Jet injector with variable nozzle position

A technology of jet pump and nozzle, applied in the field of jet pump, can solve the problem of waste of manpower and material resources, and achieve the effects of easy realization, simple production and disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

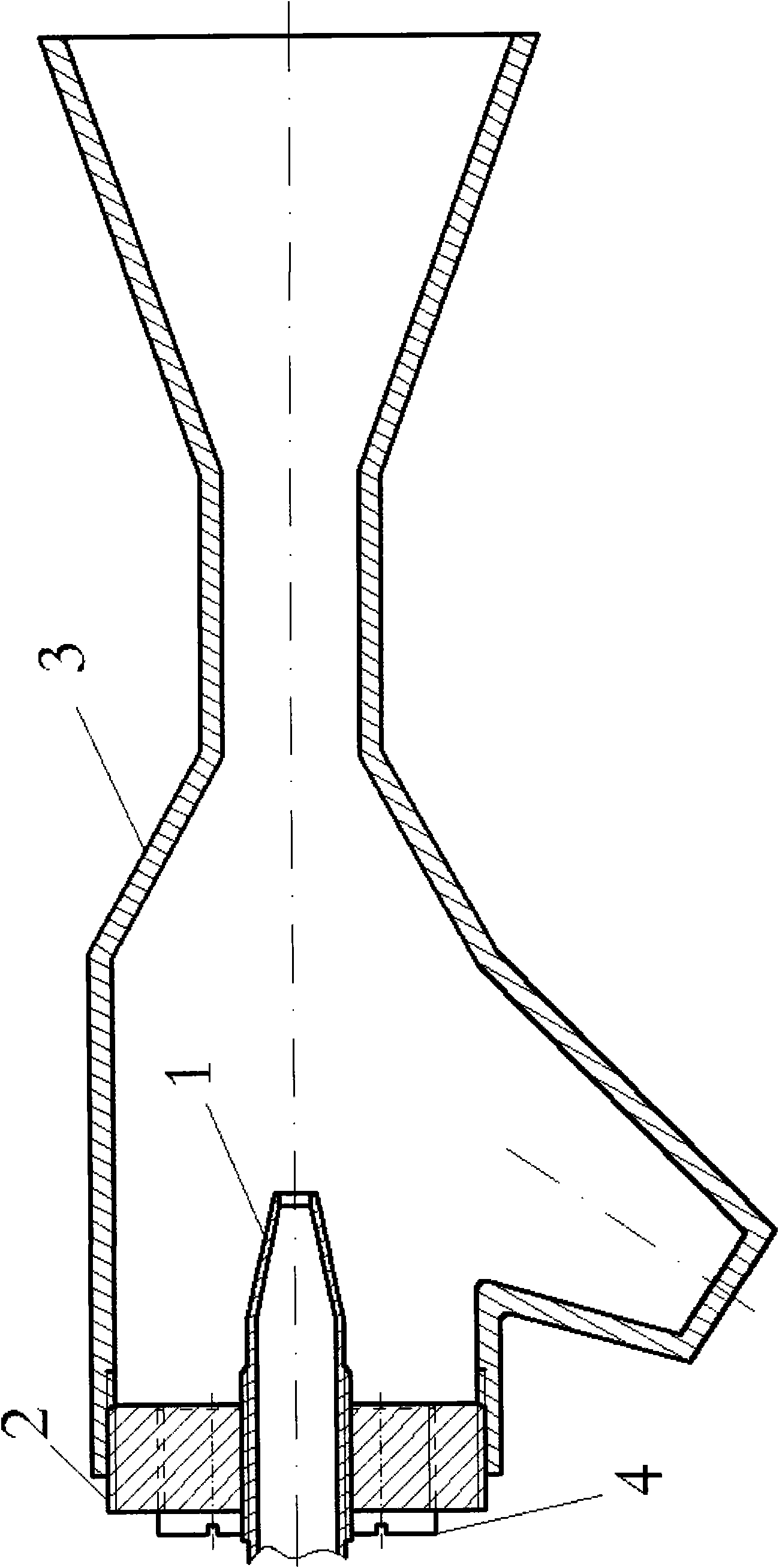

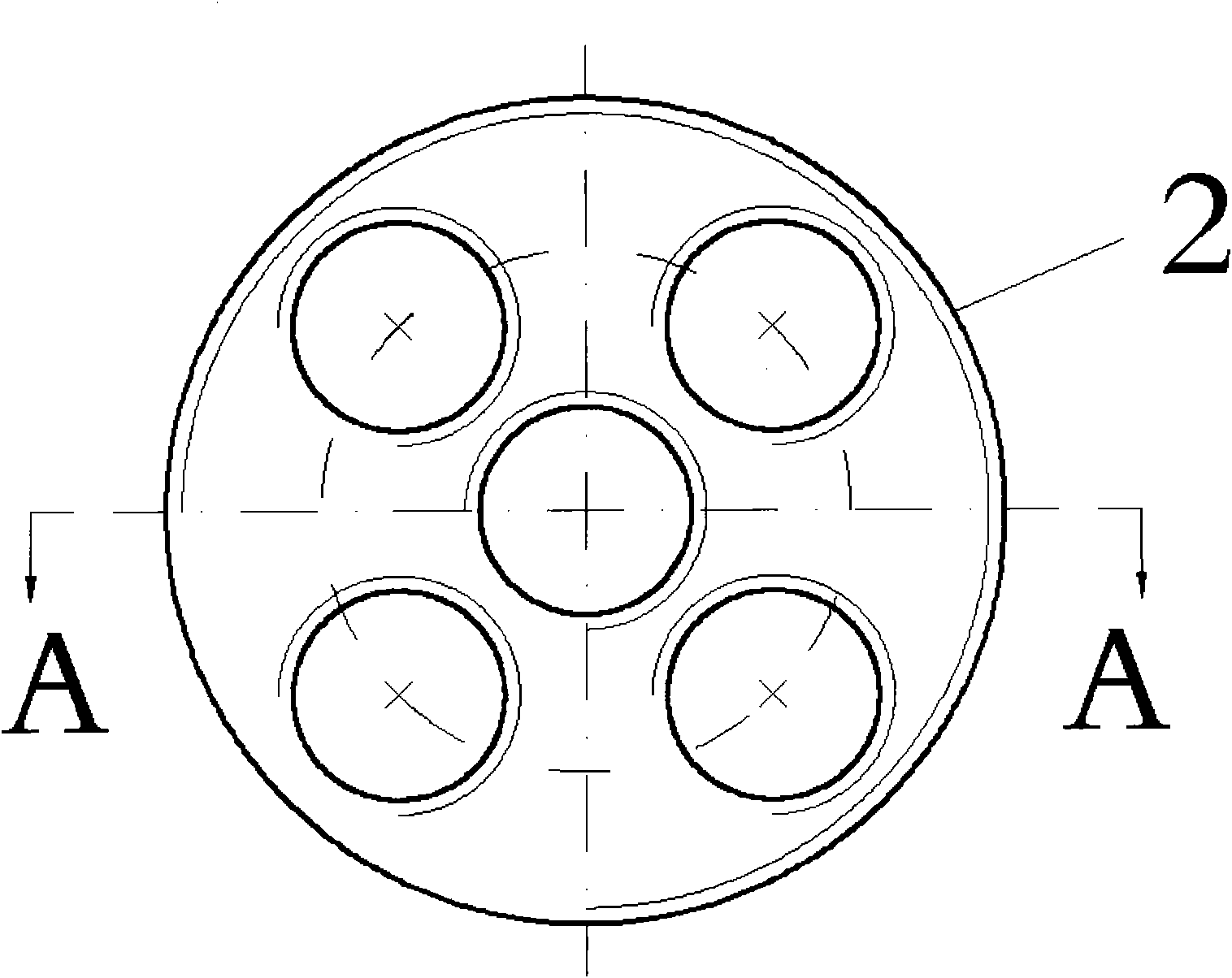

[0014] figure 1 It is a structural schematic diagram of the jet pump of the present invention. Such as figure 1 As shown, a jet pump with variable nozzle position according to the present invention has four structures: nozzle (1), side cover (2), pump body (3) and threaded cylindrical pin (4), wherein The side cover (2) and the pump body (3) are connected through a threaded part, and the nozzle (1) and the threaded cylindrical pin (4) are connected with the threaded through hole in the side cover (2) through an external thread structure.

