Patents

Literature

58results about How to "Good atomization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

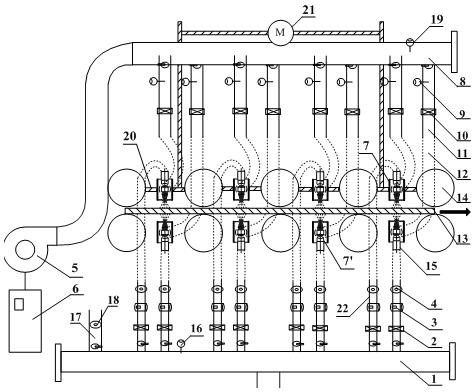

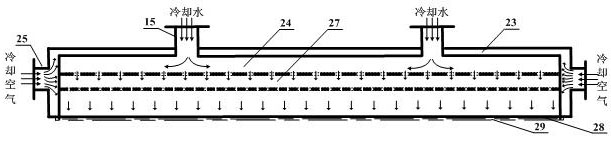

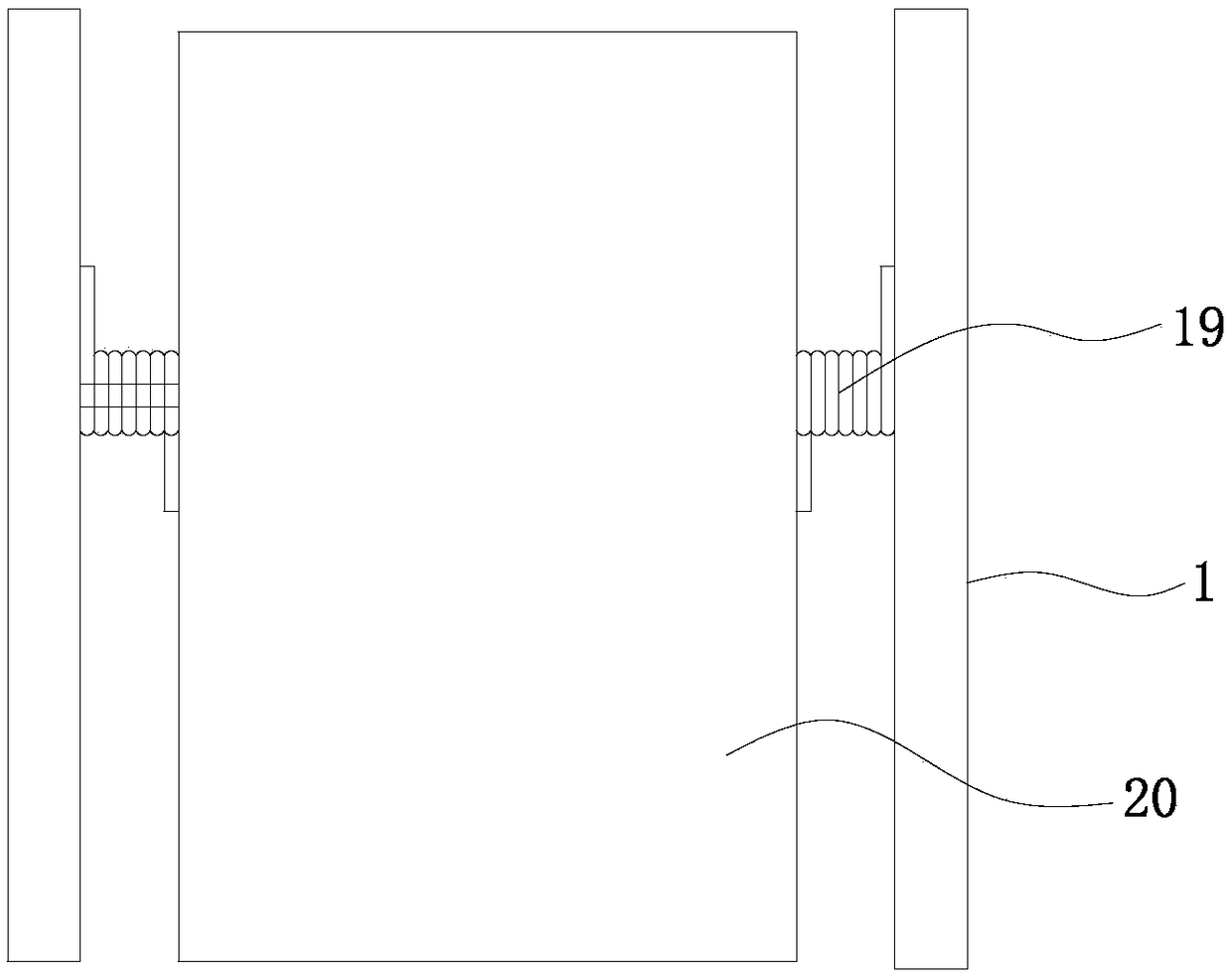

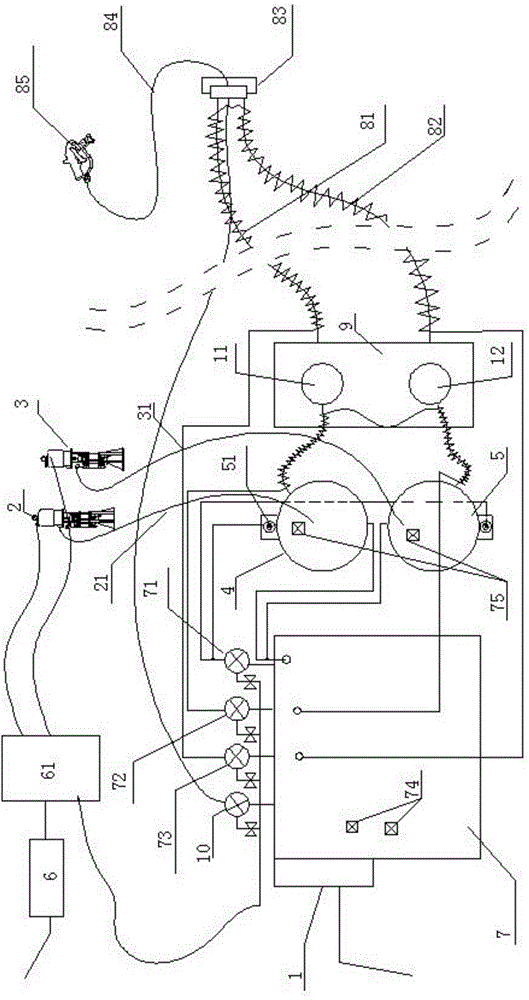

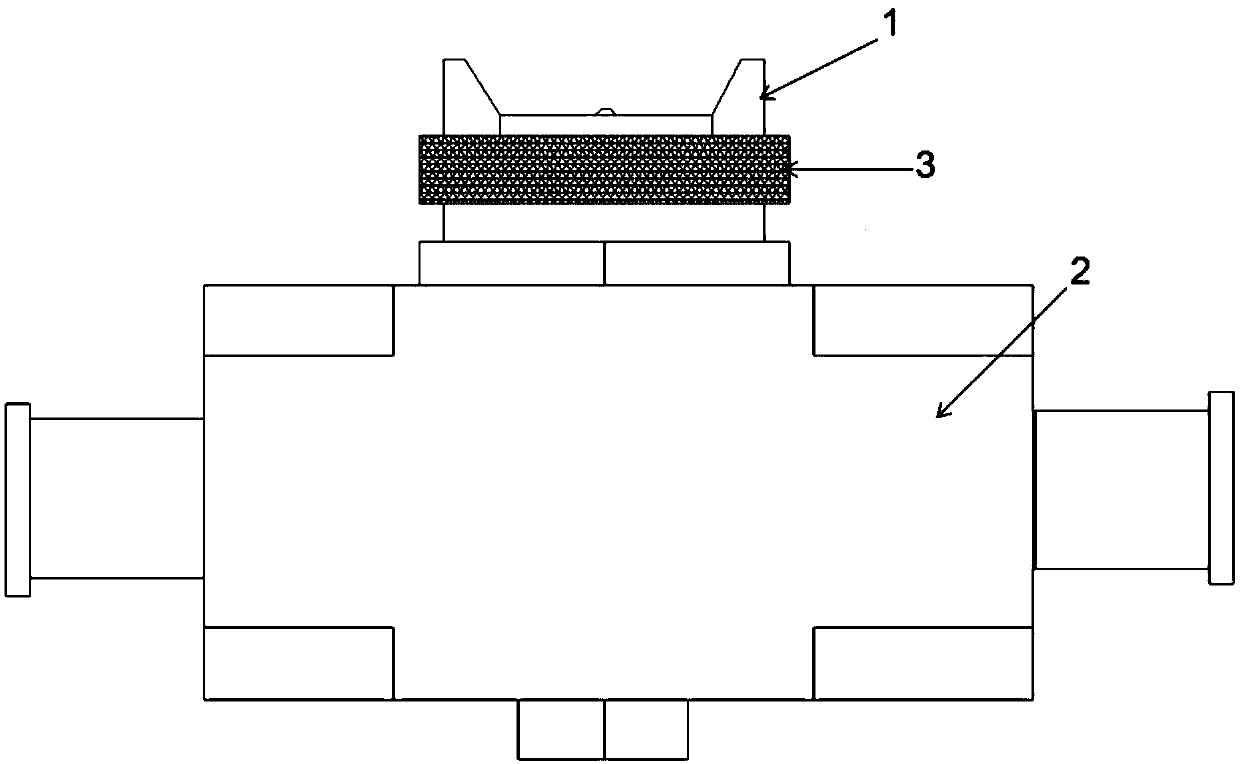

Vapor cooling system for use in offline heat treatment of thin medium and thick plates

ActiveCN102424902AGood atomization effectGood cooling uniformityQuenching devicesWater jetExperience management

The invention discloses a vapor cooling system for use in offline heat treatment of thin medium and thick plates, which comprises a water supply system, an air supply system, vapor spray nozzles and a control system, and is characterized in that: the vapor spray nozzles are symmetrically arranged above and below a rollway gap along the conveying rollway, the upper spray nozzle and an upper rollway are fixed on a movable upper frame, and the lower spray nozzle is fixed on a fixed frame; the water and air supply systems are led into the vapor spray nozzles by a shunt water collecting header anda shunt air collecting header respectively; a water supply pipe is provided with a valve, a flow meter and a regulating valve and is used for providing stable and reliable cooling water into an innerwater storage cavity in the spray nozzle from the side of the spray nozzle; and the control system consists of an experience management system and a PLC system, the experience management system makesa vapor cooling policy and cooling procedure and sends the cooling procedure to the PLC system to execute the cooling procedure, and the PLC system realizes the regulation of the intensity of coolingof the spray nozzle and the regulation of the state of water spraying. The vapor cooling system can solve the nonuniform cooling problem aroused by the high-pressure water jet cooling in the conventional thin medium and thick plate offline quenching.

Owner:NORTHEASTERN UNIV

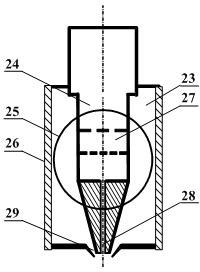

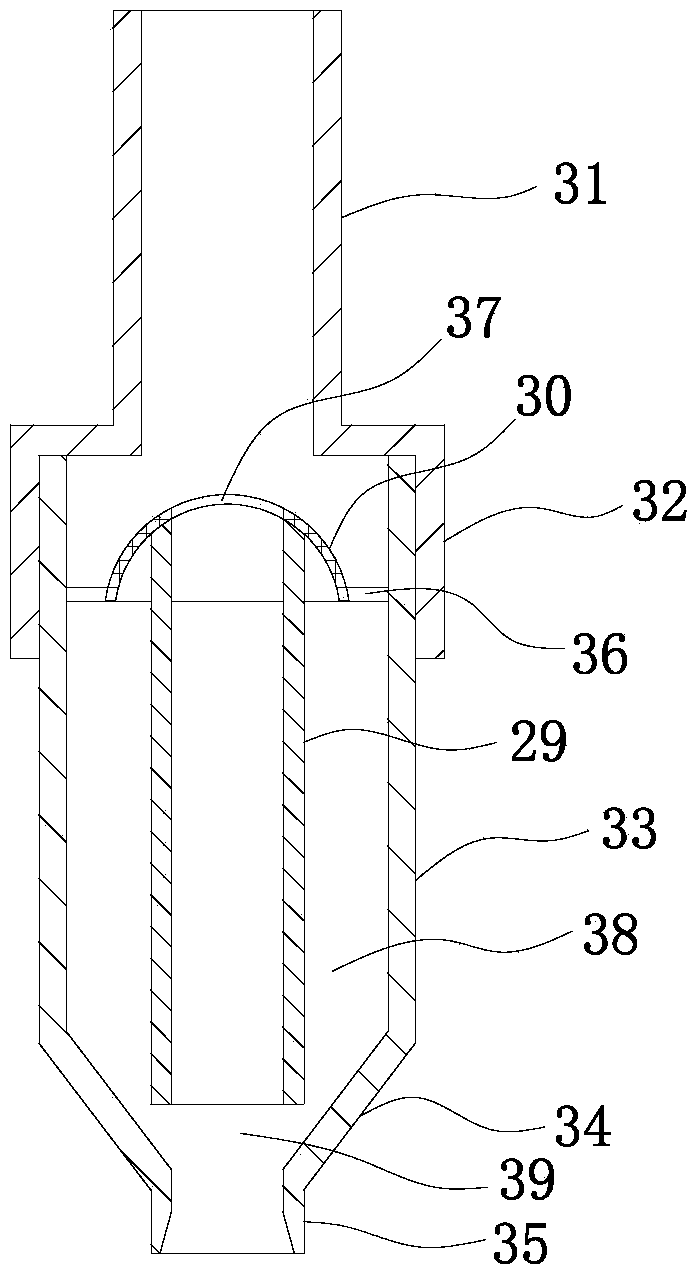

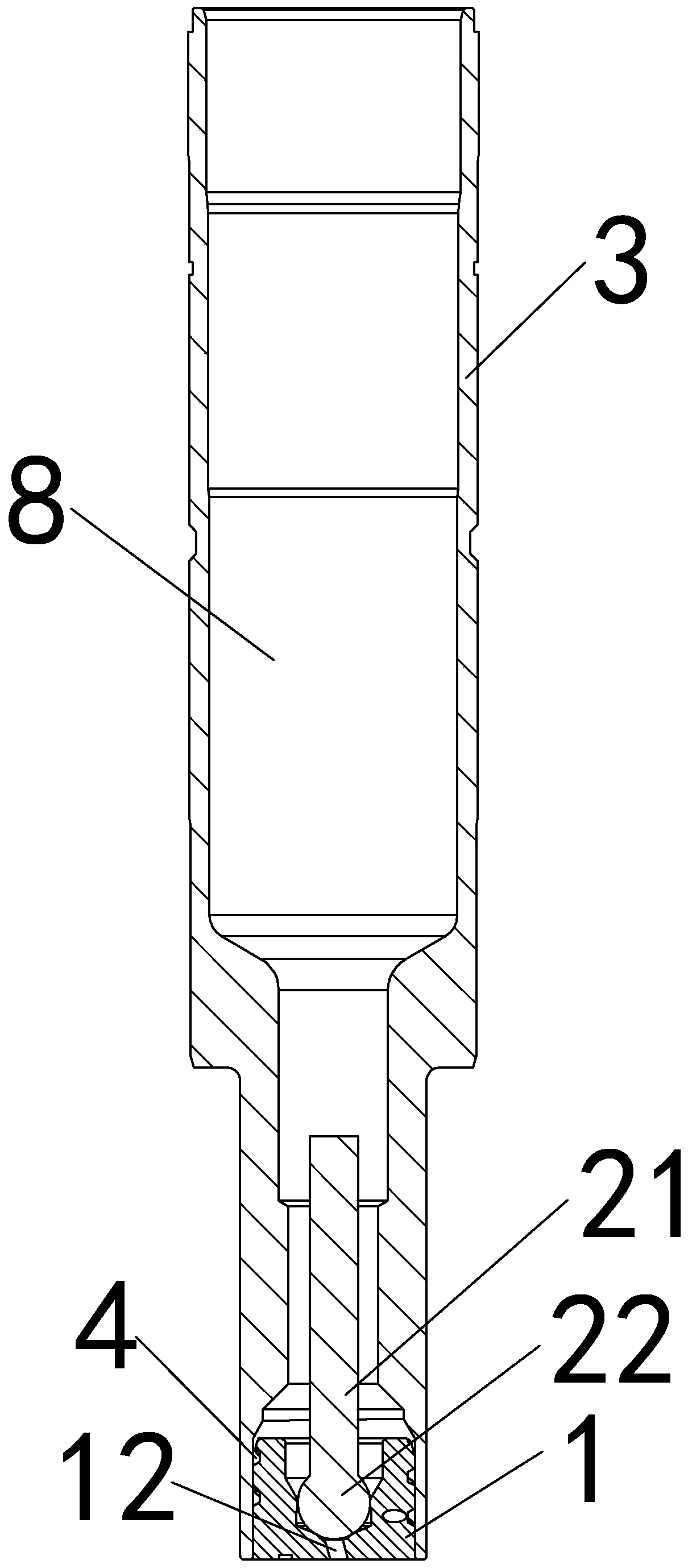

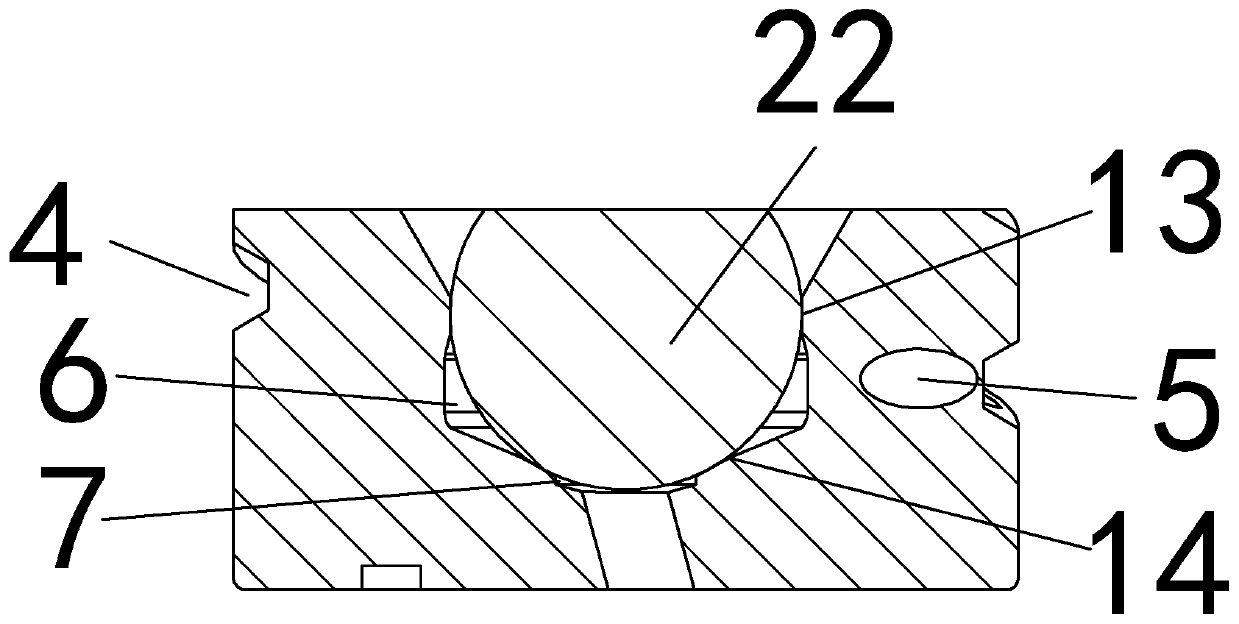

Micro water fog spray nozzle based on bubble atomization

The invention discloses a micro water fog spray nozzle based on bubble atomization. The micro water fog spray nozzle is characterized in that an air filling tube in the micro water fog spray nozzle is in threaded connection with a mixing cavity, so that the distance between each air filling hole and each spray hole can be adjusted; 2-3 rows of air filling holes are formed in the side surface of the air filling tube and 4-7 air filling holes are formed in the bottom of the air filling tube; each row of air filling holes in the side surface of the air filling tube are uniformly distributed on the circumference on which the cross section of the air filling tube is arranged and the air filling holes in the bottom of the air filling tube are also uniformly distributed along the circumference; the distances between the rows of air filling holes in the side surface of the air filling tube are the same and each air filling hole is downwardly tilted at an angle of 40-50 degrees; a spray hole is formed in the center of the bottom surface of the spray nozzle. Compared with a conventional fine water fog spray nozzle, the micro water fog spray nozzle has the advantages of small working pressure, less required atomizing air, larger spray-hole diameter, good atomizing effect, applicability to firefighting field, high extinguishing effectiveness and the like.

