LCD alignment method

A liquid crystal alignment and liquid crystal layer technology, applied in optics, optomechanical equipment, instruments, etc., can solve problems such as high residual amount of monomer materials and poor performance of liquid crystal display panels, so as to improve reliability, avoid damage, and reduce residual volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

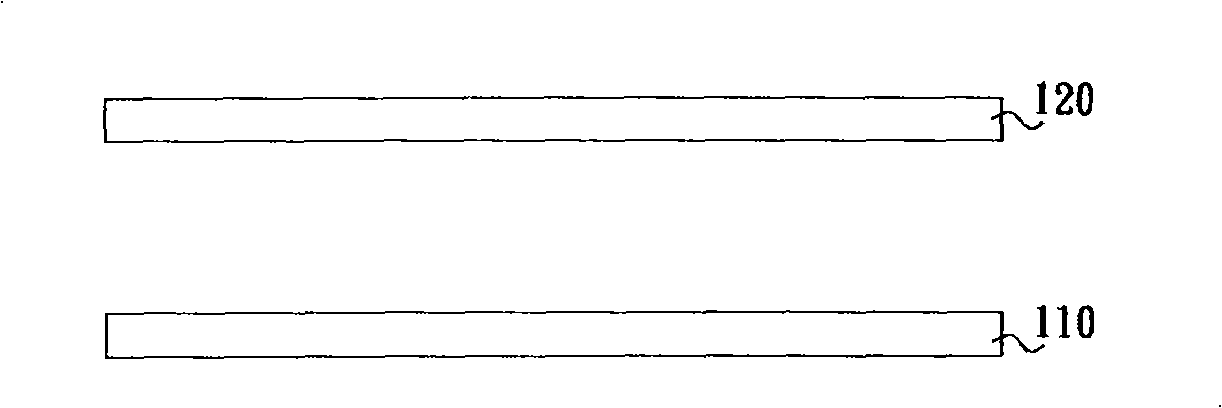

[0026] Figure 2A to Figure 2E It is a flowchart of a liquid crystal alignment method according to an embodiment of the present invention. Please refer to Figure 2A , the liquid crystal alignment method of this embodiment includes the following steps. Firstly, a first substrate 110 and a second substrate 120 are provided. The first substrate 110 is, for example, an active device array substrate, and the second substrate 120 is, for example, a pair of facing substrates.

