Ultrasonic atomizing device and atomizing method for liquid-containing binder for glass cotton

A technology of liquid binder and ultrasonic atomization, applied in the direction of liquid injection device, injection device, etc., can solve the problems of low utilization rate of liquid binder, uneven distribution of binder, etc., and achieve good atomization effect and color Uniformity and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

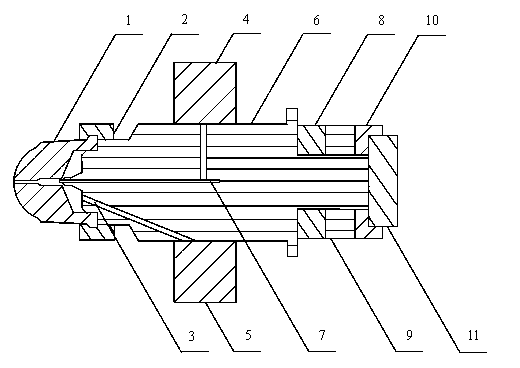

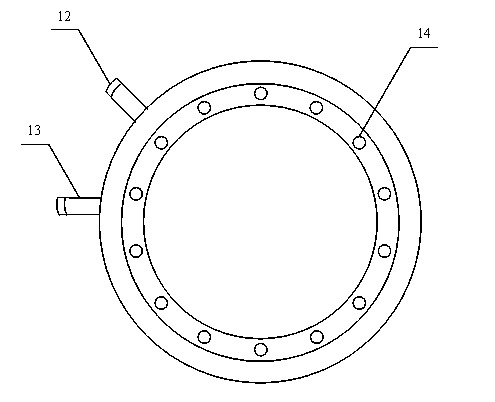

[0024] Such as figure 2 As shown, the liquid adhesive ultrasonic atomization device 14 for glass wool is sequentially loaded into the adhesive spray ring, a total of 14, and the liquid adhesive inlet 12 and the high-pressure air inlet 14 are respectively connected to the bonding agent. Agent pipeline and high pressure air gun. Such as figure 1 As shown, the liquid binder ultrasonic atomization device 14 for glass wool adopts a two-stage atomization structure of air pressure and ultrasonic vibration, including an air cap 1, a retainer ring 2, a gas channel 3, a liquid nozzle connector 4, and a gas nozzle connection Body 5, horn 6, infusion pipe 7, piezoelectric ceramic sheet 8, electrode sheet 9, cover plate 10, and bolt 11.

[0025] The electrode piece 9 is connected to the ultrasonic electric signal to make the vibrator part generate longitudinal ultrasonic vibration, and the resonance frequency is 1.7MHz. After the horn 6 starts to vibrate, the gas nozzle connecting body...

Embodiment 2

[0027] Put the liquid binder ultrasonic atomization device for glass wool into the binder spray ring in sequence, a total of 16, and connect the liquid binder inlet and high-pressure air inlet to the binder pipeline and high-pressure air gun respectively . Such as figure 1 As shown, the liquid binder ultrasonic atomization device 14 for glass wool adopts a two-stage atomization structure of air pressure and ultrasonic vibration, including an air cap 1, a retainer ring 2, a gas channel 3, a liquid nozzle connector 4, and a gas nozzle connection Body 5, horn 6, infusion pipeline 7, piezoelectric ceramic sheet 8, electrode piece 9, cover plate 10, bolt 11, add between electrode piece 9 and cover plate 10 and connect with infusion pipeline 7.

[0028] The electrode piece 9 is connected to the ultrasonic electric signal to make the vibrator part generate longitudinal ultrasonic vibration, and the resonant frequency is 1.8 MHz. When the horn 6 starts to vibrate, the gas nozzle con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com