Automatic quantification charging technology and apparatus using dytory method to prevent spontaneous combustion of coal

A technology of coal spontaneous combustion and colloidal mud, applied in safety devices, dust prevention, fire prevention, etc., can solve the problems of power supply, increased cost, and many running parts, etc., to ensure the glue forming time, convenient installation and operation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

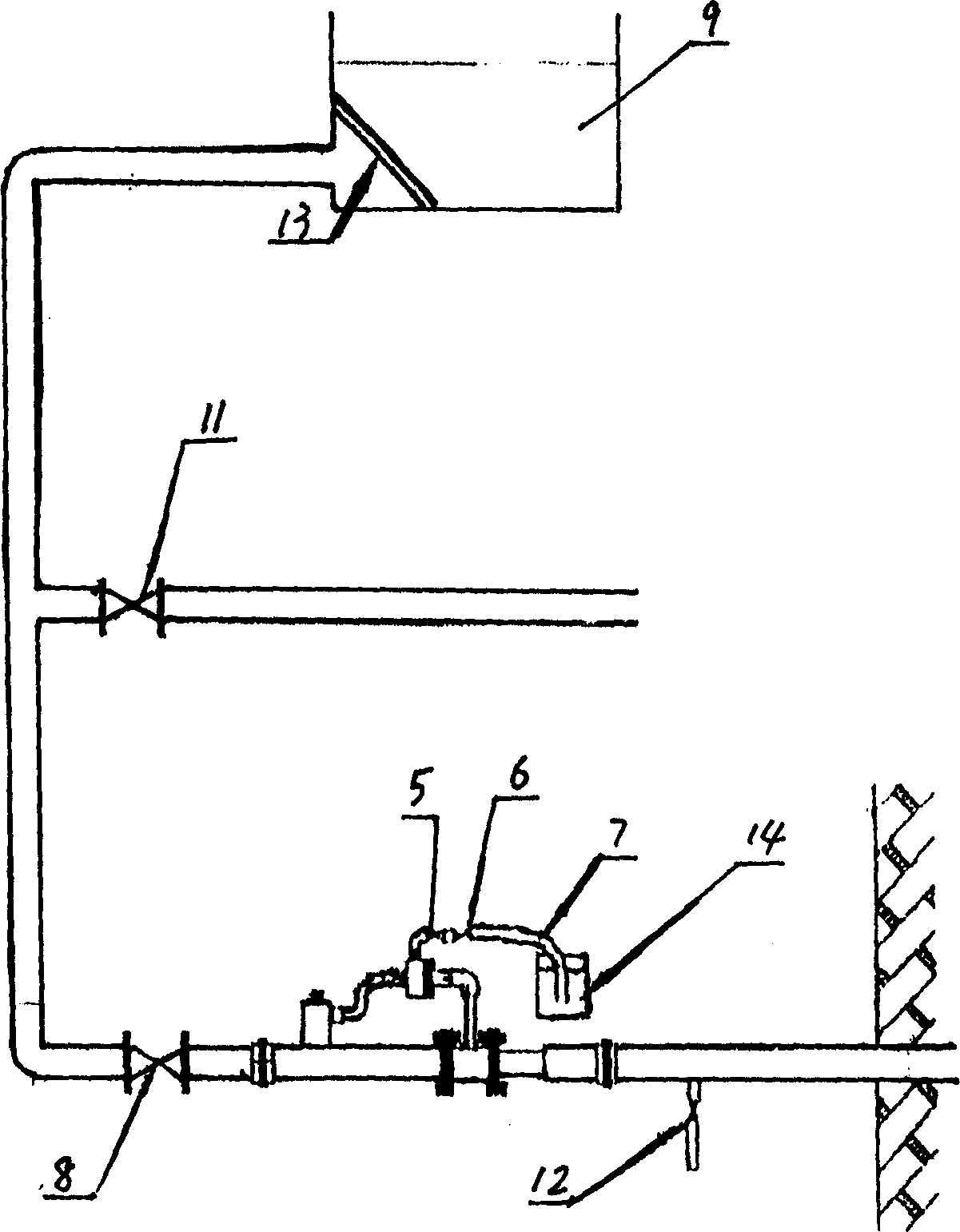

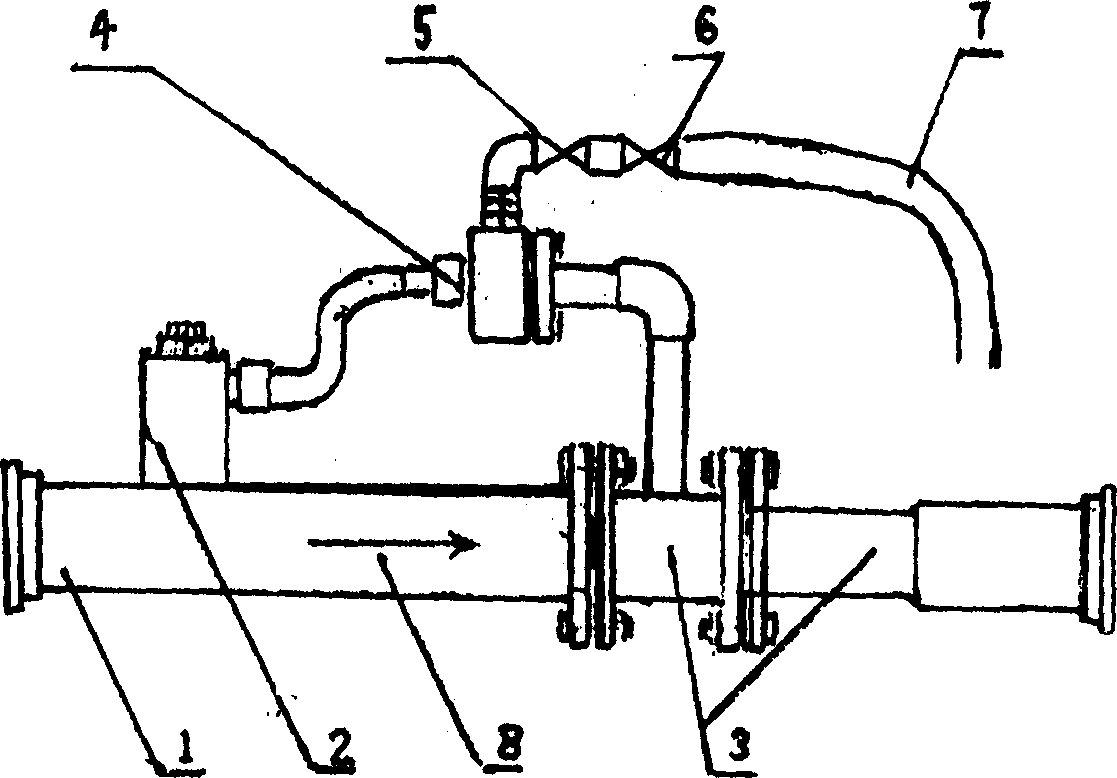

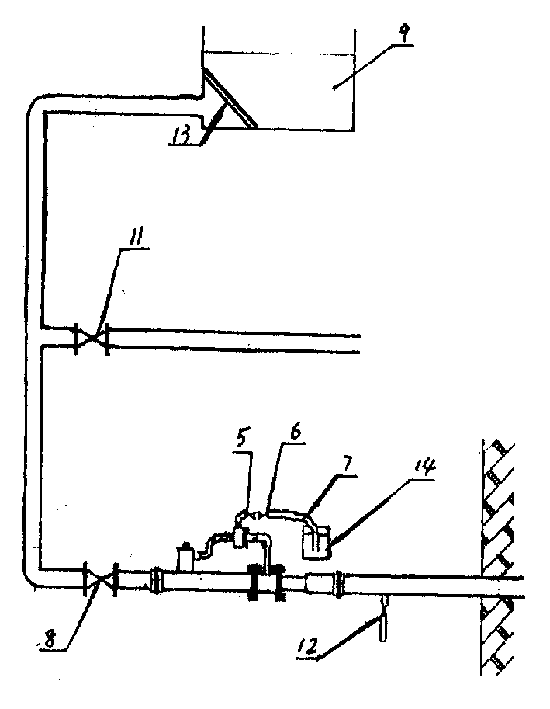

[0021] refer to figure 1 , the present invention comprises mixing water, yellow mud and water glass in proportion to form a slurry at the ground grouting station (9), filtering it through a filter (2) and sending the slurry to downhole grouting through a grouting pipeline (10) location, because the pressure and flow in the grouting pipeline for transporting the grout are relatively large, and the flow rate of the coagulant solution required is small, which is generally only 2-4% of the flow rate of the grouting liquid. If a single-stage jet pump is used If the working method is directly connected in series with the grouting pressure pipeline, the pressure drop of the pressure pipeline is too large, and the back pressure recovery is small, resulting in low efficiency of the device. Therefore, the present invention adopts a two-stage jet pump, that is, the first-stage jet pump (4) and the second-stage jet pump (3) are connected in series in the grouting pump pipeline to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com