Owner:UNIV OF SCI & TECH OF CHINA

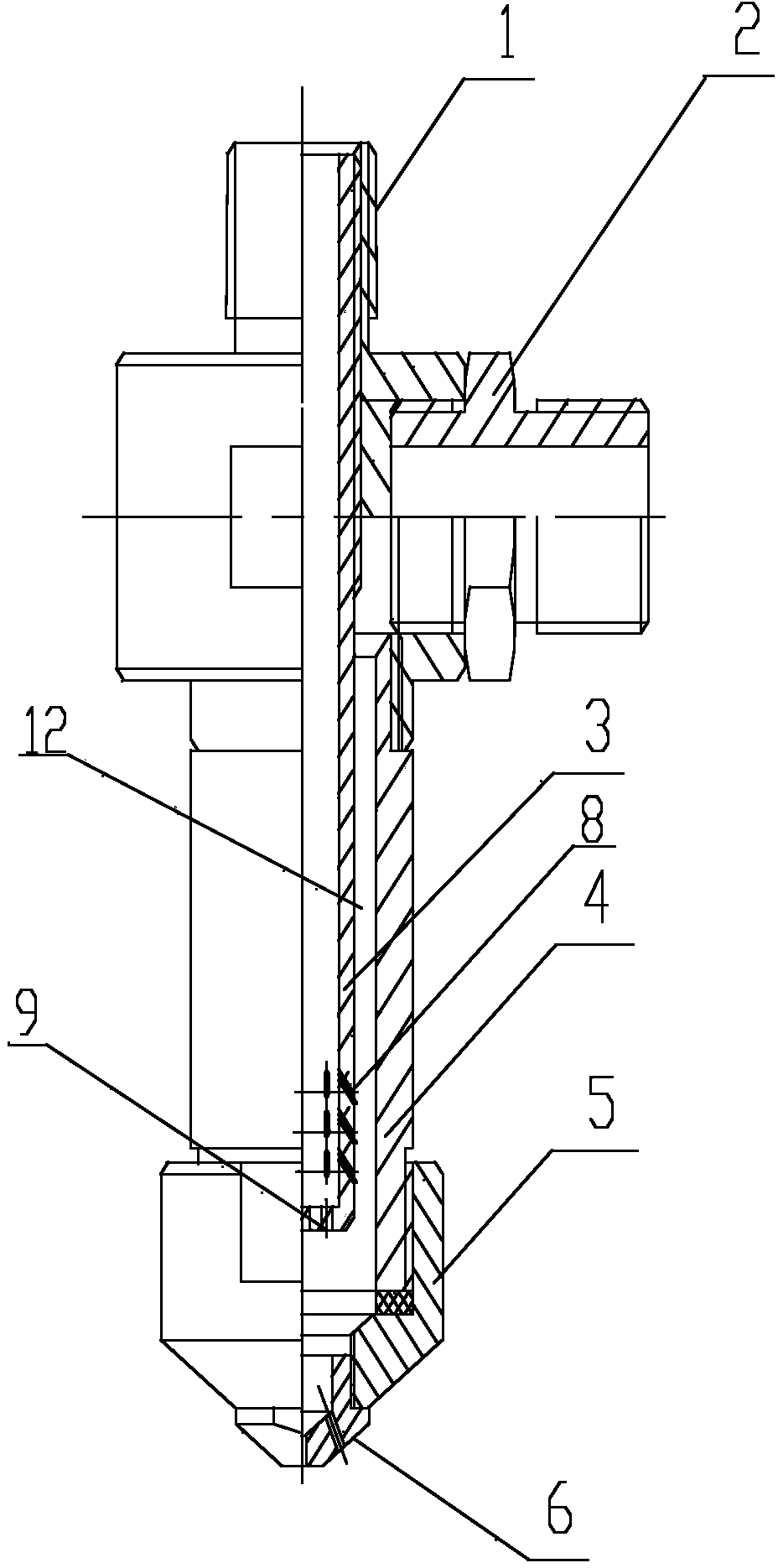

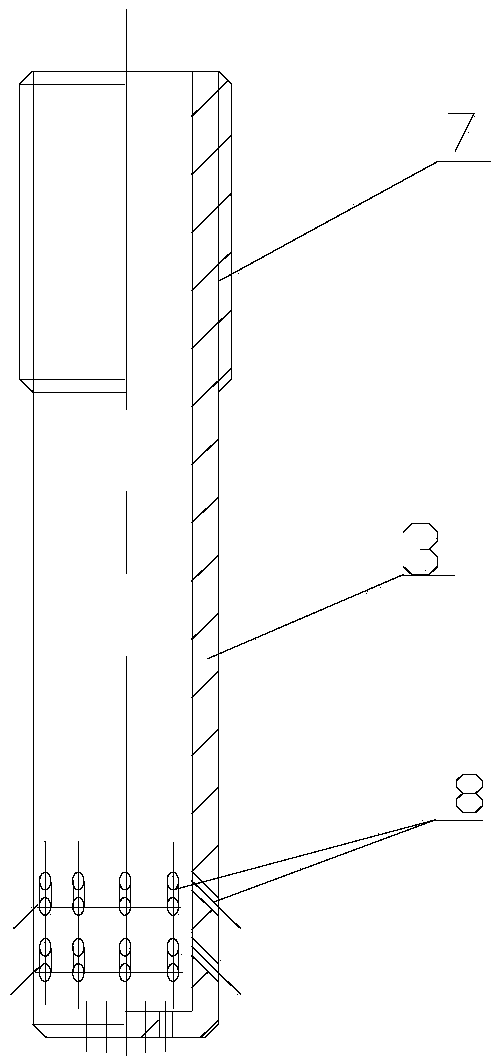

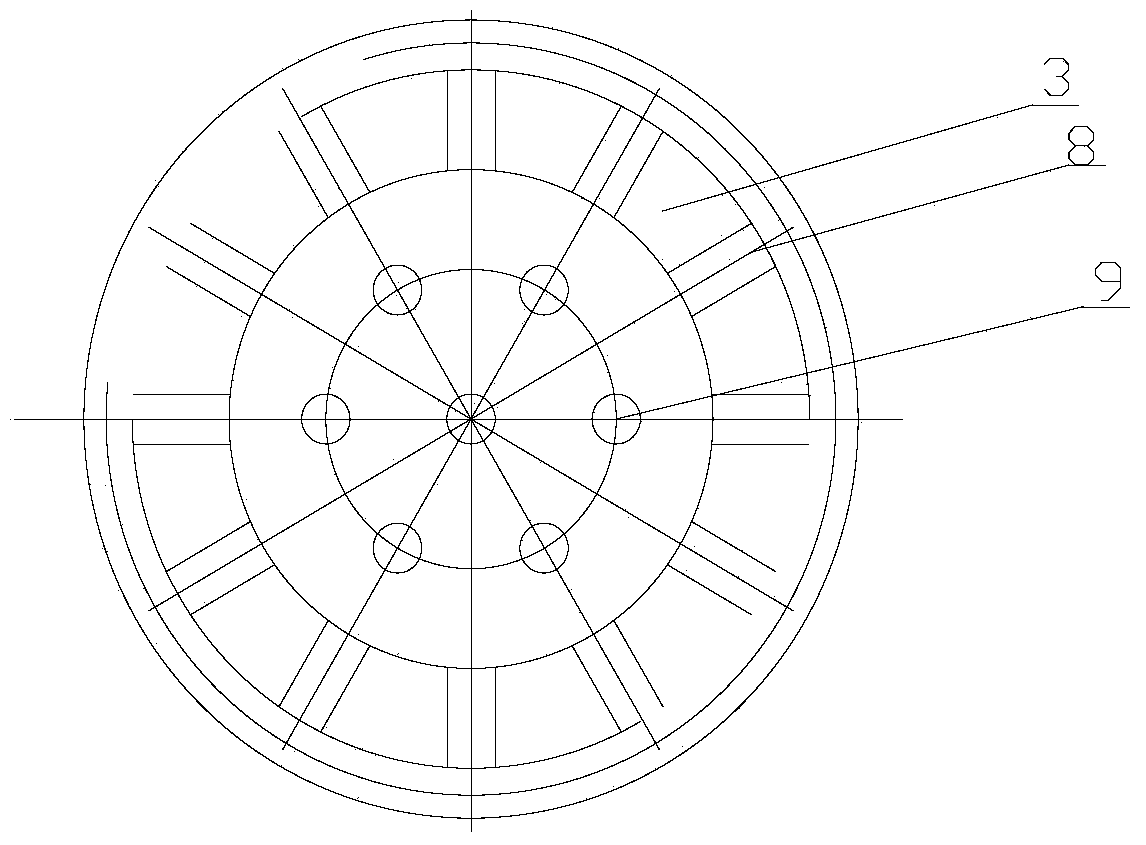

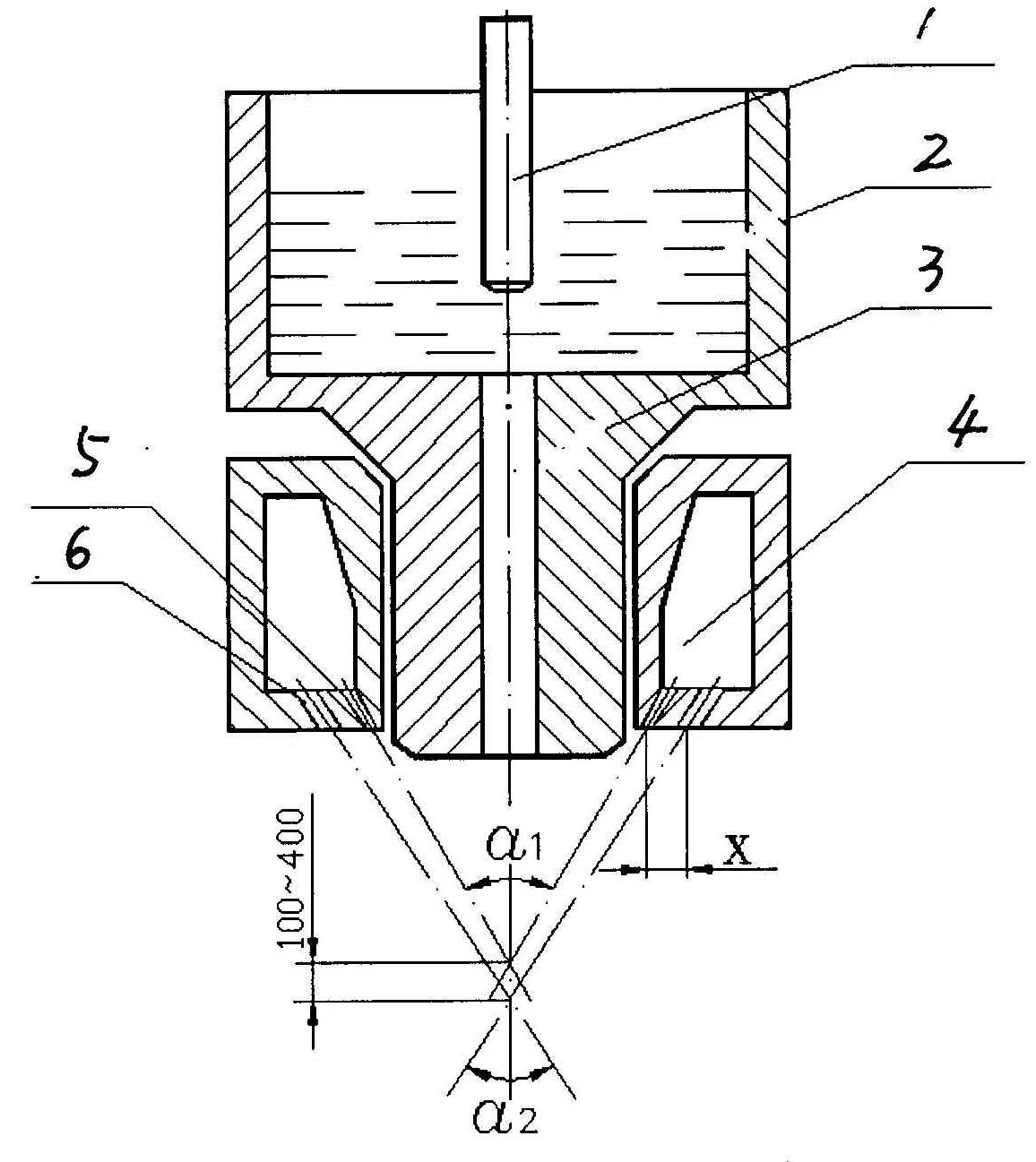

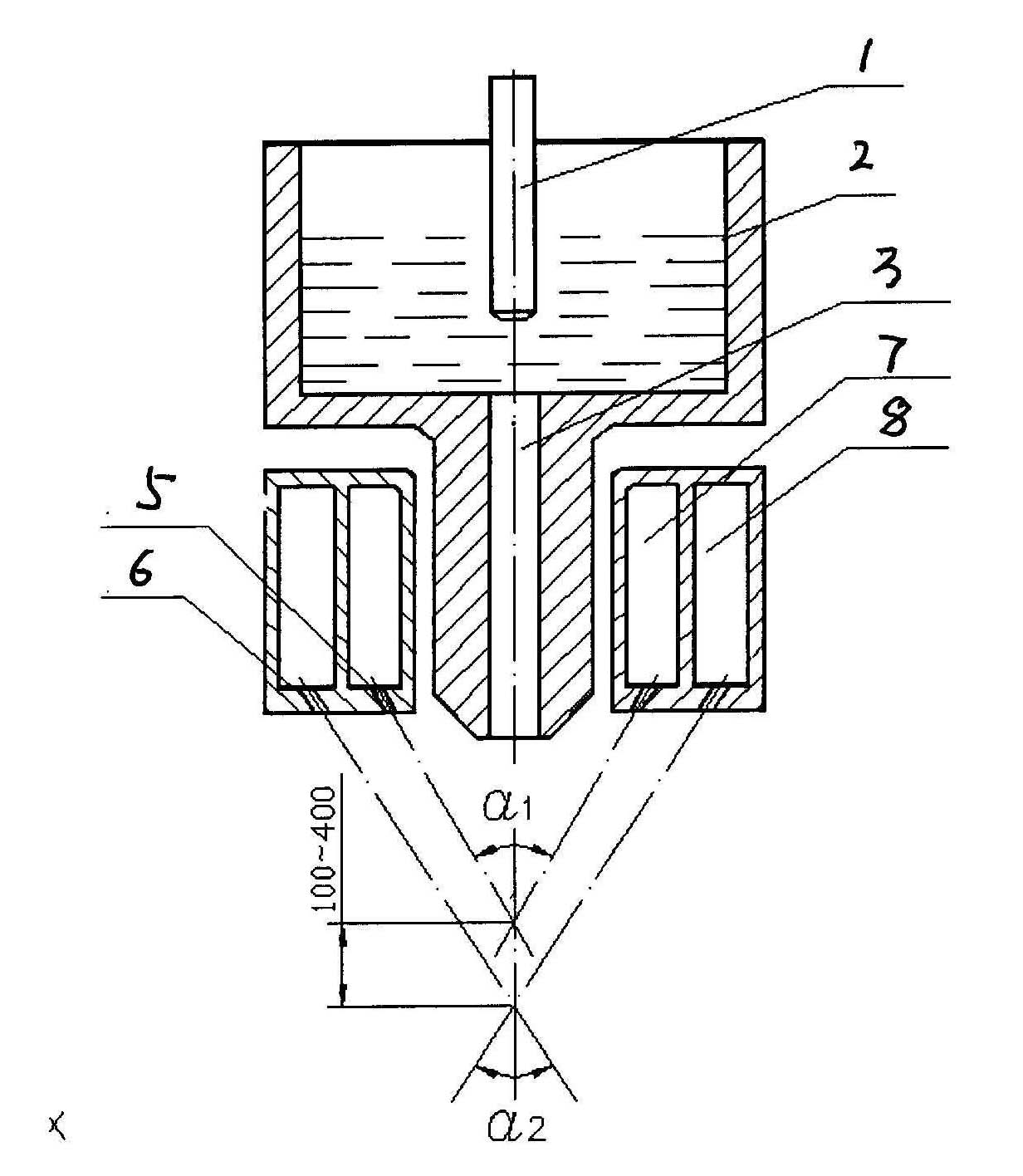

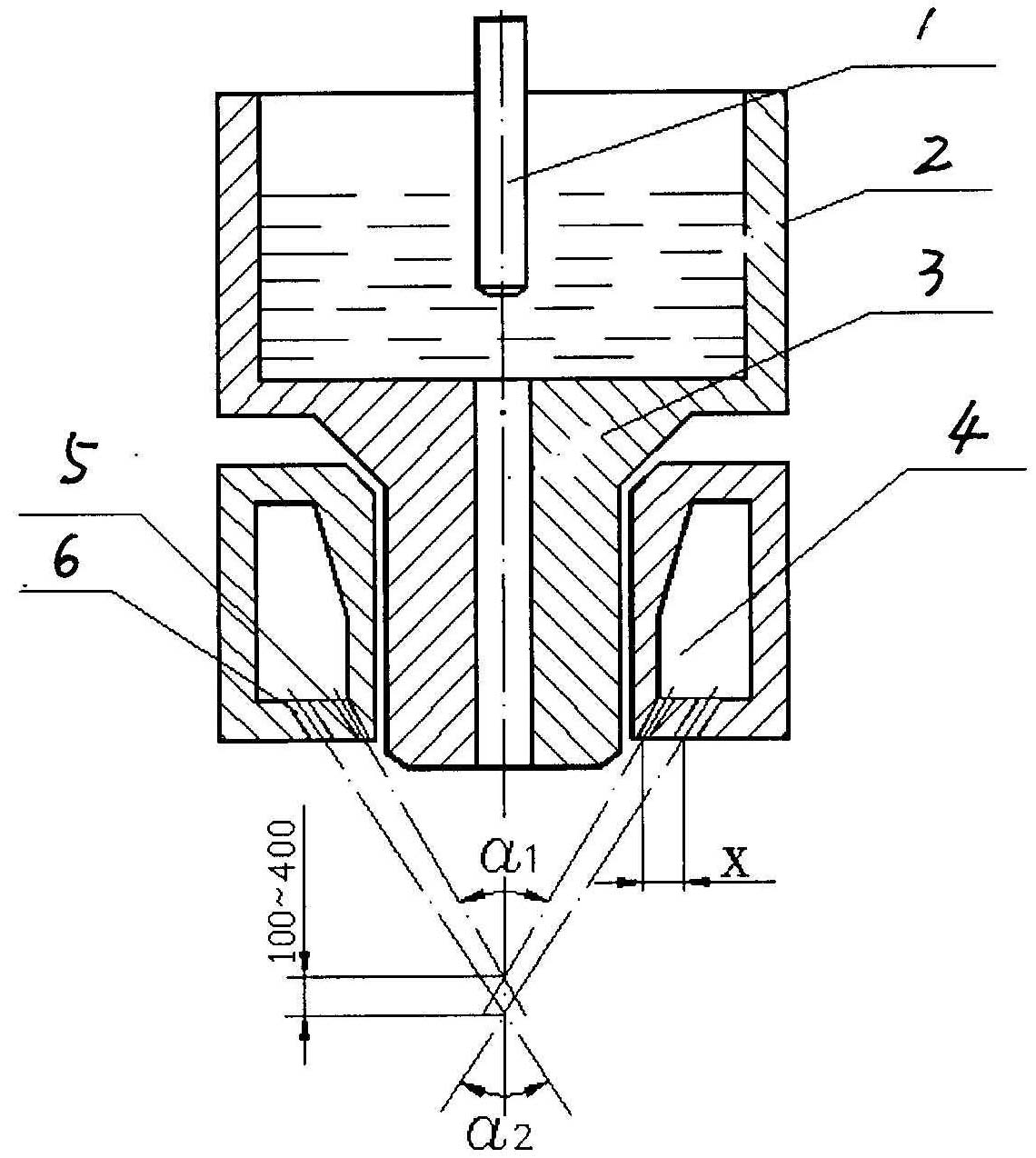

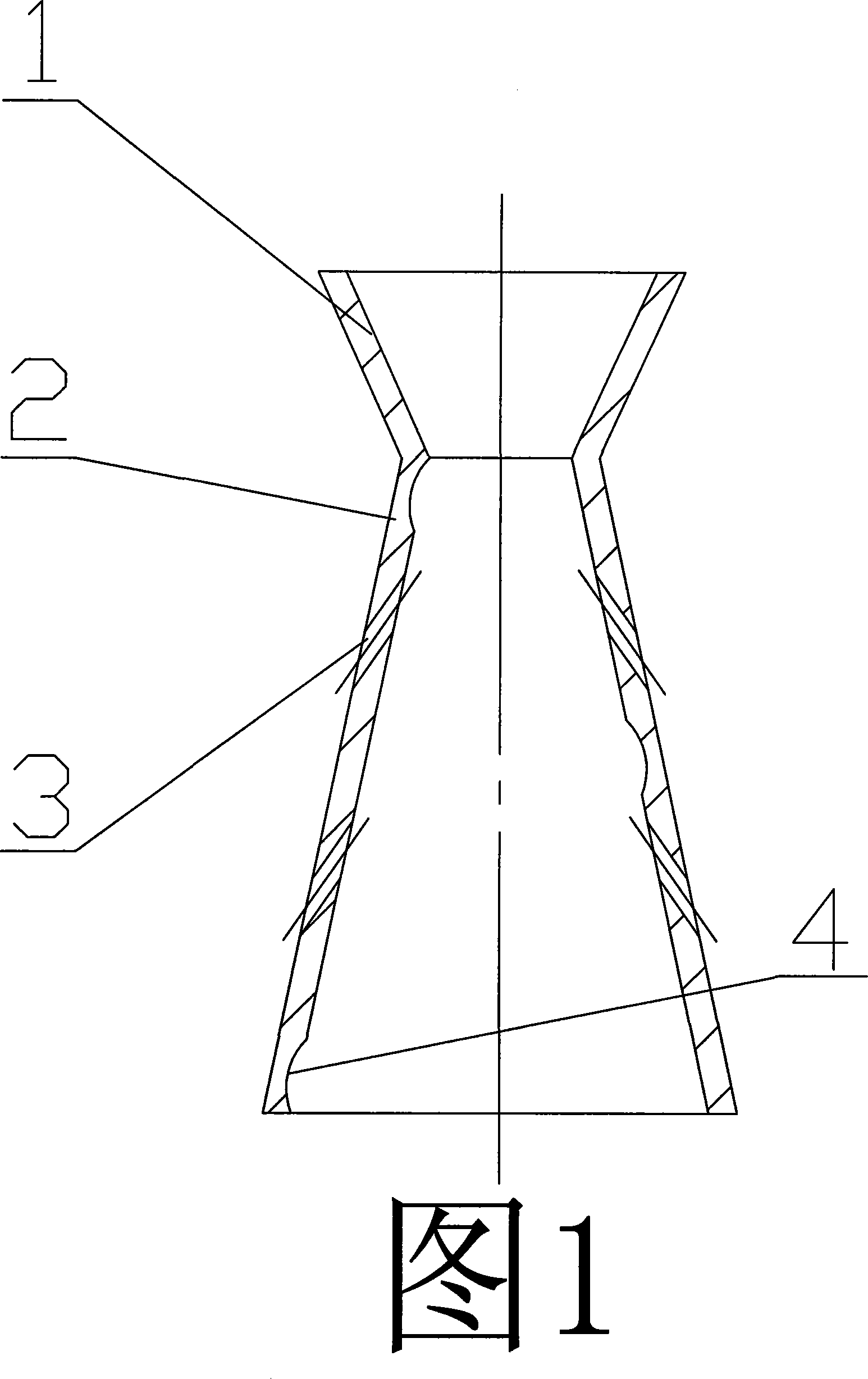

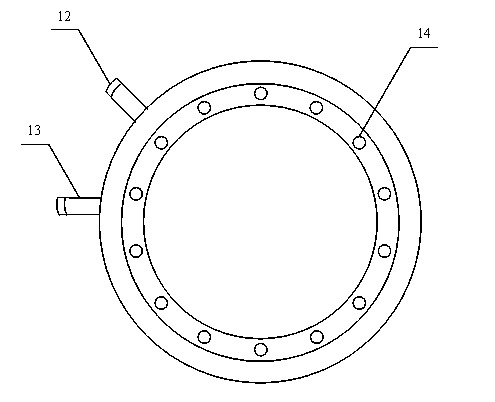

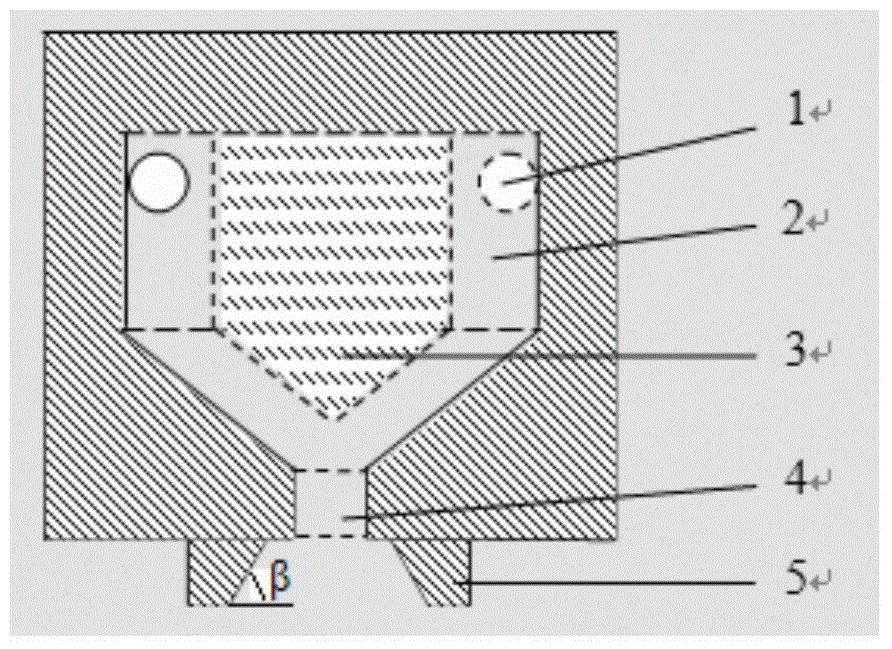

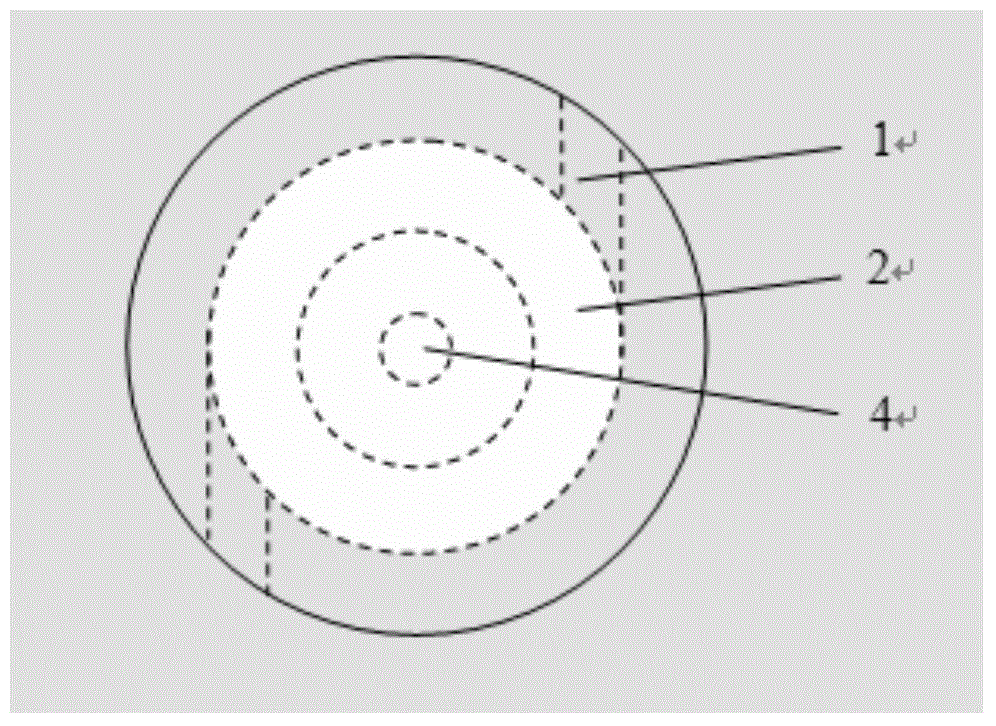

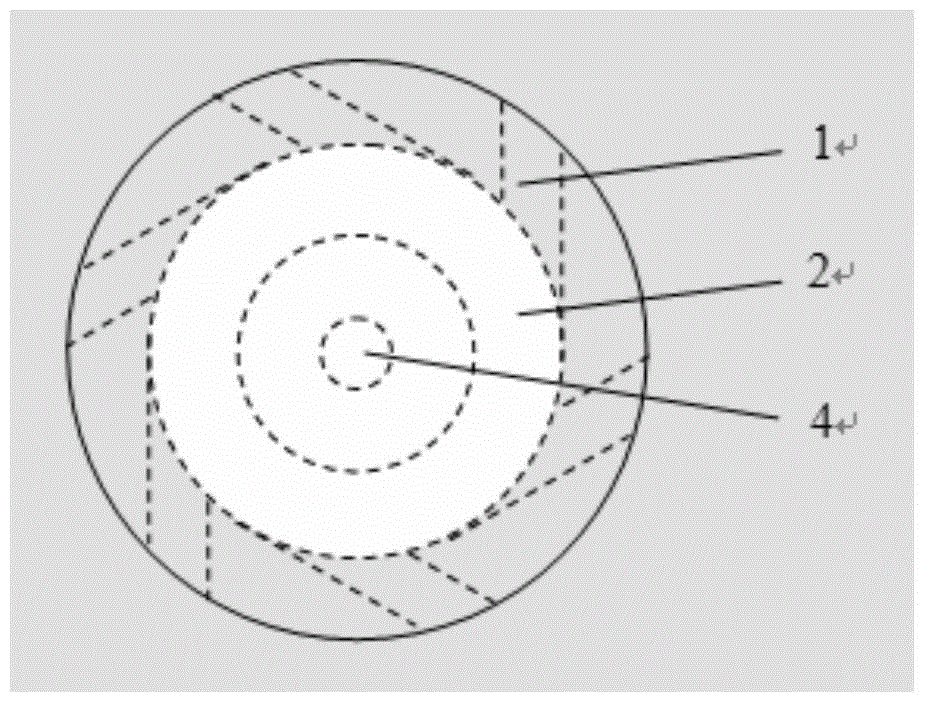

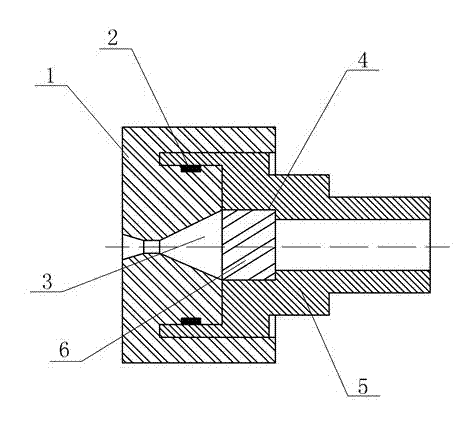

Composite atomizer for manufacturing gas atomization quick-coagulation spherical superfine metal powder

The invention relates to a composite atomizer for manufacturing gas atomization quick-coagulation spherical superfine metal powder, which comprises a crucible for containing metal liquid and an atomizer stationing chamber which is arranged around a metal liquid guiding pipe at the bottom of the crucible, is communicated with a high-speed airflow source and has an annular structure. The composite atomizer is characterized in that: inner and outer nozzle rings which are formed by a plurality of nozzles arranged in a mode of uniform distribution and have structures of concentric circles are formed around the annular bottom surface of the atomizer stationing chamber, and the nozzles are arranged in a skew mode which makes the axes of the nozzles intersected with the lower extended line of the axis of the liquid guiding pipe, wherein the axes of all nozzles on the inner nozzle rings close to the axis of the liquid guiding pipe and the axis of the liquid guiding pipe intersect at a vertical angle point alpha 1 in an atomizing area II, the axes of all nozzles on the outer nozzle rings away from the axis of the liquid guiding pipe and the axis of the liquid guiding pipe intersect at a vertical angle point alpha 2 of an atomizing area III, and the distance between the two vertical angle points is between 0.1 and 0.4 millimeter; and the atomizing pressure is controlled to be between 0.5 and 2.5 MPa.

Owner:HENAN POLYTECHNIC UNIV

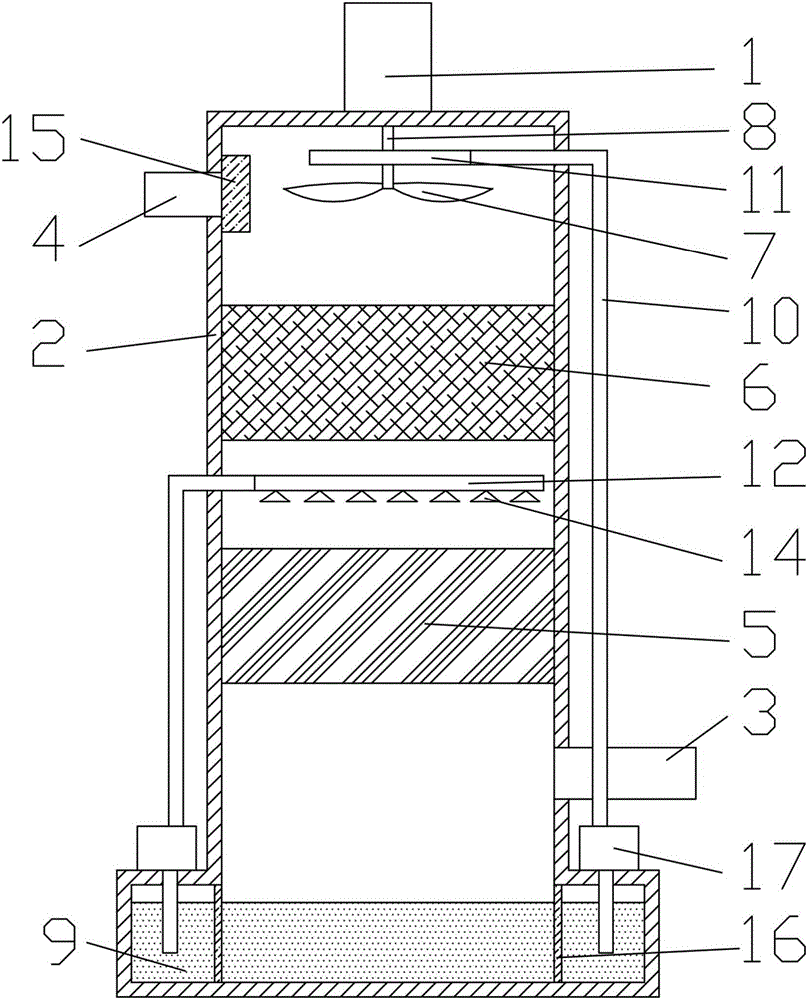

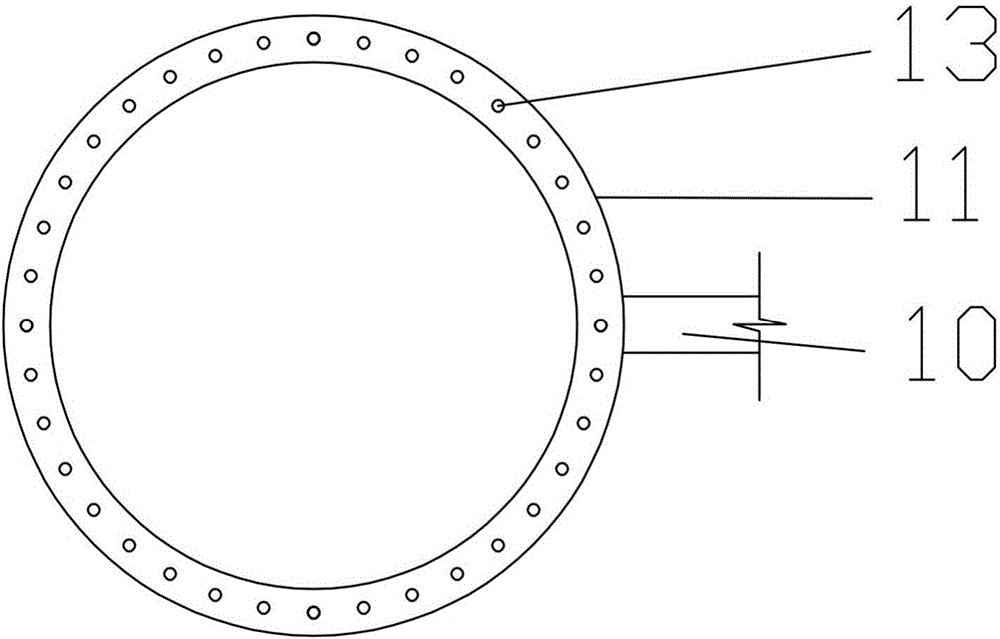

Spray tower used for industrial waste gas treatment

InactiveCN106390680AThe chemical adsorption effect is obviousGood atomization effectUsing liquid separation agentSpray towerIndustrial waste

The invention discloses a spray tower used for industrial waste gas treatment. The spray tower comprises a motor, a shell, a gas feeding tube and a gas discharging tube, the motor is arranged at the upper end of the shell, a polyhedral hollow ball packing layer is arranged in the shell, a volcanic rock flow-separated ball packing layer is arranged at the upper end of the polyhedral hollow ball packing layer, rotating blades are arranged at the upper end of the volcanic rock flow-separated ball packing layer, a spray liquid in the right lower end of the shell is connected to an annular spray tube arranged at the upper end of the rotating blades through a circulating tube, and a spray liquid in the left lower end of the shell is connected to a lower spray tube arranged between the polyhedral hollow ball packing layer and the volcanic rock flow-separated ball packing layer through a circulating tube. The spray tower has the following advantages: the spray tower has an obvious chemical adsorption effect on polluting substances in waste gas; the spray tower adopting two spray tubes and two-layer spraying has a good atomization effect, and well contacts with dusts; and the annular spray tube is arranged at the upper end of the spray tower, and the rotating blades are arranged at the lower end of the annular spray tube, so a liquid sprayed by the annular spray tube is rotated by the rotating blades, thereby the atomization effect is improved.

Owner:福建众辉环保设备有限公司

Organic volatile solvent-free environmentally friendly anti-cracking transparent UV spray priming paint

InactiveCN104830209ALow viscosityGood atomization effectPolyurea/polyurethane coatingsEpoxy resin coatingsEnvironmentally friendlyOrganic solvent

