Water particle generating device

A generation device and particle technology, which is applied in the direction of spraying device, electrostatic spraying device, corona discharge device, etc., can solve the problems of high defective rate and processing cost, extremely high requirements for the shape of the emitter electrode, and obstruction of water particle movement, etc. Reliable electrical connection, excellent atomization effect, and stable condensed water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

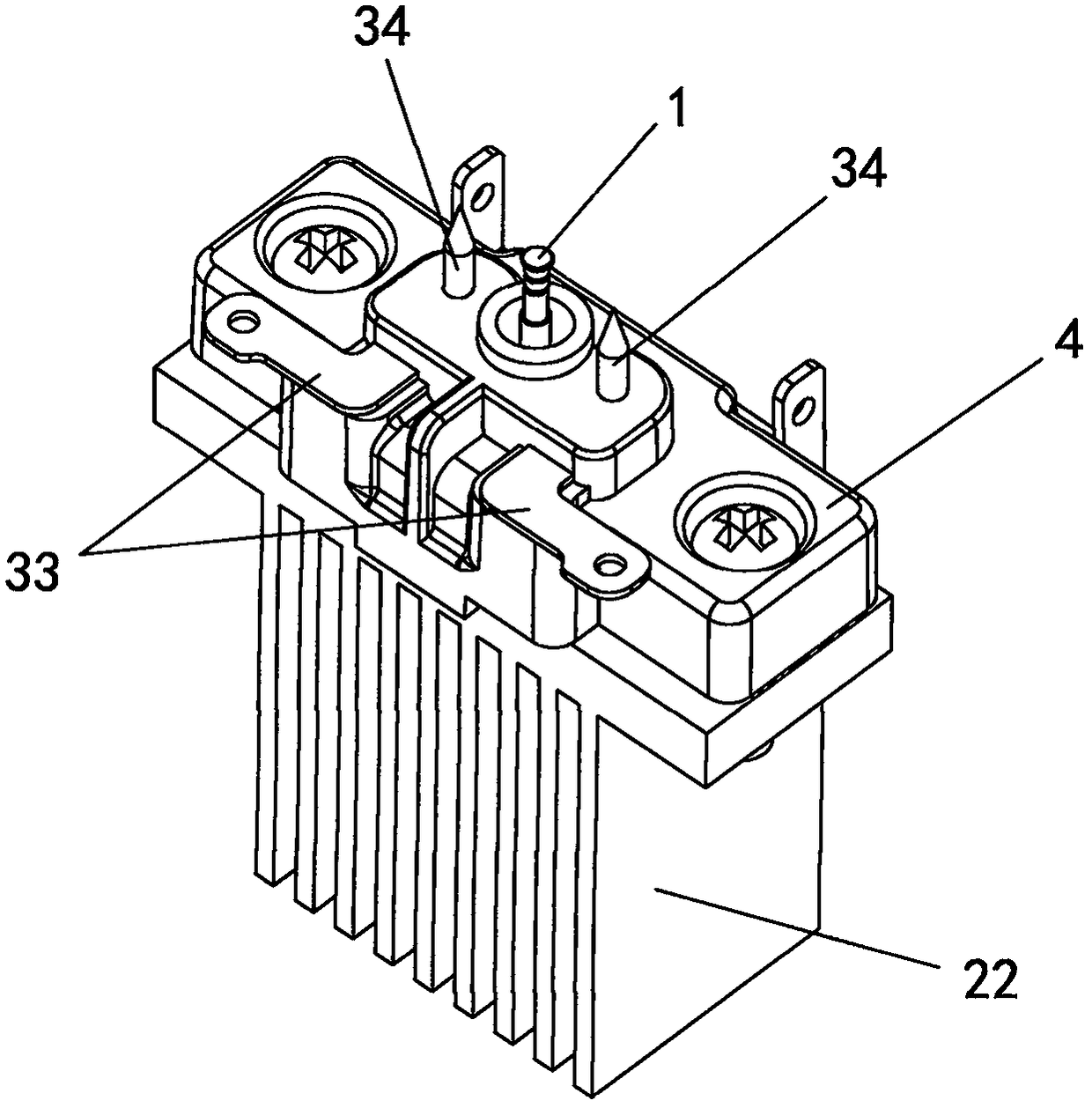

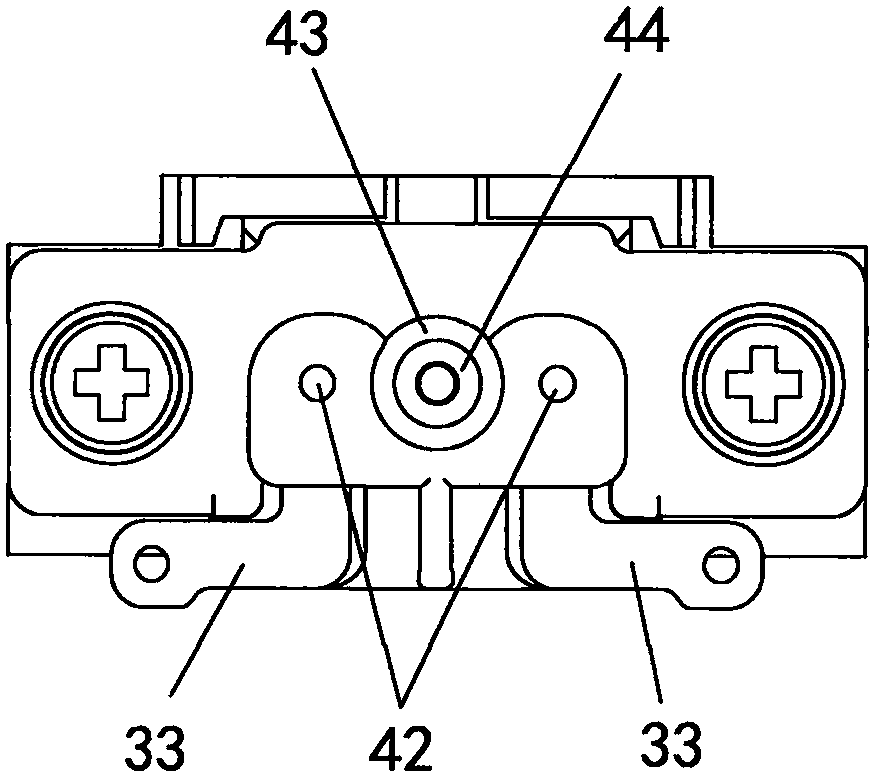

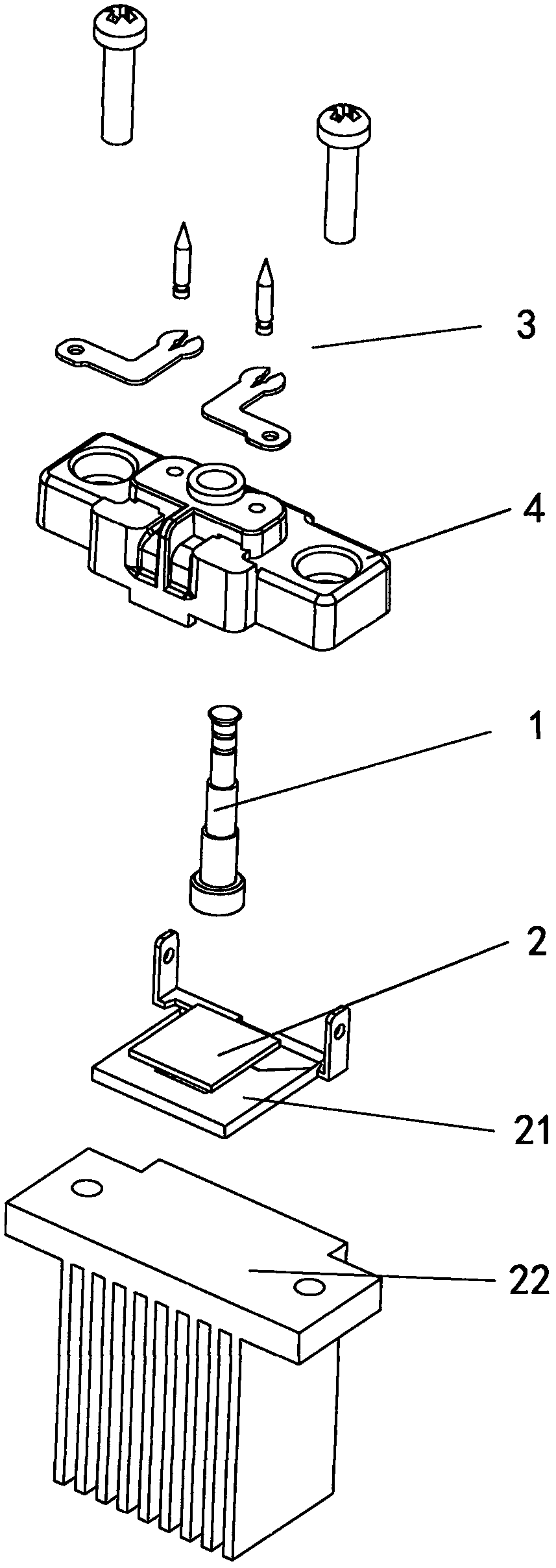

[0037] This embodiment provides a water particle generating device, such as Figure 1 to Figure 7 As shown, a water particle generating device includes: a condensation rod 1, which condenses water in the air around the condensation rod 1 on the condensation rod 1; a refrigerator 2, which contacts the condensation rod 1, and The rod 1 is cooled down; the discharge electrode group 3, the discharge electrode group 3 includes electrode one 31 and electrode two 32 that cooperate with each other, and the electrode one 31 and electrode two 32 are arranged laterally, and