Passive residual heat removal circulating performance testing system and method

A passive waste heat and test system technology, applied in the field of nuclear reactors, can solve the problems of test verification and no test system, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

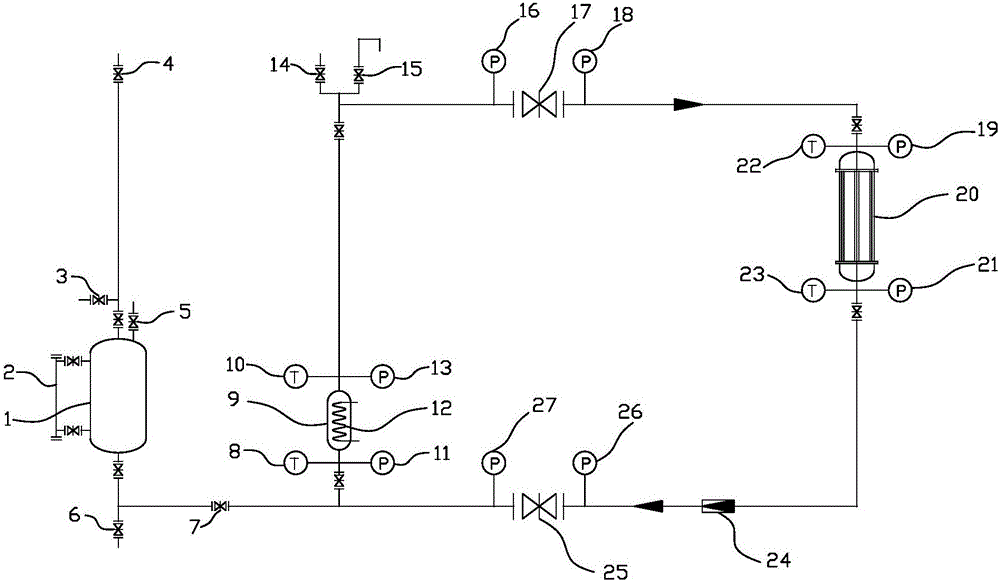

[0036] Such as figure 1 As shown, the passive waste heat removal cycle performance test system includes a waste heat removal cycle simulation system and a supersaturation pressure system, wherein the waste heat removal cycle simulation system includes an internal heat source simulation module and an external heat dissipation module, and the internal heat source simulation module . The external heat dissipation modules are connected through pipelines to form a cyclic test loop, and the supersaturated pressure system makes the internal pressure of the test system exceed the saturated vapor pressure of the circulating liquid at the test temperature. The in-core heat source simulation module of the present invention is used to simulate the heat source in an actual nuclear reactor. The in-core heat source simulation module and the out-of-core heat dissipation module together constitute a passive residual heat discharge cycle test system. By monitoring the cycle in the cycle test loo...

Embodiment 2

[0043] The test method of the passive waste heat removal cycle performance test system includes the following steps:

[0044] S1. Preparation before the test: open the first exhaust valve 14, the communication valve 7, the first resistance valve 17, the second resistance valve 25, and the second exhaust valve 4, and exhaust the residual heat through the filling valve 6 to simulate the circulation system 1. Fill the pressure storage tank 1 with water until the water overflows from the first exhaust valve 14 and the second exhaust valve 4, and turn on the electric heater 12 to slowly heat the water in the pressure storage tank 9, so that the water in the circulation test circuit At the same time, monitor the temperature at the outlet end of the pressure storage tank 9, and control the temperature at the outlet end of the pressure storage tank 9 by adjusting the heating power of the electric heater 12 to not exceed 85°C until no gas is precipitated in the waste heat discharge cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com