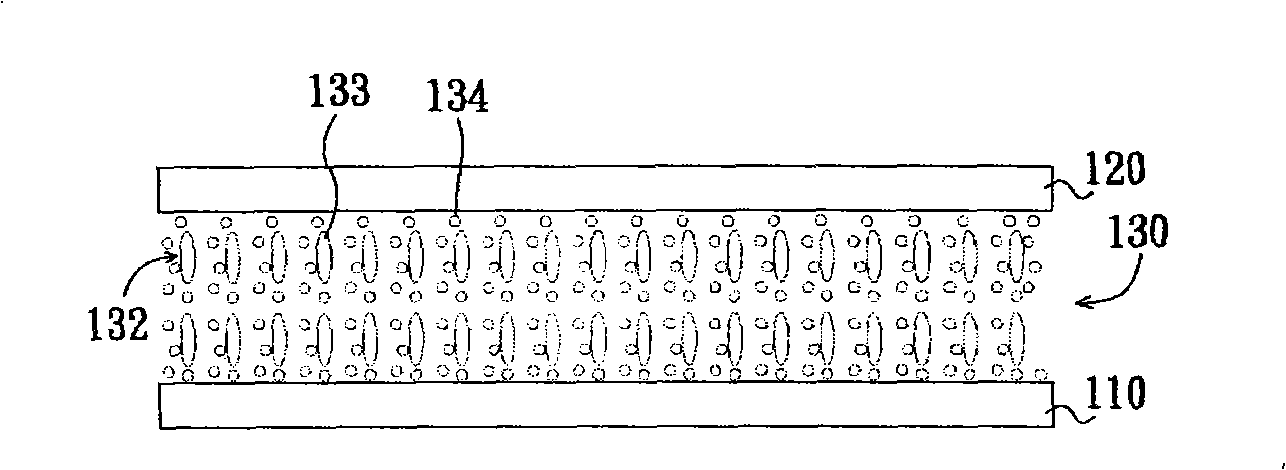

[0027] Next, if Figure 2B As shown, a liquid crystal layer 130 is provided between the first substrate 110 and the second substrate 120, wherein the liquid crystal layer 130 includes a liquid crystal composition 132, a monomer material 134 and a polymerization initiator (not shown). In addition, the liquid crystal composition 132 includes a plurality of liquid crystal molecules 133 .

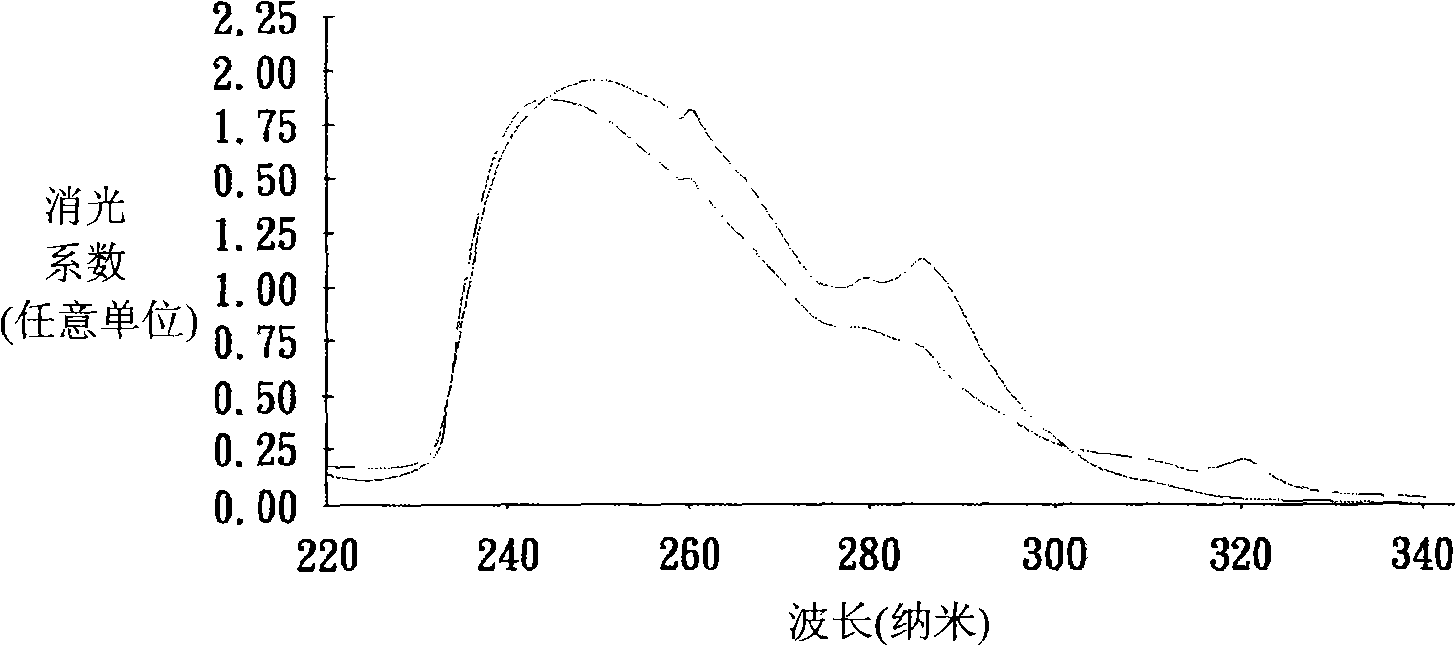

[0028] Next, apply an electric field to align the liquid crystal molecules 133 in the liquid crystal composition 132 al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com