Patents

Literature

60results about How to "Reduce residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic oxide conductive powder/polyaniline conductive polymer composite material and its preparation method

A process for preparing the electrically conductive inorganic oxide powder / electrically conductive high-molecular polyphenylamide compound includes such steps as proportionally mixing the aqueous solution of phenylamine with the aqueous solution of dopant acid, adding electrically conductive inorganic oxide, stirring,adding the aqueous solution of oxidant, reaction, and separating target product.

Owner:SOUTHWEST UNIVERSITY

LCD alignment method

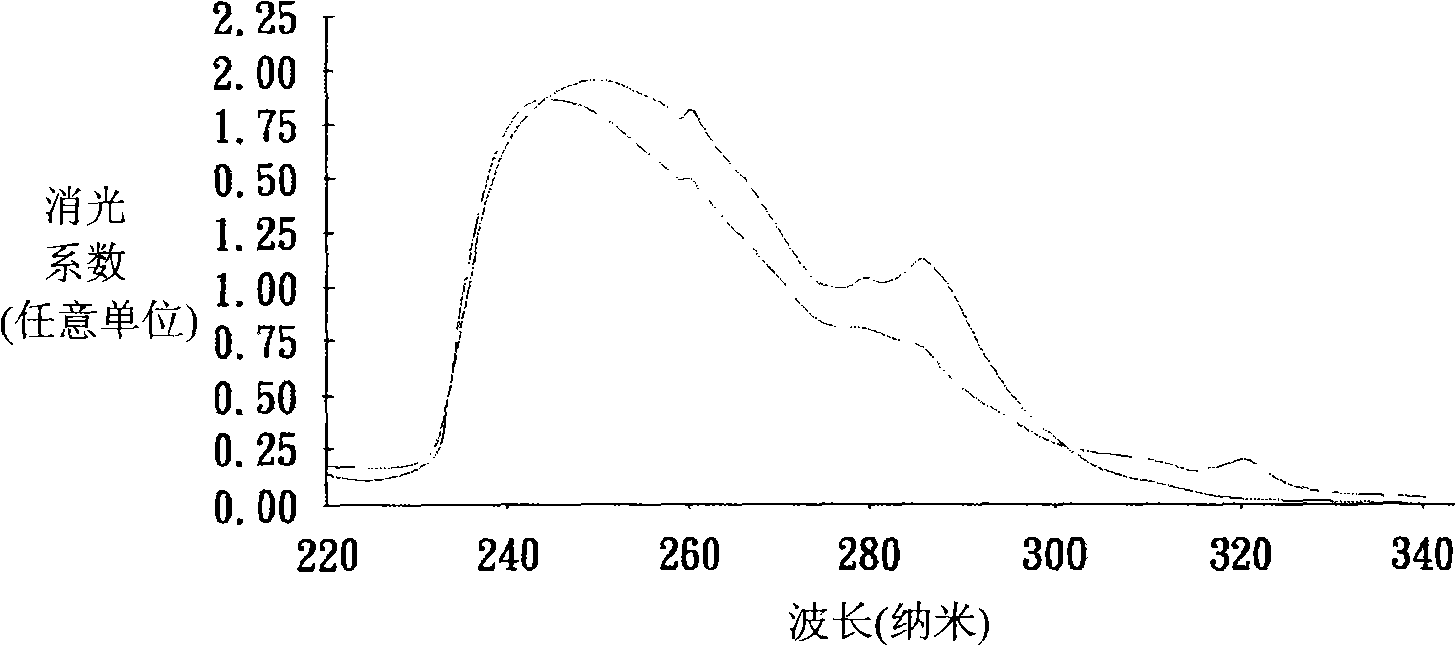

ActiveCN101266366AAvoid harmReduce residuePhotomechanical apparatusNon-linear opticsMonomerMaterials science

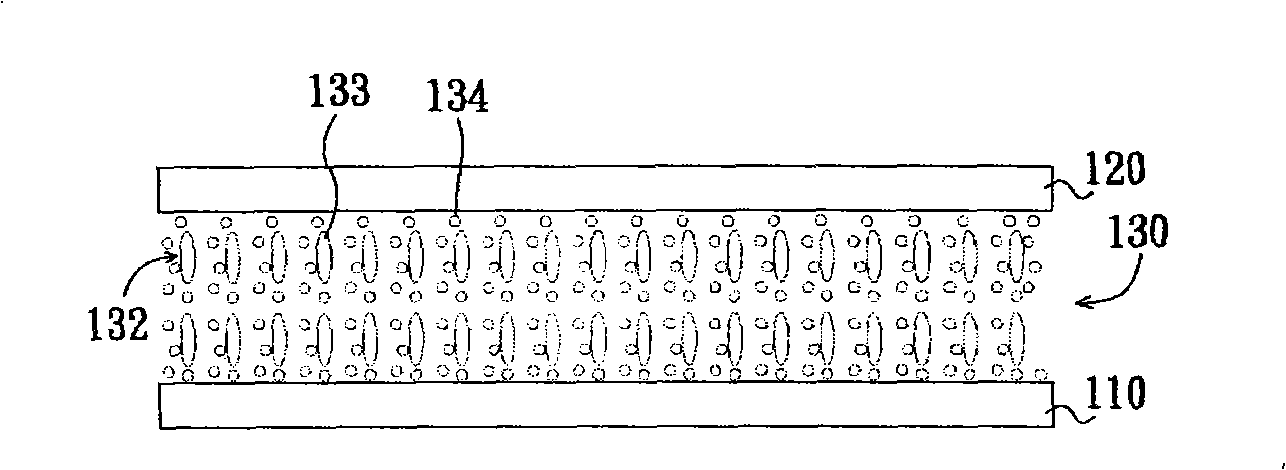

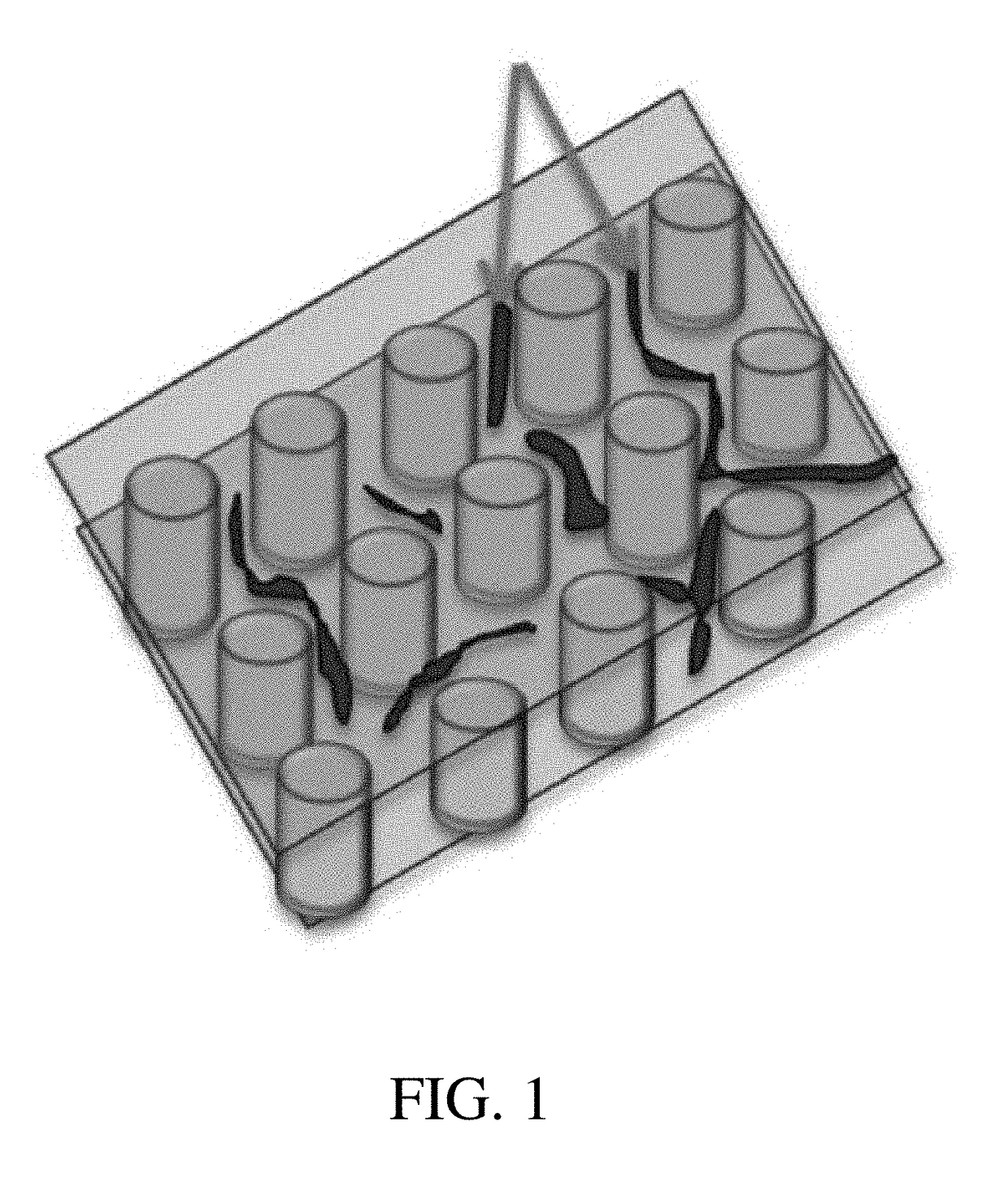

The invention discloses a liquid crystal alignment method includes the following steps: providing a first substrate and a second substrate; providing a liquid crystal layer between the first substrate and the second substrate, wherein the liquid crystal layer includes a liquid crystal composition, a monomer material and a polymerization initiation agent; executing a first exposal proceeding , in order to allow parts of the monomer material to polymerize to form two polymer steadily alignment layers, respectively a first contact face located between the liquid crystal layer and the first substrate, and a second contact face between the liquid crystal layer and the second substrate, in order to allow a plurality of liquid crystal molecules in the liquid crystal composition to align along a pre-inclination angle; and executing a second exposal proceeding , in order to allow the surplus monomer material to polymerize, wherein the second exposal proceeding uses light with the principal wavelength between 290 nanometer to 340 nanometer to irradiate the surplus monomer material. The liquid crystal alignment method can boost the reliability of the liquid crystal display board.

Owner:AU OPTRONICS CORP

Terpene resin and preparation method thereof

The invention discloses a terpene resin and a preparation method thereof. The preparation method comprises steps as follows: terpene substances are used as a raw material, AlCl3 in the presence of an aromatic solvent is used as a main catalyst, and a cocatalyst is used in the reaction; polymerization is carried out at low temperature to prepare the crude terpene resin product; and the crude terpene resin product is washed and distilled under reduced pressure to obtain the terpene resin product. The cocatalyst is trimethylchlorosilane, triethylchlorosilane, tripropylchlorosilane or tributylchlorosilane, and accounts for 1-5% of the total mass of the terpene substance raw material; the main catalyst AlCl3 accounts for 4-12% of the total mass of the terpene substance raw material; the elemental chlorine content in the prepared terpene resin product is less than 100mg / kg, and the metallic aluminum content is less than 10mg / kg; the terpene resin product does not contain metallic antimony; and the residue level of the volatile solvent is less than 25mg / kg. The product reaches to the food level.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Compositions comprising aromatic ester solvents for use in oil and/or gas wells and related methods

Compositions comprising aromatic ester solvents for use in various aspects of a life cycle of an oil and / or gas well, and related methods, are provided. In some embodiments, the composition includes an emulsion or microemulsion wherein the emulsion or microemulsion comprises an aqueous phase, a surfactant, and a non-aqueous phase. In some embodiments, the non-aqueous phase comprises a solvent blend including a first type of solvent and a second type of solvent, e.g., having a respective weight ratio of about 3:2 to 1:4. In some embodiments, the first type of solvent is a terpene and / or the second type of solvent is an aromatic ester solvent. In some embodiments, compositions are used in methods for treating an oil and / or gas well having a wellbore. In some embodiments, the composition is delivered into the wellbore, reducing residues comprising kerogens, asphaltenes, paraffins, organic scale, or combinations thereof on or near the wellbore.