An organic volatile solvent-free environmentally friendly anti-cracking transparent UV spray priming paint comprises, by mass, 30-50% of modified epoxy acrylic resin, 10-15% of modified polyurethane acrylate and 15-30% of an active monomer, and appropriate light-curable resin and the active monomer are selected to meet requirements of no cracking under hot and cold cycles in -20-120DEG C environment. The organic volatile solvent-free environmentally friendly anti-cracking transparent UV spray priming paint has the advantages of low use viscosity, good atomization effect, strong dilution ability, good wrapping property, good adherence, good wettability, good rubbing property and environmental protection, can be directly used in electrostatic spraying of devices without dilution by using an organic solvent, is suitable for industrial production, and solves the problem of cracking induced by long time high and low temperature environment in the furniture export sea transportation process.

Owner:上海君子兰新材料股份有限公司

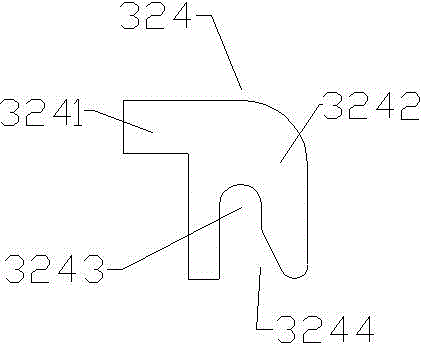

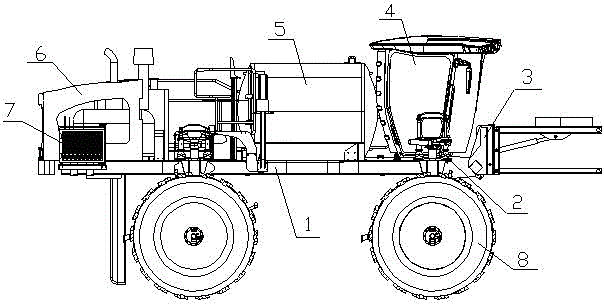

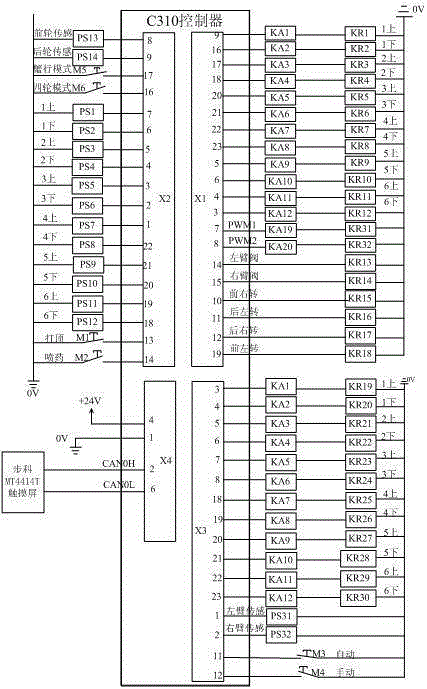

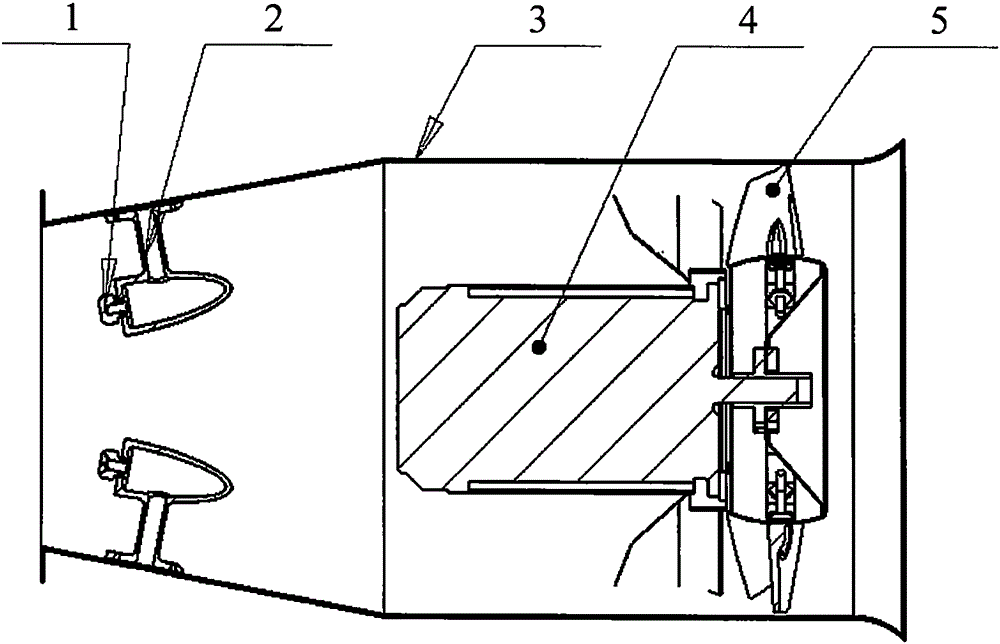

Intelligentized and multi-functional robot for plant protection

ActiveCN105211032AHigh degree of intelligenceQuick changeCuttersCutting implementsWireless transmissionVehicle frame

The invention relates to an intelligentized and multi-functional robot for plant protection. The intelligentized and multi-functional robot for plant protection comprises a control member and a vehicle frame body. The control component is used for realizing selection and automatic control of working modes of the robot for plant protection. The vehicle frame body can be connected with multiple groups of working members. A quick coupling device is arranged among all the working members and the vehicle frame body and used for realizing quick replacement among all the working members and the vehicle frame body. The intelligentized and multi-functional robot for plant protection has following beneficial effects: the intelligentized and multi-functional robot for plant protection can be used for multiple purposes and has integrated functions of fertilizer application, sowing, spraying, emasculation by topping; the intelligentized and multi-functional robot is high in intelligent degree and has functions of remote control, image monitoring, wireless transmission and acquisition of field data; manless driving can be realized; labor cost is greatly decreased; and high operation comfortable and high working precision and 99.9% accuracy are obtained.

Owner:SHANDONG SHKE MACHINERY MFG

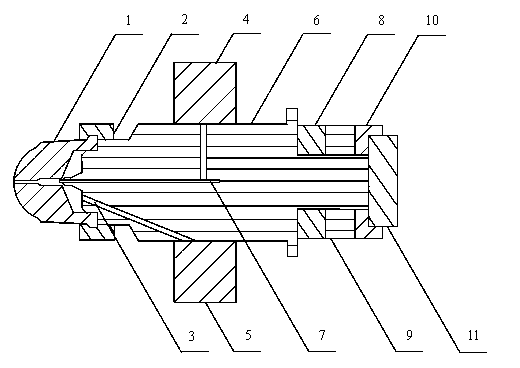

Atomized spray head

InactiveCN101099954ALarge diffusion areaGood atomization effectSpray nozzlesLiquid spraying apparatusEngineeringHelix

The present invention discloses one new type of nozzle for the atomizer in industrial no-stuffing water cooling tower. The integrated tubular atomizing nozzle includes one conic nozzle neck with through holes and helical groove in the wall, and one conic spout connected to the nozzle neck. Owing to the nozzle neck with through hole and helical groove, the air through the through holes may be well mixed with water flow and the water flow produces rotating centrifugal force, reaching excellent atomizing effect.

Owner:CHENGDU SHENGDONG TECH

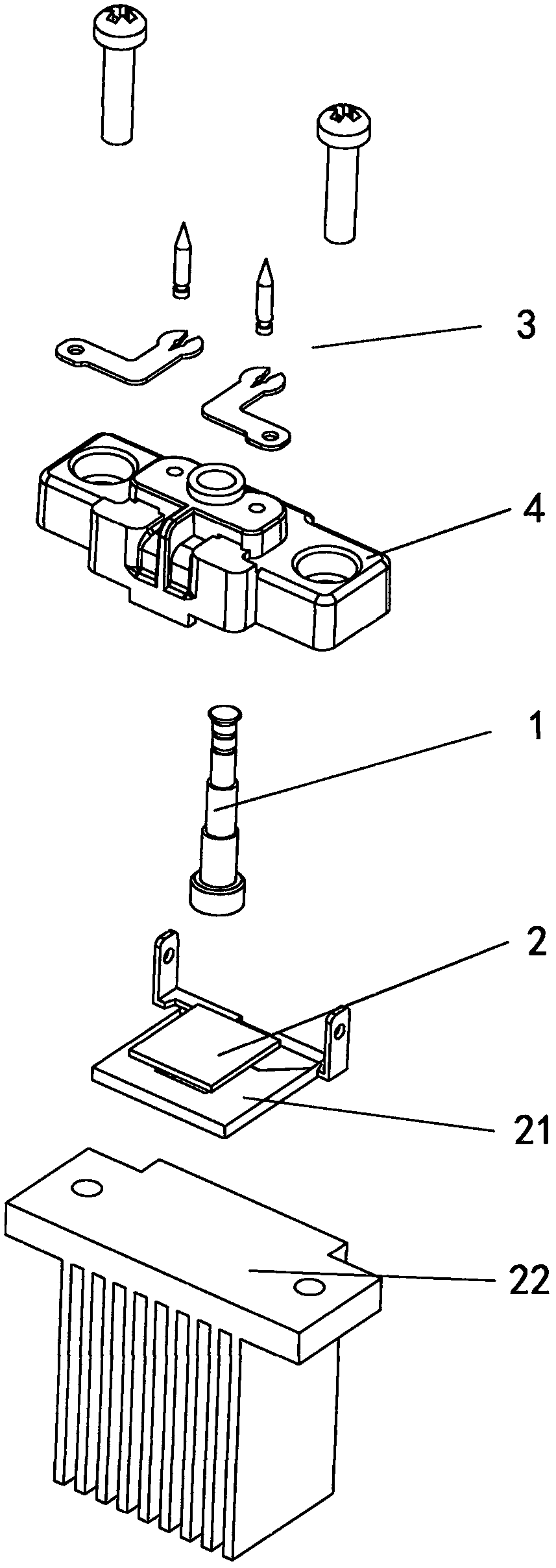

Ultrasonic atomizing device and atomizing method for liquid-containing binder for glass cotton

InactiveCN103567106AGood atomization effectImprove binder usageLiquid spraying apparatusNeedle valvePolymer chemistry

The invention relates to an ultrasonic atomizing device and an atomizing method thereof, in particular to an ultrasonic atomizing device and an atomizing method for a liquid-containing binder for glass cotton. According to the device, the coordinated function of air pressure atomizing and ultrasonic vibration atomizing is used, and a flow adjusting needle valve or an anti-blocking removing valve is selected to adjust the flow of the binder and prevent the binder from blocking. When the binder with a certain viscosity is sprayed out, a good atomizing effect is realized as the particle size of the liquid-containing binder is small, the usage rate of the binder is effectively improved, the production cost is reduced, meanwhile, the liquid-containing binder is more uniformly dispersed in glass fibers, the color difference of the glass cotton product is reduced and the tear strength of the glass cotton product is effectively improved.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

