Patents

Literature

103results about How to "Raise the vertical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

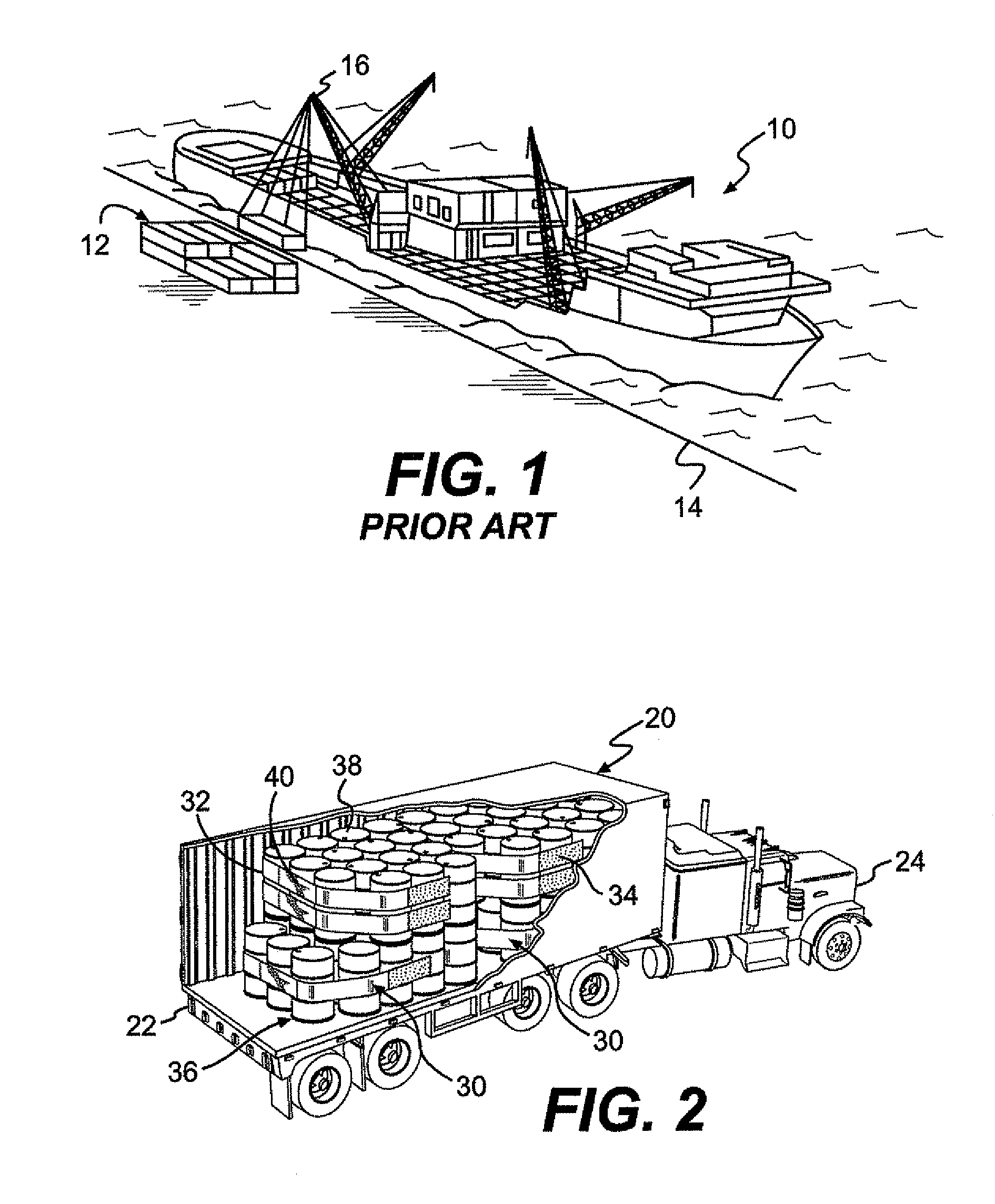

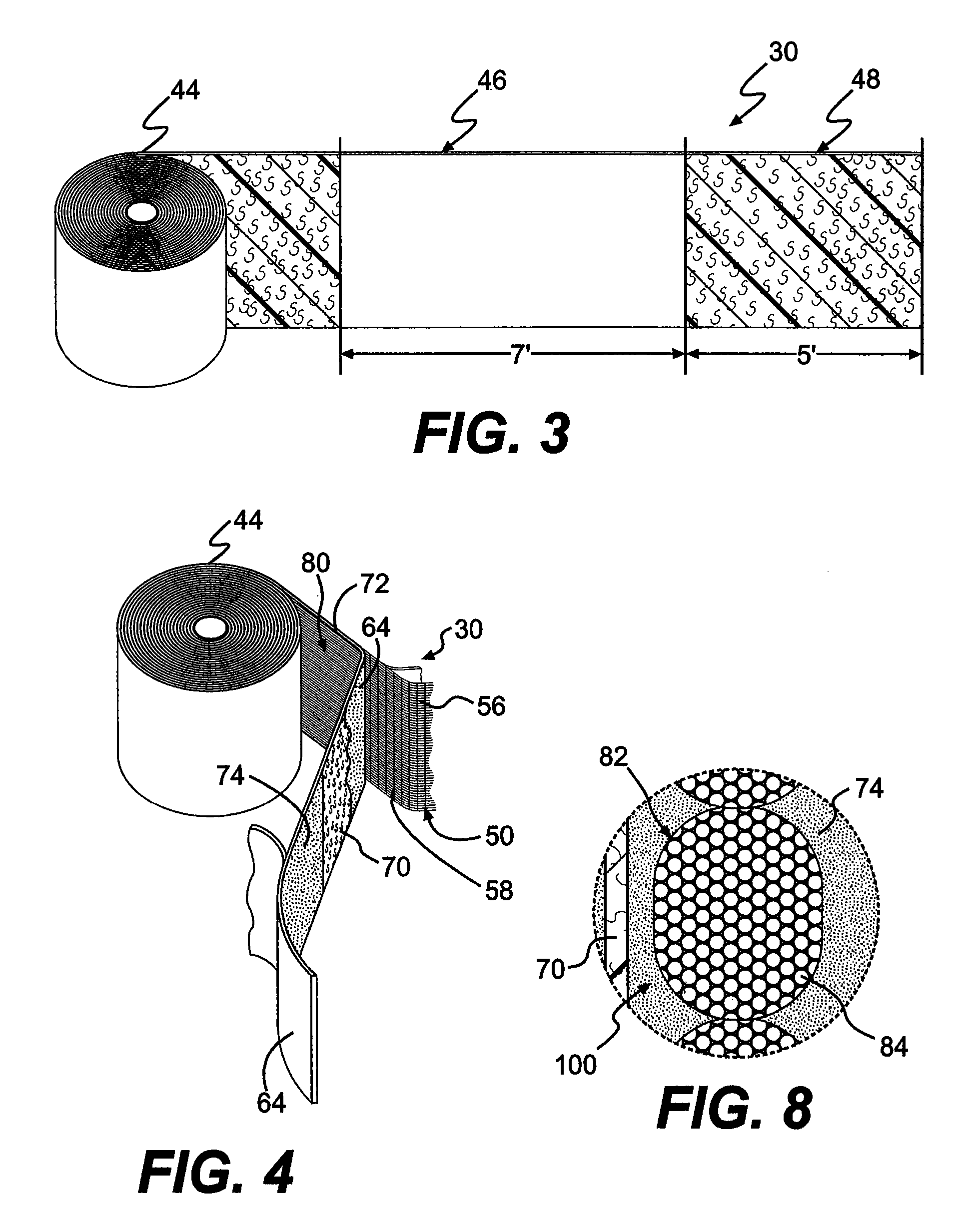

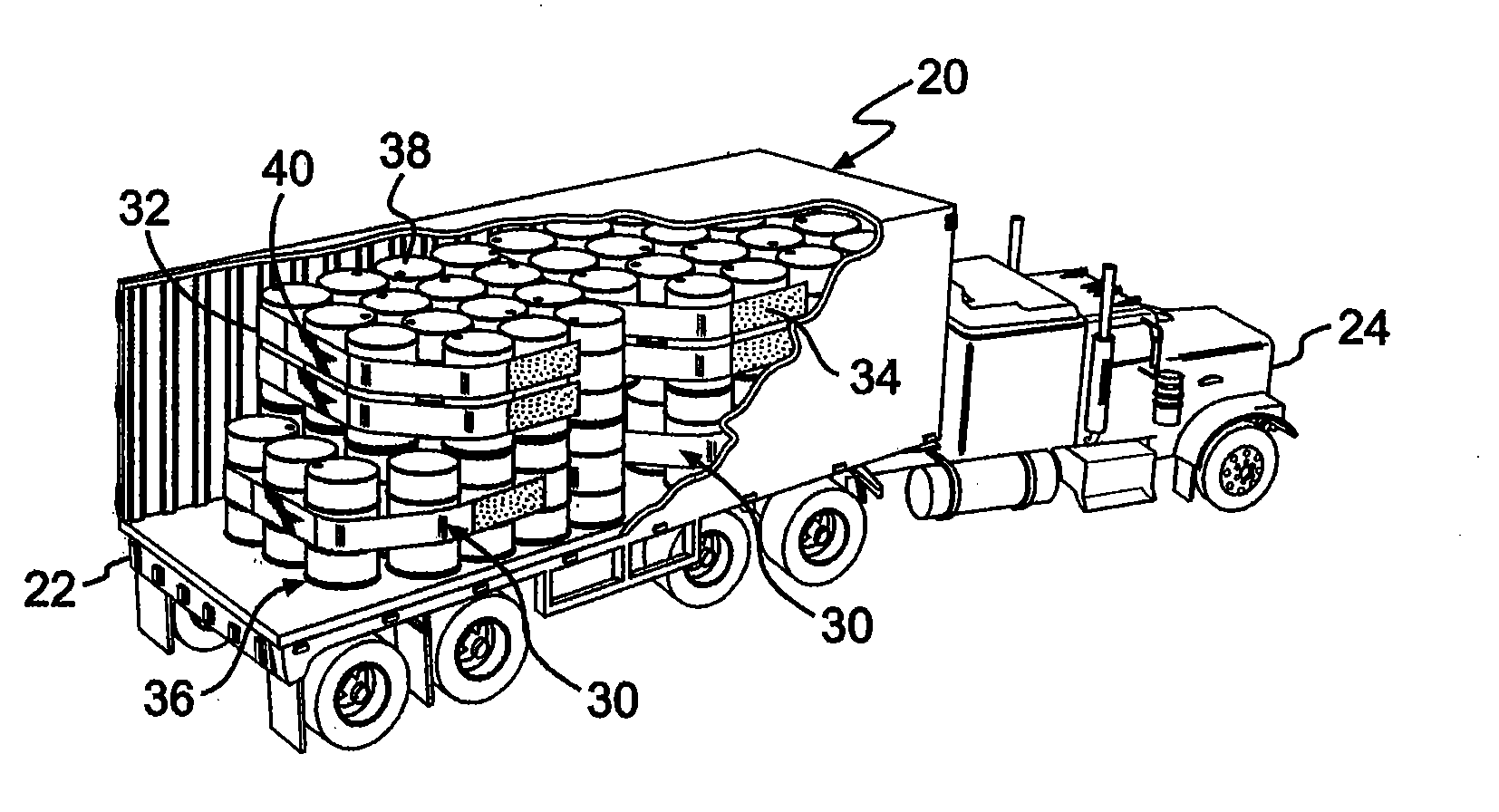

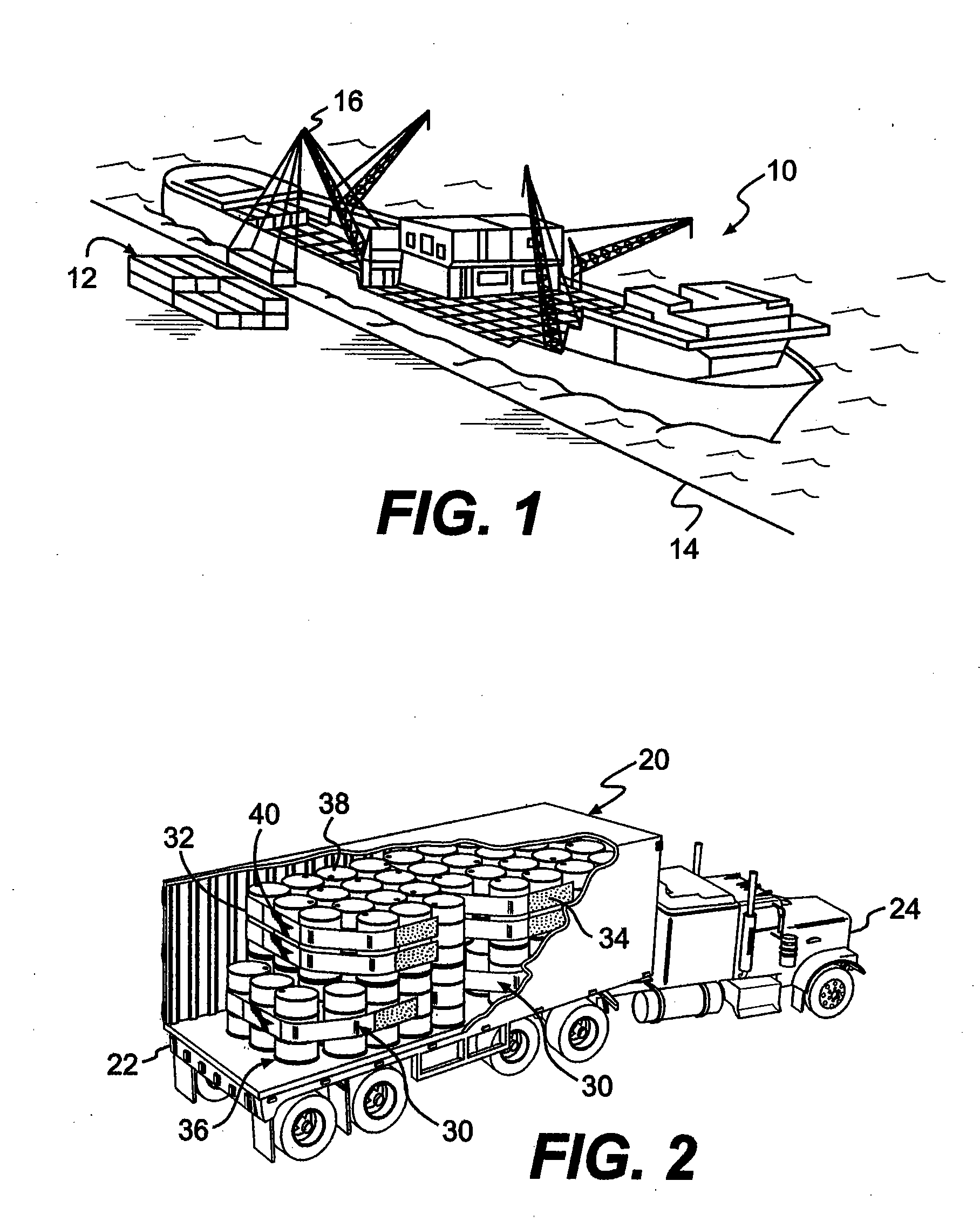

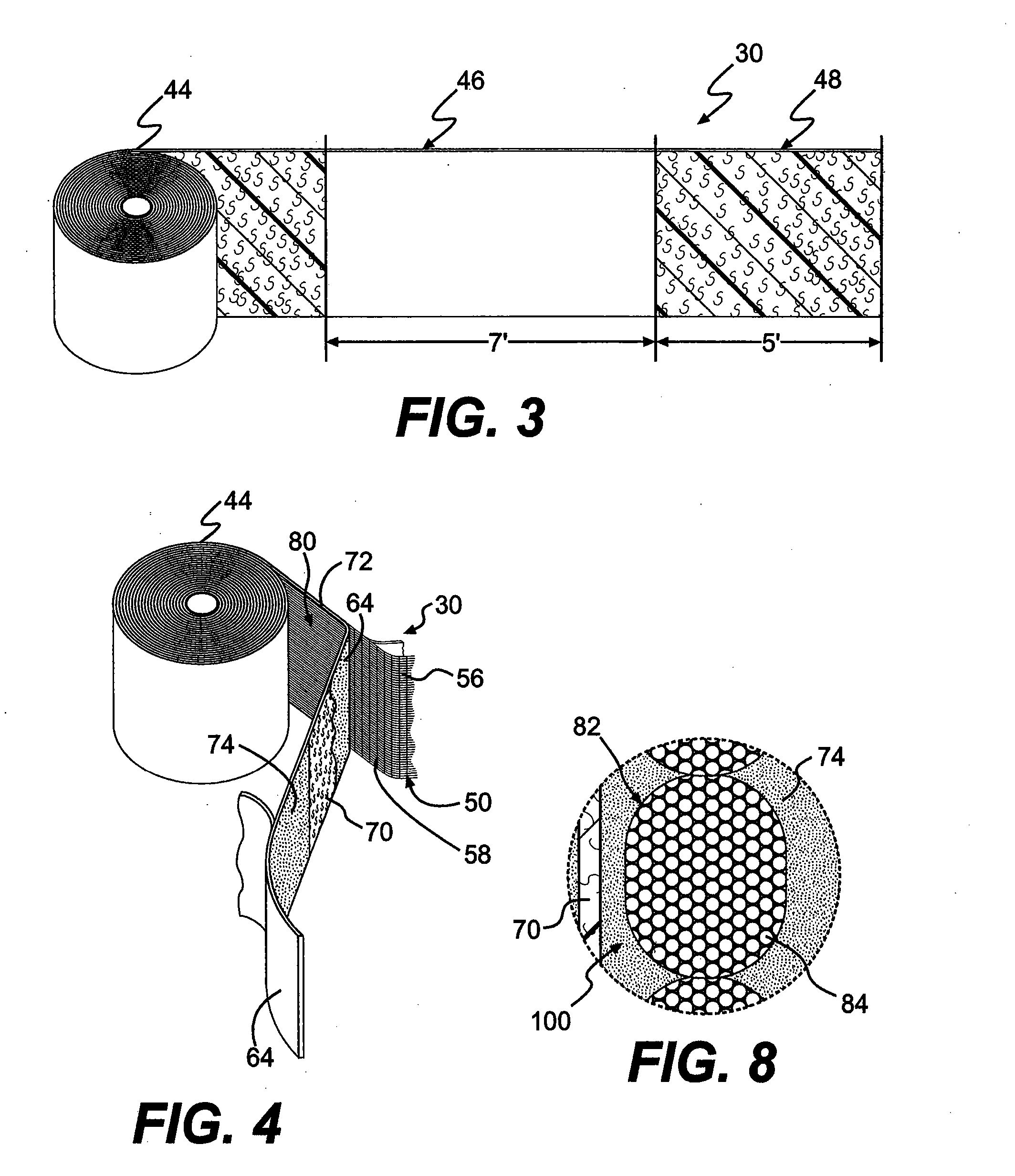

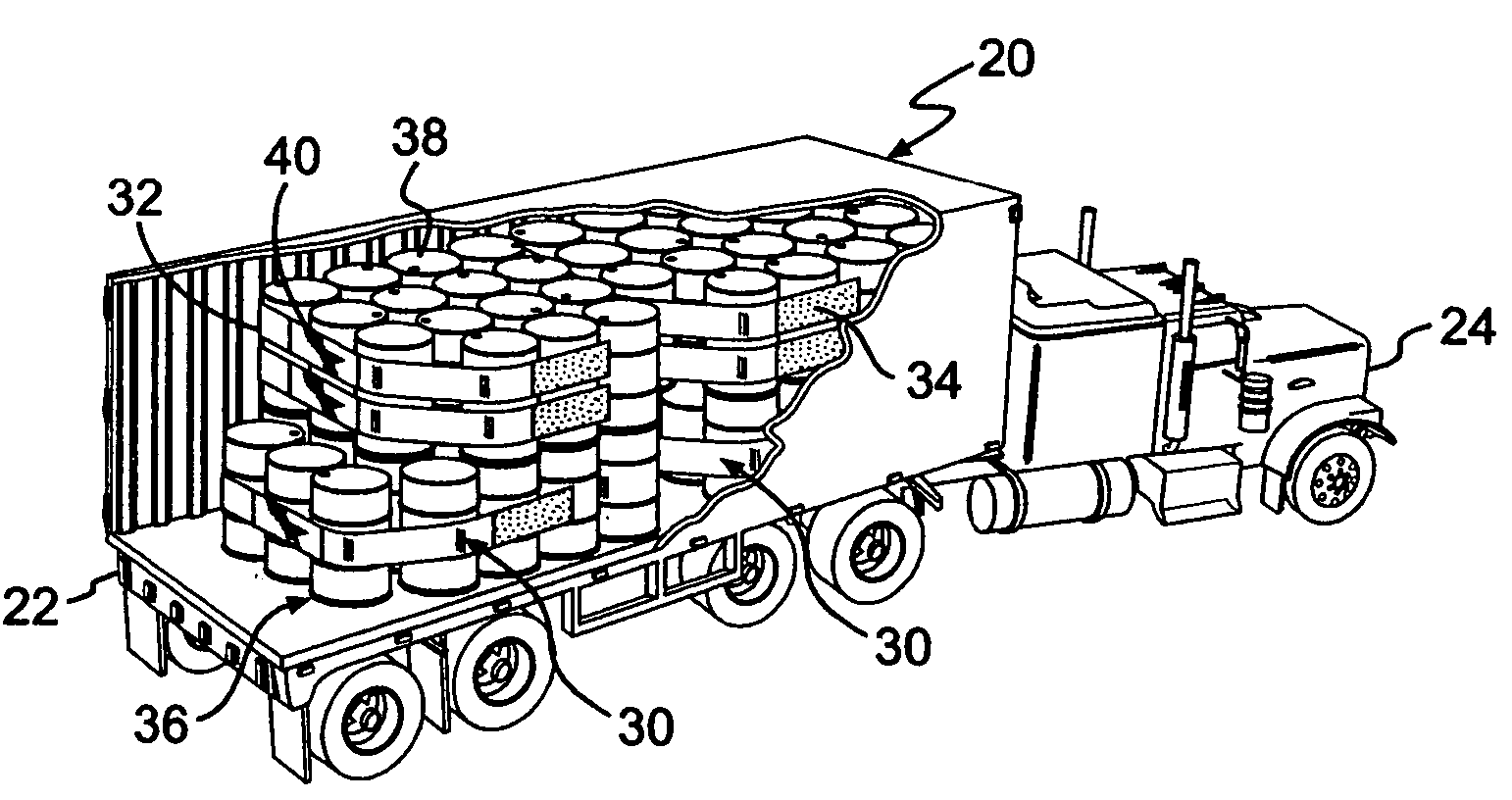

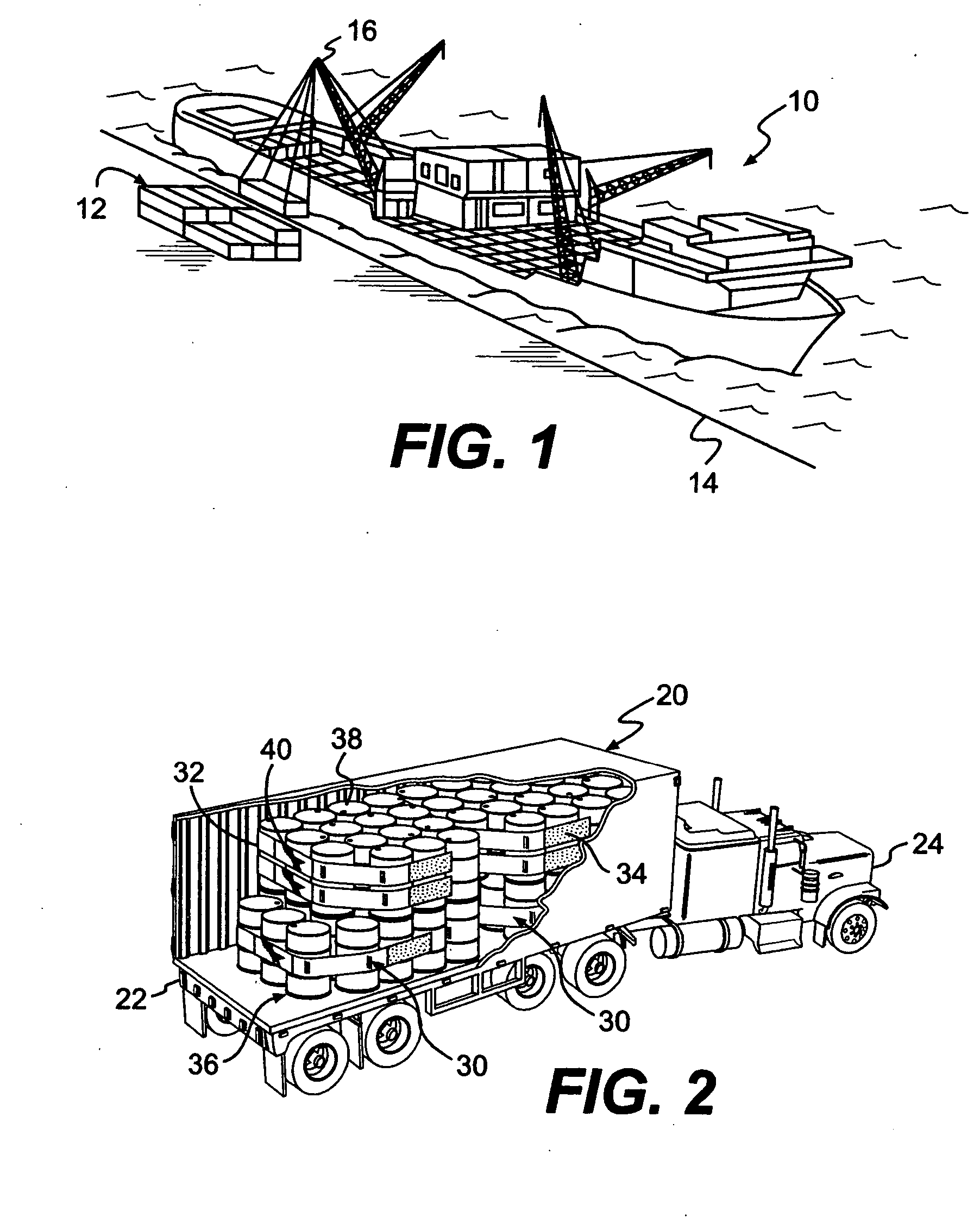

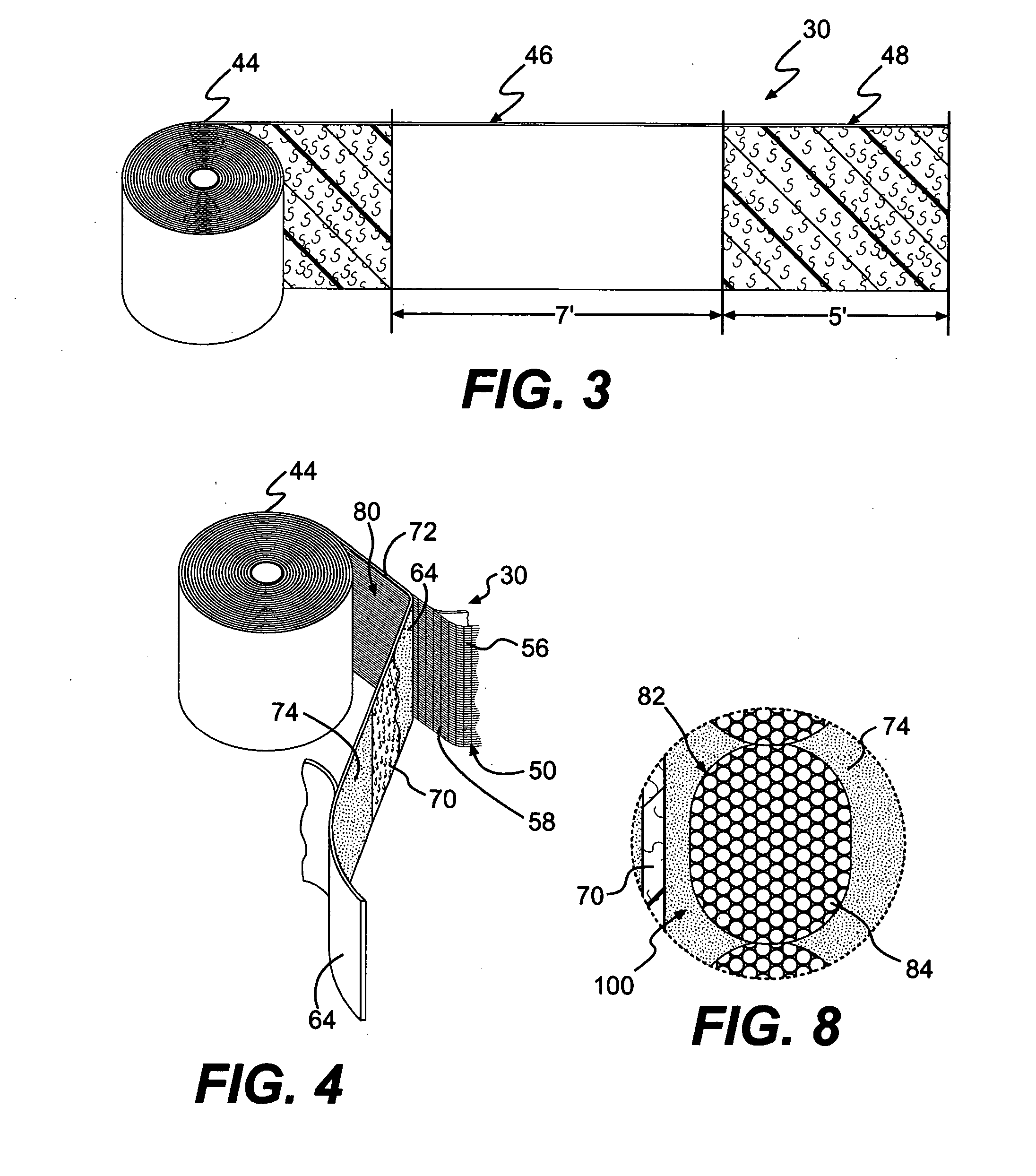

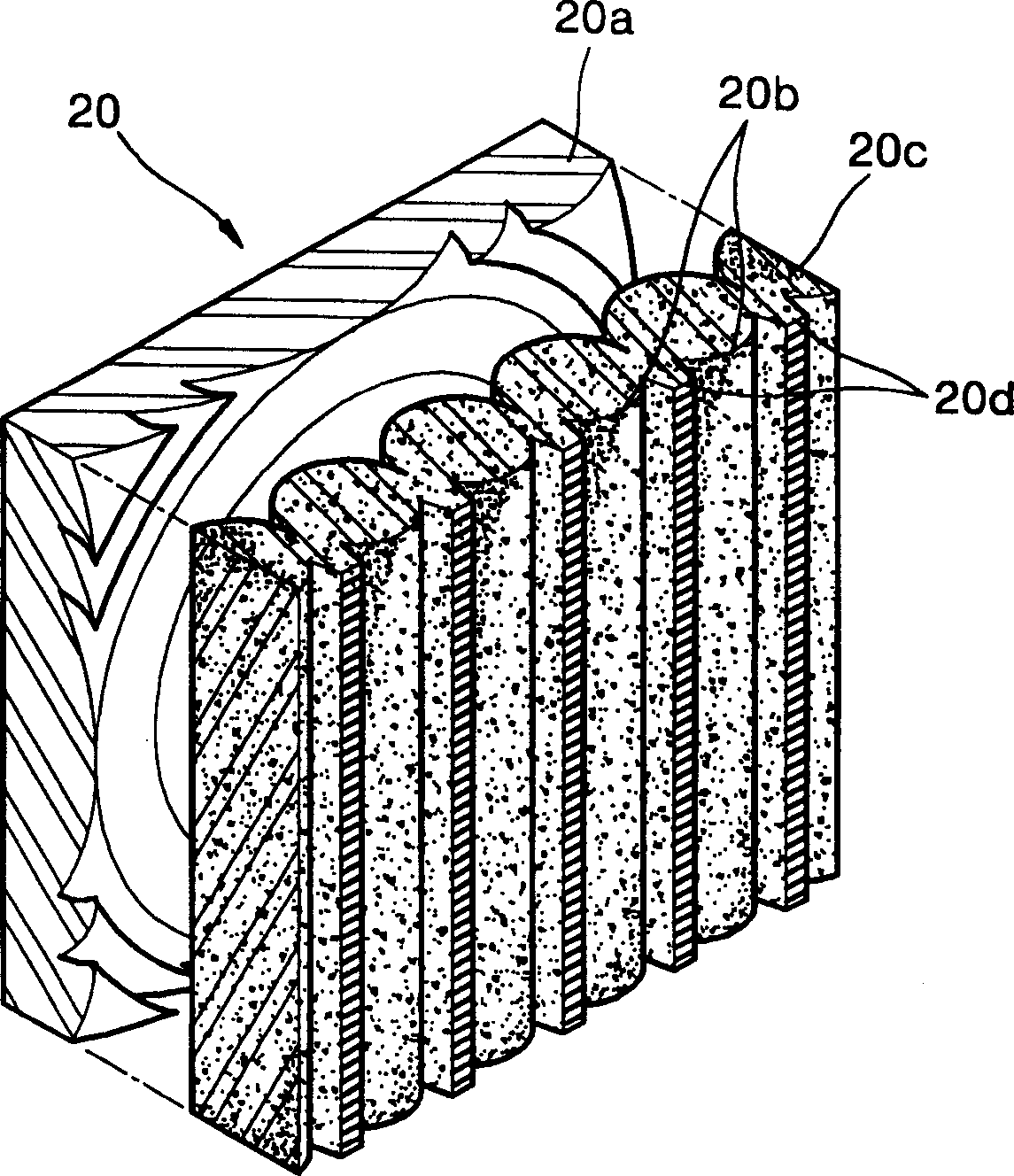

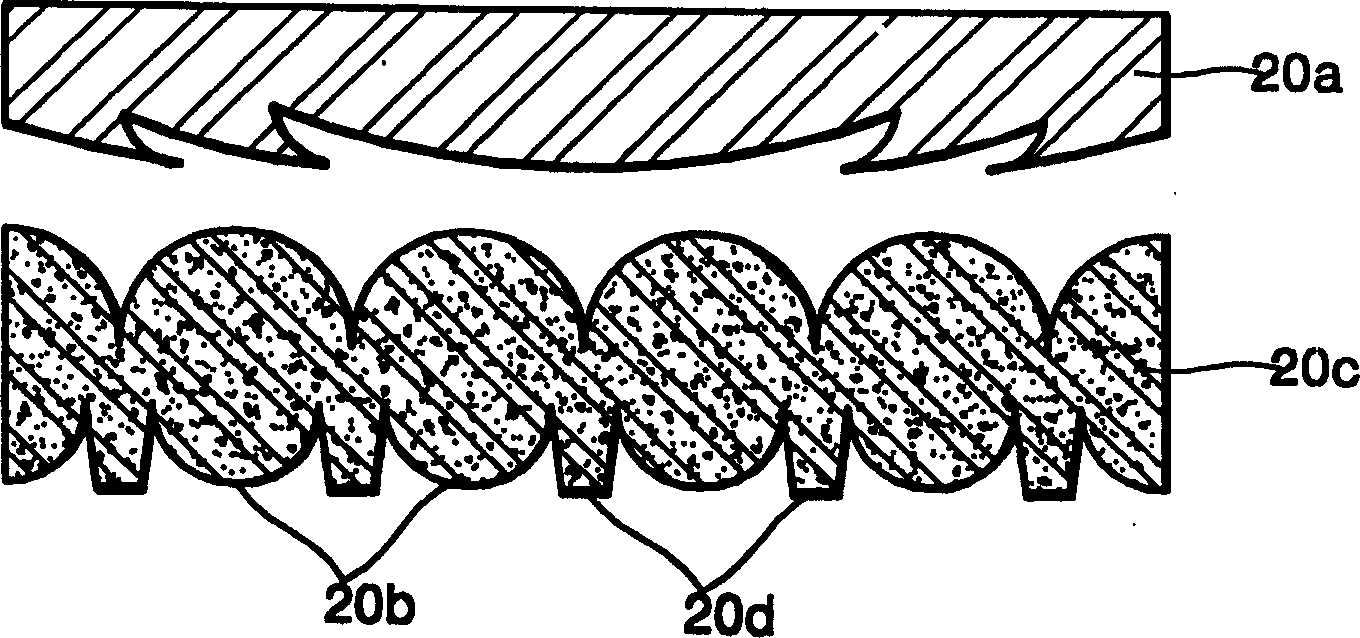

Cross-weave cargo restraint system

ActiveUS7066698B2Raise the verticalHigh strengthLayered productsFlexible elementsAdhesiveEngineering

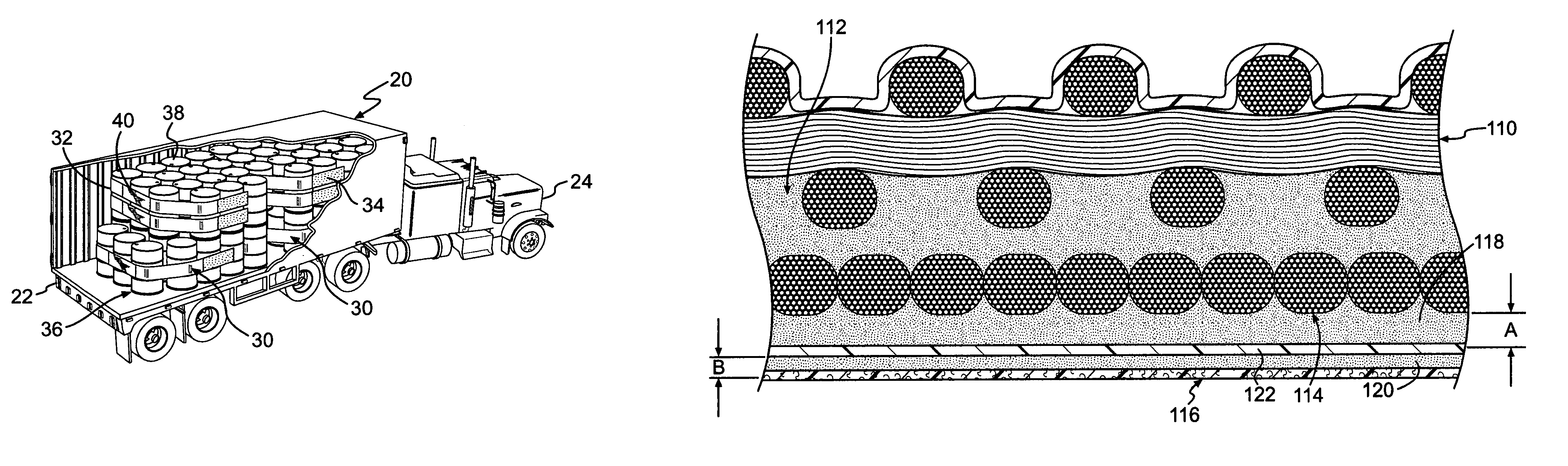

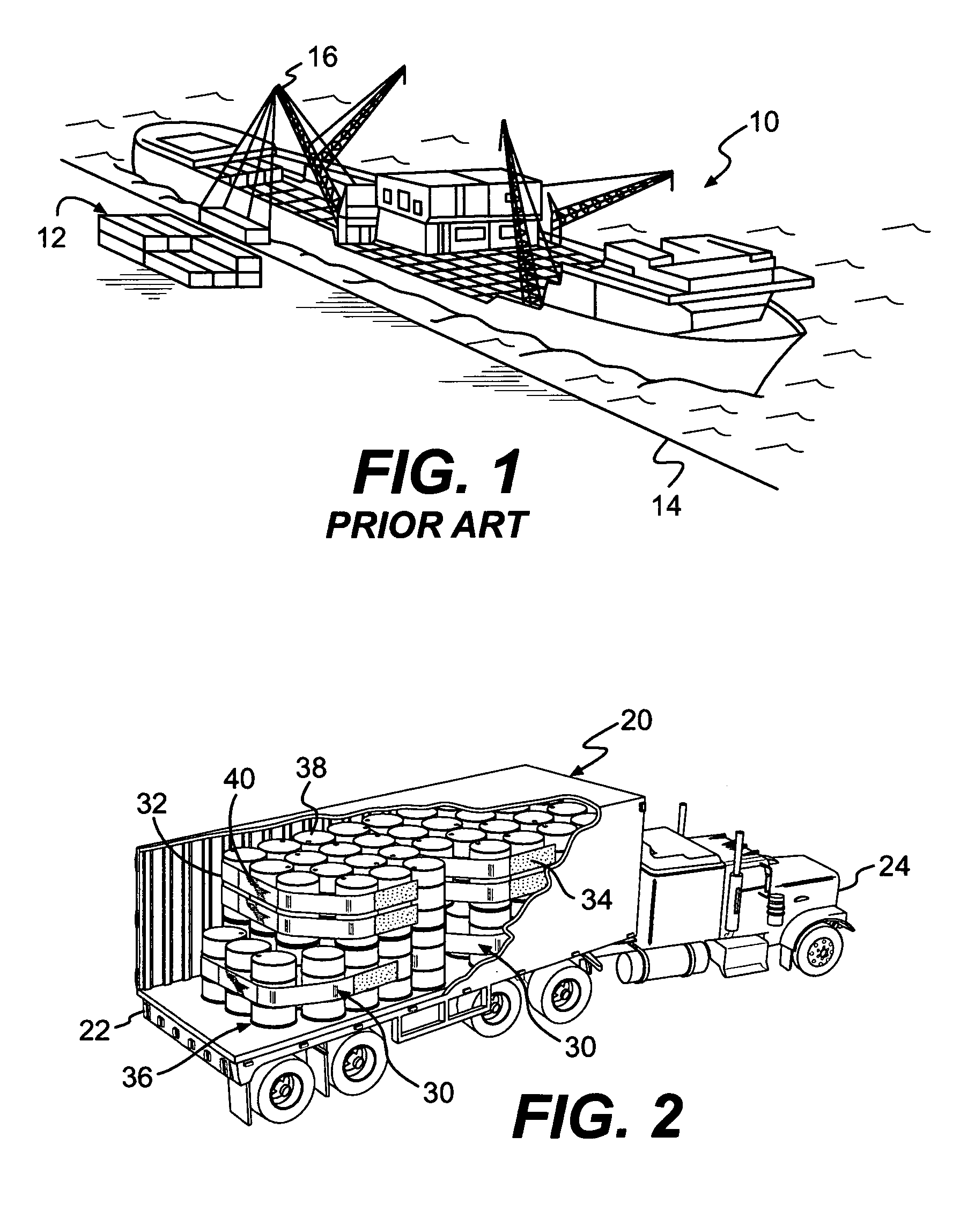

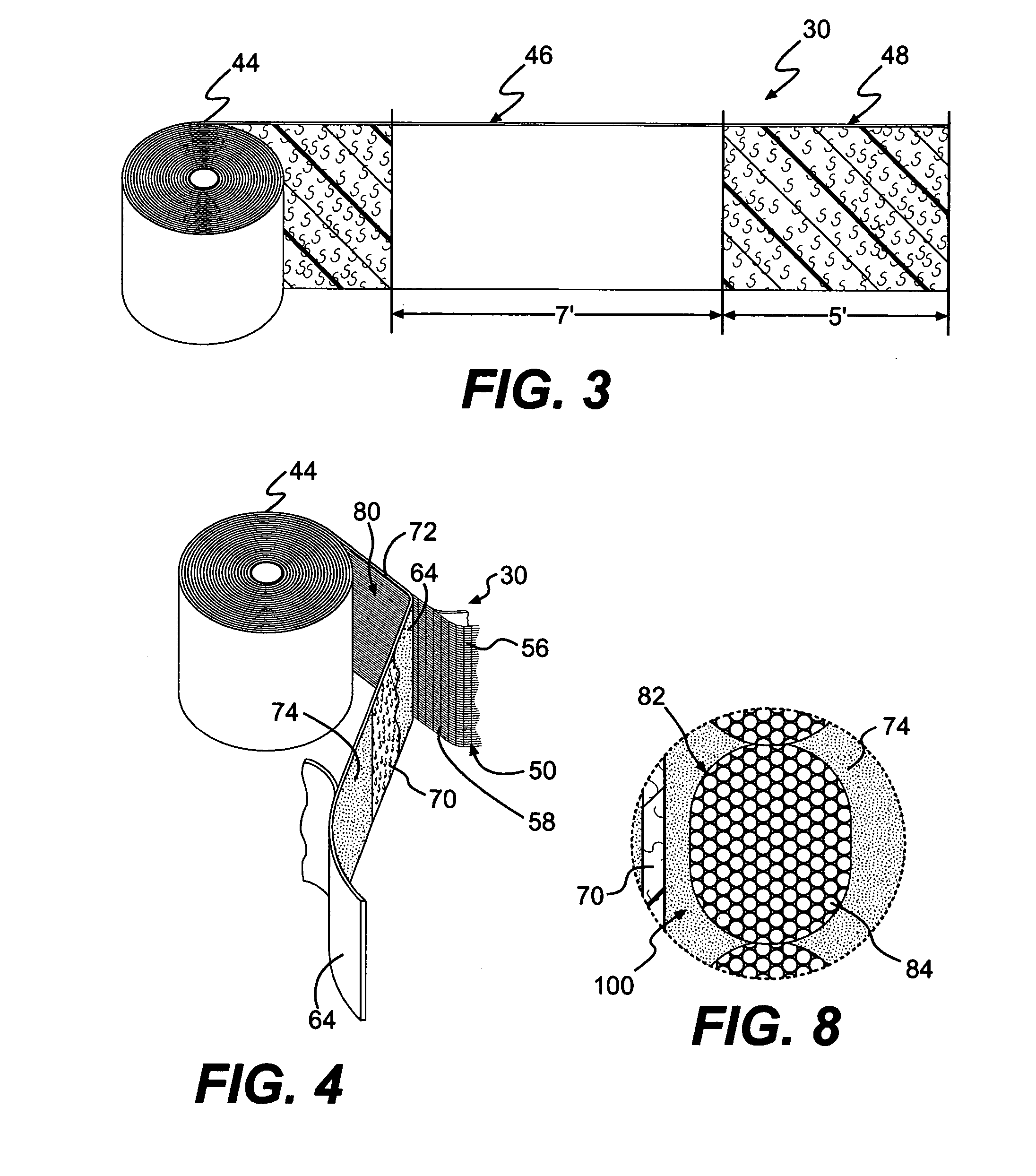

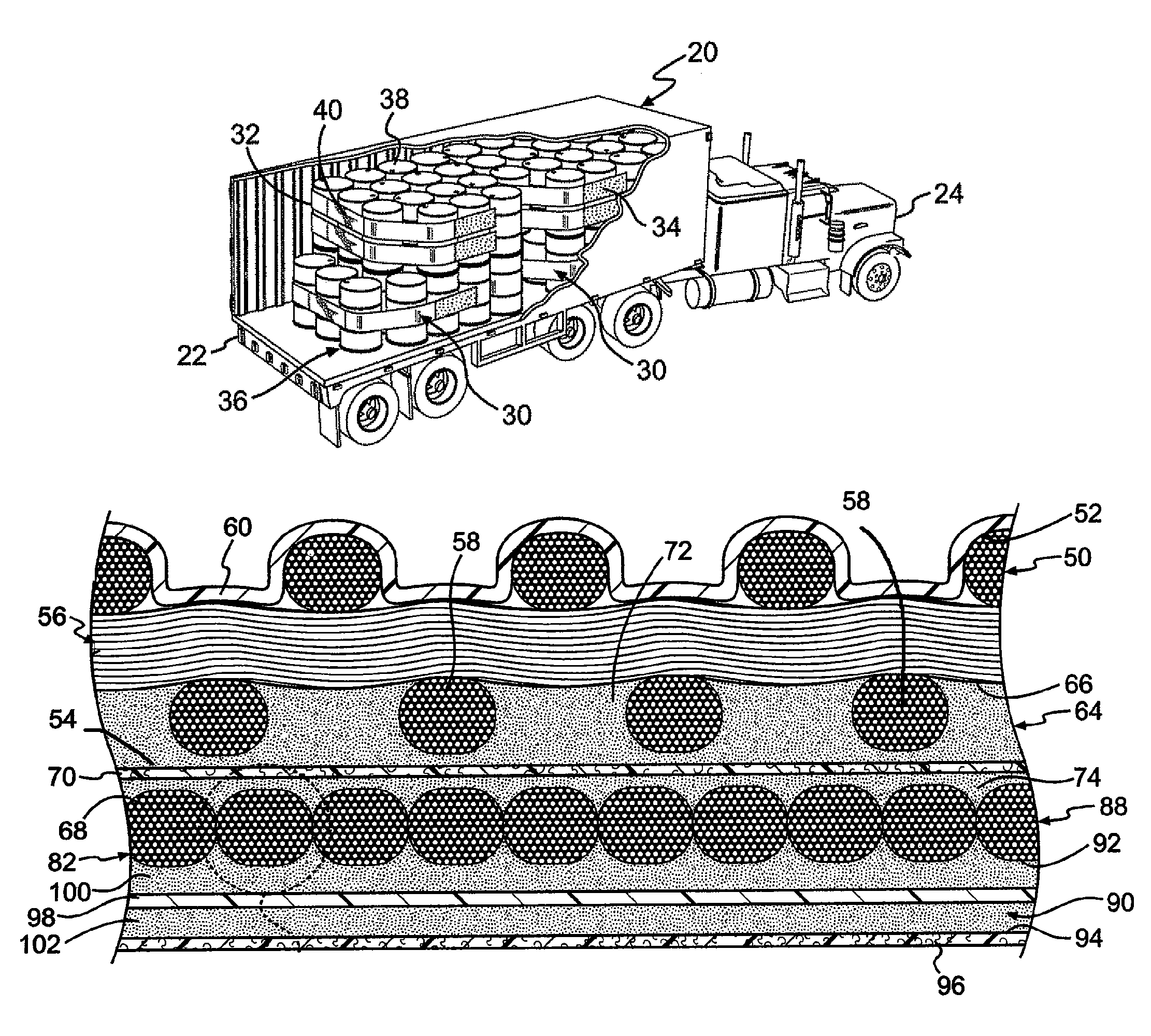

A cross-weave load restraint system and method for securing cargo within transport containers including first and second load restraining strips wherein the first strip is formed with a cross-weave material and the second strip is composed of parallel strands of reinforcement materiel. The first and second strips of reinforcement material are secured together with an adhesive layer and a second layer of adhesive is provided for attaching the cross-weave load restraining strip to an interior surface of a transport container.

Owner:MBULL HLDG LLC

Cross-weave cargo restraint system and method

Owner:MBULL HLDG LLC