Owner:FLOTEK CHEM LLC

Method for preparing film agent by using chitosan and Arabic gum as matrix

InactiveCN103127036AReduce residueGood biocompatibilityPharmaceutical non-active ingredientsPharmaceutical active ingredientsGum arabicAbsorption effect

The invention provides a method for preparing a film agent by using chitosan and Arabic gum as matrix, and relates to a preparation method of the film agent. With the adoption of the method for preparing the film agent by using the chitosan and the Arabic gum as the matrix, the problem that the conventional film agent is poor in absorption effect, or has high drug-release incomplete residual amount, or has irritation in long-term use can be solved. The preparation method provided by the invention comprises the steps of I, preparing a chitosan solution; II, preparing an Arabic gum solution; and III, mixing the chitosan solution prepared by the step I with the Arabic gum solution prepared by the step II, so as to obtain a mixed solution; heating the mixed solution; stirring after adding drugs, a plasticizer and an absorption promoter, so as to obtain a mixture; and then preparing the film agent by using the mixture through a film coating machine. The film agent is a film agent using the chitosan and the Arabic gum as the matrix. The film agent prepared by the invention has the advantages of low drug residual amount and slight irritation; the biological use rate is improved; the simple preparation process and the temperate conditions can be realized; and the desired raw auxiliary materials are cheap and easy to get. The method for preparing the film agent by using the chitosan and the Arabic gum as the matrix provided by the invention is applied to the field of preparing a pharmaceutical preparation.

Owner:HEILONGJIANG UNIV

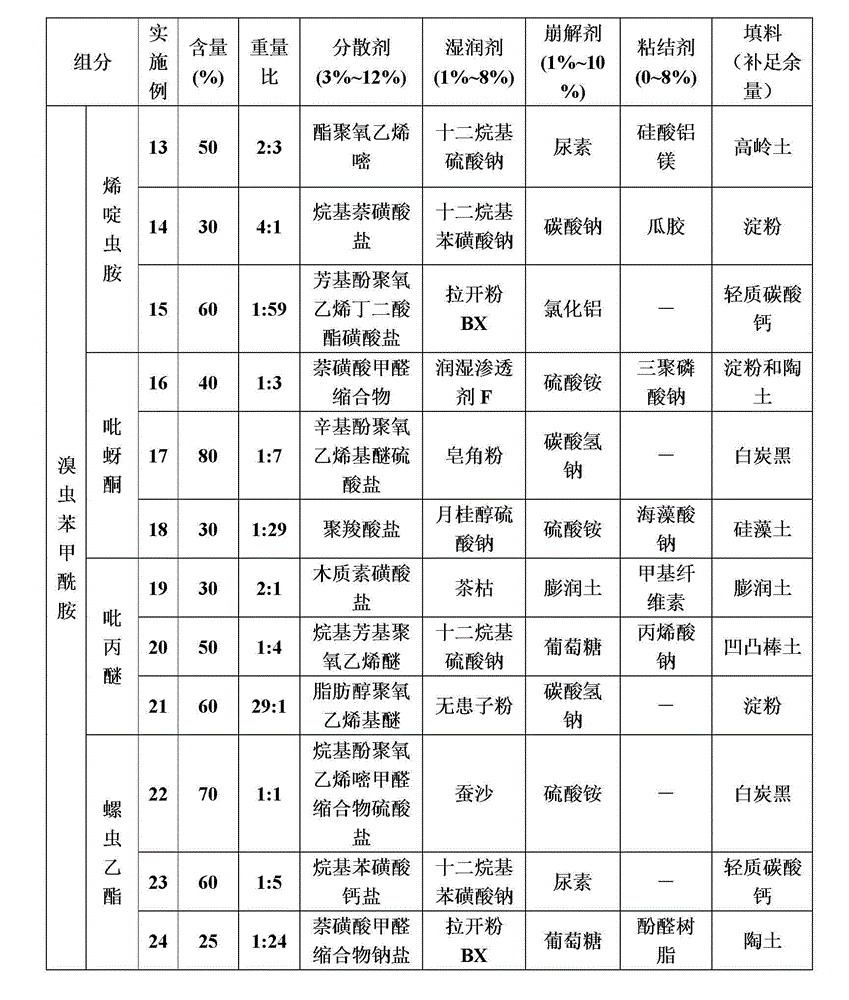

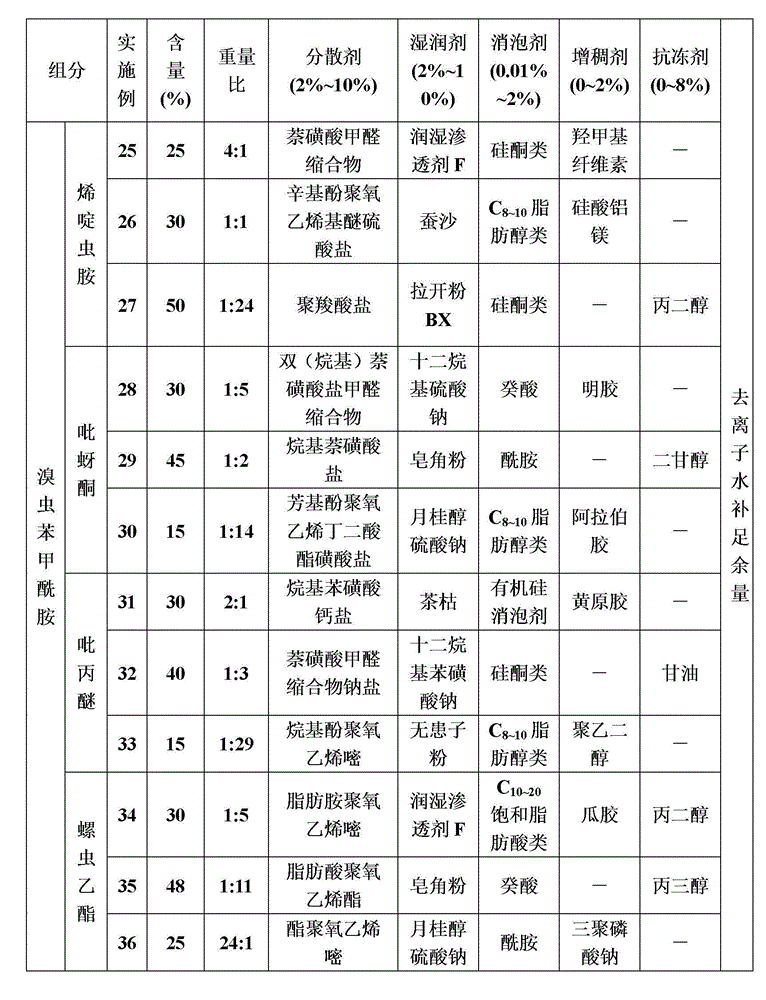

Insecticide composition containing SYP9080

InactiveCN103931630AReduced use of pesticidesReduce residueBiocideAnimal repellantsLivestockBuprofezin

The invention discloses an insecticide composition containing SYP9080. The insecticide composition containing SYP9080 comprises active ingredients A and active ingredients B, wherein the active ingredients A are selected from the SYP9080, the active ingredients B are selected from any one of the following compounds: buprofezin, spirotetramat, pymetrozine, chlorfenapyr, dicyclanil, ethiprole and pyriproxyfen, and in addition, the weight ratio of the active ingredients A to the active ingredients B is 1: 80 to 60:1. The insecticide composition has the advantages that a synergistic effect is realized on various pests harmful to agricultural production, the pesticide consumption is reduced, the residue quantity of pesticides on crops is reduced, the environment pollution is reduced, the insecticide composition is safe to people and livestock, the environmental compatibility is good, and the pests cannot easily generate insecticide resistance.

Owner:陕西汤普森生物科技有限公司

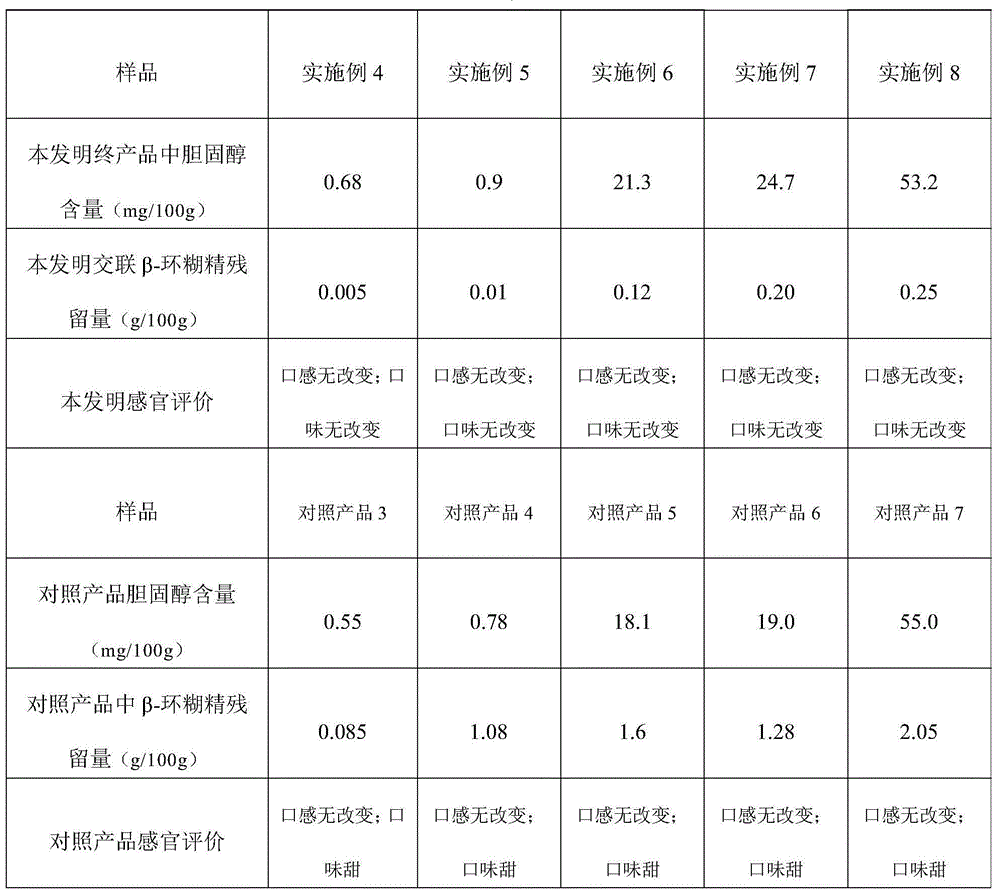

Low cholesterol dairy product and crosslinked beta-cyclodextrin, preparation method and application thereof

The invention discloses a low cholesterol dairy product and its preparation method, crosslinked beta-cyclodextrin, its preparation method and application. The preparation method of the crosslinked beta-cyclodextrin comprises the steps of: subjecting a swelled aqueous solution of beta-cyclodextrin and beta-cyclodextrin to crosslinking reaction under a pH value of 9.8-10.2 and the action of the crosslinking agent adipic acid at room temperature. Specifically, the beta-cyclodextrin and the adipic acid are in a mass ratio of 20:1-15:1. Application of the crosslinked beta-cyclodextrin provided by the invention to removal of cholesterol from a dairy product can achieve a good effect, and the crosslinked beta-cyclodextrin has a small residue amount, has no sweet taste and does not influence the product taste. Also, the crosslinked beta-cyclodextrin can realize reutilization.

