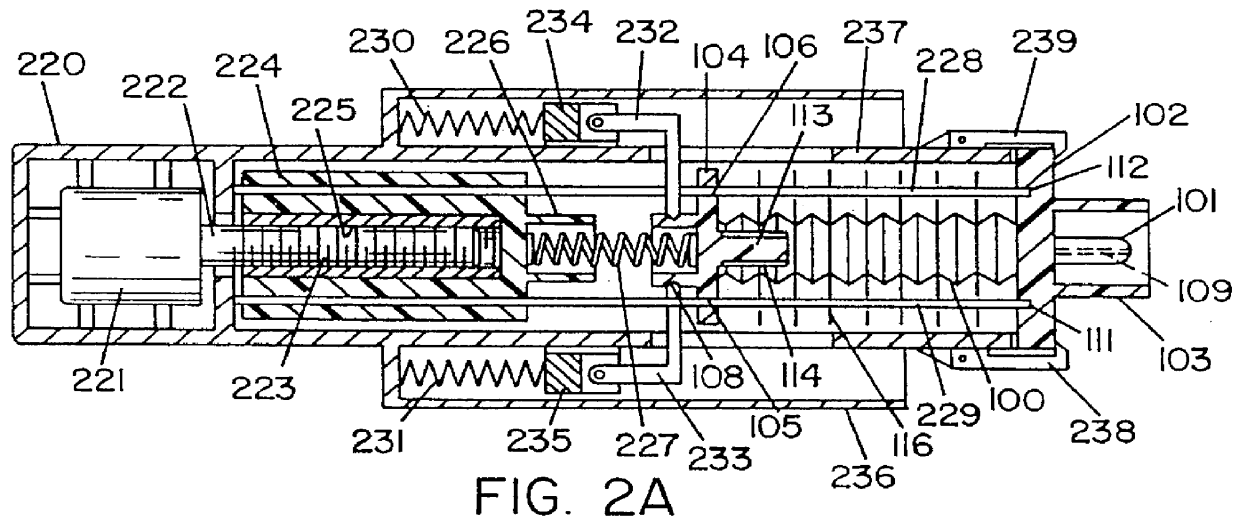

Sequential impulse/delivery fluid medicament injector

InactiveUS7217253B2Accurate and simple control mechanismEasy to useJet injection syringesOther blood circulation devicesMedication injectionSequential method

A device and two-step sequential method for providing medication for injection and infusion by a jet injector includes a cassette which connects an injector system to a reservoir. The cassette forms a fluid pathway at an interface of a cassette lower body and a cassette upper body. The cassette also forms an impulse chamber with a nozzle leading therefrom. The fluid pathway interconnects the reservoir with the impulse chamber. The medication flows from the reservoir along the fluid pathway and into the impulse chamber. Force from an impulse generator drives the fluid medicament from the impulse chamber through the nozzle, out an orifice in a tip of the nozzle, and into the skin of a patient. To prevent the pressure waves generated by the jet injector from damaging a glass reservoir, the fluid pathway is formed with pressure attenuators.

