Composite atomizer for manufacturing gas atomization quick-coagulation spherical superfine metal powder

A technology for manufacturing gas and metal powder, applied in the field of metal powder manufacturing, can solve the problems of complex atomization equipment and achieve better atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

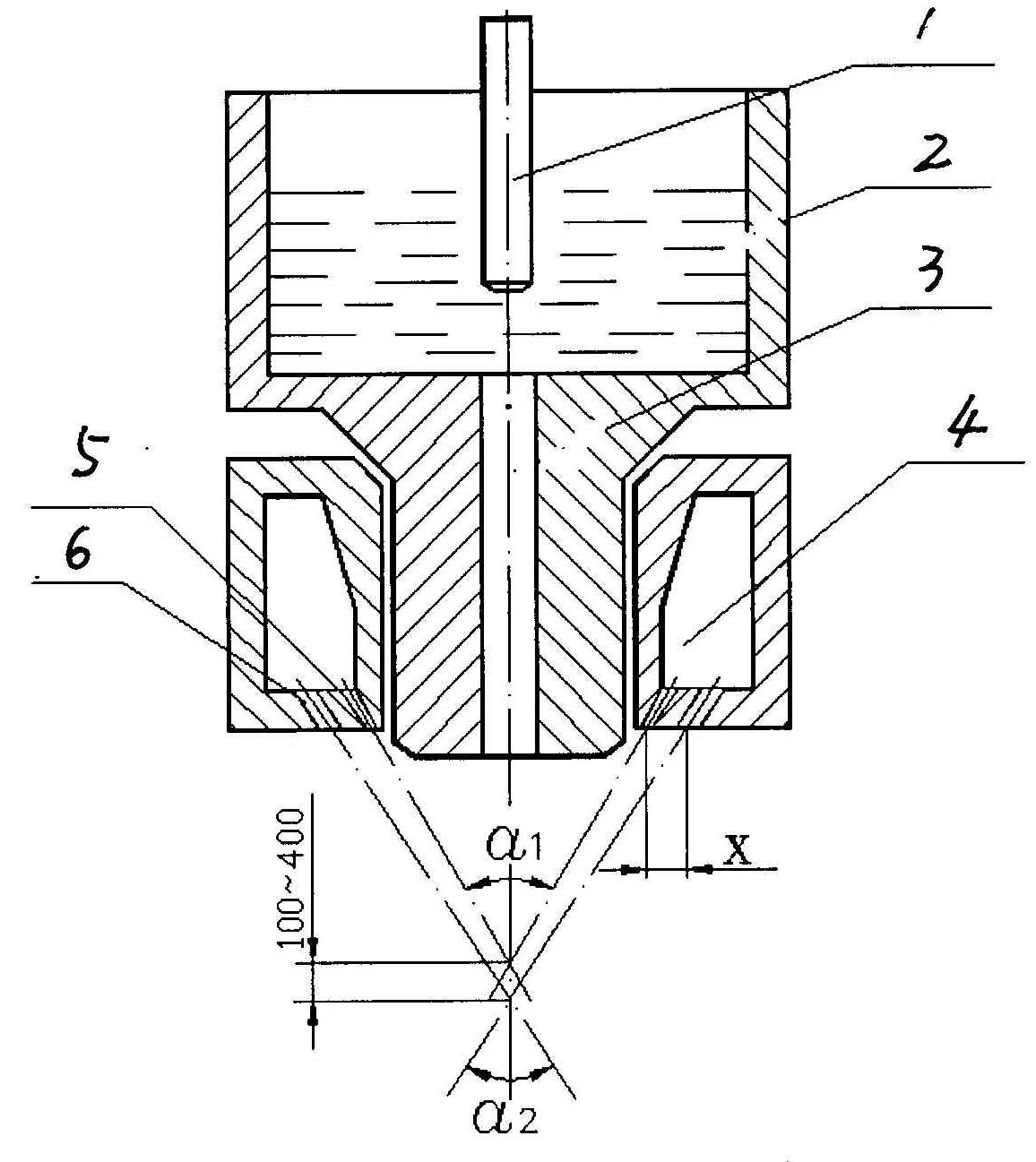

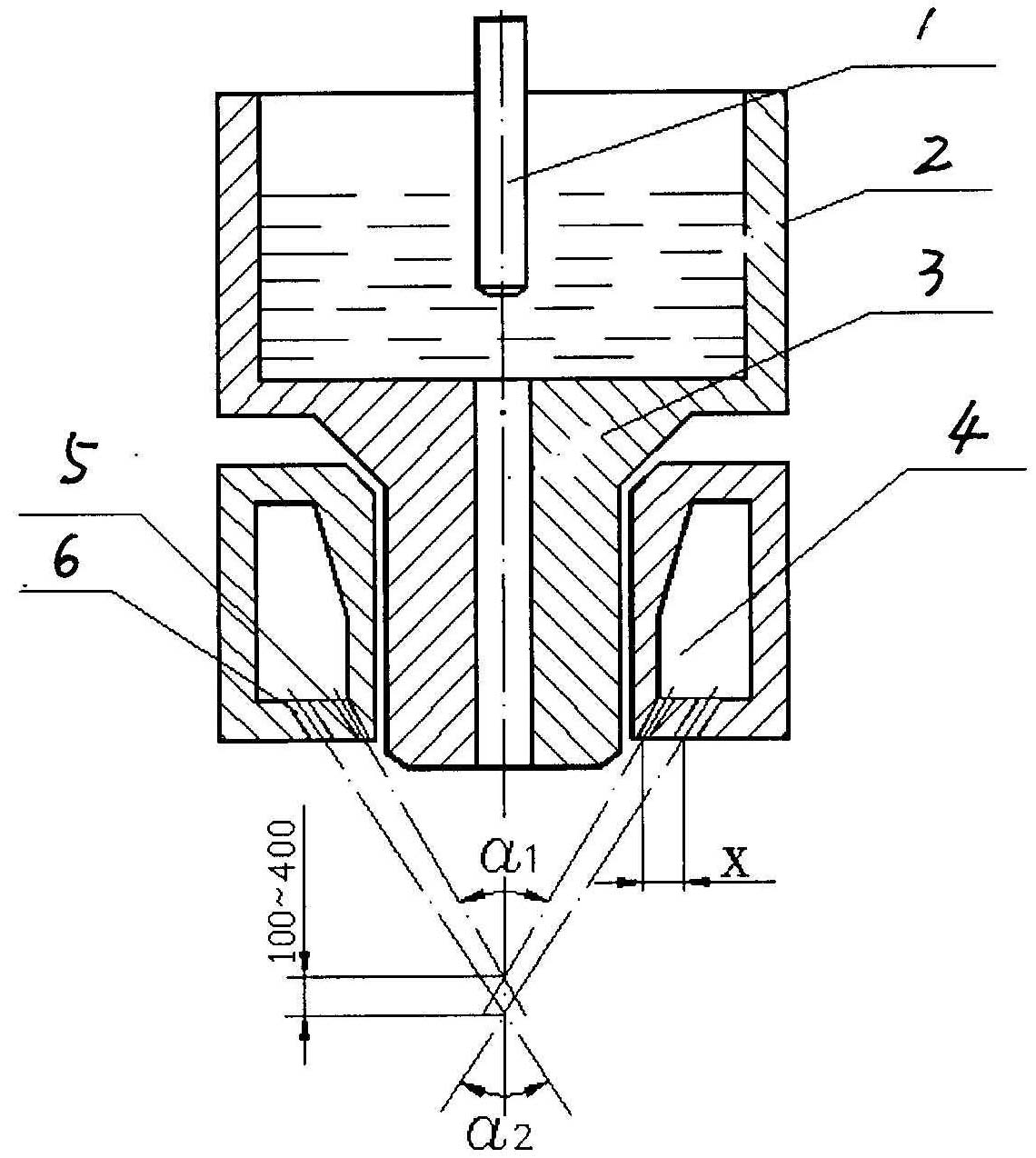

[0016] Such as figure 1 As shown, the composite atomizer for producing gas atomized and rapidly solidified spherical fine metal powder in this embodiment includes a clamp pot 2 for containing molten metal, and a metal liquid conduit 3 arranged around the bottom of the clamp pot is connected to a high-speed gas flow source An atomizer chamber 4 with an annular single-chamber structure in a continuous ring structure; surrounding the annular bottom surface of the atomizer chamber, there are two concentric circle structures formed by a number of nozzles arranged in an evenly distributed manner. The nozzle rings 5, 6 of the nozzles are all arranged in a sideways manner in which their axes intersect with the lower extension line of the catheter axis; wherein, the axes of all the nozzles on the inner nozzle ring 5 close to the catheter axis are the same Intersect with the catheter axis at the α1 vertex of the atomization zone II, and the axes of all nozzles on the outer nozzle ring 6...