Owner:BRIGHT DAIRY & FOOD

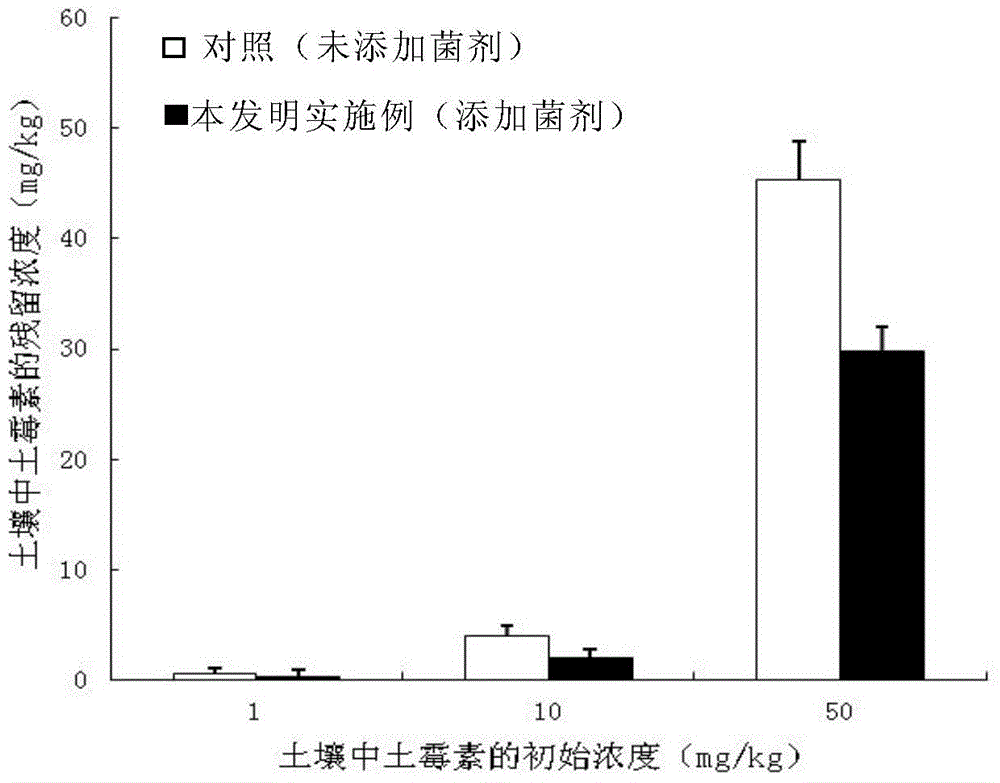

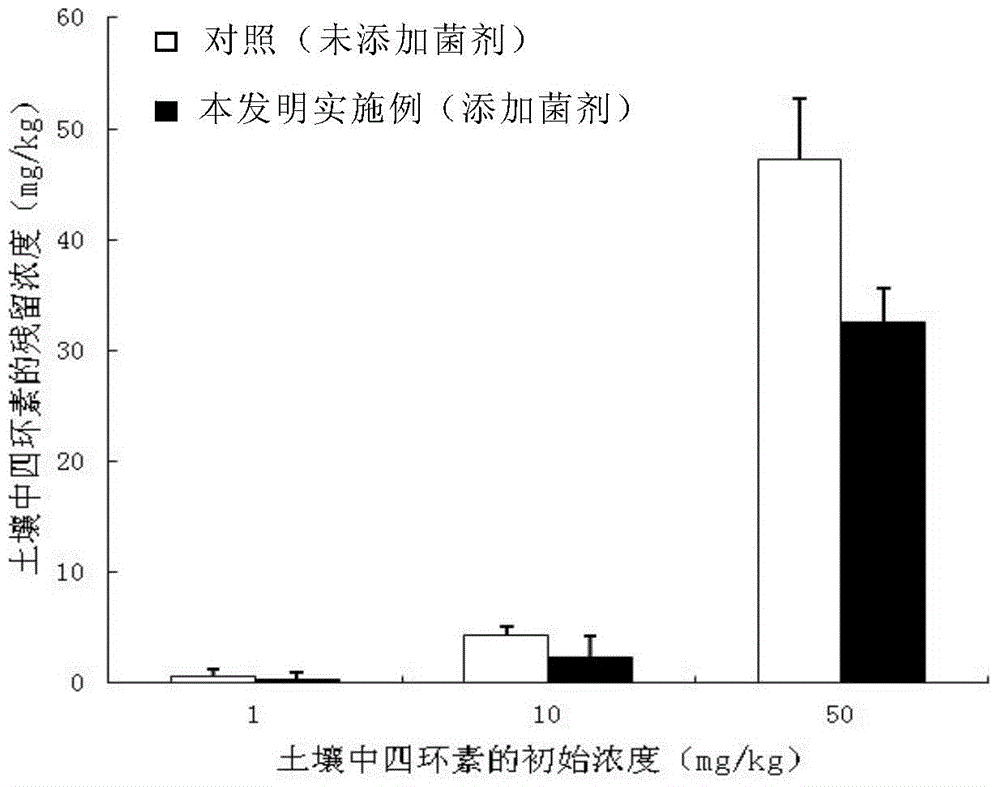

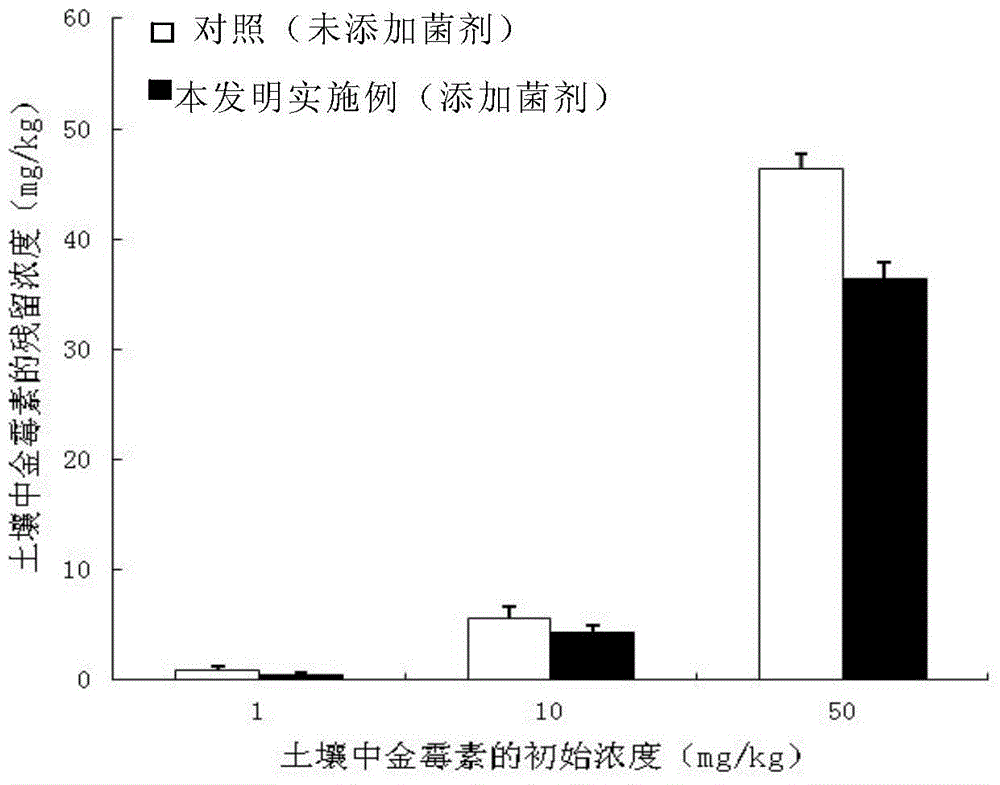

Mycorrhizal fungi inoculant and application of mycorrhizal fungi inoculant in degradation of residual tetracycline antibiotics

ActiveCN104099255AReduce residueExpand the rhizosphereFungiContaminated soil reclamationHigh concentrationCulture mediums

The invention discloses a mycorrhizal fungi inoculant and an application of the mycorrhizal fungi inoculant in degradation of residual tetracycline antibiotics. The inoculant comprises a culture medium and spores and / or mycelia of arbuscular mycorrhizal fungi mixed in the culture medium. The application of the mycorrhizal fungi inoculant in the degradation of the residual tetracycline antibiotics specially comprises the processes as follows: the mycorrhizal fungi inoculant is inoculated in soil polluted by the tetracycline antibiotics, and then a host plant is sowed in the soil, so that a soil remediation system polluted by the tetracycline antibiotics is established. The host plant is harvested after growing for 90-120 days, then the concentration of the tetracycline antibiotics in the soil is measured, and the degradation rate can reach 20%-60%. The method provides the basis for arbuscular mycorrhizal fungi used for degradation of high-concentration tetracycline antibiotics residues in the soil.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

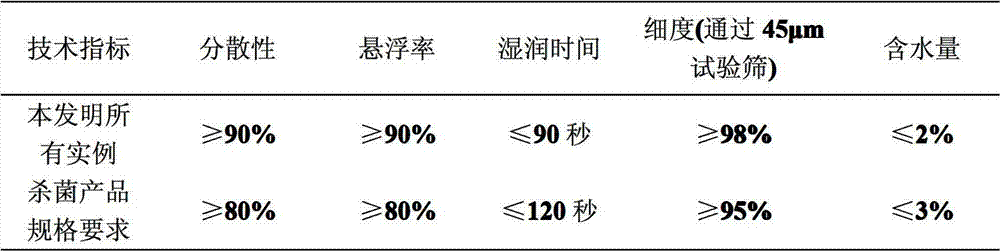

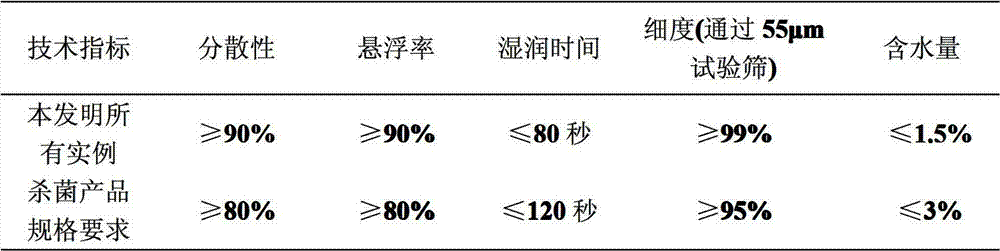

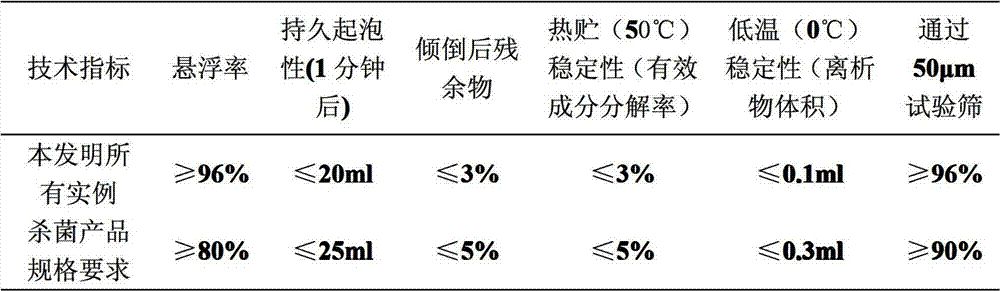

Germicidal composition containing bromothalonil and copper preparation

The invention discloses a germicidal composition containing bromothalonil and copper preparation. The composition comprises an active component A bromothalonil and an active component B selected from any of the following copper preparations: copper 8-hydroxyquinolinate, Cupravit, copper(succinate+glutarate+adipate) and cupric acetate, wherein the weight ratio of the component A and component B ratio is 1:80-80:1. The composition provided by the invention has synergism on a plurality of insects harming agricultural production, reduces drug dose of pesticide, reduces residual quantity of pesticide on crops, mitigates environmental pollution, is safe for human and livestock, has good compatibility and does not cause resistance on insects.

Owner:陕西汤普森生物科技有限公司

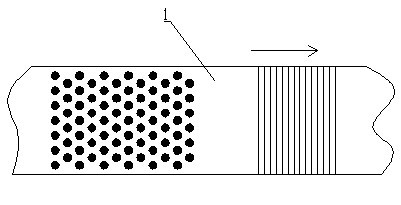

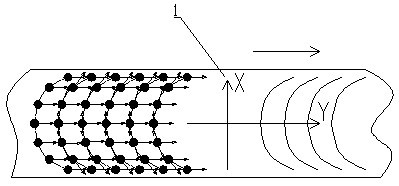

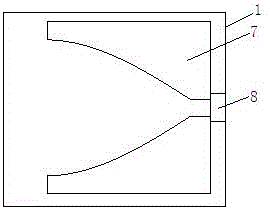

Uniform cooling device for steel plates with curved water outlets

InactiveCN102284521AReduce residueImprove cooling effectWork treatment devicesMetal rolling arrangementsSteel platesSheet steel

The invention discloses a steel plate uniform-cooling device with water outlets arranged in a shape of curve, which comprises an upper header device. A plurality of lines of water outlets which have a jetting direction vertical with the direction of a steel plate and a jetting range which covers the width of the steel plate are arranged on the upper header device; the plurality of the lines of the water outlets are arranged in parallel in a convey direction of the steel plate; projections of the water outlets on the steel plate are arranged in the shape of curve; an opening direction of the curve is as same as the convey direction of the steel plate. The manner of the water outlets of an upper header is changed from a linear manner to a curve manner, so that used cooling water absorbing acertain amount of heat fast departs the upper surface of the steel plate along a tangential direction of a back line of cooling water wall. Therefore, the residue of the cooling water on the edges isreduced; meanwhile, the device provided by the invention improves longitudinal and transverse cooling effects of the steel plate due to being good for more complete contact between fresh cooling water in the back line and the steel plate. The device provided by the invention has advantages of high transverse cooling uniformity, fast longitudinal cooling speed and less water consumption.