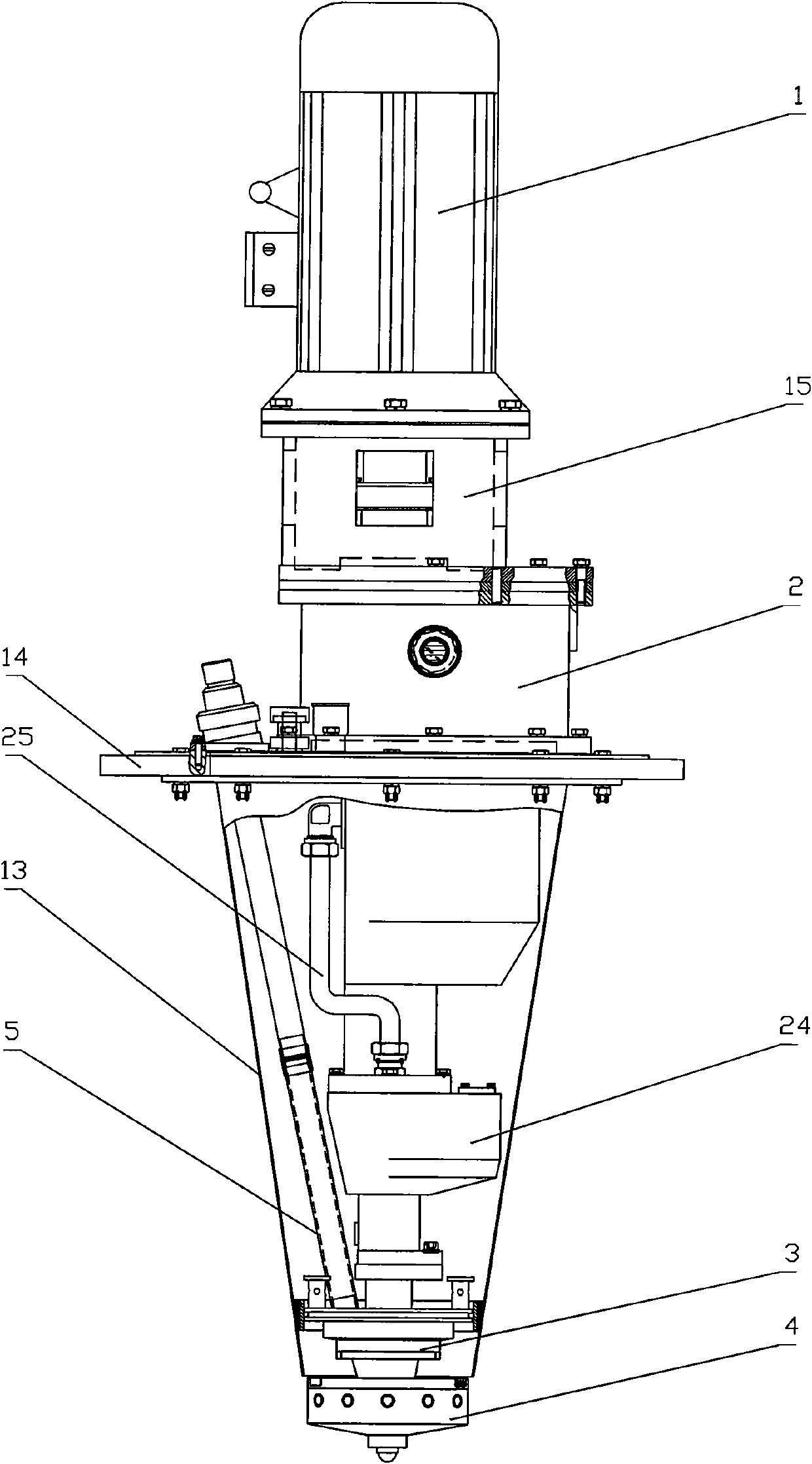

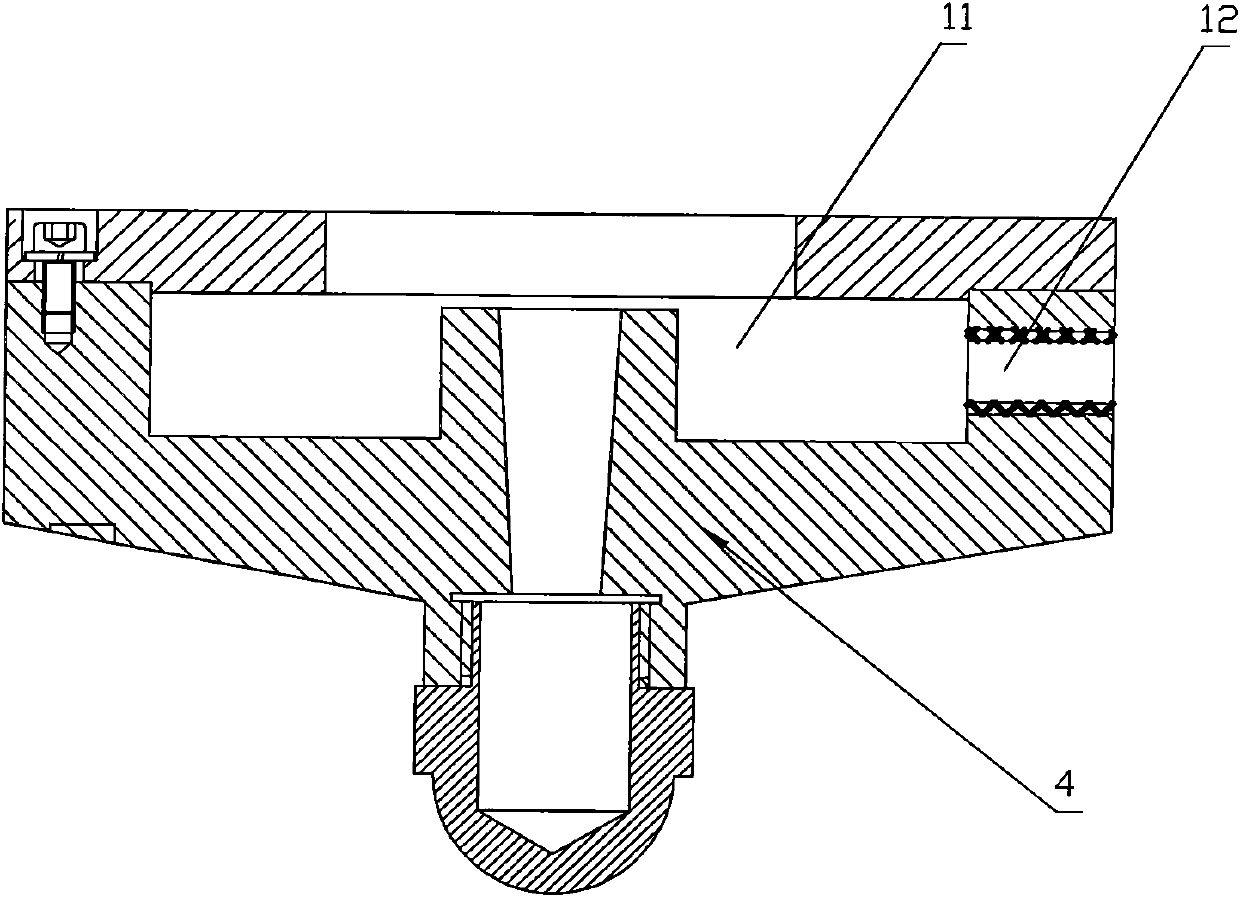

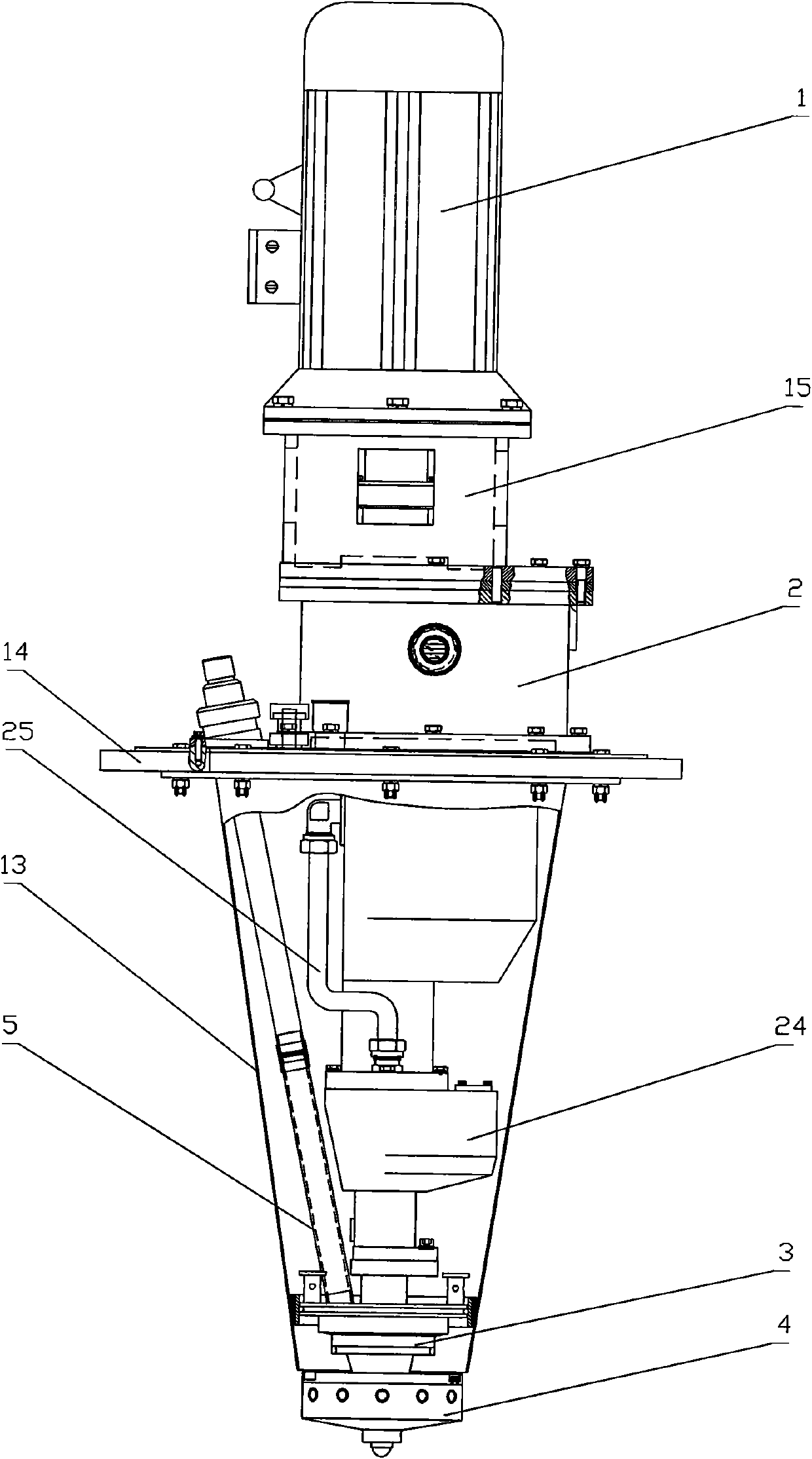

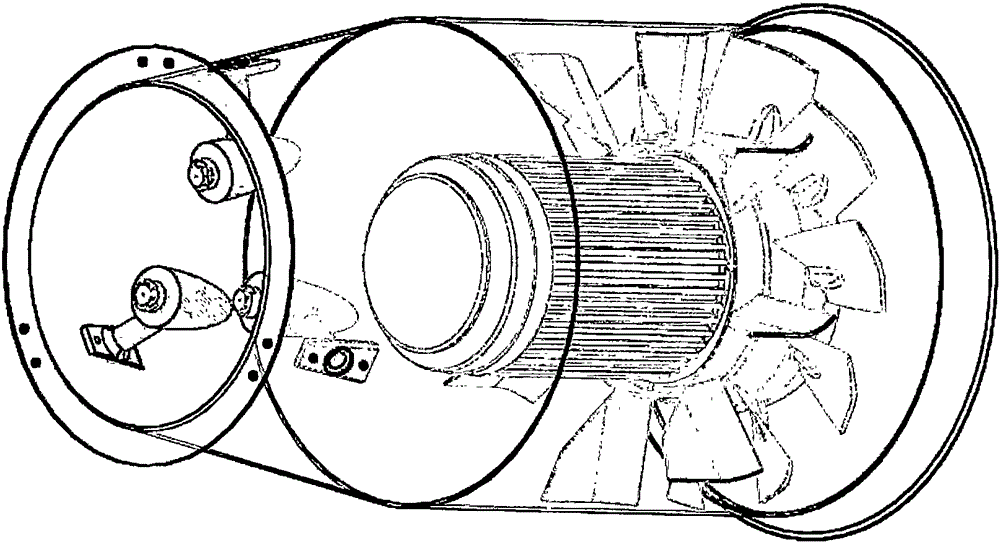

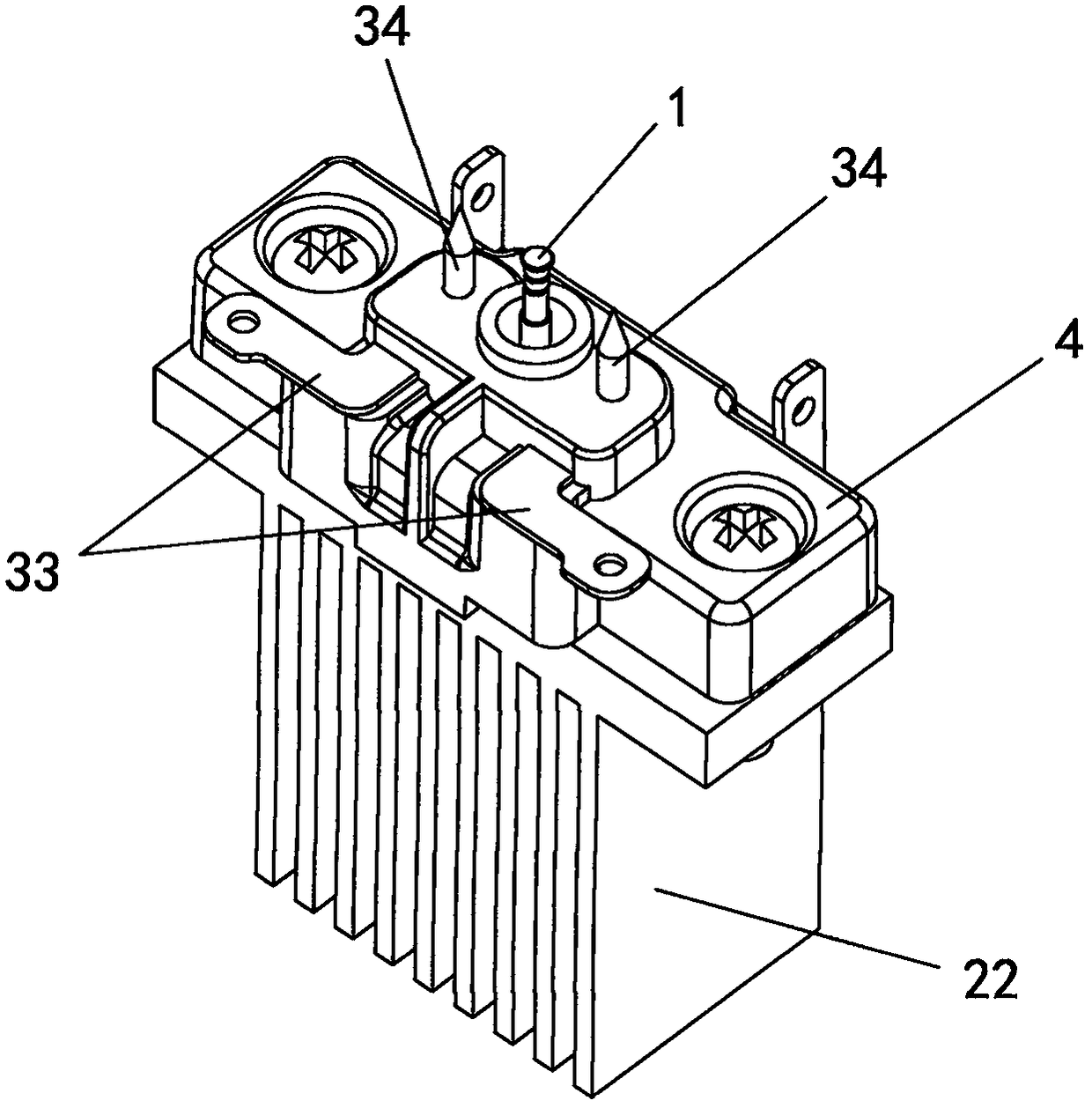

High-speed centrifugal atomization device for flue gas treatment

InactiveCN101947408AGood atomization effectFlue gas treatment reaction is thoroughDispersed particle separationSpray nozzlesPollutantProcess engineering

The invention provides a high-speed centrifugal atomization device for flue gas treatment. The device comprises a variable-frequency motor, a speed increaser, a distributing device, an atomizing disk and a feed pipe, wherein the speed increaser, the distributing device and the atomizing disk are driven by the variable-frequency motor; the feed pipe is used for conveying liquid materials required for flue gas treatment reaction; the distributing device is sleeved on an output shaft of the speed increaser and is in clearance fit with the speed increaser; the atomizing disk is fixedly sleeved at the end of the output shaft of the speed increaser; and a discharge port of the feed pipe corresponds to the distributing device. The variable-frequency motor is used for providing working power for an atomizer, and the speed increaser increases the rotating speed of the variable-frequency motor from 2,042-2,950r / min to 9,000-13,000r / min to drive the atomizing disk to rotate at a high speed. The device mainly uses the centrifugation principle, the high-speed rotating atomizing disk efficiently and controllably atomizes alkali (or acid) liquid materials required for the flue gas treatment reaction, the atomization effect is good, and the grain size of the atomized liquid materials is less than or equal to 50mu m, so that the flue gas treatment reaction is more thorough, and the residual pollutant content is lower.

Owner:牟涛

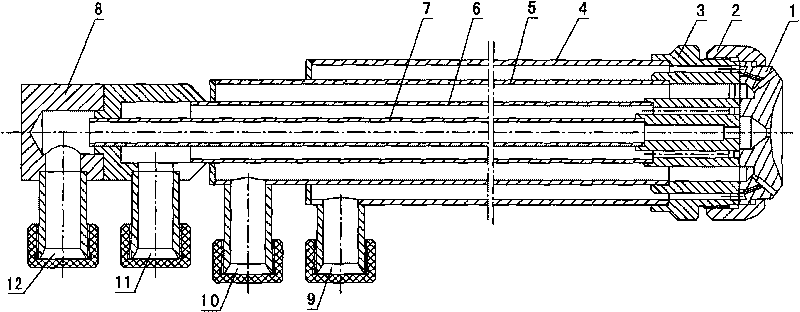

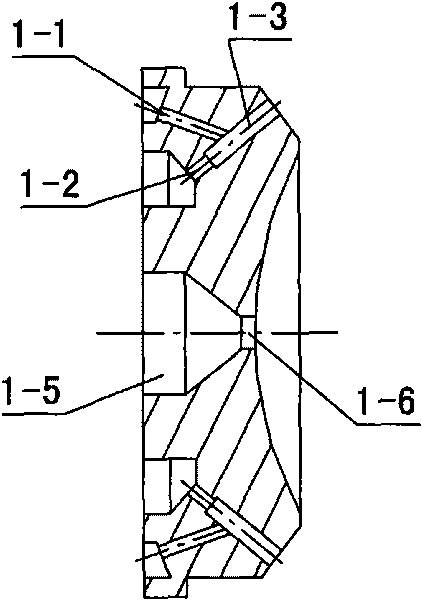

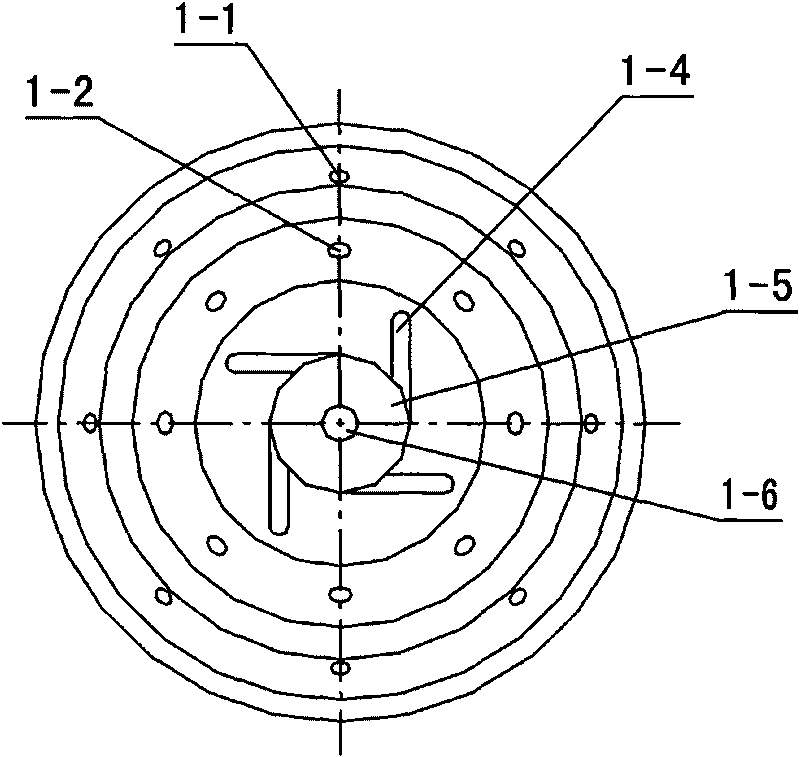

Multifunctional combined atomizing lance

The invention relates to a multifunctional combined atomizing lance, mainly comprising a combined atomizing spraying head, a compression nut, a multilayer flow divider, an outer lance tube, a medium conduct, an inner lance tube, a center lance tube, a combined lance seat and a pipe joint. The multifunctional combined atomizing lance can simultaneously atomize liquid fuel with different physical properties and independently combust or combust the liquid fuel in a mixed mode by adopting different atomizing modes. The combined atomizing spraying head is not only provided with a mechanical atomizing swirl slot and a swirl chamber, but also provided with a medium atomized oil hole, vapor hole and mixed hole structure. Various fluids enter the multilayer flow divider though self pipeline first and then enter the combined atomizing spraying head for atomizing. Fuel with lower viscosity is strongly rotated, atomized and sprayed by a center spray hole, contacted with the outside atmosphere and broken into fine oil drop to form oil mist, fuel oil with higher viscosity enters the combined atomizing spraying head, is sheared by vapor and rotated at high speed; and oil flow is impacted to generate a fluid film at an oil gun output and broken by the action of surface tension, thereby forming small granules. The multifunctional combined atomizing lance has high atomizing quality.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

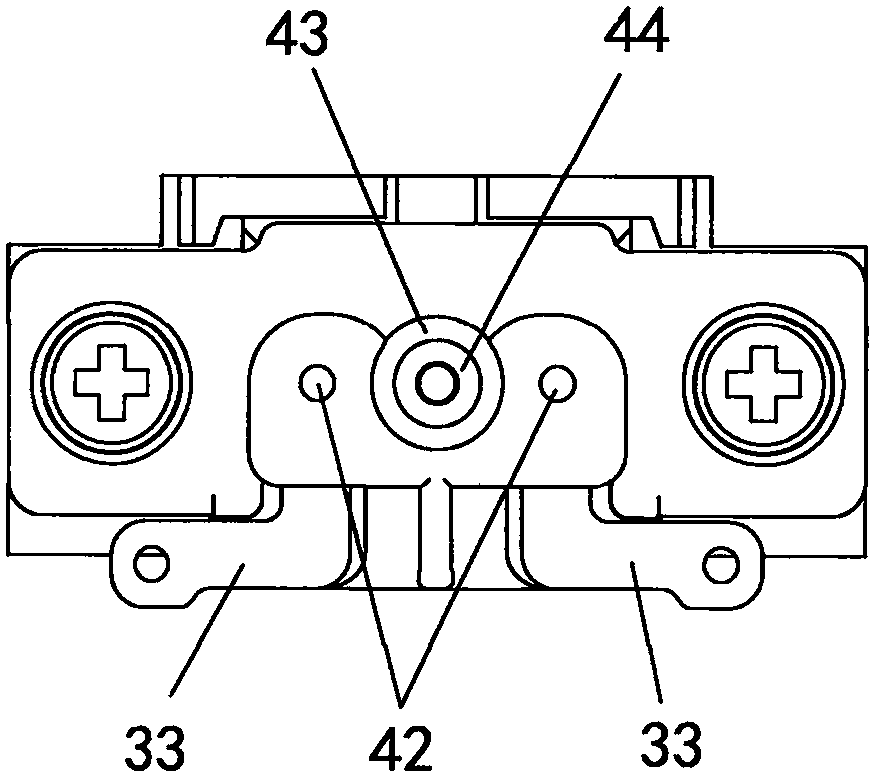

Independent spraying gun body

InactiveCN105170363AIncrease air turbulenceGood atomization effectLiquid spraying apparatusSpray nozzleMotor drive

The invention discloses an independent spraying gun body and relates to dust fall environment-friendly equipment. The independent spraying gun body comprises a gun barrel, a motor and support assembly, a wheel hub and blade assembly and independent spraying bodies, wherein one end of the gun barrel is cylindrical; the other end of the gun barrel is conical; the motor and support assembly, the wheel hub and blade assembly and the independent spraying bodies are located inside the gun barrel; the independent spraying bodies are evenly installed on the inner side of the front portion of the gun barrel in the circumferential direction, are in a rotation streamline shape and are provided with front cross sections perpendicular to the axes of the rotation parts, holes are formed in the front cross sections and are provided with nozzles, and the independent spraying bodies are hollow. External pressure liquid is introduced into the independent bodies through a pipeline and is sprayed out through the nozzles, strong wind generated when a motor drives blades to rotate blows the liquid away to form mist to be conveyed to the distance place, and the front ends of the independent bodies generate air vortexes at the same time, so that the air turbulence effect of the outlet of the gun barrel is enhanced, the sprayed liquid is atomized better, and the dust falling effect of the dust fall environment-friendly equipment is improved.

