Method and device for selecting tobacco tar and atomizing core

A technology of atomization core and acquisition module, which is applied in the field of electronic cigarettes, can solve the problems of affecting the taste of electronic cigarettes, limited application range, burning, etc., achieve good atomization effect and taste, improve atomization effect, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

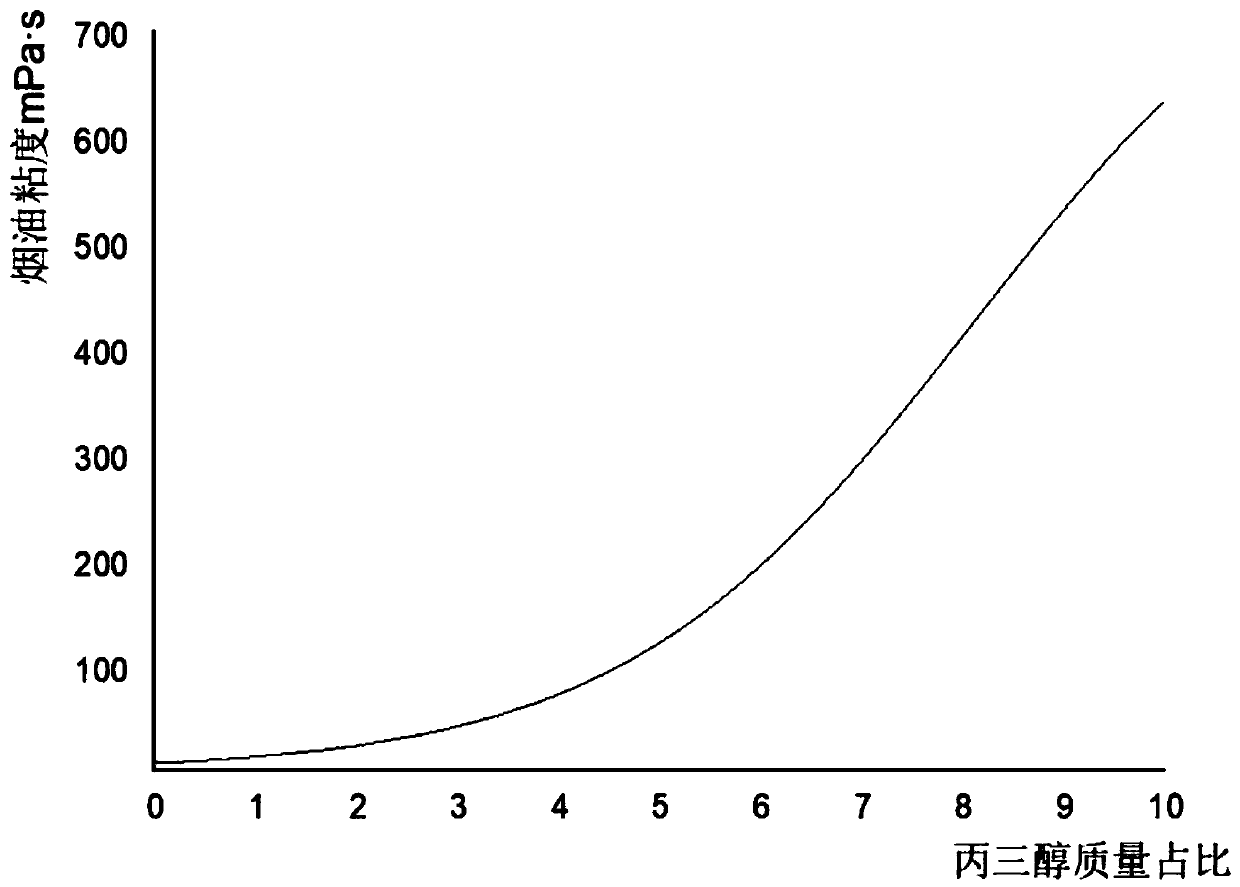

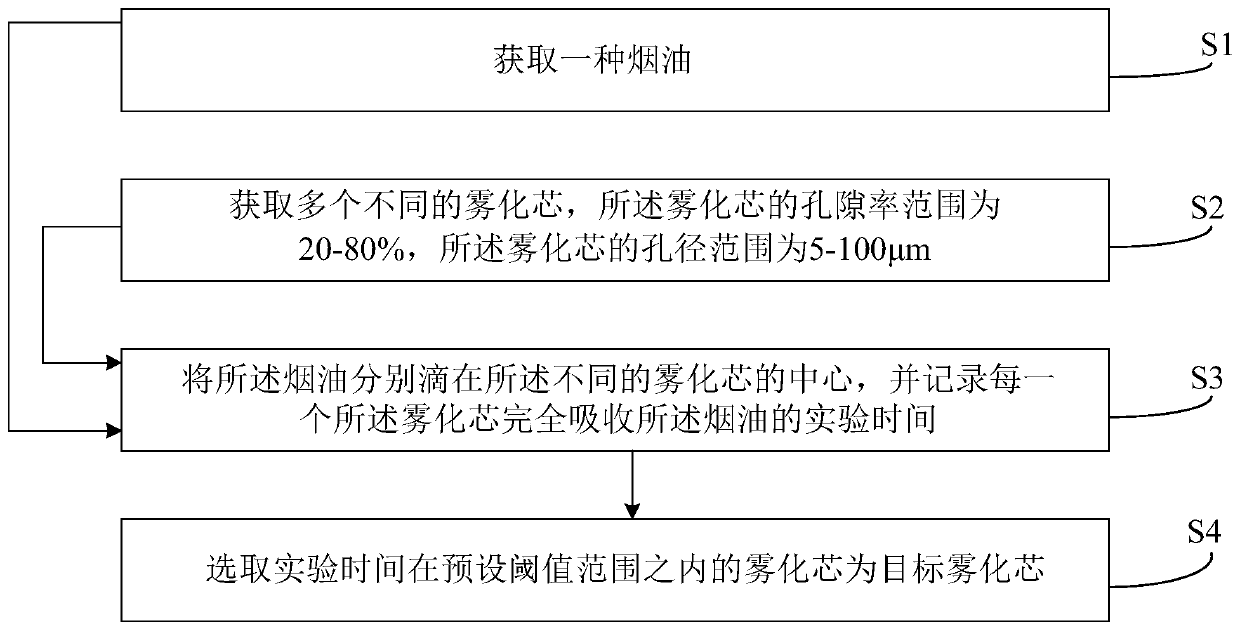

[0054] Obtain a kind of smoke oil, the viscosity of the smoke oil is 50mPa·s;

