Patents

Literature

67results about How to "Reduce the difficulty of governance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

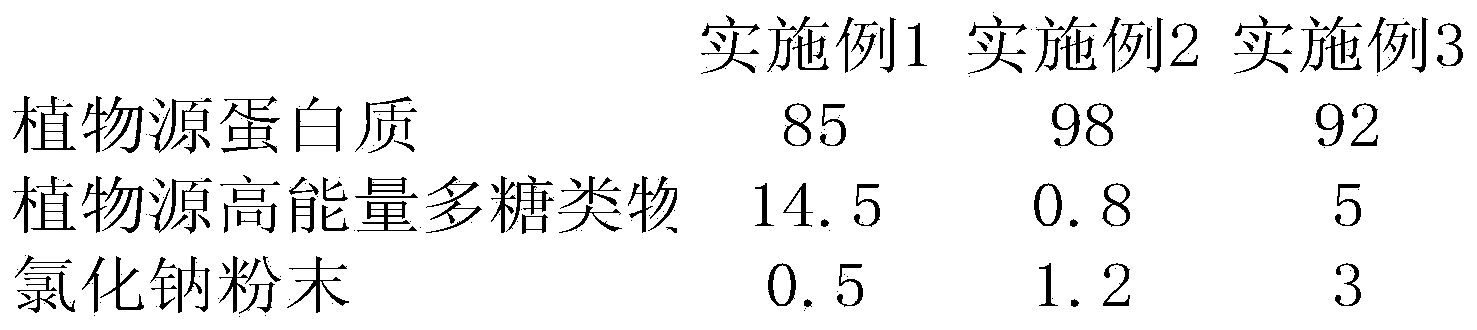

Preparation method of microbial water quality purifying fungicide

ActiveCN103820427AEasy to adaptRapid multiplicationEnergy based wastewater treatmentOn/in inorganic carrierMicroorganismFungicide

The invention discloses a mineralized water purifying agent which loads magnetotactic plant source microorganisms and a preparation method thereof. The preparation method comprises the following steps: acclimating animal source microorganisms into plant source microorganisms by using a plant source culture solution, wherein the animal source microorganisms comprise anaerobic and aerobiotic microorganisms which are in a weight ratio of 1:1; and acclimating the plant source microorganisms into plant source magnetotactic microorganisms, then loading on sandy mineral stone powder to form biological minerals so as to generate a purifying fungicide. According to the invention, purchased animal source microbial strains are acclimated to recover the original wild nature of microorganisms so as to quickly survive, adapt and propagate. The problem that common microbial water quality purifying treatment fungicide splashed just floats on the surface, cannot submerse in water and cement sludge quickly, is easy to wash away by water flows, needs to be input frequently and is high in operating cost is solved. The preparation method can be cooperated with the original comprehensive treatment system and task, so that the treatment difficulty is greatly reduced, the treatment effect is improved, and the preparation method has the price advantage compared with that of conventional dredging manner.

Owner:钟华

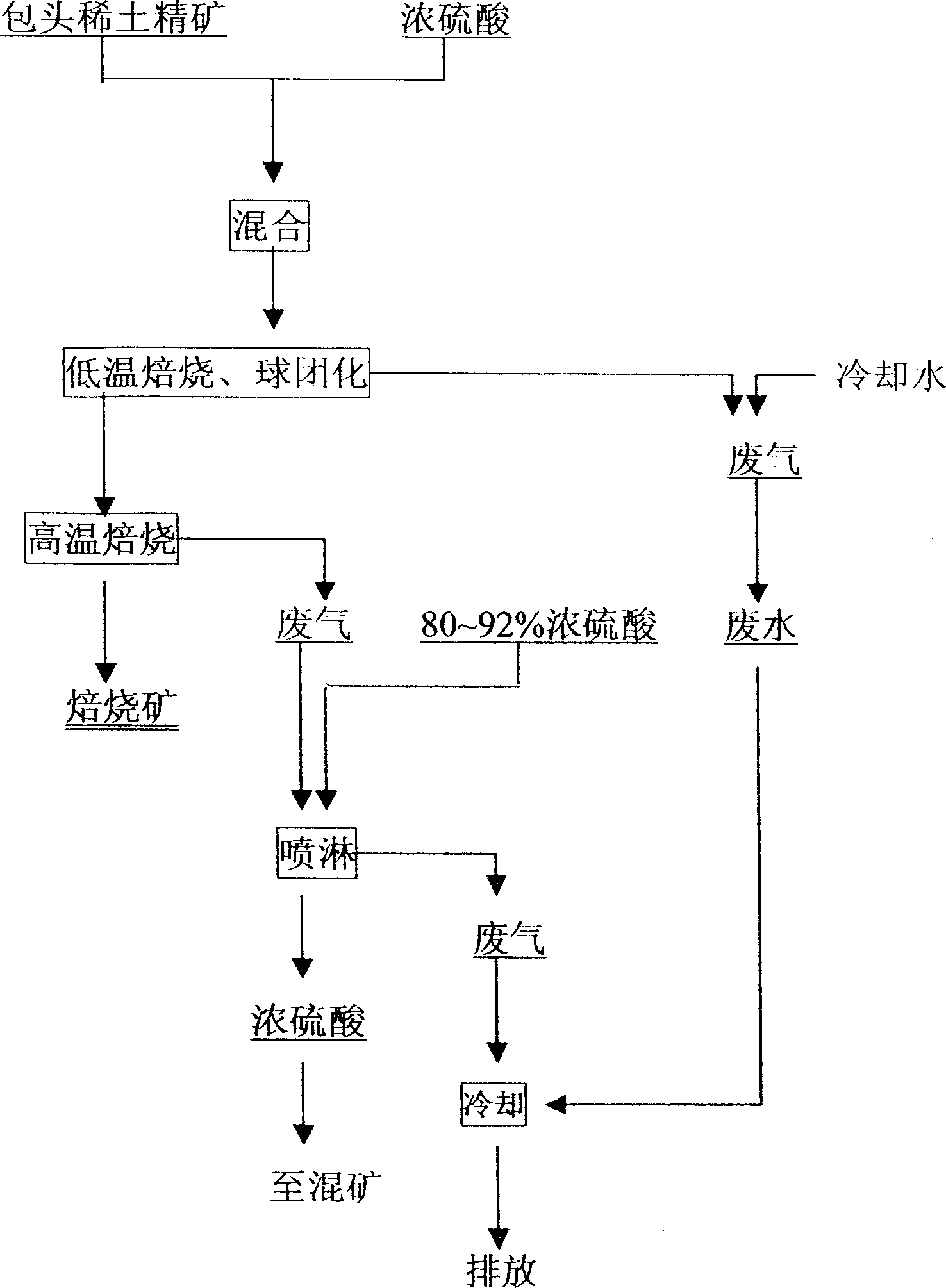

Stepped sulfuric acid treatment and roasting process for decomposing Baotou RE ore concentrate

The present invention belongs to the field of non-ferrous metallurgy technology, and is stepped roasting process for decomposing Baotou RE ore concentrate. The technological process includes the following steps: 1. mixing Baotou RE ore concentrate with concentrated sulfuric acid; 2. roasting at 100-320 deg.c for 1-7 hr and spraying water to cool produced gas; and 3. roasting at 600-850 deg.c for 1-4hr, absorbing partial harmful gas with 80-92% concentration sulfuric acid, returning the absorbed concentrated sulfuric acid, cooling gas with water from the second step, and transferring the roasted material to the next step. The present invention combines the low temperature roasting and the high temperature roasting, and has less water consumption, raised resource utilization rate and other advantages.

Owner:CHINA NORTHERN RARE EARTH (GROUP) HIGH TECH CO LTD

Production technology of extrahigh viscosity refining cotton

InactiveCN1718874AHigh whitenessIncrease brightnessOther chemical processesVegetable materialFiberViscosity

The present invention relates to a production process of extra high viscosity refined cotton. Said production process includes the following procedure:(1) selecting material; (2) cooking; (3) washing pulp; (4) bleaching pretreatment; (5) bleaching; and (6) rolling, dewatering and drying to obtain finished product. Said invention also provides the concrete requirements and steps of every procedure.

Owner:周家贵

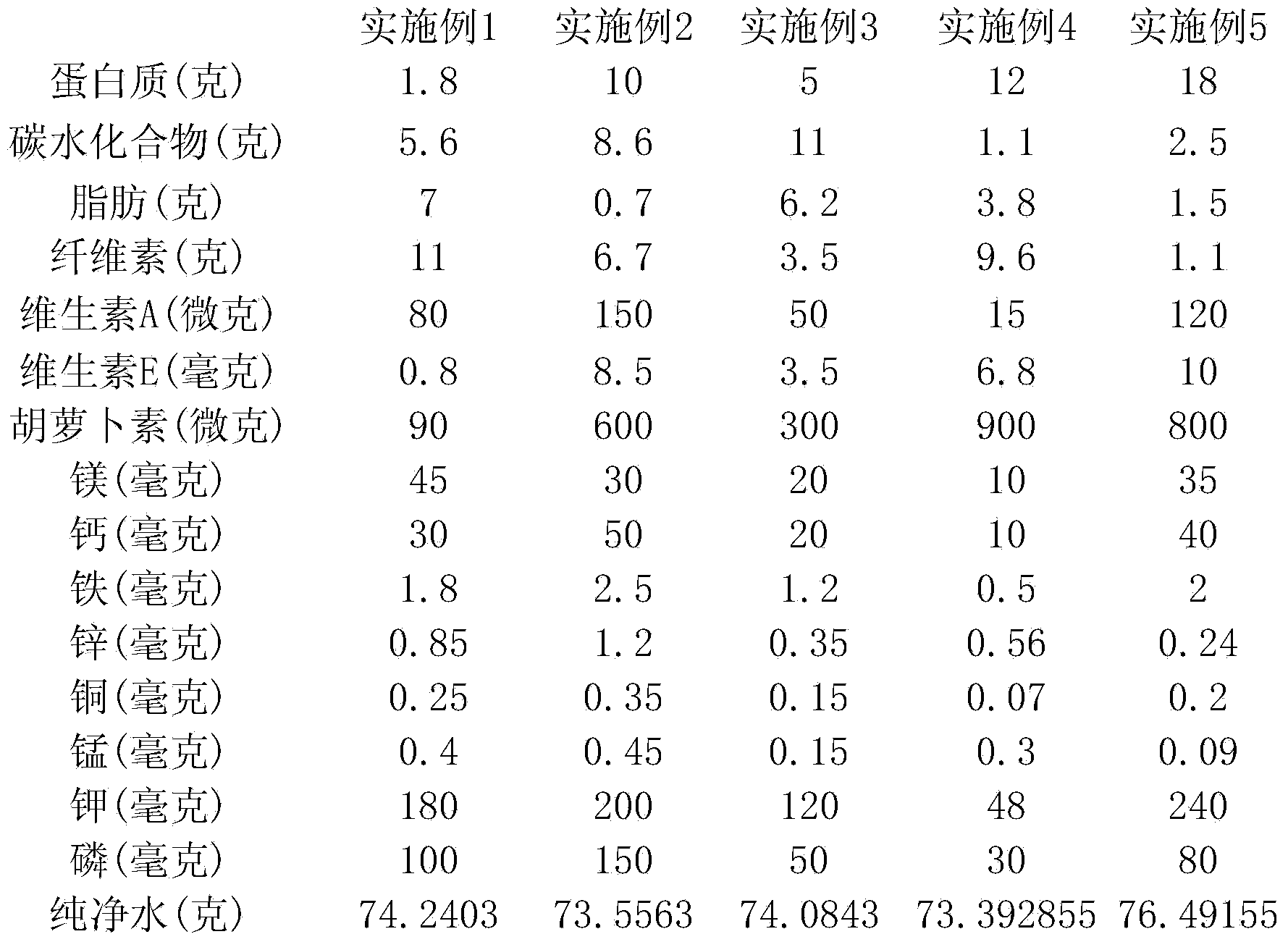

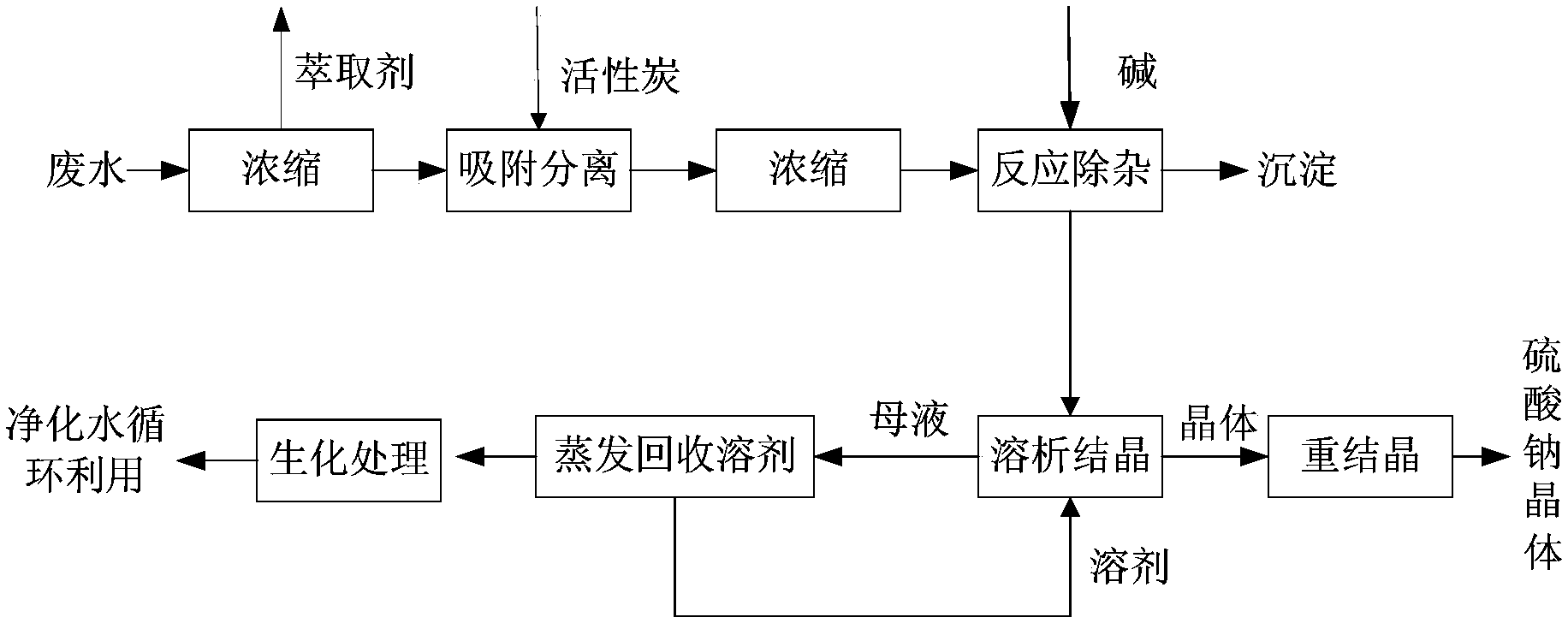

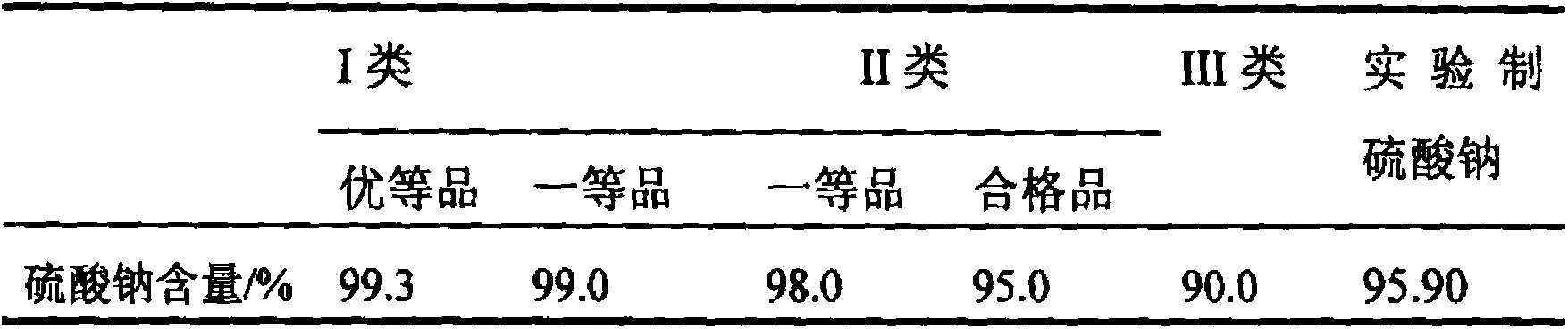

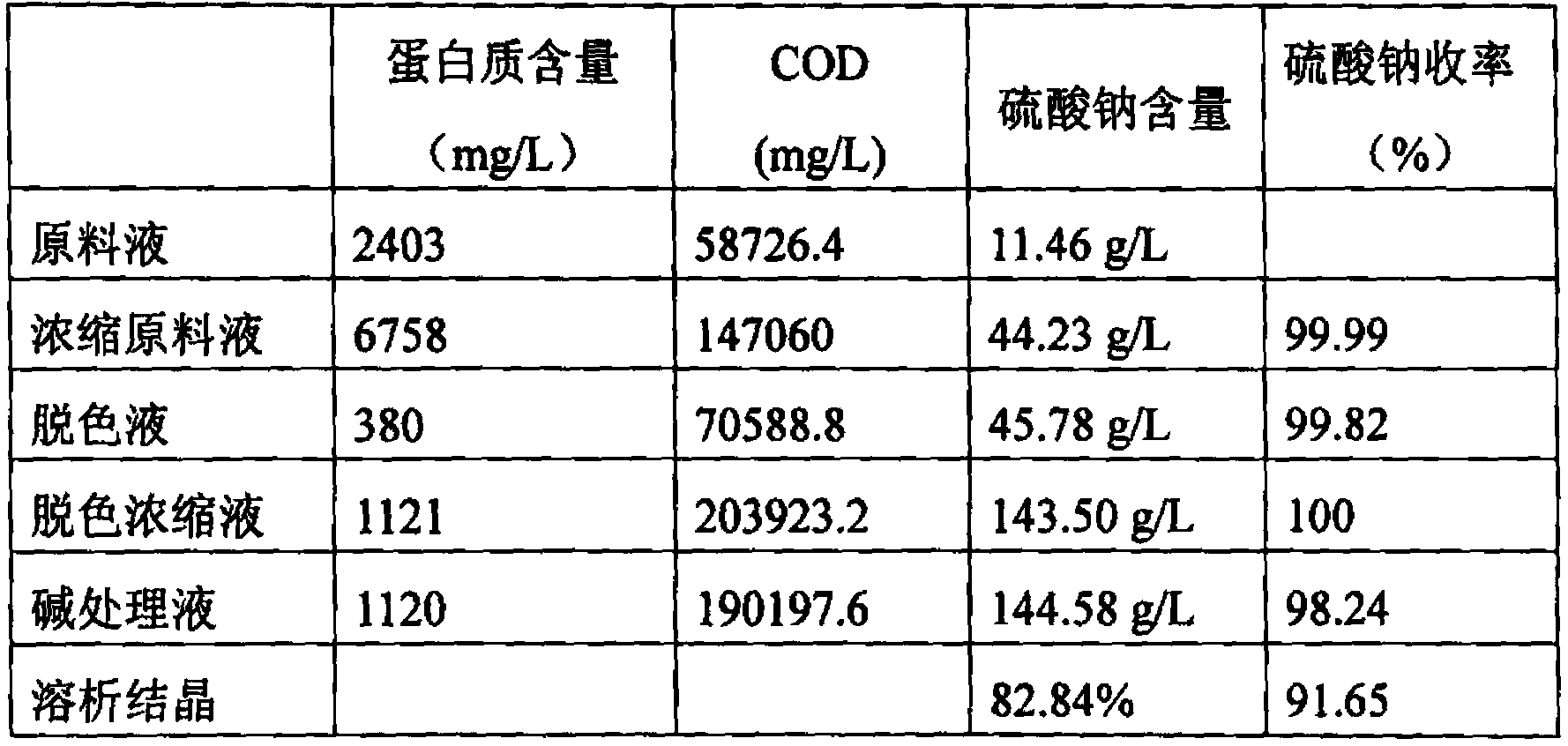

Method for purifying penicillin production waste liquid and recycling sodium sulfate

