Centrifugal atomizer

A technology of centrifugal atomization and atomization disk, which is applied in the field of electrical appliances, can solve the problems of large fog particles, large vibration of the atomization disk, and the inability to handle backflow water well, so as to increase the contact area, improve the quality of use, and prevent fogging. better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

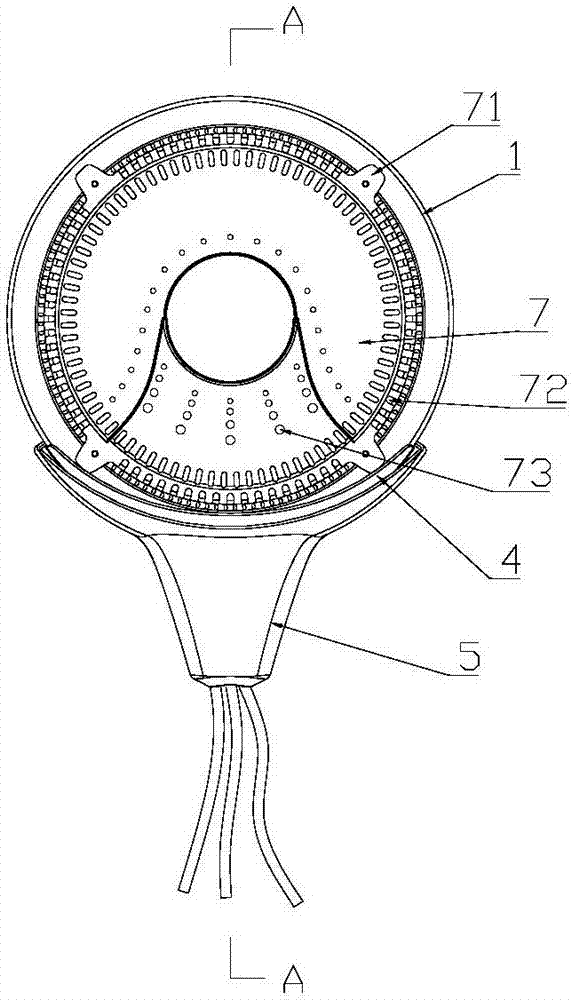

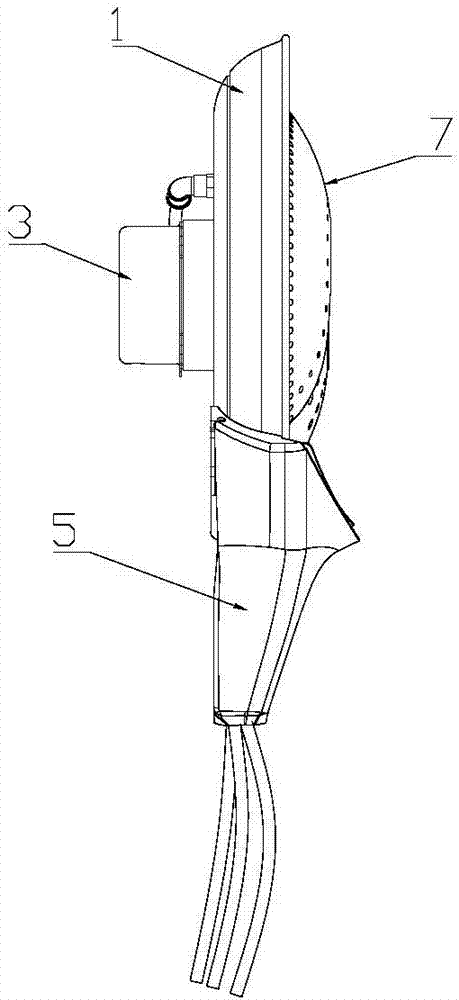

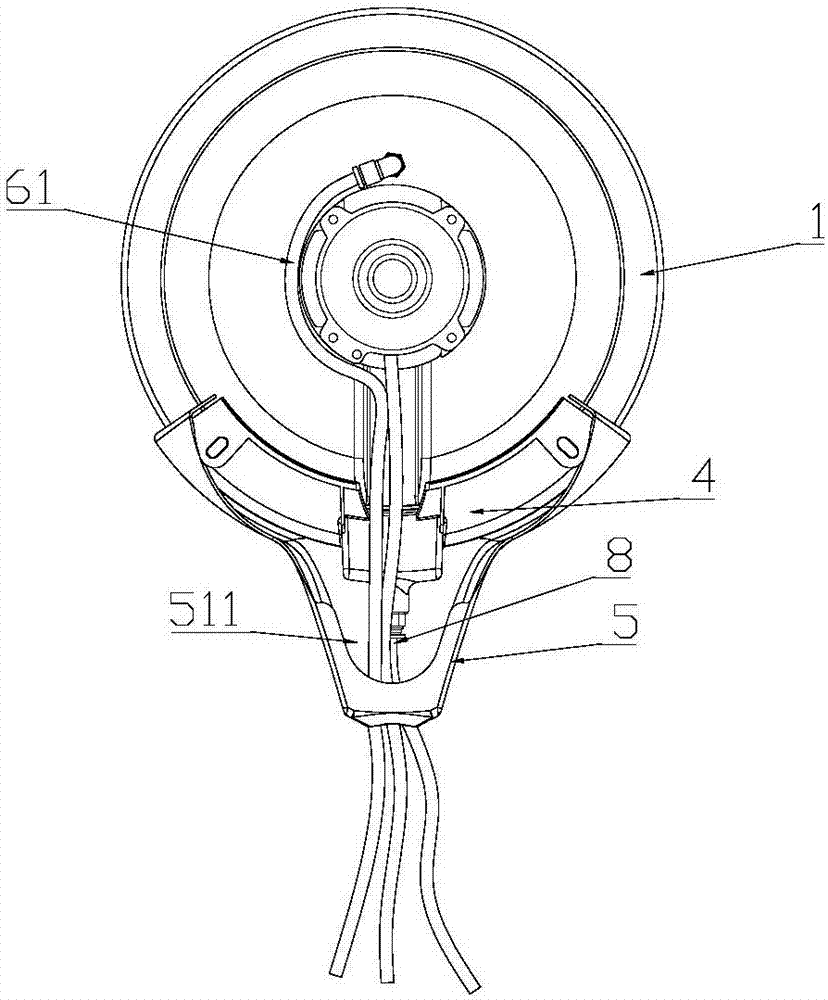

[0036] like Figure 1-Figure 6 As shown, the present invention provides a centrifugal atomizer, comprising a water collecting tray 1, an atomizing tray 2, a motor 3 for driving the atomizing tray 2 to rotate, a water supply device 6 for injecting water into the atomizing tray 2, a collecting The water tray 4 and the guide cover 5 that guides the wind to blow upward, the atomization tray 2 is located in the water collection tray 1, and the circumference of the water collection tray 1 is provided with a The atomization part 11 where the water phase collides, the water collecting pan 4 is located under the water collecting pan 1 , and the flow guide cover 5 is arranged under the water collecting pan 4 . Start the motor 3, the atomizing disc 2 rotates at high speed, the water from the water supply device falls on the atomizing disc 2, and under the action of the centrifugal force generated by the high-speed rotation of the atomizing disc 2, it diverges and accelerates along the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com