Owner:NOVO NORDISK AS

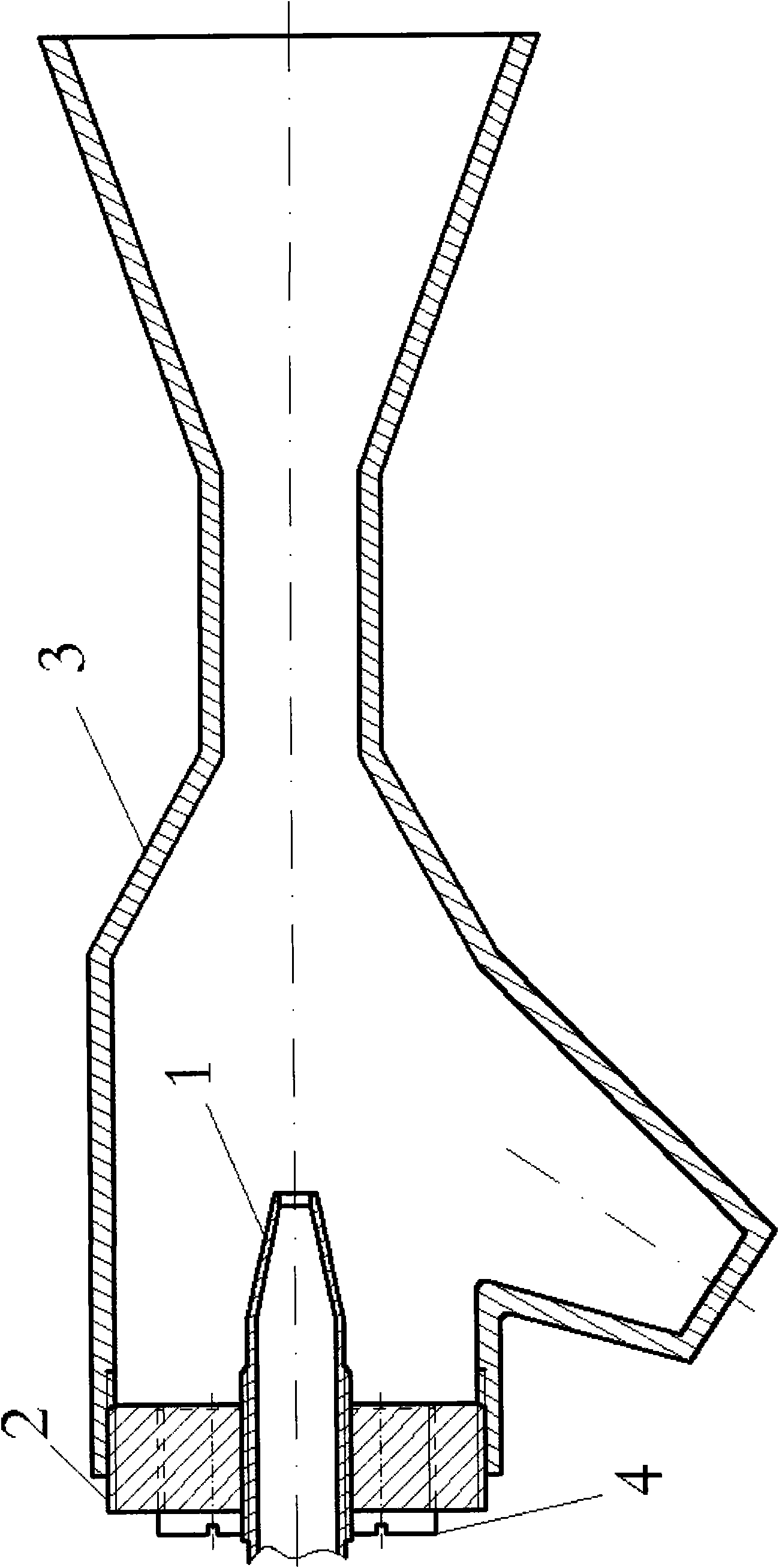

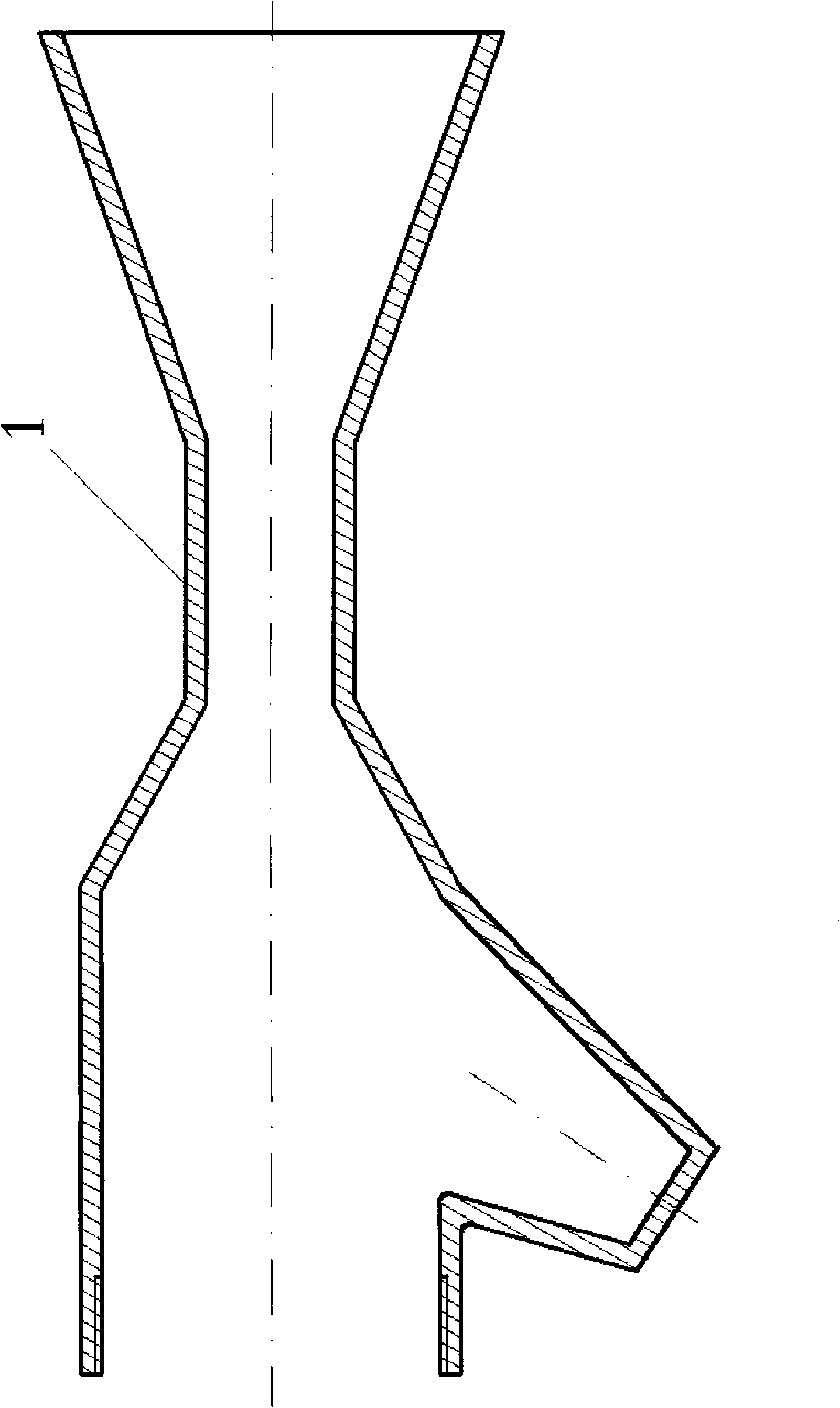

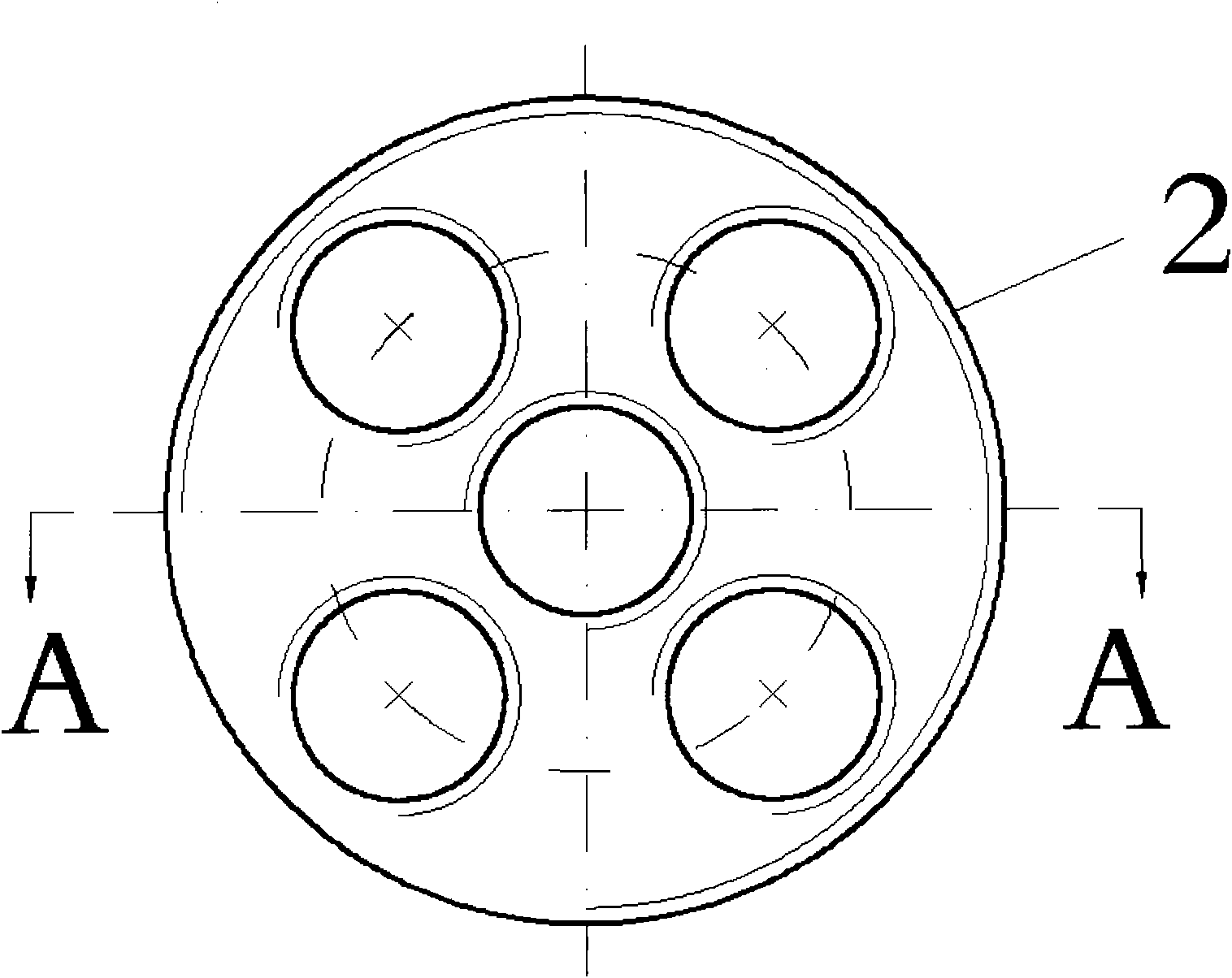

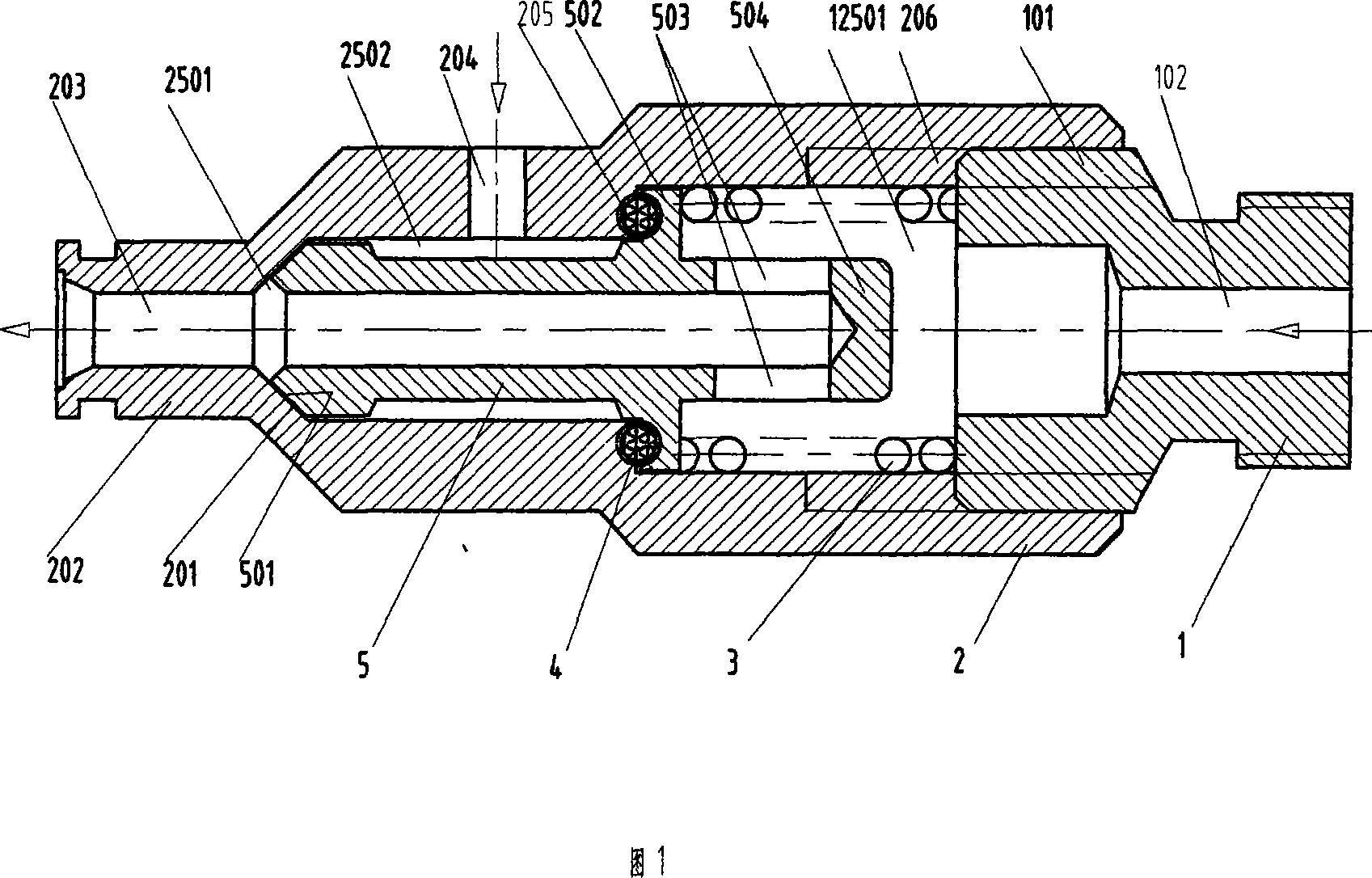

Jet injector with variable nozzle position

The invention provides a jet injector with variable nozzle position. The currently applied jet injector has fixed structure, and the nozzle position is constant in the jet injector, but the jet injector always has an asymmetric shape so that the influence of nozzles in different positions on the jet injector performance is needed to research, and jet injectors in different shapes are needed in practical tests to cause labor and material waste. The jet injector provided by the invention can randomly changes the nozzle position and adopt the technical scheme that a lateral cover (2) and a pump body (3) are connected together through thread, a nozzle (1) can be connected with any threaded hole on the lateral cover (2), and other threaded holes on the lateral cover (2) are sealed and connected with threaded cylindrical pins (4). By flexibly changing the related connecting position of the lateral cover (2) and the pump body (3) and the connecting position between the nozzle (1) and the threaded hole on the lateral cover (2), the nozzle position in the jet injector is changed, and the experimental aim is achieved.