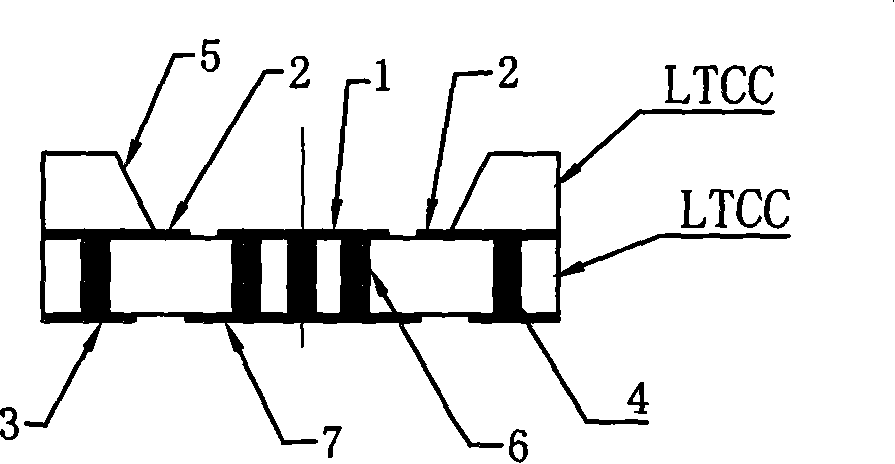

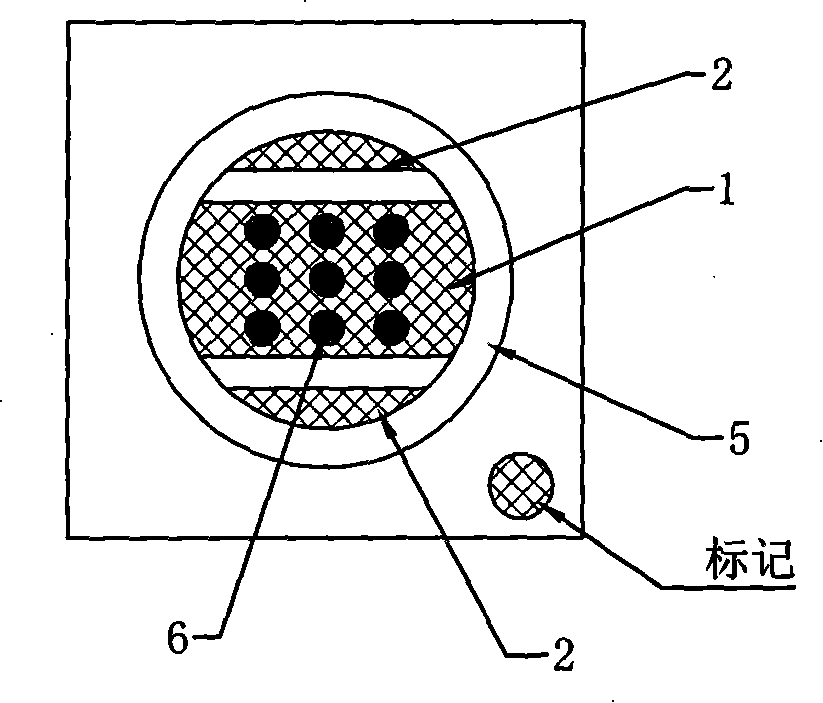

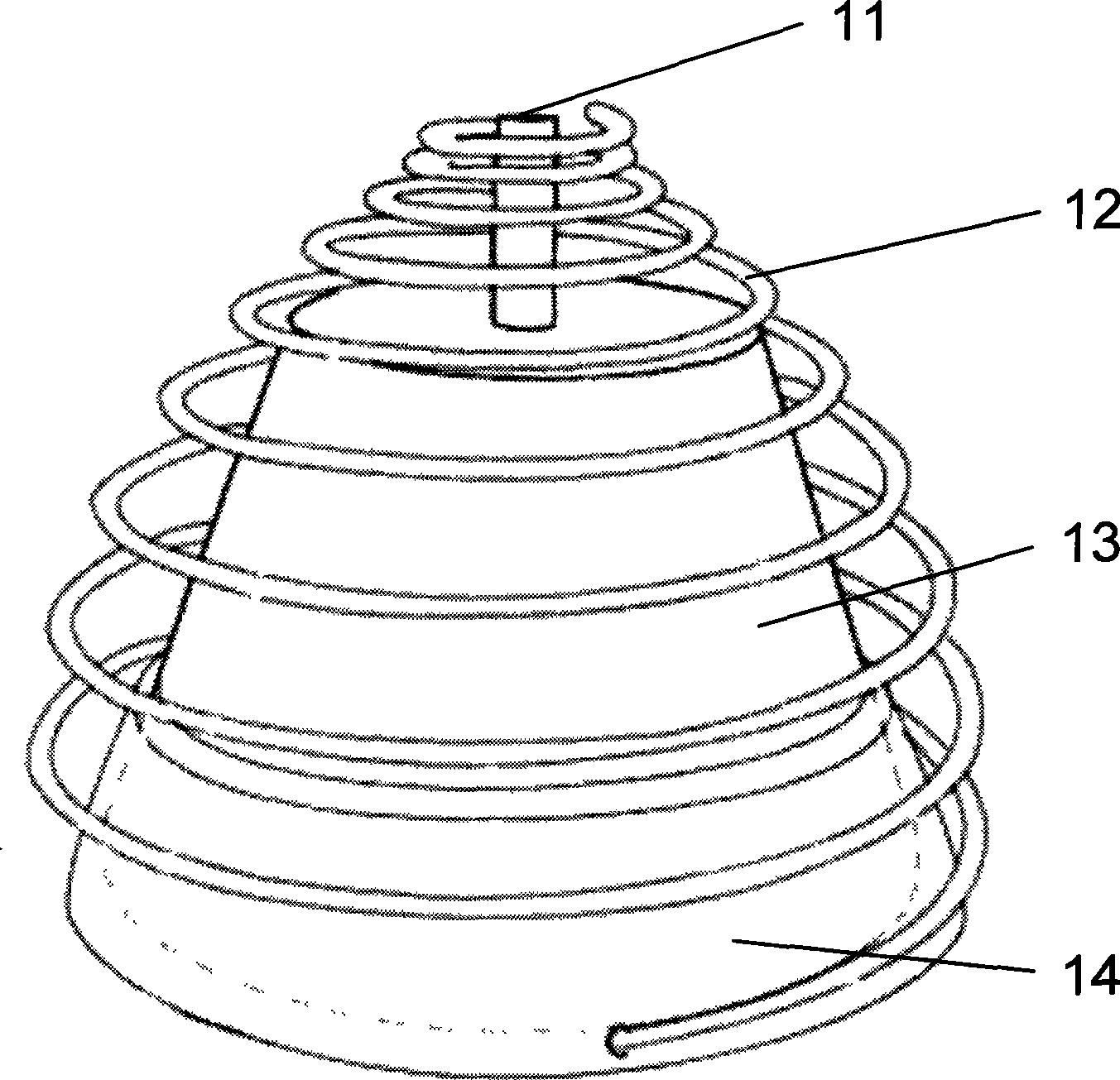

High power LED ceramic packaging base

InactiveCN101252162AImprove cooling effectImprove light attenuationSemiconductor devicesUltimate tensile strengthNitride

The present invention relates to a ceramic packaging base, in particular to an SMD high power LED ceramic packaging base. The present invention consists of an upper ceramic layer and a lower ceramic layer, wherein the upper ceramic layer provides a reflection cup; the upper ceramic layer is made of LECC glass ceramic material; the upper side of the lower ceramic layer is provided with a wire bonding area and a bottom bonding pad; the base is also provided with an electric conducting through hole; the lower ceramic layer is made of high thermal conductivity alumina ceramic material or aluminum nitride ceramic material, and is used to raise the entire mechanical strength and heat dissipation performance of the packaging base. The ceramic packaging base has the advantages of raising the heat dissipation performance of the SMD high power LED ceramic packaging base, improving the problem that temperature rise causes high light decay and life-span decrease of an LED chip, strengthening the performance of LED products in resisting high / low temperature and impact, raising the reliability as well as stability of products and reducing production cost.