Owner:赵迎生

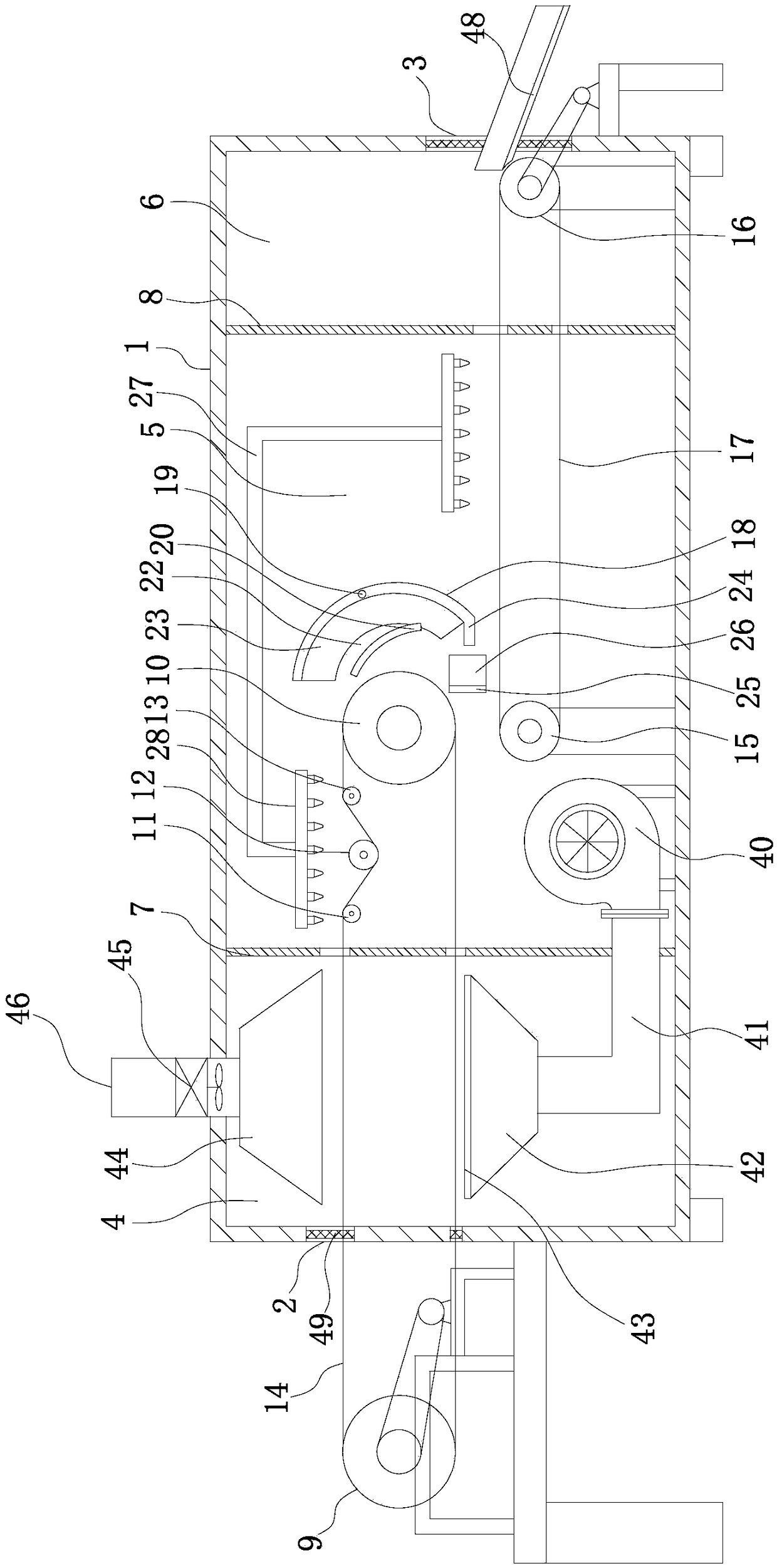

Liquid nitrogen quick-freezing equipment for swimming crabs

ActiveCN109393006APromote atomizationGood atomization effectMeat/fish preservation by freezing/coolingFreezing chamberLiquid nitrogen

The invention discloses liquid nitrogen quick-freezing equipment for swimming crabs. The liquid nitrogen quick-freezing equipment for the swimming crabs comprises a box, a material-feeding transmission mechanism and a material-discharging transmission mechanism; a material inlet and a material outlet are arranged at two ends of the box; a front clapboard and a rear clapboard are arranged inside the box; the material-feeding transmission mechanism comprises a driving feeding drum, a driven feeding drum, a front guide roller, a lower guide roller and a rear guide roller; a material-feeding conveyor belt is wound between the driving feeding drum and the driven feeding drum; the material-feeding conveyor belt sequentially passes downwards through the front guide roller, winds the lower guide roller and passes through the rear guide roller so as to form a recessed portion; the material-discharging transmission mechanism comprises a driven discharging drum and a driving discharging drum; a material-discharging conveyor belt is wound between the driving discharging drum and the driven discharging drum; the material-discharging conveyor belt and the material-feeding conveyor belt both moveclockwise; a turning-over mechanism is arranged outside a terminal of the material-feeding conveyor belt; and liquid nitrogen spraying mechanisms are arranged, inside a freezing chamber, above both the material-feeding conveyor belt and the material-discharging conveyor belt. The liquid nitrogen quick-freezing equipment for the swimming crabs is quick in freezing rate, so that, overall freezing efficiency and freezing quality of swimming crabs can be improved so as to have liquid nitrogen consumption reduced.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

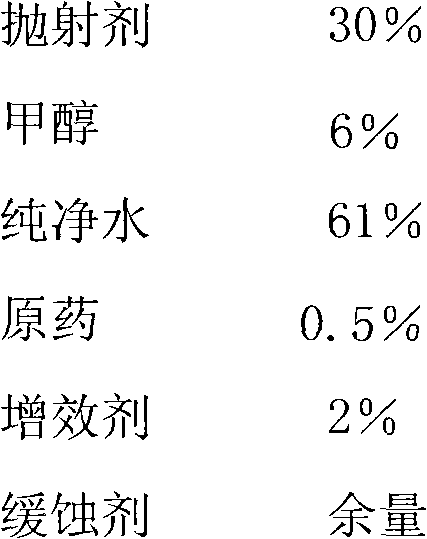

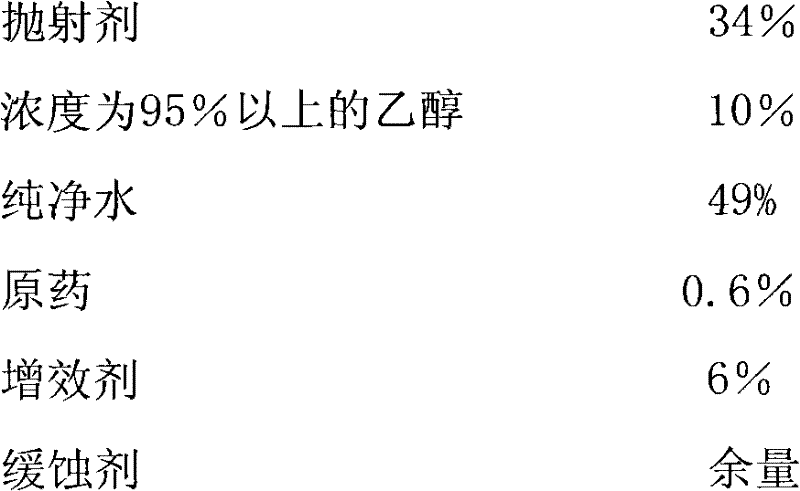

Solution type water based pesticide

Provided is a solution type water based pesticide which comprises, 30 to 40 wt% of a propellent, 6 to 10 wt% of alcohol, 48 to 63 wt% of purified water, 0.01 to 2 wt% of raw pesticides, 0.05 to 6 wt% of synergists and a proper amount of a corrosion inhibitor, wherein the alcohol is methanol or ethanol, the propellent is dimethyl ether, the raw pesticides are selected from synthetic pyrethroids or carbamates or a mixture of the two, and the synergists are 1-n-butylazaheptane-2-ketone, 1-n-octylazaheptane-2-ketone, piperonyl butoxide, normal paraffins and a composition thereof.

Owner:范兴华

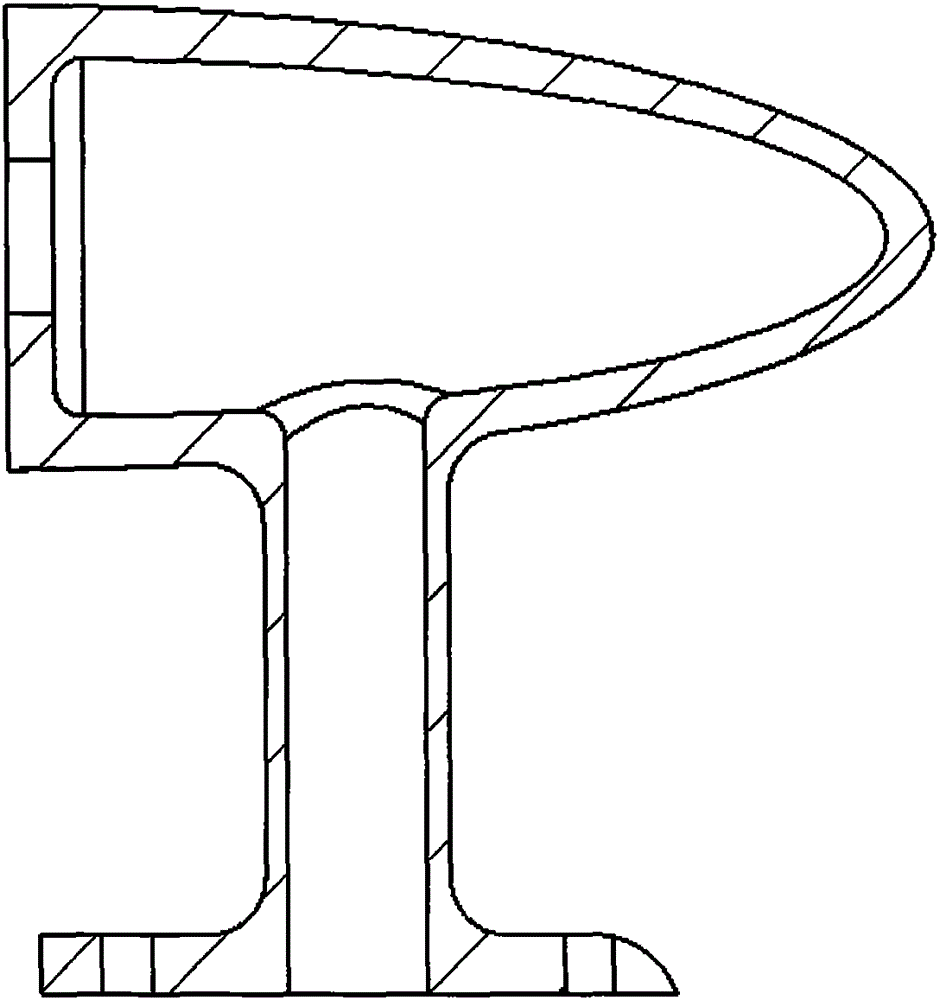

Method for preparing microsphere FCC (fluid catalytic cracking) catalyst

ActiveCN104549550AImprove atomization effectGood atomization effectMolecular sieve catalystsSpray nozzleBoehmite

The invention provides a method for preparing a microsphere FCC (fluid catalytic cracking) catalyst, wherein the method comprises the following steps: beating a molecular sieve, clay, pseudo boehmite and acid to obtain catalyst slurry, and spray-drying the catalyst slurry, and in the spray-drying process, spraying is performed through a spray nozzle, then drying is performed, and the spray nozzle comprises a spray nozzle main body with a cavity, wherein a spray nozzle inlet and spray holes are formed in the spray nozzle main body, a diversion part protrudes downwards from the top wall of the cavity of the spray nozzle main body, and the space between the outer surface of the diversion part and the inner surface of the cavity forms a rotation chamber. When the spray nozzle provided by the invention is used for spray-drying, the atomization effect is good, and when the spray nozzle is used for spray-drying to prepare the FCC catalyst, the prepared FCC catalyst has good sphericility. By adopting the method provided by the invention, the microsphere FCC catalyst with good sphericility can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water particle generating device

ActiveCN108970823AGood atomization effectThe amount of condensate is stableSpraying power supplyCorona dischargeWater particleElectrical connection

The invention relates to a water particle generating device. The water particle generating device comprises a condensation rod, a refrigerator, a discharging electrode group and a high-voltage power supply; water in air around the condensation rod is condensed on the condensation rod; the refrigerator makes contact with the condensation rod and is used for cooling the condensation rod; the discharging electrode group comprises a first electrode and a second electrode which cooperate with each other, and the first electrode and the second electrode are transversely arranged and located on the two sides of the condensation rod correspondingly; and the high-voltage power supply is used for exerting high voltage to the discharging electrode group to enable high-voltage corona to be generated between the first electrode and the second electrode, and the discharging electrode group is used for exerting the high-voltage corona to the condensation rod to enable condensate water attached to thecondensation rod to be excited by the high-voltage corona to generate atomized water particles. According to the water particle generating device, the atomization effect is good, discharging parts are installed steadily, and electrical connection is reliable.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD +1