ActiveCN103979730AReduce the difficulty of governanceReduce governance costsAlkali metal sulfite/sulfate purificationEnergy based wastewater treatmentActivated carbonChemistry

The invention relates to a method for purifying a penicillin production waste liquid and recycling sodium sulfate. The method comprises the following steps: firstly, primarily evaporating the penicillin production waste liquid; concentrating a raw material liquid in desorbing residual solvents in the waste liquid; adding activated carbon into the primarily concentrated raw material liquid, wherein the liquid phase obtained from separation is a destaining solution of which a part of organisms are removed; continuously evaporating the destaining solution to obtain a concentrated destaining solution; adding alkali into the concentrated destaining solution, reacting to remove the impurities, filtering and precipitating, wherein an obtained liquid is an alkali treated liquid; adding a dilution agent for dilution crystallization into the alkali treated liquid, performing solid-liquid separation, and recrystalizing the solid, thereby obtaining high-purity sodium sulfate crystal; feeding a liquid into a solvent recycling tower for recycling the dilution agent, and feeding a tower kettle liquid to a biochemical pool for treatment. Compared with the prior art, organisms such as protein and pigment in the penicillin production waste liquid are reduced, at the same time sodium sulfate is recycled, then circulation application of sodium sulfate and water is achieved, the treatment difficulty and cost of the penicillin production waste liquid are remarkably alleviated and lowered, and great economic and environment benefits are achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

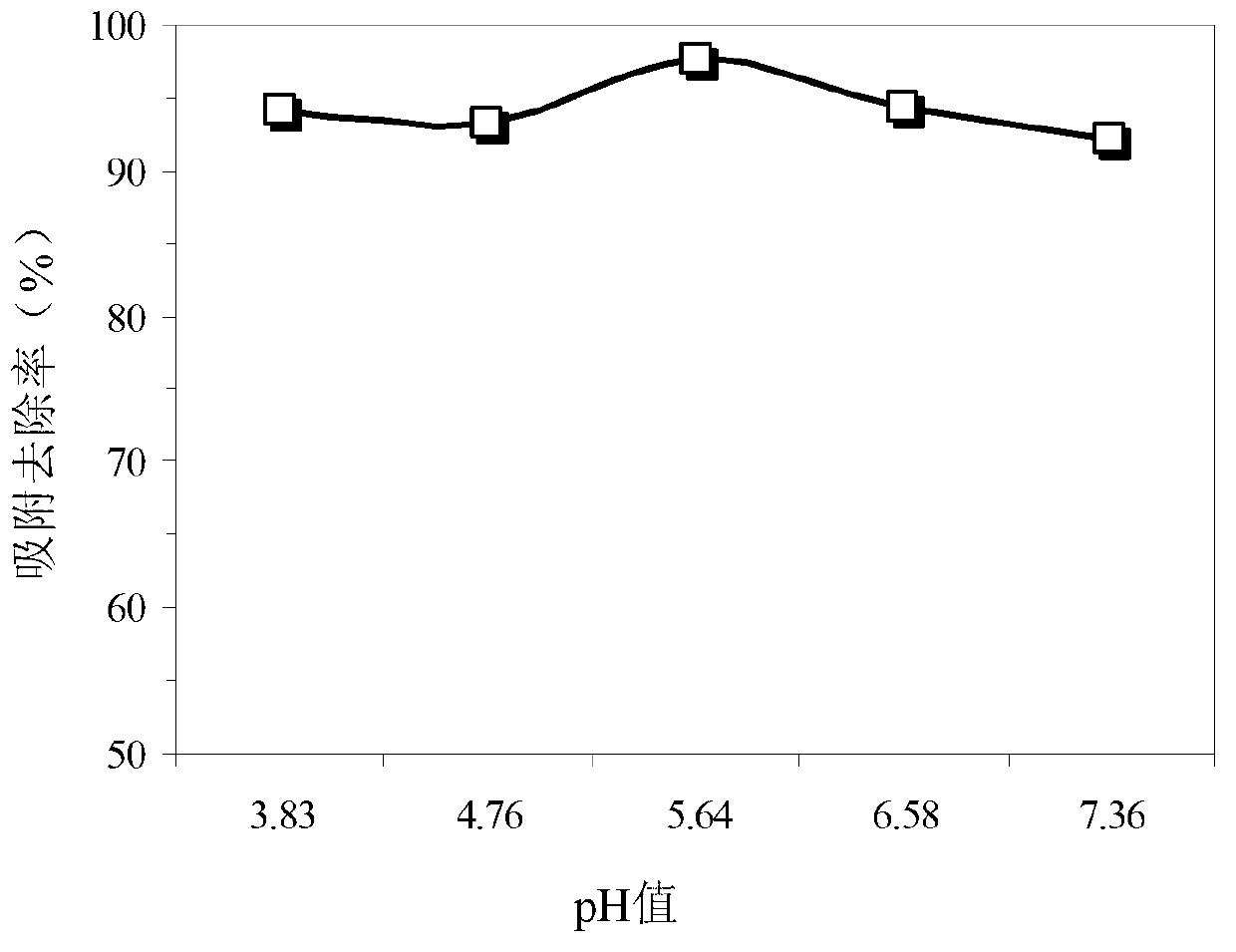

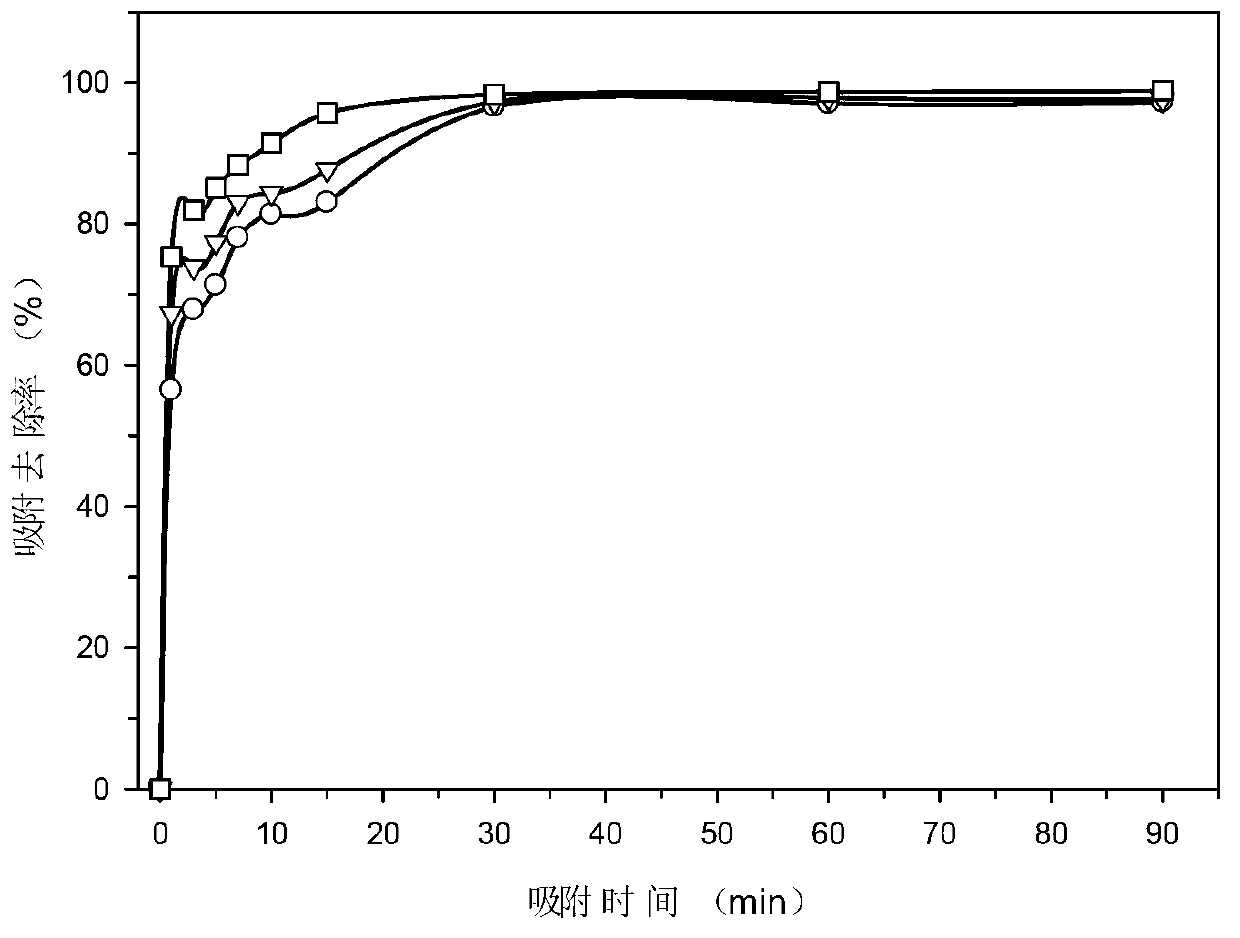

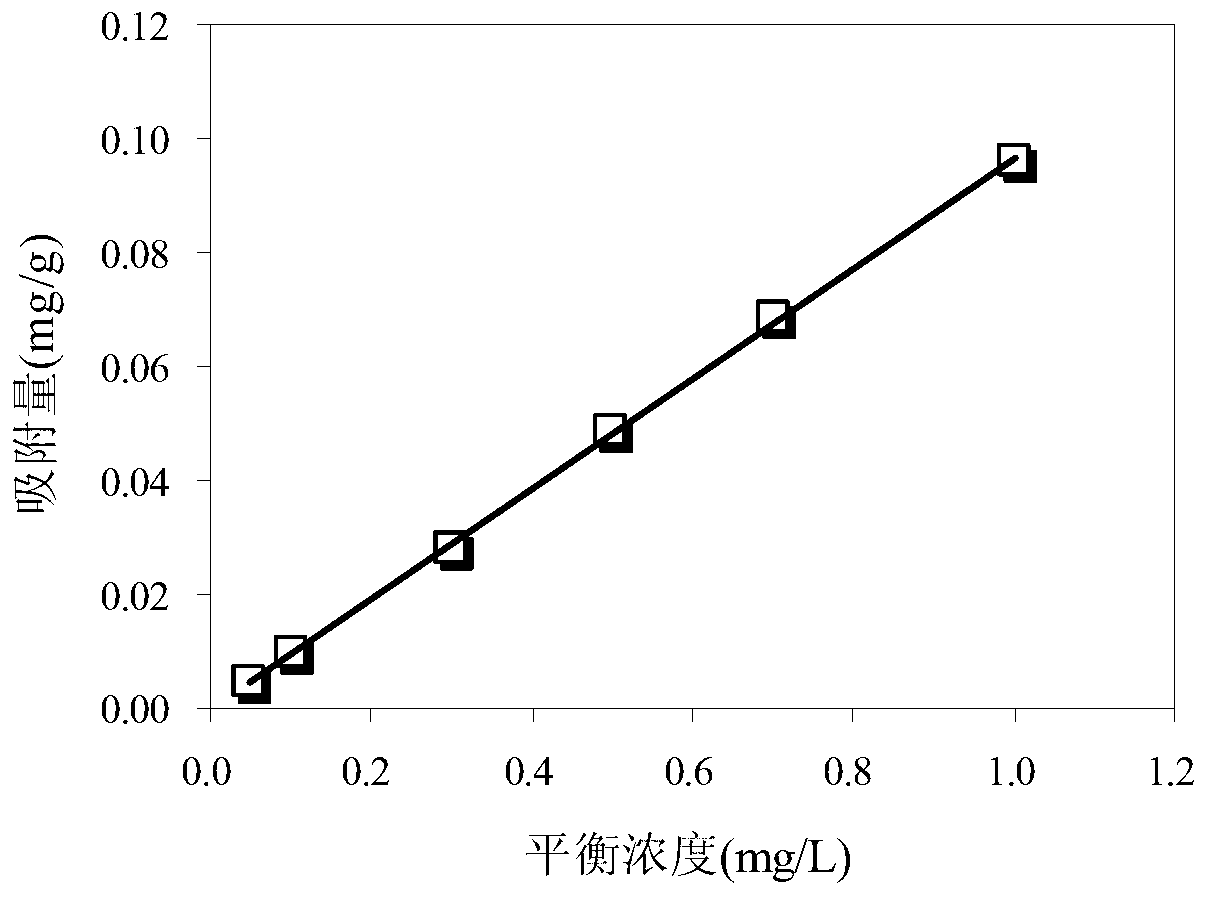

Method for treating mercury-containing wastewater by using modified blue-green algae

InactiveCN103130297AEasy accessReduce eutrophicationWater/sewage treatment by sorptionEutrophicationWastewater

The invention discloses a method for treating mercury-containing wastewater by using modified blue-green algae. The method is characterized by comprising the following steps: (1) performing acidification modification treatment on blue-green algae, thus obtaining modified blue-green algae; (2) treating the wastewater by employing the modified blue-green algae; (3) detecting the supernatant fluid of the wastewater, and discharging the wastewater after qualification; and (4) recovering the blue-green algae, namely filtering the used modified blue-green algae, desorbing the blue-green algae in a desorbing agent for 1 hour, and filtering and refrigerating the modified blue-green algae. The modified blue-green algae raw materials used in the method come from eutrophic lakes and are easily obtained, mass propagation or dead algae in the lakes are reasonably utilized, the eutrophication phenomena can be reduced, and the treatment difficulty of the lake eutrophication is lightened; and moreover, the method for adsorbing and removing the mercury-containing industrial wastewater by utilizing the modified blue-green algae is simple in process and convenient to use.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