Owner:CISDI ENG CO LTD

Composition containing benzovindiflupyr

The invention discloses a composition containing benzovindiflupyr. The sterilizing composition contains an active component A and an active component B, wherein benzovindiflupyr is adopted as the active component A, the active component B is selected from any one of the following compounds comprising tetraconazole and prothioconazole, and the weight ratio of the active component A to the active component B is 1:80-80:1. The composition has the synergistic effect on multiple diseases harmful to agricultural production, the pesticide dosage is decreased, the residual quantity of pesticides on crops is decreased, environmental pollution is reduced, the composition is safe to people and livestock, the environmental compatibility is good, and the pesticide resistance of the diseases is not easy to be developed.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

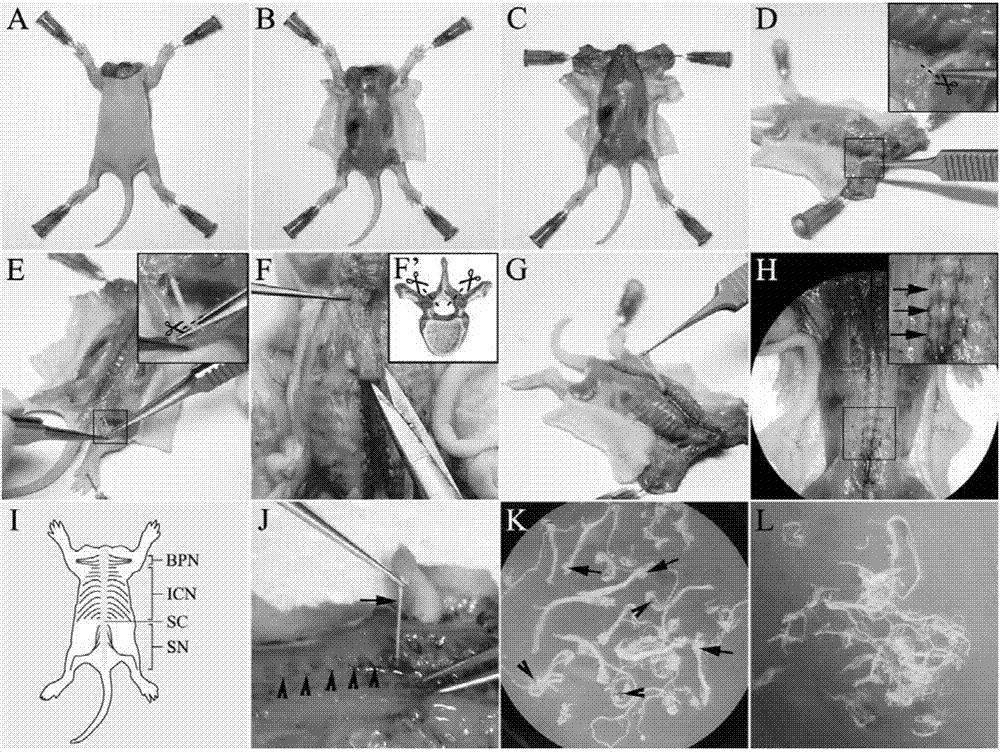

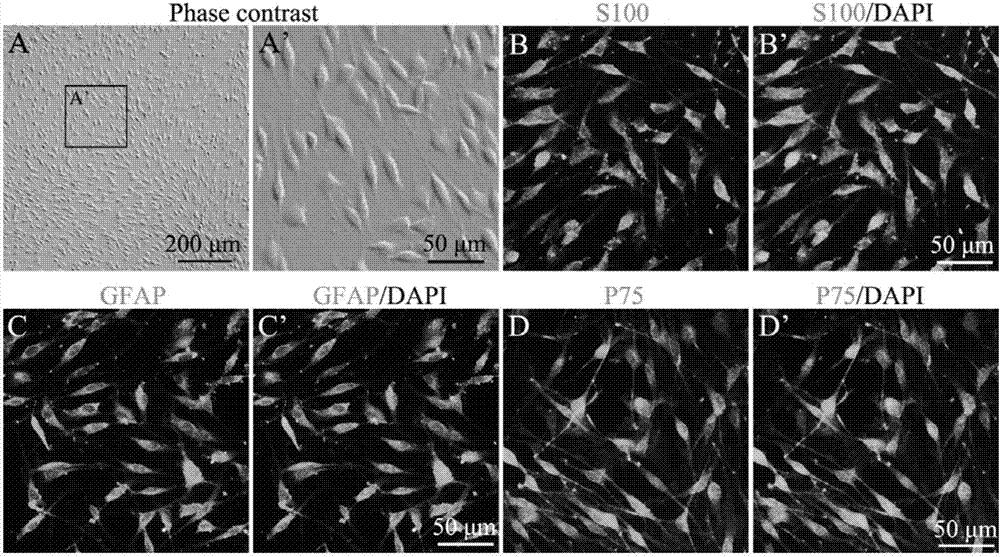

Schwann cell extraction, purification and culture method

ActiveCN107502593AReduce residueResidue reductionCell dissociation methodsNervous system cellsPeripheral nerveIntercostal nerves

The invention discloses Schwann cell extraction, purification and culture method which comprises the following steps: cutting off brachial plexus and ischiadic nerve, further removing spinal cord, and extracting peripheral nerve from different foramen intervertebrales; digesting the peripheral nerve so as to obtain a single-cell suspension; and performing amplification culture, thereby obtaining Schwann cells. By adopting the method disclosed by the invention, the nerve extracted from the foramen intervertebrales is free of epineuria and is low in fibroblast residue. According to the method, the peripheral nerve (including the brachial plexus, the intercostal nerve and the ischiadic nerve) is extracted from the foramen intervertebrales, a nerve amount which is 6-8 times of that of a conventional method is obtained, the residue of fibroblast is remarkably reduced, and thus culture and amplification of the Schwann cells are facilitated.

Owner:SOUTHERN MEDICAL UNIVERSITY

Novel shell calcium oxide produced by microwave

InactiveCN104760981AReduce residueEffectively remove pesticide residues on the surfaceChemical industryCalcium/strontium/barium oxides/hydroxidesCooking & bakingMicrowave

The invention discloses a novel shell calcium oxide produced by microwave. The raw materials of the shell calcium oxide are one or more of an oyster shell, a scallo, a pearly shell or a fan shell. The production method comprises the following steps: adding sand and water into the shell raw material in arbitrary proportion, mixing and performing abrasive cleaning, drying and smashing till the grain diameter of 0.5-3cm; and performing microwave drying through three stages, wherein the microwave intensities are in turn 100 kilowatt, 200 kilowatt and 250 kilowatt, the microwave temperatures are in turn 600 DEG C, 1200 DEG C and 1400 DEG C, and the baking times are in turn 1h, 3h and 2h; performing high micro-grinding on the dried materials till the grain diameter is 4-30 um to obtain the product. The novel microwave produced shell calcium oxide is simple in manufacture process, environmentally friendly and energy-saving, short in burning time, high in production efficiency, high in product purity and good in quality, avoids the contact with the other fuels such as coal, reduces the residues of the heavy metal and the sulfide in the product, is widely used for food adding and subsidiary agricultural product washing, and can effectively remove the pesticide residue on the surface of the subsidiary agricultural product.

Owner:赵扬合

Pesticide composition containing fluoride ether bacterium amide

The invention discloses a pesticide composition containing fluoride ether bacterium amide. The pesticide composition comprises an active ingredient A and an active ingredient B, wherein the active ingredient A is fluoride ether bacterium amide; the active ingredient B is selected from any one of the following compounds: propineb, metiram, mancozeb, zineb or zinc thiazole; the weight ratio of the active ingredient A to the active ingredient B is (1 to 80)-(80 to 1). The composition has synergistic effects on various diseases harming agricultural production, conduces to reducing the pesticide consumption, reducing the residual quantities of pesticides on crops and reducing environmental pollution, is safe to human and livestock, has good environmental compatibility, and enables the diseases not to have drug resistance easily.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

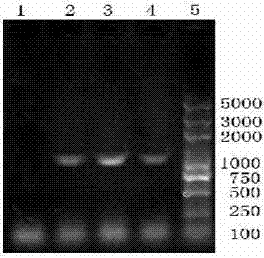

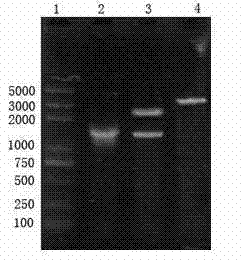

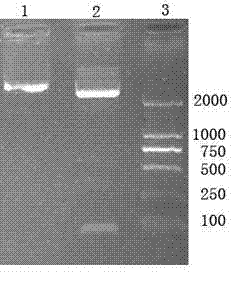

Neutral phytase transgenic recombinant lactobacillus and product and application thereof

InactiveCN102337242APromote metabolismReduce residueBacteriaMicroorganism based processesChemistryMultiple cloning site

The invention relates to a neutral phytase transgenic recombinant lactobacillus and a product and application thereof. Neutral phytase genes in AY220075 Bacillus subtilis with lactobacillus signal peptides are integrated in a genome, and an amplified sequence is a 1-1152bp basic group; signal peptide genes are 260-349th site basic groups of Z14250; and the neutral phytase genes and the signal peptide genes are inserted into multiple cloning sites after being connected and are integrated into ribosome binding sites of Lactobacillus casei L.CECT5276. The neutral phytase transgenic recombinant lactobacillus provided by the invention can be used as a feed additive for pig husbandry, can make up the defect that the intestinal tract of a pig cannot secrete phytase, can promote the metabolism of phytate phosphorus in a feedstuff raw material and reduce discharge of inorganic phosphorus, which are favorable for the protection of the environment. A host bacteria lactobacillus also has beneficial function to animal bodies, and has important application value in production of pig, poultry and other monogastric animals.

Owner:HENAN UNIV OF SCI & TECH

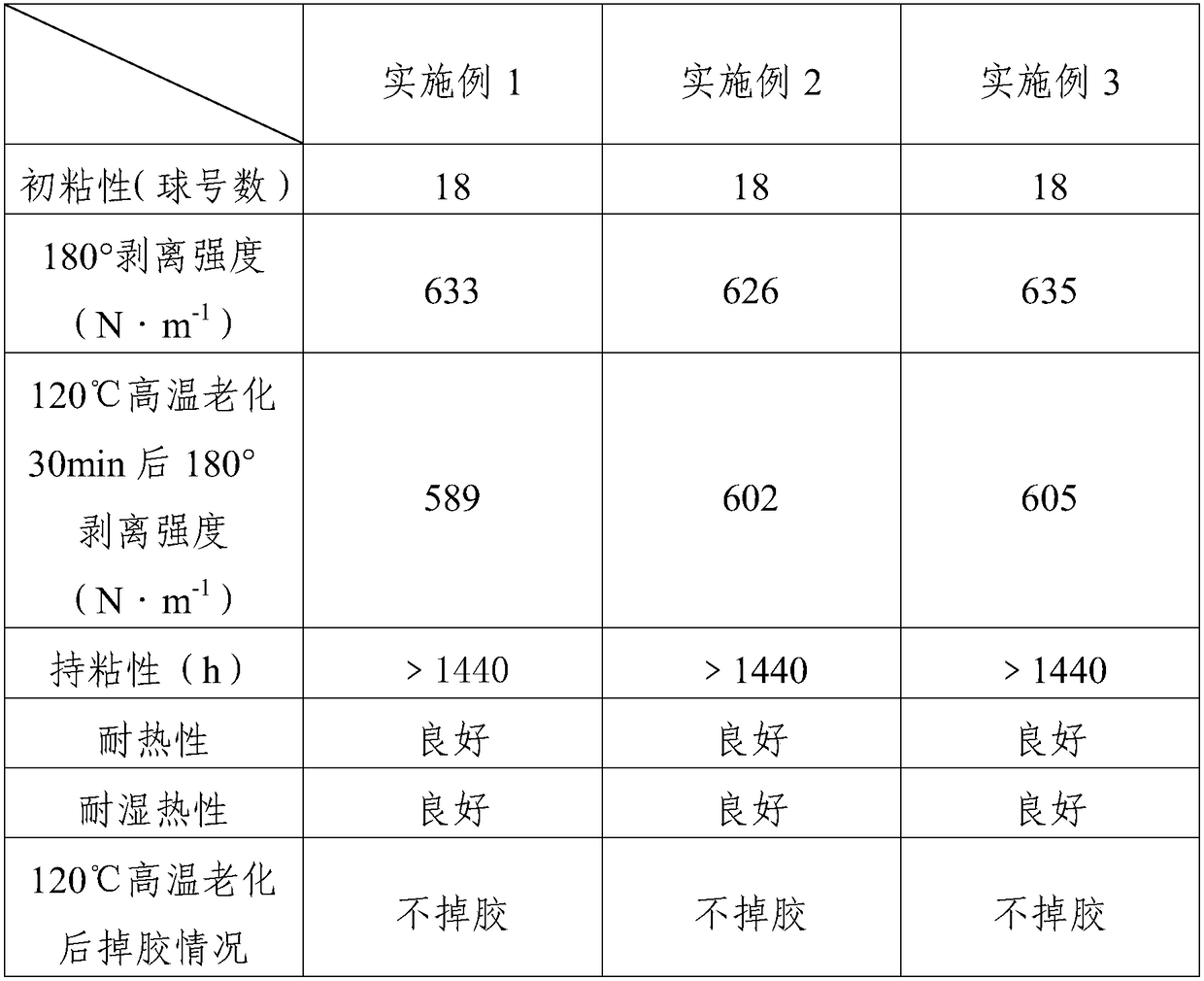

Production process of label sticker which is resistant to high temperature and high in viscosity

