Chromium pollution soil combined remediation method

A technology for joint restoration and chromium pollution, which is applied in the restoration of contaminated soil, chemical instruments and methods, fertilizer mixtures, etc. problems, to enhance the ability to resist external environmental erosion, strengthen the effect of physical and chemical stabilization, and enhance the effect of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] Take the chromium-contaminated soil in a chromium slag storage yard in Shenyang as an example.

[0045] A combined restoration method for chromium-contaminated soil, comprising the steps of:

[0046] Step 1: Reduction of chromium in chromium-contaminated soil

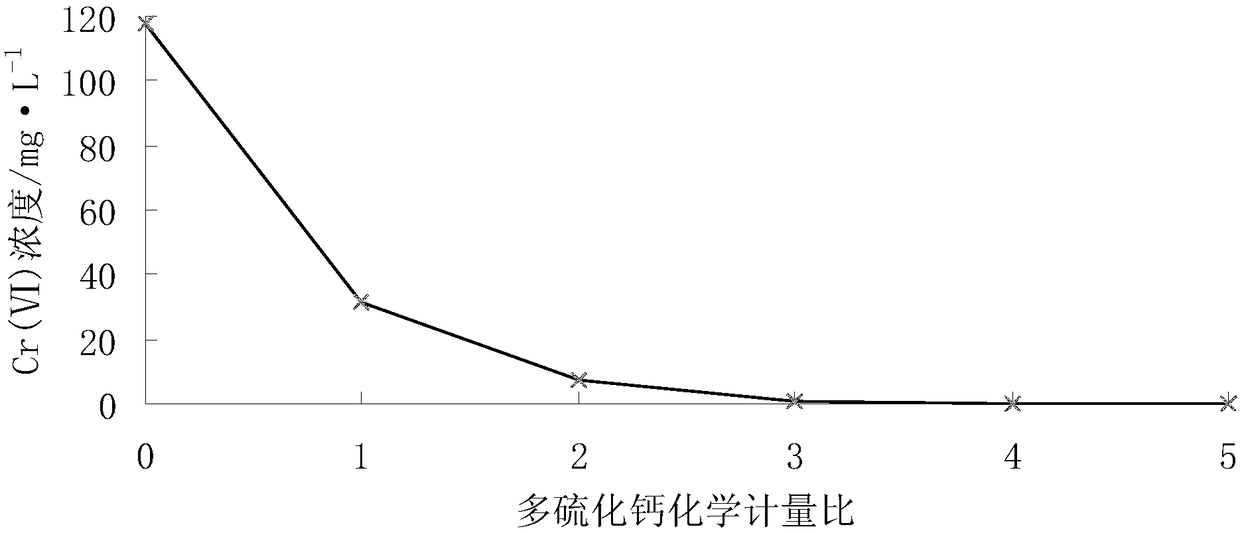