Owner:HENAN POLYTECHNIC UNIV

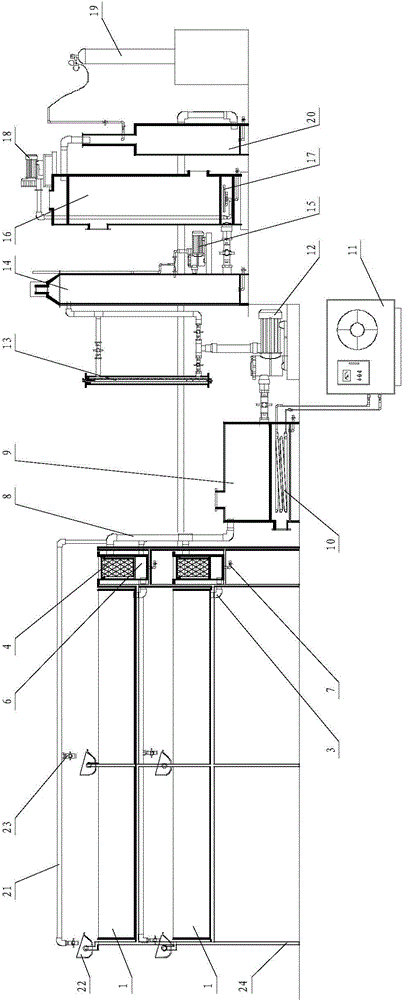

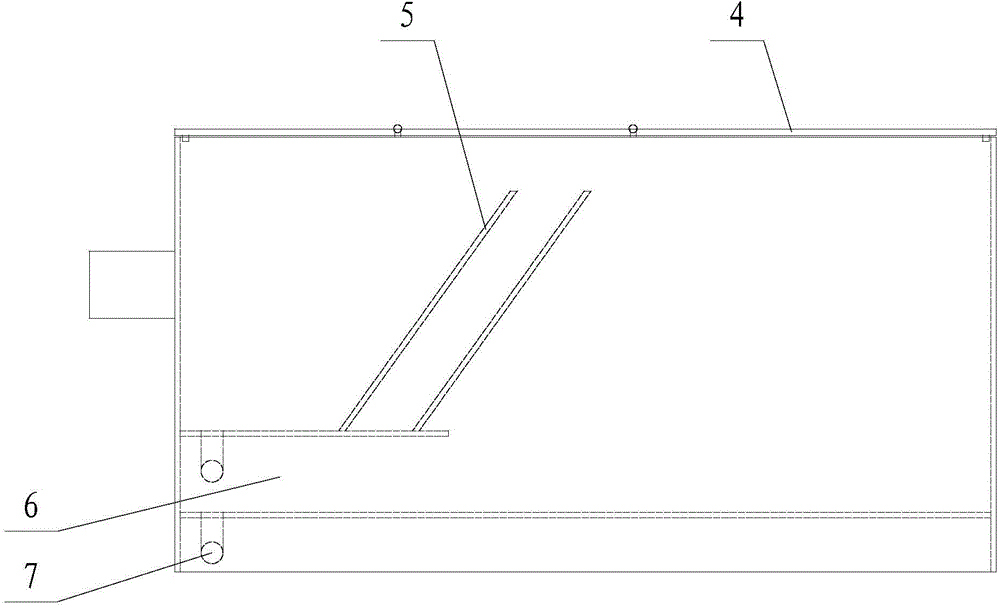

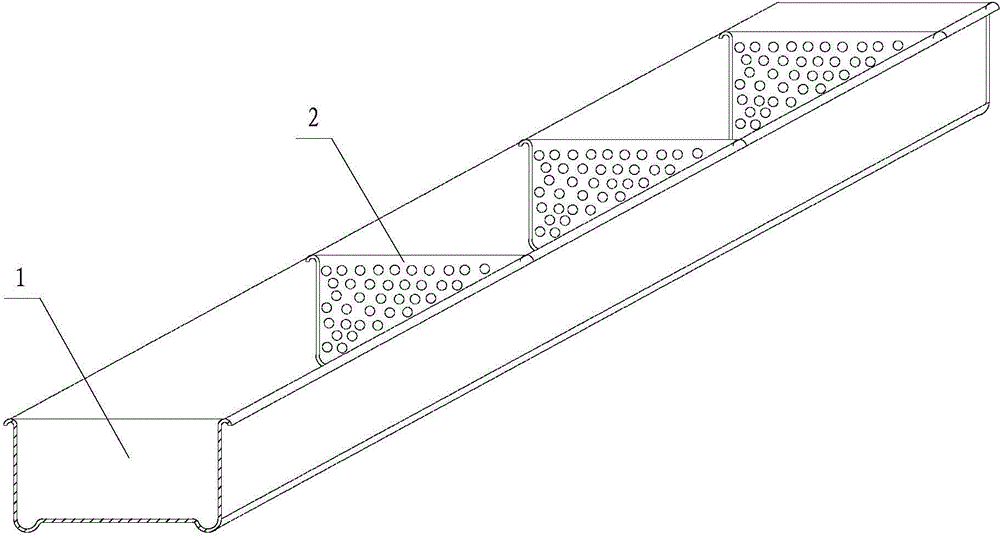

Closed circulating aquaculture system suitable for multilayer stereoscopic cultivation of abalone

The invention belongs to the aquaculture engineering field, and particularly relates to a closed circulating aquaculture system suitable for multilayer stereoscopic cultivation of abalone. The circulating aquaculture system suitable for the multilayer stereoscopic cultivation of the abalone is characterized in that a plurality of aquaculture tanks are installed on a support, a plurality of wave generation hoppers hinged on the support are arranged above each aquaculture tank, the interior of each aquaculture tank is divided into a plurality of tank bodies which are communicated, one water outlet side of each aquaculture tank is communicated with a filter tank, the lower portion of each filter tank is a sewage collection tank, a filter device is arranged on the upper portion of each filter tank, all the filter tanks are respectively communicated with a temperature regulation box with a heat exchanger installed inside, the heat exchanger is communicated with a refrigerator, temperature of seawater is controlled through the refrigerator and the heat exchanger, a water pump, a foam separator, a biological tank and an oxygen tank are sequentially communicated with the temperature regulation box, the foam separator is communicated with a jet injector, and an aeration disk communicated with an air pump us arranged in the biological tank. The circulating aquaculture system suitable for the multilayer stereoscopic cultivation of the abalone has the advantages of continuously reusing aquatic water, being capable of controlling temperature, manually generating waves, achieving rapid and thorough water purification treatment, being convenient to operate, saving energy and protecting environment and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Injector mixer of gas and fluid fuels

InactiveCN101092910AGood atomization effectLow energy ignitabilityTurbine/propulsion fuel valvesEngine controllersHydrogenSprayer

This invention relates to a gas-liquid mixed fuel sprayer containing an adjusting connecting cap, an outer body, a jet-injector, an isolation ring pad and a spread spring suitable for hydrogen-mellow mixed combustion internal combustion engines and turbine engines, which is advantaged that low energy combustion and extremely high diffusibility of hydrogen is helpful to complete combustion of liquid fuel, which is good in dispersed pulverization and burnt fully, early burning and deflagration of hydrogen is restrained to a certain stage, so the fuel system and its control method can be simplified greatly.