ActiveCN109228536AReduce residueImprove wetting performancePaper/cardboard articlesPressure sensitiveEmulsion

The invention provides a production process of a label sticker which is resistant to high temperature and high in viscosity and relates to the technical field of label stickers. The production processincludes the following steps of (1) preparing activated polyether polyol; (2) preparing a polyurethane emulsion, adding the polyurethane emulsion, isobutyl acrylate, modified nanometer silicon dioxide, a crosslinking agent and azodiisobutyronitrile into a reaction still, and raising the temperature to 80-85 DEG C for a reaction for 5-8 hours to obtain a copolymer, namely an emulsion-type pressure-sensitive adhesive; (3) on a coating machine, utilizing a coating cutter to uniformly coating the back of copperplate surface paper with the copolymer, namely the emulsion-type pressure-sensitive adhesive, bonding the copperplate surface paper to Glassine backing paper to obtain a label sticker semi-finished product, making the label stick semi-finished product pass through a drying channel whichis 80-120 cm long at the speed of 20-30 cm / min under the temperature of 70-75 DEG C, and then obtaining a label sticker finished product, wherein the thickness of an adhesive film is 0.04-0.15 mm. The label sticker applying the copolymer, namely the emulsion-type pressure-sensitive adhesive, is resistant to high temperature, high in viscosity, resistant to a damp and hot environment and long in bonding time.

Owner:杭州大唐印刷有限公司

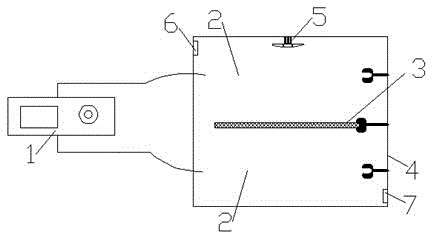

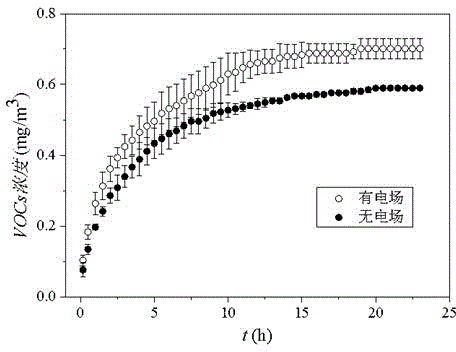

Novel removal device for VOCs in building boards

The invention discloses a novel removal device for VOCs in building boards. The removal device comprises a direct-current high-voltage power source, plate electrodes, a VOCs treatment chamber and a fan. The plate electrodes are a pair of electrodes in parallel and are arranged inside the VOCs treatment chamber, the fan is fixed to the top end inside the VOCs treatment chamber, and an air inlet is further formed in the top of the VOCs treatment chamber. An exhaust port is formed in the bottom of the VOCs treatment chamber, a feeding port is formed in the side face of the VOCs treatment chamber and directly faces the part between the pair of electrodes in parallel, the direct-current high-voltage power source generates a stable electric field, voltage strength is 40 kV / m-80 kV / m, and the two electrodes of the direct-current high-voltage power source are connected with the pair of electrodes respectively. Through increasing the quantity of released VOCs in the boards, the quantity of residual VOCs in the boards is smaller, and the boards are environmentally friendlier and safer. The novel removal device has the advantages of being simple in structure, low in cost, convenient to operate, high in efficiency and the like.

Owner:SOUTHEAST UNIV

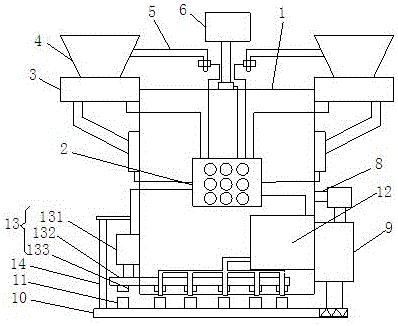

Blending and feeding device for processing and production of feeds

The invention discloses a blending and feeding device for processing and production of feeds. The blending and feeding device comprises a blending box, wherein a controller is arranged on the front surface of the blending box and is electrically connected with weighing sensors located on the side surface of the blending box, the weighing sensors are arranged at the bottom ends of weighing hoppers, and the weighing hoppers are respectively arranged on top ends of the left and right sides of blending box; a measuring cylinder located on the top end of the blending box is connected to one end, far from the weighing hoppers, of a screw feeder; paddles are arranged in the blending box and are arranged at one end of a rotating shaft, an upper output shaft of a double-shaft motor is connected to the other end of the rotating shaft through a universal coupling, and the double-shaft motor is arranged on the right side surface of the blending box; and a lower output shaft of the double-shaft motor is in transmission connection with a conveying device, and a containing cylinder is arranged on the conveying device. The blending and feeding device meets the requirements of increasing the blending uniformity, reducing the residual quantity and shortening the blending time.

Owner:WUXI FUMEI LIGHT ALLOY TECH

Method for processing Chinese yam by low-sulfur fumigation combined with salt grilling

ActiveCN102524361AReduce residueGuarantee the quality of medicinal materialsFruits/vegetable preservation by dehydrationSulfur dioxideSalt solution

The invention relates to a method for processing medicinal Chinese yam by low-sulfur fumigation combined with salt grilling, which is characterized in that the method comprises the following steps: fumigating peeled Chinese yam in a fumigating box, infiltrating the fumigated peeled Chinese yam in salt solution. The method of the invention can effectively reduce the amount of residual sulfur dioxide in Chinese yam, and ensures the quality of medicinal materials. Through the method, Chinese yam is easy in dehydration and drying, has white color and beautiful appearance, and is convenient for long-term preservation.

Owner:瑞金市工业投资发展有限公司

Bactericidal composition containing giant knotweed extract and ZJ0712 or pyraoxystrobin

The invention discloses a bactericidal composition containing giant knotweed extract and ZJ0712 or pyraoxystrobin. The bactericidal composition comprises an active component A and an active component B, wherein the active component A is giant knotweed extract, the active component B is any compound selected from the group consisting of ZJ0712 and pyraoxystrobin, and a weight ratio of the active component A to the active component B is 1: 80 to 60: 1. The bactericidal composition provided by the invention exerts a synergistic effect on a plurality of diseases harming agricultural production, reduces the dosage of pesticides, decreases the residual quantity of pesticides on crops, mitigates environmental pollution, is safe to human beings and livestock, has good environmental compatibility and enables diseases not to easily generate resistance.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

Insecticidal composition containing propylene glycol alginate and carbamates

The invention discloses an insecticidal composition containing propylene glycol alginate and carbamates, in particular to an insecticidal composition comprising an active component A and an active component B. The active component A is selected from the propylene glycol alginate, the active component B is selected from one of the following compounds: isoprocarb, tsumacide, indoxacarb, carbaryl, methomyl and fenobucarb, and the weight ratio of the active component A to the active component B is 1: 80 to 40: 1. The composition has synergism on multiple injurious insects which are harmful to the agricultural production, the consumption of farm chemicals can be reduced, the residue of the farm chemicals on crops can be reduced, the environmental pollution can be reduced, safety for the human beings and animals can be realized, the environmental compatibility is good, and the drug resistance of the injurious insect is difficult to generate.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