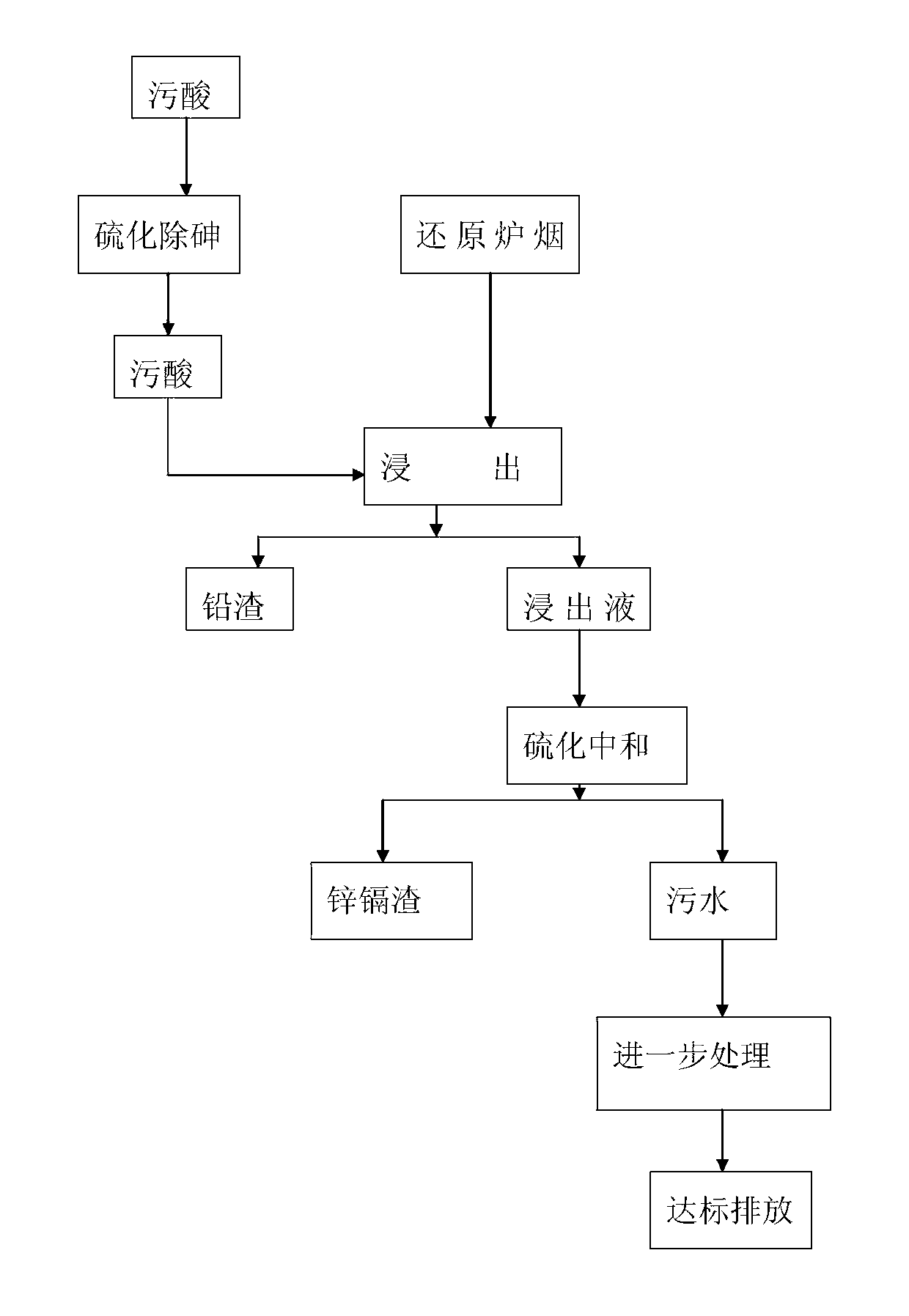

Process for recovering lead, zinc and cadmium in soot on recovery section in process of treating waste acid generated in lead smelting

InactiveCN102994764ALow running costAvoid harmProcess efficiency improvementLead smeltingNon-ferrous extractive metallurgy

The invention relates to the field of nonferrous metal smelting and particularly relates to a process for recovering lead, zinc and cadmium in soot on a recovery section in the process of treating waste acid generated in lead smelting. The soot of a reduction furnace is subjected to a leaching reaction by using arsenic sulfide removal waste acid in the lead smelting industry to generate lead slag to be recovered, and then, the leaching agent is continued to be neutralized by using sodium sulphide and sodium hydroxide to generate high-grade zinc and cadmium slag to be recovered. According to the invention, the waste acid is used for separating the lead, zinc and cadmium in the soot of the reduction furnace for lead smelting, so that the operation cost is low; the problem of production operation damage caused by circulated accumulation of the zinc and cadmium in lead smelting is solved and the pressure of a lead smelting system is relieved under the condition of low cost; and the lead slag which is low in arsenic content and suitable for being treated by a lead system and the zinc and cadmium slag which is suitable for being treated by a zinc system can be generated, and meanwhile, the waste acid is also treated, so that not only is the treatment cost of the waste acid reduced, but also the treatment difficulty is lowered.

Owner:HENAN YUGUANG GOLD & LEAD

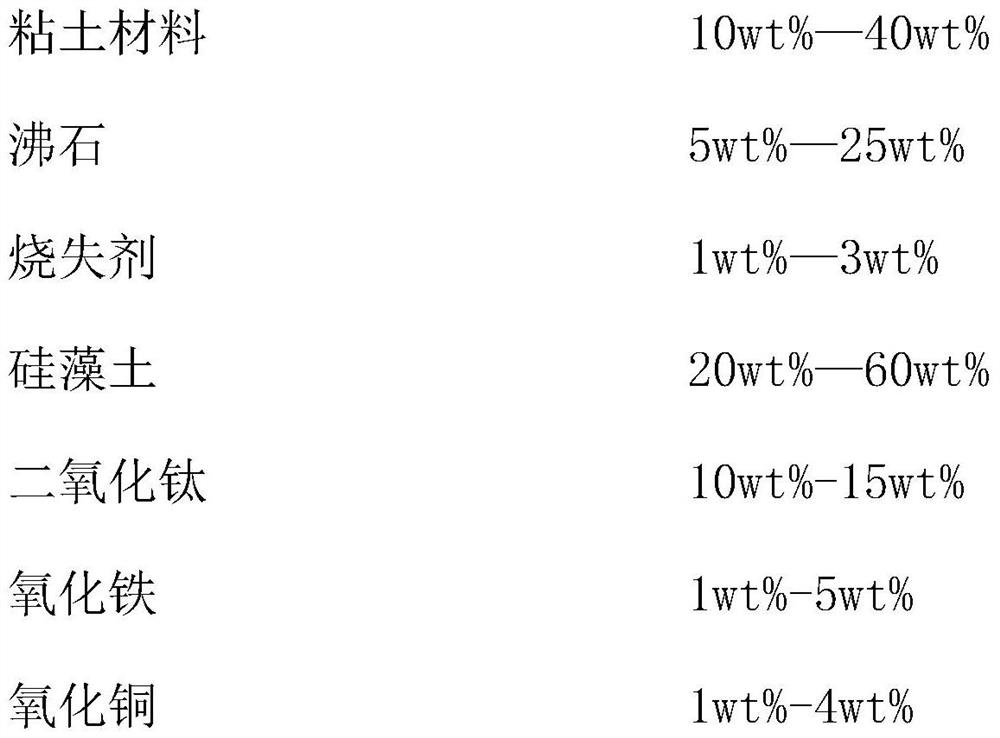

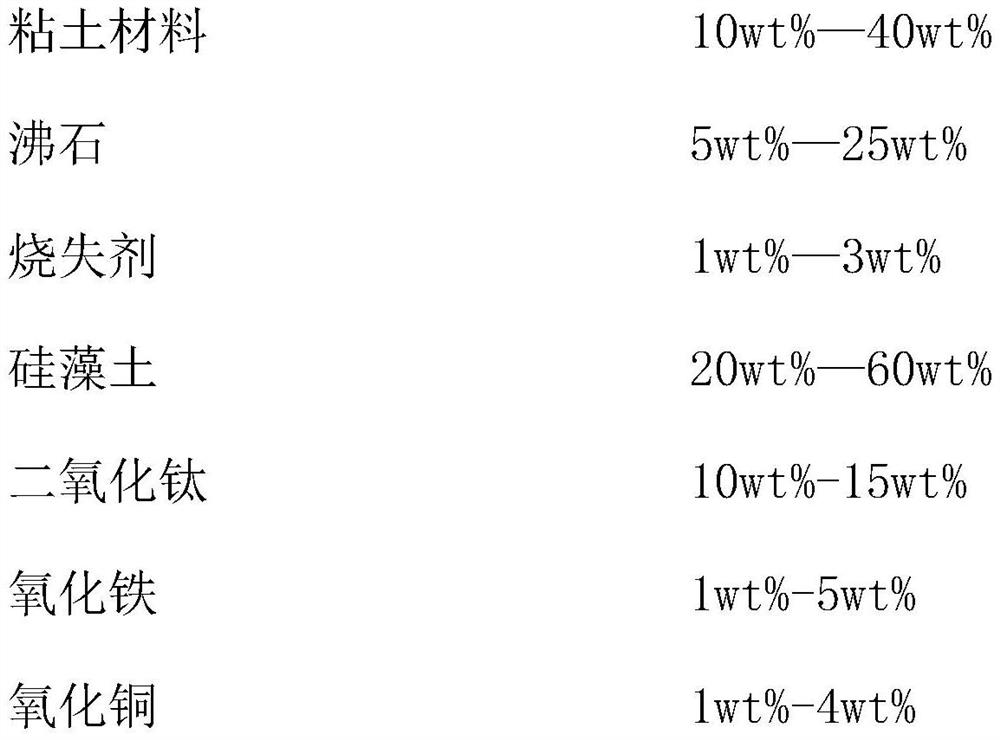

Catalyst capable of simultaneously removing CO, SO2 and NOx

InactiveCN111715234ALarge specific surface areaSimple preparation processGas treatmentHeterogenous catalyst chemical elementsPtru catalystFlue gas

The invention discloses a catalyst capable of simultaneously removing CO, SO2 and NOx and a preparation method of the catalyst. According to the catalyst capable of simultaneously removing CO, SO2 andNOx, cheap clay and fly ash are used as catalyst carriers; the invention comprises pre-oxidizing (acidifying) by using concentrated nitric acid, dissolving active ingredients of the low-temperature catalyst by using water, and then enabling metal oxide to be attached to the catalyst carrier capable of simultaneously removing CO, SO2 and NOx by using an equivalent impregnation method, so as to form the catalyst capable of removing CO and SO2 and NOx in low-temperature flue gas purification. The catalyst capable of removing CO, SO2 and NOx at the same time is simple in preparation process and low in cost, the technical effect of removing CO and SO2 and NOx at the same time can be achieved, the treatment cost and treatment difficulty of enterprises are reduced, and the invention has huge industrial application value.

Owner:BEIJING ZHENJI ENVIRONMENTAL TECH

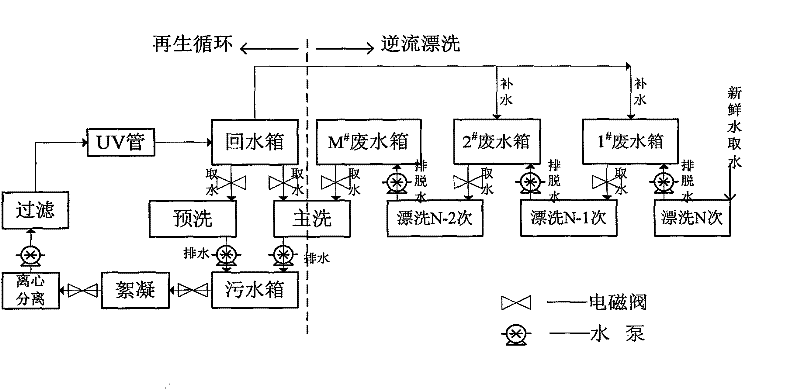

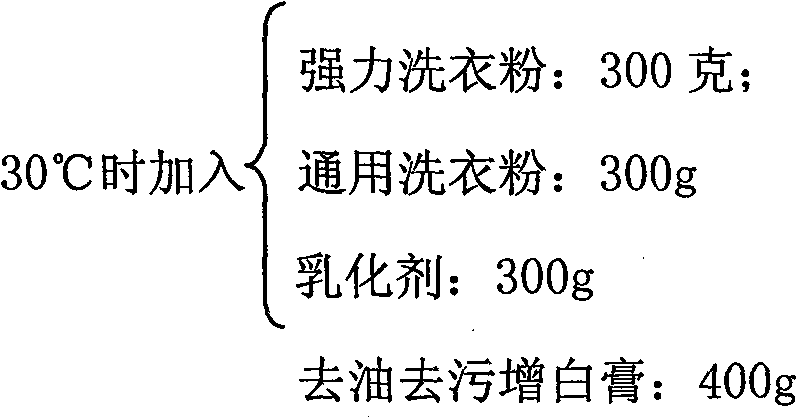

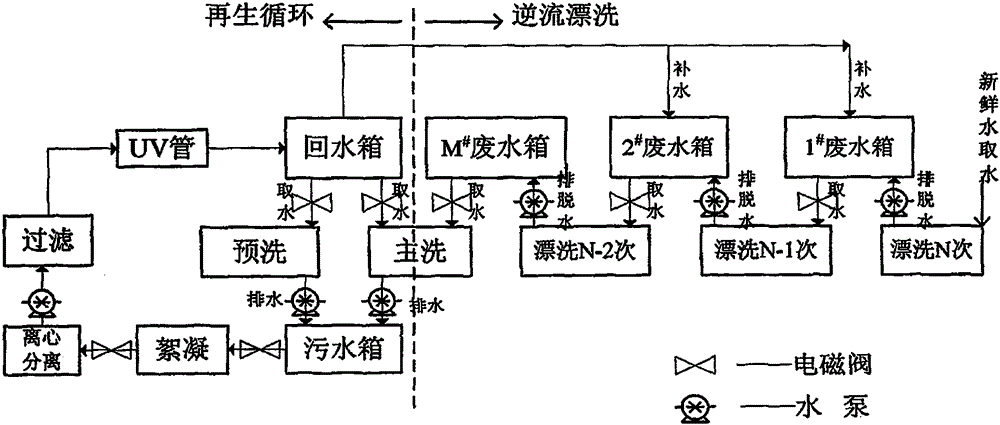

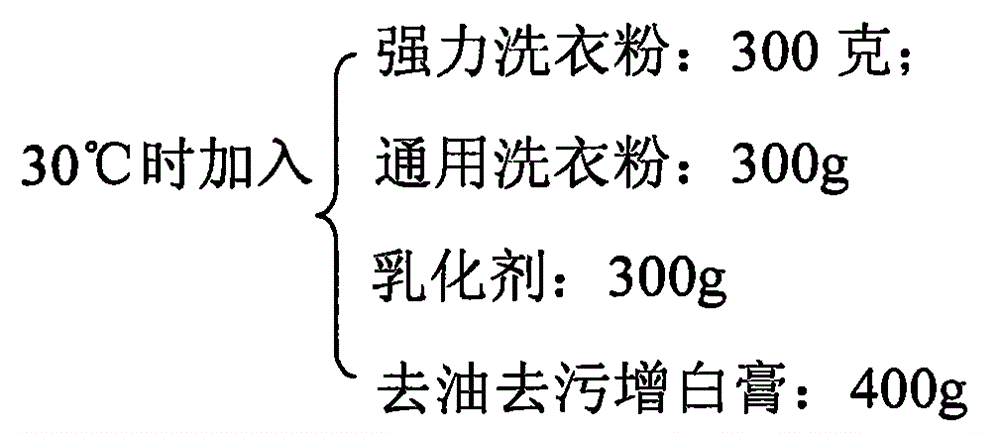

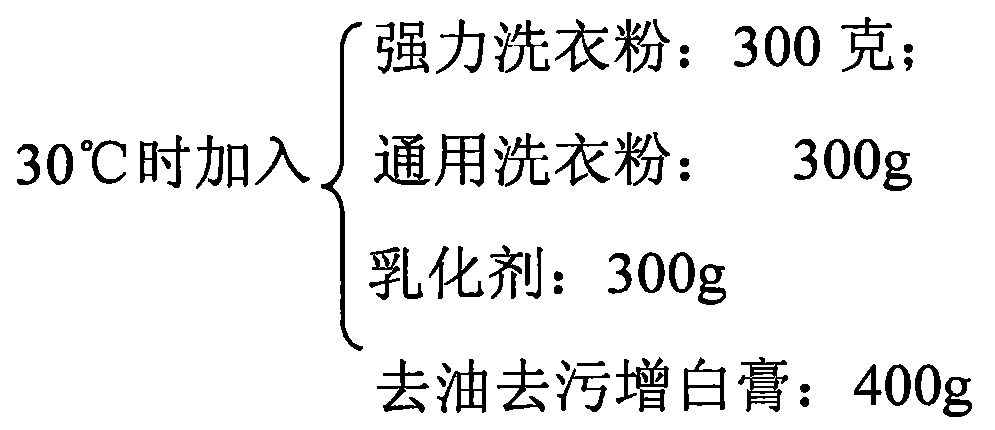

Method for regenerating and recycling laundry waste water

InactiveCN102303933AGovernance is highly targetedGood effectWater/sewage treatment by irradiationMultistage water/sewage treatmentWater useFlocculation

The invention relates to a method for regenerating and recycling laundry waste water, which is mainly used for regenerating and recycling laundry waste water discharged from intermittent industrial laundry machines which run independently in the laundry process of the laundry and dyeing industry. The aim of the invention is to treat laundry waste water by combining direct reuse of the laundry waste water or regeneration and recycling of the laundry water. The method comprises process treatment and front-end treatment. The process treatment is to direct reuse waste water which is laundry water from a laundry process flow in a countercurrent rinsing manner. An operation system in which the rinsing water flows continuously in a semi-intermittent manner and in which the laundry moves in an intermittent manner is designed for the intermittent industrial laundry machines which run independently, so as to realize the water use flow of the laundry water in countercurrent rinsing, and reduce volume of waste water in the rinsing phase; and under the conventional laundry process conditions, 50 to 70 percent of fresh water can be saved. The front-end treatment is to collect and treat waste water from the prewashing and waste water from the main washing in the production of laundry machines independently and treat the waste water by means of flocculation, centrifugal separation, filtration and the like, wherein the treated water is used in prewashing, main washing and rinsing and the reuse rate is 80 percent. The laundry waste water regenerating and recycling system constructed by combining process treatment and front-end treatment techniques comprehensively reduces consumption of fresh water by over 80 percent.

Owner:BEIJING INST OF CLOTHING TECH

Production technology of extra low viscose refined cotton

ActiveCN1718917ASmall range of variationHigh in alpha-celluloseWashing/displacing pulp-treating liquorsPulp bleachingPulp and paper industryViscosity

The production process of extra low-viscosity refined cotton includes the following steps: (1) selecting material; (2) cooking; (3) washing pulp; (4) pretreatment for bleaching; (5) bleaching; and (6) rolling, dewatering and drying to obtain finished product. It uses cotton linters whose maturity is greater than or equal to 80%, appearance does not impurity or other fibre and fibre longth is 8-10mm as raw material, its cooking step adopts sectional cooking, and the bleaching step adopts sectional bleaching.