Owner:李钢坤

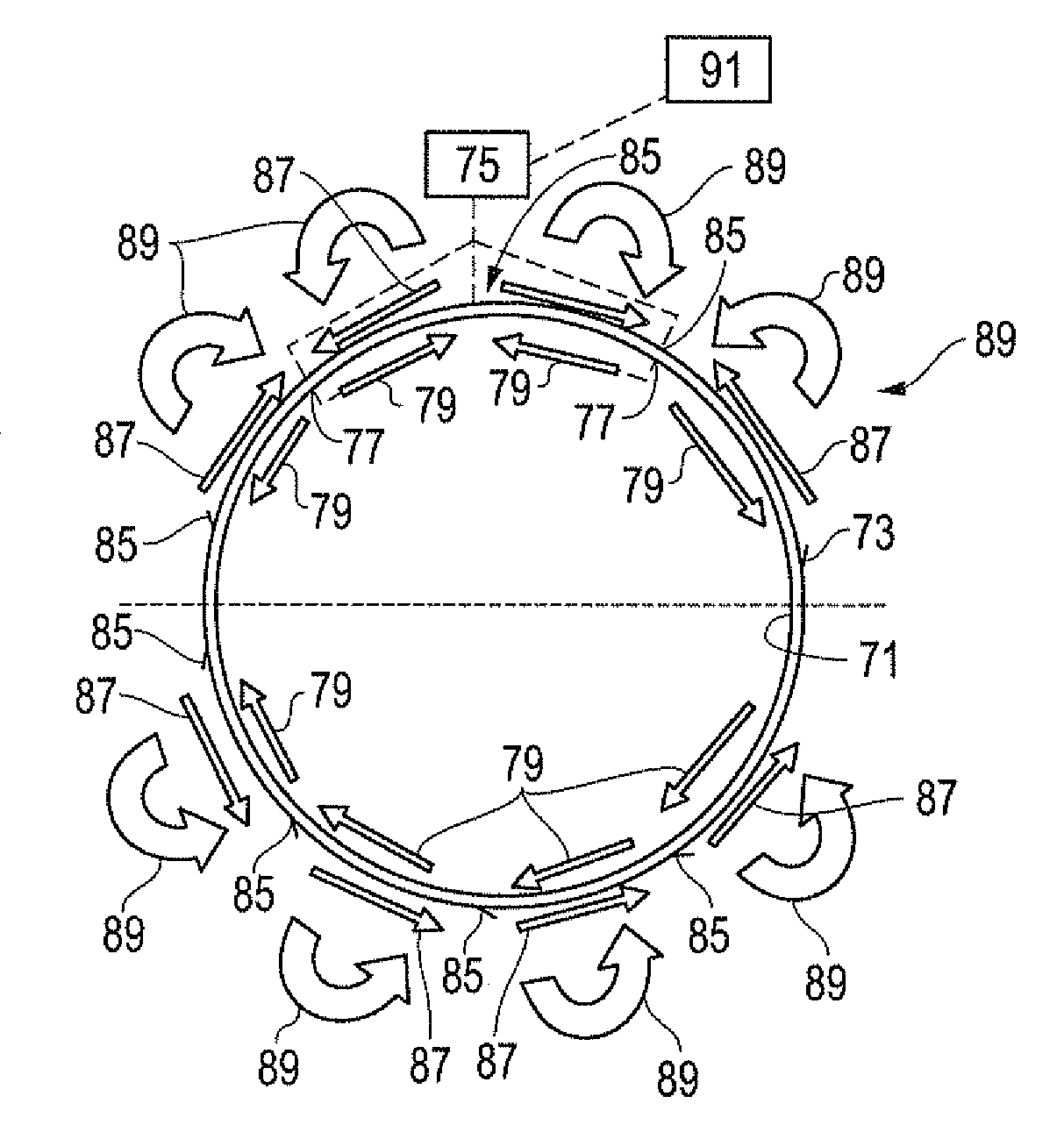

System, method and apparatus for fluidic effectors for enhanced fluid flow mixing

ActiveUS20090314885A1Well mixedReduce noisePower plant exhaust arrangementsSilencing apparatusJet injectorInjection rate

A fluidic effector provides enhanced plume mixing for an aircraft engine. Air jet injectors are located on both the external and internal cowl surfaces and angled in opposite directions to induce large scale vortices in the exhaust plume. The vortices mix actuation air with the exhaust plume to produce ejector action. The plume mixes out quickly, thereby lowering jet noise and jet exhaust temperature. The injectors have orientations and injection rates that are adjustable to allow variable mixing rates for use at different flight and engine conditions.