Owner:CHAOZHOU THREE CIRCLE GRP

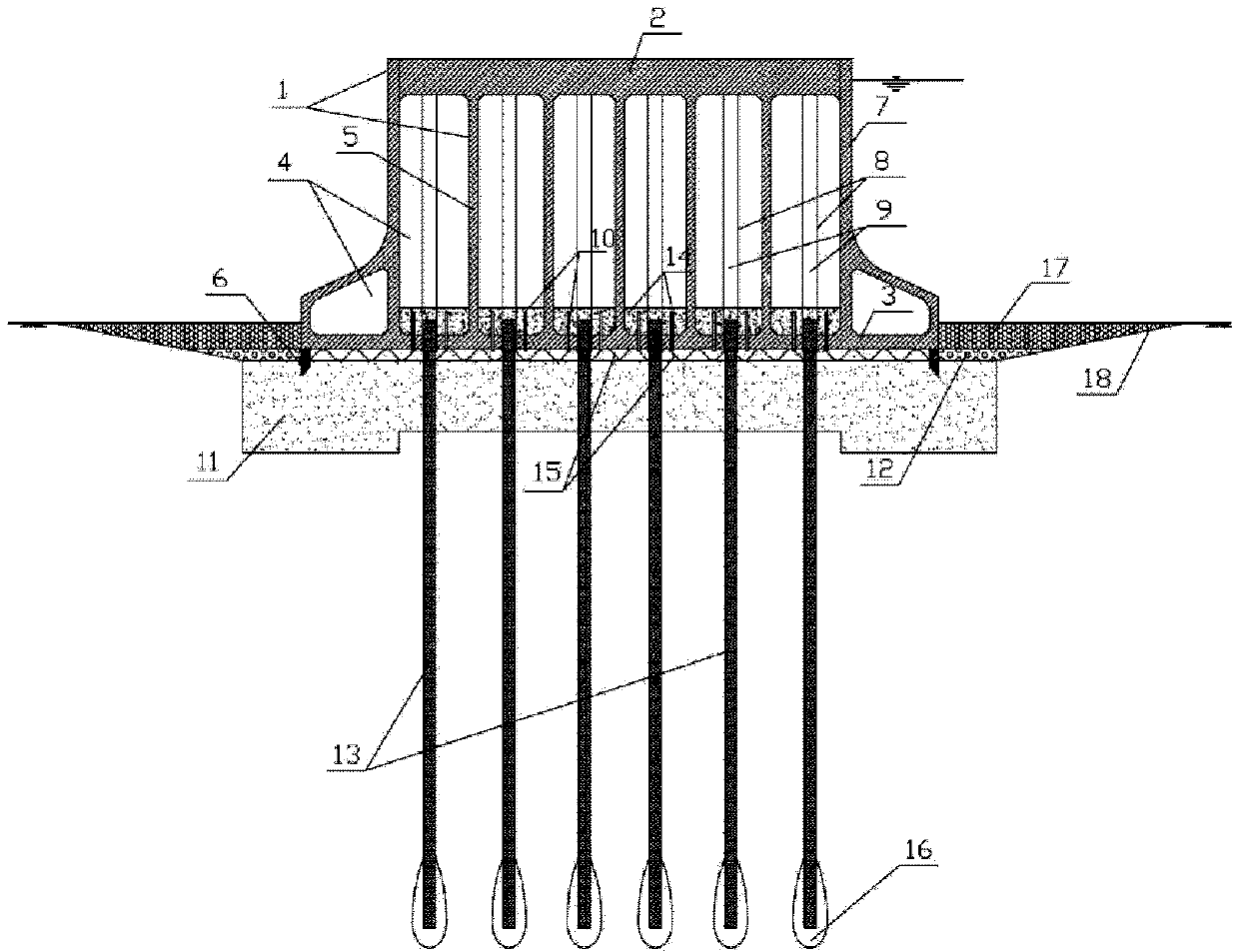

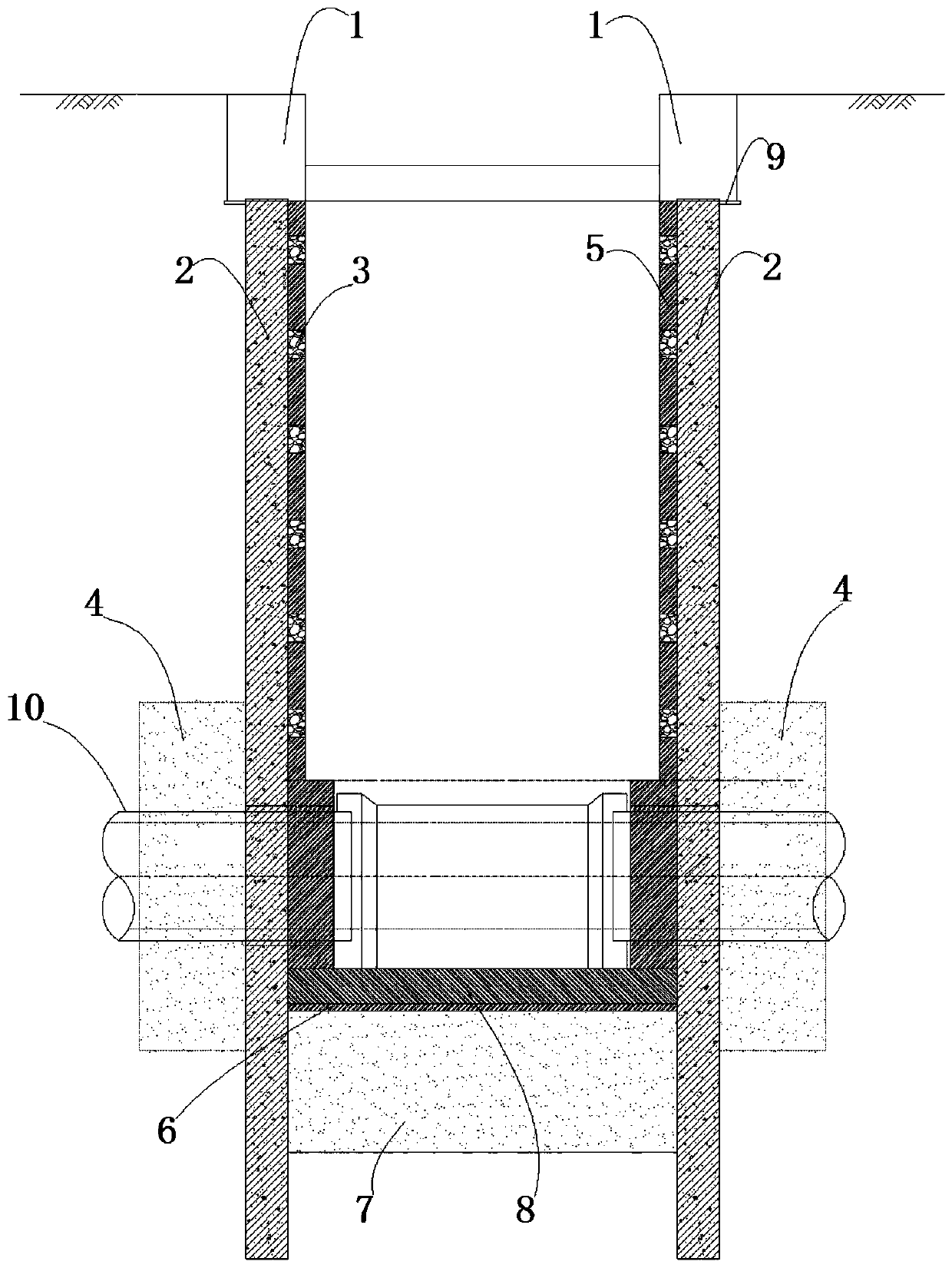

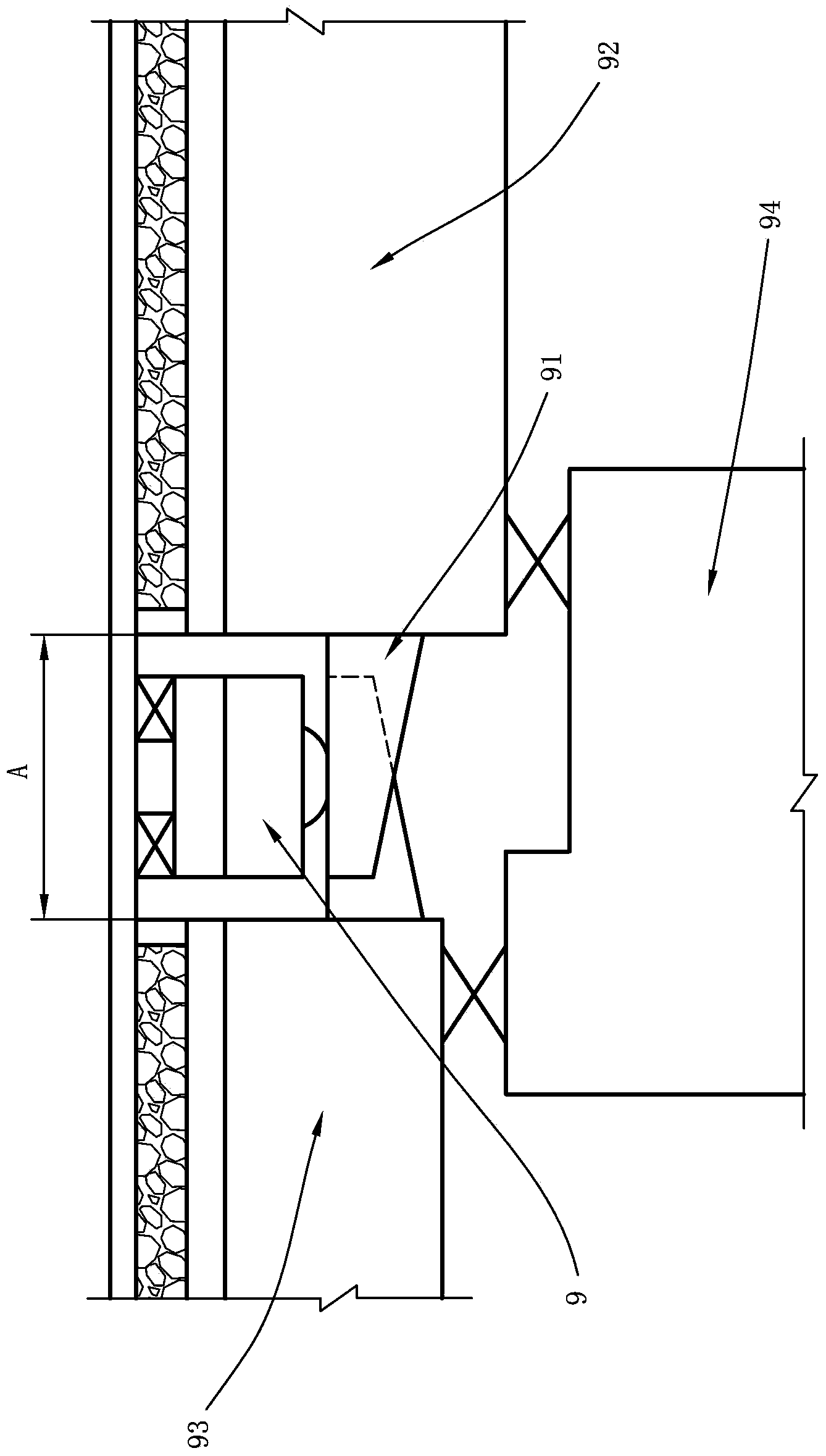

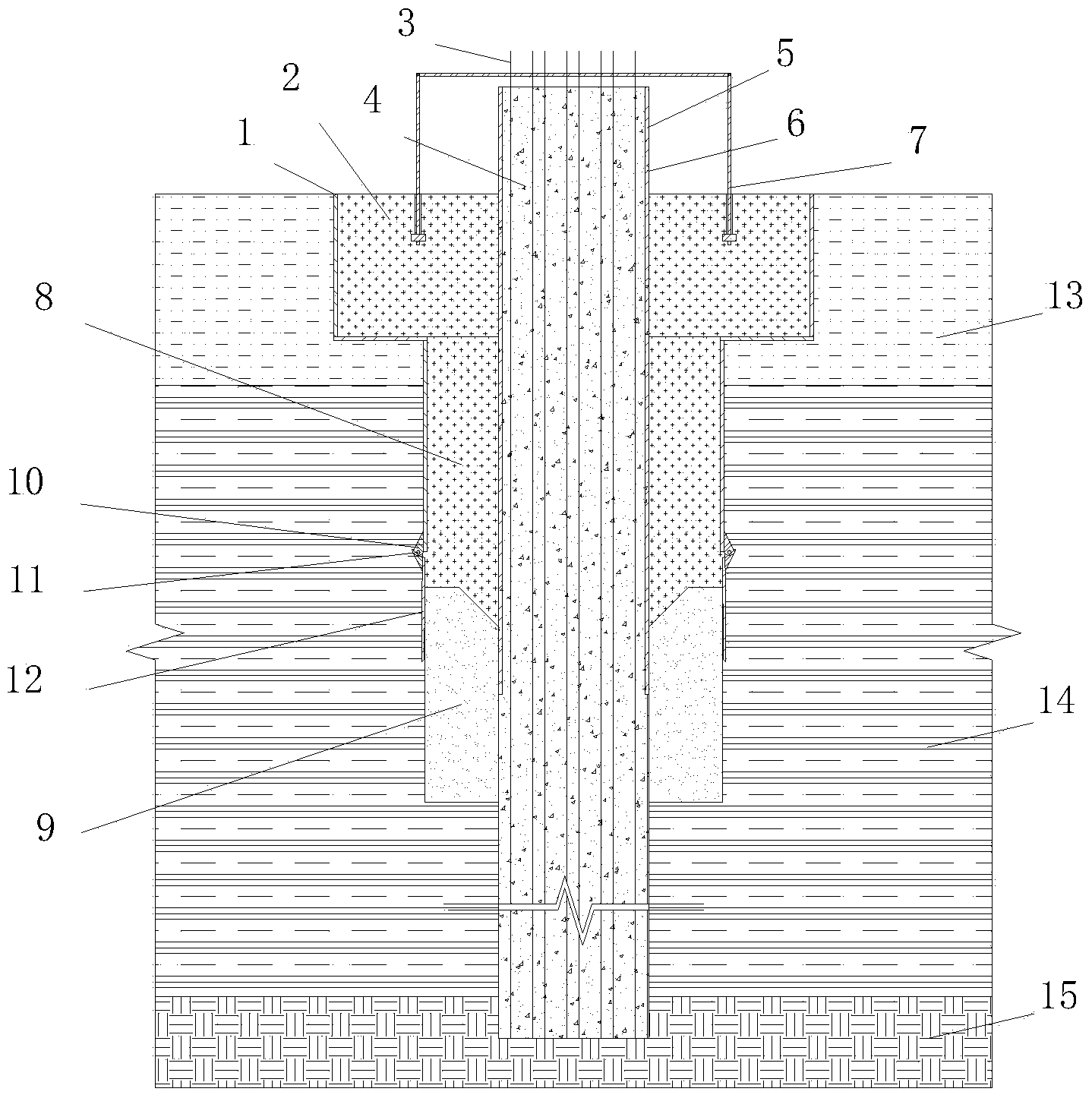

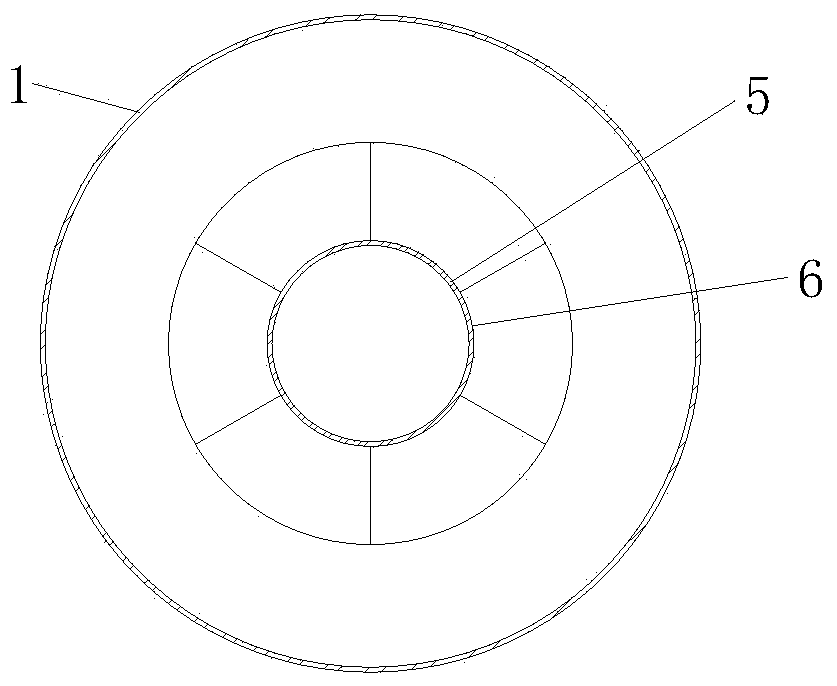

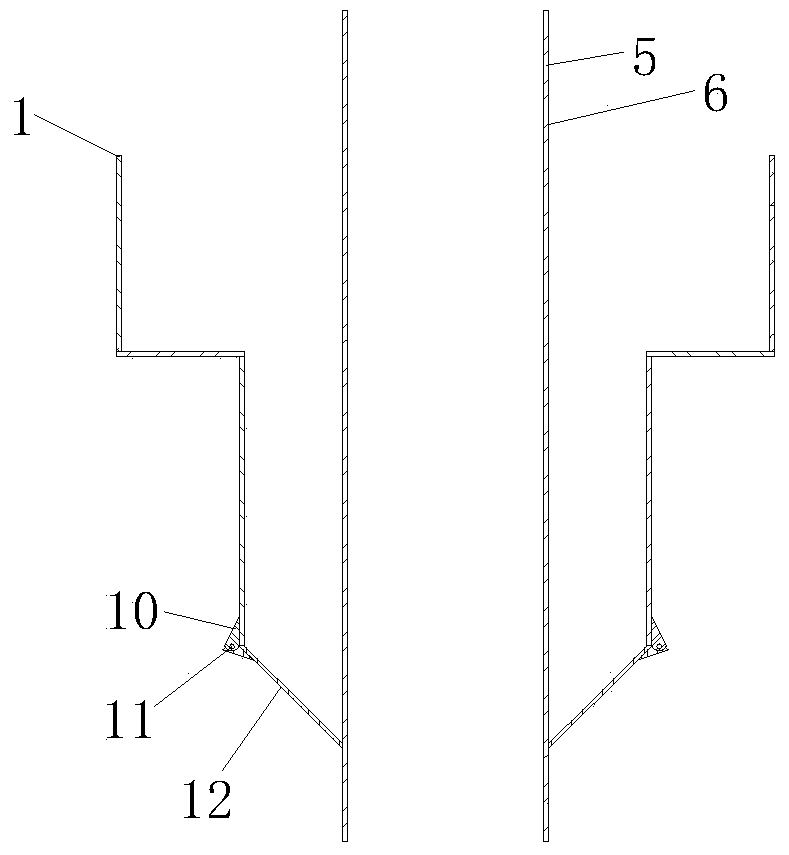

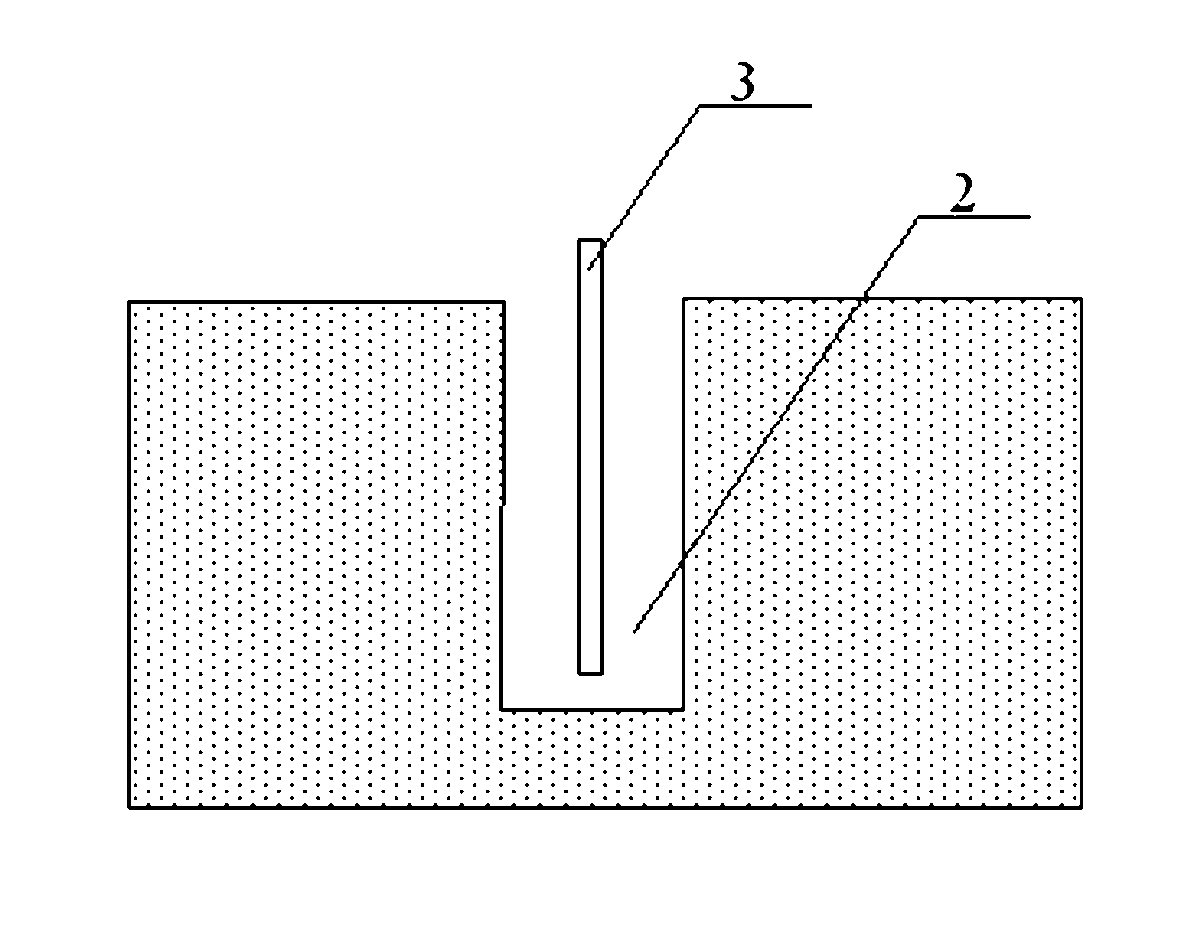

Caisson and pile combined foundation of consolidated subsoil and construction method of caisson and pile combined foundation

The invention discloses a caisson and pile combined foundation of consolidated subsoil and a construction method of the caisson and pile combined foundation. The caisson and pile combined foundation of the consolidated subsoil comprises the consolidated subsoil, a sand-gravel cushion, a caisson, bored piles, pile bottom grout, top seal concrete and scour protection. The main construction method comprises the following steps: consolidating the foundation with an underwater compaction sand pile or a deep-layer cement mixing pile; laying the sand-gravel cushion on the consolidated subsoil; sinking the caisson with a skirt, pile sinking guide holes and grouting reserved pipes on the sand-gravel cushion; after the caisson is located, constructing bored piles through the pile sinking guide holes; after construction of the bored piles, casting the top seal concrete at the bottom in the caisson; grouting the bottom of the caisson through the grouting reserved pipes at the bottom of the caisson, carrying out pile bottom grouting through grouting pipes in the pile, and at last casting the top plate of the caisson. In the construction process, the scour protection shall be performed around the caisson according to requirements. The caisson and pile combined foundation of the consolidated subsoil and the construction method of the caisson and pile combined foundation, disclosed by the invention, can effectively improve vertical and horizontal bearing capacity of the caisson, and control sedimentation and horizontal displacement of the caisson.

