Method for producing alloy plastic die steel using direct hot delivery and hot charging technique

A technology for producing plastic mold steel and alloys, which is applied in the field of medium and thick steel plates, can solve the problems of high cost and low yield, and achieve the effects of increasing yield and yield, reducing energy consumption, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The liquidus temperature of the molten steel with the composition shown in Table 1 is 1490°C. A billet with a cross-section of 220×1800mm is poured on the slab continuous casting machine. The superheat degree during normal pouring is controlled at 10-30°C. , the casting speed is 0.9m / min; when 10≤ΔT<25℃, the casting speed is 0.8m / min; when 25≤ΔT<30℃, the casting speed is 0.75m / min. Under the matching of the temperature and the casting speed, the solidification of the slab is realized through automatic water distribution and cooling.

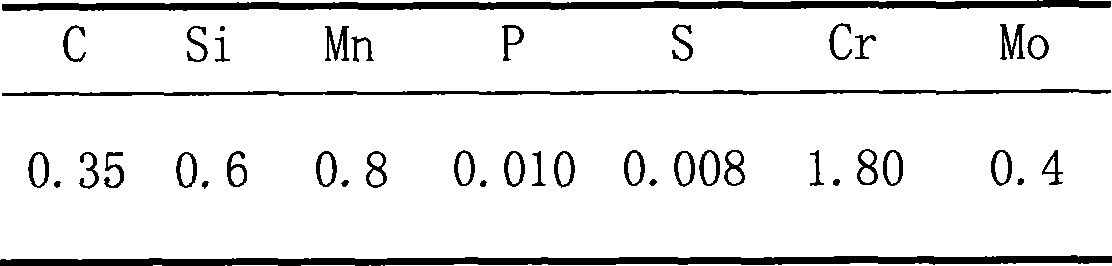

[0017] Table 1 Billet Chemical Composition of Example 1, %

[0018]

[0019] Using the above process, the P20 steel billet with a section of 220×1800mm was cast on the slab continuous casting machine. The surface of the billet has no defects and does not need to be cleaned, which meets the requirements of hot delivery and hot charging of the billet.

Embodiment 2

[0021] The temperature of the steel billet during online cutting is above 850°C. After cutting, the billet is directly sent to the heating furnace through the hot-feeding roller table. At the bainite transformation temperature, the bainite transformation before entering the furnace can be avoided.

[0022] The P20 steel ingot smelted in a 100kg vacuum furnace was used to simulate the hot delivery and hot charging of the continuous casting slab. The composition of the steel ingot is shown in Table 2.

[0023] The steel ingot composition of table 2 embodiment 2, %

[0024]

[0025]

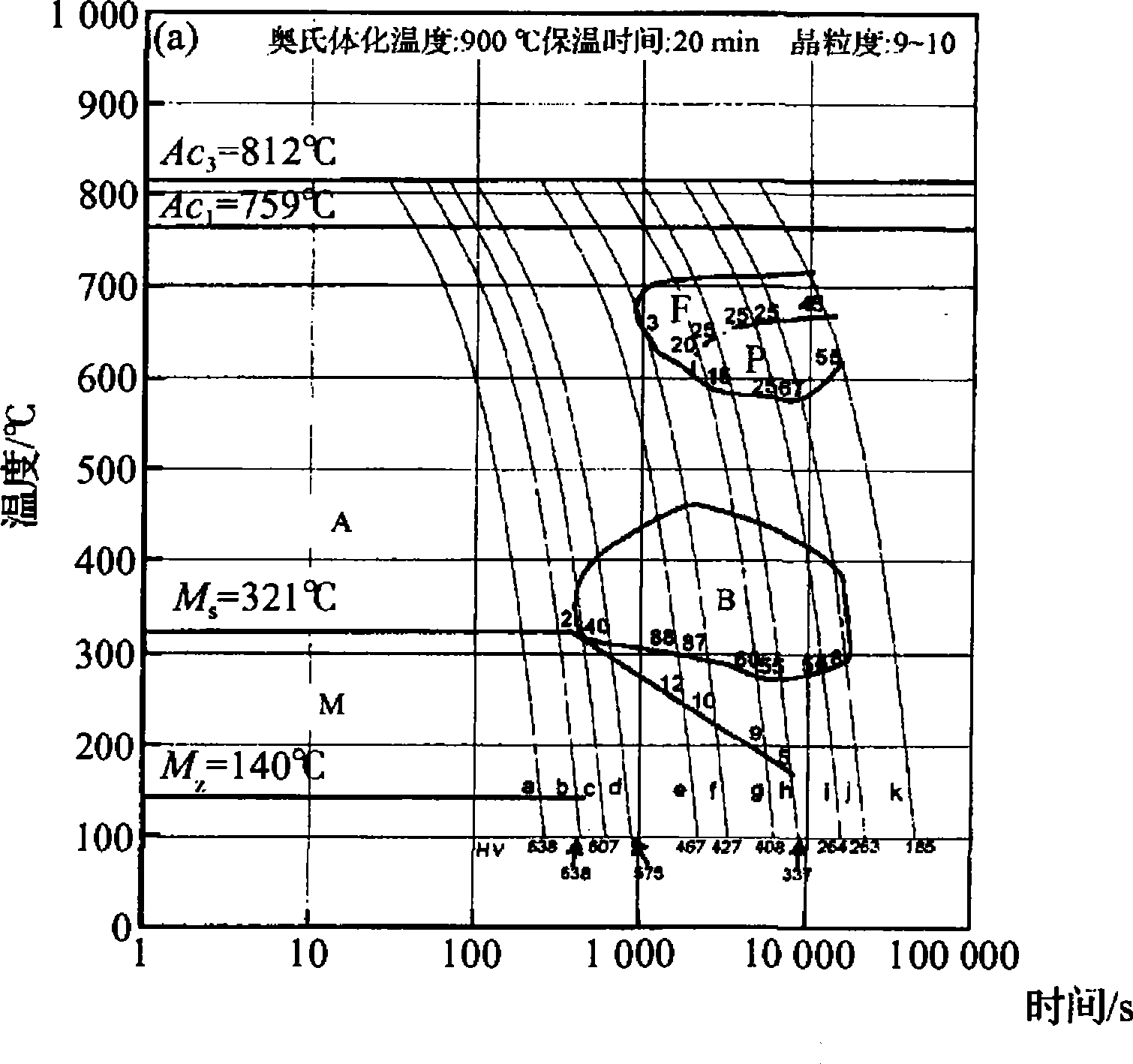

[0026] Such as figure 1 As shown, the bainite transformation temperature range of the experimental steel ingot is 300-470°C, and the bainite transformation will occur under air-cooling conditions.

[0027] 1# steel ingot is annealed at 550°C after demoulding, and the annealed cold ingot is heated in a heating furnace. The temperature in the soaking section of the heating furnace is 400-500°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com