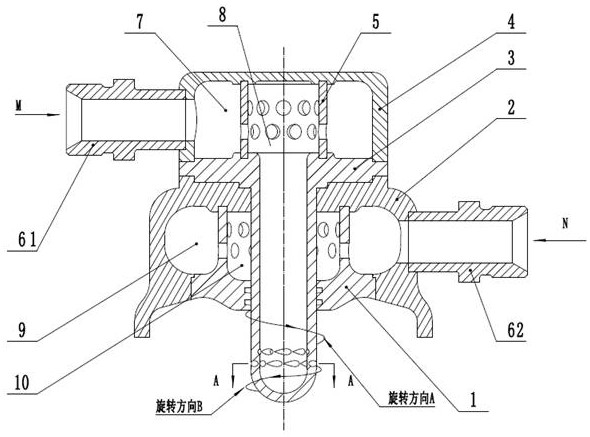

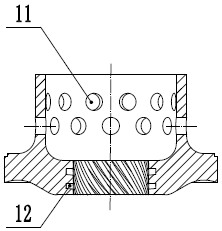

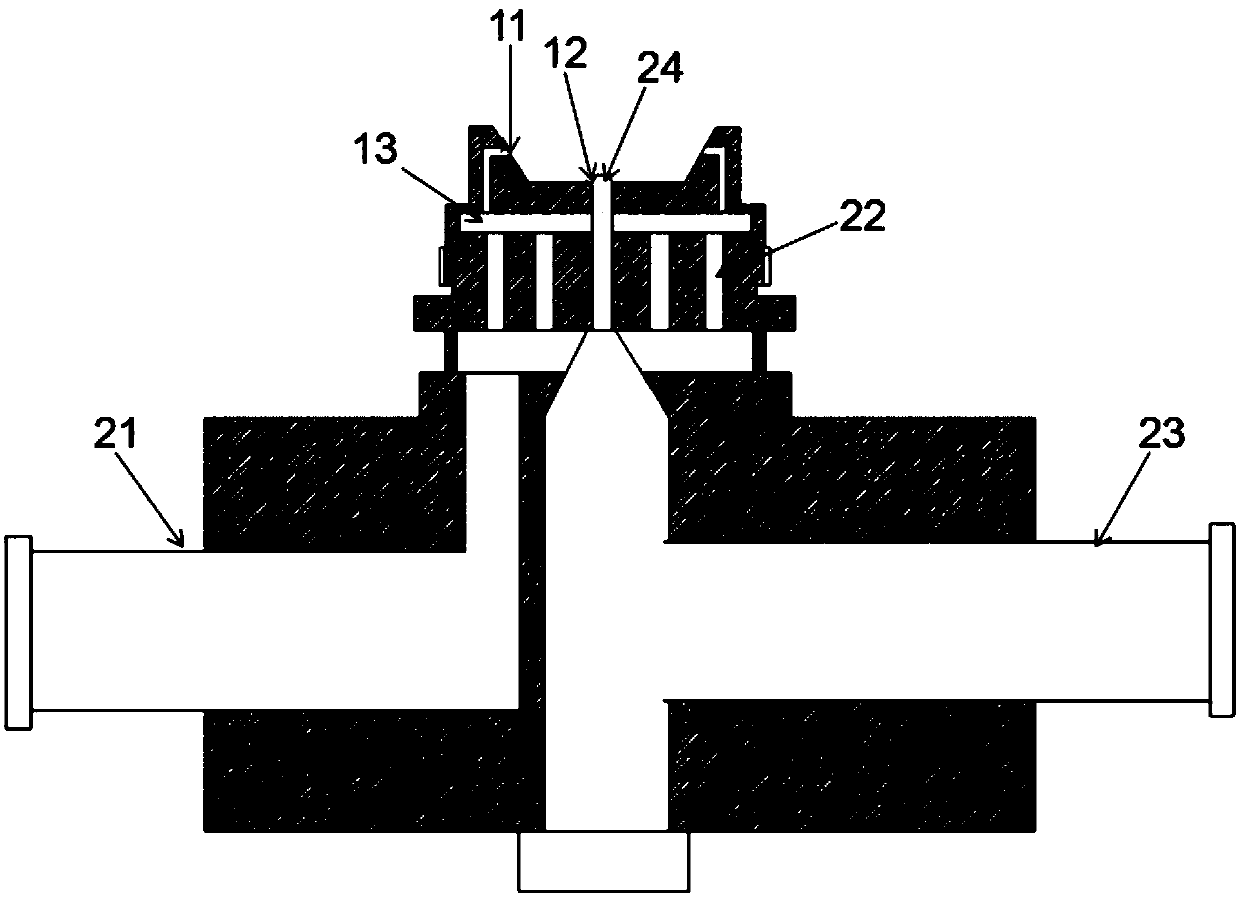

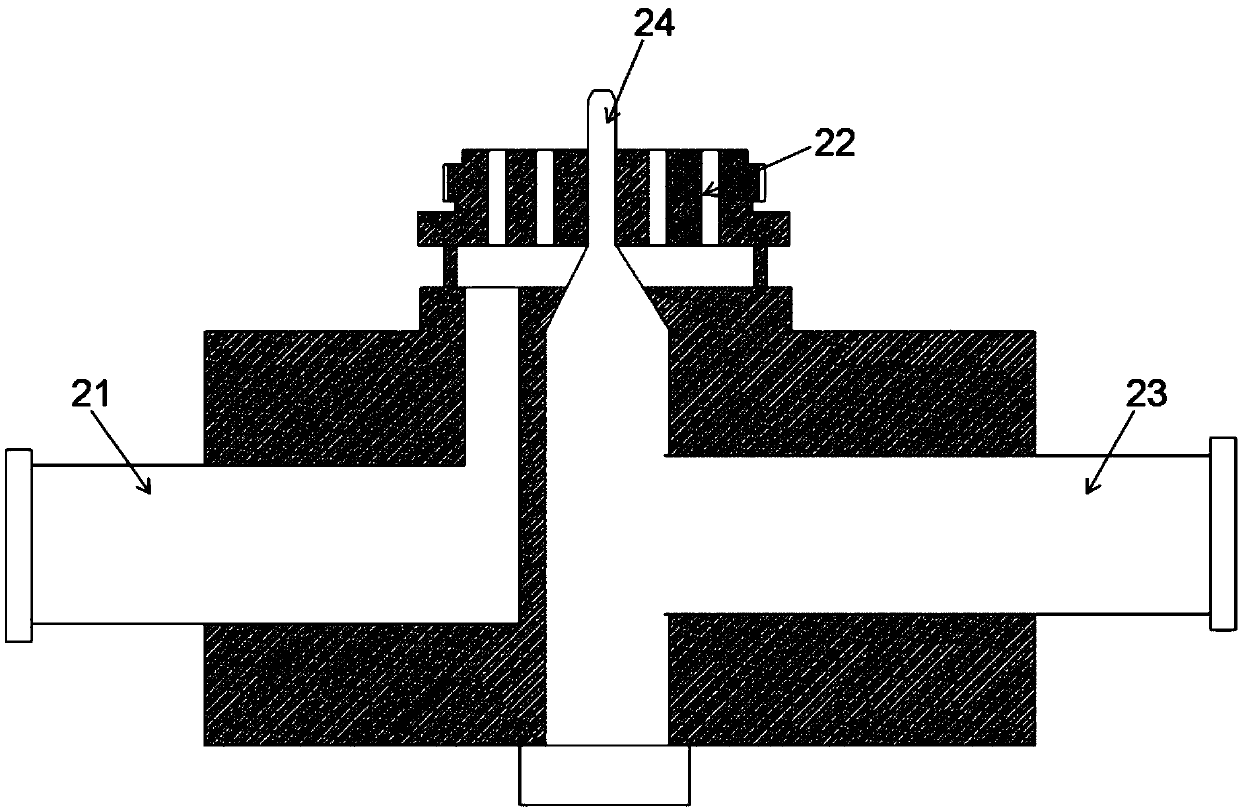

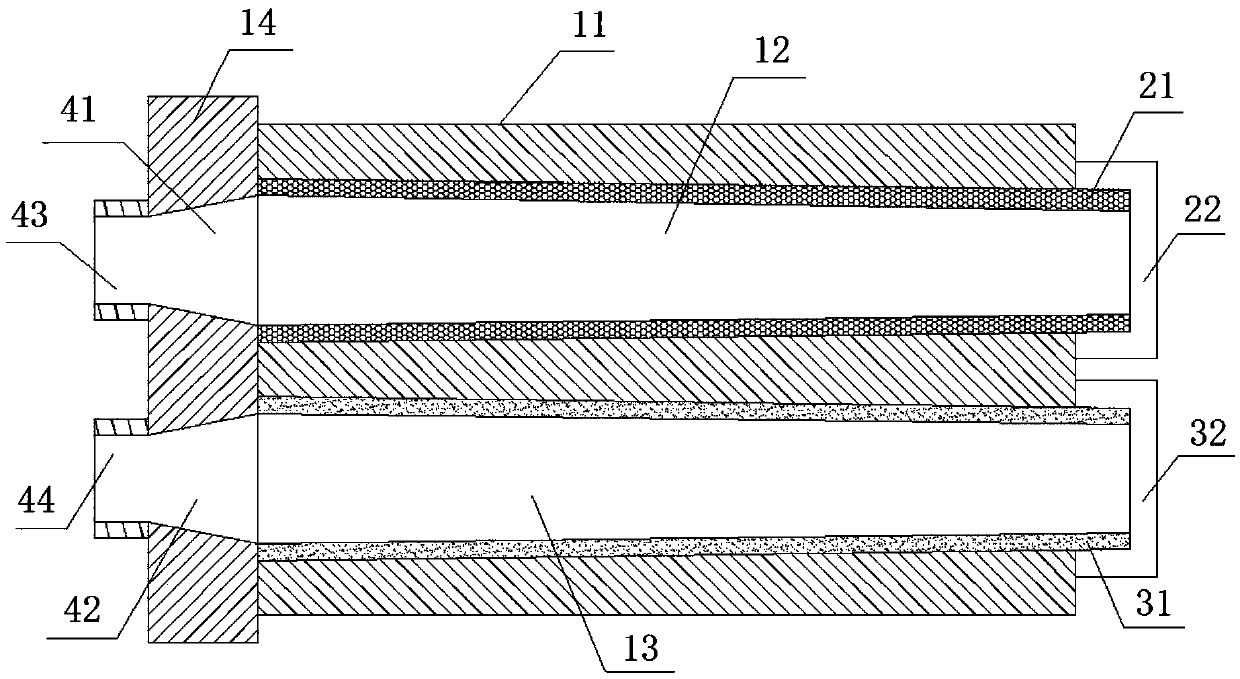

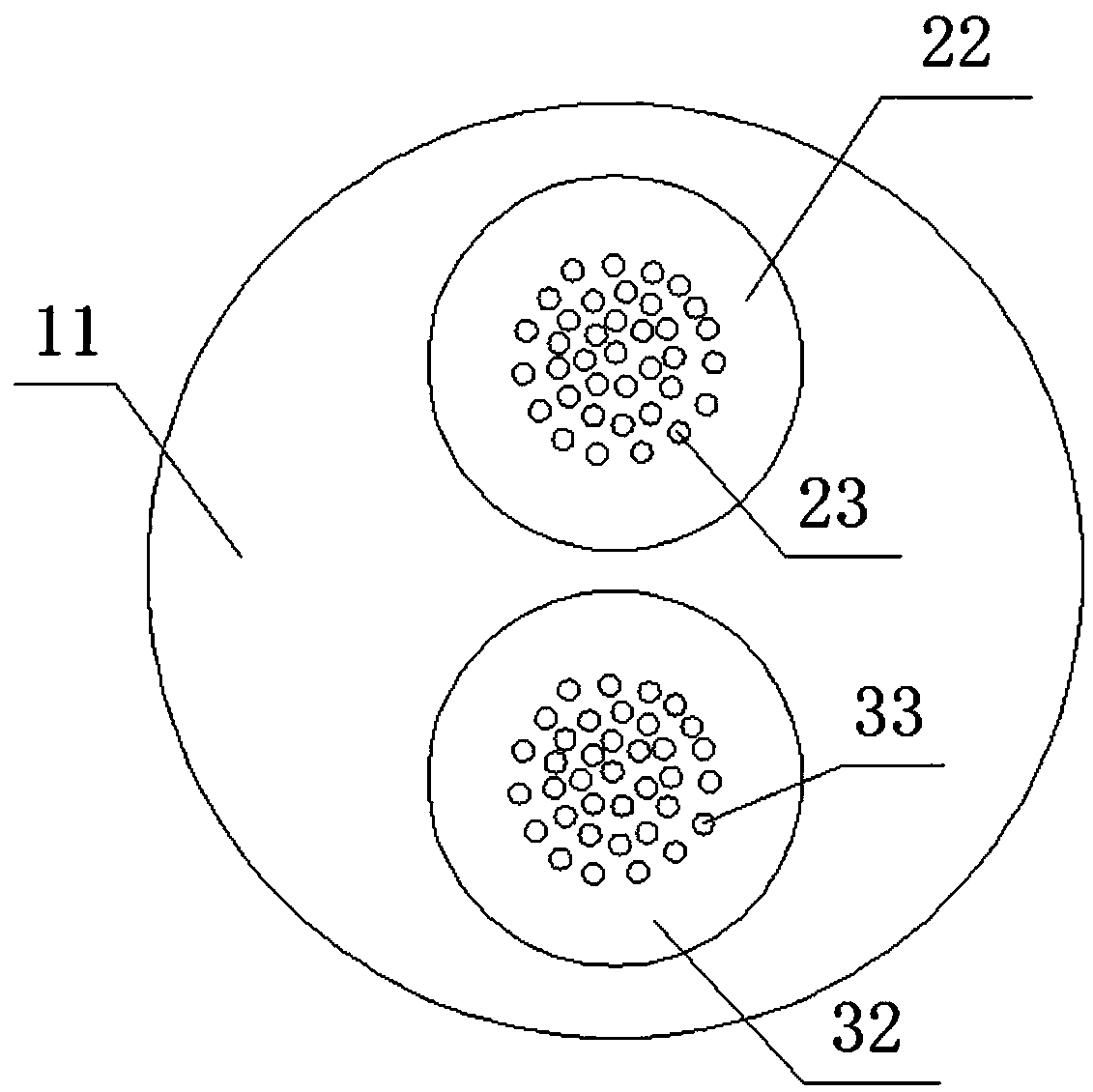

Pintle injector for liquid rocket engine

The invention relates to the technical field of engines, in particular to a pintle injector for a liquid rocket engine. According to the pintle injector for the liquid rocket engine, a plurality of tangential holes are formed in the head of one end of a pintle body in a surrounding mode, and a plurality of rotational flow holes are formed in the attaching position of a bottom cover and the pintle body; thus, the rotation directions of a second propellant sprayed out of the rotational flow holes and a first propellant sprayed out of the tangential holes are opposite, and the second propellant and the first propellant are collided and mixed with each other; therefore, the atomization effect of the two propellants is better, and the mixing effect is more uniform; and thus, the atomization and mixing characteristics of the pintle injector for the liquid rocket engine are improved, and the combustion efficiency of the liquid rocket engine is improved.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

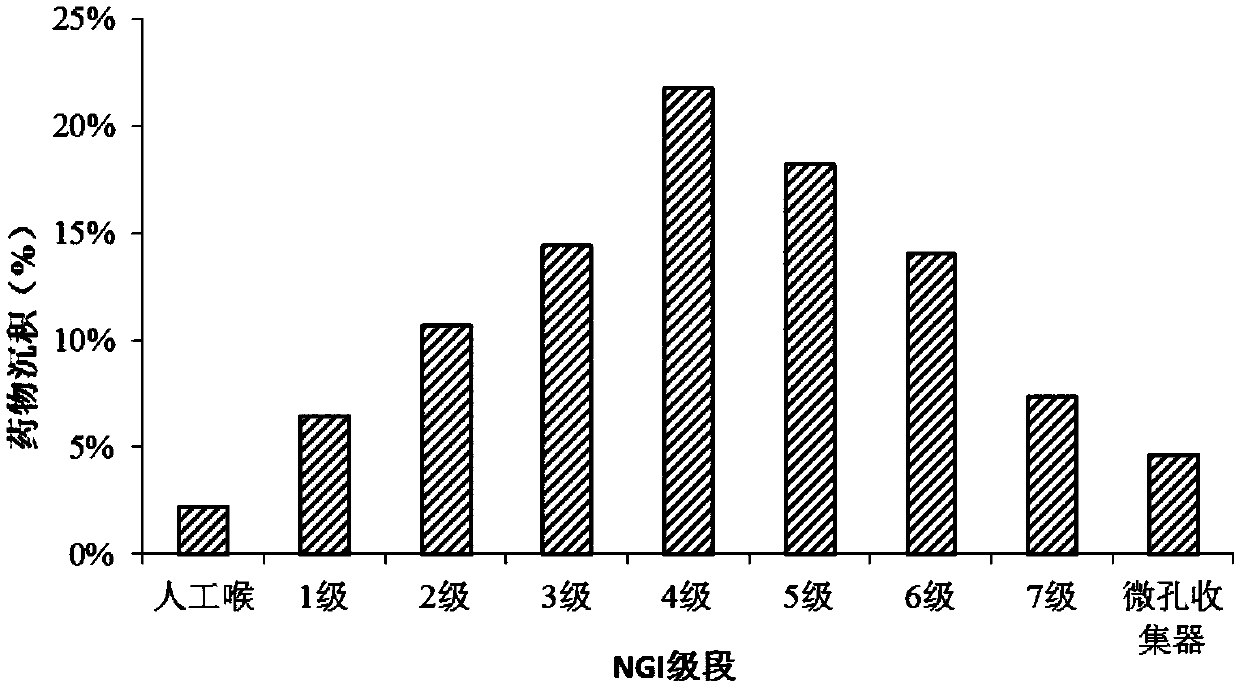

Inhalation preparation and preparation method and application thereof

ActiveCN109512880AAvoid significant reductions in volatile contentGood atomization effectPowder deliverySpray deliveryInhalation preparationsAdjuvant

The invention provides an inhalation preparation and a preparation method and application thereof. The inhalation preparation is prepared from an active component, namely a pummelo peel extract and apharmaceutic adjuvant suitable for inhalation administration; the pummelo peel extract is a pummelo peel extracting solution or a mixture of pummelo peel volatile oil and the pummelo peel extracting solution or a mixture of pummelo peel distillate and the pummelo peel extracting solution; the pummelo peel extract contained in every 100 ml of inhalation preparation is prepared from 10-60 g of pummelo peel; and the pH value of the inhalation preparation is regulated to 4.0-8.5 through a pH regulating agent. The pummelo peel extracting solution and the pummelo peel volatile oil or the pummelo peel distillate serve as the active component, after the volatile oil or the distillate is subjected to clathration by cyclodextrin, the acidity or alkalinity is regulated to the appropriate concentration through cooperation, and finally uniformity and stability of the atomized inhalation preparation of the pummelo peel are ensured.

Owner:GUANGZHOU XIANGXUE PHARMA CO LTD +1

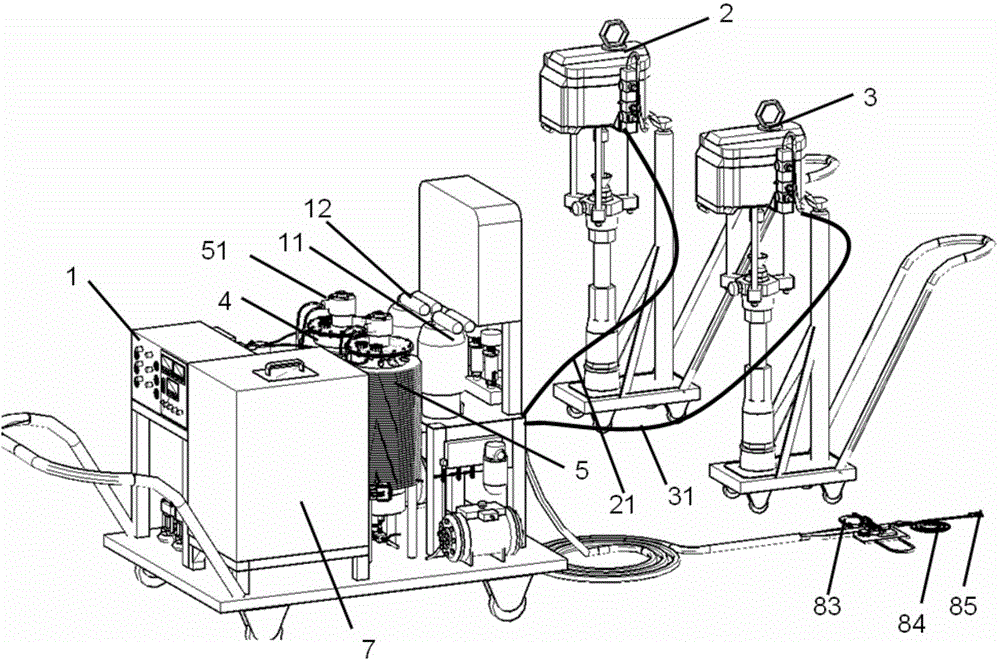

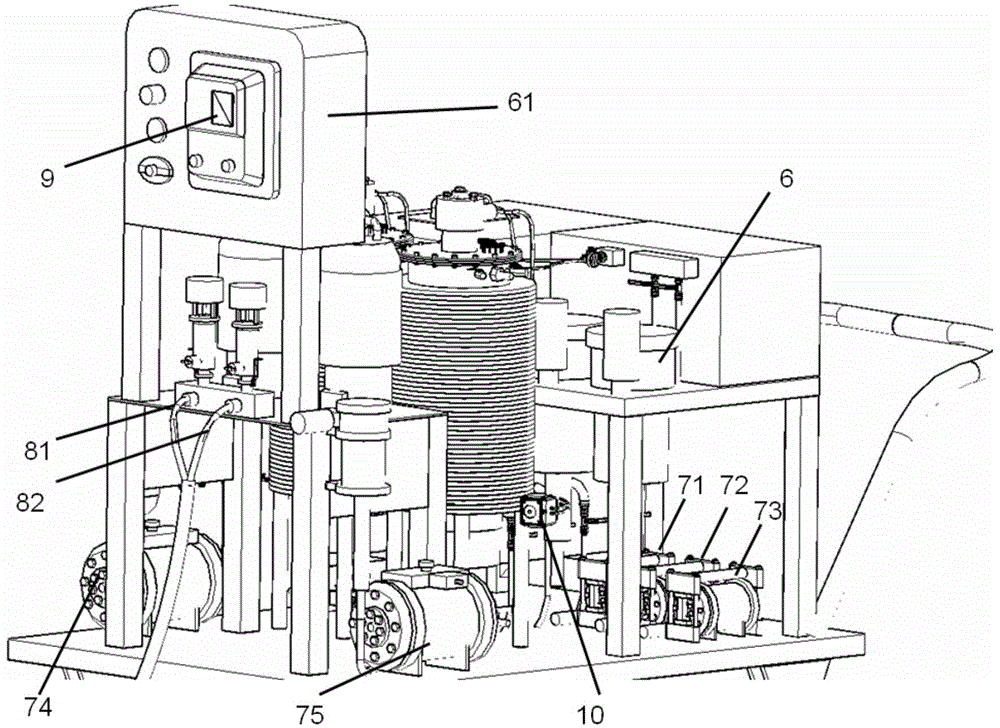

Dual-component high-pressure proportion-adjustable fire retardant coating spraying device

InactiveCN104084332AGood atomization effectImprove spraying efficiencyLiquid spraying apparatusAgricultural engineeringEngineering

The invention provides a dual-component high-pressure proportion-adjustable fire retardant coating spraying device which comprises a control mechanism, a main air feed pump, a feeding mechanism, a heating mechanism, a proportioning mechanism, a spraying mechanism and a cleaning mechanism. The control mechanism is a digital electronic controller, the input end of the main air feed pump is connected with an external air source, the output end of the main air feed pump is connected with the feeding mechanism, the heating mechanism, the proportioning mechanism, the spraying mechanism and the cleaning mechanism through an air pressure adjusting device, and a switch of the main air feed pump is connected with a main air switch of the digital electronic controller. According to the dual-component high-pressure proportion-adjustable fire retardant coating spraying device, the spraying efficiency is high, and the coating quality is good.