Owner:CCCC HIGHWAY CONSULTANTS +1

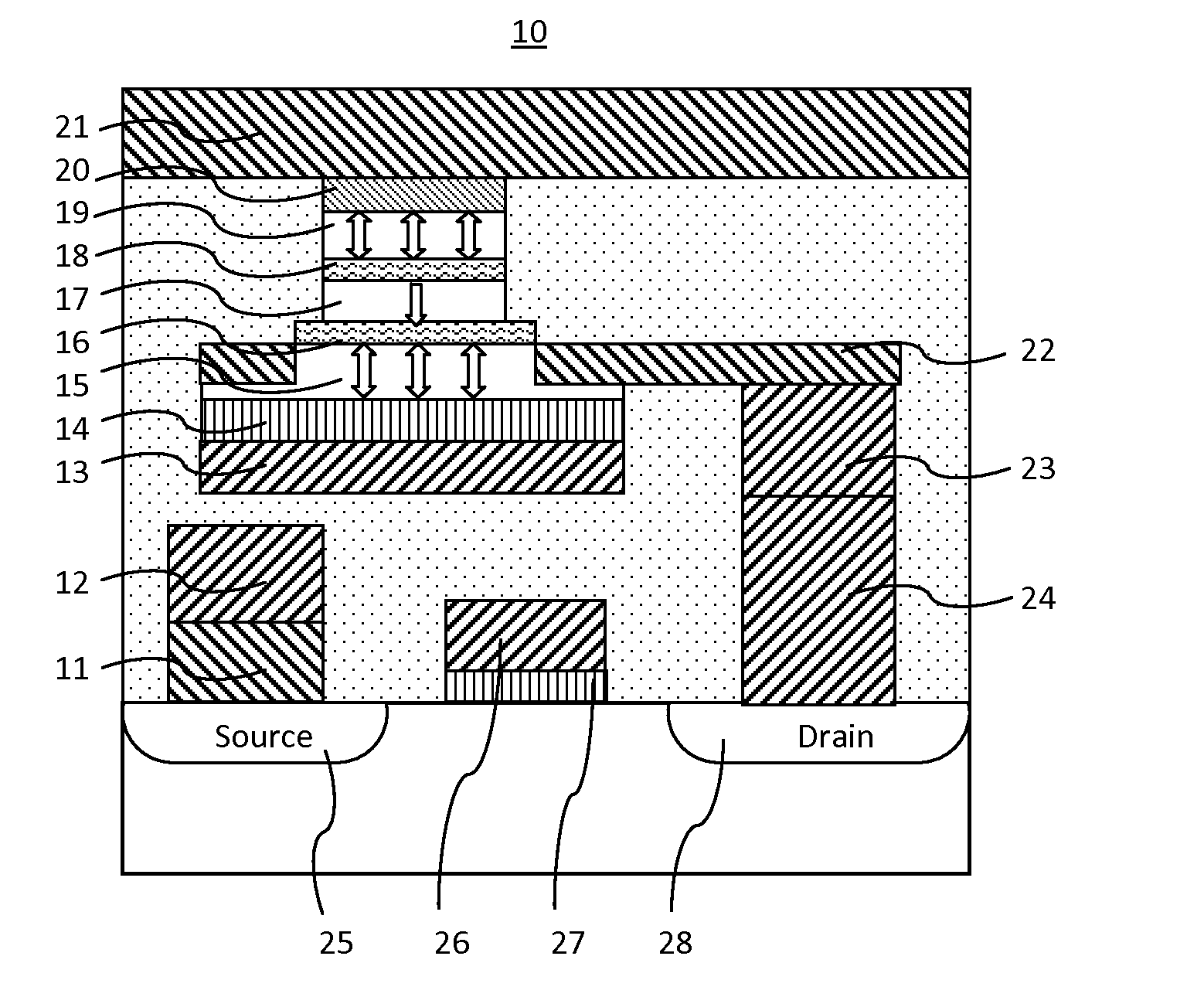

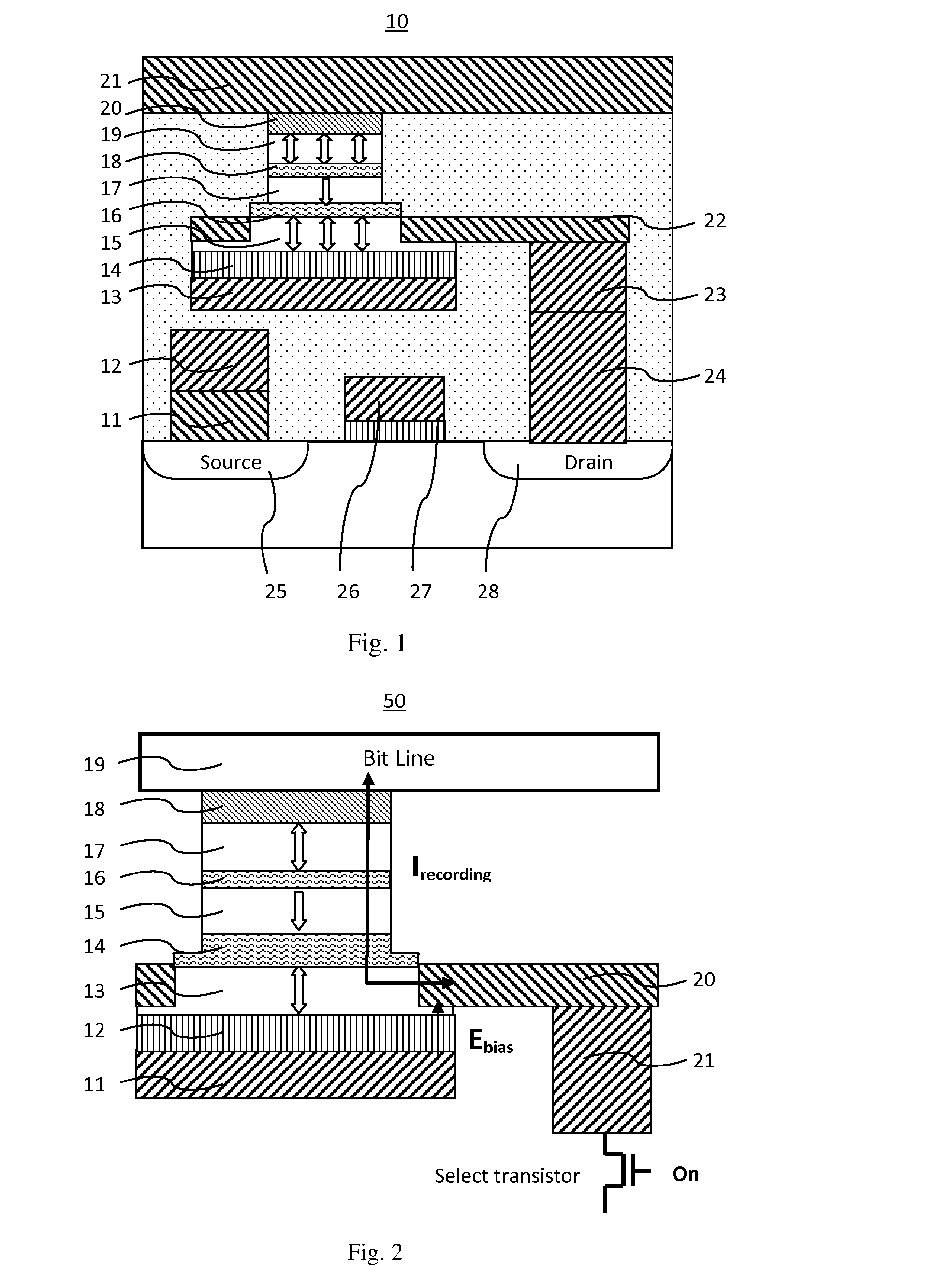

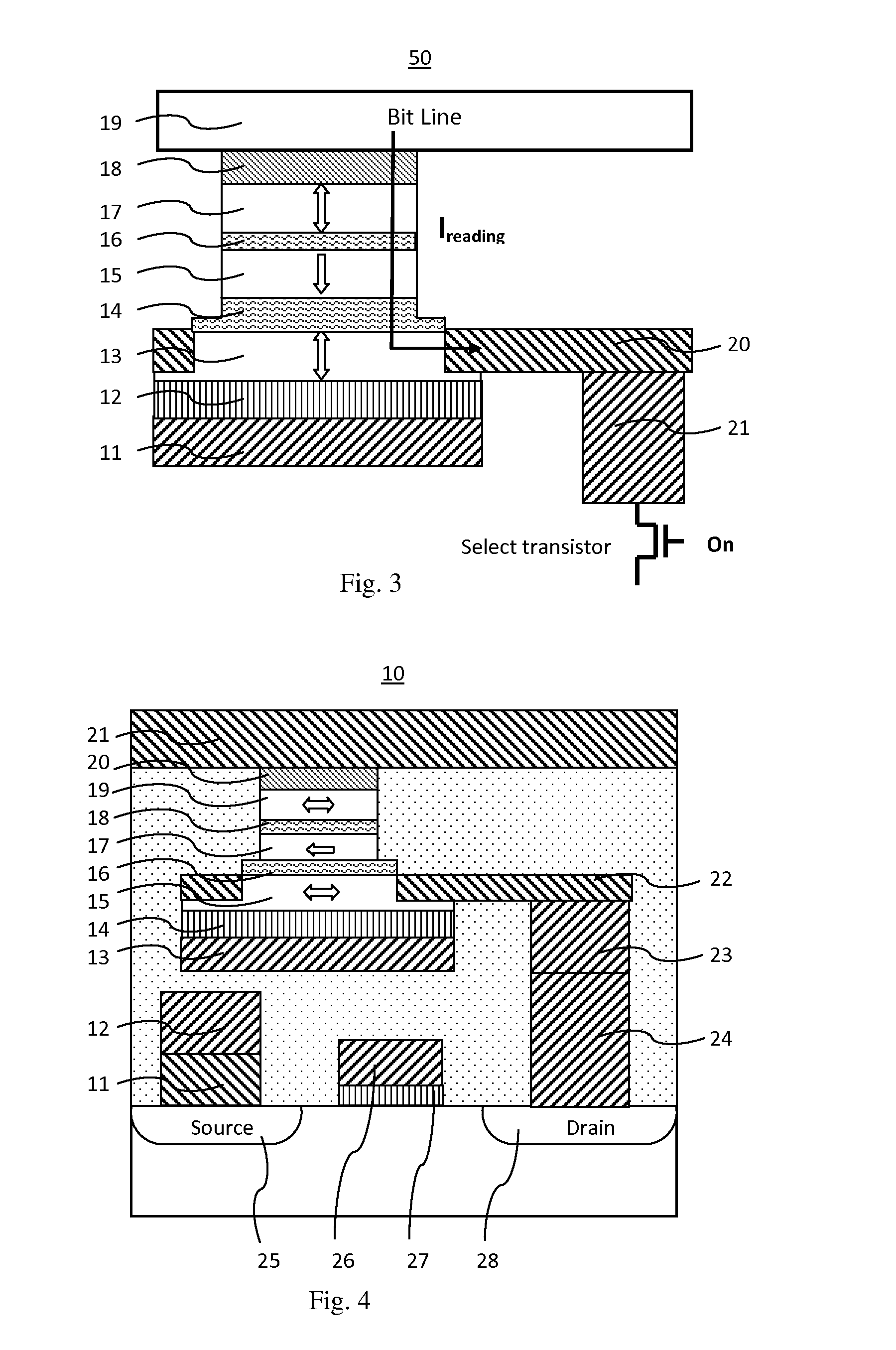

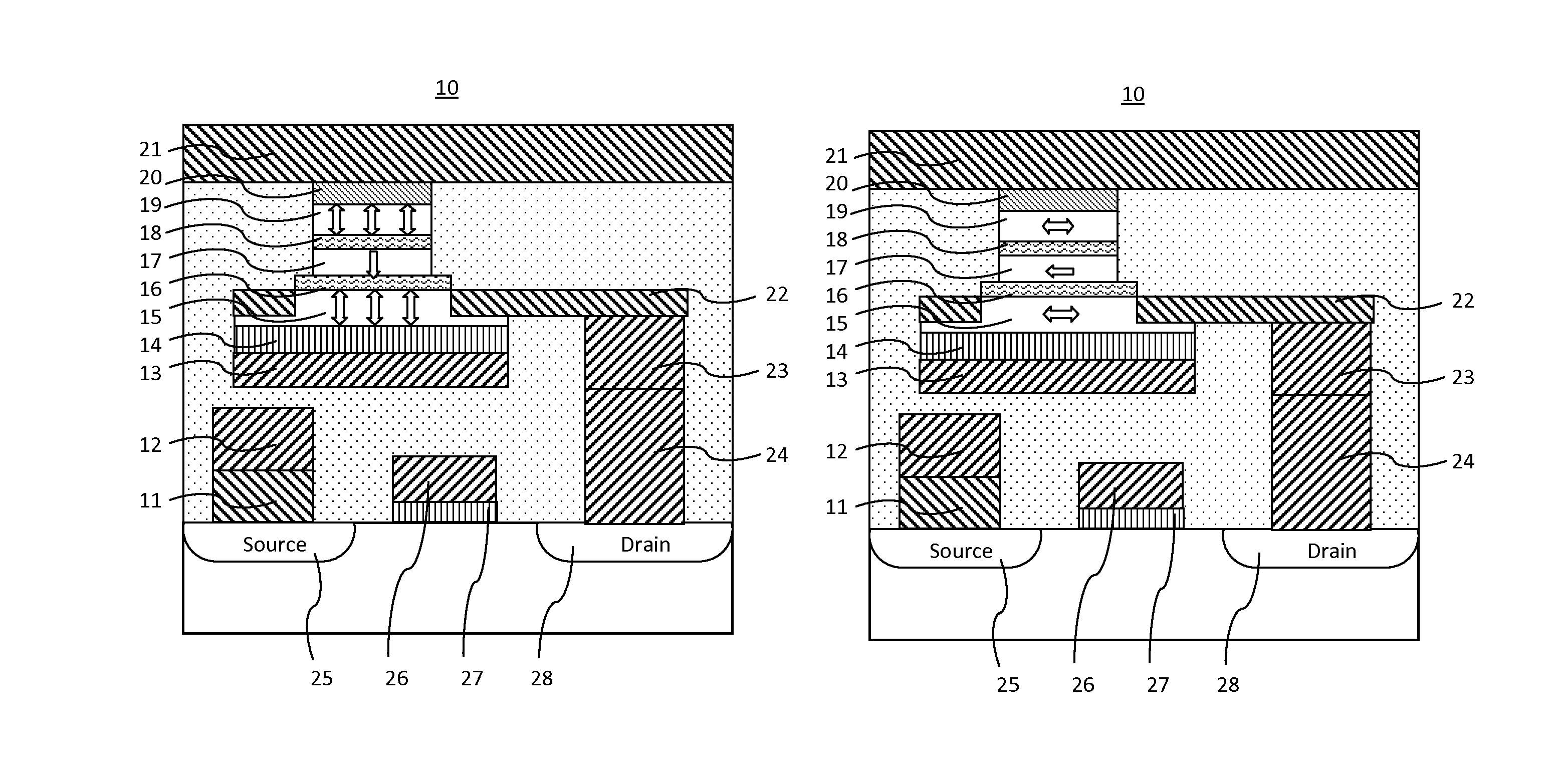

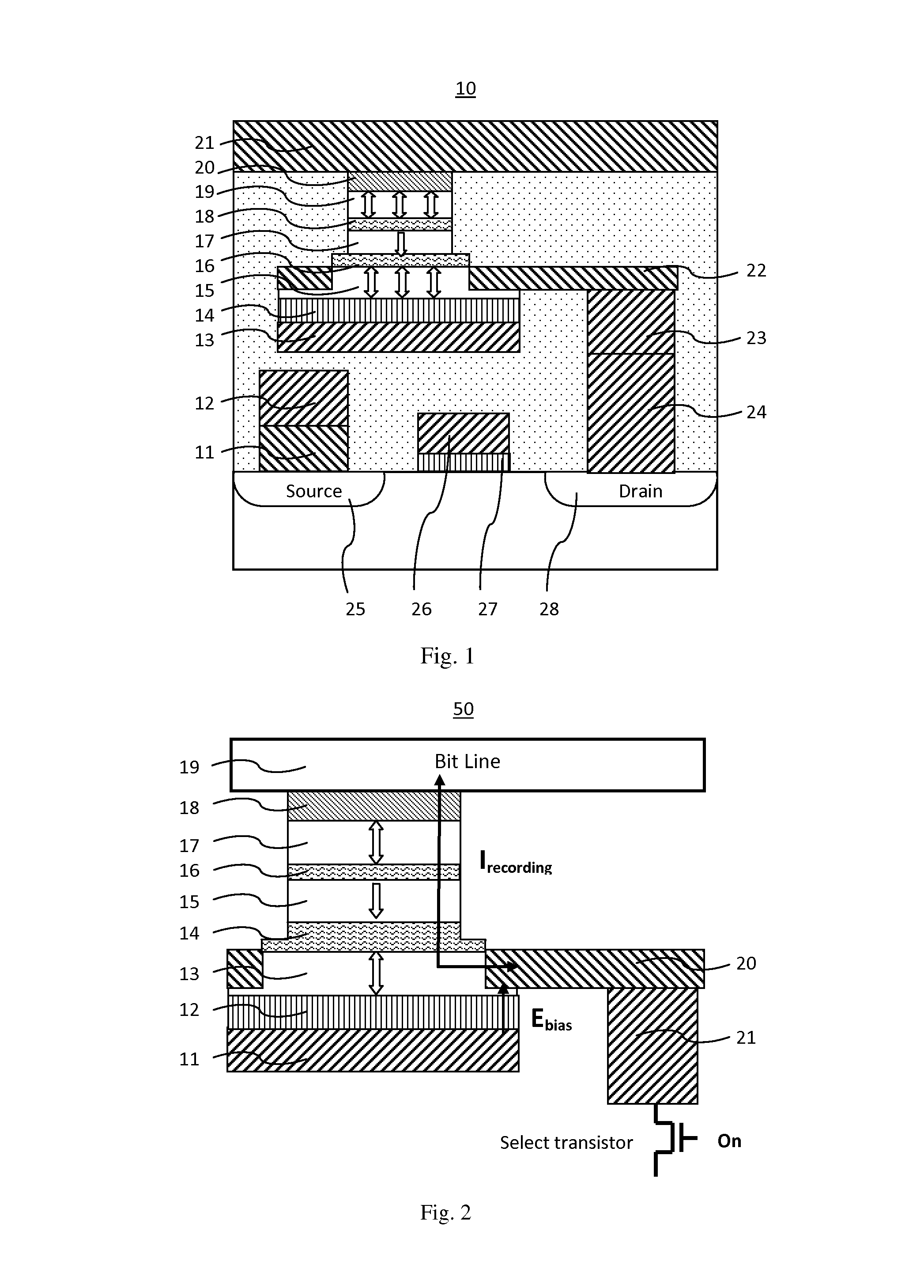

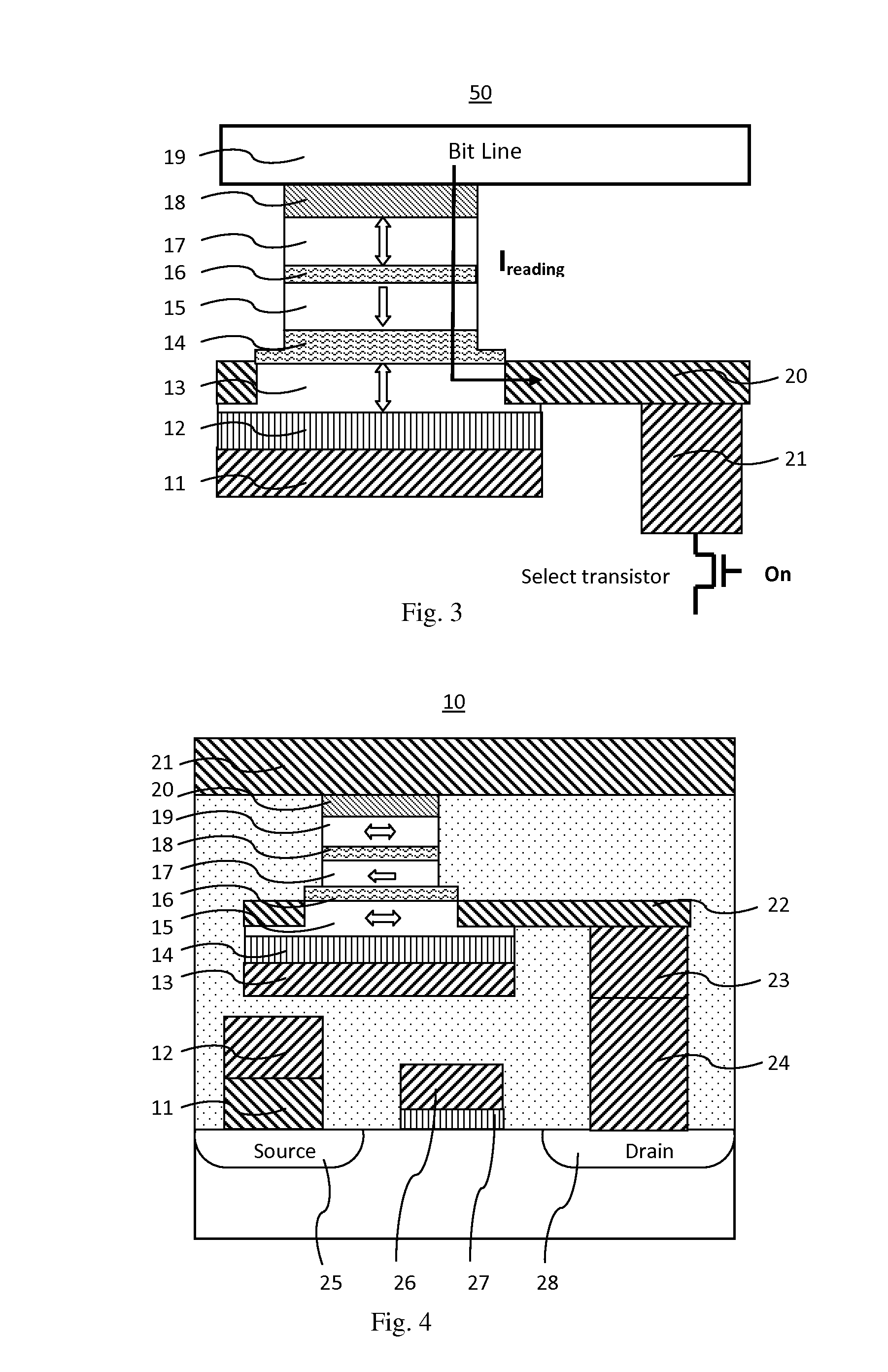

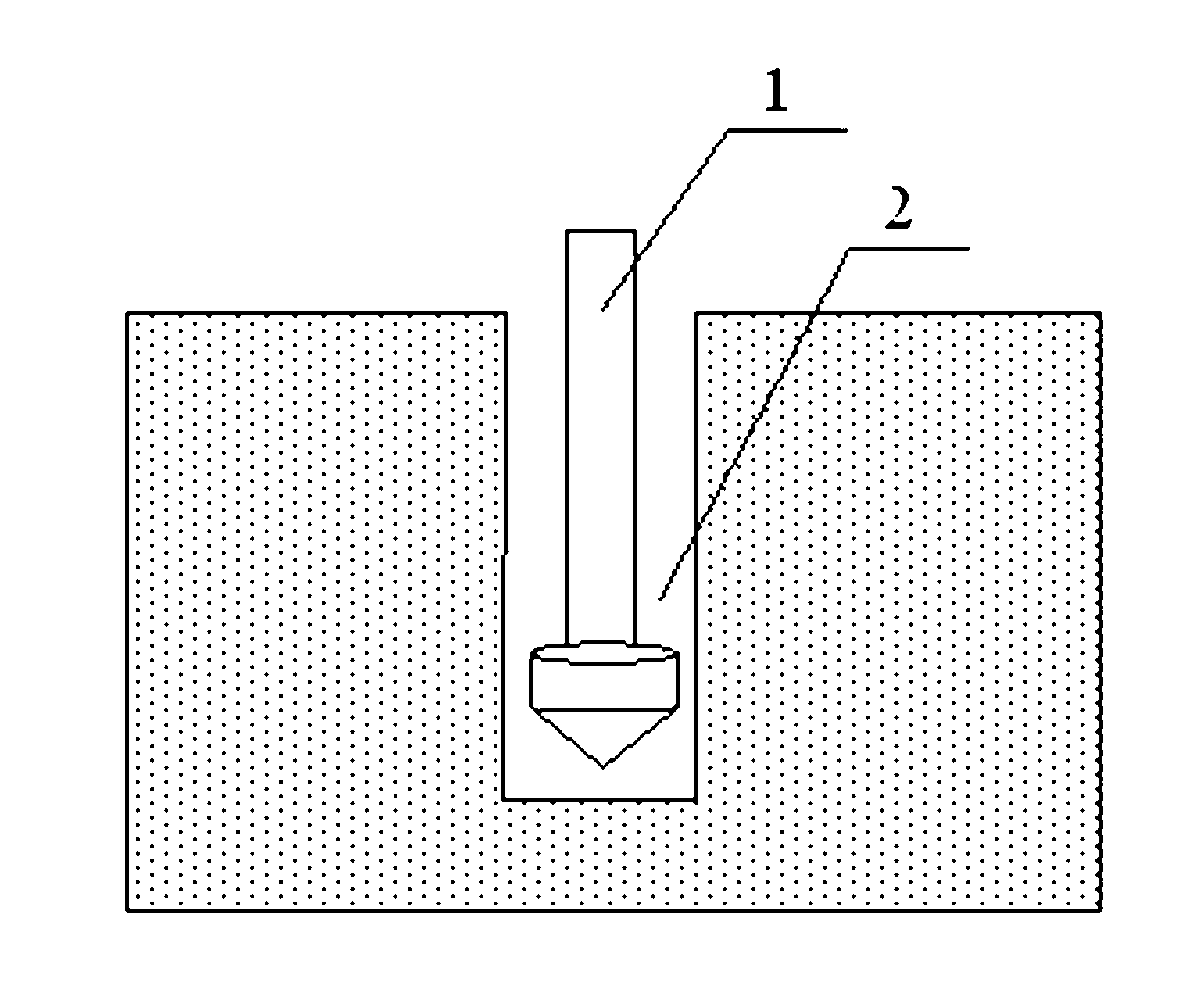

Magnetoresistive element

ActiveUS20140254252A1Decreasing perpendicular anisotropy strengthEasy to switchDigital storageThin magnetic filmsMagnetic reluctanceHemt circuits

A STT-MRAM comprises apparatus, and method of operating a double-MTJ magnetoresistive memory and a plurality of magnetoresistive memory element having a first recording layer which has an interface interaction with an underneath dielectric functional layer and having a second recording layer which has no interface interaction with an underneath dielectric functional layer. The energy switch barrier of the first recording layer is reduced under an electric field applying along a perpendicular direction of the functional with a proper voltage on a digital line from a control circuitry; accordingly, the magnetization of the first recording layer is readily reversible in a low spin-transfer switching current while the magnetization of the second recording layer is readily reversible in a high spin-transfer switching current, enabling two separate bits recording in a double MTJ stack.

Owner:GUO YIMIN

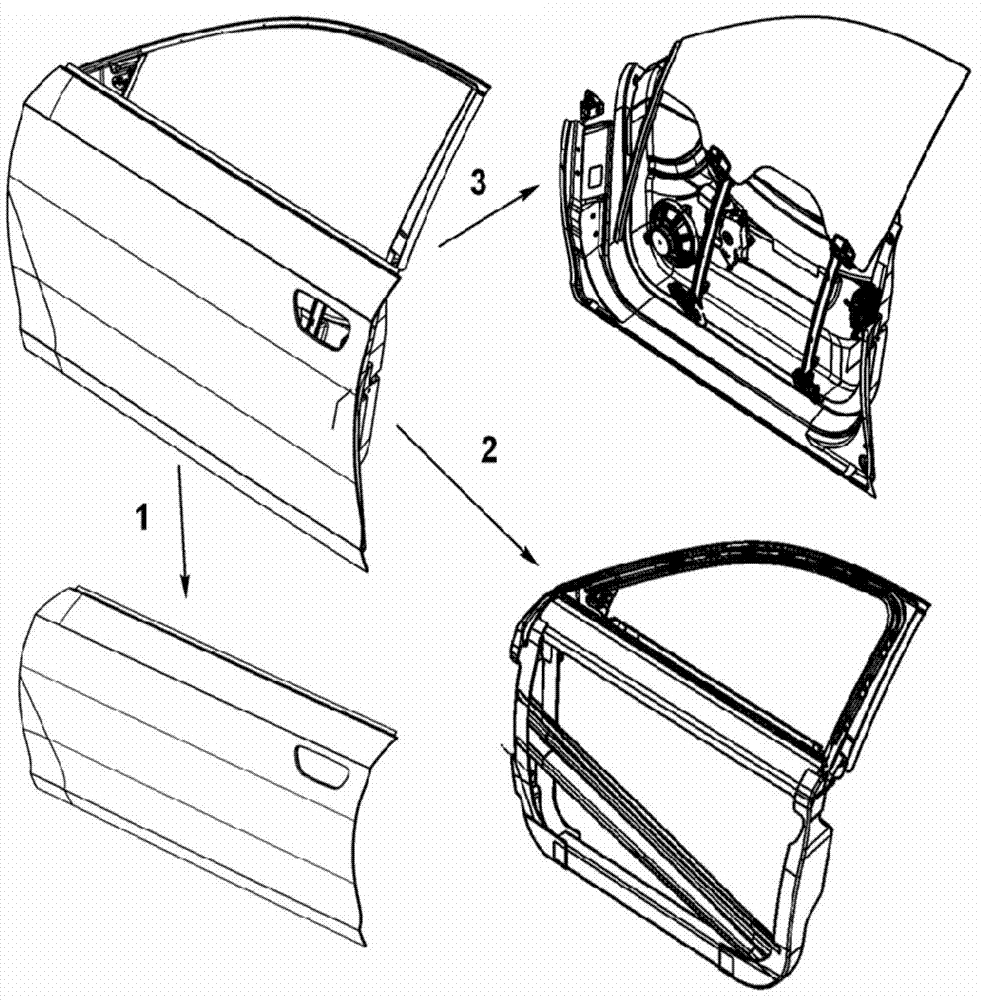

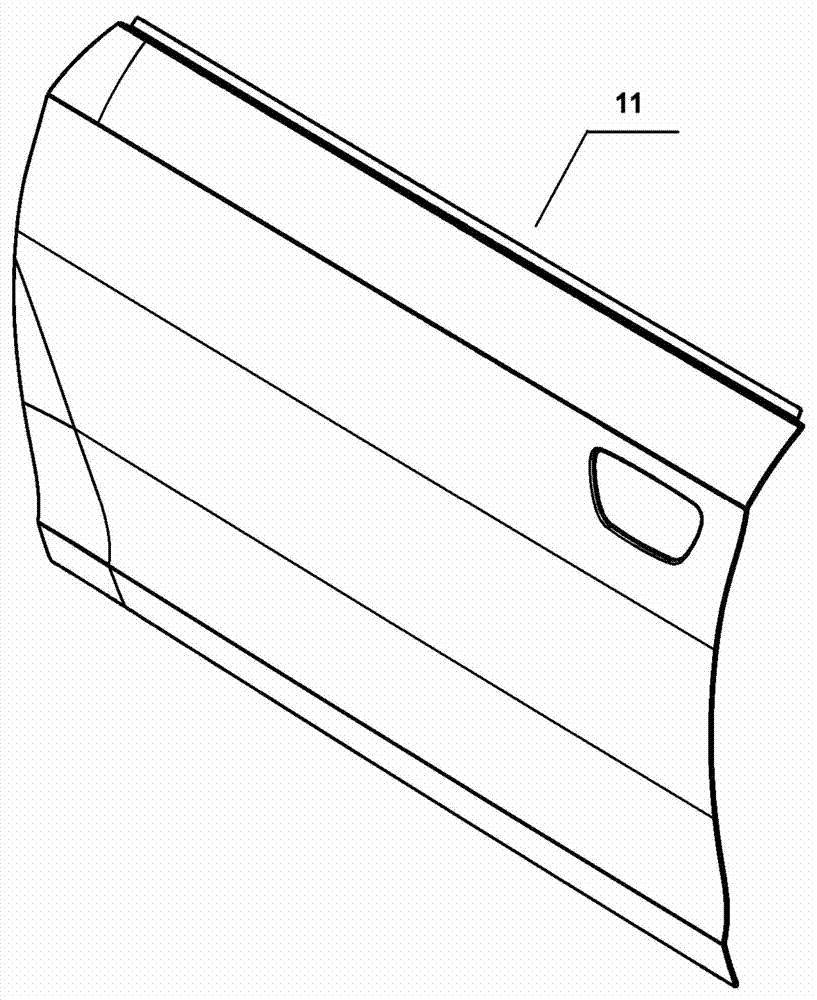

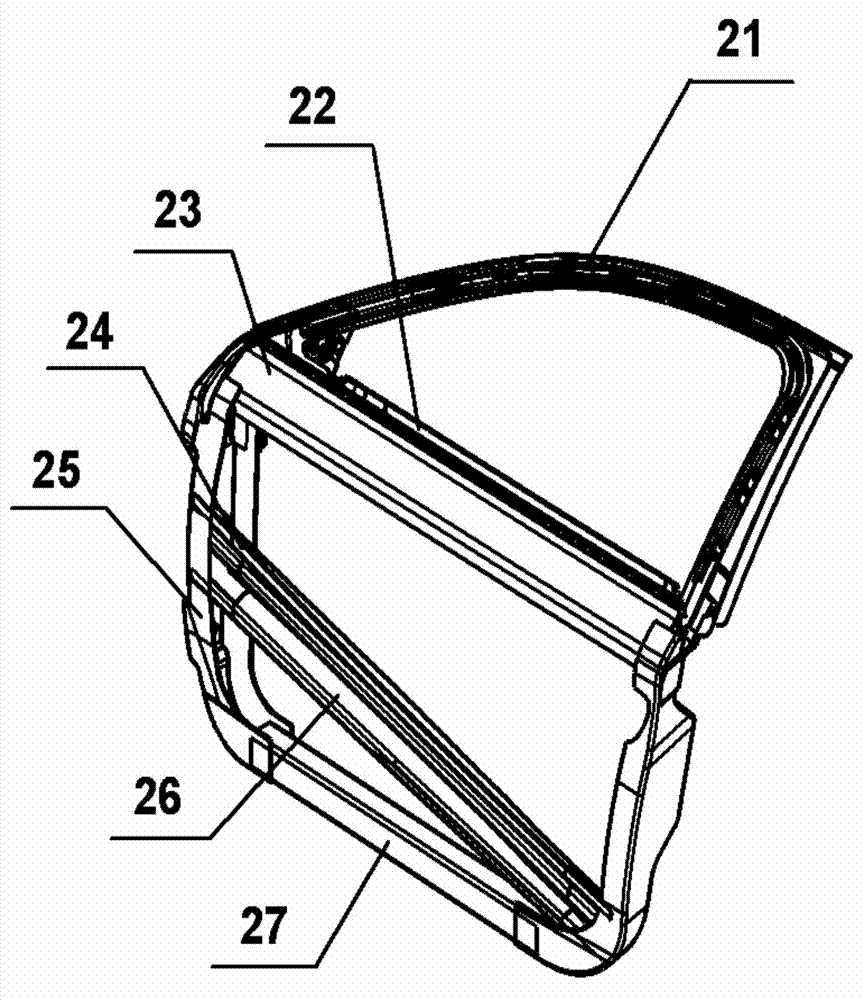

Modularized vehicle door with steel, aluminum and plastic mixed

The invention relates to a modularized vehicle door with steel, aluminum and plastic mixed. Compared with a total complex structure of a traditional vehicle door, according to the modularized vehicle door with steel, aluminum and plastic mixed, the original complex vehicle door structure is modularized, and the vehicle door structure is divided into three functional modules which include a vehicle door outer plate, a vehicle door frame, a vehicle door inner plate and an accessory module. According to the functionality of all parts of the vehicle door, traditional vehicle door modules are functionalized, and good vehicle door manufacturing and assembling manufacturability is achieved. The modularized vehicle door with steel, aluminum and plastic mixed is specifically characterized in that the vehicle door outer plate is not a main stressed part in the vehicle door structure, the strength and rigidity requirements are moderate, and the purpose generally lies in the effect that the functional requirements for meeting external shapes are improved; the vehicle door inner plate is not a main stressed part, either, and can be made of composite materials or plastic. According to the modularized vehicle door with steel, aluminum and plastic mixed, factors in all the aspects of strength, rigidity, appearance and weight are taken into comprehensive consideration, the vehicle door outer plate can be made of thinner metal material plates and aluminum alloy materials, and the aluminum alloy materials are light, small in specific gravity, high in strength, good in ductility, and high in corrosion resistance and meanwhile has good forming performance, machinability and the like.

Owner:HUNAN UNIV

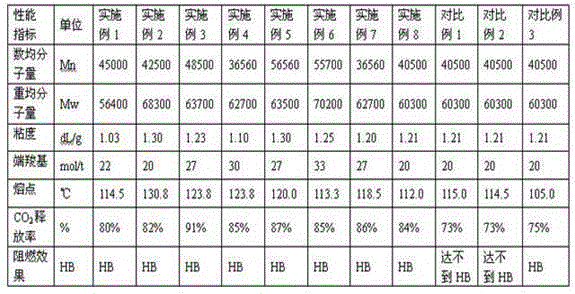

Poly(butylene succinate) and preparation method thereof

The invention discloses a poly(butylene succinate) which is prepared by copolymerizing succinic acid, butylene glycol and cyclic dibasic alcohol. The poly(butylene succinate) comprises succinic acid residue, butylene glycol residue and cyclic diol residue, wherein the butylene glycol residue accounts for 90-98% of the total dibasic alcohol, and the cyclic diol residue accounts for 2-10% of the total dibasic alcohol. The preparation method comprises the following steps: reacting succinic acid, butylene glycol and cyclic dibasic alcohol at 200-230 DEG C under the action of a catalyst to perform direct esterification, thereby obtaining an esterified substance; adding a stabilizer, and carrying out pre-polycondensation reaction at 220-250 DEG C to obtain a prepolymer; carrying out polycondensation reaction on the prepolymer at 235-250 DEG C while gradually reducing the vacuum degree of the reaction system to less than 150Pa; and after the polycondensation finishes, adding carbodiimide compounds into the reaction product, and mixing for 2-15 minutes, thereby obtaining the poly(butylene succinate). The polyester synthesized by the method disclosed by the invention has the advantages of high heat resistance, high melting point, controllable degradation rate, excellent mechanical properties and excellent processability.

