Atomized spray head

A technology of atomizing nozzles and nozzles, which is applied in the directions of spray devices, spray devices, liquid spray devices, etc., can solve the problems affecting the effect of heat transfer and mass transfer, and the diffusion area of atomized water flow is small, so as to achieve good atomization effect, The effect of wide diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

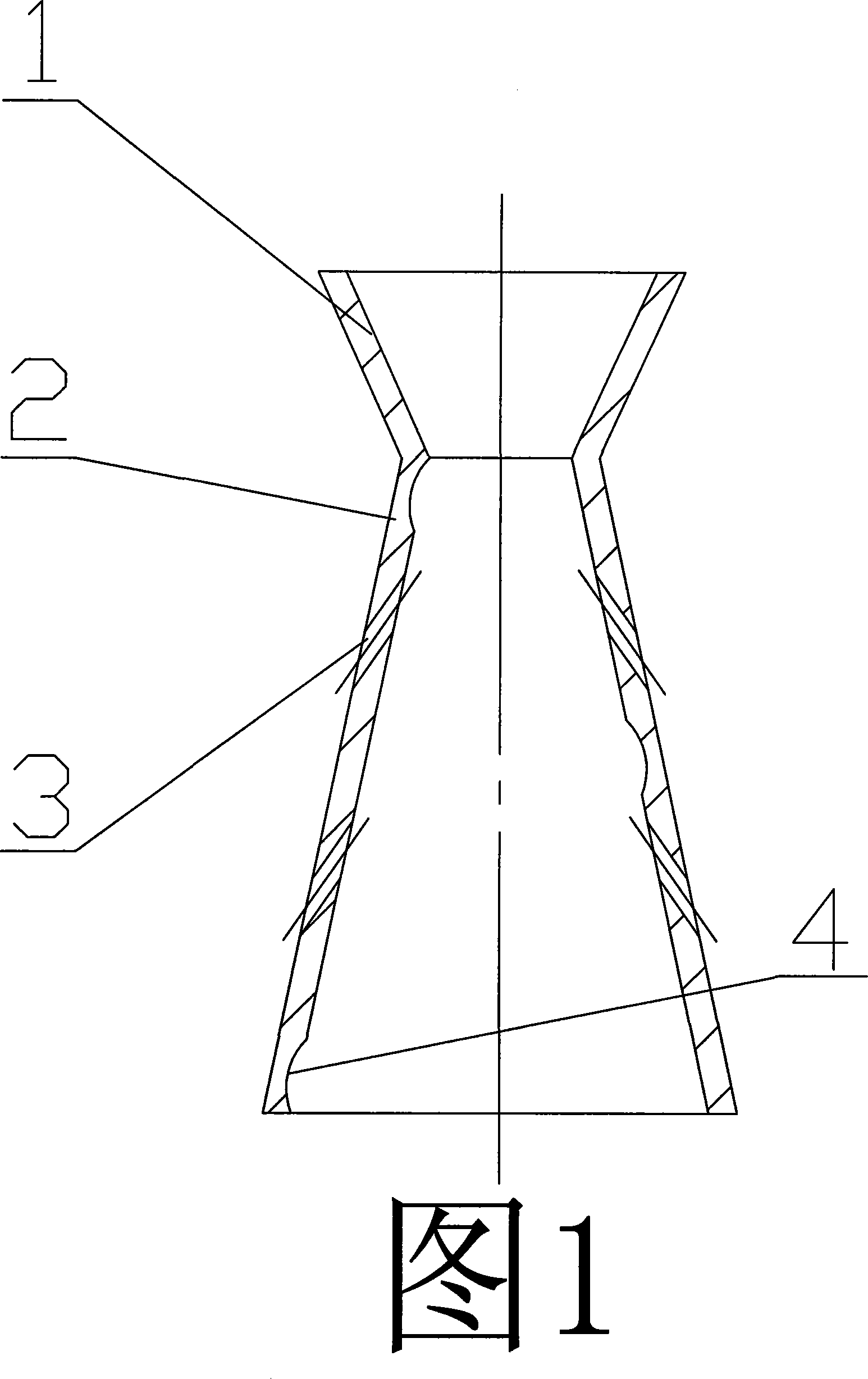

[0012] As shown in Figure 1, the present invention is a tubular integral body made up of a spray neck 2 that is tapered inside and outside, and a nozzle 1 that is connected to the upper end of the spray neck 2 and that is inverted tapered inside and outside. A right-handed spiral groove 4 is formed on the inner wall of the nozzle neck 2 and the through hole 3 inclined from the outside to the inside, and the spiral groove 4 runs through the entire inner wall of the nozzle neck 2 continuously.

[0013] Of course, the present invention is not limited to the above embodiments, and the spiral groove 4 may be a left-handed or right-handed spiral groove 4 with at least one end and the same direction of rotation.

[0014] The present invention can be obtained by processing a whole piece of iron bar by metal machining method; it can also obtain cast iron blank by casting method, and then process spiral groove 4 and through hole 3 by metal machining method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com