Owner:CHINA NAT OFFSHORE OIL CORP +3

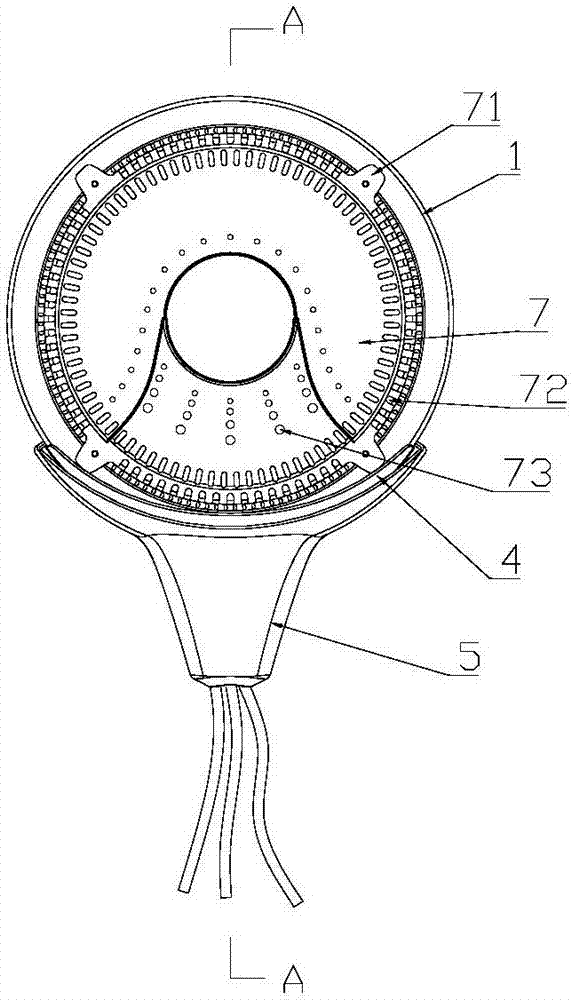

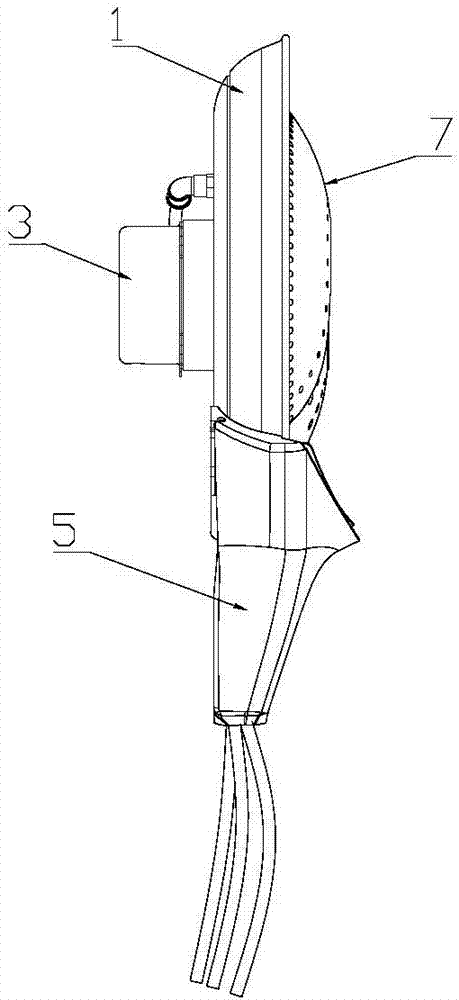

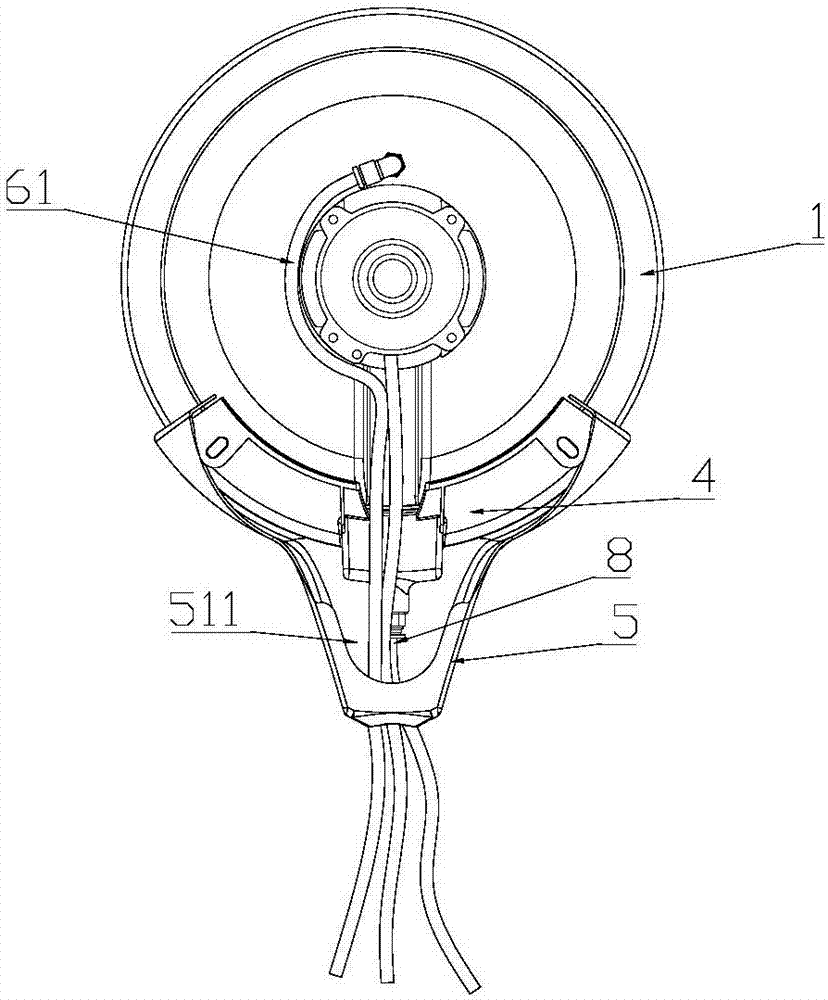

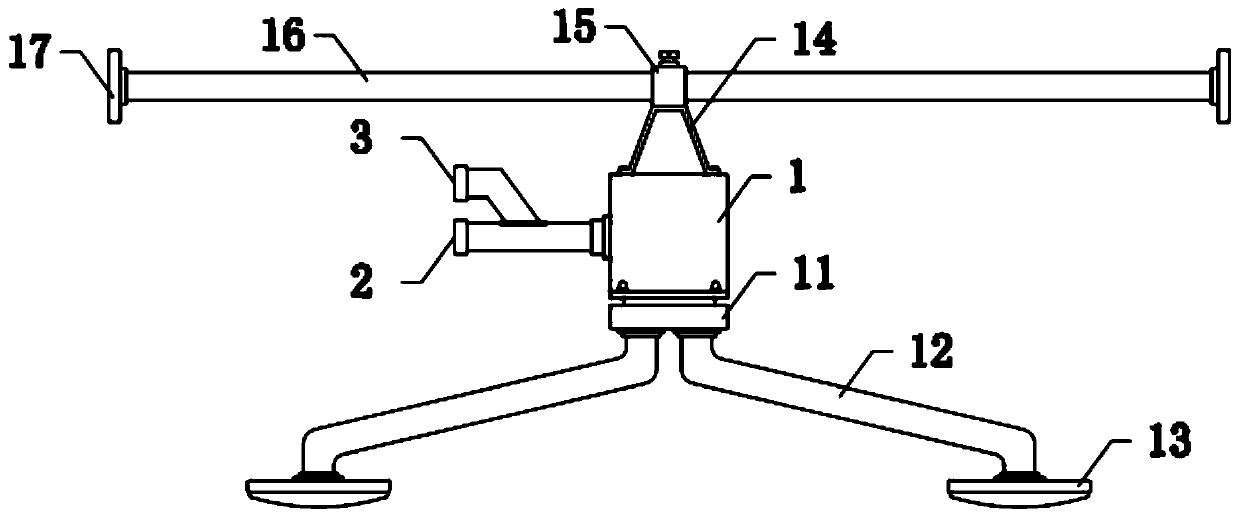

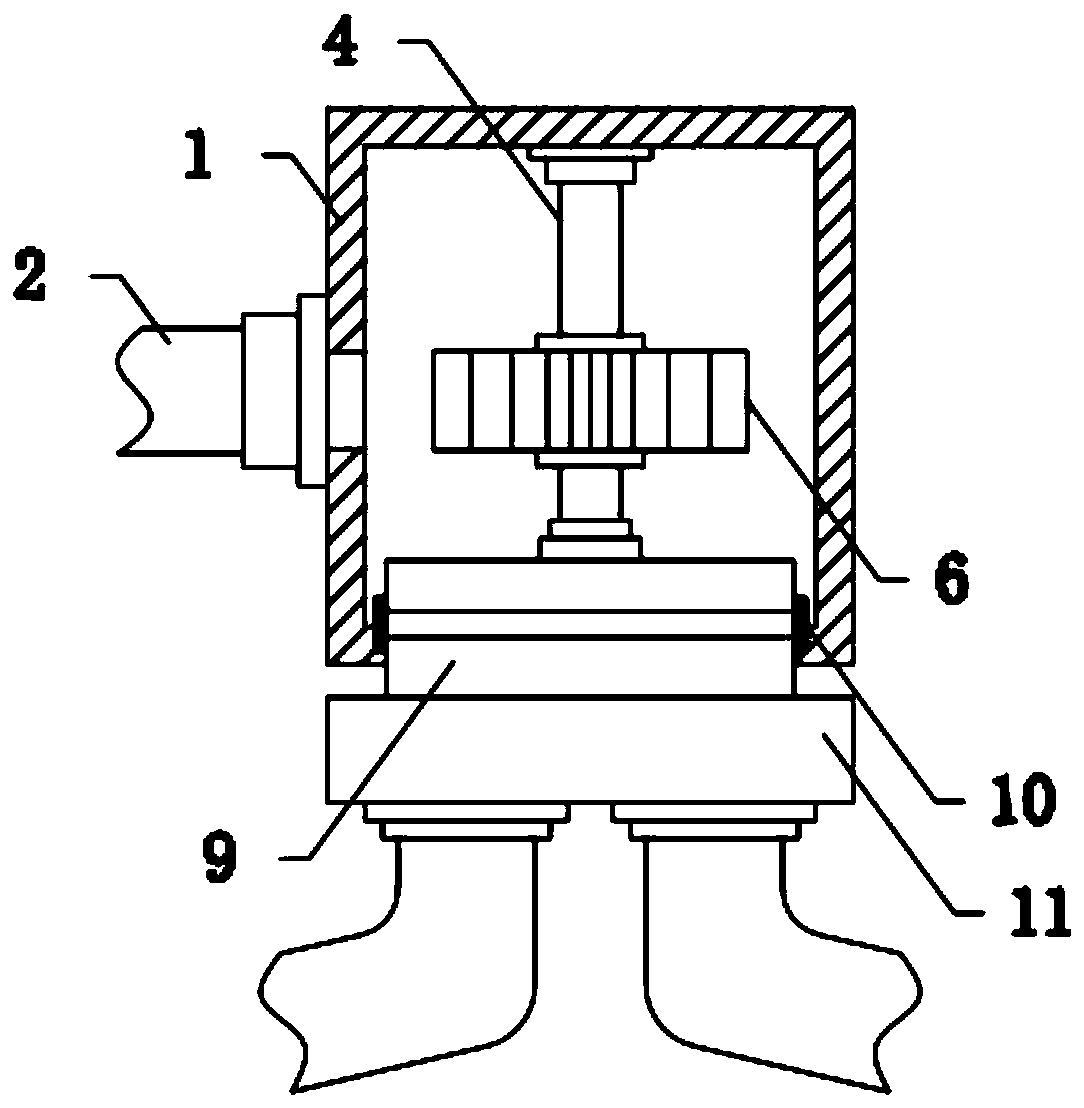

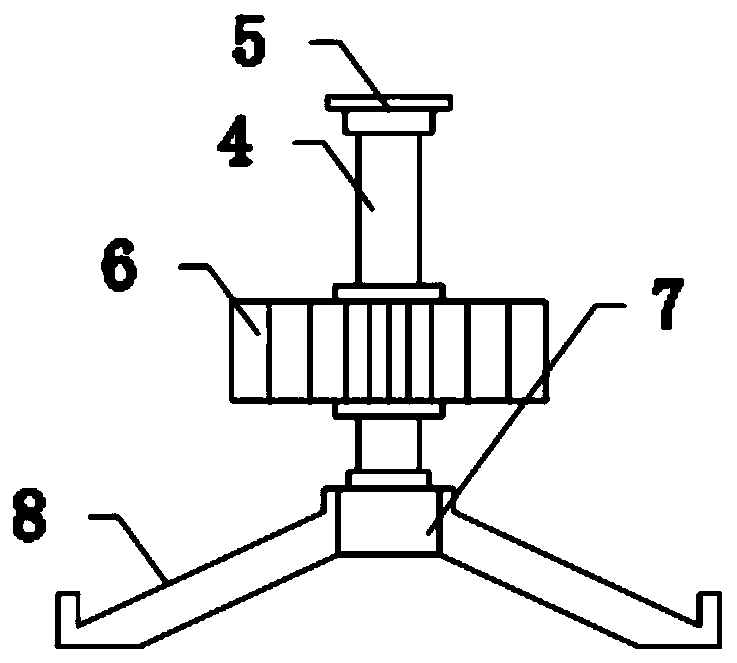

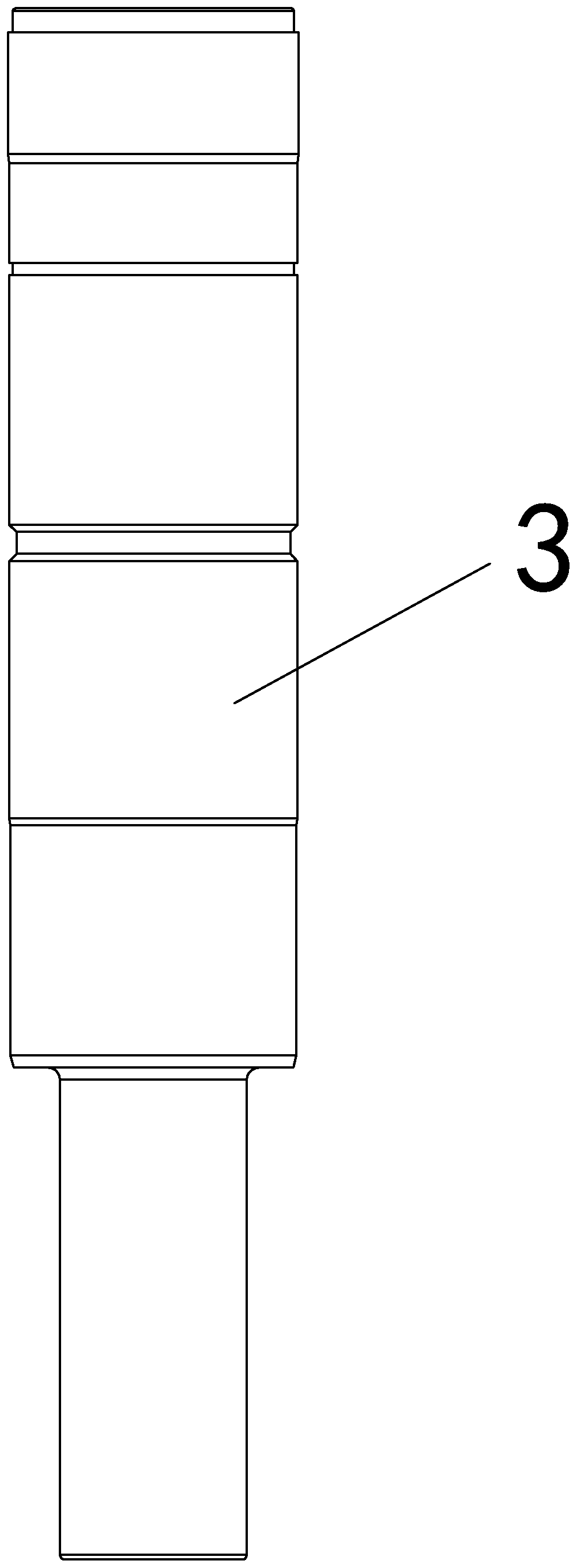

Centrifugal atomizer

InactiveCN107138302AGood atomization effectSmooth rotationMovable spraying apparatusElectric machineryEngineering

The invention provides a centrifugal atomizer. The centrifugal atomizer comprises a water collecting tray, an atomizing tray, a motor, a water supply device, a water receiving tray and an air guide sleeve, wherein the motor is used for driving the atomizing tray to rotate; the water supply device is used for feeding water to the atomizing tray; the air guide sleeve is used for guiding the air to be blown out upwards; the atomizing tray is positioned inside the water collecting tray; an atomizing part having collision with water which is ejected at a high speed from the periphery of the atomizing tray is arranged on the circumference of the water collecting tray; the water receiving tray is positioned below the water collecting tray; and the air guide sleeve is arranged below the water receiving tray. The atomizer provided by the invention can prevent the water mist formed by atomization from being condensed into water droplets on the outer wall of the water receiving tray so that no water droplets drop on the ground and water accumulation is prevented.

Owner:GUANGDONG ZHAOQING DETON

Efficient nozzle for ship desulfurization system

InactiveCN110548367AGood atomization effectImprove desulfurization effectGas treatmentMovable spraying apparatusSpray nozzleSeawater

The invention belongs to the technical field of ship desulfurization, and in particular, relates to an efficient nozzle for a ship desulfurization system. The efficient nozzle comprises a liquid accumulation barrel; the left side wall of the liquid accumulation barrel is connected with a liquid inlet through a flange; the side wall of the liquid inlet is connected with an air inlet pipe through aflange; a rotating shaft is longitudinally arranged in an inner cavity of the liquid accumulation barrel; the upper end of the rotating shaft is in shaft connection with a supporting bearing, the supporting bearing is arranged at the upper end of the inner cavity of the liquid accumulation barrel through a shaft seat, and the outer wall of the rotating shaft is sleeved with a driving impeller. Through the effect of uniformly dispersing seawater, the amount of entering seawater is small, the atomization effect is good, large-area contact with flue gas can be achieved, and thus the desulfurization effect can be improved; through cooperation of the driving impeller, the rotating shaft, the supporting bearing and the like, the connecting base and the liquid accumulation barrel can relatively rotate, so that the connecting base can drive a liquid outlet pipe and a liquid outlet spray head to rotate, the spraying position can be enlarged, and the spraying uniformity is guaranteed.

Owner:上海蓝魂环保科技有限公司

Spiral nozzle

InactiveCN109944728AImprove atomization performanceGood atomization effectFuel injection apparatusMachines/enginesEngineeringNozzle

The invention relates to a spiral nozzle which comprises a valve body, a valve seat, a valve core and an oil circuit, wherein an oil inlet is formed in one end of the valve body, the other end of thevalve body is connected with the valve seat, an atomizing hole is formed in the valve seat, the valve core is arranged in the valve body, one end of the valve core is connected with the valve seat ina sealed mode, the oil circuit is arranged between the valve core and the valve body, the two ends of the oil circuit respectively communicate with the oil inlet and the atomizing hole, the valve seatis provided with a swirling structure which plays a swirling effect on media, and the oil circuit communicates with the atomizing hole through the swirling structure. According to the spiral nozzle,the spiral groove is innovatively additionally arranged on the valve seat, so that the media start to rotate under the interaction of shearing pressure in the vertical direction and the spiral direction, and enter the atomizing hole of the valve seat at a higher speed, and the atomization performance of the nozzle is greatly improved.

Owner:JIANGSU BATON TECH CO LTD

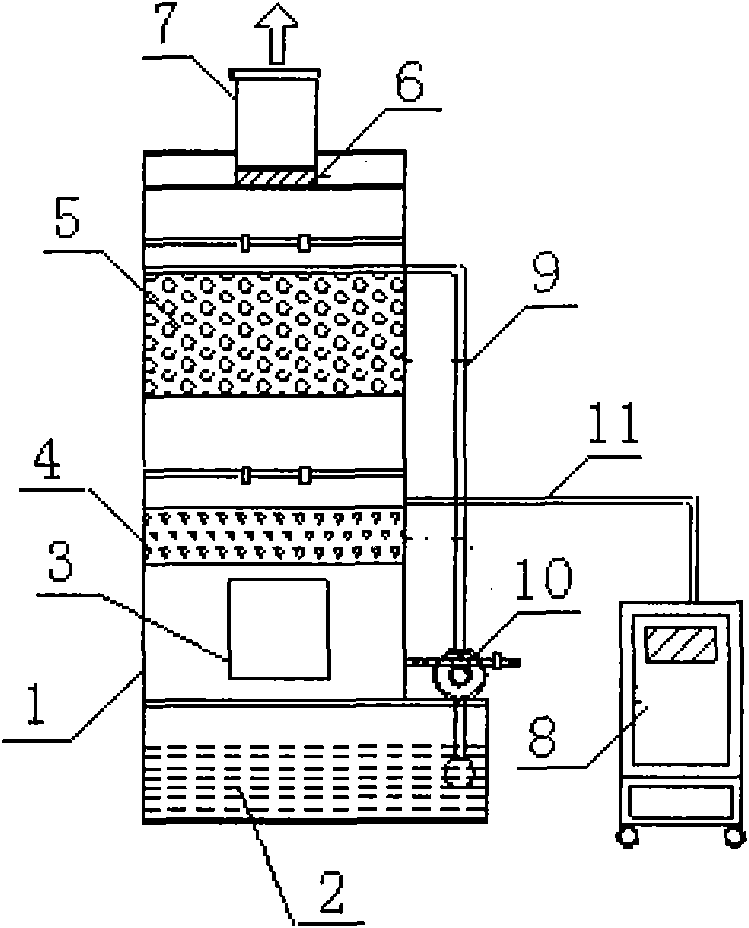

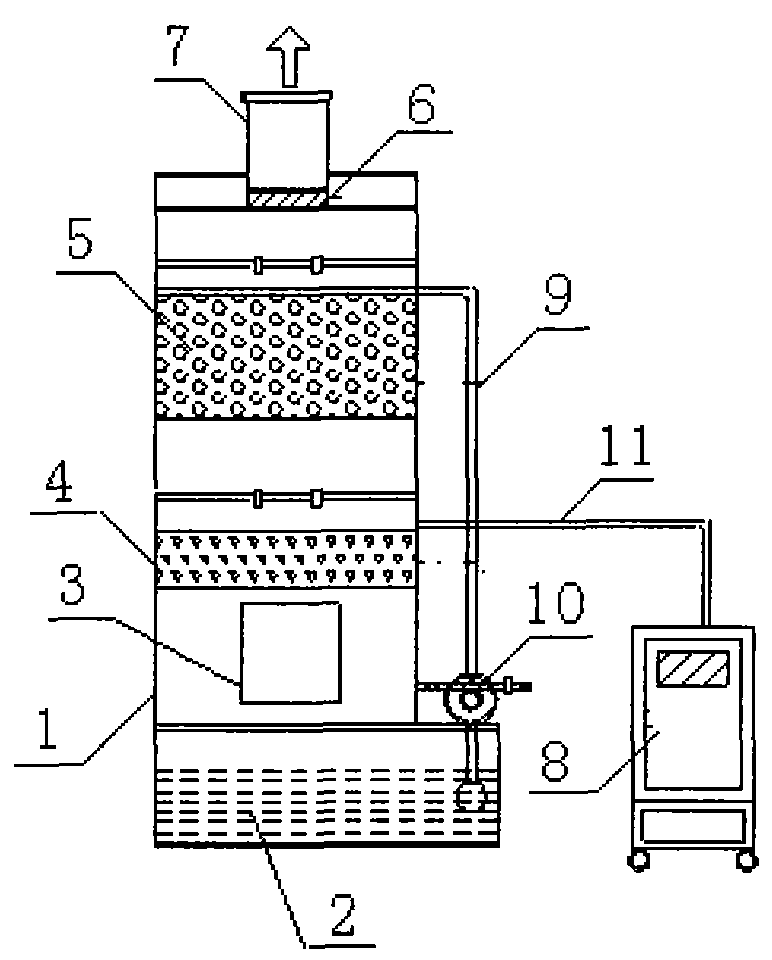

High-activity biological waste gas purification tower

InactiveCN102371119AGood atomization effectImprove purification effectDispersed particle separationAir quality improvementBiological wasteExhaust gas

The invention discloses a high-activity biological waste gas purification tower, comprising a tower body, wherein, the top of the tower body is provided with a clean air outlet; the bottom of the tower body is provided with a water tank and an exhaust gas inlet; a main control system is arranged at the side part of the water tank; the interior of the tower body is divided into an upper layer, a middle layer, and a lower layer, the upper layer is an aerosol separating layer, the middle layer is a bioactive exhaust gas washing layer, the lower layer is an ultramicro atomization purifying layer, and the position orders of the bioactive exhaust gas washing layer and the ultramicro atomization purifying layer can be adjusted; the ultramicro atomization purifying layer is provided with atomization catalysts and communicated with the exhaust gas inlet; the aerosol separating layer uses metal polyhedron balls as the filler and is communicated with the clean air outlet; the ultramicro atomization purifying layer is connected with the water tank through a transfer line, and the transfer line is provided with a control valve. According to the invention, exhaust gas is processed by using the combination of ultramicro atomization and washing, and multitime purification and aerosol separation, thus the advantages of good purification effect and low energy consumption of the system are achieved.

Owner:SHANGHAI ZHENZIQIN ENVIRONMENTAL TECH

Atomizing device for deaerators

InactiveCN103706491AReduce evaporationGood atomization effectMovable spraying apparatusSpray nozzlesEngineeringStructural engineering

Owner:CHONGQING JUKANG BUILDING MATERIAL

High viscosity lysozyme dimer protein fluid atomization device

PendingCN108672121AIncrease productivityGood atomization effectLiquid spraying apparatusEngineeringViscosity

The invention discloses a high viscosity lysozyme dimer protein fluid atomization device. The high viscosity lysozyme dimer protein fluid atomization device comprises an atomizing nozzle, a mixture seat and a combination cap. The mixture seat is provided with a compressed air inlet, multiple compressed air uniform distribution holes, a material inlet and a shower nozzle. The atomizing nozzle is provided with a first steady pressure compressed air exit, a second steady pressure compressed air exit and a compressed air steady pressure cavity. The first steady pressure compressed air exit and thesecond steady pressure compressed air exit are communicated with the compressed air steady pressure cavity correspondingly. The height of the shower nozzle is higher than the second steady pressure compressed air exit, wherein the diameter of the second steady pressure compressed air exit is larger than the diameter of the shower nozzle. The spraying direction of the first steady pressure compressed air exit is at a 90-degree included angle to the spraying direction of the shower nozzle. The spraying direction of the second steady pressure compressed air exit is parallel to the spraying direction of the shower nozzle. By means of the high viscosity lysozyme dimer protein fluid atomization device, the problem of difficulty to atomize lysozyme dimer protein fluid with high viscosity and poor fluidity is solved.

Owner:SHANGHAI E K M BIOTECH

Novel connecting rod efficient reduction box

A new connecting rod high-efficiency reducer, including a case, a connecting rod is arranged in the case, an output shaft is arranged between the connecting rod and the case, an output flange is connected next to the output shaft, and a Sealing device, the sealing device is an inverted M-shaped structure, the sealing device is provided with an oil injection port, and there are dispersed parts in the oil injection port, among which the dispersed parts are of fine mesh structure, and a sealing device is provided in the case of the reducer, which can enhance the sealing of the case The optimization of performance and sealing performance can prevent the machine from oil leakage and ensure the normal and stable operation of the reducer. There are dispersing parts in the oil injection port, which can make the oil more dispersed and atomized better, and can allow the lubricating oil to drip into the Faster, with noise canceling components on the chassis to further eliminate noise pollution.