Owner:KINGFA SCI & TECH CO LTD +2

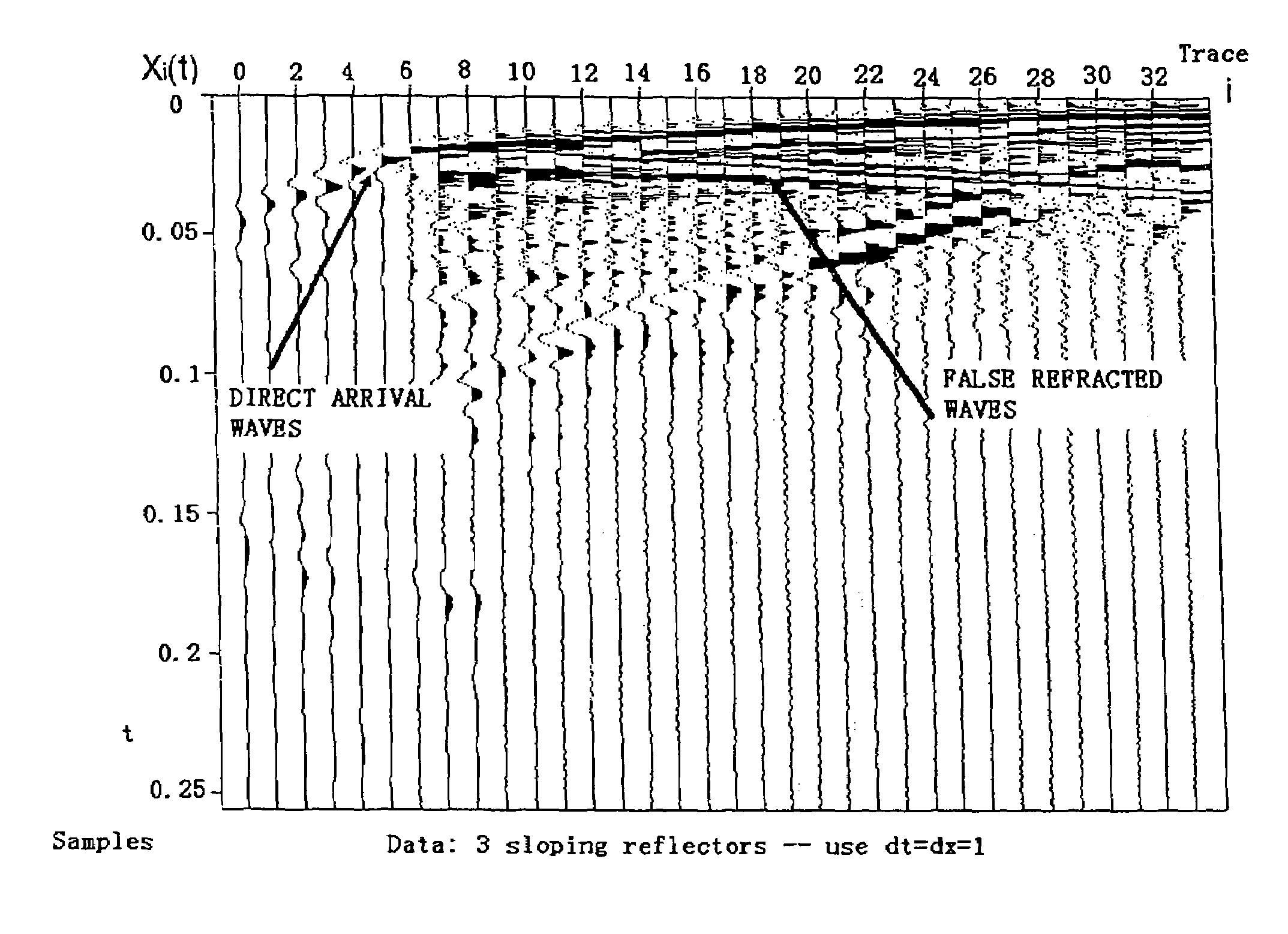

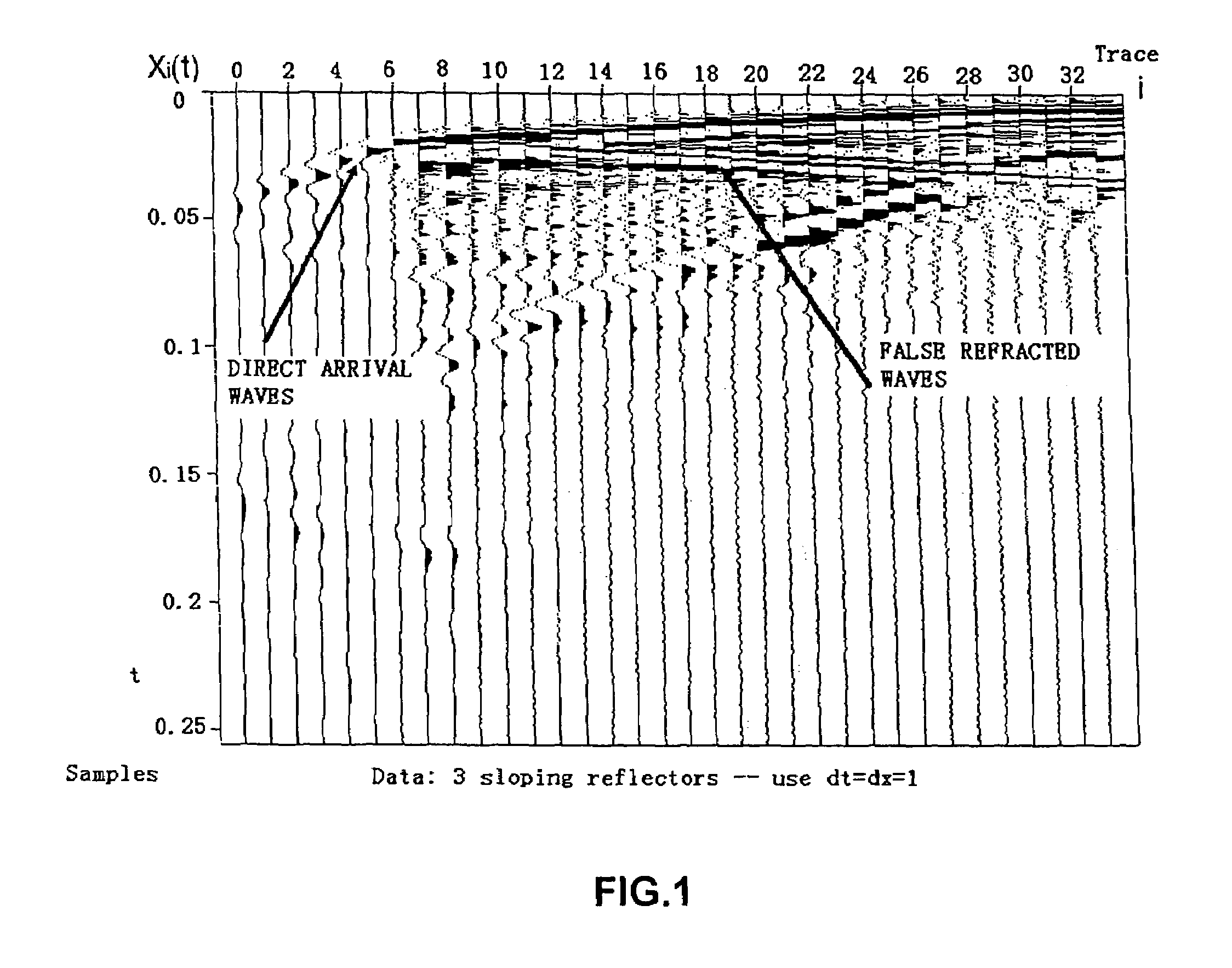

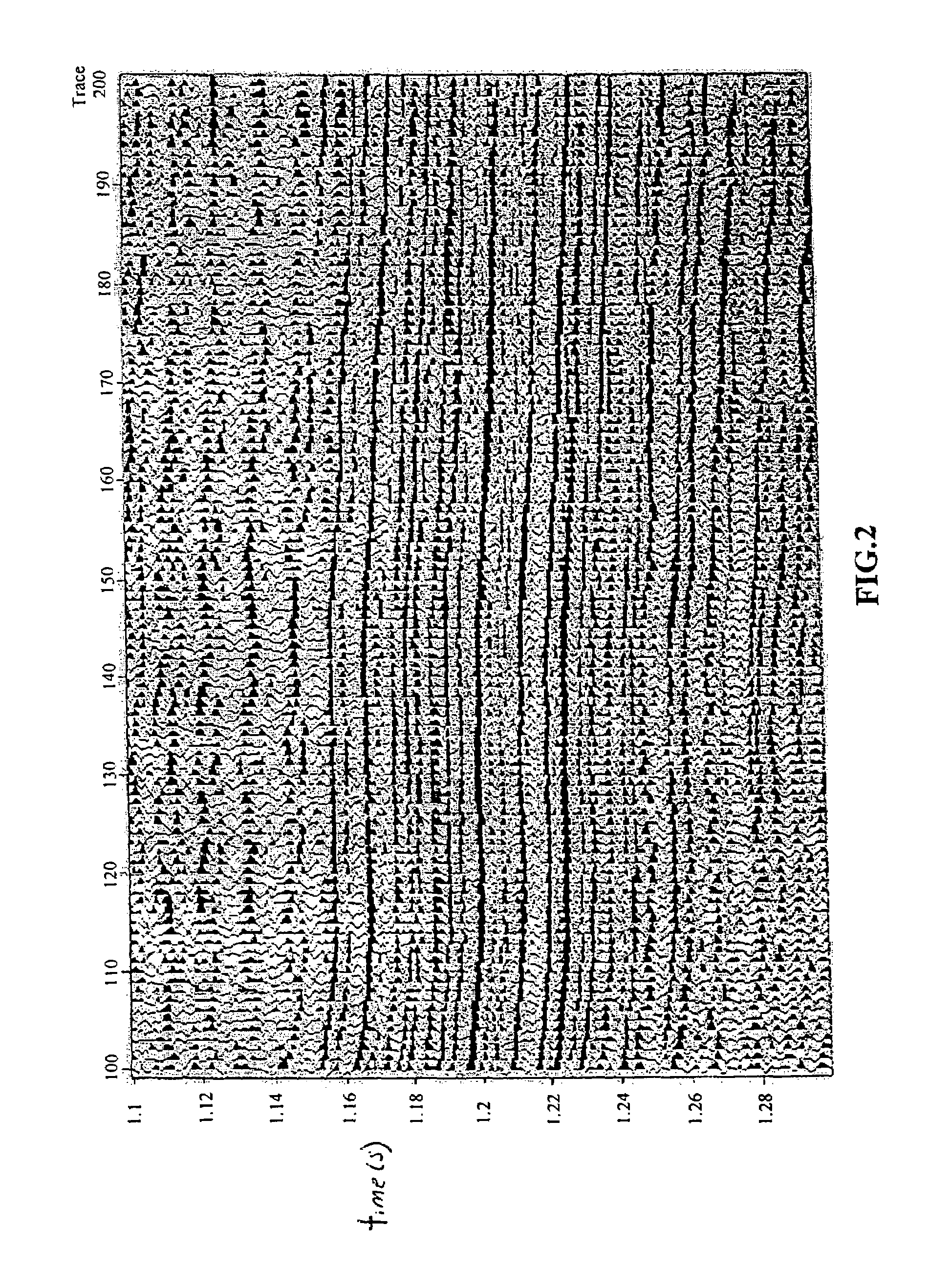

Method for improving the seismic resolution

ActiveUS7414919B2Enhance apparent dominant frequencyHigh resolutionSeismic data acquisitionSeismic signal processingFrequency spectrumSeismic survey

Owner:PETROCHINA CO LTD +1

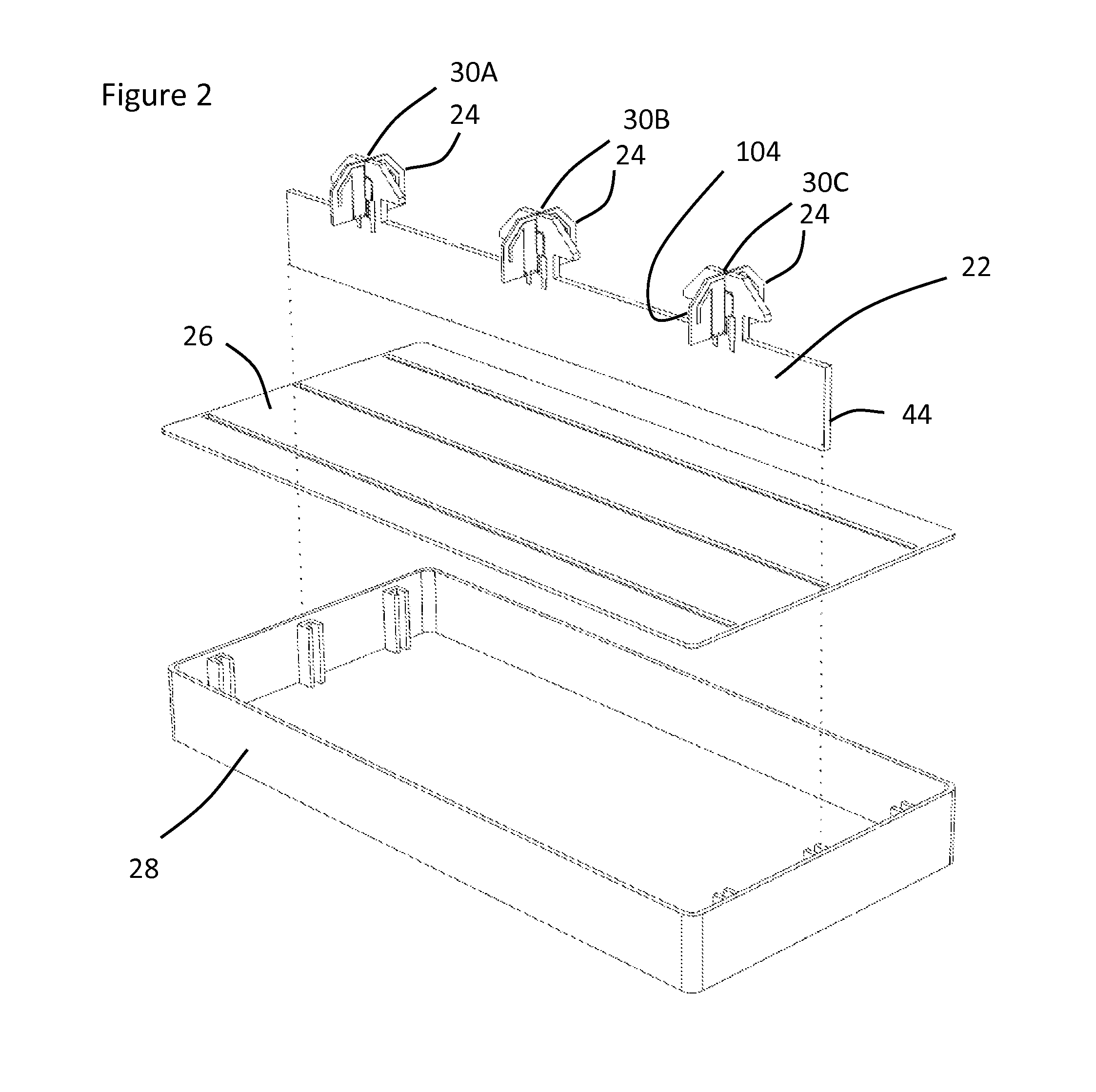

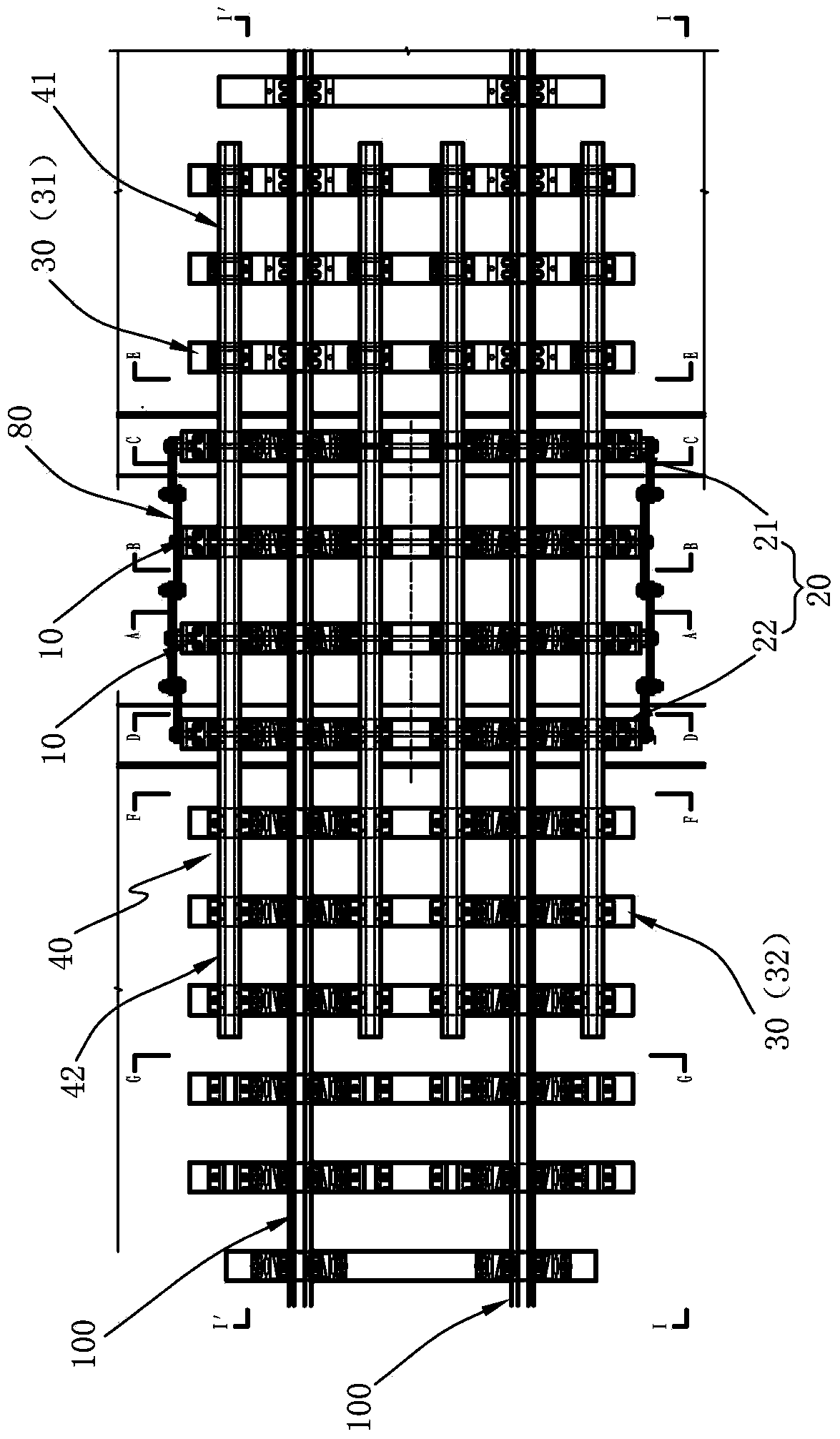

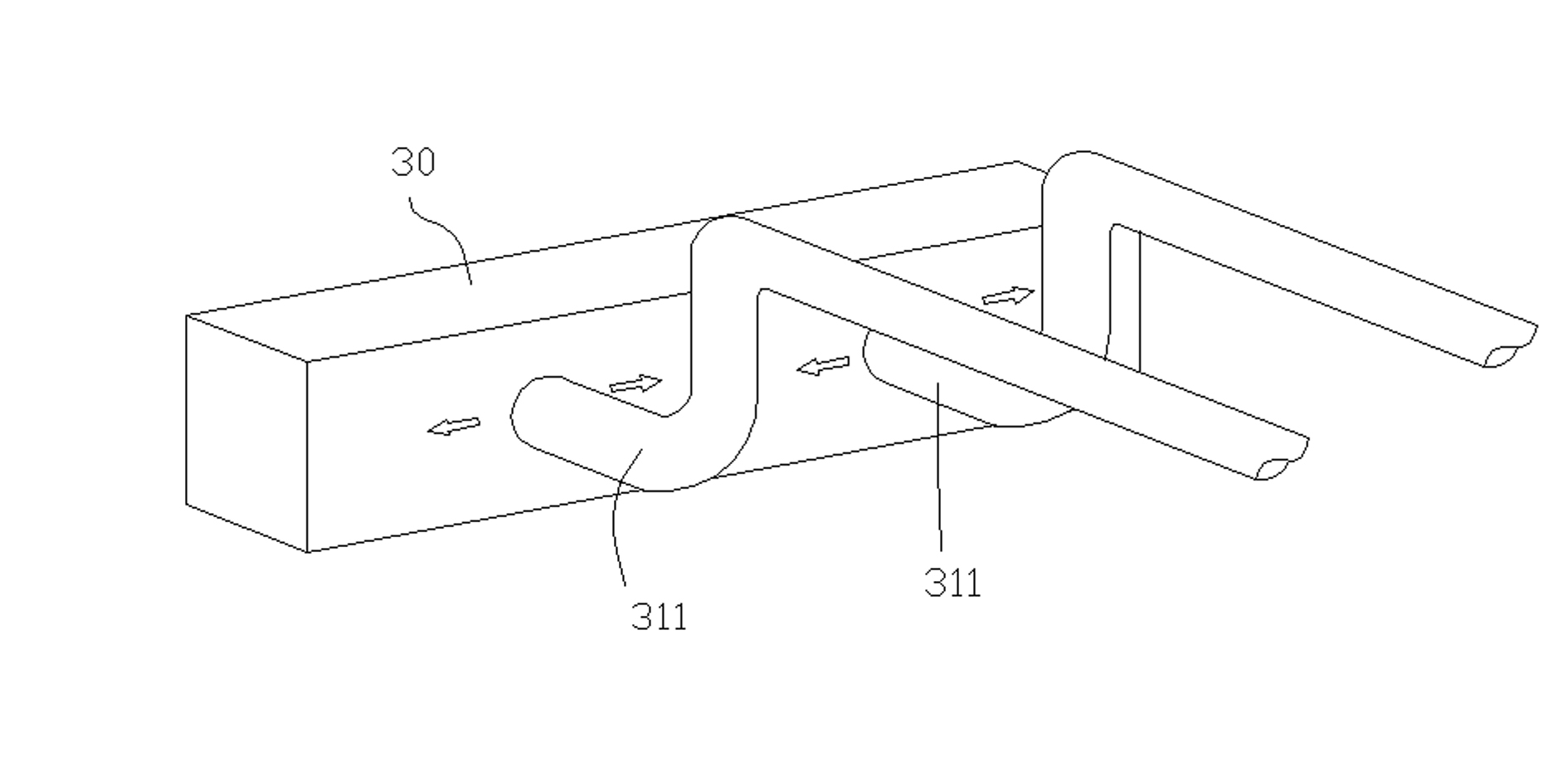

Crossed-dipole antenna array structure

ActiveUS9397404B1Improve verticalityRaise the verticalIndividually energised antenna arraysPolarised antenna unit combinationsPlanar substrateDielectric substrate

The invention is directed to a crossed-dipole antenna structure that, in one embodiment, is comprised of: (a) a first planar dielectric substrate with a feed portion and an antenna portion that supports a first dipole antenna and (b) a second planar dielectric substrate that supports a second dipole antenna or substantial portion of such an antenna. The first and second planar dielectric substrates are positioned substantially perpendicular to one another and so as to form a crossed-dipole antenna from the first and second dipole antennas. The feed portion of the first planar dielectric substrate is electrically and mechanically connected to the second planar substrate by a plurality of solder joints established in the corners defined by the intersections of the first and second planar dielectric substrates.

Owner:FIRST RF CORP

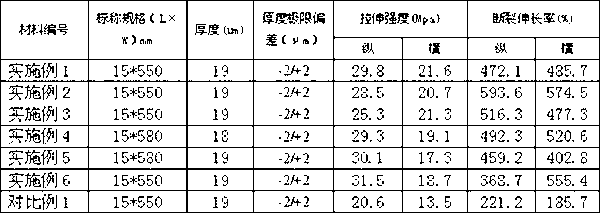

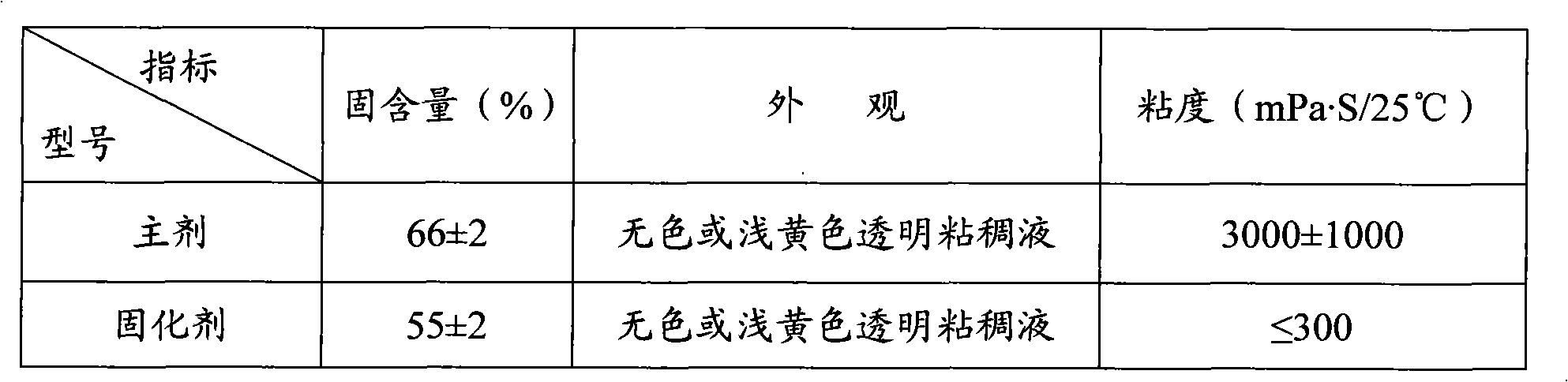

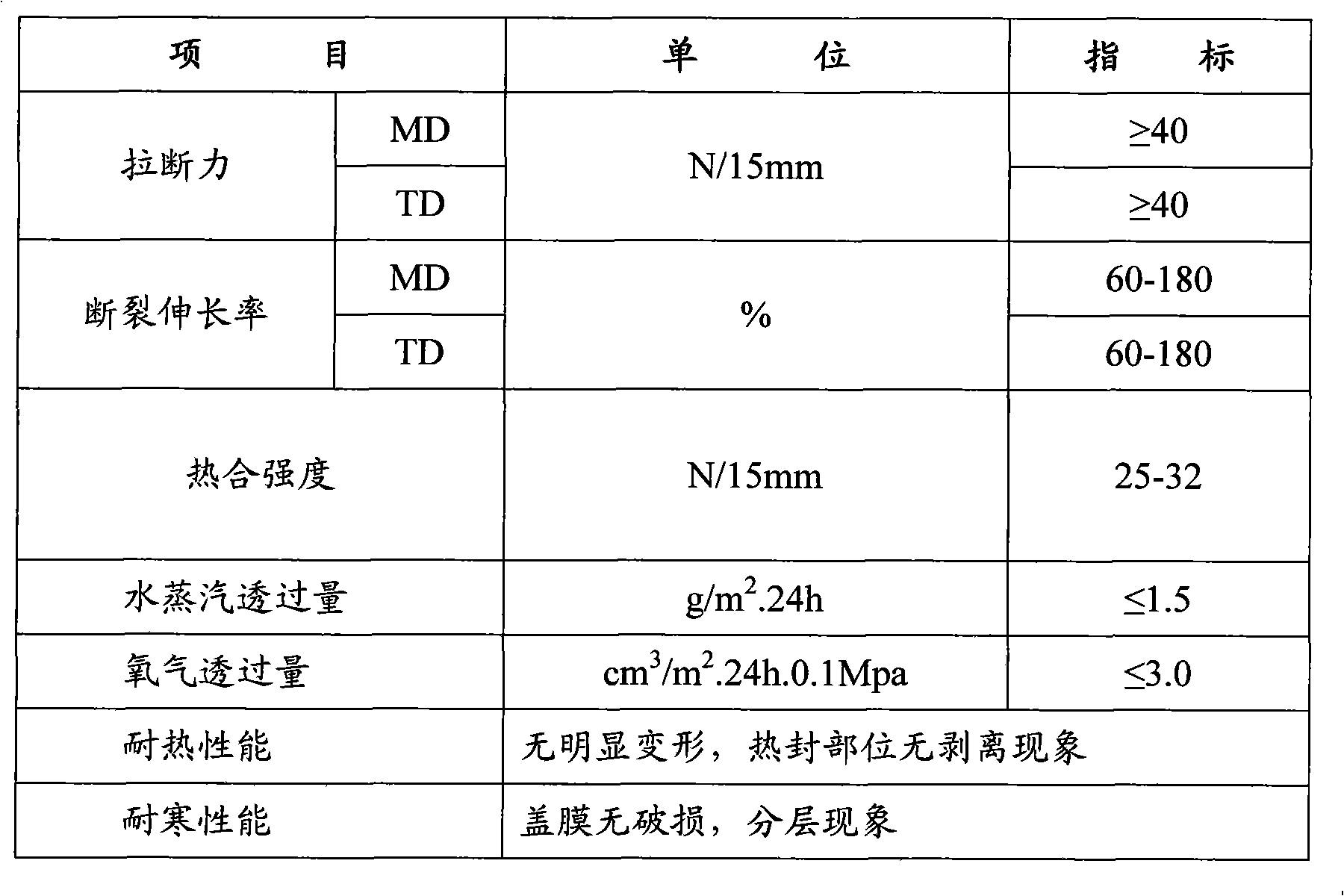

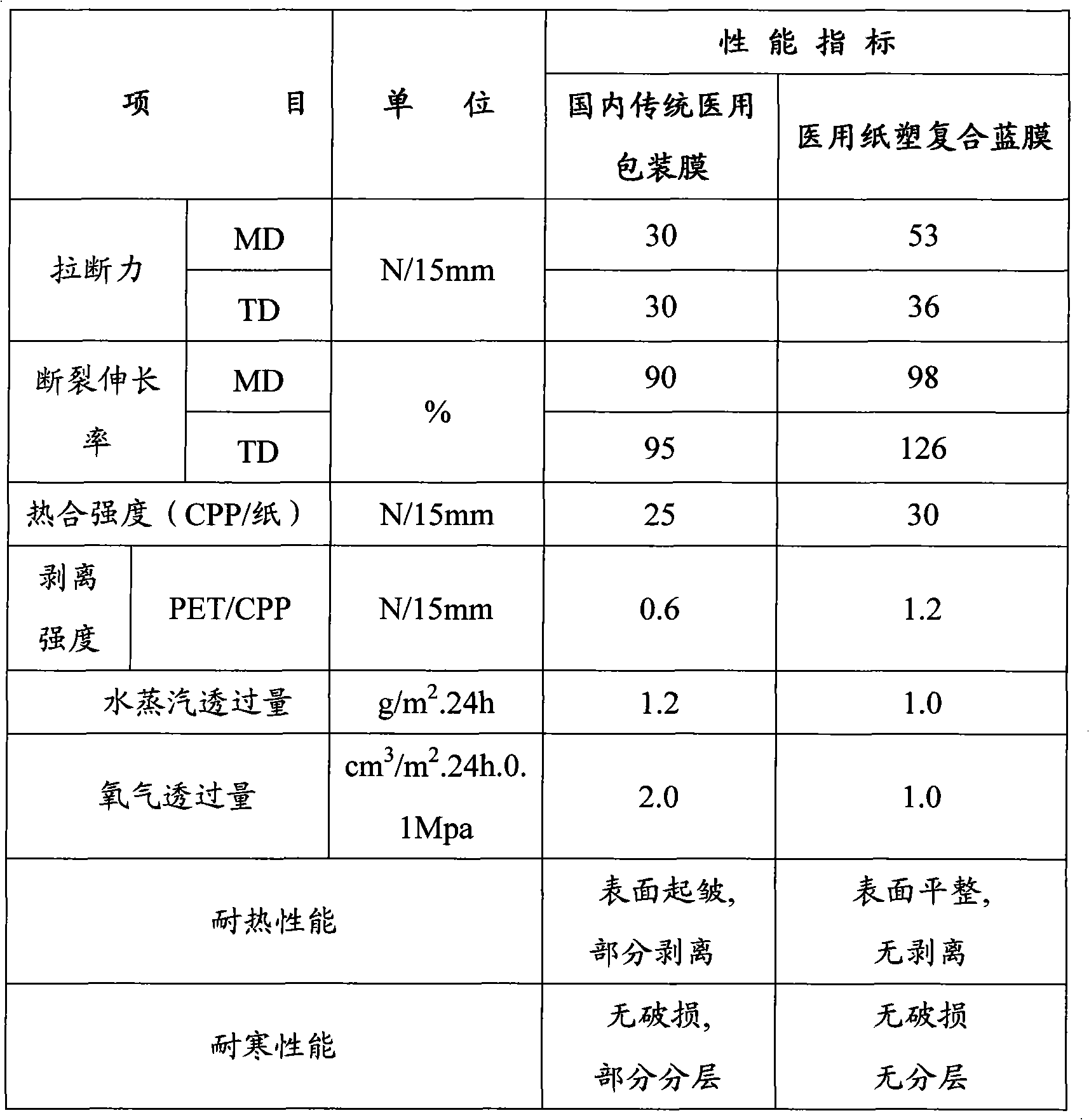

Medical paper-plastic composite blue film and preparation method thereof

ActiveCN101607458AImprove mechanical propertiesImprove folding resistanceNon-macromolecular adhesive additivesLamination ancillary operationsButenePolyester

The invention discloses a medical paper-plastic composite blue film and a preparation method thereof, the medical paper-plastic composite blue film is formed by combining a biaxially orientated polyester film which is printed and coated and a cast polypropylene film, the cast polypropylene film is divided into three layers of a corona layer, an intermediate layer and a heat seal layer, the raw material component of the corona layer is additive-free binary copolymer propylene resin RF401, the raw material components of the intermediate layer are 85-95% of binary random copolymer polypropylene resin F800E and 5-15% of ethylene-butene elastomer A-4085S, and the raw material components of the heat seal layer are 85-90% of binary copolymer propylene resin RF402 containing anti-sticky slipping agent, 5-15% of ethylene-butene elastomer A-4085S, 1-2% of inorganic anti-sticky agent ABPP10S and 0.5-1.5% of slip modified masterbatch SE07PP. The preparation method comprises the steps of printing, preparation of the cast polypropylene film, combination of the biaxially orientated polyester film and the cast polypropylene film and cutting. The medical paper-plastic composite blue film is matched with medical packing paper which can carry out heat sealing, steam sterilization and air infiltration blocking for carrying out packing of medical items, thereby reducing the packing cost and realizing safety performance of packing applications and environment-friendly treatment of packing wastes.

