Production process of label sticker which is resistant to high temperature and high in viscosity

A production process and high-viscosity technology, applied in the direction of cardboard items, etc., to achieve the effects of less residue, improved cross-linking degree, and improved peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

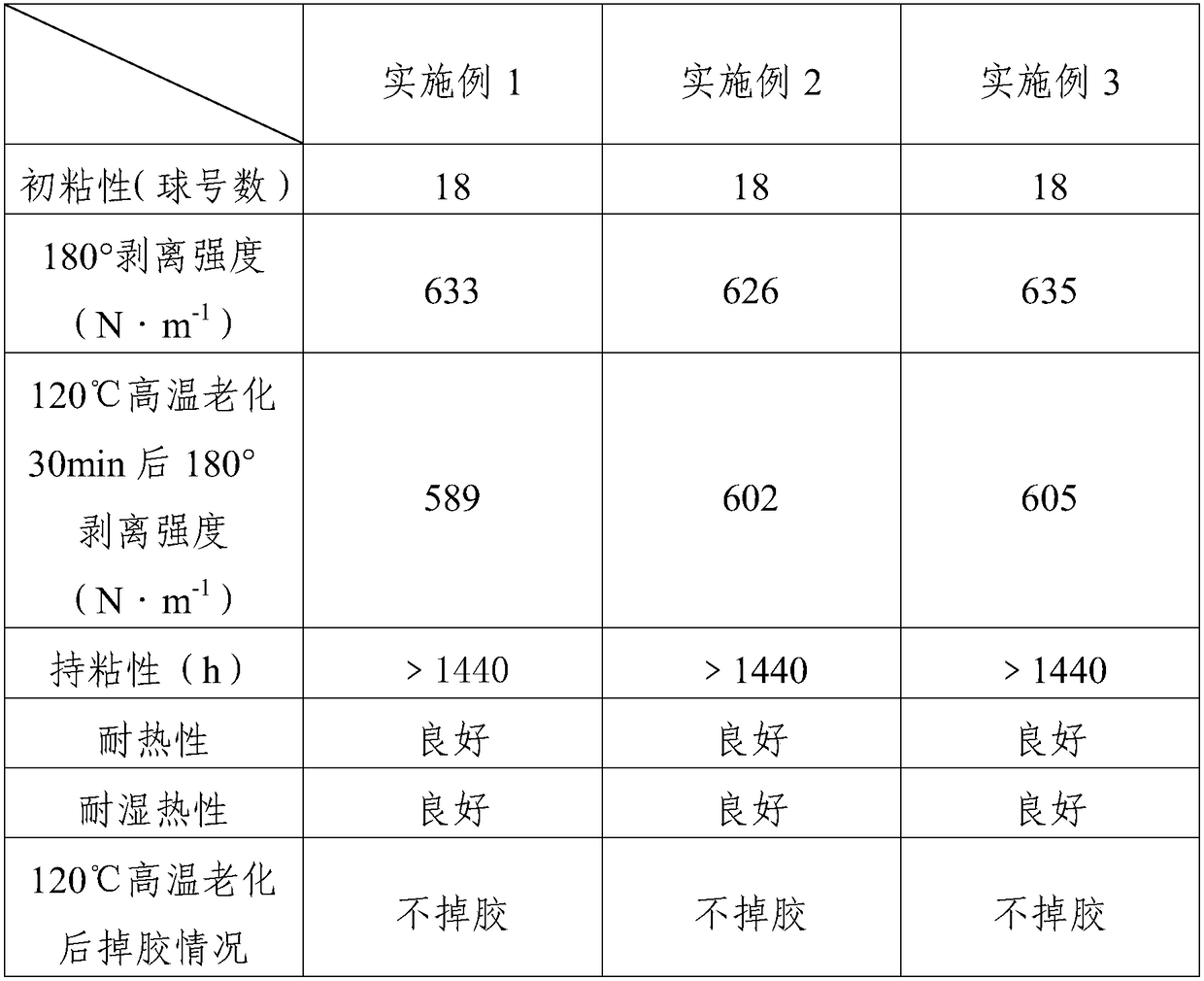

Embodiment 1

[0031] A production process for a high-temperature-resistant high-viscosity label sticker, comprising the following steps:

[0032] (1) Mix and stir octylphenol, ethylene glycol, appropriate amount of propylene oxide, and γ-alumina-supported sodium hydroxide catalyst. When the reaction is triggered, add the remaining propylene oxide several times, and react at 140°C to obtain For intermediate A, add 35% deionized water of its mass to intermediate A after natural cooling, raise the temperature to 90°C and stir for 40 minutes, then separate and remove the water phase to obtain intermediate B, add concentrated Sulfuric acid, after stirring for 10 minutes, distill water under high temperature and reduced pressure for 6 hours, cool down to 38°C and slowly add B (C 6 f 5 ) 3 Catalyst, heat preservation reaction for 4 hours, suction filtration, washing with water until neutral, and then distilling water at high temperature and reduced pressure for 6 hours to obtain active polyether...

Embodiment 2

[0040] A production process for a high-temperature-resistant high-viscosity label sticker, comprising the following steps:

[0041] (1) Mix and stir octylphenol, ethylene glycol, appropriate amount of propylene oxide, and γ-alumina-supported sodium bicarbonate catalyst. When the reaction is triggered, add the remaining propylene oxide several times, and react at 150°C to obtain For intermediate A, add 40% deionized water of its mass to intermediate A after natural cooling, raise the temperature to 90°C and stir for 33 minutes, then separate the liquid to remove the water phase to obtain intermediate B, add concentrated Sulfuric acid, after stirring for 20min, distill water under high temperature and reduced pressure for 10h, cool down to 38°C and slowly add B(C 6 f 5 ) 3 Catalyst, heat preservation reaction for 4 hours, suction filtration, washing with water until neutral, and then distilling water at high temperature and reduced pressure for 10 hours to obtain active polyet...

Embodiment 3

[0049] A production process for a high-temperature-resistant high-viscosity label sticker, comprising the following steps:

[0050] (1) Mix and stir octylphenol, ethylene glycol, appropriate amount of propylene oxide, and γ-alumina-supported sodium carbonate catalyst. When the reaction is triggered, add the remaining propylene oxide in several times, and react at 130°C to obtain an intermediate Body A, add 38% of its mass deionized water to the naturally cooled Intermediate A, raise the temperature to 85°C and stir for 50 minutes, then separate the liquid to remove the water phase to obtain Intermediate B, add concentrated sulfuric acid to Intermediate B , after stirring for 20min, distill water under high temperature and reduced pressure for 6h, cool down to 40°C and slowly add B (C 6 f 5 ) 3 Catalyst, heat preservation reaction for 5 hours, suction filtration, washing with water until neutral, and then distilling water at high temperature and reduced pressure for 10 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com