Special adhering resin for plastic-lined steel pipe and preparation method thereof

A technology for bonding resin and plastic-lined steel pipes. It is applied in the directions of adhesives, adhesive types, and graft polymer adhesives. It can solve problems such as poor metal bonding properties, achieve excellent mechanical properties, and improve grafting. rate and grafting efficiency, the effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

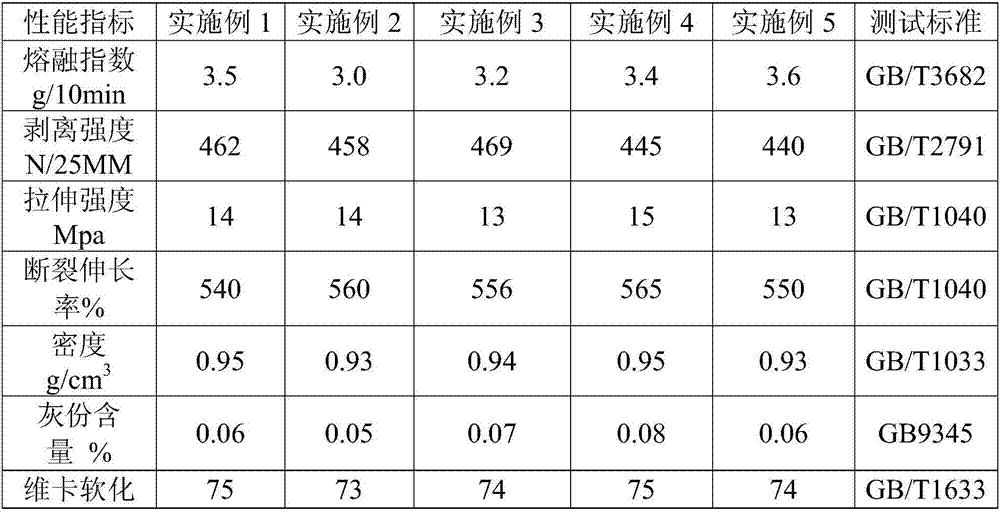

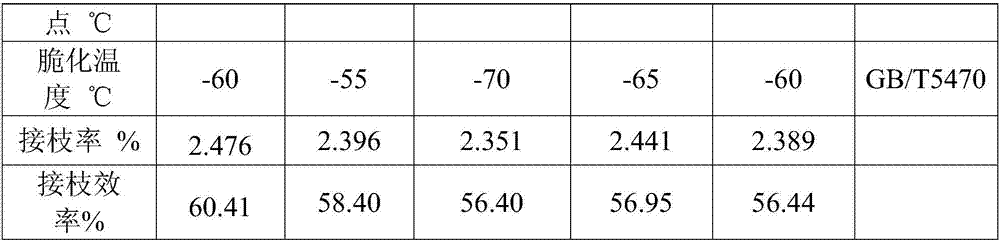

Examples

Embodiment 1

[0025] This embodiment provides a special adhesive resin for plastic-lined steel pipes, a special adhesive resin for plastic-lined steel pipes, which is prepared from the following raw materials in parts by weight: 100 parts of polyolefin, 3 parts of butylene maleate, 2 parts of norbornene diacid anhydride, 5 parts of styrene, 1.5 parts of acrylic acid, 0.2 parts of initiator, 1 part of antioxidant, 3.5 parts of acetone.

[0026] Wherein, the polyolefin is high-density polyethylene, linear low-density polyethylene, and ethylene-vinyl acetate copolymer with a weight ratio of 1:1:1.

[0027] Wherein, the initiator is dicumyl peroxide.

[0028] Wherein, the antioxidant agent is antioxidant 1010.

[0029] The preparation method of the special adhesive resin for the above-mentioned plastic-lined steel pipe comprises the following steps:

[0030] (1) Polyolefin, butylene maleate, norbornene dioic anhydride and acetone are added to the extruder;

[0031] (2) After the melting sect...

Embodiment 2

[0034] This embodiment provides a special adhesive resin for plastic-lined steel pipes, which is prepared from the following raw materials in parts by weight: 100 parts of polyolefin, 2 parts of butylene maleate, 3 parts of norbornene diacid anhydride, styrene 3 parts, 2 parts of acrylic acid, 0.05 parts of initiator, 2 parts of antioxidant, 2 parts of acetone.

[0035] Wherein, the polyolefin is high-density polyethylene.

[0036] Wherein, the initiator is benzoyl peroxide.

[0037] Wherein, the antioxidant agent is antioxidant 168.

[0038] The preparation method of the special adhesive resin for the above-mentioned plastic-lined steel pipe comprises the following steps:

[0039] (1) Polyolefin, butylene maleate, norbornene dioic anhydride and acetone are added to the extruder;

[0040] (2) After the melting section of the extruder, add styrene, acrylic acid, initiator and antioxidant, extrude and granulate, and the processing temperature is 150-200°C to obtain the produc...

Embodiment 3

[0043] This embodiment provides a special adhesive resin for plastic-lined steel pipes, which is prepared from the following raw materials in parts by weight: 100 parts of polyolefin, 4 parts of butylene maleate, 1 part of norbornene diacid anhydride, styrene 7 parts, 1 part of acrylic acid, 0.4 parts of initiator, 5 parts of acetone.

[0044] Wherein, the polyolefin is linear low density polyethylene.

[0045] Wherein, the initiator is benzoyl peroxide.

[0046] The preparation method of the special adhesive resin for the above-mentioned plastic-lined steel pipe comprises the following steps:

[0047] (1) Polyolefin, butylene maleate, norbornene dioic anhydride and acetone are added to the extruder;

[0048] (2) After the melting section of the extruder, add styrene, acrylic acid, initiator and antioxidant, extrude and granulate, and the processing temperature is 150-200°C to obtain the product.

[0049] Among them, the extruder uses a twin-screw extruder for graft granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com