Owner:HUANGSHAN NOVEL

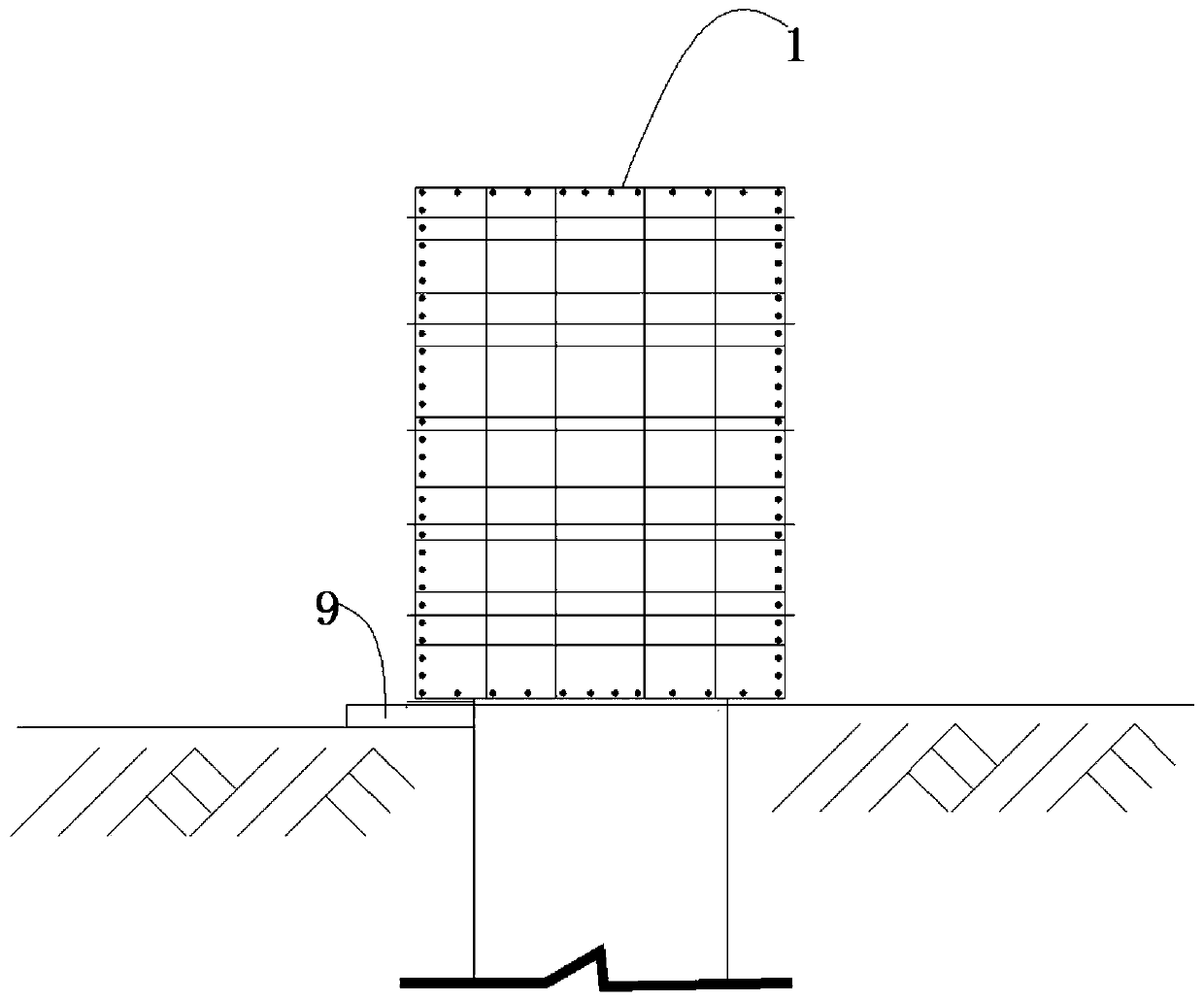

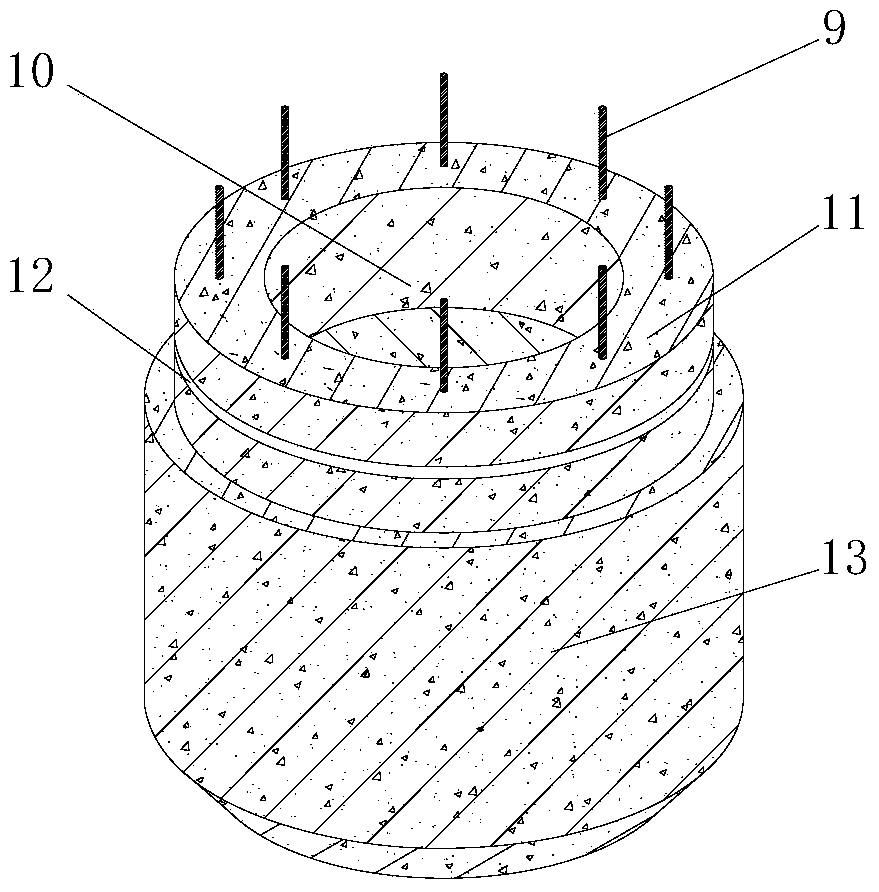

Pipe-jacking working well applicable to desert waterless sand area and construction method

PendingCN109797778AGood effectLarge pile diameterArtificial islandsShaft sinkingStructural engineeringEngineering

The invention provides a pipe-jacking working well applicable to desert waterless sand area and a construction method. The pipe-jacking working well is characterized in that a plurality of bore pilesare circumferentially uniformly arranged around the circle center the working well to form the main protecting and stress structure of the working well, a crown beam is arranged at the top of each bored pile, each circular crown beam and the working well are of a concentric circle structure, a liner is located on the inner side of each bored pile and vertically arranged along the depth direction of the working well, hidden beams are embedded into each liner and arranged at intervals along the length direction of the liner from top to bottom, a bottom plate is located at the bottom of the working well, a well bottom reinforcing jet grouting pile is arranged below the bottom plate, and hole reinforcing jet grouting piles located at positions where jacking pipe joints enter and exit holes arearranged on the outer sides of the bored piles. The pipe-jacking working well has the advantages that soil stability during excavation can be guaranteed by the bored piles, and the bored piles can bear large counter force needed by pipe-jacking construction; the liners can increase sand stability among the piles and evenly transmits horizontal load to the bored piles.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

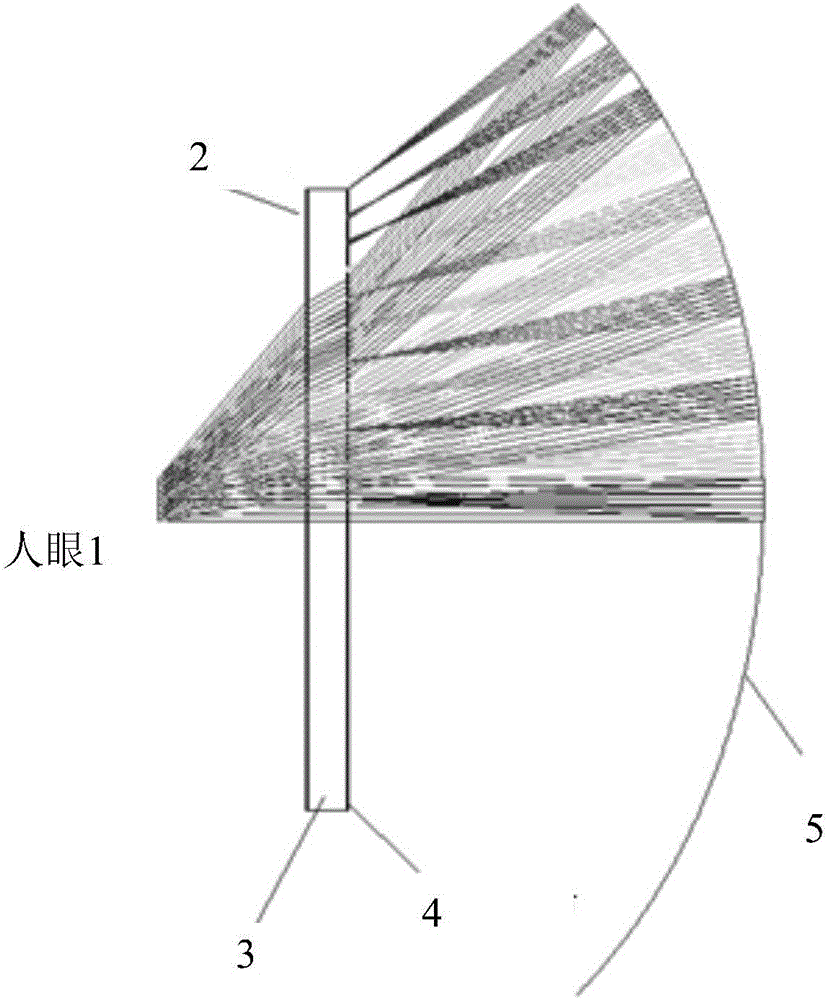

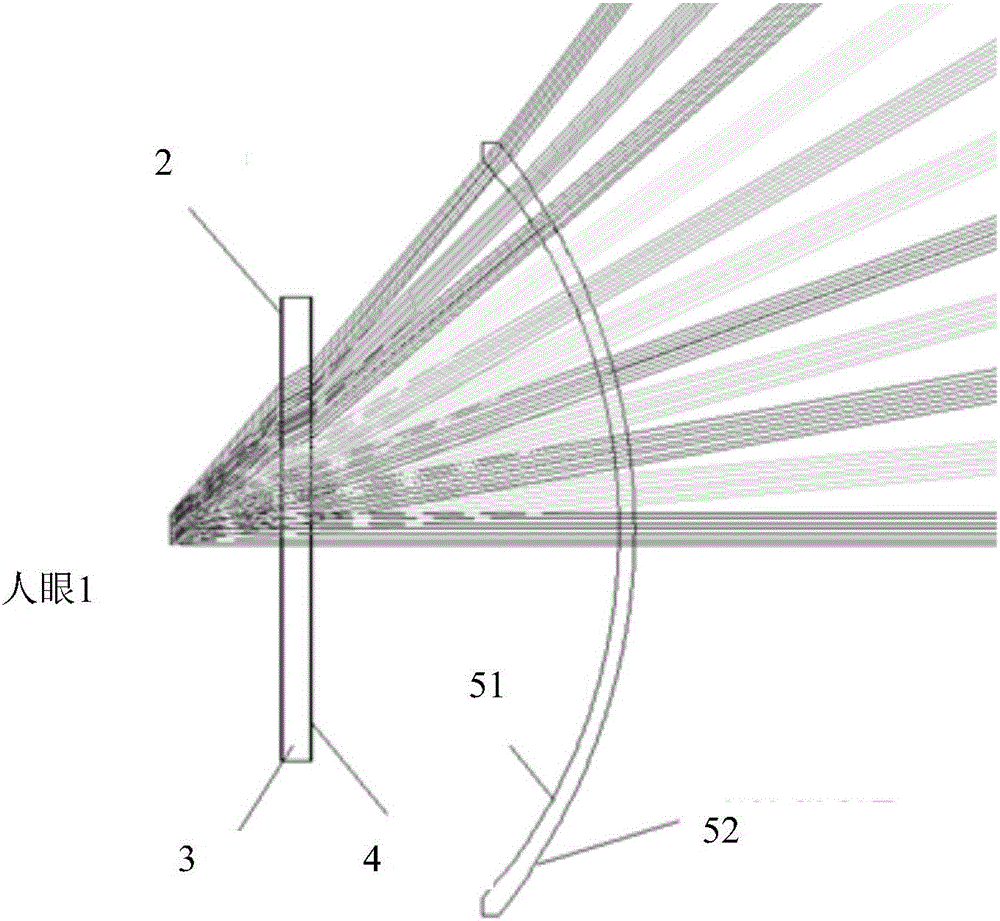

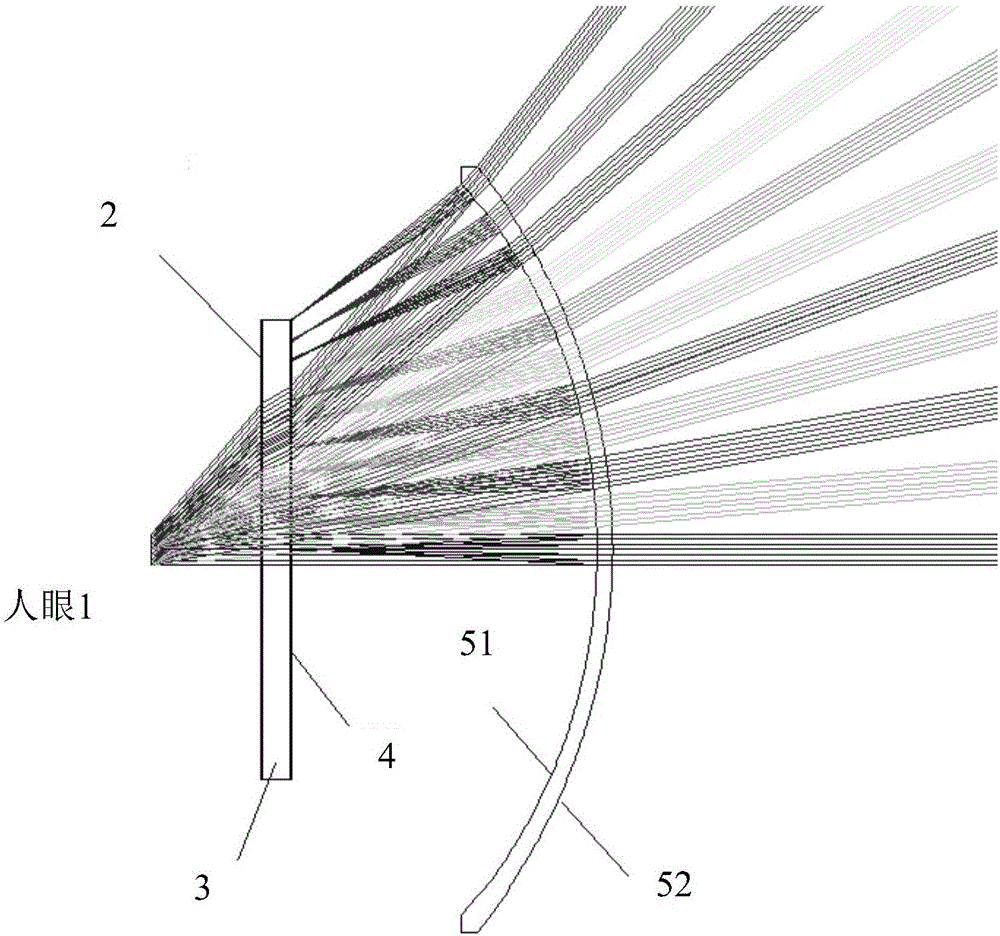

Optical system for augmented reality device

InactiveCN106842571ALarge field of viewSmall color differenceOptical elementsOptic systemComputer science

The invention provides an optical system for an augmented reality device. A transparent display screen is arranged between the human eyes and a reflection and transmission light splitter, the two sides of the display screen are provided with a polarizing device and a 1 / 8 or 1 / 4 wave plate, the display screen is set to be transparent, and augmented content can be reflected and then forms a virtual image to be seen by the human eyes; in addition, light in reality can pass through the display screen, the human eyes can see the reality, linear polarization light transmitted from the front face of the display screen is absorbed by an absorption type polarization device and cannot enter the human eyes, stray light is effectively cut off, linear polarization light transmitted from the back face of the display screen is sequentially transmitted by the 1 / 8 or 1 / 4 wave plate, reflected by the reflection and transmission light splitter, transmitted by the 1 / 8 or 1 / 4 wave plate, transmitted by the display screen, and transmitted by the absorption type polarization device, and then enters the human eyes, and therefore the view angle of the augmented portion is enlarged.

Owner:上海乐蜗信息科技有限公司

Glass reinforced plastic section material and preparation method thereof and cooling tower

The invention discloses a glass reinforced plastic section material. The glass reinforced plastic section material is prepared from, by mass, 35-40% of glass fiber roving, 20-30% of 90-degree unidirectional cloth, 0.2-0.8% of polyester surface mat, 10-15% of powdery aluminum hydroxide, 20-30% of isophthalic unsaturated polyester resin, 0.2-0.3% of a peroxide curing agent, 0.5-0.7% of a release agent, 0.5-0.7% of a low shrinkage agent, 0.05-0.07% of an anti-ultraviolet agent and 0.4-0.6% of pigment paste, wherein the 90-degree unidirectional cloth is made by weaving of alkali-free glass fibers, and the proportions are based on mass of the glass reinforced plastic section material. The glass reinforced plastic section material meets the requirement that flame propagation rate is smaller than or equal to 25 according to ASTM E84-2009 Standard Test Method for Surface Burning Characteristics of Building Materials, and mechanical properties of the glass reinforced plastic section material meet standards of CTI STD-137-2013 Fiberglass Pultruded Structural Products for Use in Cooling Towers. The invention further discloses a production method of the glass reinforced plastic section material and a cooling tower manufactured with the glass reinforced plastic section material.

Owner:南京斯贝尔复合材料有限责任公司

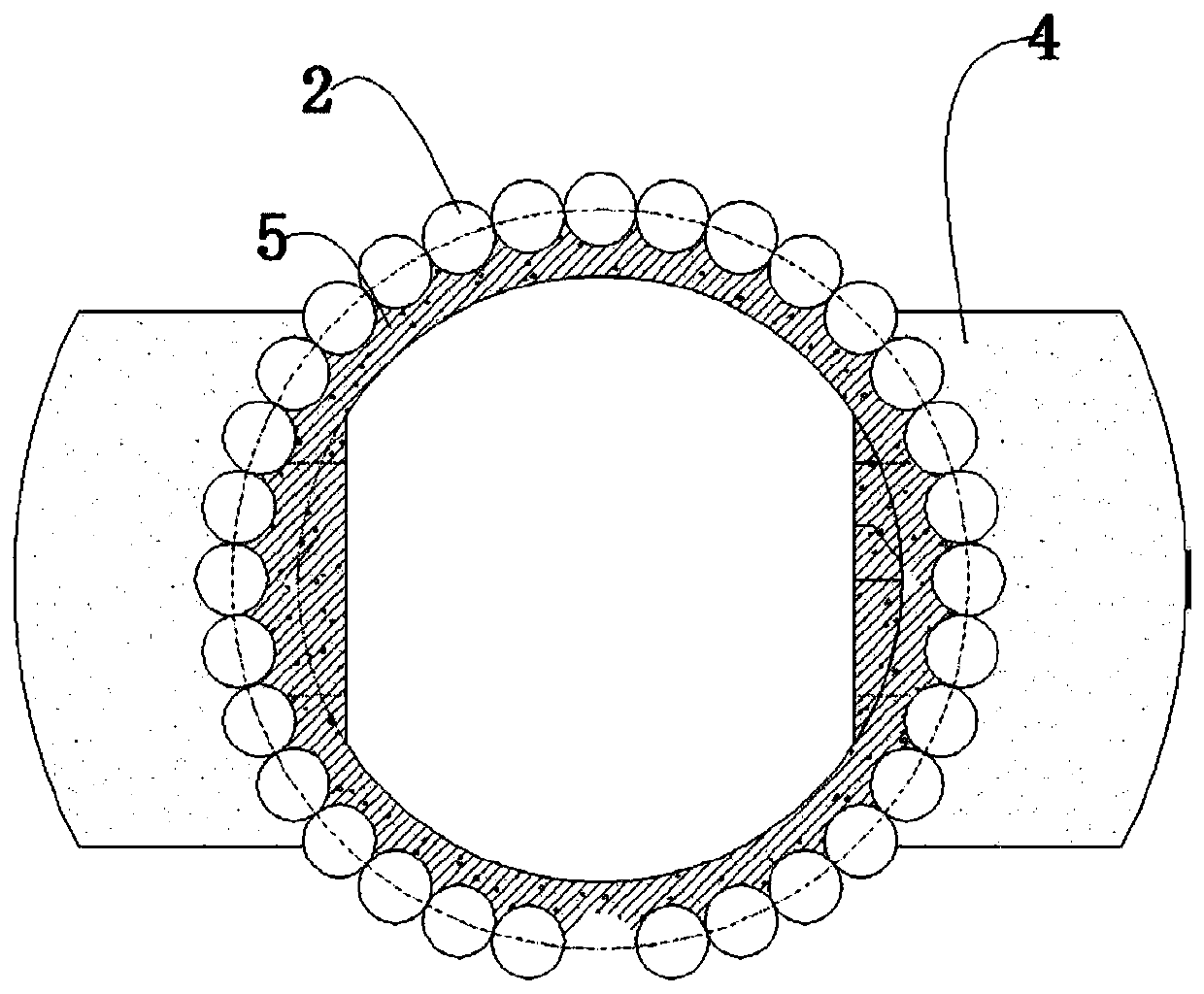

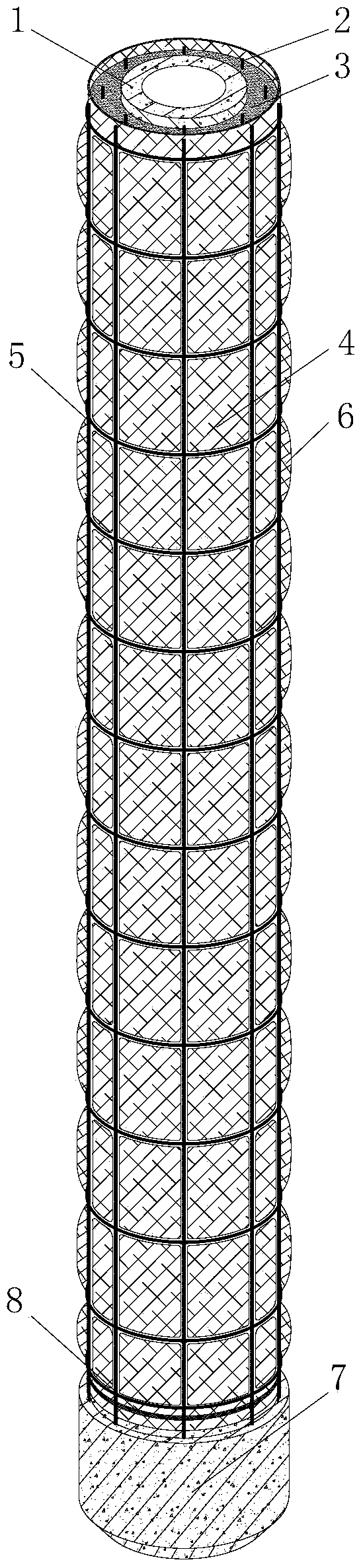

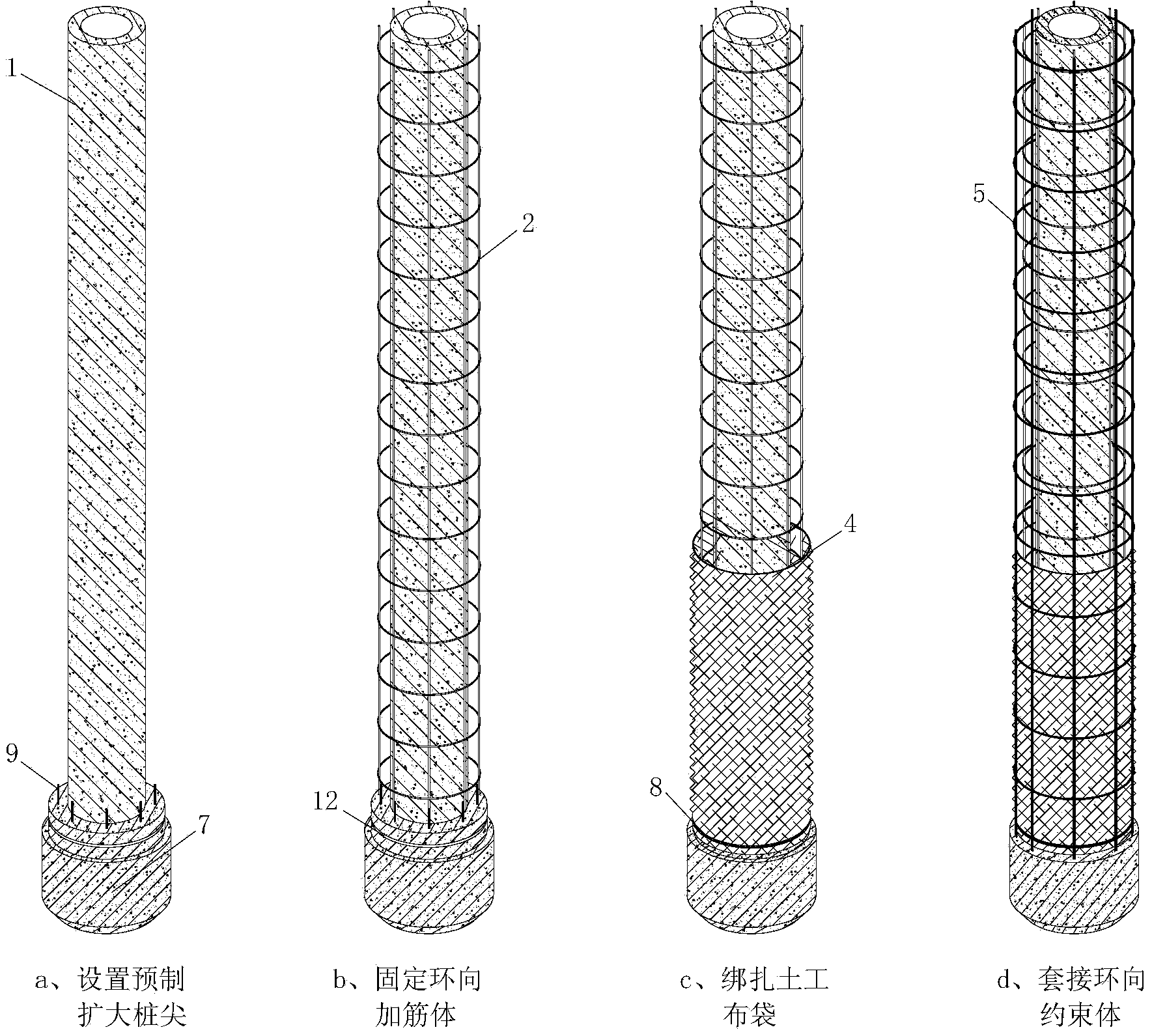

Prestressed pipe pile coated with active material pile body and construction method

ActiveCN104005404ALarge bearing capacityHigh side frictionBulkheads/pilesEconomic benefitsStructural engineering

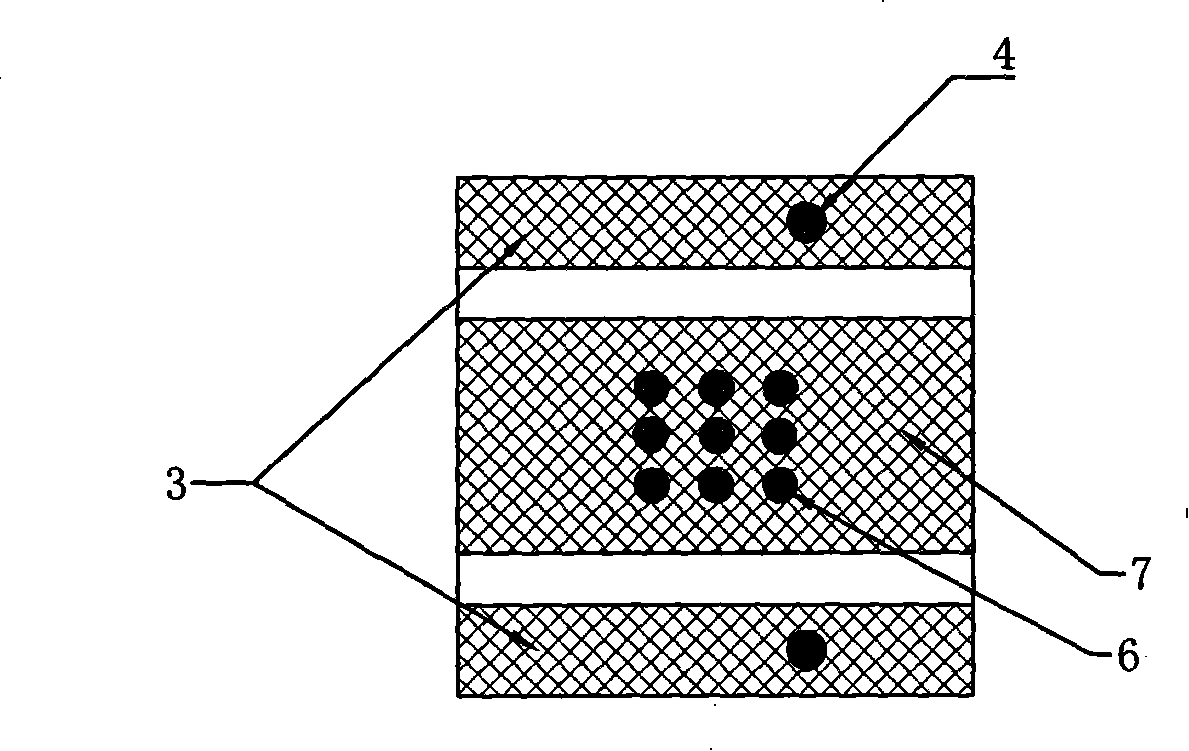

The invention relates to a prestressed pipe pile coated with an active material pile body. The prestressed pipe pile is characterized in that the prestressed pipe pile is coated with a geotechnical cloth bag in the whole pile length, the bottom end of the pile is provided with a precast enlarged pile tip, the bottom of the geotechnical cloth bag is fixed to the precast enlarged pile tip in a binding mode, an annular reinforcing rib body is arranged inside the geotechnical cloth bag, the bottom of the annular reinforcing rib body is fixedly connected with a connecting rib on the precast enlarged pile tip, a meshed annular constraint body is tightly clamped to the exterior of the geotechnical cloth bag, the portion between the prestressed pipe pile and the geotechnical cloth bag is filled with active materials, and after absorbing water and swelling, the active materials are tightened by the meshed annular constraint body to form block-shaped protrusions. According to the prestressed pipe pile coated with the active material pile body, the active material hydration swelling effect is utilized, the geotechnical cloth bag and the meshed annular constraint body with which the geotechnical cloth bag is coated are matched for shaping, and the performance of the pile body can be improved; after the prestressed pipe pile is coated with the active material pile body, pile body concrete can be prevented from being corroded by underwater, and the higher technical and economic benefits are obtained. The invention further discloses a construction method of the pile body.