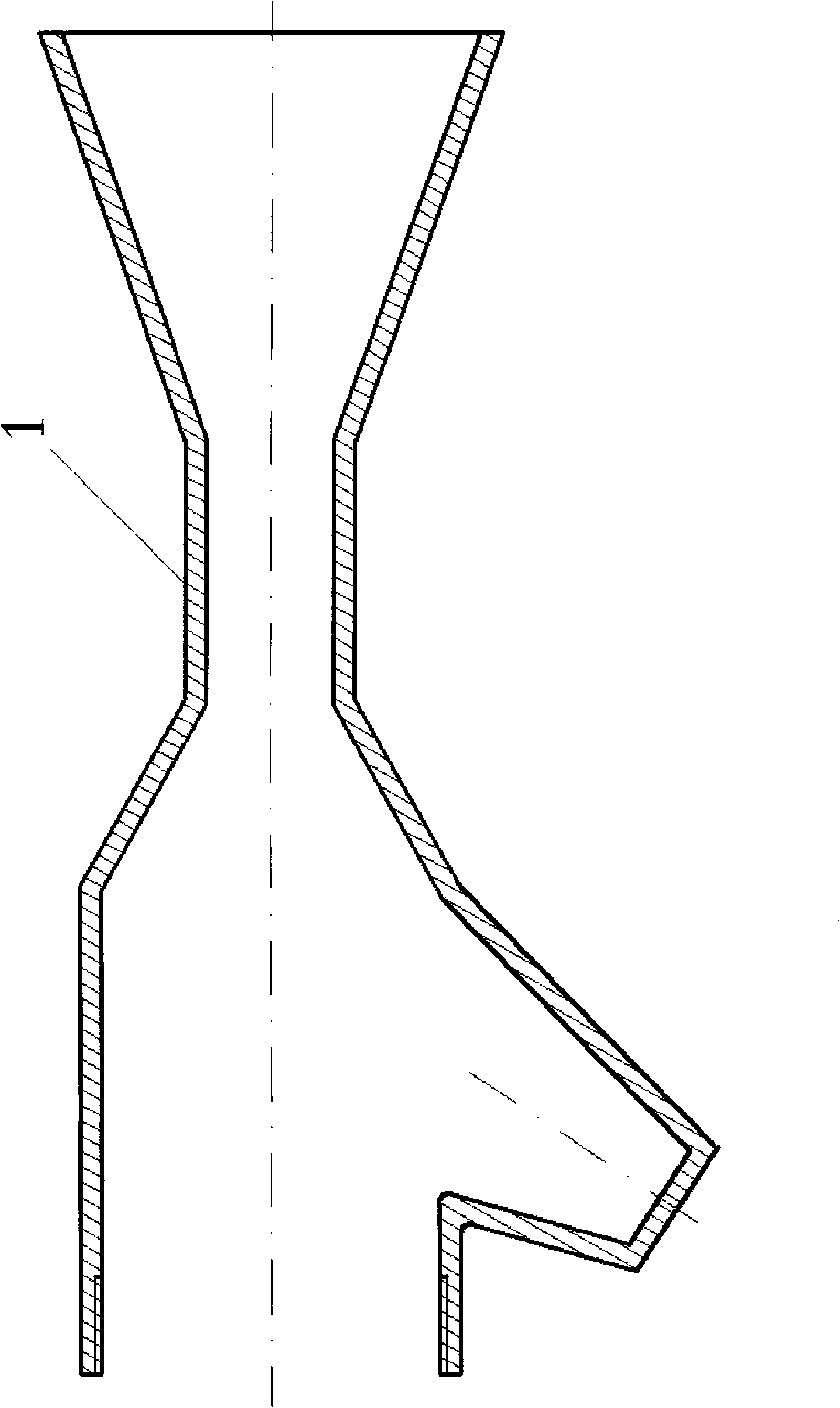

[0015] figure 2 It is a schematic diagram of the pump body structure of the jet pump of the present invention. Such as figure 2 As shown, the pump body (3) has a threaded hole structure at one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com