Injector mixer of gas and fluid fuels

A fuel mixing, injector technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

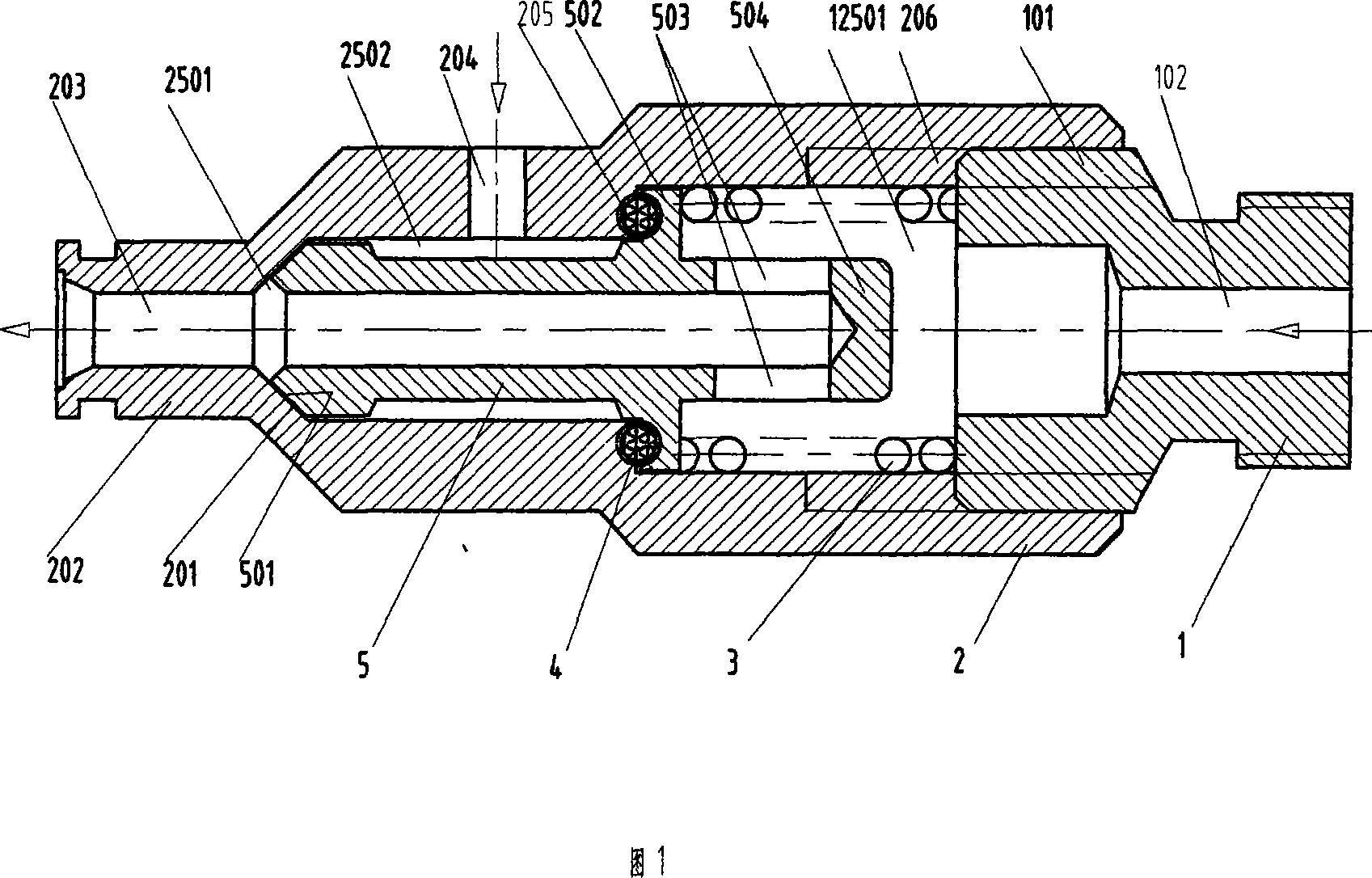

[0027] As shown in Figure 1, the technical solution adopted by the purpose of the present invention is to include the adjustment connecting cap 1 to thread the outer body 2, the built-in injection body 5 in the outer body 2, the inner table surface 205 of the outer body 2 and the convex ring 503 of the injection body 2 There is spacer ring pad 4 between the left side, stage clip 3 is arranged between the right side of projection body 5 protruding ring 503 and the left end face of adjusting connection nut 1 .

[0028] In the present invention, the inner thread 206 of the outer body 2 is engaged with the outer thread 101 of the adjustment connecting cap 1 , and the inner tapered surface 201 of the outer body 2 is in coincident contact with the outer tapered surface 501 of the injection body 5 .

[0029] In the present invention, the adjustment connecting cap 1 has an external thread 101 and a gas fuel injection channel 102 .

[0030] In the present invention, the jetting body 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com