Owner:HUBEI JINHANJIANG REFINED COTTON

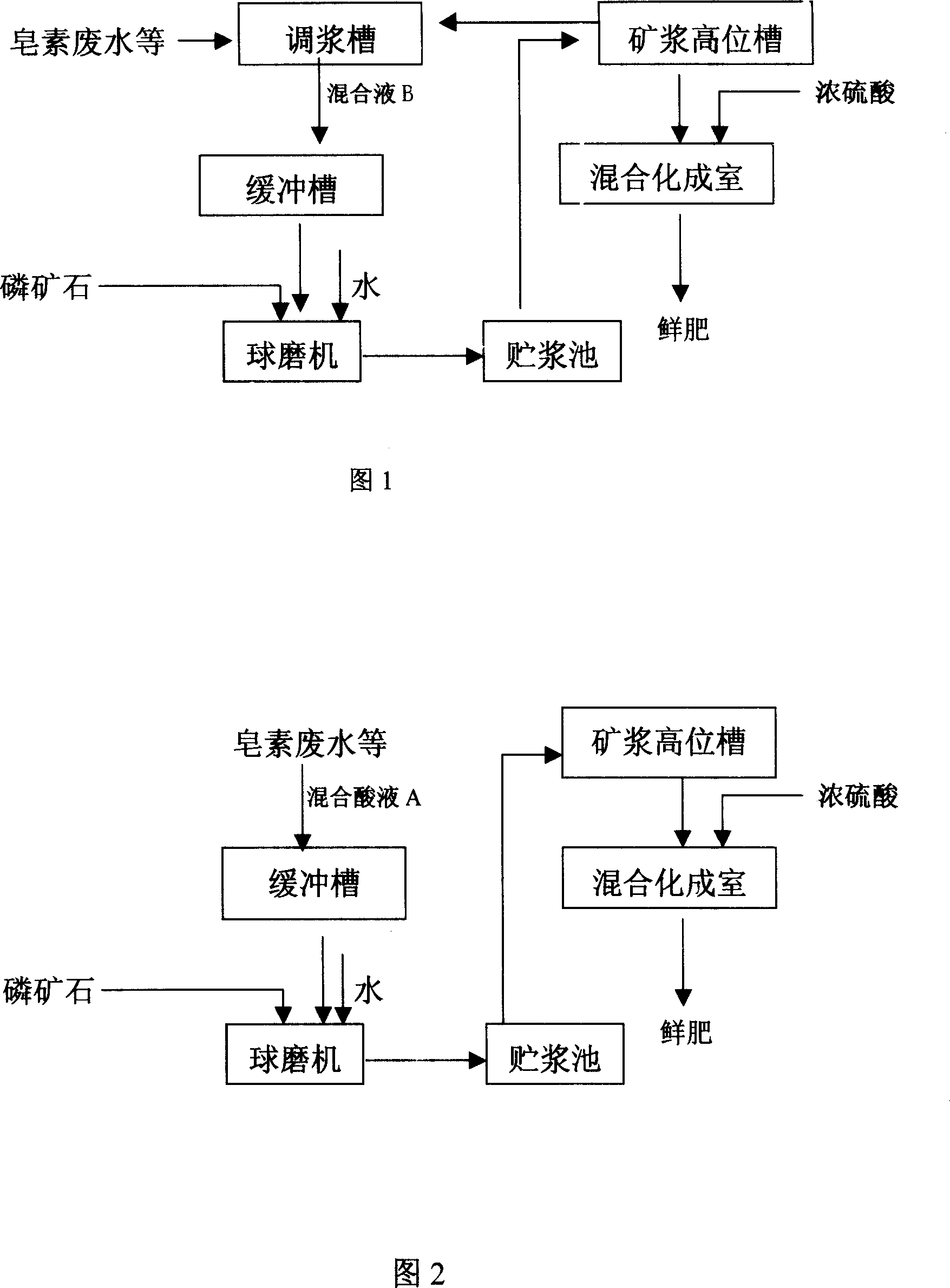

Method for wastewater comprehensive utilization of saponin production

InactiveCN101134625AReduce the difficulty of governanceLow running costMultistage water/sewage treatmentPhosphorus compoundsChemistryHigh concentration

The process of utilizing saponin producing effluent includes the following steps: adding assistant to high concentration effluent and merging partial eluate to obtain mixed acid solution, and grinding together with phosphate ore in a ball mill to obtain slurry; flowing the slurry through one storing tank and one high level tank to one reducing chamber and reacting with concentrated sulfuric acid solution to prepare calcium superphosphate. The process of eliminating pollution of saponin producing effluent has low cost.

Owner:倪文斌

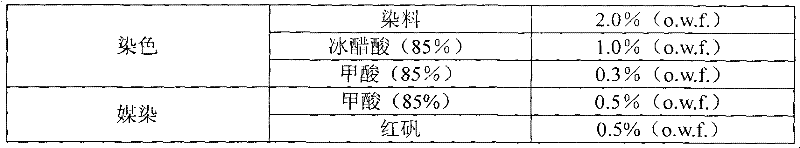

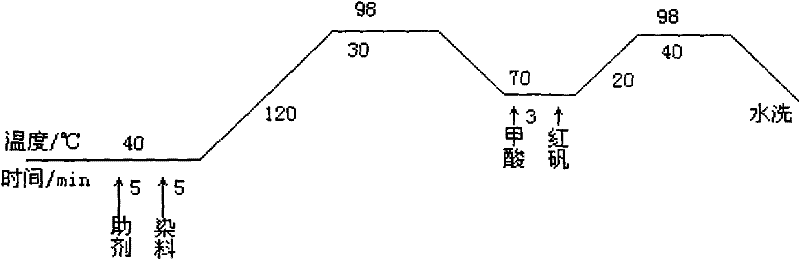

Method for regenerating and recycling wool dyeing wastewater

ActiveCN102249442AGovernance is highly targetedGood effectMultistage water/sewage treatmentWaste water treatment from textile industryIndustrial waste waterFiltration

The invention relates to a method for regenerating and recycling wool dyeing wastewater. The method is mainly used for regeneration and recycling of dyeing wastewater in the dyeing process in the fur dyeing and finishing industry. The front-end treatment technical route of dyeing and finishing wastewater is that: industrial wastewater produced in the dyeing process in the dyeing and finishing production is collected and treated independently and is recycled in the process, a regeneration and recycling system is established, and the using amount of fresh water is saved. Dyeing wastewater is flocculated by using organic flocculant, and flocculate and filtrate are separated by screening and combination of material filtration and separation modes, and the filtrate is adsorbed by using adsorbent to ensure that the dyeing wastewater can meet the regeneration and recycling requirement. In a laboratory and a woolen mill, recycle water dyeing experiment is performed by using acid mordant dyes and lanaset dyes, and the one-time dyeing wastewater recycling rate is over 80 percent; and the color difference level of fresh water for dyes for two kinds of fur and a recycle water dyeing sample are both above level 4.

Owner:BEIJING INST OF CLOTHING TECH

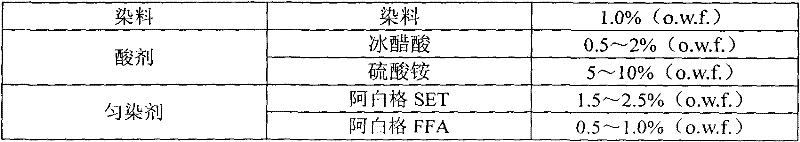

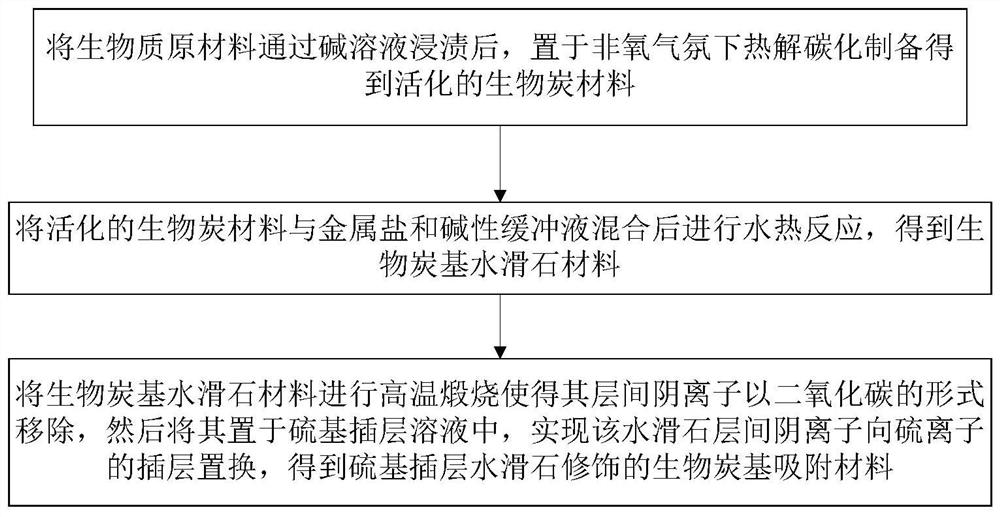

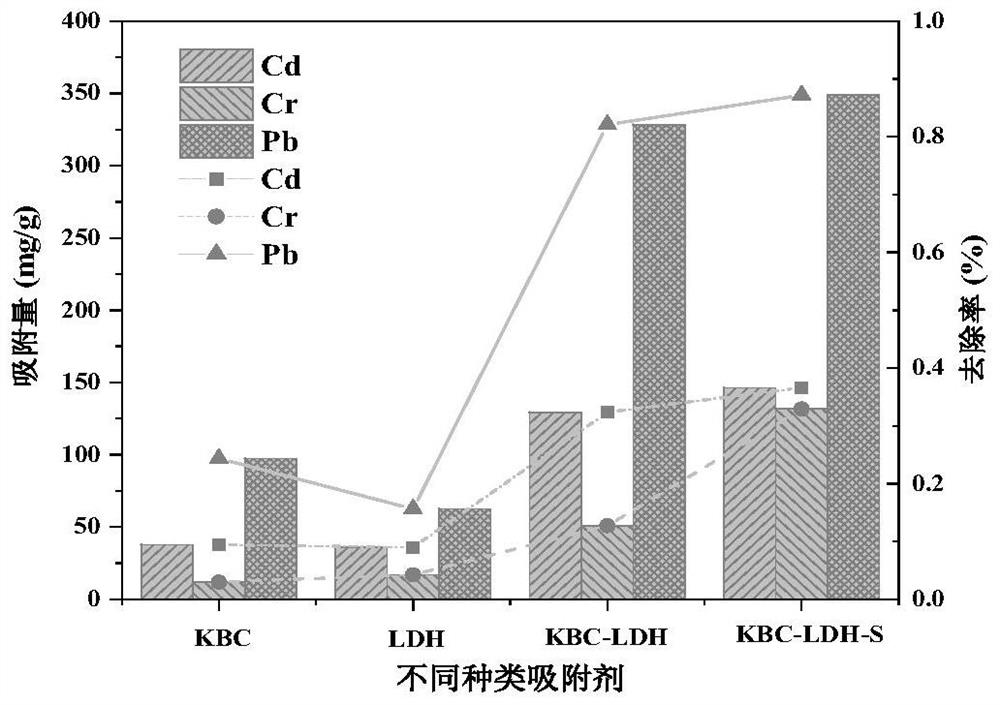

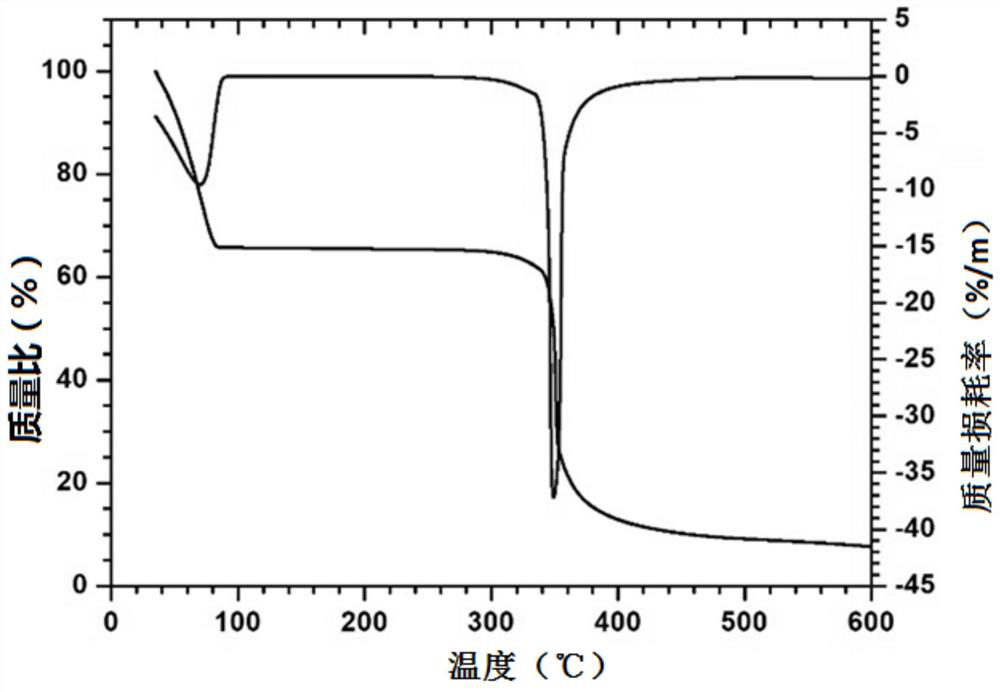

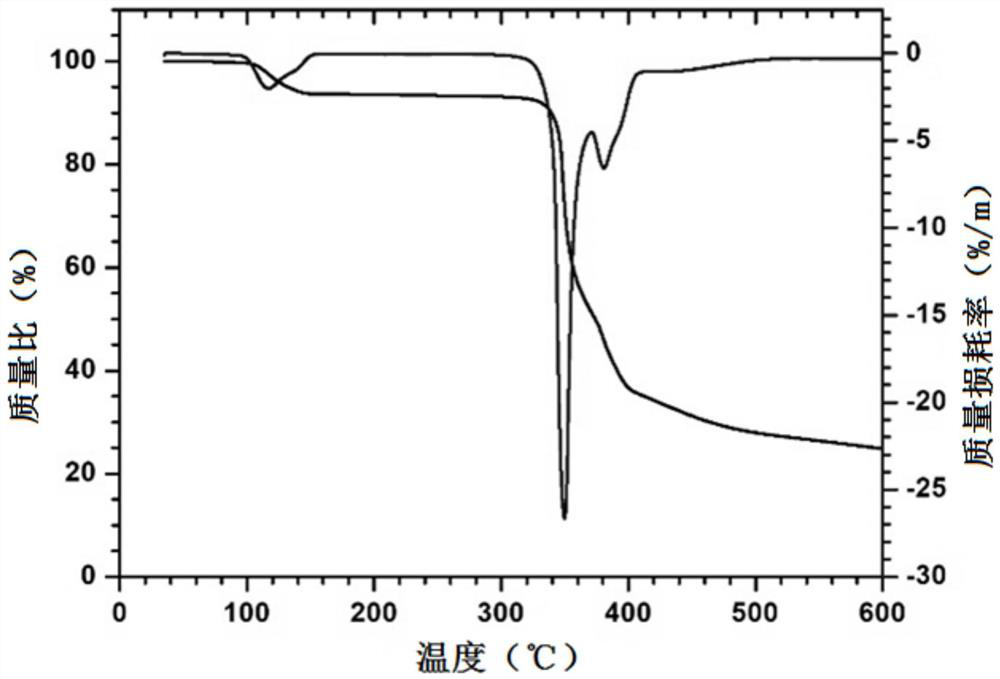

Sulfur-based intercalated hydrotalcite modified charcoal-based adsorption material and preparation and application thereof

PendingCN114082403AIncrease loadImprove stabilityOther chemical processesWater contaminantsSorbentCarbonization

The invention belongs to the technical field of wastewater treatment and soil remediation, and particularly relates to a sulfur-based intercalated hydrotalcite modified charcoal-based adsorption material and preparation and application thereof. The preparation method comprises the following steps: dipping a biomass raw material in an alkali liquor, carrying out pyrolysis carbonization to obtain an activated biochar material, carrying out hydrotalcite loading under a hydrothermal condition by taking the biochar material as a substrate, and finally replacing interlayer anions of hydrotalcite with sulfenyl anions. The adsorbent obtained by the preparation method not only has the adsorption capacity of independent biochar and hydrotalcite on heavy metals, but also can obtain a loose and porous biochar material by activating a biomass material, and then the biochar material can be further expanded through a hydrothermal reaction, and the loading capacity and the loading stability of the hydrotalcite are improved; finally, the adsorption capacity of the heavy metal anions is remarkably improved through interlayer replacement of the sulfenyl anions.