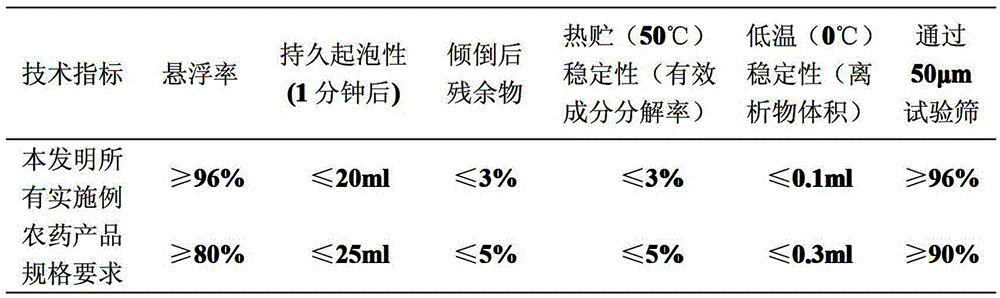

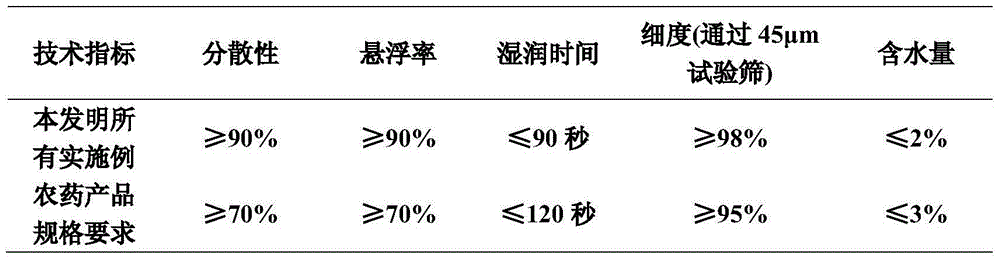

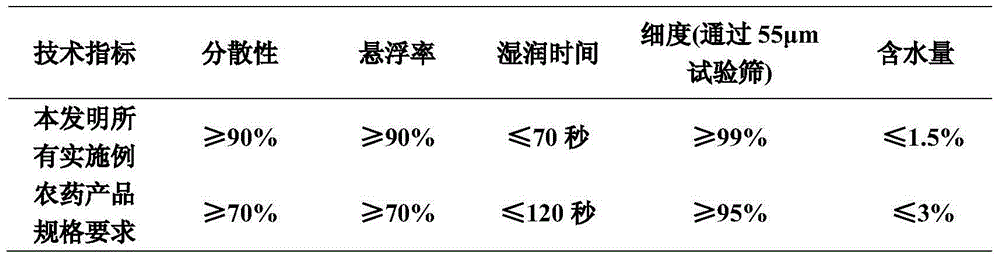

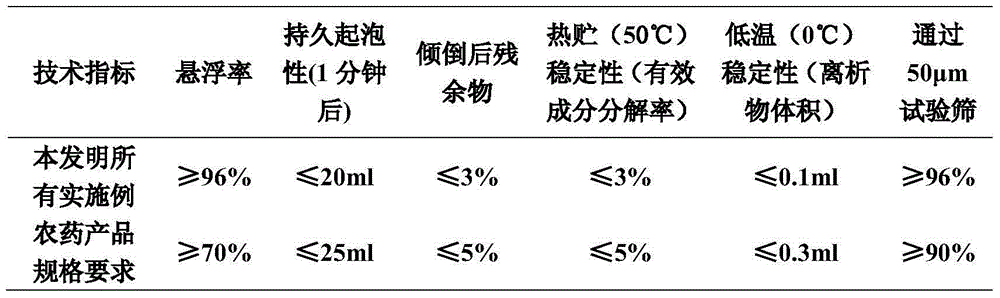

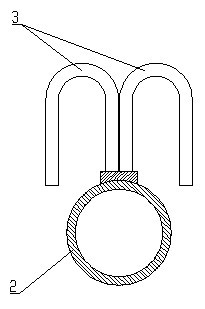

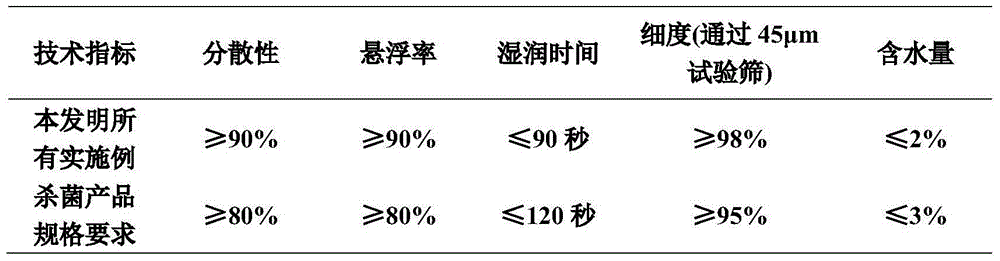

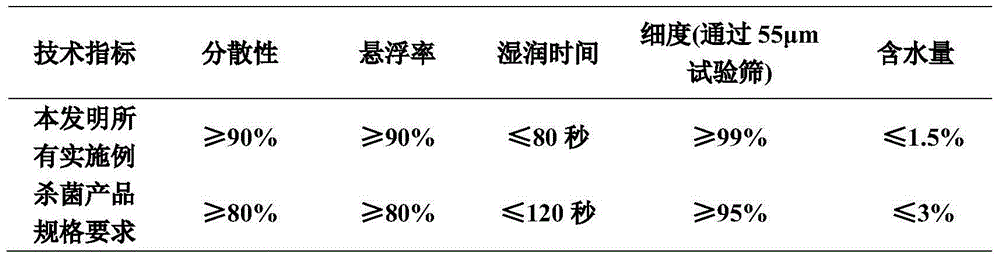

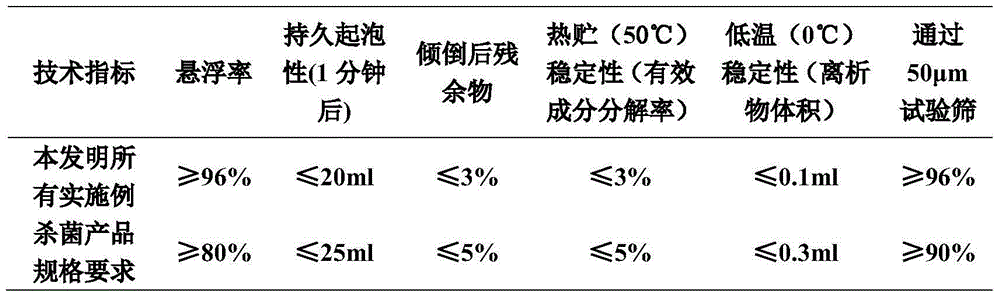

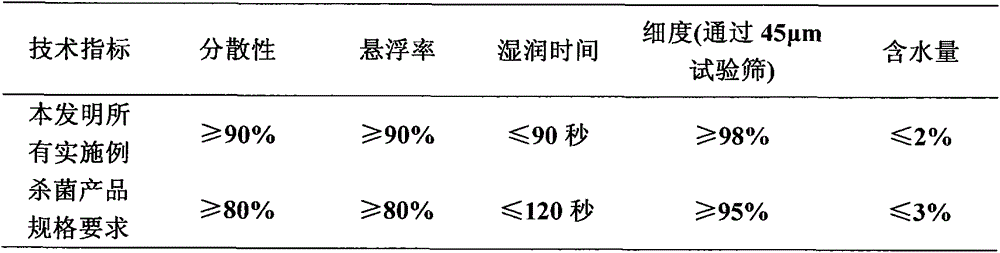

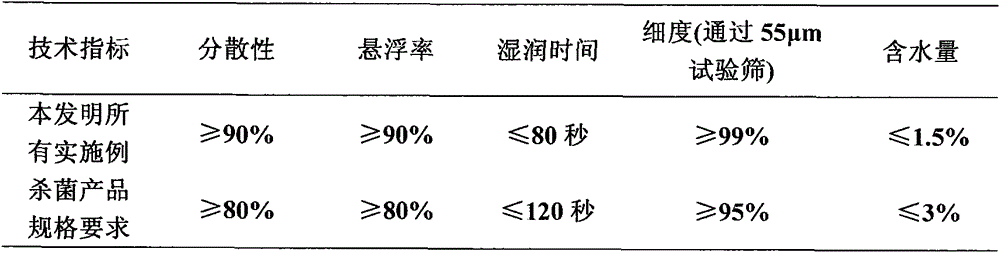

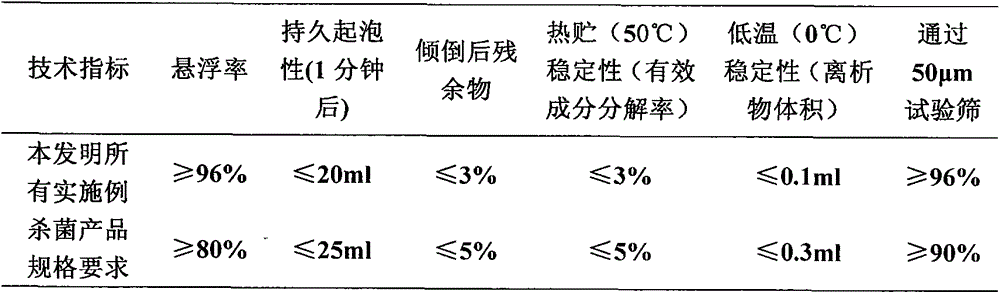

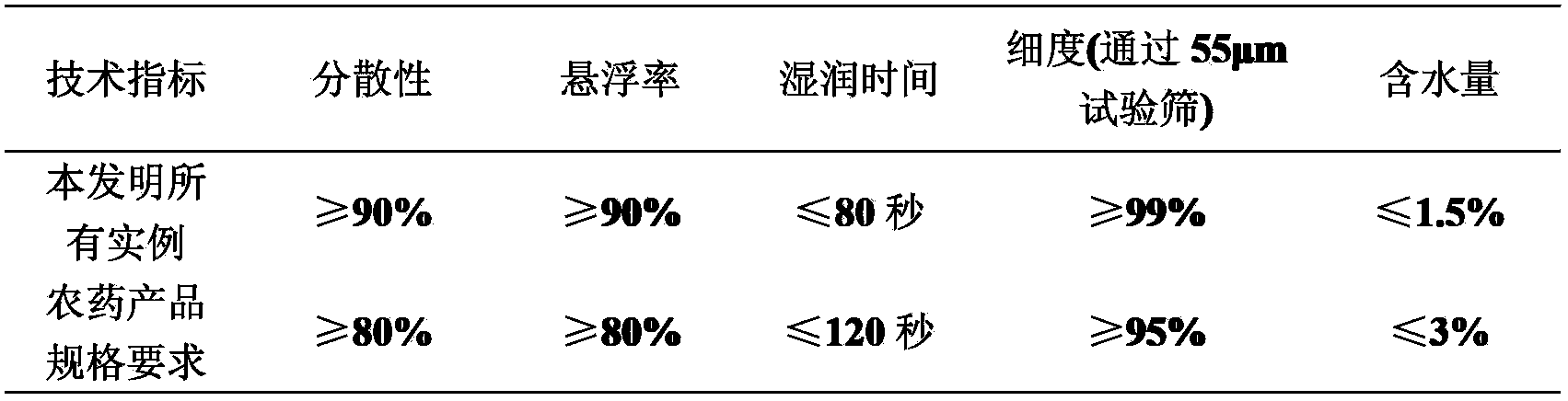

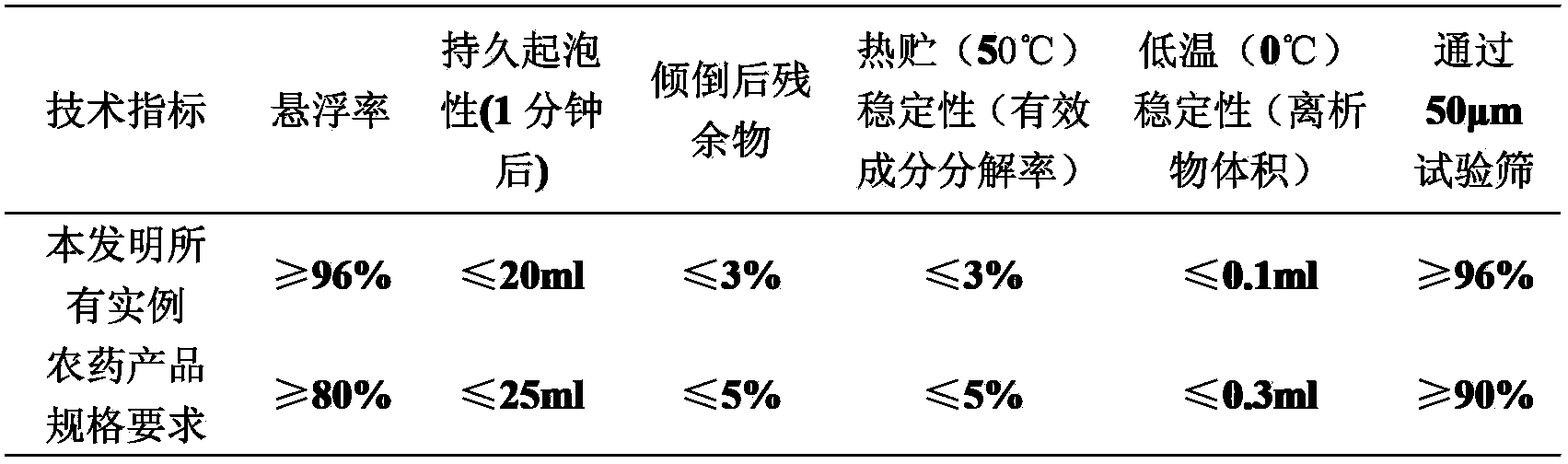

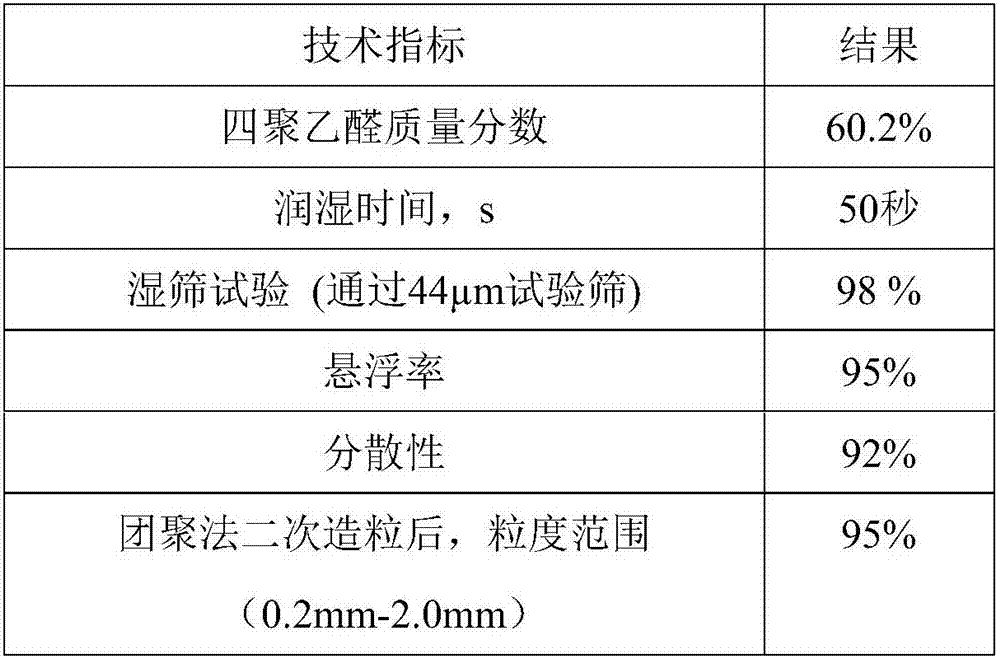

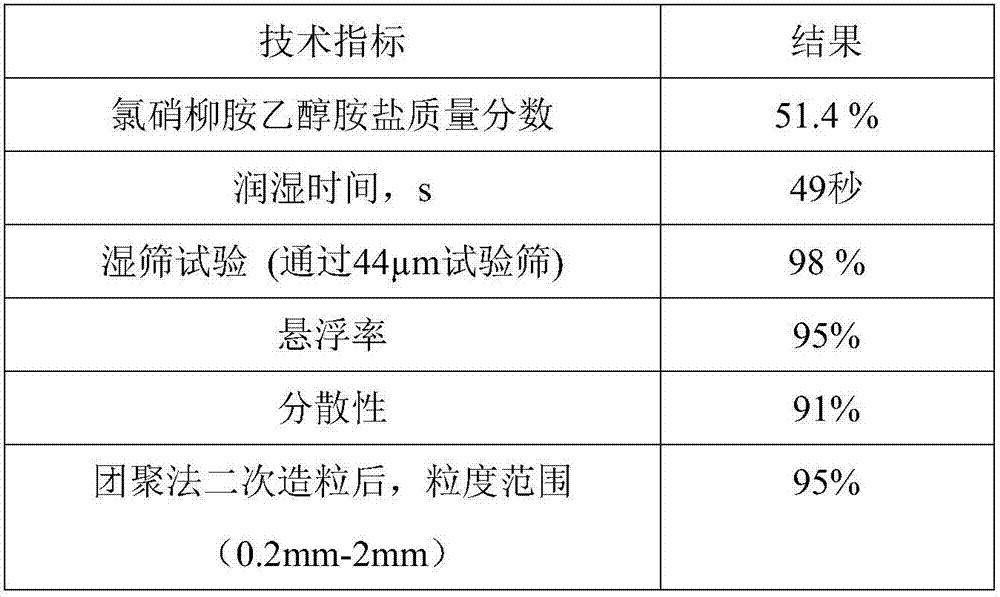

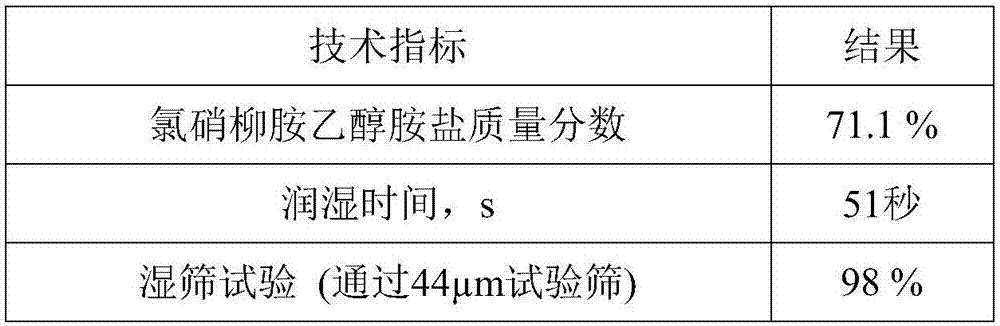

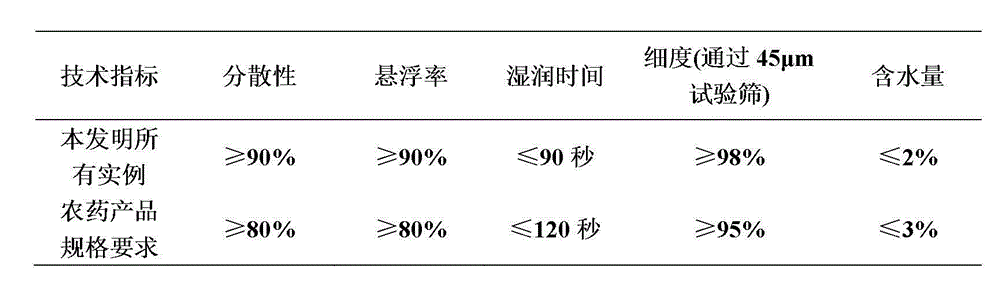

Water dispersible granule for prevention and control of molluscs and preparation method of water dispersible granule

ActiveCN107006459AGood killing effectReduce governance costsBiocideMolluscicidesDispersityWater dispersible

The invention discloses a water dispersible granule for prevention and control of molluscs and a preparation method of the water dispersible granule. The water dispersible granule comprises the following ingredients by mass percentage: 0-85% of metaldehyde, 0-85% of niclosamide ethanolamine salt, 1-3% of wetting agent, 5-20% of emulsification dispersant, 0-5% of disintegrating agent, 0-10% of binding agent, 0.5% of defoaming agent, and a carrier to reach 100%, wherein the mass percentage of metaldehyde and the mass percentage of niclosamide ethanolamine salt cannot be 0% at the same time. The water dispersible granule is convenient to transport, lower in transportation cost, high in active ingredient content, good in dispersity, high in suspensibility and higher in storage stability; no dust is generated basically in a production process; the environmental control cost is low; the water dispersible granule is sprayed for application