the electrode one 31 and electrode two 32 are arranged horizontally. Two 32 are respectively located at both sides of the condensation rod 1; a high-voltage power supply applies a high voltage to the discharge electrode group 3, so that a high-voltage corona is generated between the electrode one 31 and the electrode two 32; wherein, the discharge electrode The electrode group 3 applies a high-voltage corona to the co...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that, if Figure 8 and Figure 9 As shown, the discharge tip 34 is a discharge needle with a tapered tip, the connecting lock piece 33 is installed on the side of the insulating bracket away from the refrigerator 2, the end of the connecting lock piece 33 wraps the discharge needle, and makes The conical tip of the discharge needle acts on the condensation rod 1. The connecting lock piece 33 of the present invention wraps the discharge needle, which can maximize the contact area between the two, ensure the effect of electrical connection, and avoid sparks at the connection between the two.

[0047] In this embodiment, the condensation surface 11 does not need to be provided with a water collecting tank, and the condensation surface 11 of the condensation rod is also provided with a slow flow step 13 that gradually increases from the top to the bottom of the circumference, which can also realize the guarantee. ...

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that, if Figure 10 In the water particle generating device shown, the discharge tip 34 is a discharge sheet with sharp corners, and the discharge sheet is integrally formed with the connecting lock piece 33 , and the sharp corner of the discharge sheet acts on the condensation rod 1 . The discharge tip 34 is designed in a sheet shape, and is integrally formed with the connecting lock piece 33, which reduces the difficulty of forming the discharge electrode group, and the relative area between the two discharge tips is larger, ensuring that the cooling rod 1 is in a place where the discharge electrode group withstands high voltage. In the generated high-voltage corona, the position of the high-voltage corona and the condensed water is not easily dislocated, and the atomization effect of the condensed water condensed on the condensing rod 1 is better. In this embodiment, the discharge gap L between the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com