High viscosity lysozyme dimer protein fluid atomization device

A lysozyme dimer, high-viscosity technology, applied in liquid spray devices, spray devices, etc., can solve the problems of poor lysozyme dimer protein liquid, difficult to atomize, etc., to improve production efficiency, excellent mist, etc. effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

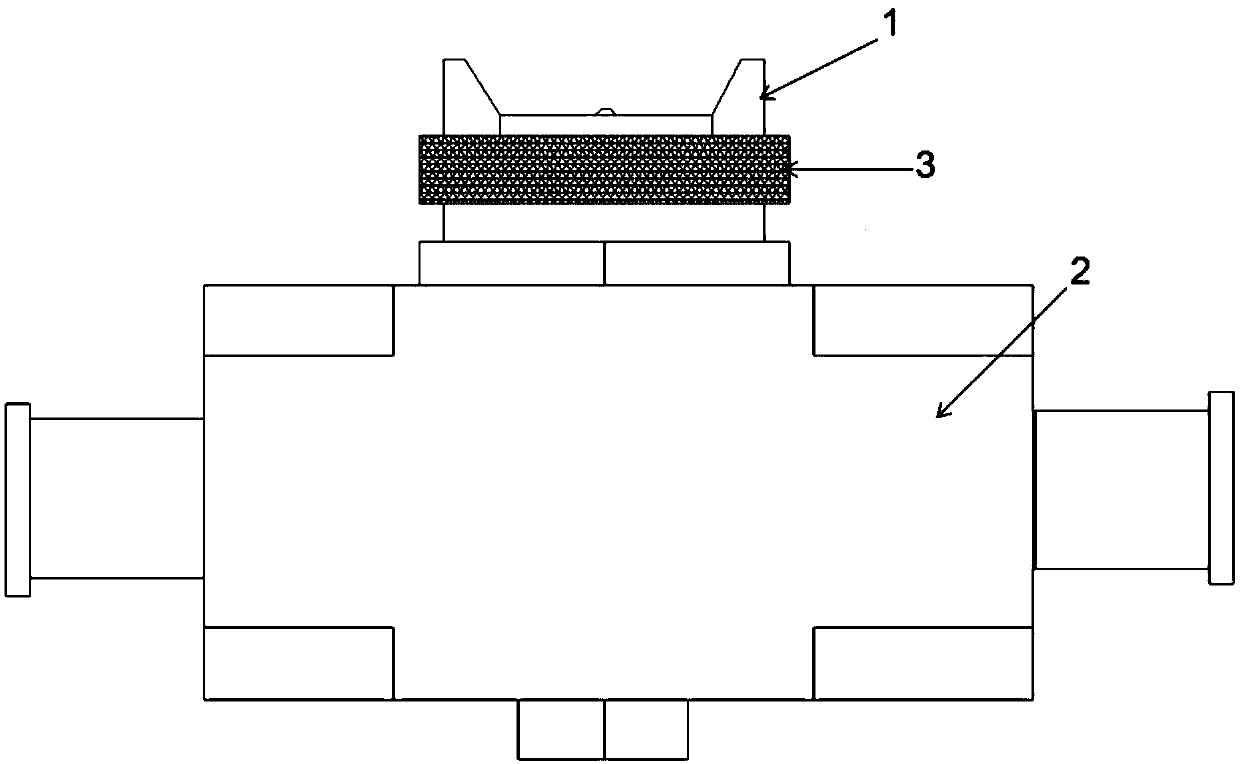

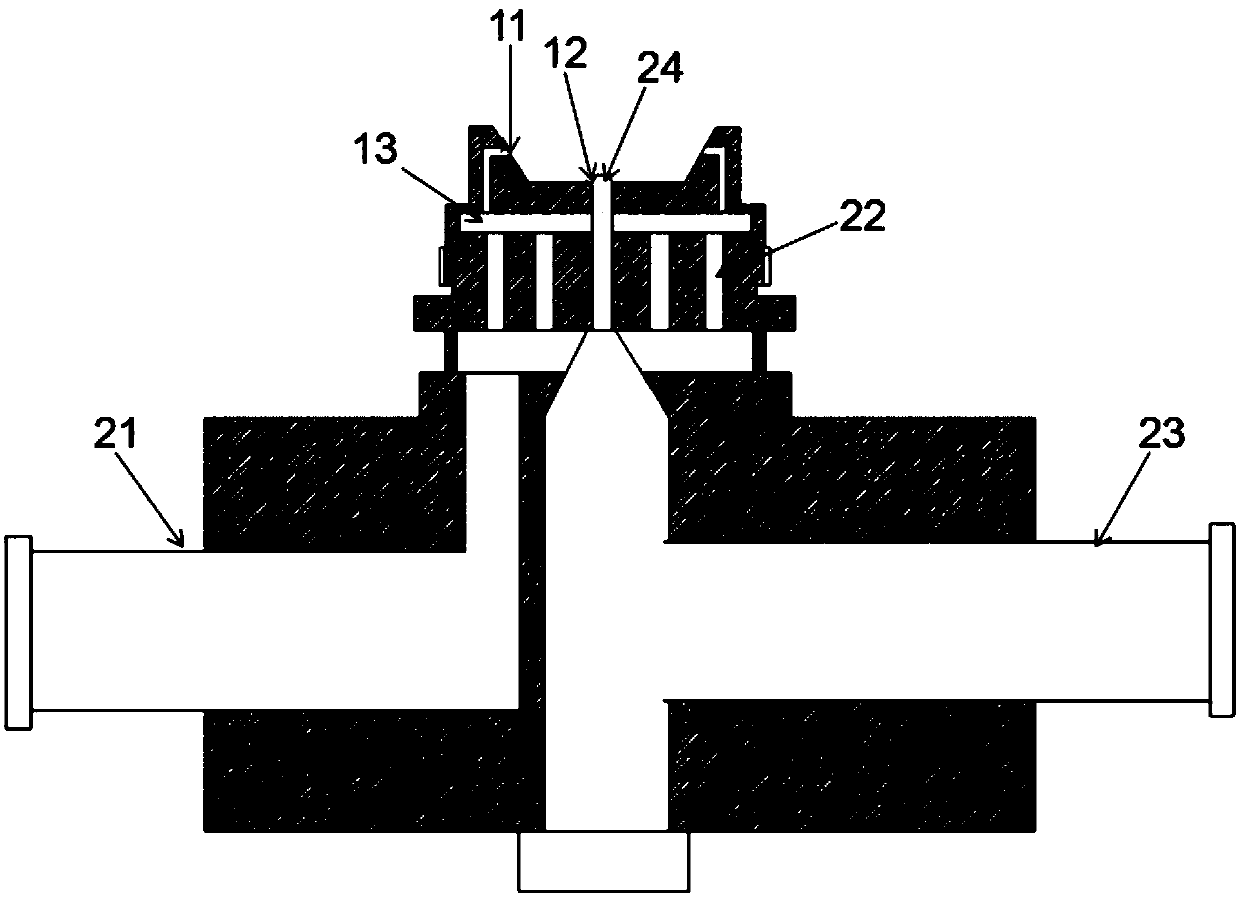

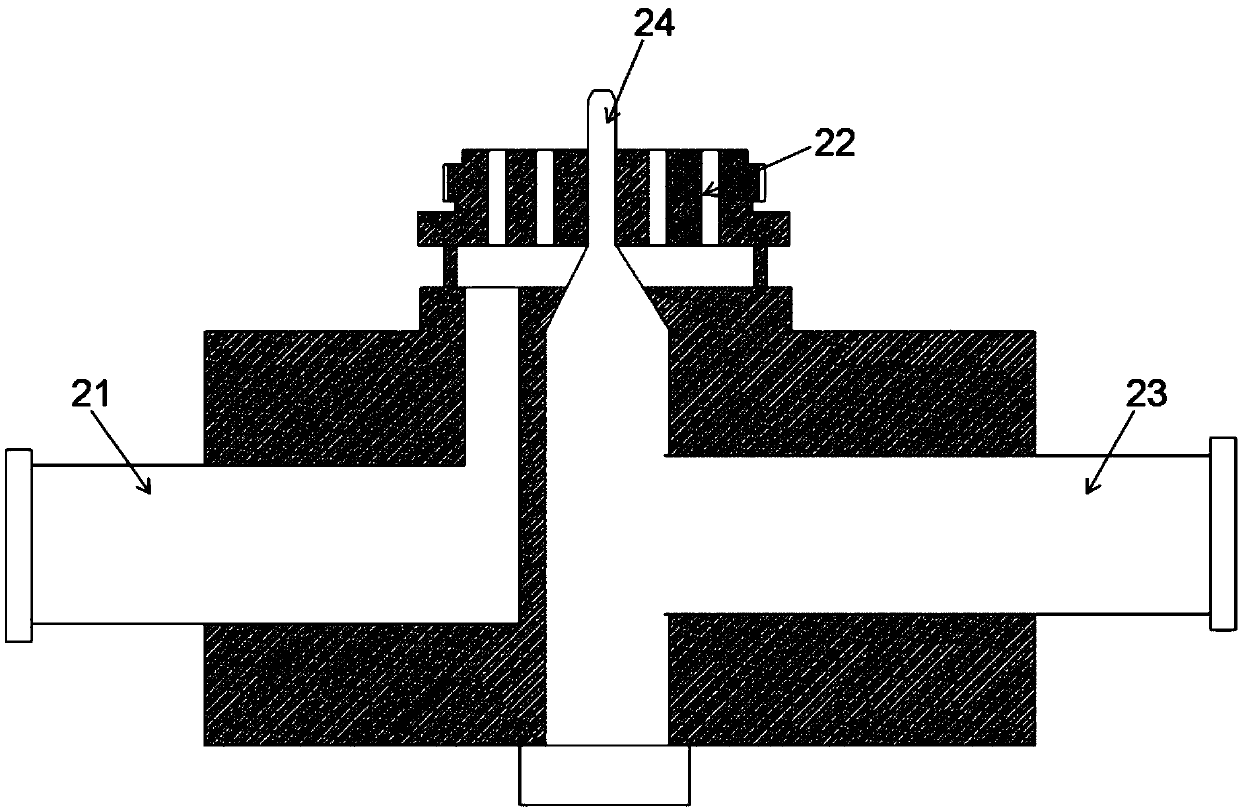

[0023] like figure 1 and figure 2 As shown, the present invention provides a high-viscosity lysozyme dimer protein liquid atomization device, which comprises: atomization nozzle 1, mixing seat 2 and two ends connected with atomization nozzle 1 and mixing seat 2 respectively combo cap 3; as image 3 As shown, the mixing seat 2 has a compressed air inlet 21, a plurality of compressed air uniform distribution holes 22 communicated with the compressed air inlet 21, a material inlet 23 and a nozzle 24 communicated with the material inlet 23; Figure 4 As shown, the atomizing nozzle 1 has a first stabilized compressed air outlet 11, a second stabilized compressed air outlet 12 for the nozzle 24 to pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com