after the water dispersible granule is diluted with water; the residue of the water dispersible granule in an environment is reduced; the possibility of spray head blocking is low; no dust drift exists during use; the influence on an operator and the surrounding environment is smaller; and the possibility of hazards and environmental pollution is low.

Owner:广东农密生物科技有限公司

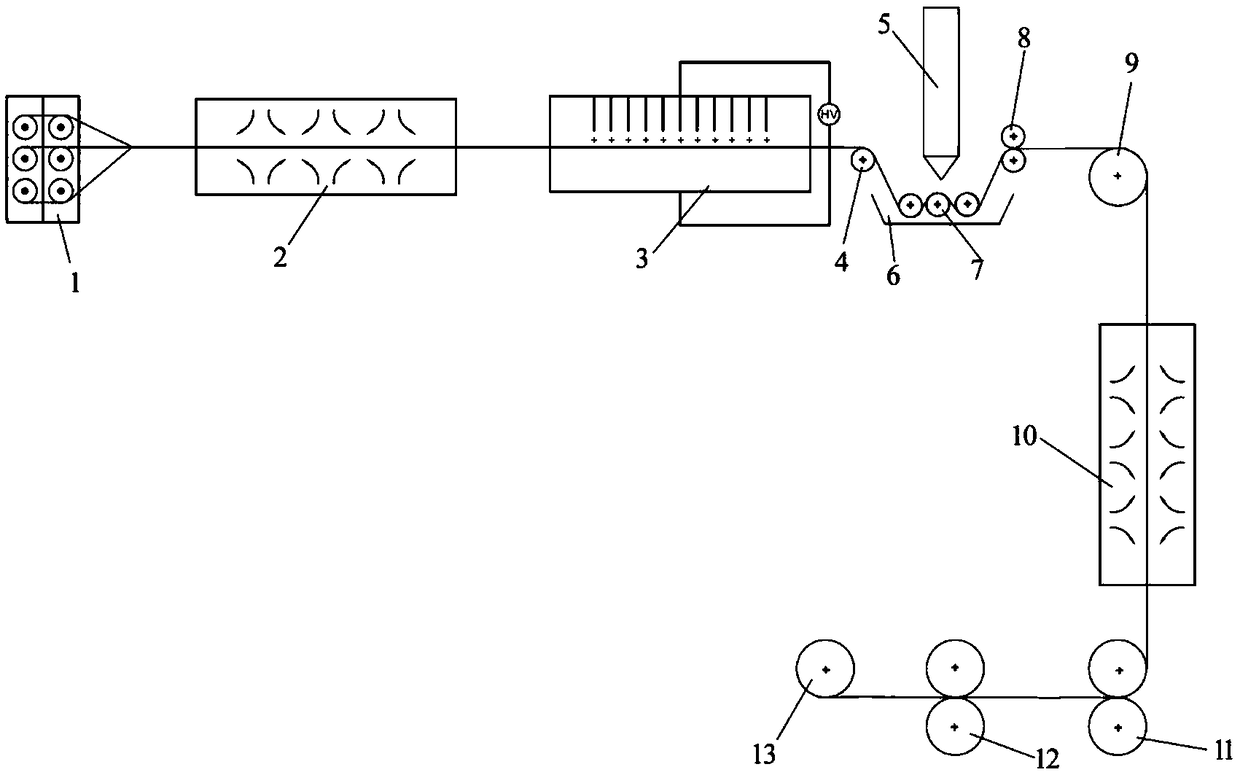

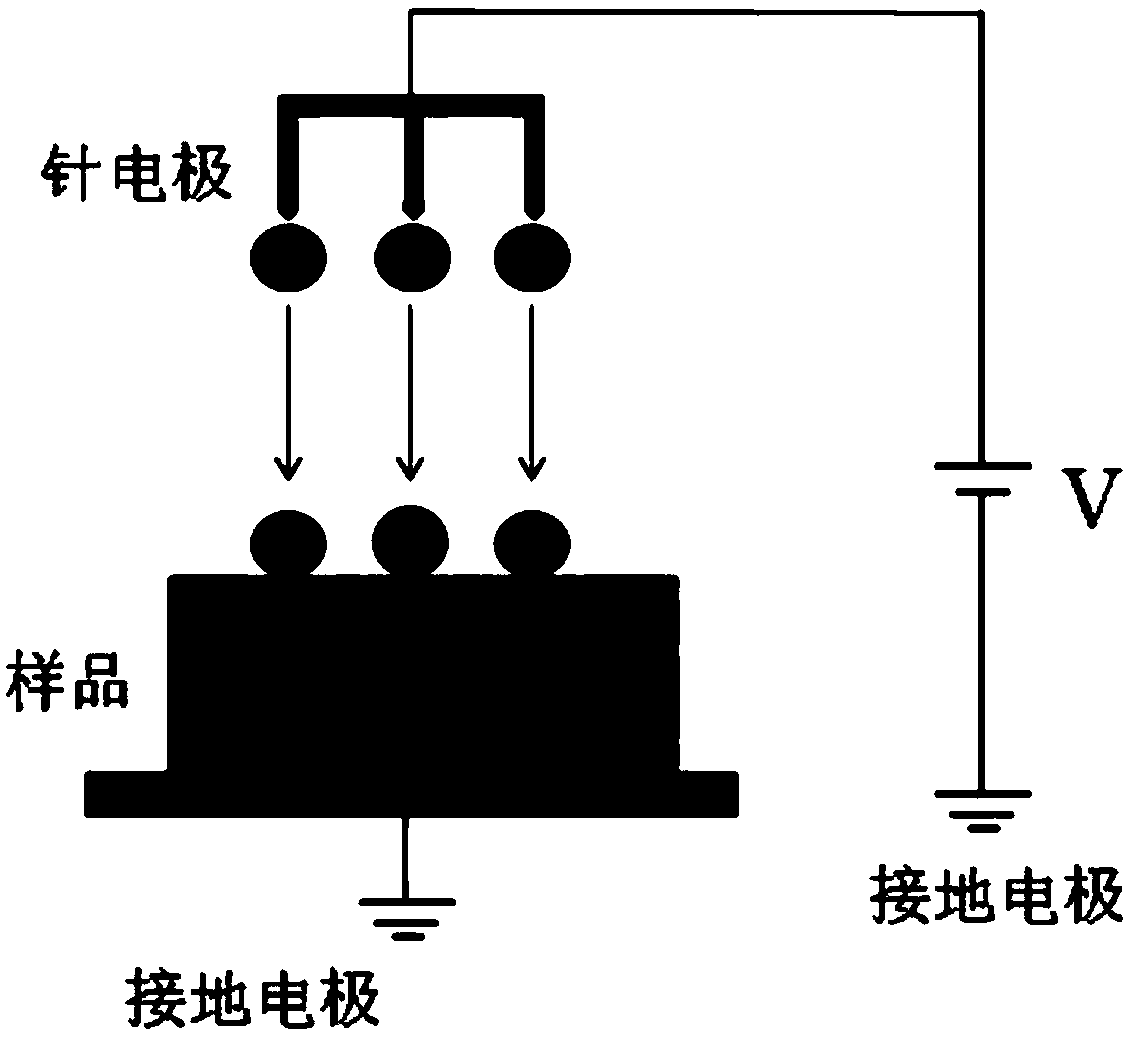

Preparation method of basalt fiber fabric reinforced nylon 6 prepreg composite material

The invention provides a preparation method of a basalt fiber fabric reinforced nylon 6 prepreg composite material. The preparation method of the basalt fiber fabric reinforced nylon 6 prepreg composite material comprises the following steps: 1) dividing a caprolactam melt into two portions with equal weights, and separately storing the two portions in a liquid charging device A and a liquid charging device B; and adding a caprolactam anionic polymerization catalyst in the liquid feeding device A and mixing uniformly, adding a caprolactam anionic polymerization co-catalyst in the liquid feeding device B and mixing uniformly, adding the mixture in the liquid charging device A and the mixture in the liquid charging device B in a double-screw extruder, uniformly mixing the mixtures by the double-screw extruder and extruding mixed melt into an impregnating tank; 2) dragging a basalt fiber fabric into a corona charging device, charging and then feeding the basalt fiber fabric into the impregnating tank; and 3) heating the basalt fiber fabric treated in step 2), triggering caprolactam anionic polymerization reaction, rolling and cooling. The basalt fiber fabric can be fully impregnated by the caprolactam melt so as to prepare the high-performance basalt fiber fabric reinforced nylon 6 prepreg composite material.