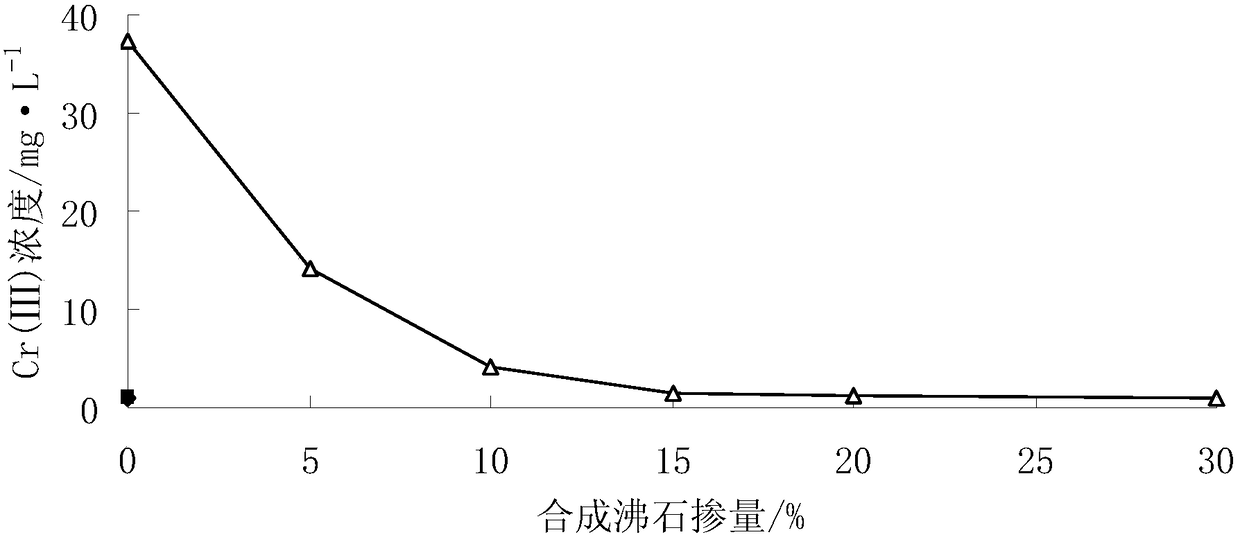

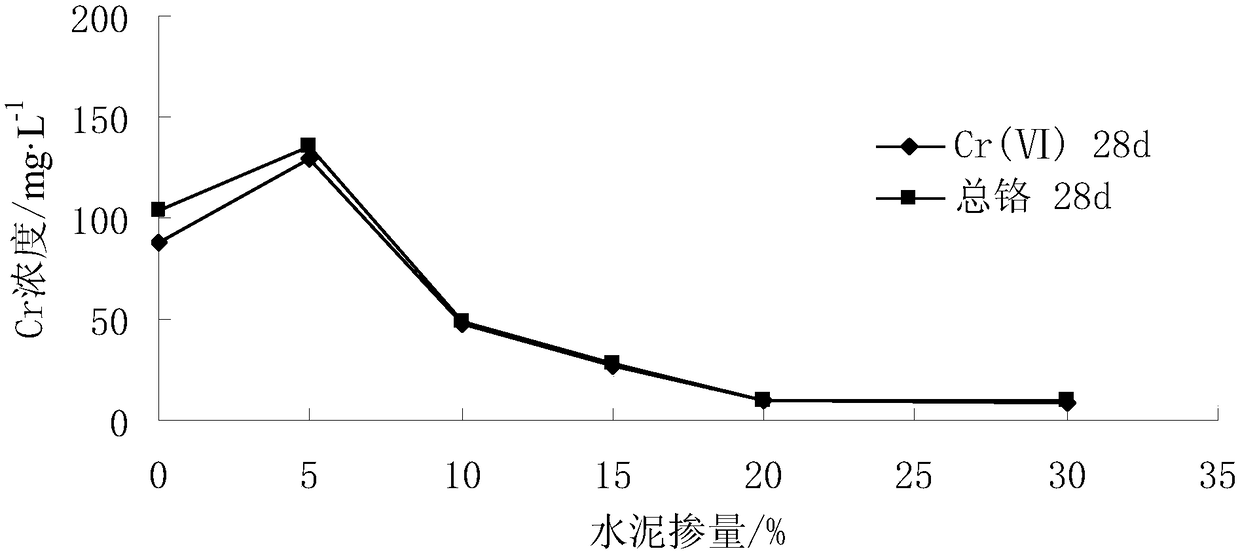

[0047] Determine the content of chromium in the chromium-contaminated soil. The measured average content of hexavalent chromium is 3000mg / kg, and the measured average content of total chromium is 6500mg / kg. The optimum moisture content of the chromium-contaminated soil is measured, and the optimum moisture content is measured to be 22%; select The calcium polysulfide solution is a concentration of 29% CaS 5 Water agent, mix chromium-contaminated soil with calcium polysulfide solution and stir evenly, the stirring time is 10 minutes, and the molar ratio of chromium in cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com