Owner:LOCKHEED MARTIN CORP

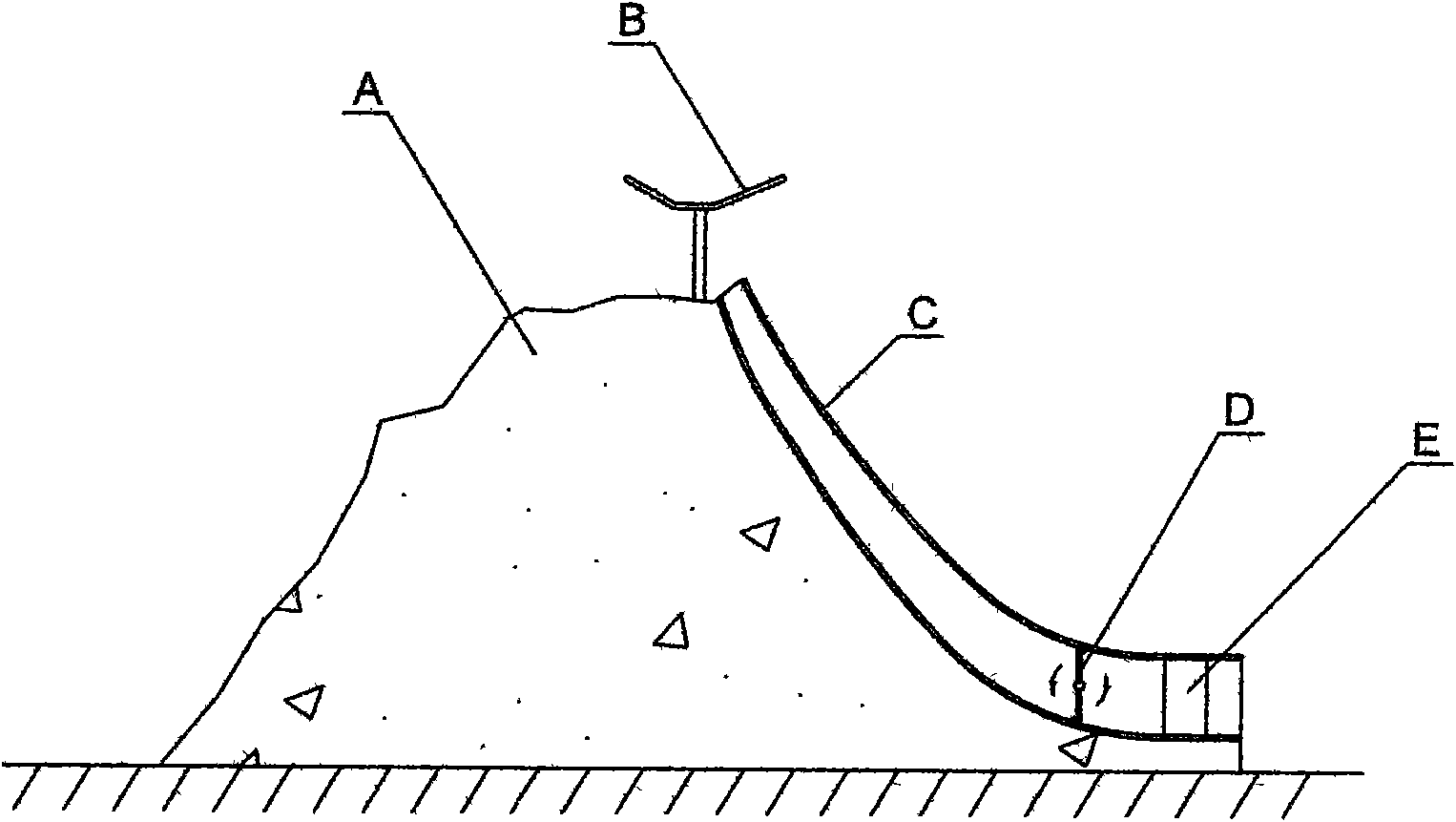

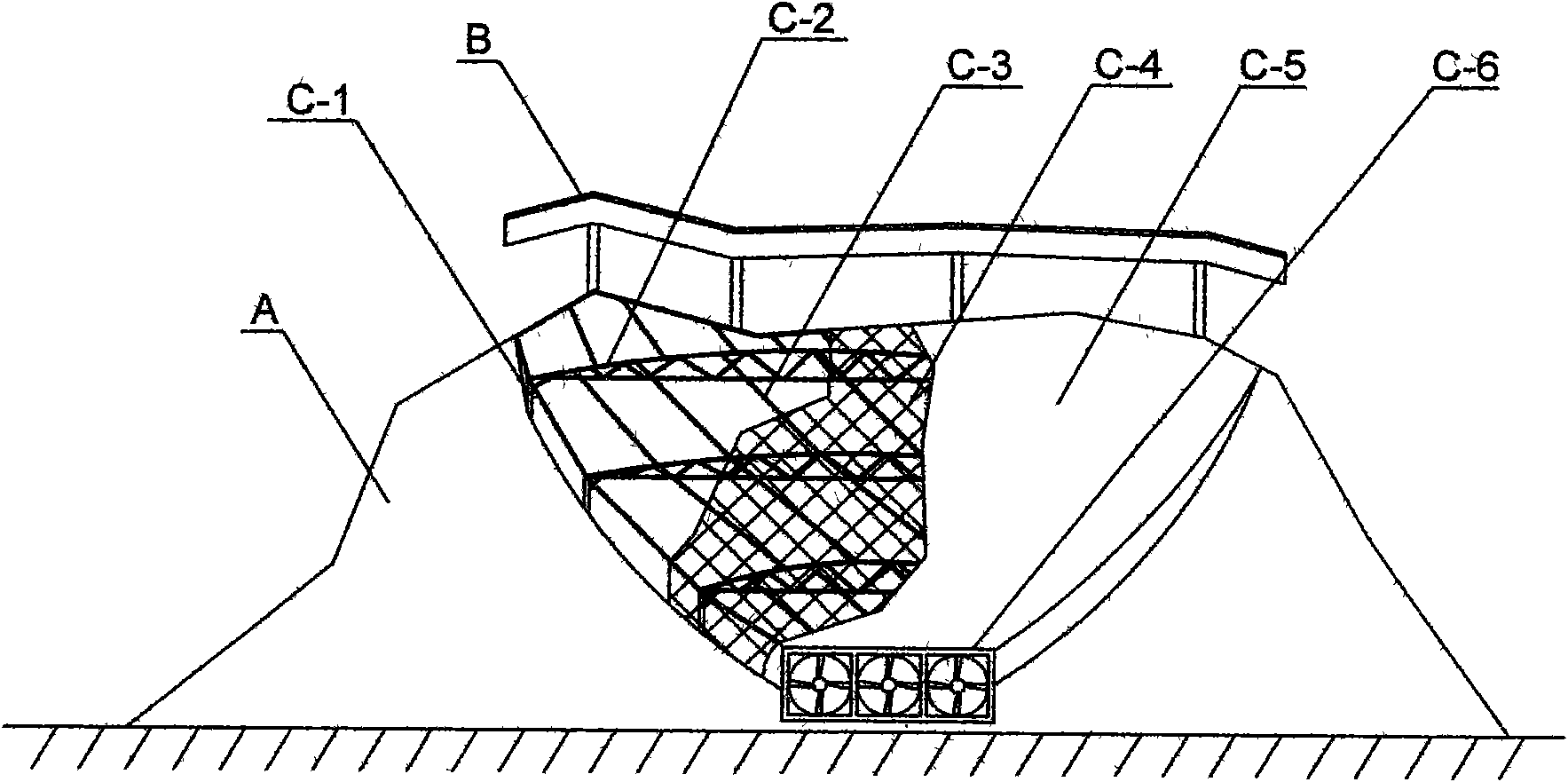

Wind power generation principle and facility of mountain massif jet injector

InactiveCN101581275AAbundant resourcesImprove wind energy utilization efficiencyFinal product manufactureEnergy industryMassifLow-pressure area

The invention discloses a wind power generation principle and a facility of a mountain massif jet injector, belonging to the technical field of wind power generation facility machining. The wind power generation principle and the facility are technically characterized in that jet injector pipes made of canvas or glass fiber reinforced plastic are spanned on high points protruding out of a flat, such as islands, mountain massifs and earth hummocks; jet action is formed by airflow above the jet injector pipes spanned on the high points protruding out of the flat for air in the jet injector pipes to form a low-pressure area; ground air moves along the inside of the jet injector pipes to the low-pressure area under the action of atmospheric pressure to form wind power; and the wind power drives a turbine on a generator to generate electricity. The invention has high wind energy efficiency and low investment cost, can utilize abundant resources of the high points protruding the flat such as the islands, the mountain massifs and the earth hummocks, is convenient to generalize and provide a product design for solving sustainable development problem of energy shortage and environment pollution, to which attention is paid all over the world.

