Catalyst capable of simultaneously removing CO, SO2 and NOx

A catalyst, SO2 technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst activation/preparation, etc., to achieve the effect of increasing specific surface area, huge industrial application value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

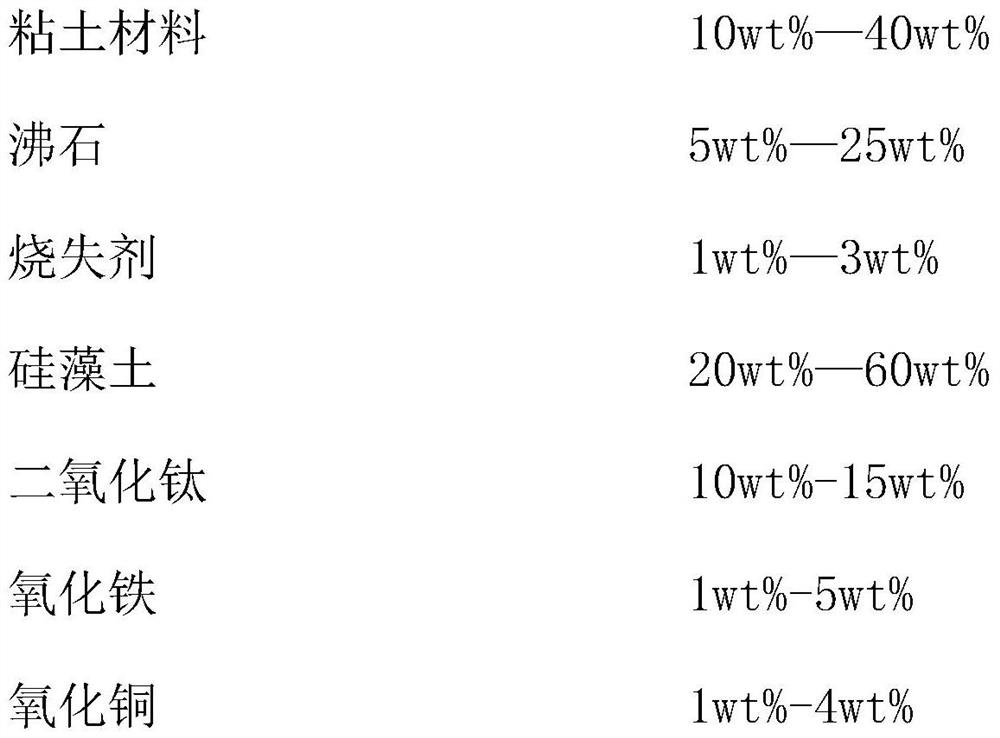

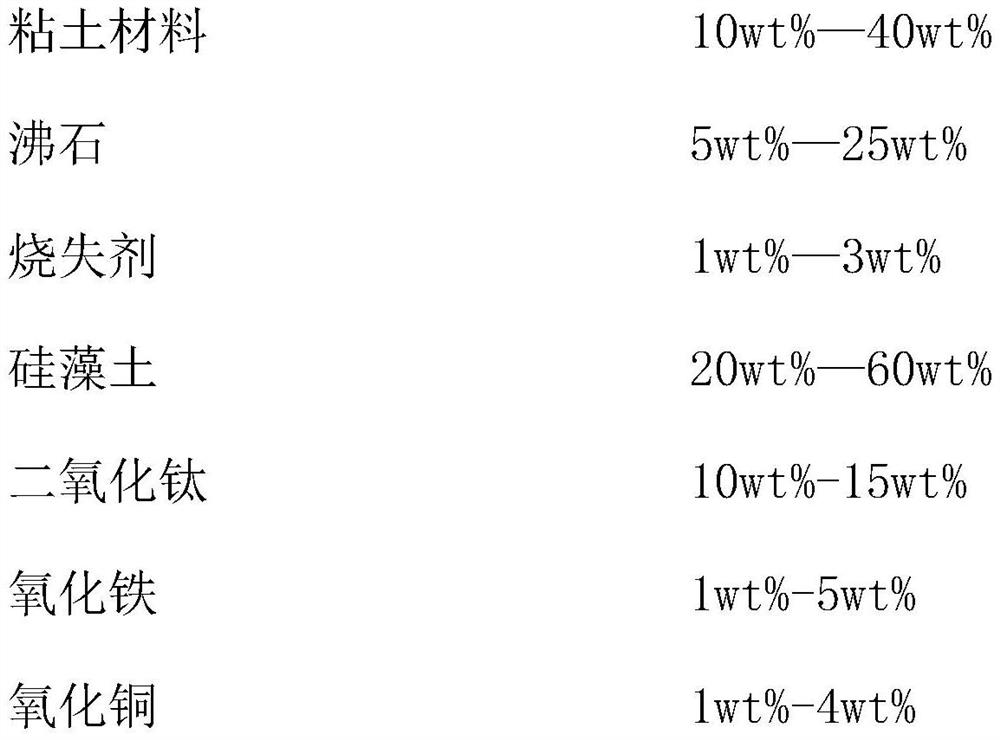

Method used

Image

Examples

Embodiment 1

[0033] (1) Mix 35 parts of montmorillonite clay, 25 parts of zeolite, 1.5 parts of loss-of-ignition agent, 30 parts of diatomaceous earth, 2.5 parts of iron oxide, and 1 part of copper oxide according to the proportion, add appropriate amount of water and stir evenly into mud shape, put it in a cool and dry place to stale naturally;

[0034] (2) Obtain the required catalyst green body by compression molding or extrusion molding the aged mud;

[0035] (3) Dry the green body naturally in the shade for 24 hours, then dry it in a hot air drying oven at 200°C for 2 hours, place the dried catalyst body in a muffle furnace at a temperature of 950°C for 8 hours, and obtain a porous ceramic substrate Catalyst carrier;

[0036] (4) Soak the porous ceramic-based catalyst carrier in nitric acid with a concentration of 35% for acidification, and the soaking time is 2 hours;

[0037] (5) The active components of the catalyst are attached to the surface of the catalyst carrier by equal imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com