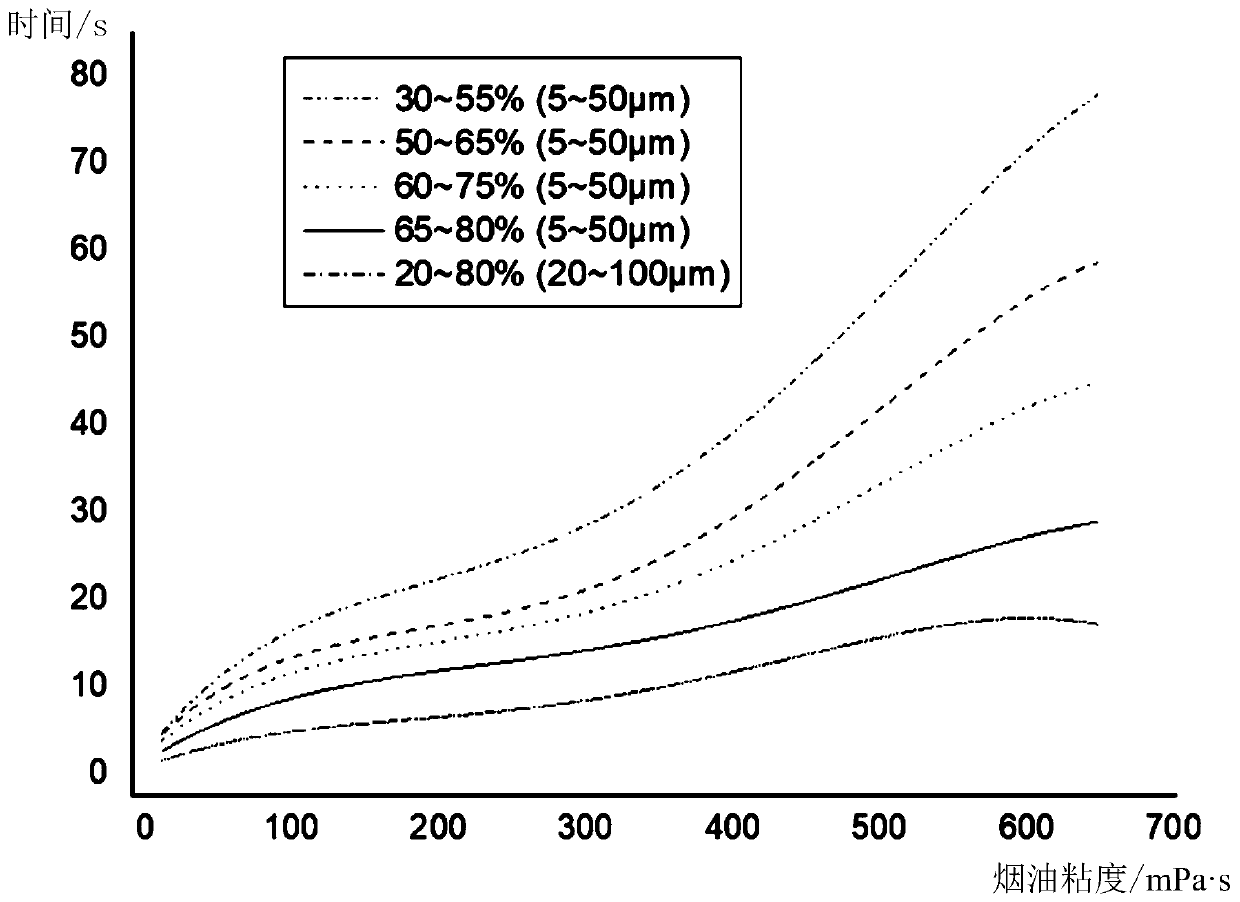

[0055] Prepare multiple different atomizing cores, the atomizing cores are diatomite-based porous ceramics, and the porosity (pore diameter) of the atomizing cores are: 30-55% (5-50 μm), 50-65% (5-50 μm ), 60-70% (5-50 μm), 65-80% (5-50 μm), 20-80% (20-100 μm).

[0056] Drop the e-liquid on the centers of the different atomizing cores respectively, and record the experimental time for each atomizing core to completely absorb the e-liquid;

[0057] As shown in Table 1:

[0058]

[0059]

[0060] According to the results in Table 1, when the porosity (aperture) of the atomizing core is 30-55% (5-50 μm), the experiment time is 11.33s, which is within the preset threshold range, and it is the target atomizing core; therefore , when the viscosity of the e-liquid is 50mPa·s, the porosity range of the adapted atomizing core is: 30-55%, and the pore diameter range is: 5-50μm.

Embodiment 2

[0062] Obtain a kind of smoke oil, the viscosity of the smoke oil is 100mPa·s;

[0063] Prepare multiple different atomizing cores, the atomizing cores are diatomite-based porous ceramics, and the porosity (pore diameter) of the atomizing cores are: 30-55% (5-50 μm), 50-65% (5-50 μm ), 60-70% (5-50 μm), 65-80% (5-50 μm), 20-80% (20-100 μm).

[0064] Drop the e-liquid on the centers of the different atomizing cores respectively, and record the experimental time for each atomizing core to completely absorb the e-liquid;

[0065] As shown in table 2:

[0066]

[0067] According to the results in Table 2, when the porosity (aperture) of the atomizing core is 30-55% (5-50μm), the experiment time is 16.60s, and the target atomizing core is within the preset threshold range; The porosity (pore diameter) of the atomizing core is: 50-65% (5-50μm), the experiment time is 13.48s, within the preset threshold range, it is the target atomizing core; the porosity (pore diameter) of the ...

Embodiment 3

[0069] Obtain a kind of smoke oil, the viscosity of the smoke oil is 200mPa·s;

[0070] Prepare multiple different atomizing cores, the atomizing cores are diatomite-based porous ceramics, and the porosity (pore diameter) of the atomizing cores are: 30-55% (5-50 μm), 50-65% (5-50 μm ), 60-70% (5-50 μm), 65-80% (5-50 μm), 20-80% (20-100 μm).

[0071] Drop the e-liquid on the centers of the different atomizing cores respectively, and record the experimental time for each atomizing core to completely absorb the e-liquid;

[0072] as shown in Table 3:

[0073]

[0074] According to the results in Table 3, when the porosity (aperture) of the atomizing core is 50-65% (5-50μm), the experiment time is 17.10s, and the target atomizing core is within the preset threshold range; The porosity (pore diameter) of the atomizing core is: 60-70% (5-50μm), the experiment time is 15.24s, within the preset threshold range, it is the target atomizing core; the porosity (pore diameter) of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com