Owner:李启山 +2

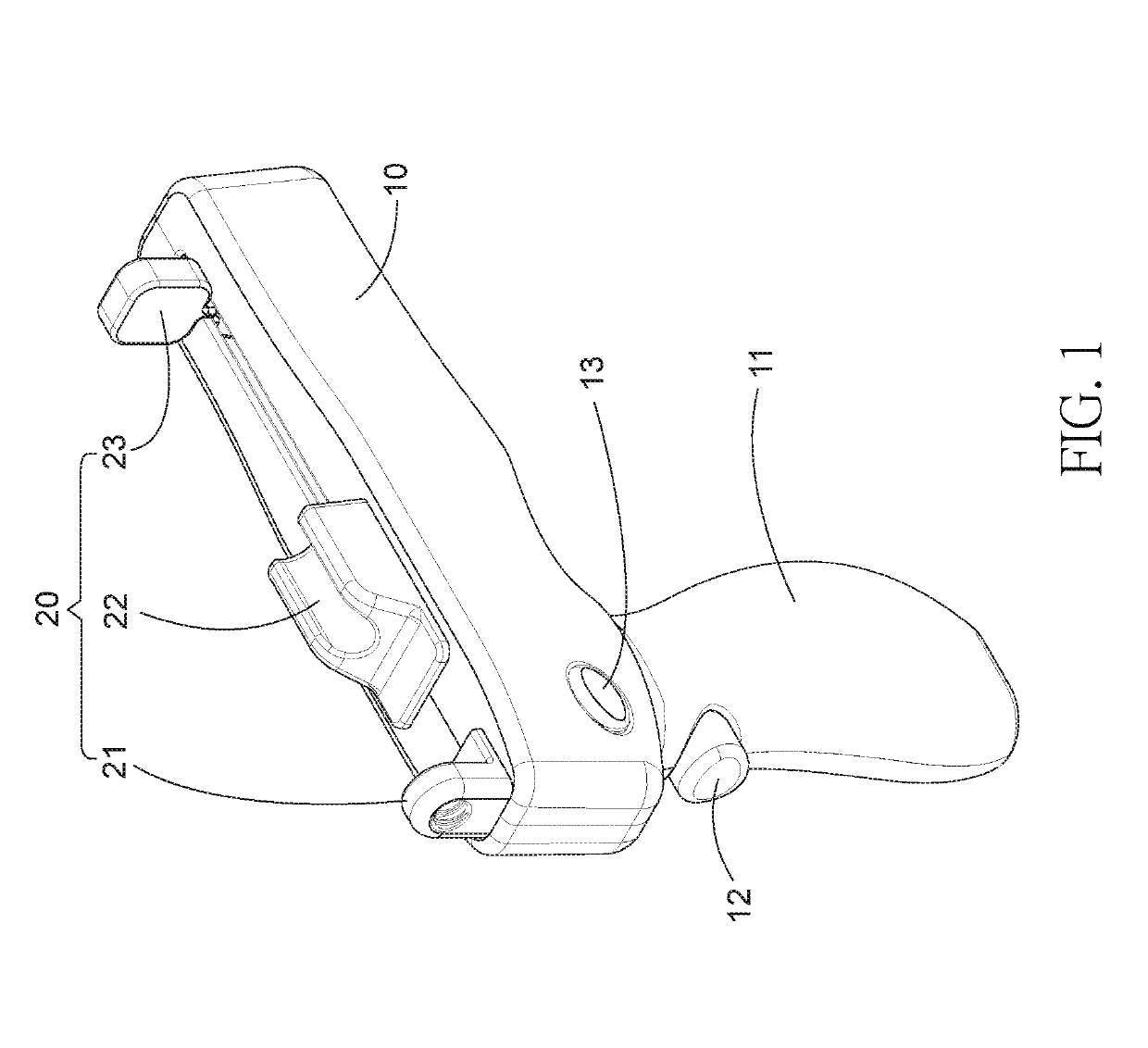

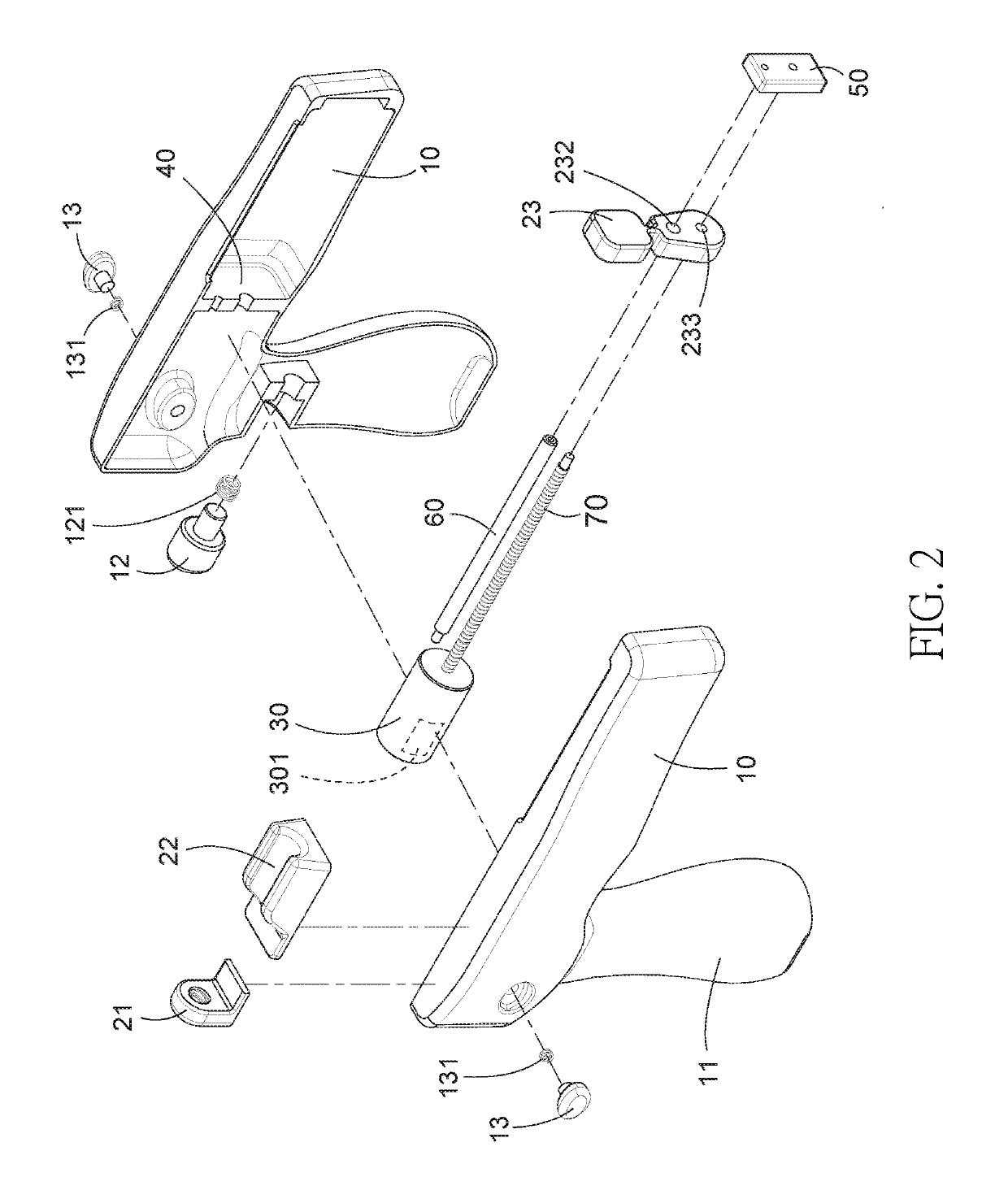

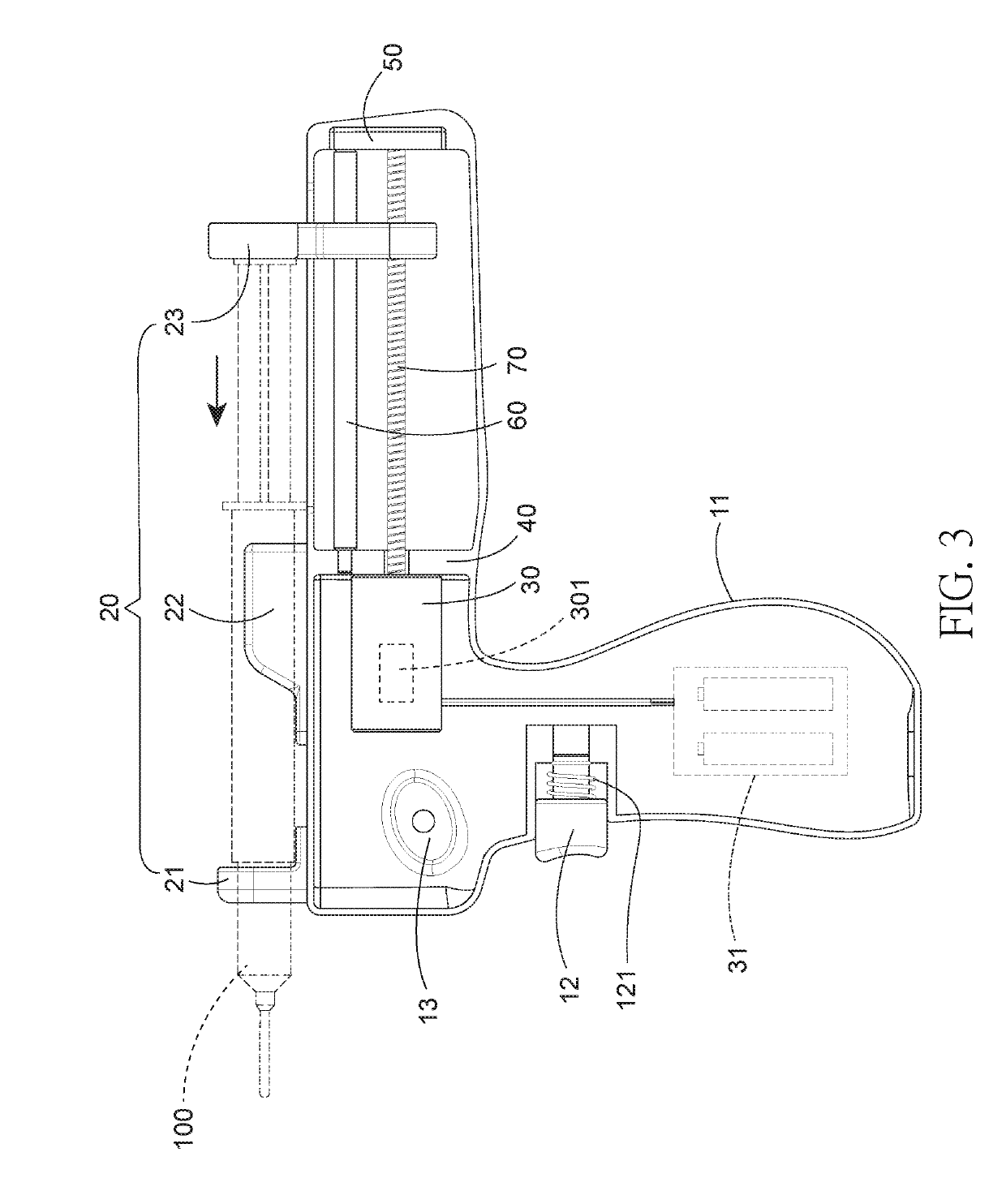

Automatic Jet Injector for Administering Tissue

ActiveUS20190307960A1Easy to moveSet a rotational speed of the power sourceJet injection syringesAutomatic syringesJet injectorElectrical and Electronics engineering

An automatic jet injector for administering tissue is provided with a housing including a grip and a pushbutton; a syringe positioning device on a top of the housing and including an intermediate support and a rear pushing board having a lower through hole and a threaded hole under the through hole; a power source in the housing and including a power supply configured to supply power to the power source by pressing the pushbutton; a fastening member in the housing and being adjacent to a rear end of the housing; a positioning member being adjacent to the power source; a reciprocating screw having a front end operatively connected to the power source and a rear end fastened in the fastening member; a rod having a front end fastened in the positioning member and a rear end fastened in the fastening member; and a control device.

Owner:BEYOUNG SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com