Vapor cooling system for use in offline heat treatment of thin medium and thick plates

A cooling system and thin-gauge technology, applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve problems such as uneven cooling, achieve stable gas supply, solve uneven surface temperature distribution and plate shape problems, and improve automatic control level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

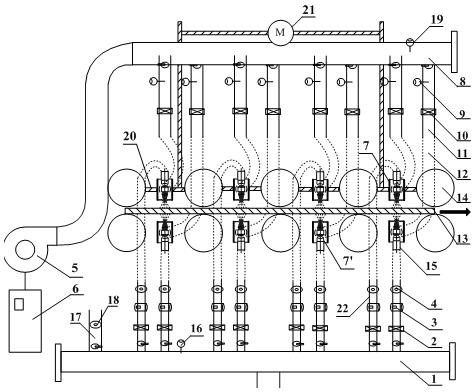

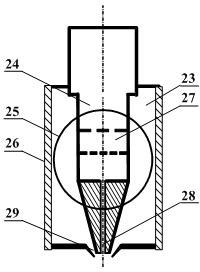

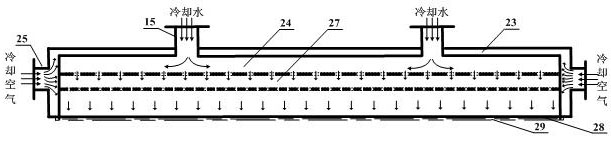

[0029] This embodiment provides a technical solution for the operation of the vapor mist cooling device configured with the vapor mist cooling system of the present invention, such as Figure 1~3 shown. When the vapor-mist cooling system starts to implement the cooling procedure, the water supply system, the air supply system, and the lifting transmission system work according to the following technical scheme: the water supply system opens the water supply pipeline opening and closing valve 2 of the working cooling section according to the cooling procedure. At this time, the cooling water is supplied by The diversion water collection pipe 1 enters the water storage cavity 24 of the steam mist nozzle through the opening and closing valve 2, the flow meter 3, the regulating valve 4, and the water inlet 15 in turn, and automatically adjusts the pressure relief and protection according to the water pressure measured by the pressure sensor 16 on the diversion water collection pipe...

Embodiment 2

[0031] This embodiment provides an operation plan for the vapor mist cooling device to implement the vapor mist cooling control system, such as Figure 4 shown. When the steel plate is ready to be released, the heat treatment furnace sends a ready-to-release signal to the steam-mist cooling system, and at the same time transmits the number of the steel plate to be released. The steam-mist cooling system reads the number of the steel plate to be released to the factory-level MES or planning management system. Steel plate planning information, which includes steel type, steel plate specification, start cooling temperature, final cooling temperature and cooling speed. The experience management system formulates cooling strategies based on the acquired plan information, invokes experience management procedures and sends them to PLC for execution. The PLC system monitors the implementation of the regulations in real time, and controls the regulating valves and on-off valves in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com