Owner:HUAZHONG UNIV OF SCI & TECH

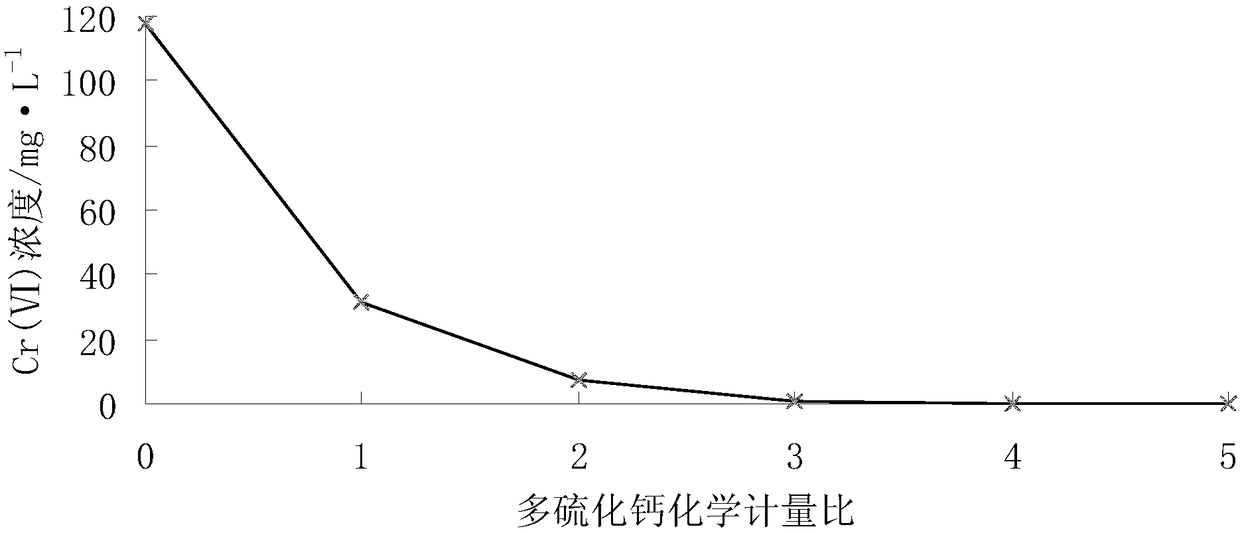

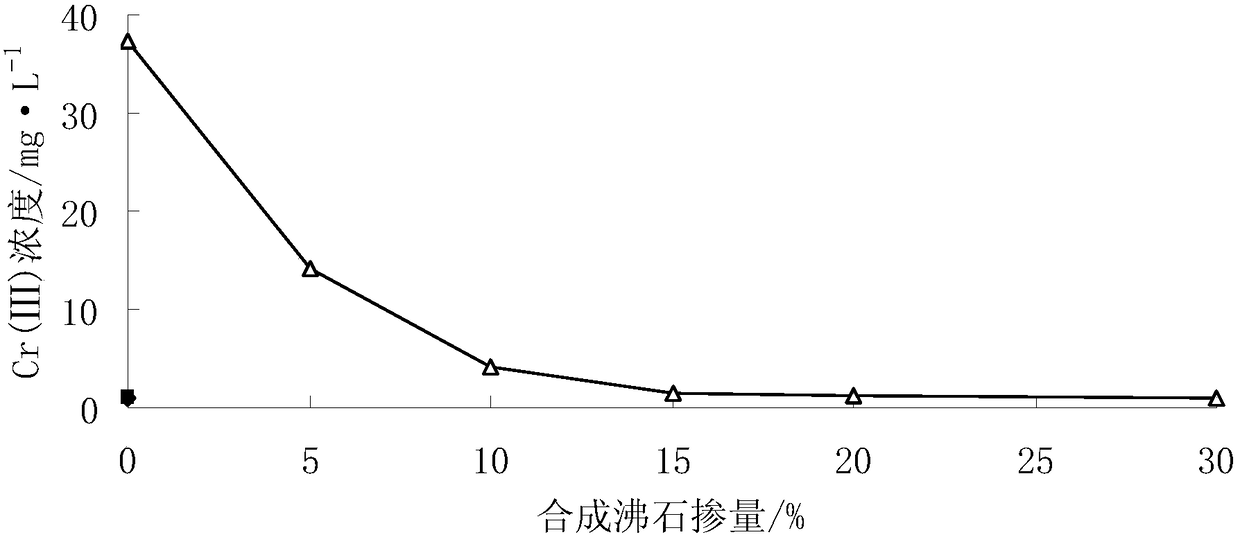

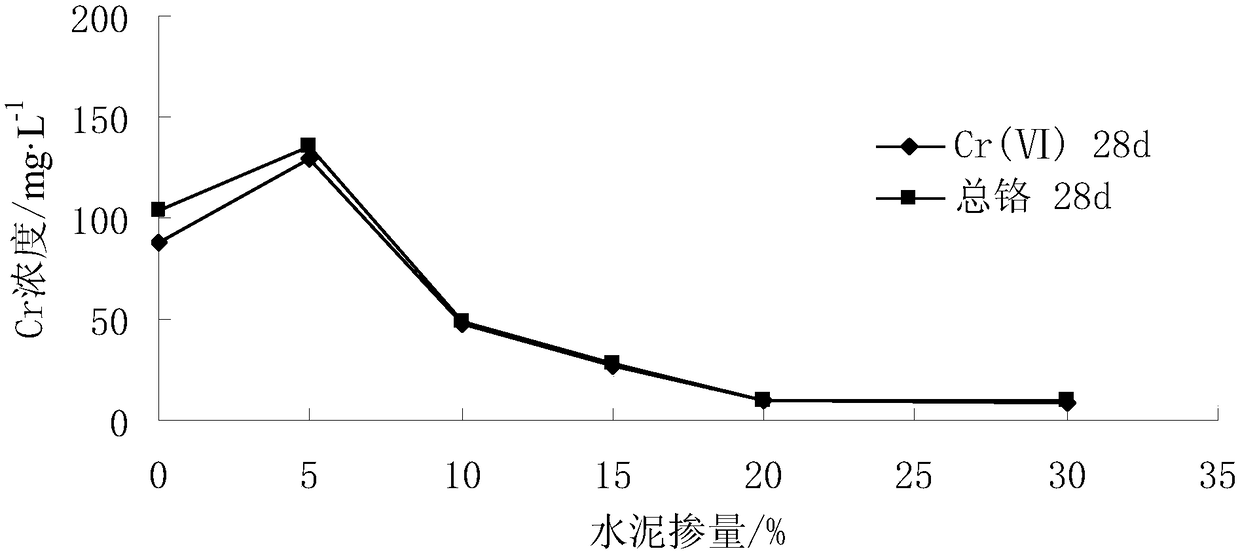

Chromium pollution soil combined remediation method

ActiveCN108160684ARaise the pHEnhance the ability to resist external environmental erosionOther chemical processesContaminated soil reclamationPollution soilMixed materials

A chromium pollution soil combined remediation method includes the steps that the concentration and the content of chromium and the optimum moisture content in chromium pollution soil are determined;a calcium polysulfide solution is selected, the chromium pollution soil and the calcium polysulfide solution are mixed and stirred according to a molar ratio of 2:1-3:1, and mixed material is added with water to maintain the optimum moisture content until the chromium of the chromium pollution soil is reduced from sexavalence to trivalence; coal ash is selected to compose zeolite, the amount of admixture is 10%-15%, the zeolite and the chromium pollution soil are mixed and stirred, mixed material is added with water to maintain the optimum moisture content until the steady absorption of the chromium of the chromium pollution soil is completed; and cement is selected, the amount of admixture is 5%-10% or 15%-20%, the cement is mixed and stirred with the chromium pollution soil, mixed material is added with water to maintain the optimum moisture content, and curing period is maintained for 7-28 days until the solidification of the chromium pollution soil is completed. The chromium pollution soil combined remediation method has the characteristics of good remediation effect, good long-term stability of the remediation effect, no secondary pollution, lower remediation cost and remediation mode reclamation.

Owner:LIAONING TECHNICAL UNIVERSITY

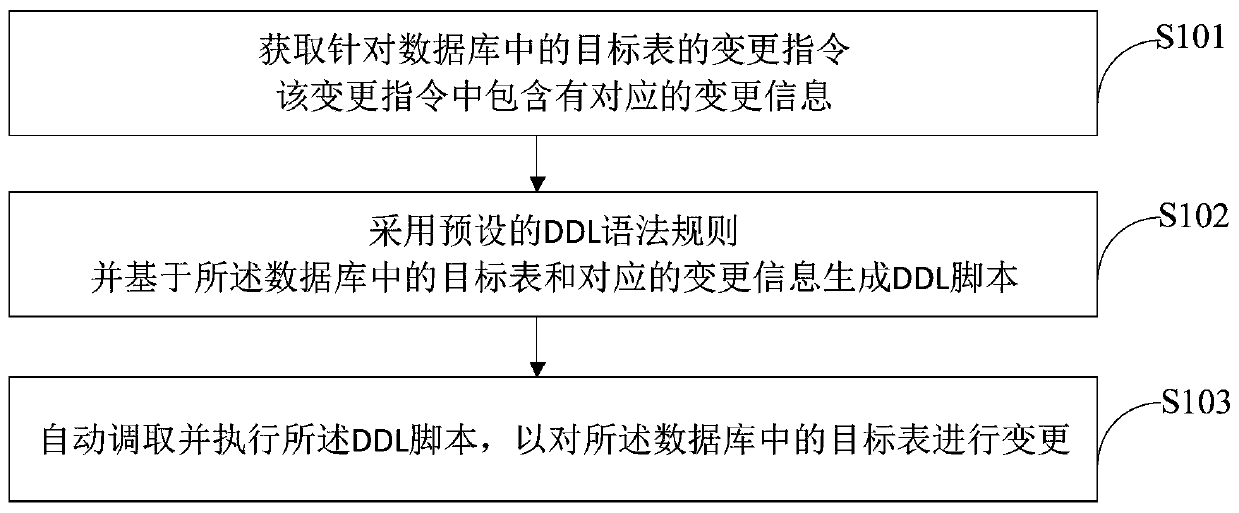

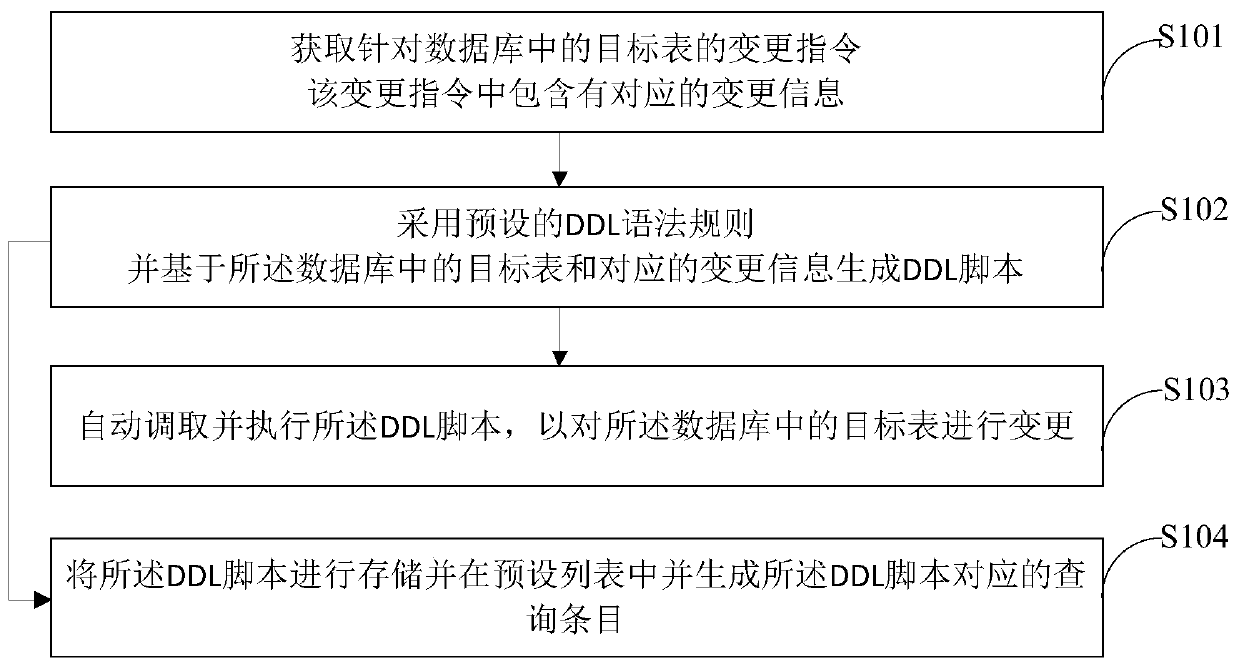

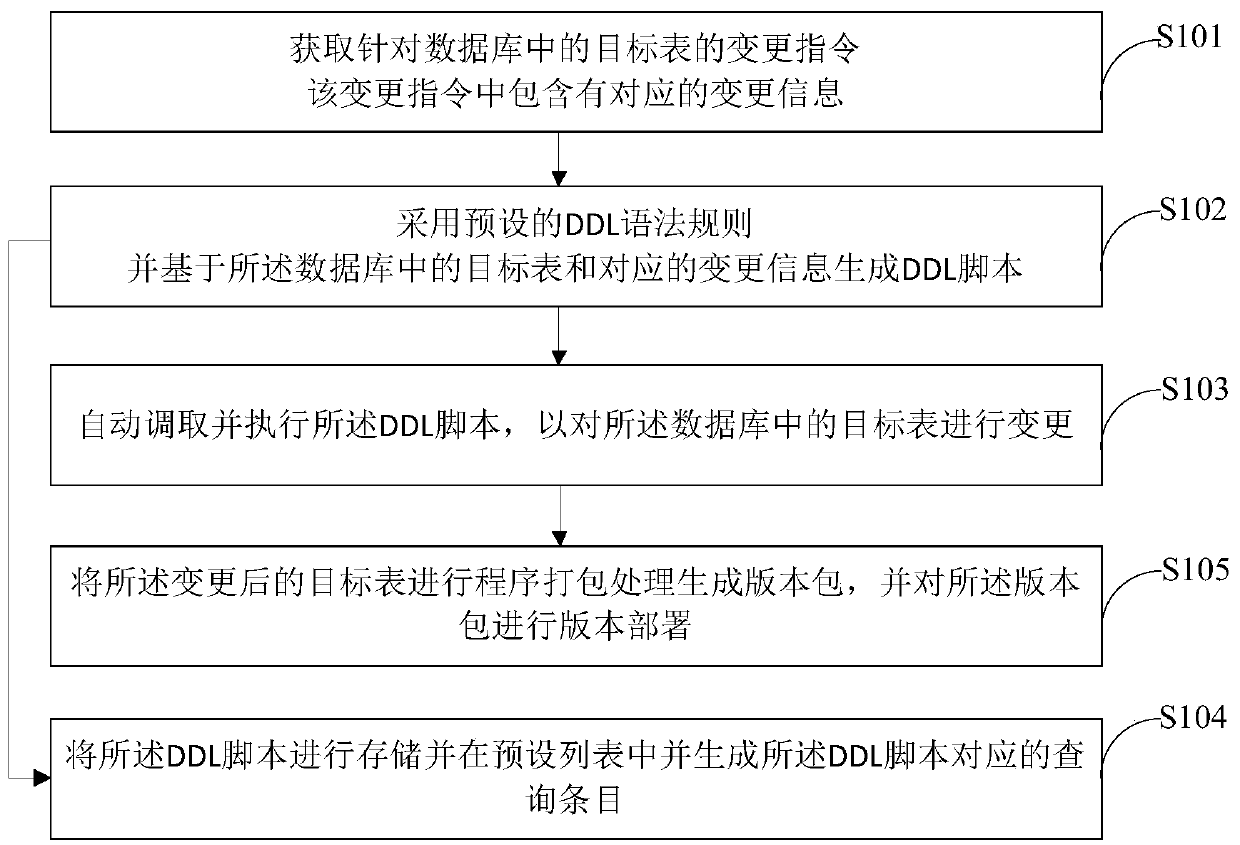

Method and device for changing tables in database

ActiveCN110633284AImprove accuracyEasy to changeSpecial data processing applicationsDatabase indexingData miningUsability

The invention provides a method and device for changing tables in a database. The method comprises the steps: obtaining a change instruction for a target table in the database, wherein the change instruction comprises corresponding change information; adopting a preset DDL grammar rule, and generating a DDL script based on the target table in the database and the corresponding change information;and automatically calling and executing the DDL script so as to change the target table in the database. According to the method, the change information of the table can be converted into the DDL script, so that the table is changed, and then the table change accuracy is improved, and the table change operation is simple, and the usability is high, and the generalizability is high; and the DDL script is automatically called and executed, so that missing submission of a change file of the table can be avoided, and the consistency of each environment table is further ensured, and the data governance and maintenance difficulty is reduced.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Hue adjusting process for high-whiteness coating white cardboard

ActiveCN102517996AReduce consumptionReduce the difficulty of governanceLuminescent/fluorescent substance additionPaper/cardboardCardboardWhitening Agents

The invention discloses a hue adjusting process for a high-whiteness coating white cardboard. An adding point of dye is selected at a head box through which core pulp passes; an adding point of a fluorescent whitening agent is selected at a feeding trough of which the surface is sized. According to the hue adjusting process disclosed by the invention, the dye and the whitening agent are separately added; when the hue is adjusted, control points are few and the adjusting time of the whiteness and the hue is short; and the adjusted finished paper not only meets the whiteness standard, but also achieves stable and uniform effects of the hue. According to the hue adjusting process disclosed by the invention, the consumption of the dye and the whitening agent is reduced and the quantity of the whitening agent in white water is little, so that the cost is reduced and the difficulty in wastewater treatment is reduced.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER

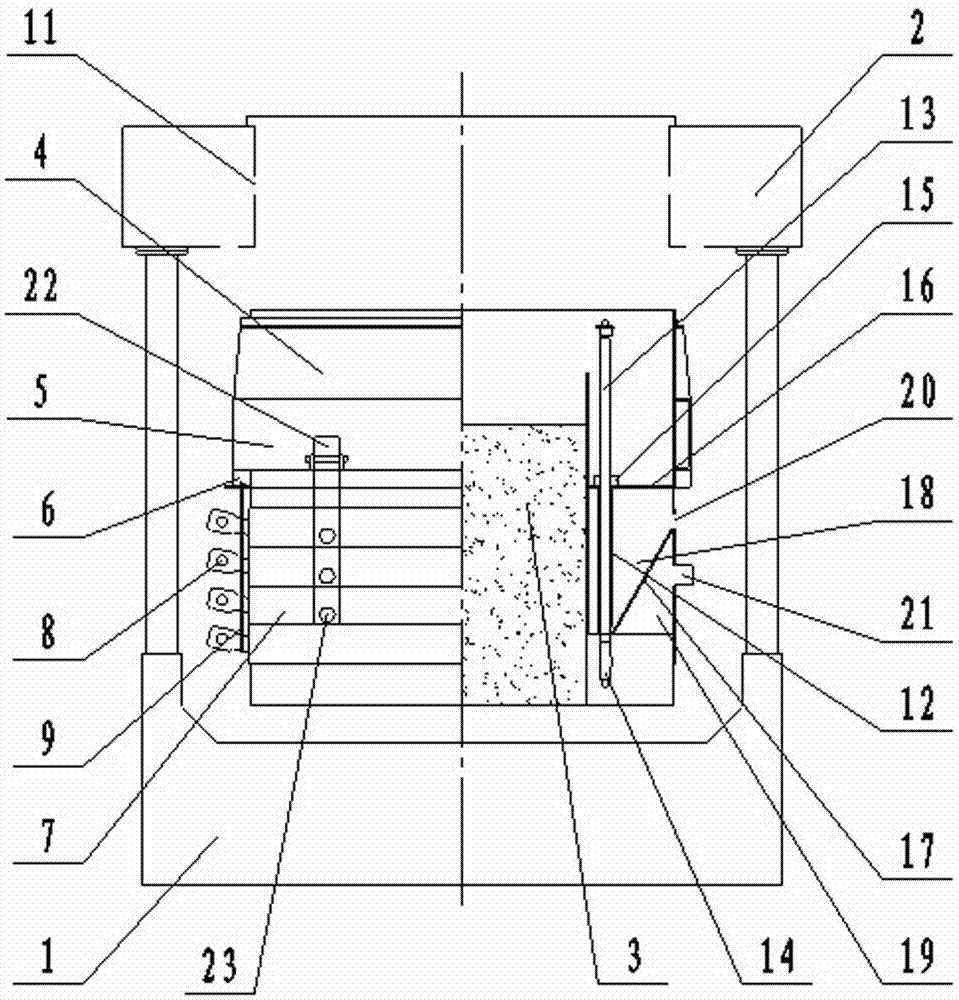

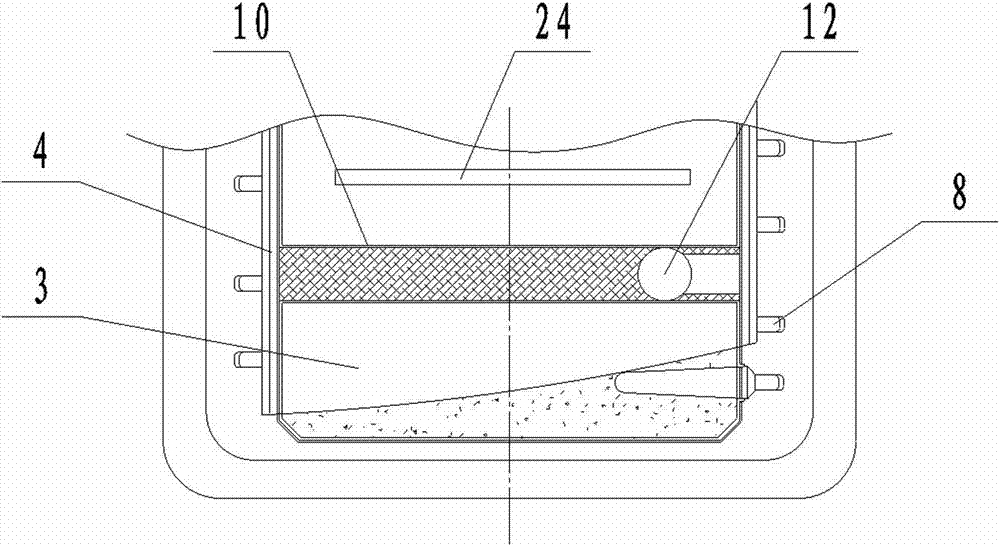

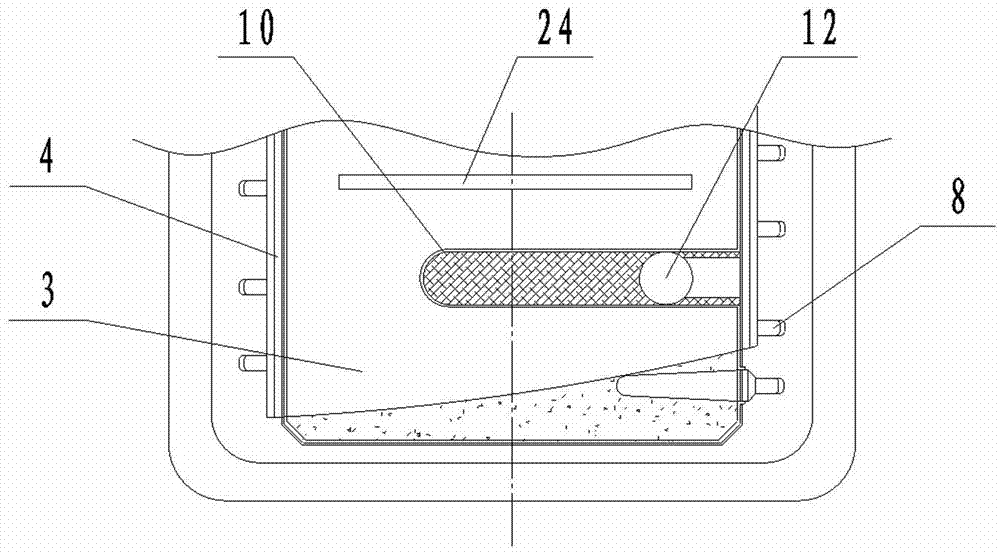

Continuous anodic electrolytic cell for preparing high performance aluminum alloy

InactiveCN102560542AReasonable and reliable structural designReduce the difficulty of governanceMagnesiumOxide

The invention specifically relates to a continuous anodic electrolytic cell for preparing a high performance aluminum alloy, which solves the problems that the existing aluminum electrolytic cells are complex in operation and hard to control. A continuous anodic device is composed of an anodic body and an anodic box body, wherein a metal frame is arranged on the upper portion of the box body, a sealing shield plate frame is arranged on the lower portion of the anodic box body, a bearing hook is arranged between a sublayer current conducing rod and a bearing hook connecting piece arranged on the metal frame, one or two of a padding frame and a crust breaking and blanking exhaust mechanism are arranged between the metal frame and the anodic body, padding in the padding frame is prepared by scandium, titanium, manganese, copper, zinc, strontium, silicon, nickel, chromium, magnesium and rare earth which have a positive reduction potential higher than that of aluminum, or prepared by hydroxide, oxide, fluoride, chloride, sulfide, phosphate, sulphate and carbonate of the scandium, the titanium, the manganese, the copper, the zinc, the strontium, the silicon, the nickel, the chromium, the magnesium and the rare earth, an exhaust port is arranged on a metal platform. The continuous anodic electrolytic cell for preparing the high performance aluminum alloy has the advantages of simple production technology, short process, small controlling difficulty, small energy consumption, small pollution, low cost and high quality.

Method for producing general superphosphate from waste water of yellow ginger processing by dry method

InactiveCN1814546ASolve governance technical problemsLow running costPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhosphorus compoundsHydrolysateWastewater

The invention relates to a method to process waste water to produce ordinary calcium superphosphate in dry method by ginger. The method includes following steps: adopting hydrochloric acid or sulfuric acid hydrolyzed material to take filtering or centrifugal separation to gain eluate low concentrated waste water and fluosilicic acid mixture acid solution; adding antifoaming agent into mixture acid solution and mixing phosphate rock powder to form mixture; adding concentrated oil of vitriol and mixture acid solution in the formation room to gain vitriol acid solution to make ordinary calcium superphosphate. The invention decreases the process difficult and lowers cost. For the place that both has ordinary superphosphate producing company and saponin producing company, the invention also could solve saponin waste water pollution problem, and the cost is only 1 / 5-1 / 10 of the existing method.

Owner:倪文斌

Method for reclaiming oxalic acid from terramycin purification liquid

InactiveCN101085731AReduce dosageReduce the difficulty of governanceWater contaminantsWater/sewage treatmentAbsorption columnIon-exchange resin

The invention relates to a method of recovering oxalic acid from supercidin cleaning liquor. It comprises following steps: filtering supercidin cleaning liquor and getting clarified solution, feeding clarified solution to absorption column filled with weak basic ion exchange resin which is treated with normal method, the oxalic acid is adsorbed, the liquor is discharged to subsequent process: adding ammonial solution to adjust supercidin isoelectric point for separation by crystallization, ading ammonial solution to said ion exchange resin column to remove oxalic acid and getting ammonium oxalate, recovering oxalic acid. The invention is characterized by high oxalic acid recovery rate of 89- 93.6%, reduced ammonia solution consumption by 80%, increased supercidin recovery rate of 95%, simple process, reusable resin and low cost.