Owner:YANGZHOU YIFENG BRONZE PROD

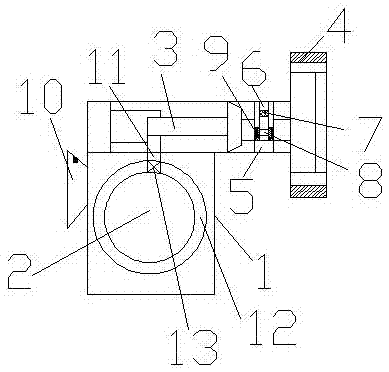

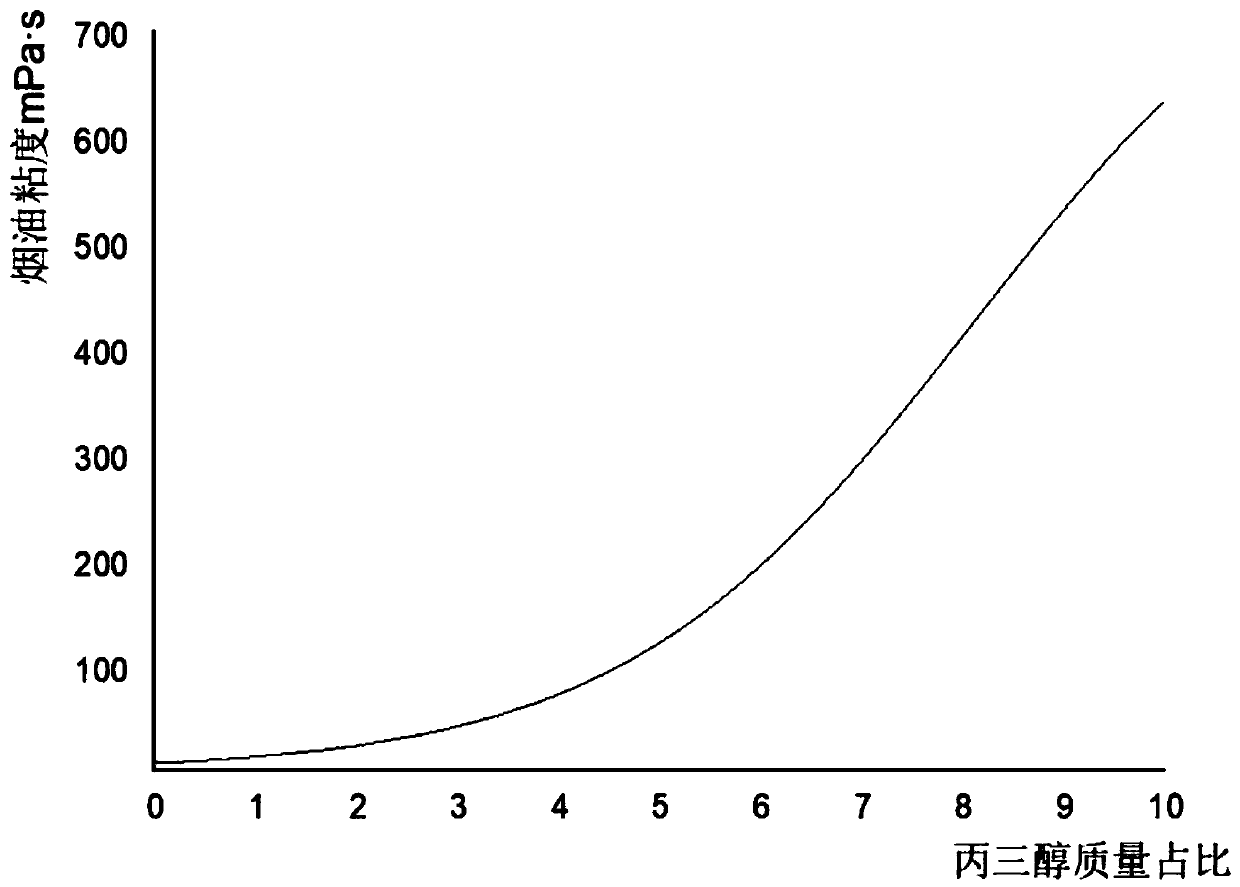

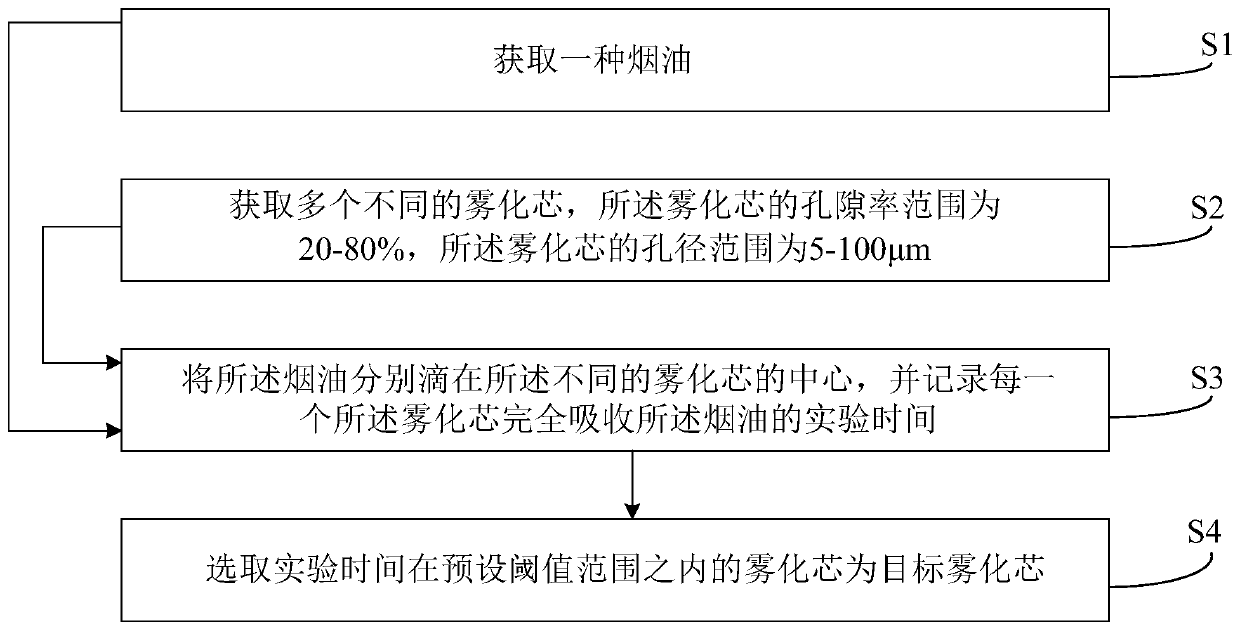

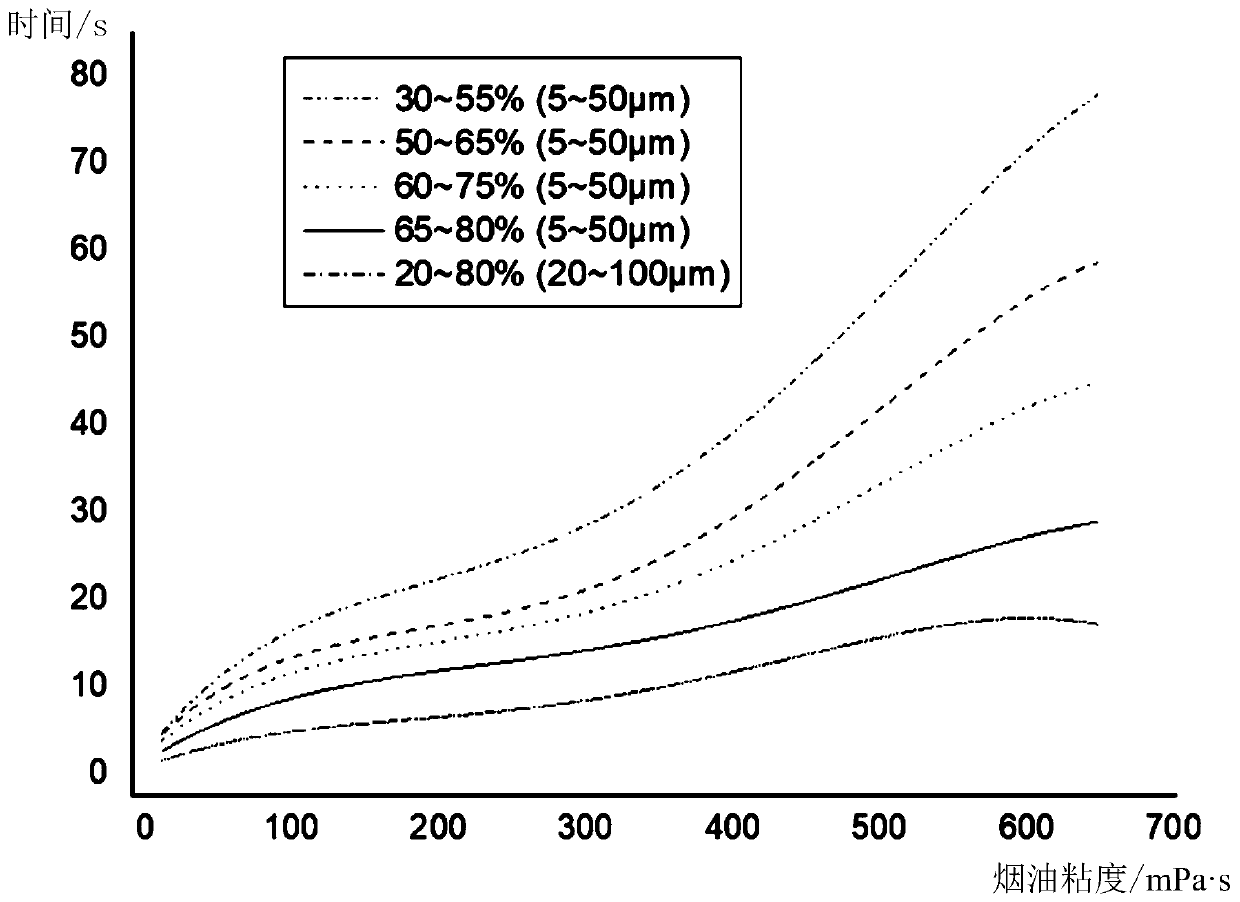

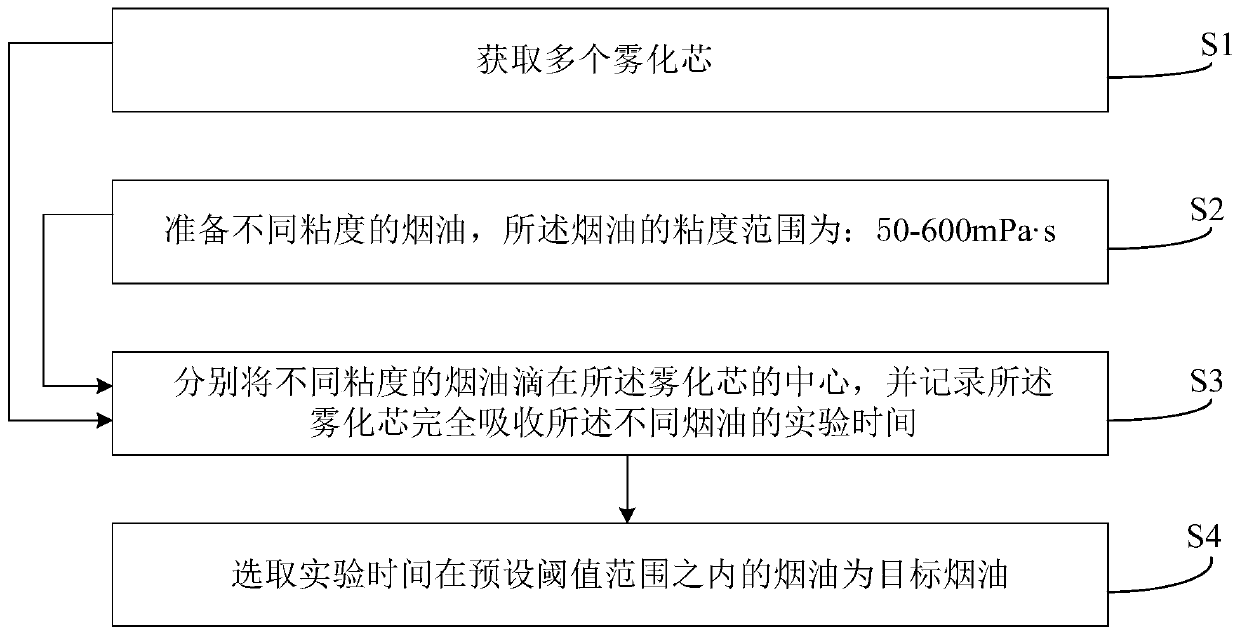

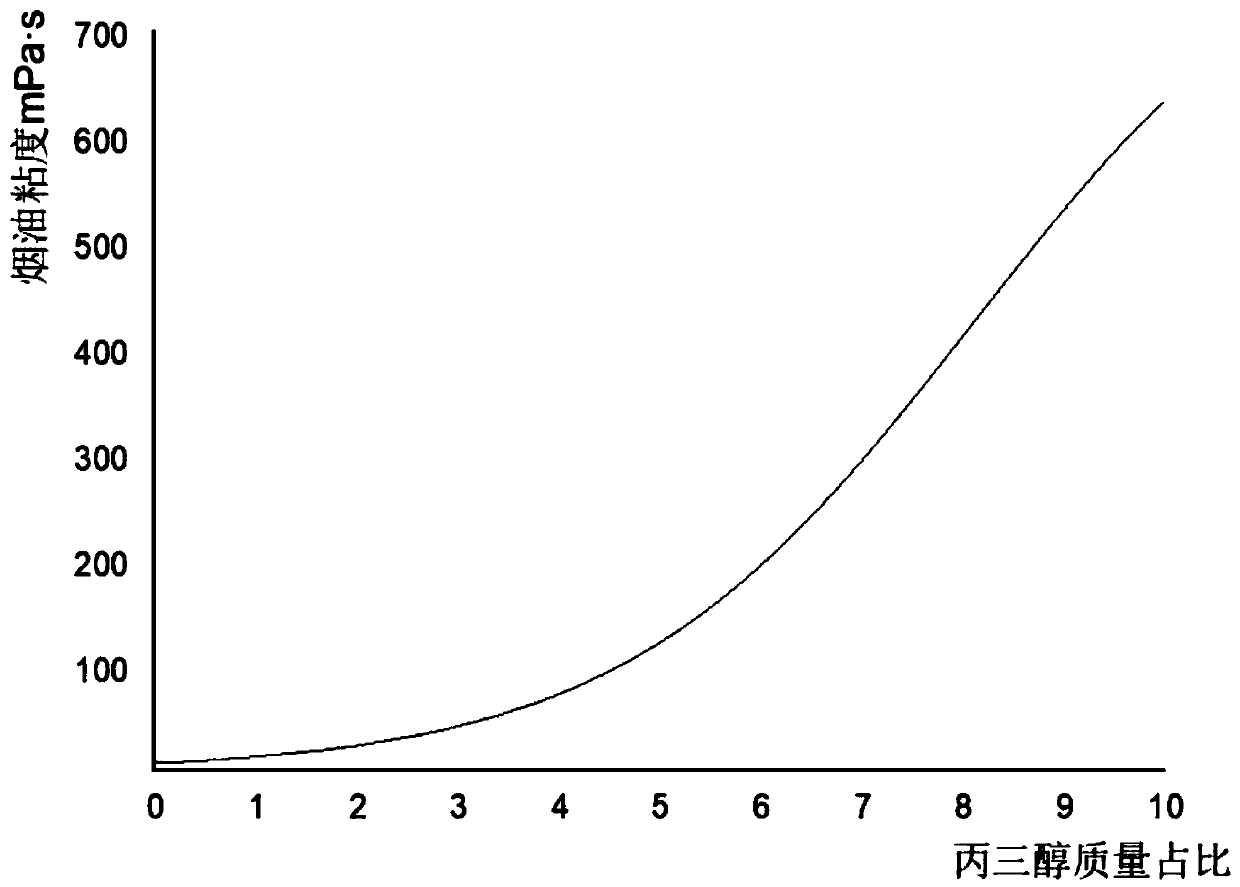

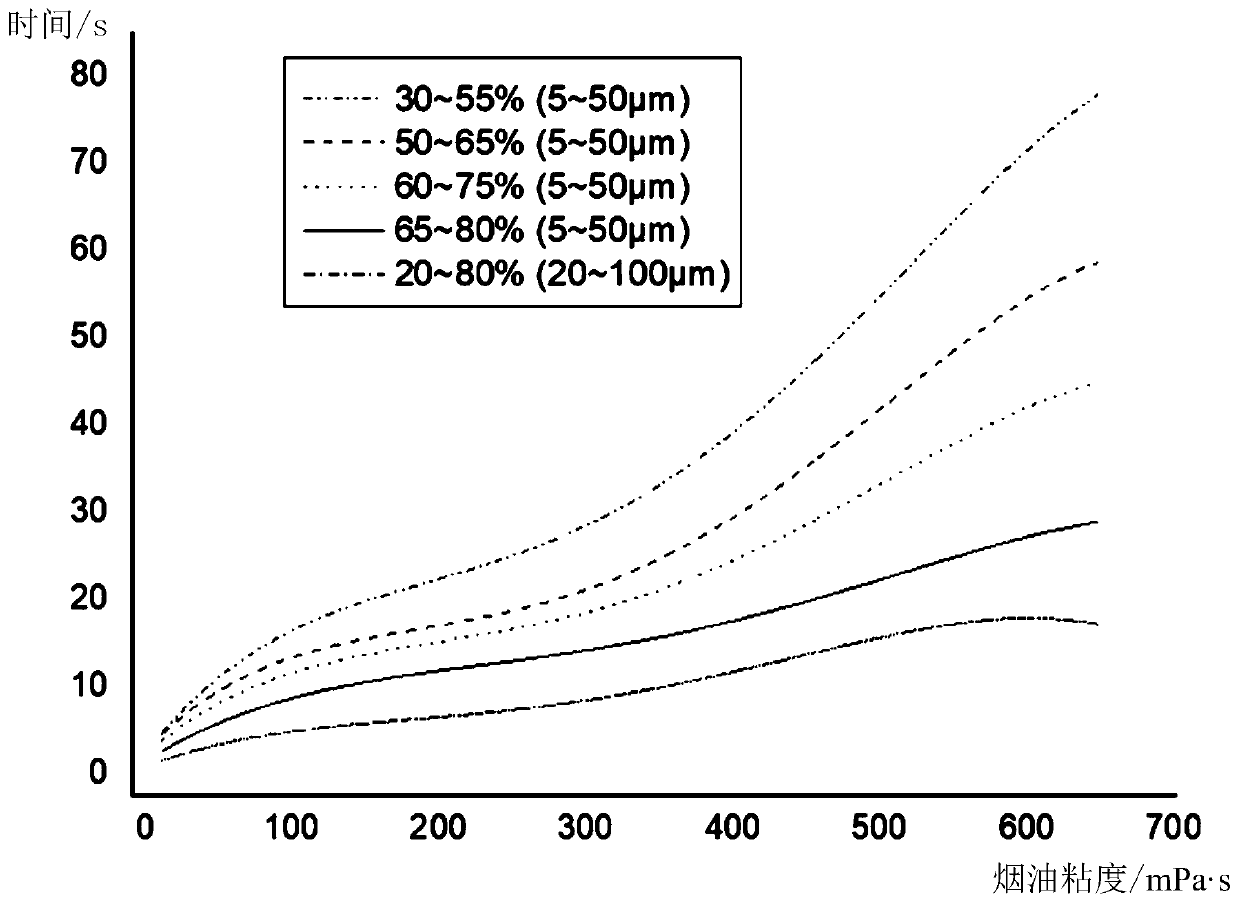

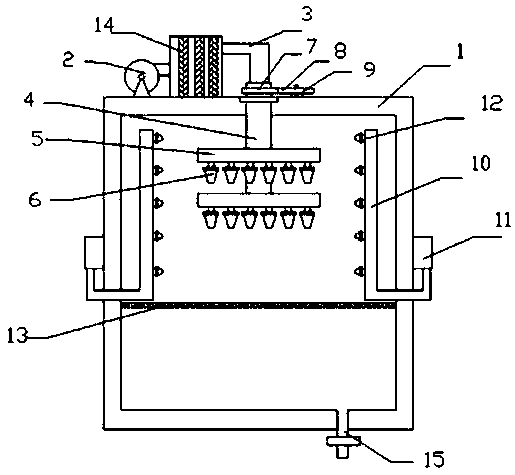

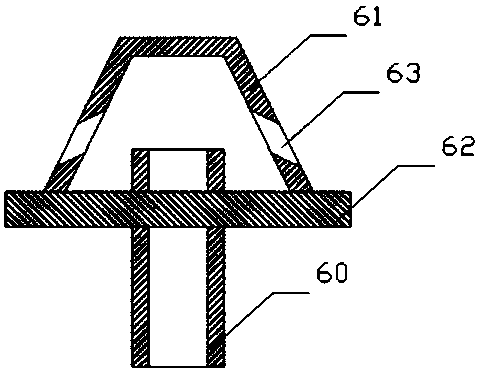

Method and device for selecting tobacco tar and atomizing core

The invention relates to the technical field of electronic cigarettes, in particular to a method and a device for selecting tobacco tar and an atomizing core. The tobacco tar is atomized by using theatomizing core, wherein the atomizing core is porous ceramic; the tobacco tar comprises the following components of propylene glycol and / or glycerol, wherein the viscosity range of the tobacco tar is50-600mPa.s; the porosity of the atomizing core is 20-80%; and the pore diameter of the atomizing core is 5-100[mu]m. According to the method and the device for selecting the atomizing core, under thecondition that the viscosity of the tobacco tar is known, the relation among the porosity and the pore diameter of the atomizing core and the experiment time is obtained, the result is accurate and reliable, and the application range is wide; under the condition that the viscosity of the tobacco tar is the same, the higher the porosity and the pore diameter of the atomizing core are, the shorterthe experiment time is; and different atomizing cores can be selected according to different kinds of tobacco tar for enabling the pore diameter and porosity of the atomizing core to be matched with the viscosity of the tobacco tar, so that the atomizing effect of the electronic cigarette and the user experience effect are improved.

Owner:东莞市陶陶新材料科技有限公司

Novel automobile fuel injection nozzle

InactiveCN111365155AGood atomization effectFully contactedFuel injection apparatusMachines/enginesInjector nozzleGasoline

The invention discloses a novel automobile fuel injection nozzle, which comprises a cylindrical fuel injection nozzle main body; two ends of the fuel injection nozzle body are penetrated and fixedly embedded with a gasoline pipe and an air pipe which are mutually parallel; the same ends of the gasoline pipe and the air pipe extend from the fuel injection nozzle main body respectively to form a gasoline nozzle and an air nozzle; the gasoline nozzle and the air nozzle are fixedly and respectively provided with a gasoline cap and an air cap; a plurality of atomizing holes and shunts holes are evenly and respectively formed in the gasoline cap and the air cap; one end of the fuel injection nozzle main body away from the gasoline nozzle and the air nozzle is provided with a base; and an oil inlet and an air inlet, an oil inlet socket pipe and an air inlet socket pipe are arranged on the base. The novel automobile fuel injection nozzle has the advantages of simple structure, smooth fuel supply, and good gasoline atomization and combustion effects.

Owner:BORUN HONGDA (TIANJIN) TECH DEV CO LTD

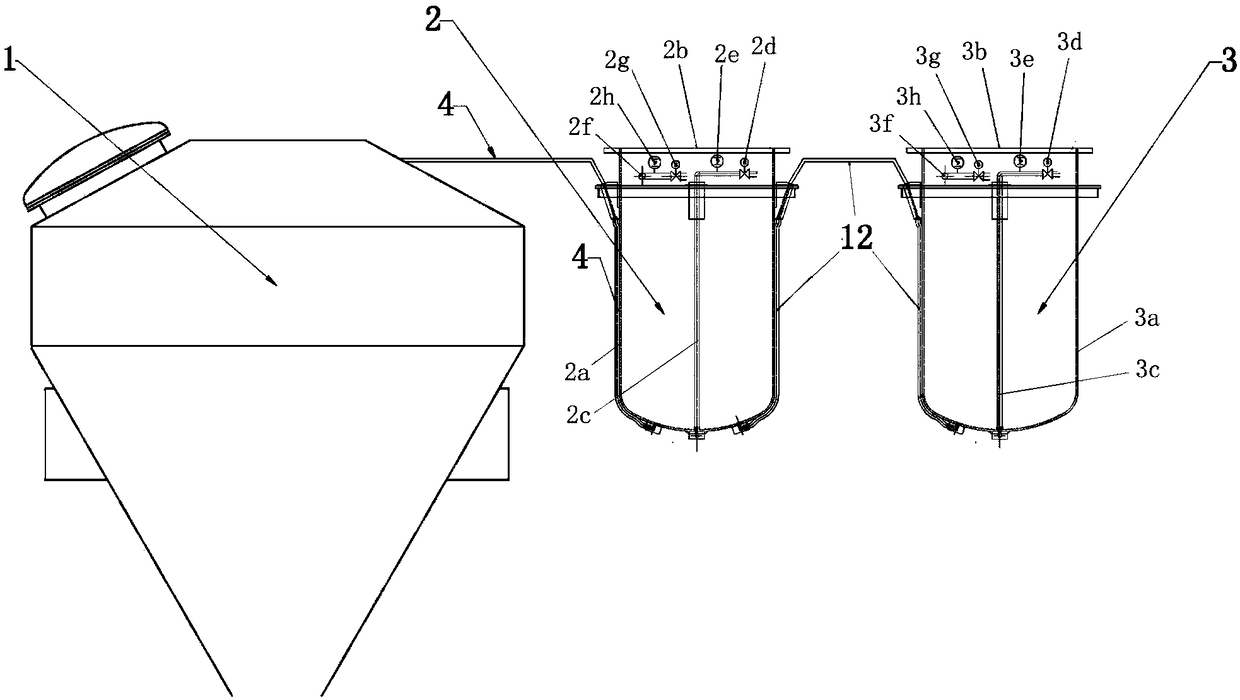

Solder powder production device and production method capable of feeding automatically and stably

The invention relates to a solder powder production device and a production method capable of feeding automatically and stably. The device comprises a melting furnace and a feeding furnace mutually connected through a conveying pipe, and an atomizing barrel connected with the feeding furnace through a feeding pipe, wherein the feeding furnace comprises a feeding furnace body with a furnace cover,a feeding furnace nitrogen input pipe directly inserted to the bottom part of the feeding furnace body from the center of the feeding furnace body, a feeding furnace nitrogenization electromagnetic valve and a feeding furnace bottom part pressure sensor on the feeding furnace nitrogen input pipe, a feeding furnace top part pressure sensor, a feeding furnace exhaust port and a feeding furnace exhaust electromagnetic valve; and the melting furnace comprises a melting furnace body with a furnace cover, a melting furnace nitrogen input pipe directly inserted to the bottom part of the melting furnace body from the center of the melting furnace body, a melting furnace nitrogenization electromagnetic valve and a melting furnace bottom part pressure sensor on the melting furnace nitrogen input pipe, a melting furnace top part pressure sensor, a melting furnace exhaust port and a melting furnace exhaust electromagnetic valve. According to the solder powder production device and the production method capable of feeding automatically and stably provided by the invention, the atomizing barrel can be stably fed controllably at constant speed.

Owner:云南锡业锡材有限公司

Atomizing core, and method and device for selecting tobacco tar

The invention relates to the technical field of electronic cigarettes, and in particular to an atomizing core, and a method and device for selecting tobacco tar. The atomizing core of the invention isused for atomizing the tobacco tar. The atomizing core is porous ceramic. The porosity of the atomizing core ranges from 20% to 80%. The pore diameter of the atomizing core ranges from 5 micrometersto 100 micrometers. The atomizing core of the invention is used for atomizing the tobacco tar. The atomization effect and taste of the tobacco tar are good. The method and device for selecting tobaccotar provides the relationship between the viscosity of the tobacco tar and the experiment time obtained when the pore diameter and the porosity of the atomizing core are known, thereby obtaining an accurate and reliable result. Therefore, the atomizing core has a wide range of being applied. When the pore diameter and the porosity of the atomizing core are the same, the higher the viscosity of the tobacco tar, the longer the experiment time. Different tobacco tar can be selected according to different atomizing cores to enable the pore diameter and the porosity of the atomizing core to be adaptive to the viscosity of the tobacco tar, thereby improving the atomization effect of an electronic cigarette and experiencing effect of a user.

Owner:东莞市陶陶新材料科技有限公司

Sewage treatment tank

InactiveCN109607866AGood atomization effectIncrease contact areaTreatment involving filtrationMultistage water/sewage treatmentGastric tube feedingWater pipe

The invention discloses a sewage treatment tank. The tank comprises a tank body, a water pump and a water inlet pipe are mounted at the top of the tank body, the water pump is connected with the waterinlet pipe, a water inlet spray assembly and a medicine inlet assembly are mounted in the tank body, the water inlet spray assembly comprises a main water pipe and an auxiliary water pipe, the auxiliary water pipe is communicated with the main water pipe, the auxiliary water pipe is vertical to the main water pipe, a plurality of water outlet holes are formed in the auxiliary water pipe, spray pipes are installed on the water outlet holes, a medicine feeding assembly comprises a medicine feeding tube and a blower, the blower is fixed to the side surface of the tank body, one end of the medicine feeding tube extends into the tank body, the other end extends out of the tank body, one end extending outside the tank body is connected with the blower, a plurality of medicine outlets are formedin the medicine feeding tube extending into the tank body, and medicine blowing tubes are installed at each medicine outlet. The tank can make sewage fully contact with medicine powder, improve a purification effect and improve a purified water quality.

Owner:GUANGZHOU JINRUN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com