Owner:德达交通建设发展集团有限公司

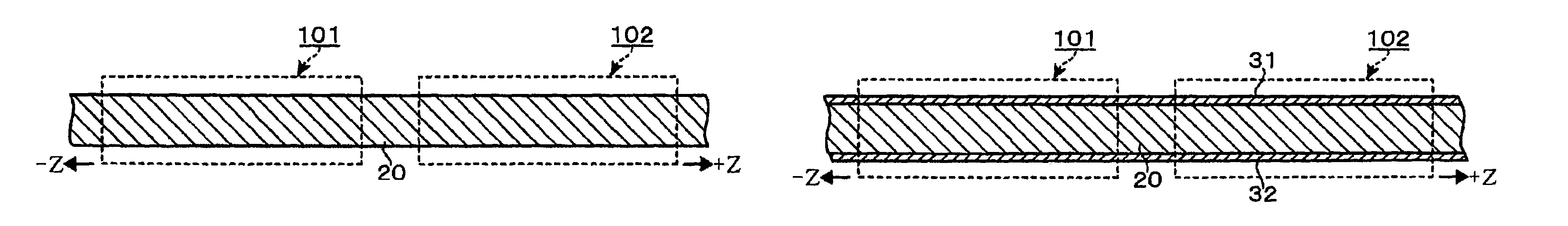

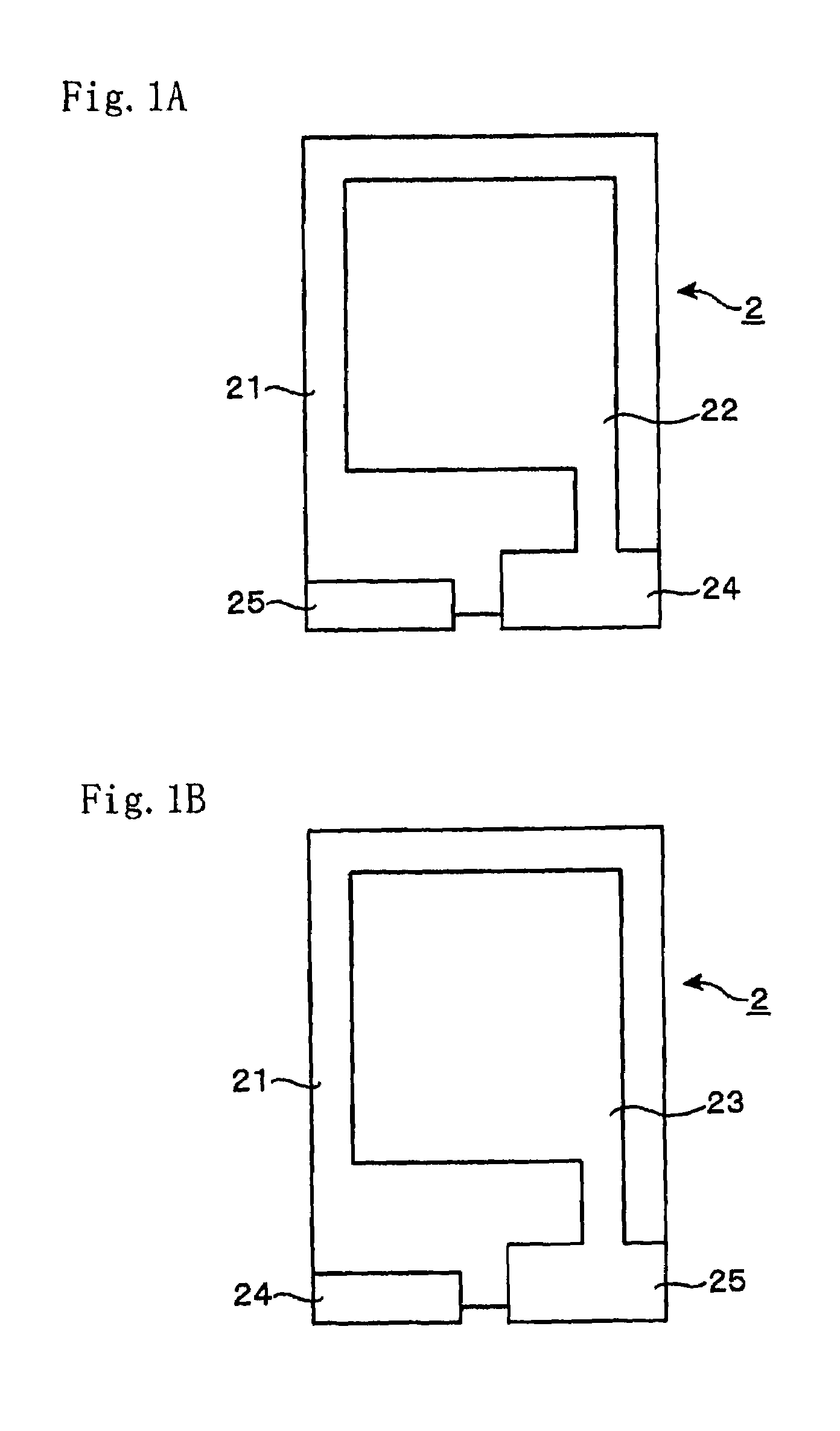

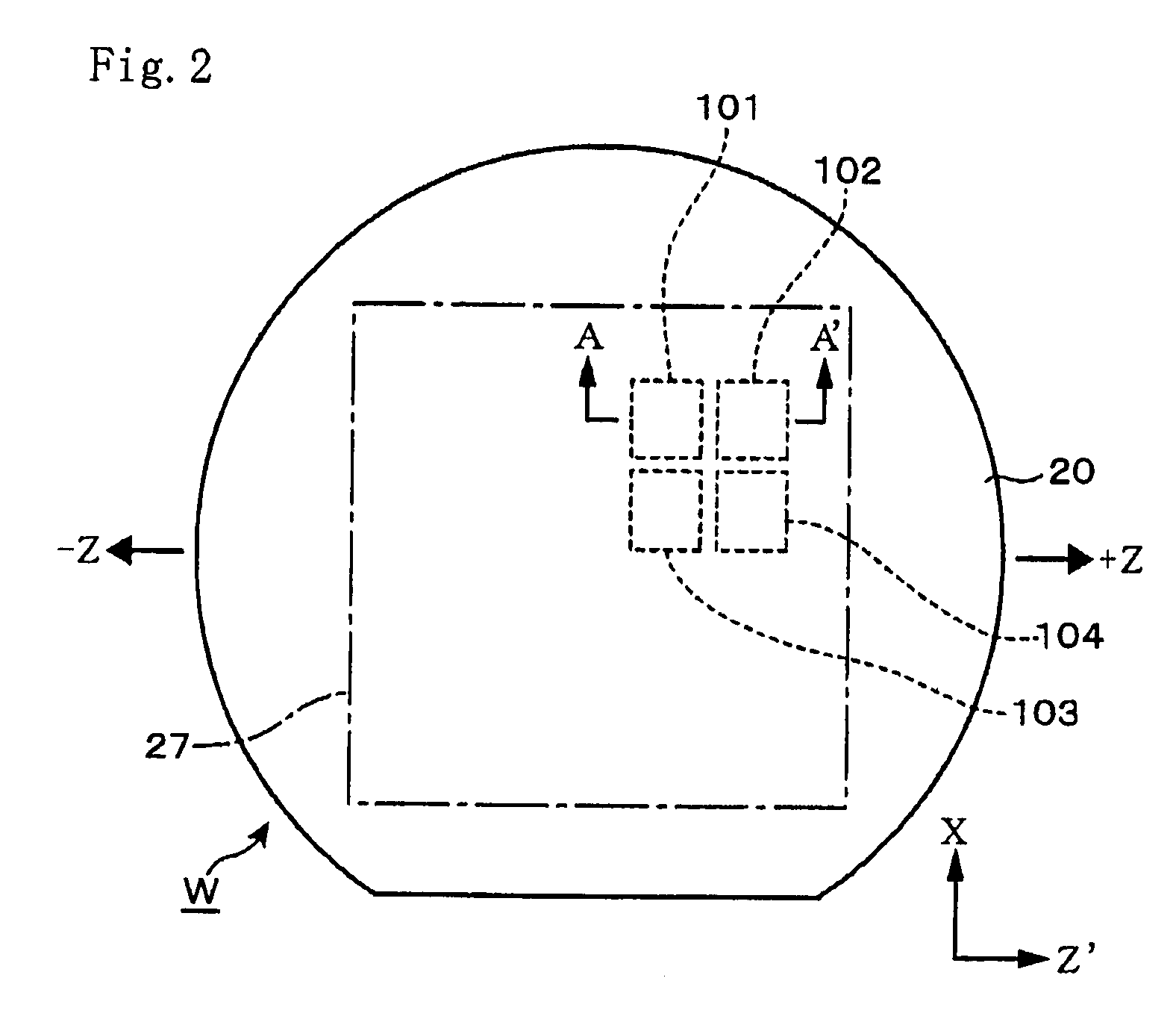

Method for manufacturing quartz piece

InactiveUS7690095B2Deterioration of CI and temperature characteristic failure can be restrainedInhibit deteriorationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical engineering

To provide a method for manufacturing a quartz piece which can suppress the deterioration of the CI and the temperature characteristic failure by forming the end surface of the quartz piece perpendicularly. A method for manufacturing a quartz piece that has a shape having two sides facing each other from a quartz substrate, includes the steps of: forming an etching mask provided with an opening area for forming the outside shape along one side out of the two sides which face each other, and provided with no opening area on the other side out of the two sides facing each other, on one surface side of the quartz substrate; and forming an etching mask provided with an opening area for forming an outside shape along the other side out of the two sides which face each other, and provided with no opening area on the one side, on the other surface side of the quartz substrate. Formation of protrusions is reduced when, at the time of etching from one surface side of the quartz substrate, the rate of etching in the direction from the one side toward the other side is greater than the rate of etching in the direction from the other side toward the one side due to the anisotropy of quartz, and at the time of etching from the other surface side of the quartz substrate, the rate of etching in the direction from the other side toward the one side is greater than the rate of etching in the direction from the one side toward the other side due to the anisotropy of quartz.

Owner:NIHON DEMPA KOGYO CO LTD

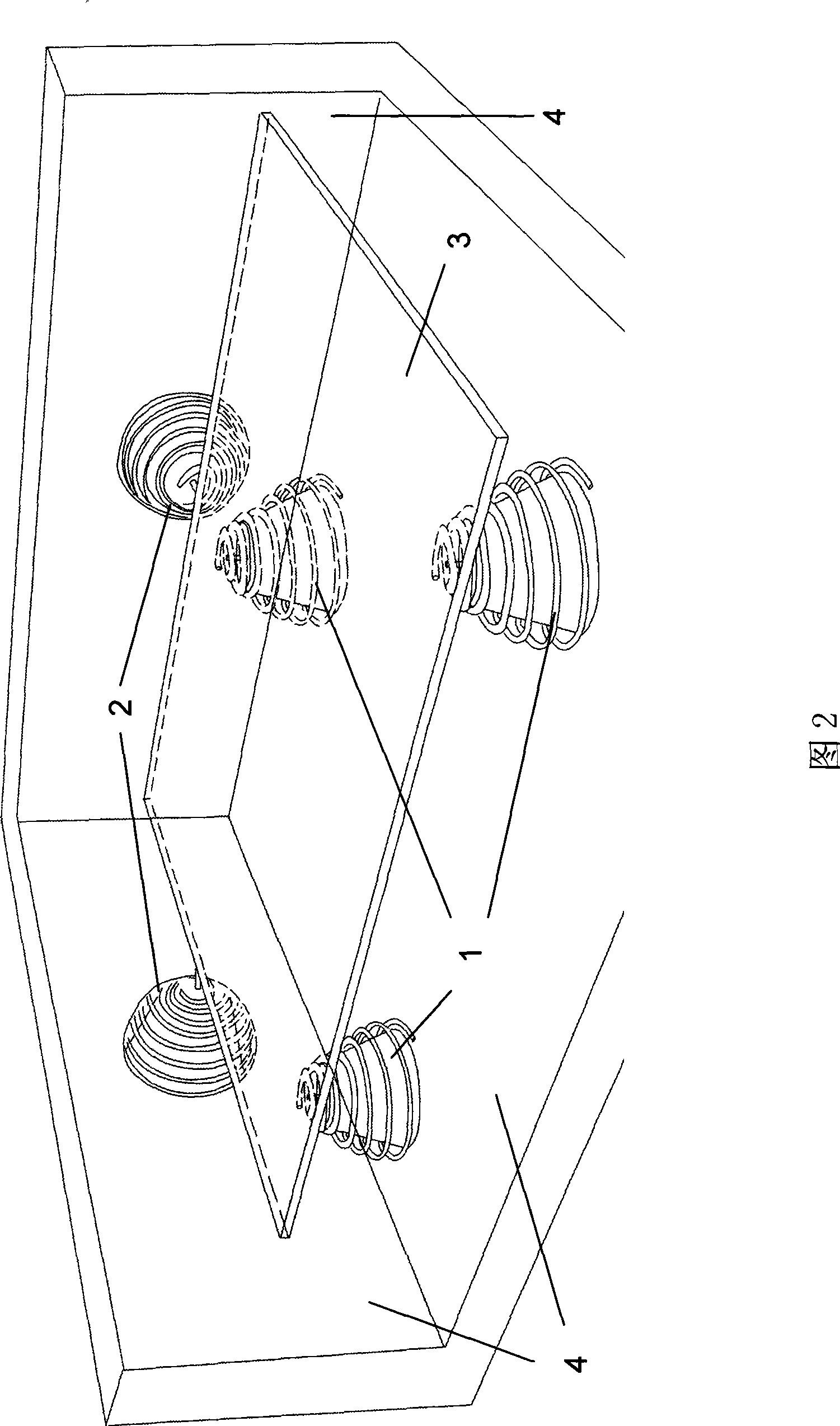

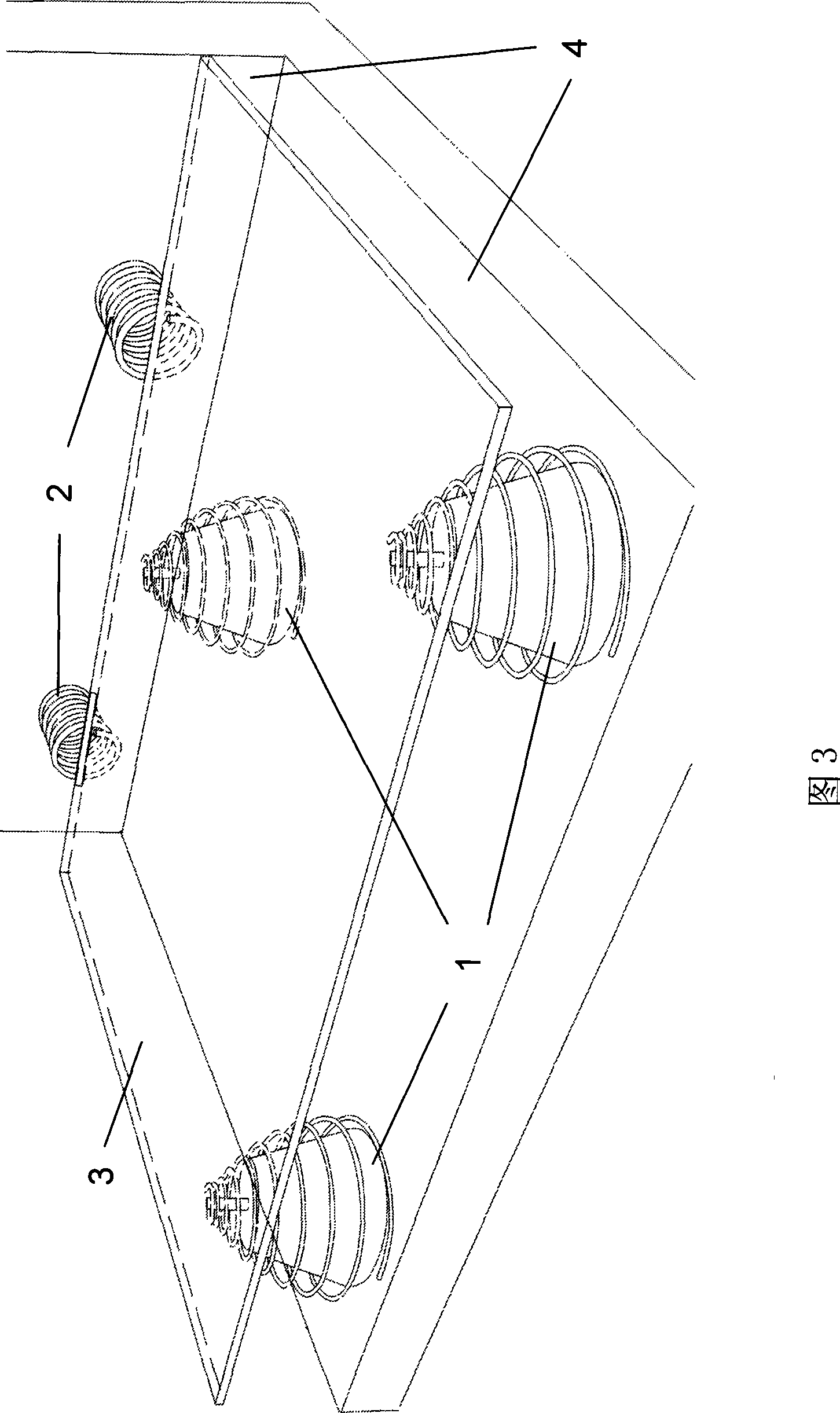

Suspended type shockproof system

InactiveCN101363499AAvoid vibration effectsRaise the verticalUndesired vibrations/sounds insulation/absorptionVibration suppression adjustmentsCD-ROMEngineering

The invention relates to an anti-vibration system, in particular to a suspended type anti-vibration system used in electronic products such as a CD-ROM drive, a hard disk, an electronic circuit board, etc. The anti-vibration system comprises at least three buffer cells and a plurality of limit parts; the buffer cell comprises a hollow elastic part, a connecting part which is fixedly connected to the upper end face of the elastic part; when in use, the buffer cells are arranged to be a polygon, the connecting part in each buffer cell is fixedly connected with the lower end face of a part needing vibration damping, and all the limit parts are connected to the top face or side of the part needing vibration damping. The suspended type anti-vibration system can isolate the part needing vibration damping from a vibration source, thus preventing the part needing vibration damping from being affected by vibration directly; furthermore, the suspended type anti-vibration system has the advantage of withstanding large longitudinal and transverse continuous vibration shock.

Owner:杨敏

Cross-weave cargo restraint system and method

ActiveUS20060198712A1Simple and efficient removalEffectively useFlexible elementsLoad securingEngineeringAdhesive

A cross-weave load restraint system and method for securing cargo within transport containers including first and second load restraining strips wherein the first strip is formed with a cross-weave material and the second strip is composed of parallel strands of reinforcement materiel. The first and second strips of reinforcement material are secured together with an adhesive layer and a second layer of adhesive is provided for attaching the cross-weave load restraining strip to an interior surface of a transport container.

Owner:MBULL HLDG LLC

Cross-weave cargo restraint system and method

ActiveUS20050123371A1Installed quickly and reliably and efficientlyEfficient removalLayered productsFlexible elementsAdhesiveEngineering

A cross-weave load restraint system and method for securing cargo within transport containers including first and second load restraining strips wherein the first strip is formed with a cross-weave material and the second strip is composed of parallel strands of reinforcement materiel. The first and second strips of reinforcement material are secured together with an adhesive layer and a second layer of adhesive is provided for attaching the cross-weave load restraining strip to an interior surface of a transport container.

Owner:MBULL HLDG LLC

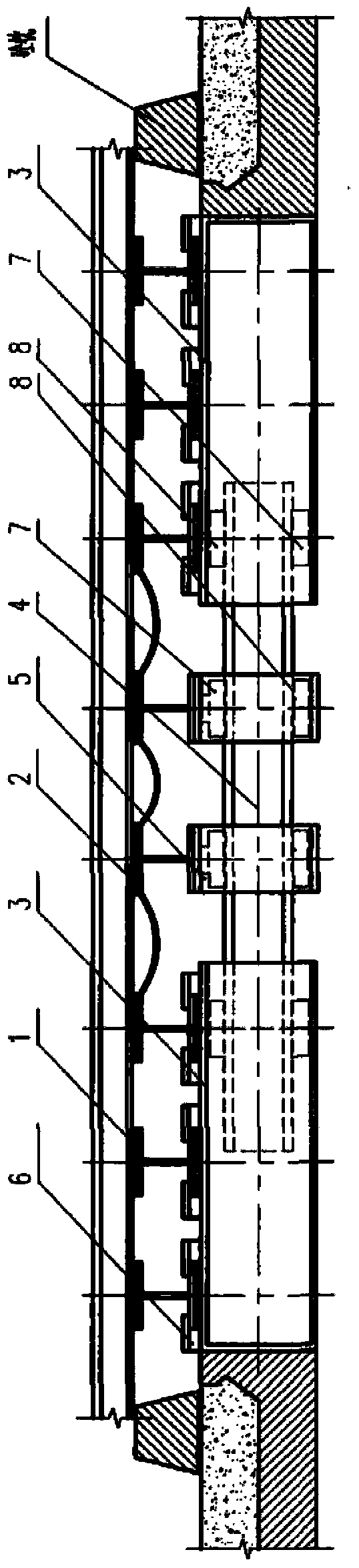

Large-displacement railroad bridge end expansion device

ActiveCN103469726AGuaranteed displacement synchronizationIncreased vertical and lateral flexural stiffnessBridge structural detailsStructural engineering

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +2

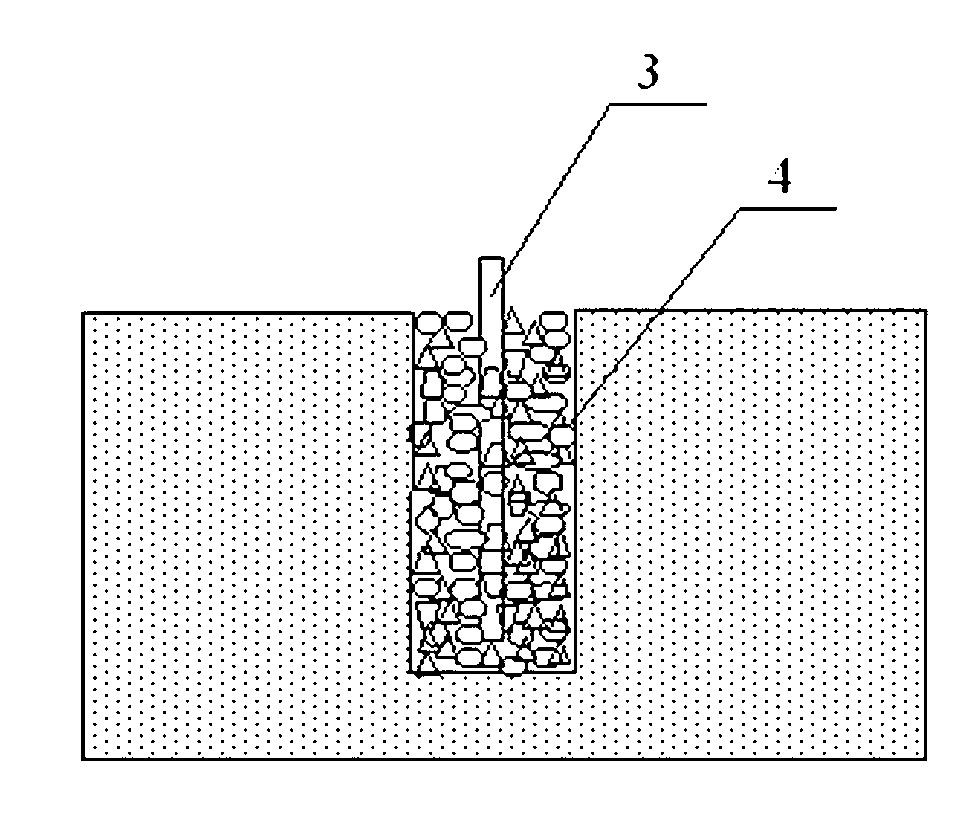

Structure for preventing perforation and slurry leakage of cast-in-situ bored pile in water and construction method of structure

ActiveCN104358252AReduce construction costsAvoid difficult extractionBulkheads/pilesRebarReinforced concrete

The invention relates to a structure for preventing perforation and slurry leakage of a cast-in-situ bored pile in water and a construction method of the structure. An outer protecting cylinder is arranged at the periphery of a reinforced concrete cast-in-situ bored pile, an activated material slurry fixed protecting disk and an activated material slurry fixed protecting wall are arranged between the reinforced concrete cast-in-situ bored pile and the outer protecting cylinder from top to bottom, and a cement soil water stop protecting wall is arranged below the activated material slurry fixed protecting wall; the diameter of the activated material slurry fixed protecting disk is greater than that of the activated material slurry fixed protecting wall and that of the cement soil water stop protecting wall; a reinforcement cage positioning embedded part is arranged in the middle of the activated material slurry fixed protecting disk; the reinforced concrete cast-in-situ bored pile is formed by placing a reinforcement cage in an inner protecting cylinder and then pouring concrete. The protecting cylinder structure is high in stability, good in environmental protection and lower in cost, is capable of effectively preventing the perforation and the slurry leakage of the cast-in-situ bored pile in the water, and has better technical and economical benefits.