Owner:NANJING UNIV

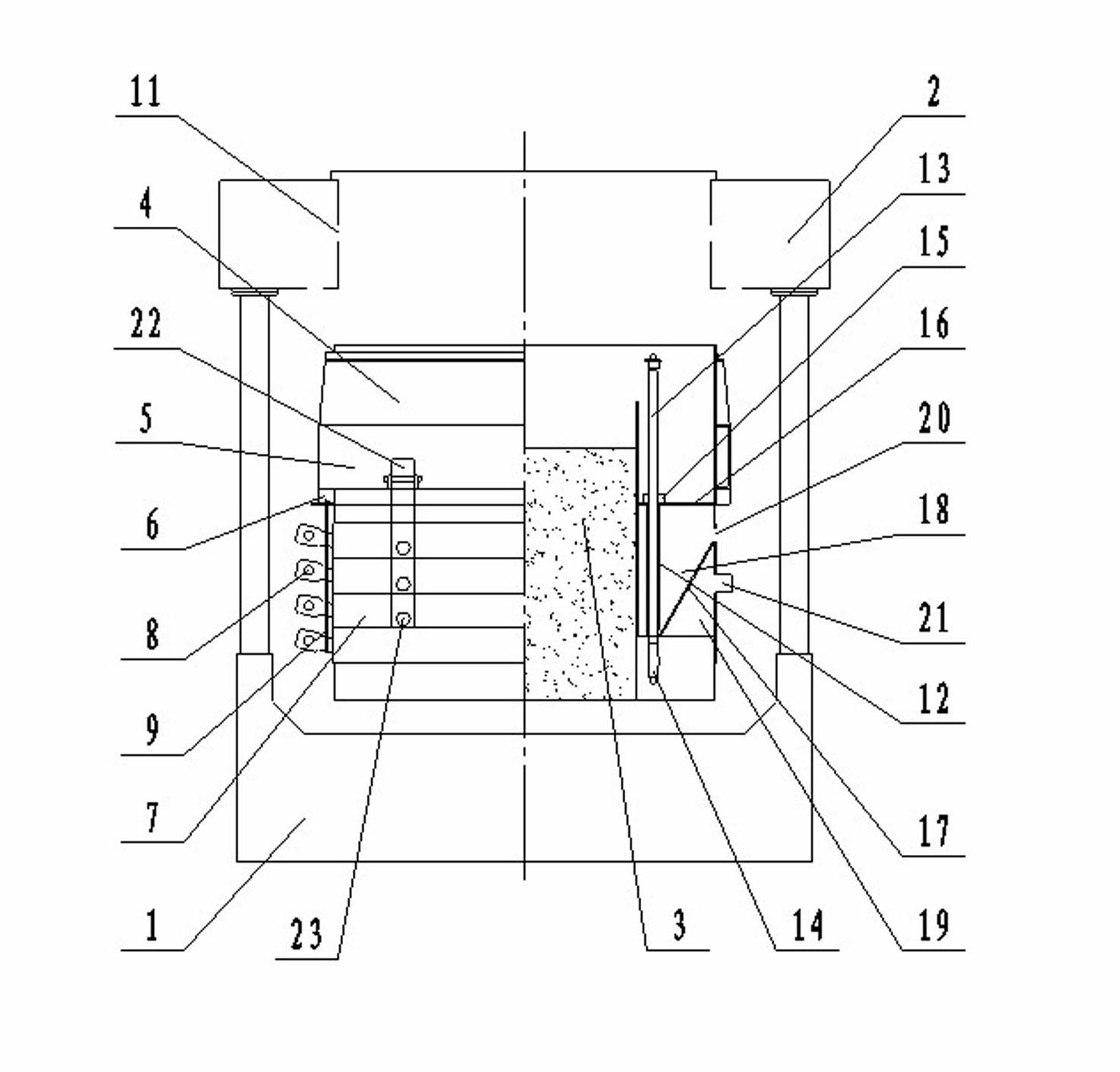

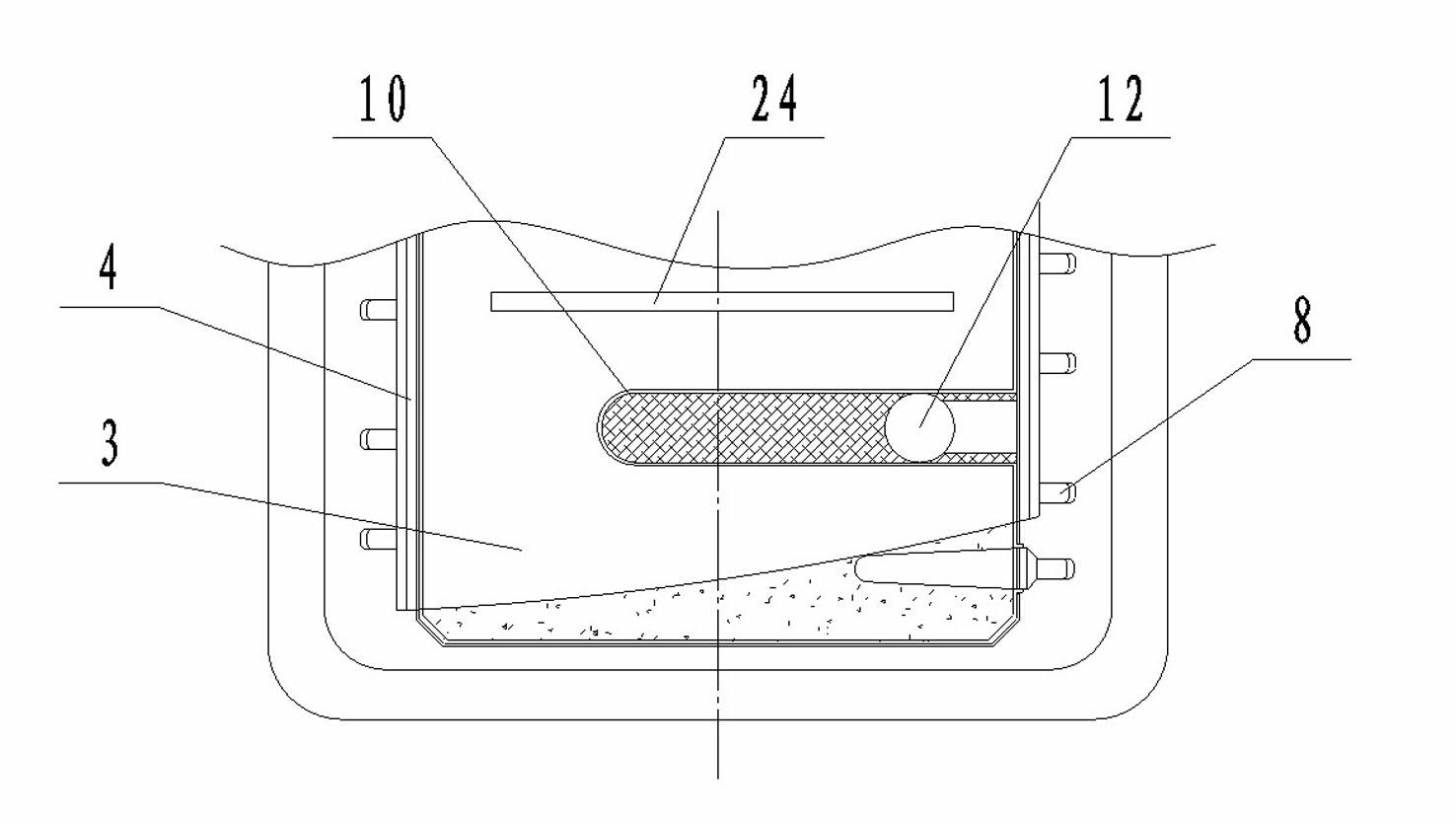

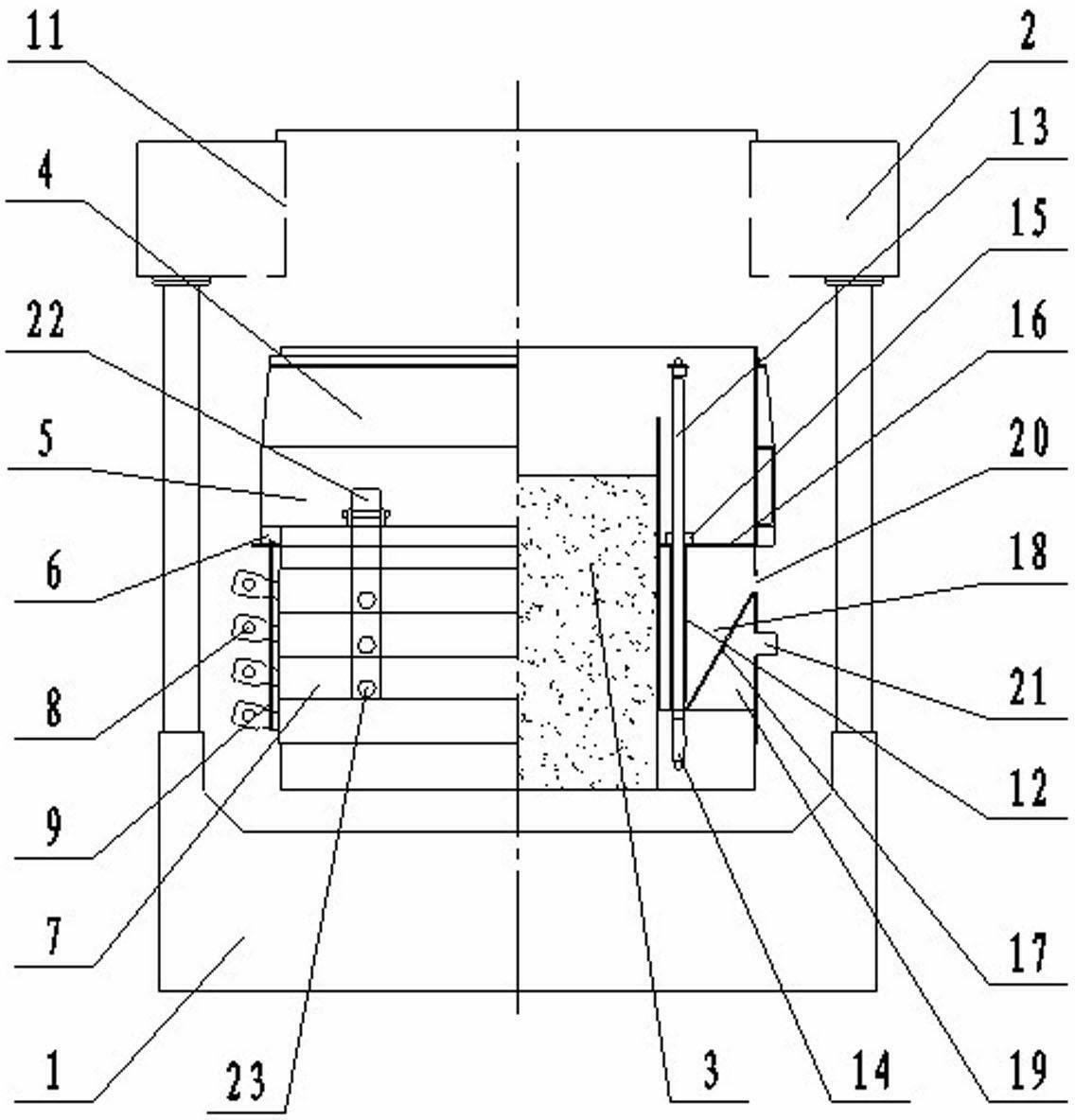

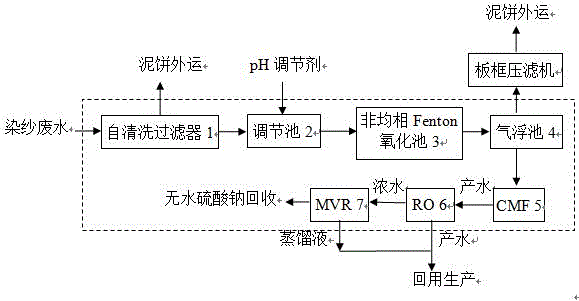

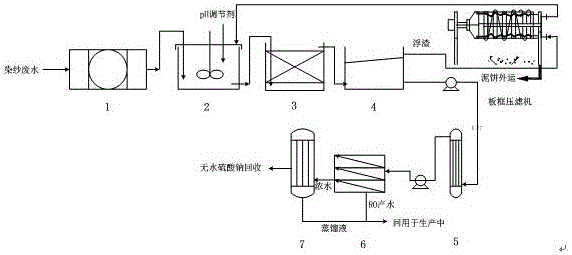

Yarn-dyed fabric yarn dyeing waste water treatment and online recycling method and device

PendingCN106430792AEfficient handlingEfficient recyclingGeneral water supply conservationTreatment involving filtrationWater useYarn

The invention discloses a yarn-dyed fabric yarn dyeing waste water treatment and online recycling method and device. The device mainly comprises a self-cleaning filter, an adjusting pond, a heterogeneous Fenton oxidation pond, an air flotation pond, a double membrane system and an MVR system which are connected in sequence. The method comprises the steps that yarn dyeing waste water is independently treated, anhydrous sodium sulfate in the yarn dyeing waste water is subjected to resource recycling, the content of refractory organics and salt in the comprehensive waste water can be effectively reduced, and the utilization rate of raw materials is increased. The experiment result shows that the whole device can recycle 90% or above of the yarn dyeing waste water, the salt in the waste water can be effectively removed, the salt removing rate is larger than 99%, distillate generated by an RO water producing and MVR system can be recycled to be used for various production links, the new water use amount is replaced, the generation amount of pollutants is controlled from the source, and the idea of cleaner production is fully embodied.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

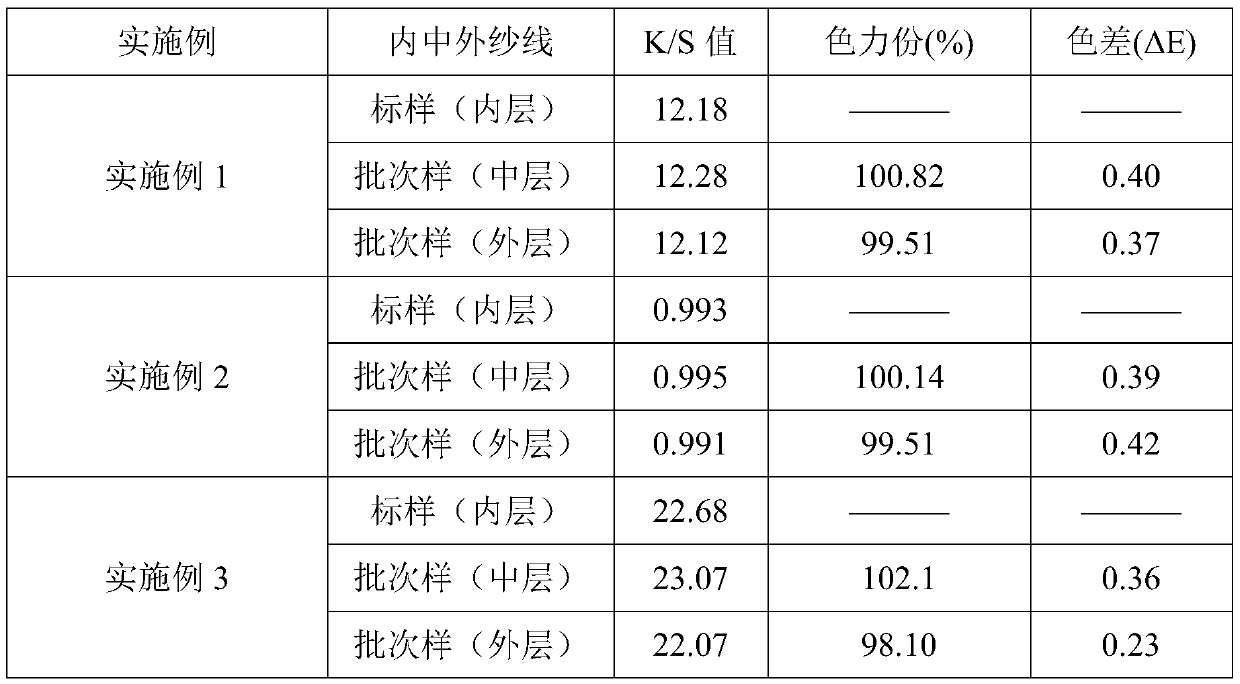

Little-water medium dyeing method for cellulosic fiber cheese

The invention belongs to the technical field of spinning dyeing and finishing, and particularly relates to a little-water medium dyeing method for a cellulosic fiber cheese. By conducting the four processes of pretreatment, dyeing, after treatment and dyeing medium separation and recovery on the cheese, little-water medium dyeing is realized for the cellulosic fiber cheese. According to the dyeingmethod, under a dyeing condition of low salt and alkali and little water, dyeing is conducted, the usage amount of water, anhydrous sodium sulphate and sodium carbonate is reduced by 60-85% comparedwith common dyeing, and meanwhile the utilization rate of dye can be increased by 5-10%. By the adoption of the dyeing method, dyeing is conducted, all fastnesses of yarn can reach the third-fourth level, compared with common water bath dyeing, the dyed medium can be rapidly recovered and recycled, the recovery rate of the medium is up to 95%, and the problems that during traditional active dye water bath dyeing, the amount of consumed water and the quantity of discharged pollutants are high, and the content of salt in wastewater is high are effectively solved.

Owner:LUTAI TEXTILE

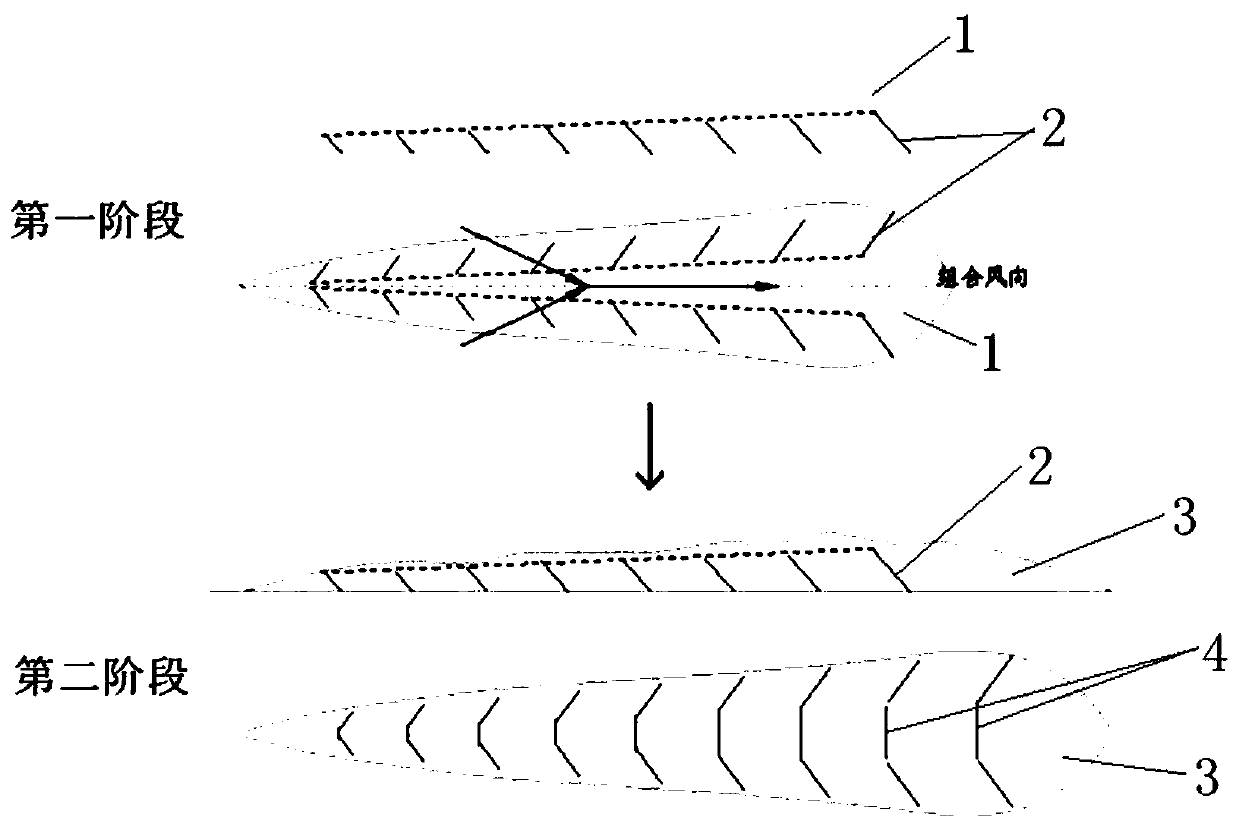

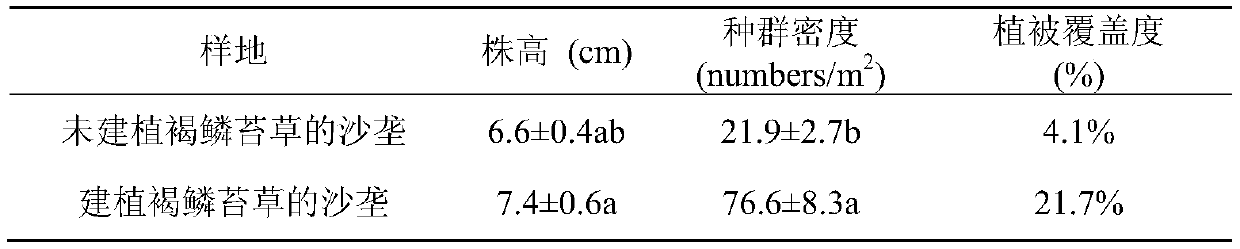

Method for achieving sand stabilization of high-cold region through carex brunnescens

InactiveCN110235707AGood sand fixing effectImprove sand fixation effectClimate change adaptationPlant cultivationSting plantLawn

The invention relates to a method for achieving sand stabilization of a high-cold region through carex brunnescens. The method comprises the steps that in a first stage, first carex brunnescens living sand barrier queues are planted with the spacing of 10-20 m in the lower middle portions of the two sides of a moving longitudinal dune in the direction perpendicular to prevailing wind; in a second stage, after the longitudinal dune is leveled off through wind erosion, second carex brunnescens living sand barrier queues are planted on a large scale with the spacing of 0.5-1.0 m on a wind erosion flat ground located in the middle, living sand barriers at the left and right sides are integrally connected through the second carex brunnescens living sand barrier queues, and then stable sand stabilization surfaces can be formed. According to the method, a technique of utilizing carex brunnescens for sand stabilization is provided for achieving ecological management and sand stabilization practice of desertified grassland in the high-cold region, the cost for sand prevention and control is reduced, the sand stabilization period is shortened, the sand control effect is improved, a solid foundation is laid for better utilizing resource plants carex brunnescens in the future, and a new research prospect is opened up for ecological restoration of the desertified grassland in the high-cold region.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

Production method of acrylate monomer modified cellulose fiber fabric

The invention belongs to the technical field of textile dyeing and finishing and particularly relates to a production method of acrylate monomer modified cellulose fiber fabric. The production method includes: stirring and evenly mixing an emulsifier and deionized water, and sequentially adding acrylate monomers and an initiator to perform emulsification reaction to prepare a modified acrylate emulsion; soaking cellulose fiber fabric in the modified acrylate emulsion system for 1-15 minutes, using a padder to control fabric wet pick up at 65-110%, sealing the cellulose fiber fabric after padding, and placing into a drying oven to perform constant-temperature piling; subjecting the modified cellulose fiber fabric to soaping and drying. The production method has the advantages that the modification process of the cellulose fiber fabric is environmentally friendly and controllable, and the modified cellulose fiber fabric is soft in touch.

