Uniform cooling device for steel plates with curved water outlets

A technology of uniform cooling and water outlet, used in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of ineffective use and ineffectiveness, improve cooling effect, reduce water consumption, and reduce residues amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

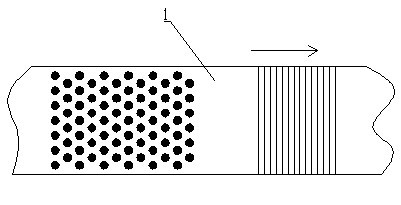

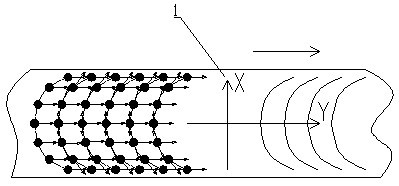

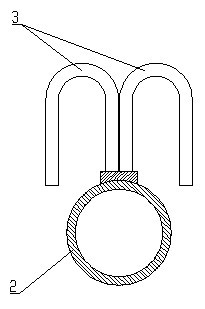

[0021] The following will be combined with Figure 2-4 The present invention is described in detail ( figure 2 The direction indicated by the arrow above the middle steel plate 1 is the steel plate conveying direction): The steel plate uniform cooling device with curved water outlets in this embodiment includes an upper header device, and the upper header device is provided with a spraying direction perpendicular to the steel plate 1 and The spray range covers the width of the steel plate with multiple outlets, and the multiple outlets are arranged side by side along the steel plate conveying direction. In the prior art, the multiple outlets are arranged in a straight line. In this embodiment, the projection of each outlet on the steel plate is in a curved distribution. The opening direction of the curve is the same as the conveying direction of the steel plate 1 . This layout structure utilizes the characteristics of the flow field formed by water spraying at the water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com