Embodiment 2

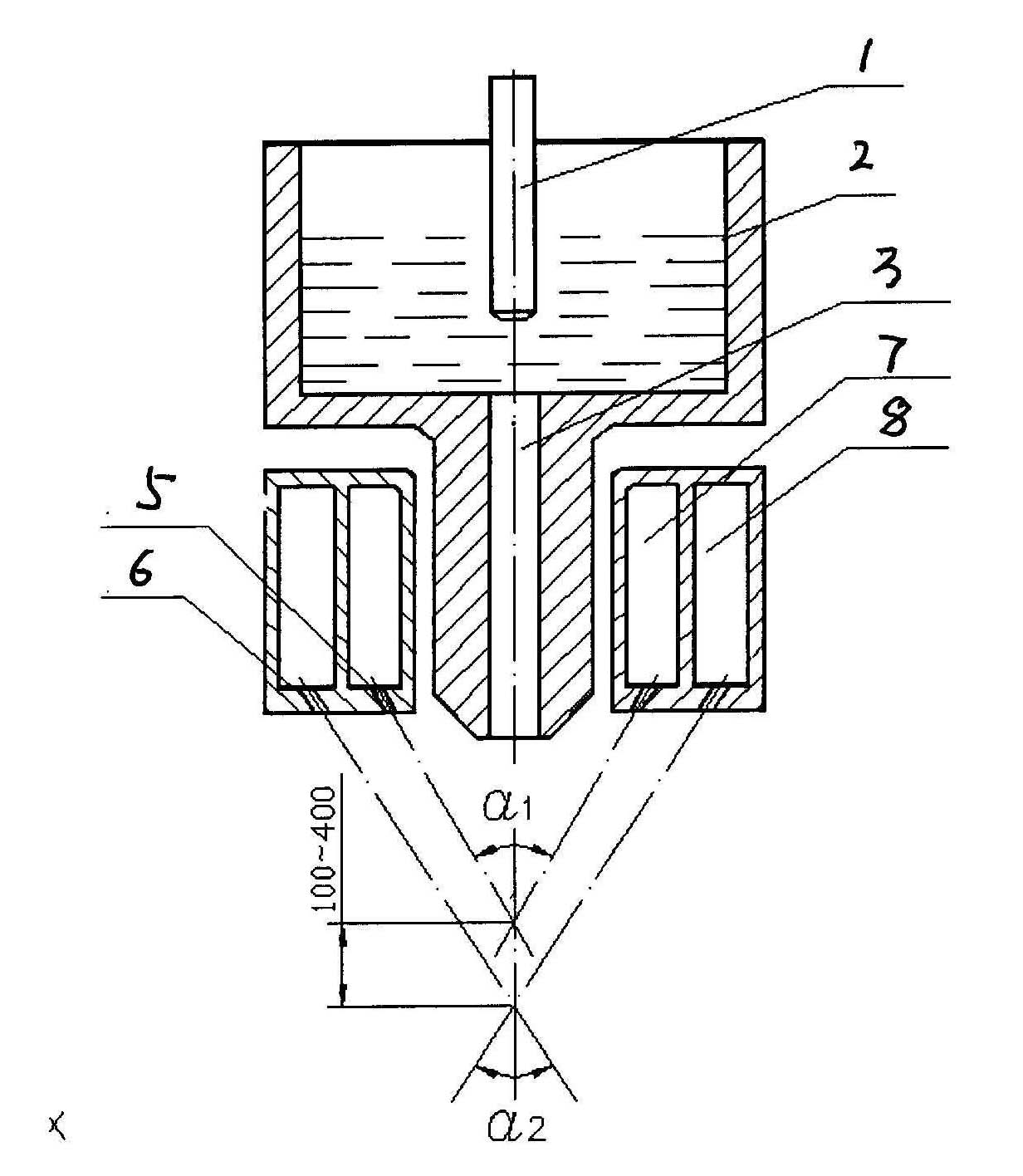

[0018] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the atomizer chamber is an inner and outer ring cavity structure separated by a vertically arranged annular partition, and the nozzles arranged on the inner nozzle ring 5 All communicate with the inner ring chamber 7 , and the nozzles arranged on the outer nozzle ring 6 communicate with the outer ring chamber 8 .

[0019] When the composite atomizer of the present invention is used for the manufacture of amorphous Al-Ni-Y alloy spherical powder, the gas atomization pressure is 1.0Mpa, and the cooling rate reaches 10 6 K / s, the average particle size of the prepared Al-Ni-Y amorphous powder is 7-12 μm.

[0020] When the composite atomizer of the present invention is used in the manufacture of Al-Mn quasi-crystal spherical powder, the atomization pressure is 1.5 Mpa, and the average particle size of the prepared Al-Mn quasi-crystal powder is 10-14 μm.

[0021] When the compound a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com