Novel removal device for VOCs in building boards

A technology for removal of building boards, applied in wood processing equipment, manufacturing tools, etc., can solve problems such as secondary pollution of ammonia gas, and achieve the effects of reducing hazards, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

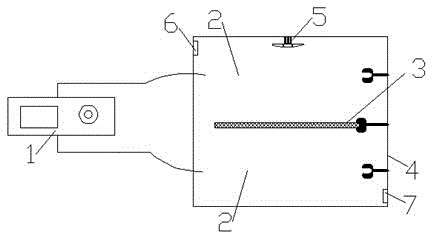

[0019] Such as figure 1 A new type of VOCs removal device for building panels is shown, which is mainly composed of a DC high-voltage power supply 1, an electrode plate 2, a VOCs treatment room 4 and a fan 5. The top side of the VOCs treatment room is provided with an air inlet 6, and the bottom is provided with a Exhaust port 7.

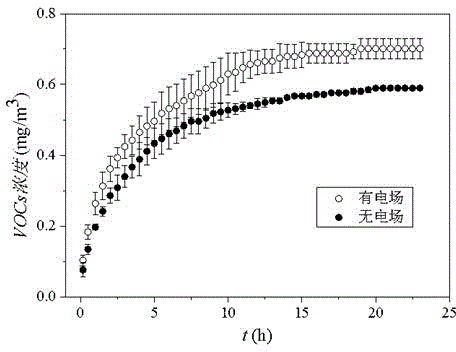

[0020] Put the building board sample from the feed port on the side of the VOCs treatment chamber, fix it through the bracket on the wall, and place it between the two electrode plates. Turn on the DC high-voltage power supply to generate a stable high-voltage electrostatic field between the electrode plates, thereby accelerating and improving the volatilization of VOCs in the plates. At the same time, through the air supply port on the top side of the VOCs treatment room, ordinary air is sent into the treatment room, and then bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com