Owner:JIANGSU HARMONY & MIGHTY SCI & TECH DEV CO LTD

Pesticide composition containing chlorfenapyr benzamide

The invention discloses a pesticide composition containing chlorfenapyr benzamide, which is a pesticide composition containing an active ingredient A and an active ingredient B, wherein the active ingredient A is selected from chlorfenapyr benzamide; and the active ingredient B is selected from any one of the following compounds: nitenpyram, pymetrozine, pyriproxyfen and spirotetramat; and the weight ratio of the active ingredient A to the active ingredient B is 1:80 to 60:1. The composition has synergistic action on multiple pests harming agricultural production, reduces the pesticide dosage, reduces the residue of pesticide on crops, reduces environmental pollution, and is safe to human and livestock, good in environmental compatibility and not inclined to generation of pesticide resistance to pests.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

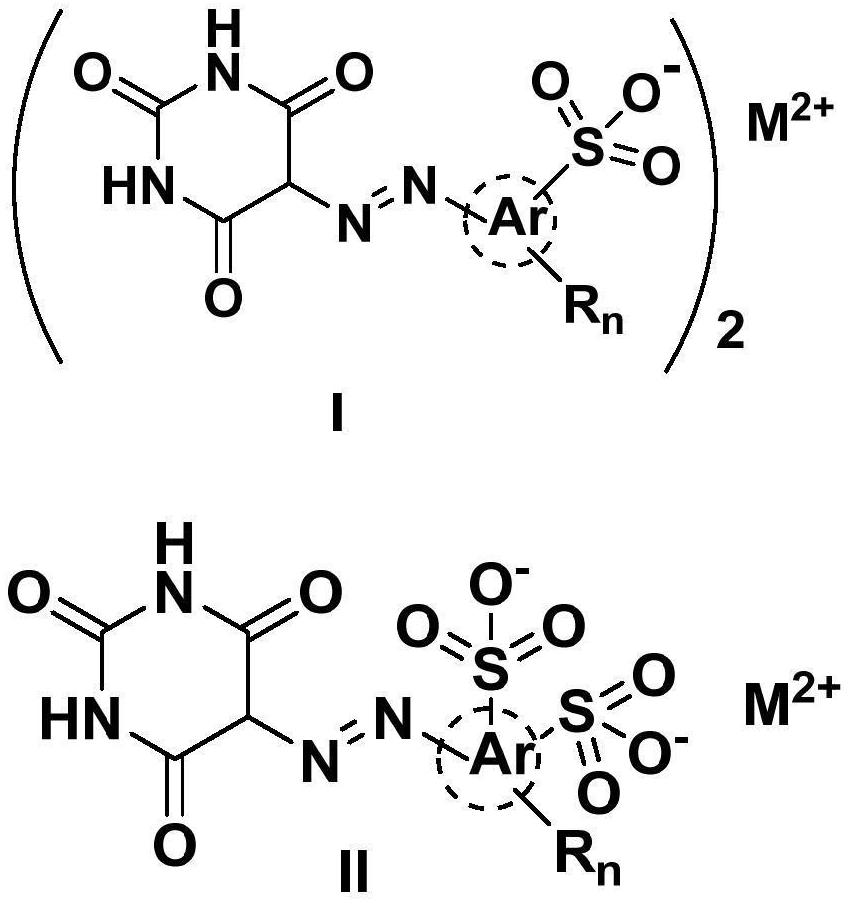

Monoazo lake pigment and preparation method thereof

ActiveCN112322073AReduce residueReduce governance difficulty and economic costsMonoazo dyesOrganic chemistryEnvironmental chemistryLake pigment

The invention discloses a monoazo lake pigment. The structural general formula of the monoazo lake pigment is one of the structures described in the description: M is one of Ca, Ba and Sr; R is H, OH,NO2, Cl, Br or C1 to C4 alkyl, and n is a positive integer from 1 to 3; and Ar is described in the description. According to the preparation method of the monoazo lake pigment, sodium chloride or sodium hydrogen sulfate / sodium sulfate can be prevented from being generated in the process of preparing the aromatic primary amine diazonium salt. Meanwhile, in the coupling reaction process, alkali containing a sodium element is not adopted, generation of inorganic sodium salt can be avoided in the manufacturing process of the monoazo lake pigment, and conditions are provided for clean treatment and comprehensive utilization of coupling reaction liquid.

Owner:瑞素士化学(上海)有限公司

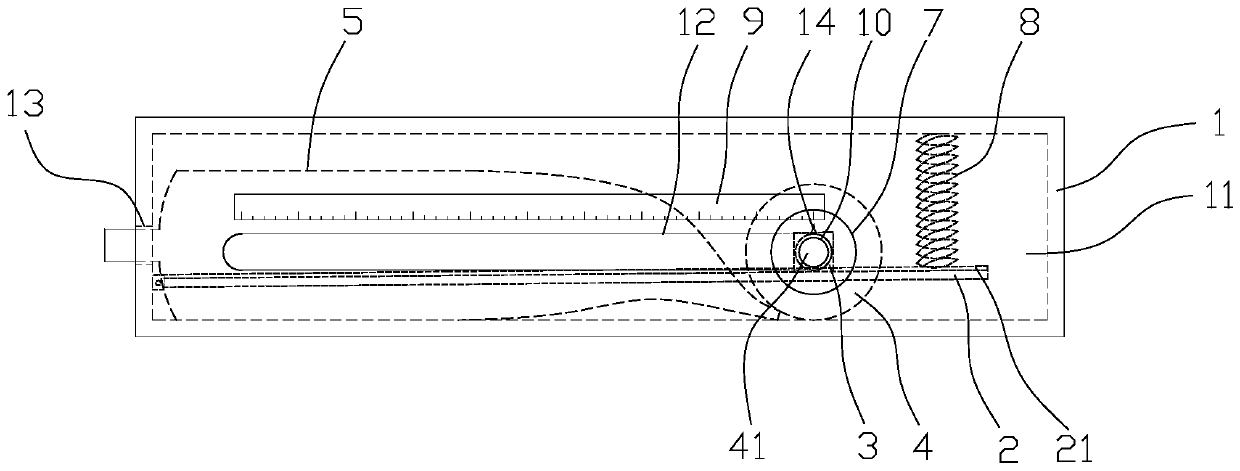

Toothpaste box

ActiveCN109775117AReduce residueReduce wasteFlexible containersPliable tubular containersToothpasteEngineering

The invention discloses a toothpaste box which is used for extruding toothpaste from a toothpaste shell. The toothpaste box comprises a shell, a support is installed in an inner cavity arranged in theshell, a sliding base is installed on a guide rail arranged on the support, a pressing roller is installed on the sliding base, one end of a roller shaft stretches out of a communication port formedin the side wall on one side and provided with a rotary knob, the front end of the support is hinged to the inner wall of the front end of the shell, a compressed spring is installed between the rearend of the support and the inner wall of the shell and used for compressing the rear end of the support, and the side wall of the front end of the shell is provided with an installation opening through which a port of the toothpaste shell stretches out. The toothpaste shell below the toothpaste box is extruded downwards and pushed forwards through the pressing roller which can roll forwards, therefore, toothpaste in the toothpaste shell is extruded from an outlet in the front end, the toothpaste shell is supported by the bottom face of an inner cavity of the shell and directly pushed downwardsthrough the pressing roller, the pressing roller can move downwards along with swing of the support to reduce the distance between the pressing roller and the bottom face of the inner cavity, therefore, the toothpaste box is applicable to toothpaste shells with different thicknesses and can extrude various toothpaste shells sufficiently, the residual amount of toothpaste is reduced, and toothpaste waste is reduced.

Owner:姜佳文

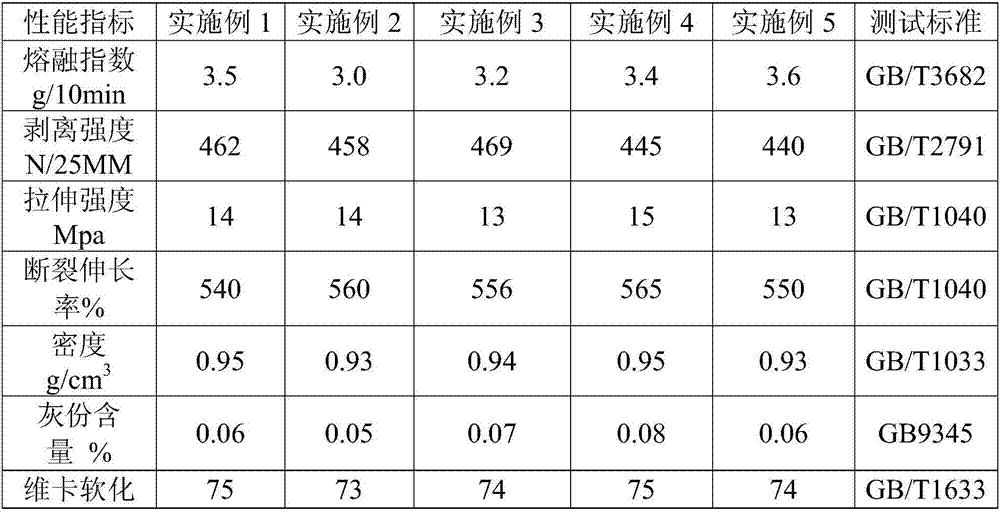

Special adhering resin for plastic-lined steel pipe and preparation method thereof

InactiveCN107118719AHigh grafting rate and grafting efficiencyReduce residueGraft polymer adhesivesAntioxidantGrafting

The invention discloses special adhering resin for a plastic-lined steel pipe and a preparation method thereof, and belongs to the technical field of macromolecular materials. The special adhering resin is prepared from the following raw materials in parts by weight: 100 parts of polyolefin, 2 to 4 parts of dibutyl maleate, 1 to 3 parts of carbic anhydride, 3 to 7 parts of styrene, 0.05 to 0.4 part of initiator, 0 to 2 parts of antioxidant, and 2 to 5 parts of acetone. The special adhering resin has the advantages that under the synergistic action of multiple monomers of dibutyl maleate, carbic anhydride, styrene and polyolefin, the grafting rate and grafting efficiency are improved; while the requirement of high grafting rate is met, the low residue content is realized, and the utilization rate of polyolefin is high; the special adhering resin is specially designed for the plastic-lined steel pipe, the adhering force with a galvanized pipe, a stainless steel pipe, tinplate and other metals is good, and the special adhering resin is suitable for various types of cold water and hot water plastic-lined pipelines.

Owner:ANHUI GUODENG PIPE IND TECH CO LTD

A compound sterilization composition containing copper(succinate+glutarate+adipate)

A compound sterilization composition containing copper(succinate+glutarate+adipate) is disclosed. Effective components of the composition comprise an active component A and an active component B, wherein the active component A is the copper(succinate+glutarate+adipate), the active component B is one compound selected from aureonuclemycin, ningnanmycin and oxytetracycline hydrochloride, and the weight ratio of the active component A to the active component B is 1:80-80:1. The composition has synergistic effects for a plurality of diseases endangering agriculture production, reduces the using amount of pesticides, reduces the residual amount of pesticides on crops, reduces environment pollution, and is safe to human and livestock and good in environment compatibility. Drug resistance for diseases is not liable to generate.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

Calcium-based catalyst, and method used for catalytic synthesis of alkanolamide surfactant with calcium-based catalyst

ActiveCN110152645AImprove conversion rateReduce residueOrganic compound preparationTransportation and packagingCalciumAlcohol

The invention discloses a calcium-based catalyst, and a method used for catalytic synthesis of an alkanolamide surfactant with the calcium-based catalyst, and belongs to the technical field of surfactant synthesis. The composite calcium-based catalyst is used for catalyzing reaction of grease or fatty ester with alkyl alcohol amine to synthesize the alkanolamide surfactant light in color and low in free alkyl alcohol amine content, and it is beneficial for applications in daily chemical products. The calcium-based catalyst possesses slow release characteristic, is capable of maintaining relatively catalytic reaction activity at reaction late period, and ensuring high efficiency conversion of alkyl alcohol amine into the alkanolamide surfactant; alkyl alcohol amine conversion rate is high;alkyl alcohol amine residual amount in obtained product is low; nitrosamine risk of the product caused by alkyl alcohol amine residue is reduced greatly; reaction early period rate is reduced greatlythrough catalyst slow release control, so that poor heat transfer in synthesis process and product color darkening caused by too fast reaction rate at the early stage are avoided effectively.

Owner:JIANGNAN UNIV

Bactericidal composition containing fenarimol

The invention discloses a bactericidal composition containing fenarimol. The bactericidal composition contains an active component A and an active component B, wherein the active component A is fenarimol, the active component B is any one compound selected from the group consisting of carbendazim, thiophanate-methyl, prochloraz or a salt thereof and triflumizole, and a weight ratio of the active component A to the active component B is 1: 80 to 60: 1. The bactericidal composition exerts a synergistic effect on a plurality of diseases doing harm to agricultural production, reduces the usage amount of a pesticide and residual quantity of the pesticide on crops, mitigates environmental pollution, is safe to human beings and livestock, has good environmental acceptability and enables diseases not to easily generate drug resistance.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com