Owner:LUTAI TEXTILE

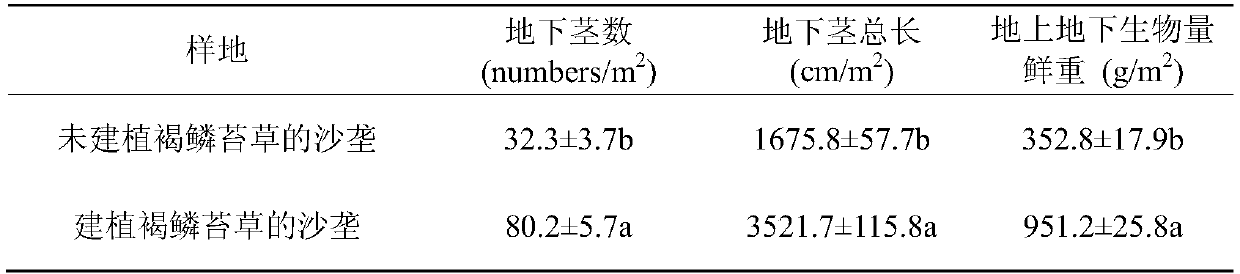

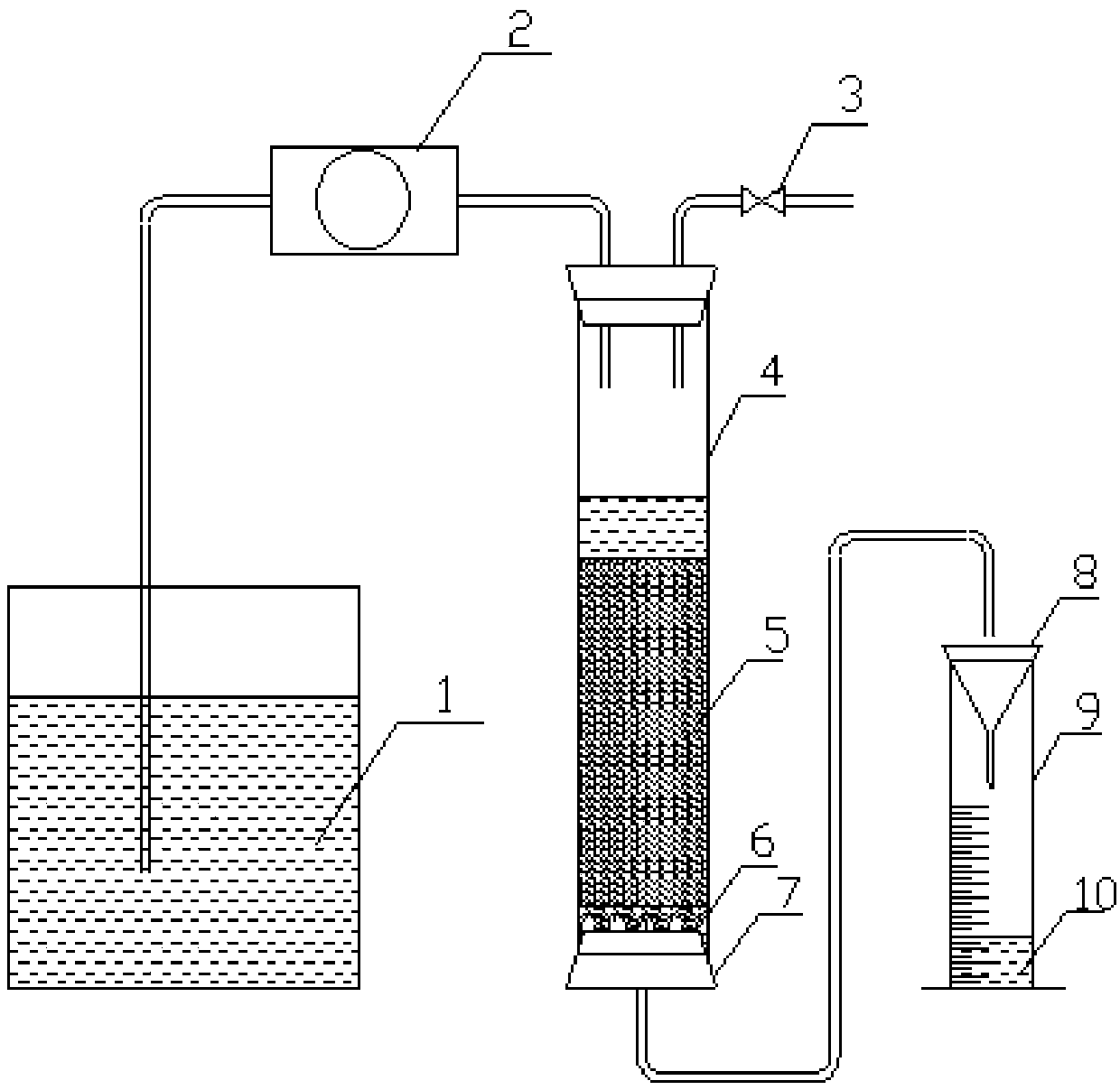

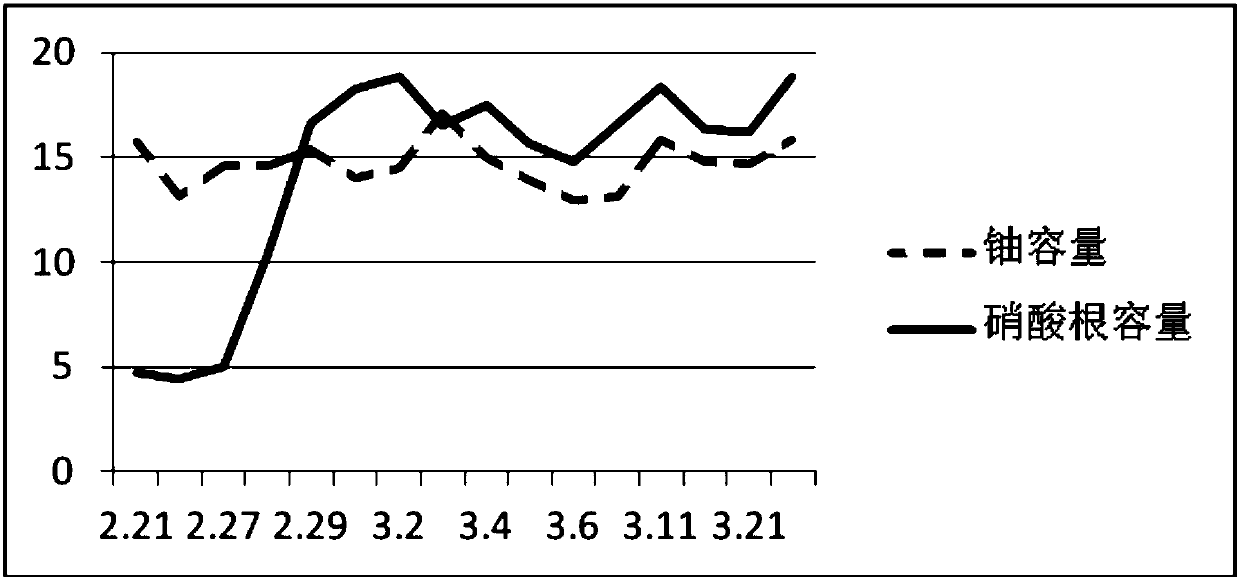

Using method of recovery adsorption tower in in-situ leaching mining uranium water treatment technology

InactiveCN109987676ARealize innovative utilizationHigh recovery rateIon-exchange process apparatusWater/sewage treatment by ion-exchangeIon exchangeTower

The invention belongs to the technical field of mobile bed uranium water treatment, and more specifically relates to a using method of a recovery adsorption tower in in-situ leaching mining uranium water treatment technology. The using method is capable of solving problems in the prior art that in not only adsorption process resin saturation capacity is influenced by transformation tail liquid introduction adsorption process, adsorption resin saturation capacity fluctuation is relatively large, and after transformation, solution enters into underground ore bed with leaching solution, so that mine later stage underground water treatment difficulty is increased. The using method comprises following steps: feasibility test of transformation tail liquid introduction into the recovery adsorption tower, and transformation tail liquid introduction into the recovery adsorption tower. The using method is capable of realizing recovery adsorption tower innovation utilization, recycling uranium intransformation tail liquid, increasing water treatment recovery rate, recycling nitrate radicals in transformation tail liquid, reducing production cost, stabilizing adsorption process resin uraniumcapacity, achieving ion exchange mobile bed uranium mining technology liquid phase balance, achieving liquid phase closed circulation, reducing underground nitrate radical accumulation, and reducing mine later stage underground water treatment difficulty.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC

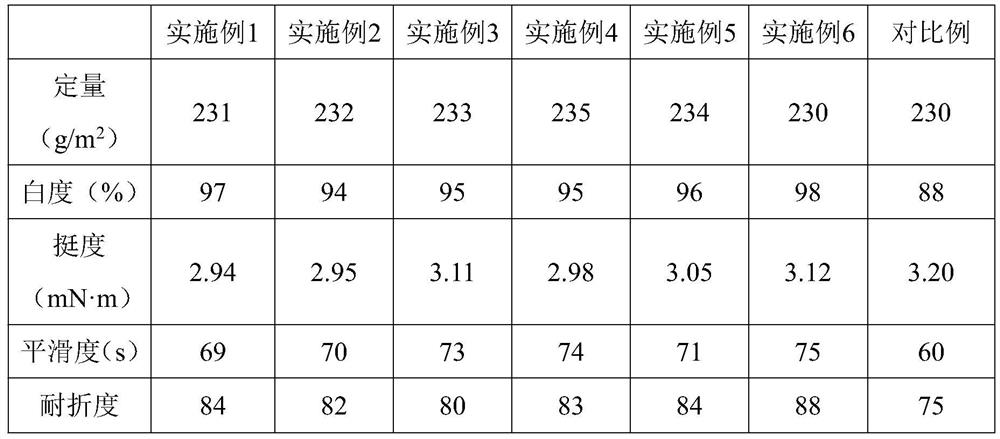

High-whiteness coated ivory board and preparation method thereof

PendingCN113668281AAvoid yellowingGood printability of paperCoatings with pigmentsSpecial paperPolymer scienceWhitening Agents

The invention relates to the field of papermaking, and discloses a high-whiteness coated ivory board and a preparation method thereof. The high-whiteness coated ivory board comprises raw paper and a coating layer covering the surface of the raw paper, wherein the raw paper comprises a surface paper layer, a core paper layer and a bottom paper layer, the coating layer comprises a pre-coating layer, a surface coating layer and a back coating layer, the paper pulp of the raw paper comprises 80-90 parts of hardwood pulp and 10-20 parts of softwood pulp, the paper pulp is formed by bleaching treatment through a biological enzyme method, the coating materials of the pre-coating layer, each of the surface coating layer and the back coating layer comprises a pigment, a coating adhesive and a coating additive, the pigment comprises 85-95 parts of ground calcium carbonate and 5-15 parts of kaolin, and the coating additive comprises a fluorescent whitening agent accounting for 0.05-0.10% of the total weight of the coating materials. The preparation method comprises the steps of paper pulp preparation, net loading, squeezing and water removal, preliminary drying, on-line coating in a machine, drying and subsequent calendaring, reeling, cutting and packaging. The invention provides a method for preparing the high-whiteness coated ivory board by using a biological enzyme method for bleaching and using a small amount of a whitening agent, and the whiteness of the prepared coated ivory board is 94% or above.

Owner:湖北骏马纸业有限公司

Production method of antioxidizer 300

ActiveCN109651213AReduce the difficulty of governanceHigh purityOrganic compound preparationSulfide preparationSolventChemistry

The invention relates to a production method of an antioxidizer 300 and belongs to the technical field of manufacturing of an alkylphenol sulfide antioxidizer. The production method comprises the following steps that 1, saturated aliphatic hydrocarbon solvent oil with high boiling range is used as a solvent, 6-tert-butyl-m-cresol and sulfur chloride conduct a sulpho reaction, and 4,4'-sulpho bis(6-tert-butyl-m-cresol) is generated; 2, after the sulpho reaction is completed, low-molecular-weight alcohol is added; 3, the temperature is increased, hydrogen chloride and alcohol are generated through evaporation and then cooled to the normal temperature, a weak base aqueous solution is added, the pH value of the material is adjusted to be neutral, and through filtering, a coarse product is obtained. The production method is scientific, reasonable, simple and easy to implement, the small amount of residual hydrogen chloride which needs to be neutralized is only produced in the production process, and the produced antioxidizer 300 coarse product has few impurities and is high in purity.

Owner:淄博万科化工有限公司

Multi-continuous-electrode electrolytic tank for preparation of high-performance aluminum material

Regeneration and cyclic utilization method for linen laundry wastewater

InactiveCN105152425AGovernance is highly targetedGood effectOther washing machinesTextile treatment machine arrangementsWater useFlocculation

The invention relates to a method for regeneration and cyclic utilization of laundry wastewater. By way of combining direct reuse of laundry wastewater and regeneration and cyclic utilization, the laundry wastewater is treated, comprising course treatment and front-end treatment. The course treatment means that rinse water in a laundry process flow is directly reused in form of countercurrent rinsing. By designing an operating system where the rinse water continuously flows in a semi-intermittent manner and the washed matters are intermittent for an independently operated intermittent industrial washing machine, a water use flow of countercurrent rinsing of the rinse water is realized, the wastewater amount of a rinsing stage is reduced, and 50-70% of fresh water dosage can be saved. The front-end treatment means that wastewater generated in pre-washing and principle-washing in laundry production is independently collected and treated, and the treated water after flocculation, centrifugal separation and filtration is used in pre-washing, principle-washing and rinsing, so that the reuse rate reaches 80%; the laundry wastewater regeneration and cyclic utilization system established by combining the technologies of course treatment and front-end treatment comprehensively saves over 80% of fresh water dosage.

Owner:BEIJING INST OF CLOTHING TECH

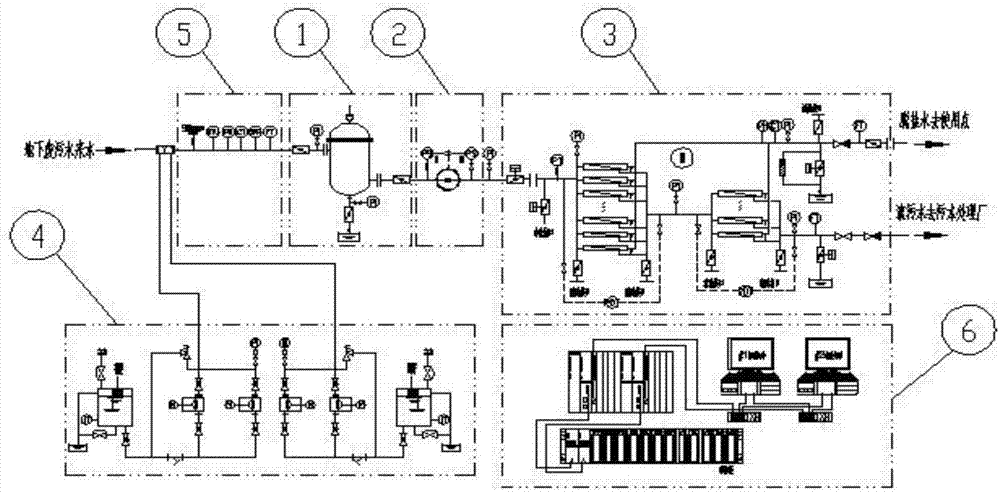

Membrane treatment method and apparatus for underground wastewater

InactiveCN103693778AHigh chromaImprove CODMultistage water/sewage treatmentContaminated groundwater/leachate treatmentAutomatic controlControl system

The invention discloses a membrane treatment device for underground wastewater. The membrane treatment device comprises a precision filter system, a booster pump system, a membrane treatment main device system, a dosing system, an instrument analysis and monitoring system, and an automatic control system 6, wherein the underground wastewater sequentially flows from the precision filter system and the booster pump system to the membrane treatment main device system through a pipeline; the dosing system is used for adding chemicals on an underground wastewater inlet; instrument monitoring points of the instrument analysis and monitoring system are respectively arranged on pipeline measuring points of the precision filter system and the booster pump system; the automatic control system is connected to an input of the instrument analysis and monitoring system, and an output of the instrument analysis and monitoring system is connected to corresponding control ends of the membrane treatment main device and the dosing system; the instrument analysis and monitoring system and the automatic control system are arranged on a same platform or in a plant, and are integrally connected through various corrosion resistant pipelines and cables; through a valve and a water pump of the membrane treatment main device system, operation under different pressures and flows is realized, so that underground water polluted in various ways is treated.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

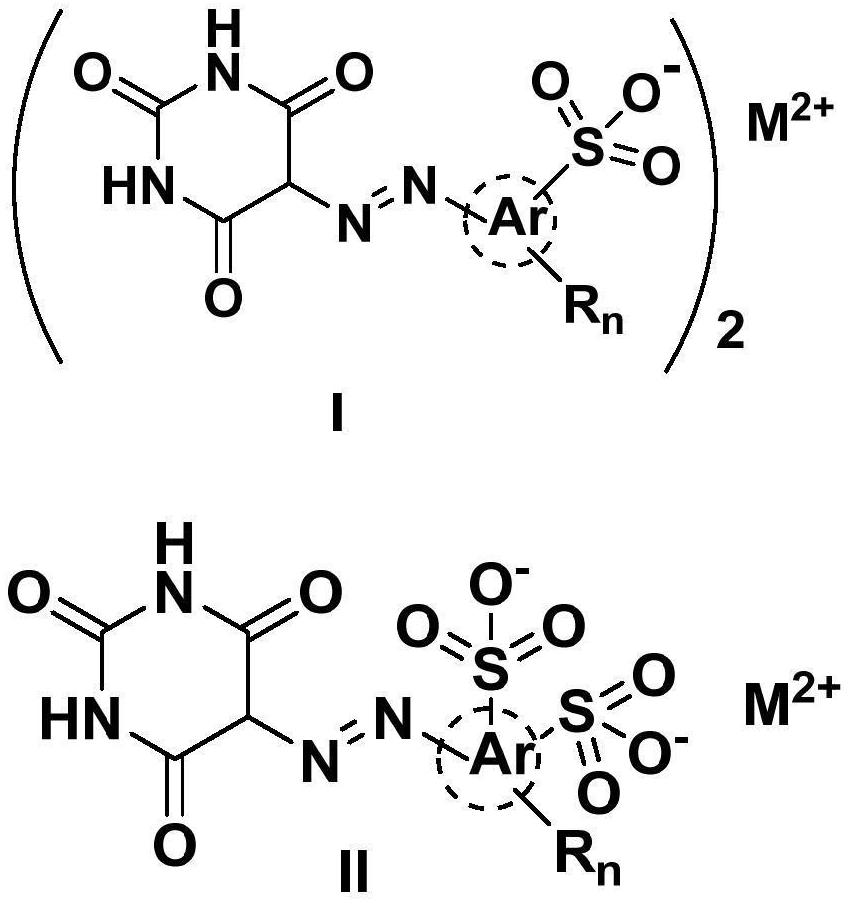

Monoazo lake pigment and preparation method thereof

ActiveCN112322073AReduce residueReduce governance difficulty and economic costsMonoazo dyesOrganic chemistryEnvironmental chemistryLake pigment

The invention discloses a monoazo lake pigment. The structural general formula of the monoazo lake pigment is one of the structures described in the description: M is one of Ca, Ba and Sr; R is H, OH,NO2, Cl, Br or C1 to C4 alkyl, and n is a positive integer from 1 to 3; and Ar is described in the description. According to the preparation method of the monoazo lake pigment, sodium chloride or sodium hydrogen sulfate / sodium sulfate can be prevented from being generated in the process of preparing the aromatic primary amine diazonium salt. Meanwhile, in the coupling reaction process, alkali containing a sodium element is not adopted, generation of inorganic sodium salt can be avoided in the manufacturing process of the monoazo lake pigment, and conditions are provided for clean treatment and comprehensive utilization of coupling reaction liquid.

Owner:瑞素士化学(上海)有限公司

Method for treating papermaking wastewater

InactiveCN103848519AReduce the difficulty of governanceReduce manufacturing costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSulfite saltPapermaking

The invention discloses a method for treating papermaking wastewater. The method comprises the steps of discharging the papermaking wastewater into a pollution discharge pond for settling, and then discharging the papermaking wastewater into a regulation pond; adding a reducing agent namely sodium sulfite, settling, and then discharging an upper aqueous solution into a mechanical speed-up clarifying pond with a stirring machine; adding flocculating agents namely basic aluminum chloride and polyacrylamide to separate colloidal substances in the solution, and filtering through a pressure filter to generate fore treatment water; discharging the fore treatment water into a reaction tank, and generating fore pretreatment water through a multi-medium filter; treating the fore pretreatment water to obtain reclaimed water; treating the reclaimed water to produce water according with recycling production. By adopting the method provided by the invention, the problem for recycling of the wastewater generated during papermaking is solved, water resources are saved, and the production cost is reduced.

Owner:泾县中小企业生产力促进中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com