Owner:德州市公路工程总公司

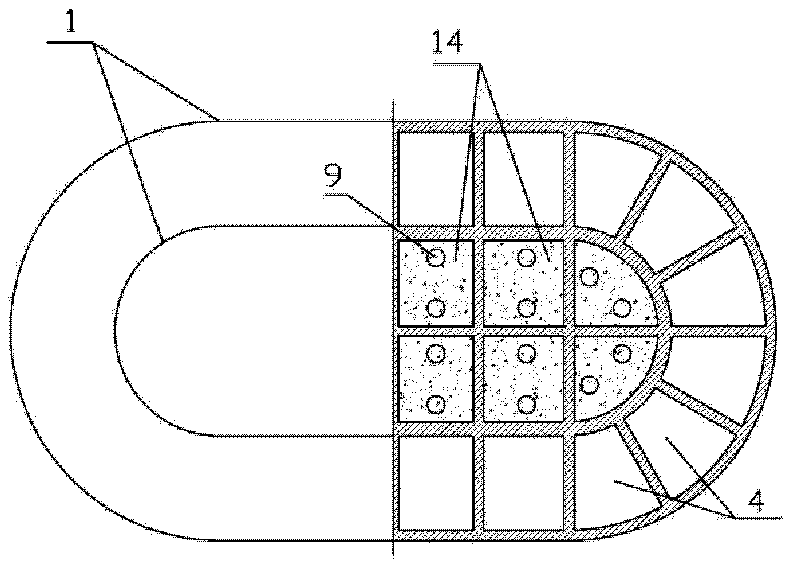

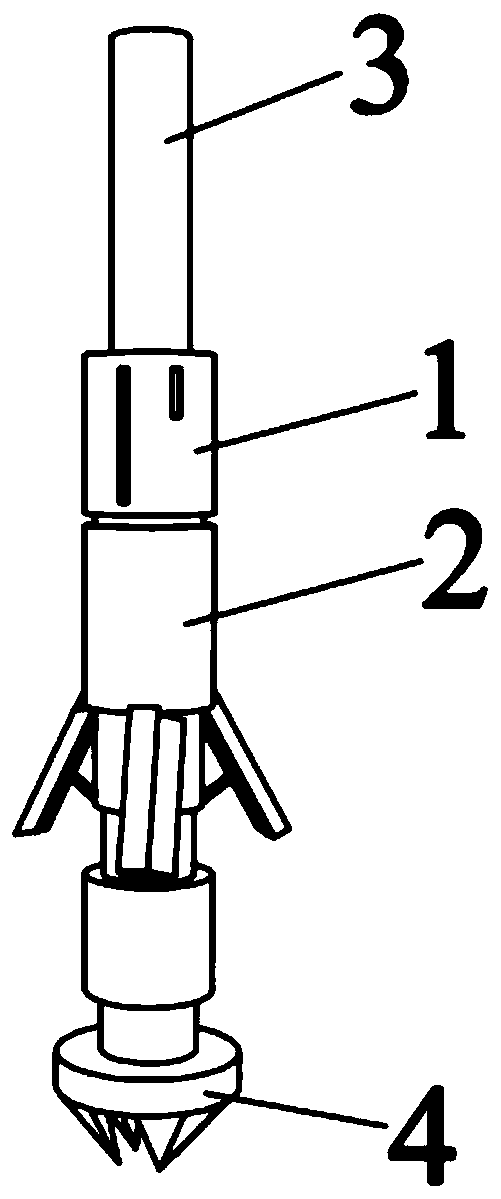

Rotary cut-expanded branch pile machine and construction method of cut-expanded branch pile

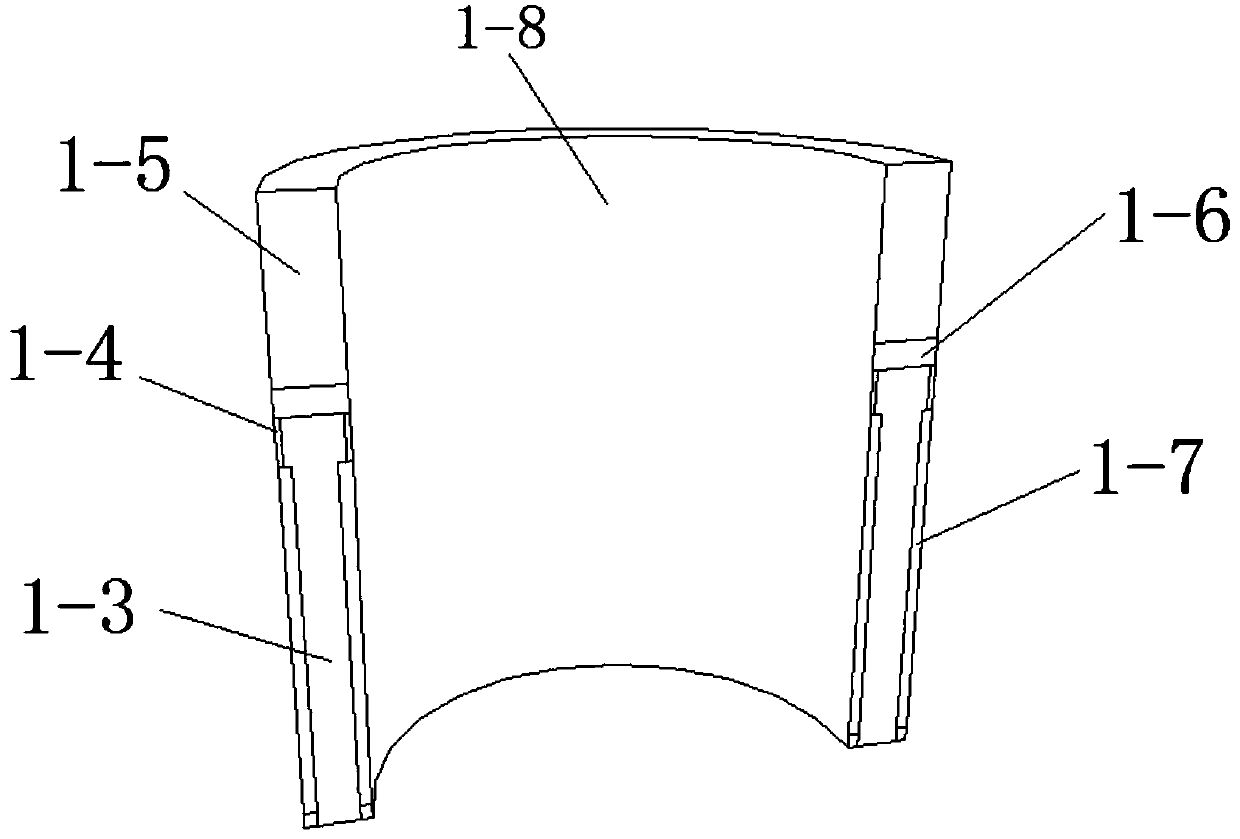

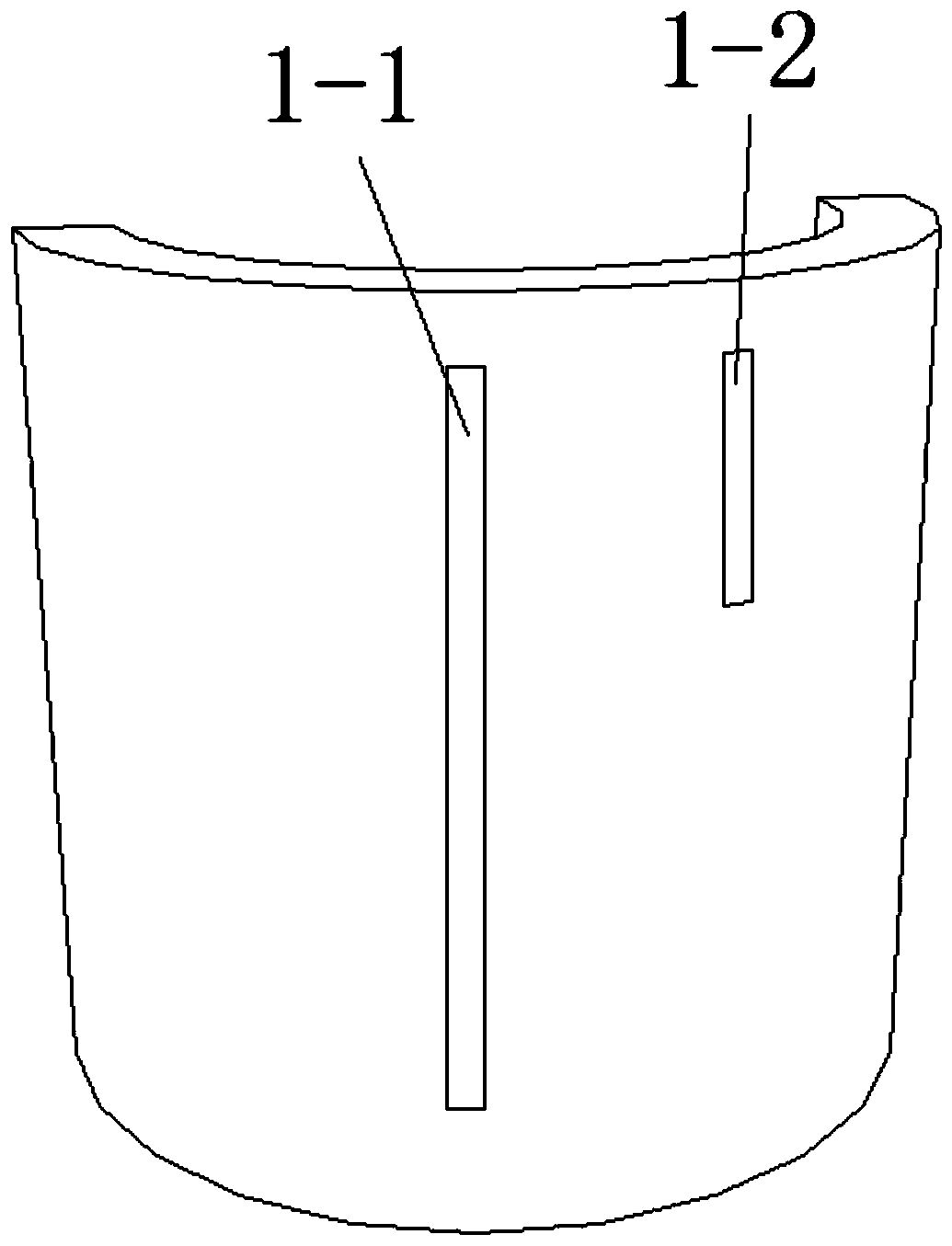

PendingCN111042738APrevent slipping outGuaranteed stabilityDrill bitsDirectional drillingDrill bitHydraulic pressure

The invention discloses a rotary cut-expanded branch pile machine and a construction method of a cut-expanded branch pile. The cut-expanded branch pile comprises a drill rod, and a rotary cut-expanding assembly is fixed to the drill rod. The rotary cut-expanding assembly comprises a first force transferring barrel, and a plurality of soil cutting steel plates are hinged to the lower end of the first force transferring barrel. First sliding grooves are formed in the inner walls of the soil cutting steel plates. The lower end of a second force transferring barrel stretches inwards to form a pressing block, and a buckle seat is fixed to a connecting barrel. A spring is mounted on the side wall of the buckle seat, the lower end of the spring and the lower end of a mounting groove are fixed, and the upper end of the spring seat and a buckle are fixedly connected. One end of each connecting rod is fixed into the corresponding first sliding groove, and the other ends of the connecting rods are mounted on the buckle. When the drill bit reaches a target position, the soil cutting steel plates work under the action of a hydraulic component, the rotary speed and angles of the soil cutting steel plates achieve stepless speed change, and finally a tree-shaped branch plate cavity is formed in the same position. Compared with a common branch pile, the formed tree-shaped branch pile has the advantages that the size is larger, and the vertical and transverse axial bearing capacity of a pile foundation is remarkably improved.

Owner:CHANGAN UNIV

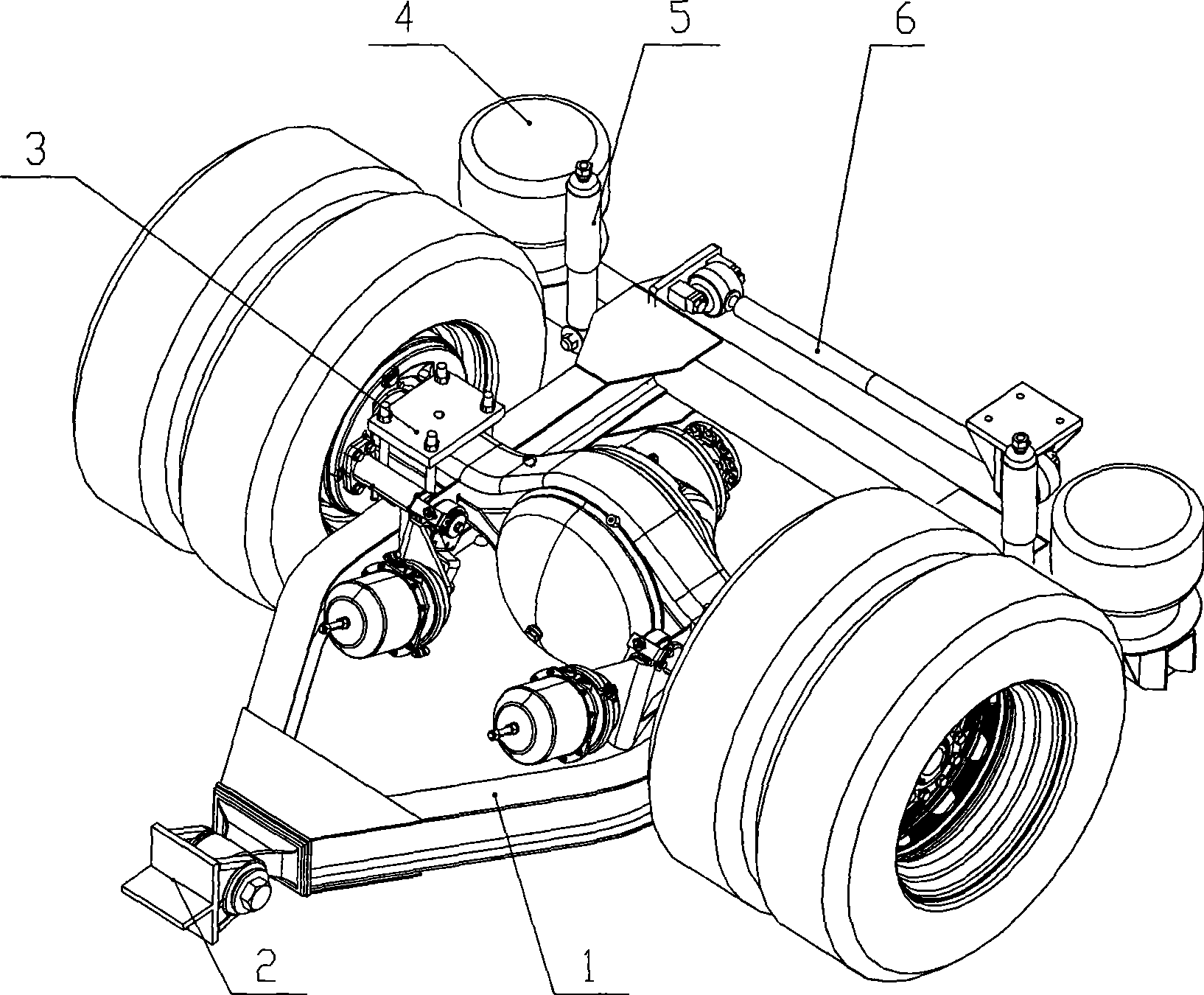

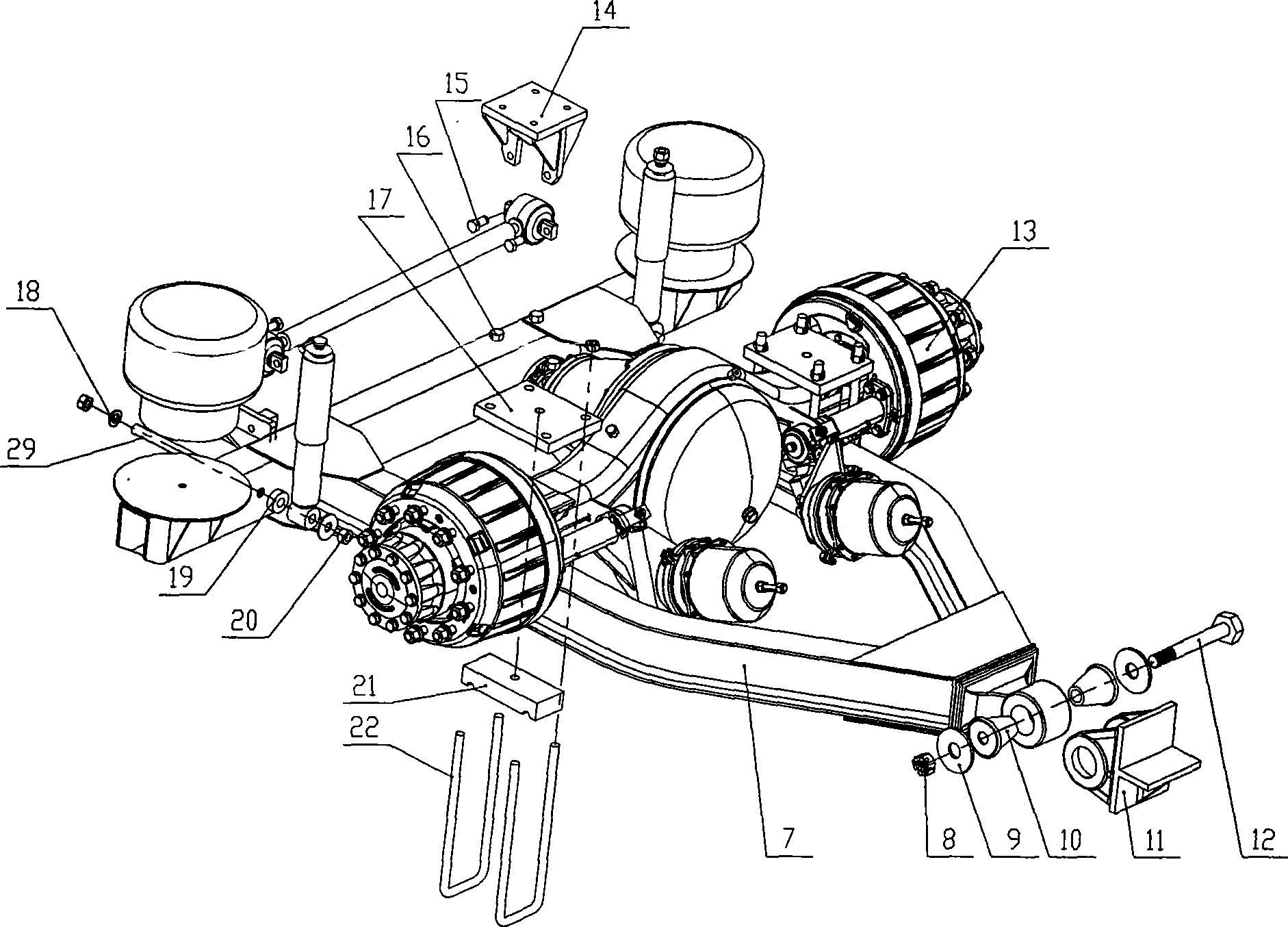

Special A type rack type air spring rear suspension for large-scale bus

InactiveCN101503051ALower natural frequencyAdd constraintsInterconnection systemsResilient suspensionsAir springControl valves

The invention relates to a special A-type frame air spring rear suspension for a large coach, comprising an A-type frame; the front end of the A-type frame is connected with a link assembly; the two sides of the rear end of the A-type frame are sequentially provided with an air spring assembly and an absorber; the A-type frame is provided with a flexible connection end bracket of a height control valve; the rear end of the A-type frame is connected with a transverse stabilizer bar. The invention has simple structure, light weight, little peculiar parts, multiple general parts and low cost; and the rear suspension is easy to manufacture, and the axle location is accurate and reliable without regulation.

Owner:ZHONGTONG BUS HLDG

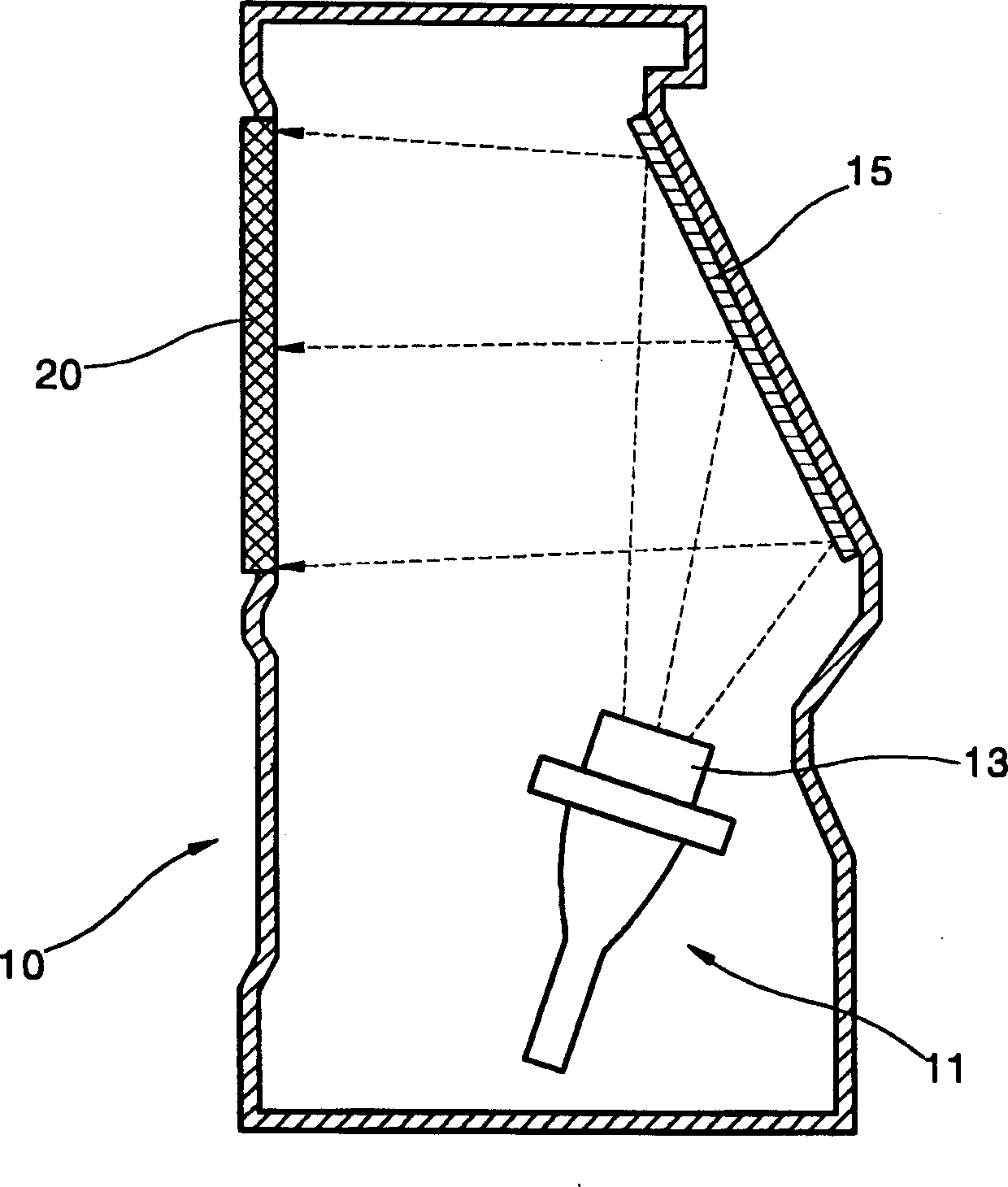

Apparatus for increasing brightness of projection television

InactiveCN1427623AIncreased vertical and horizontal viewing anglesIncrease brightnessTelevision system detailsBuilt-on/built-in screen projectorsAstigmatismLiquid-crystal display

A high-brightness projection television is provided which includes a screen having a first lens for refracting an incident beam into a convergent beam, a second lens for refracting the beam refracted by the first lens into a divergent beam, and a protection plate for protecting at least the second lens, wherein an optical emission material is included in at least one of the above elements to convert invisible lights included in the incident beam into visible lights. Alternatively, the projection television may include an optical emission layer having the optical emission material between a light source and an image generator such as a liquid crystal display (LCD). Accordingly, vertical and horizontal angles of view are increased and overall brightness of the image is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

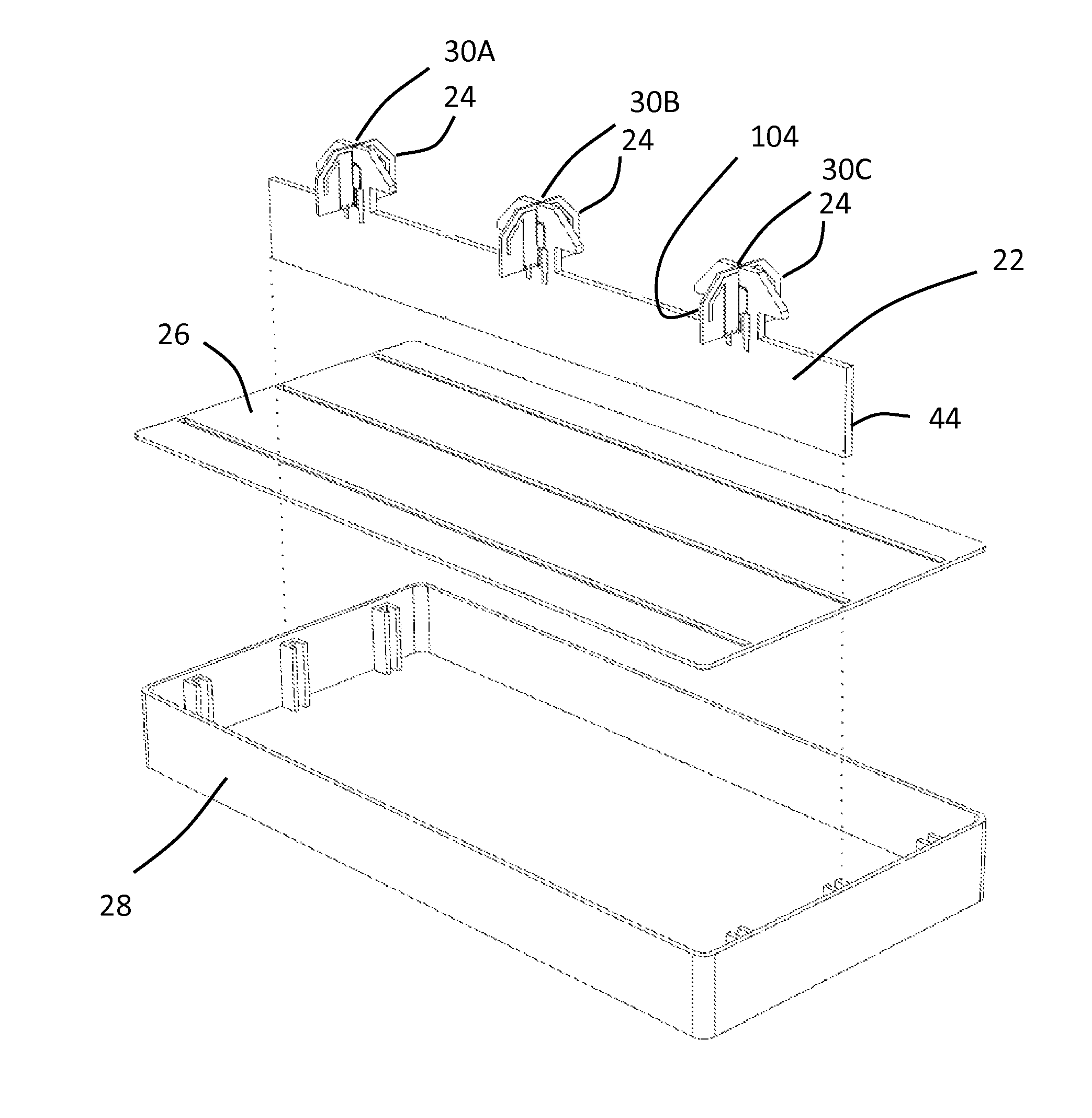

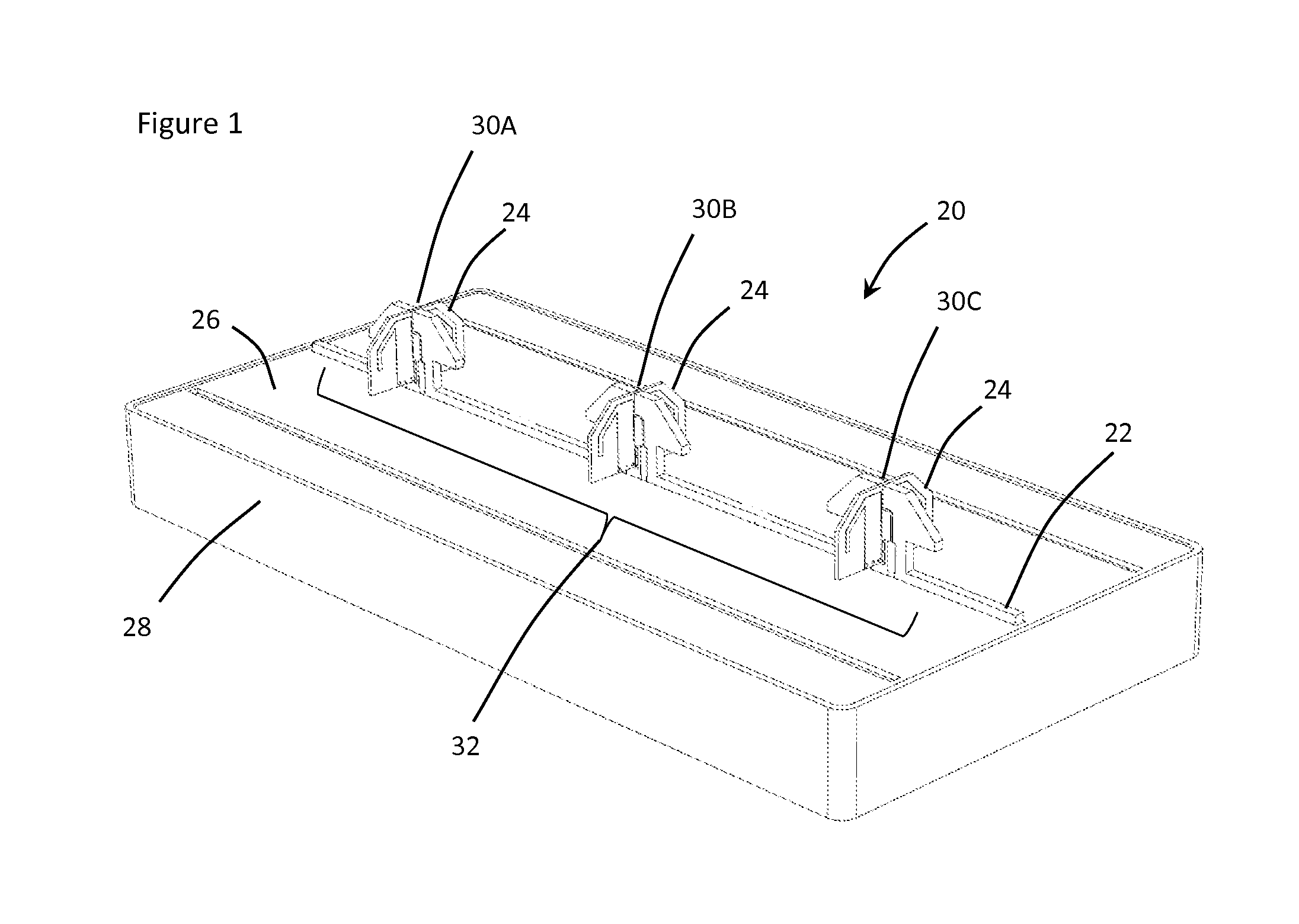

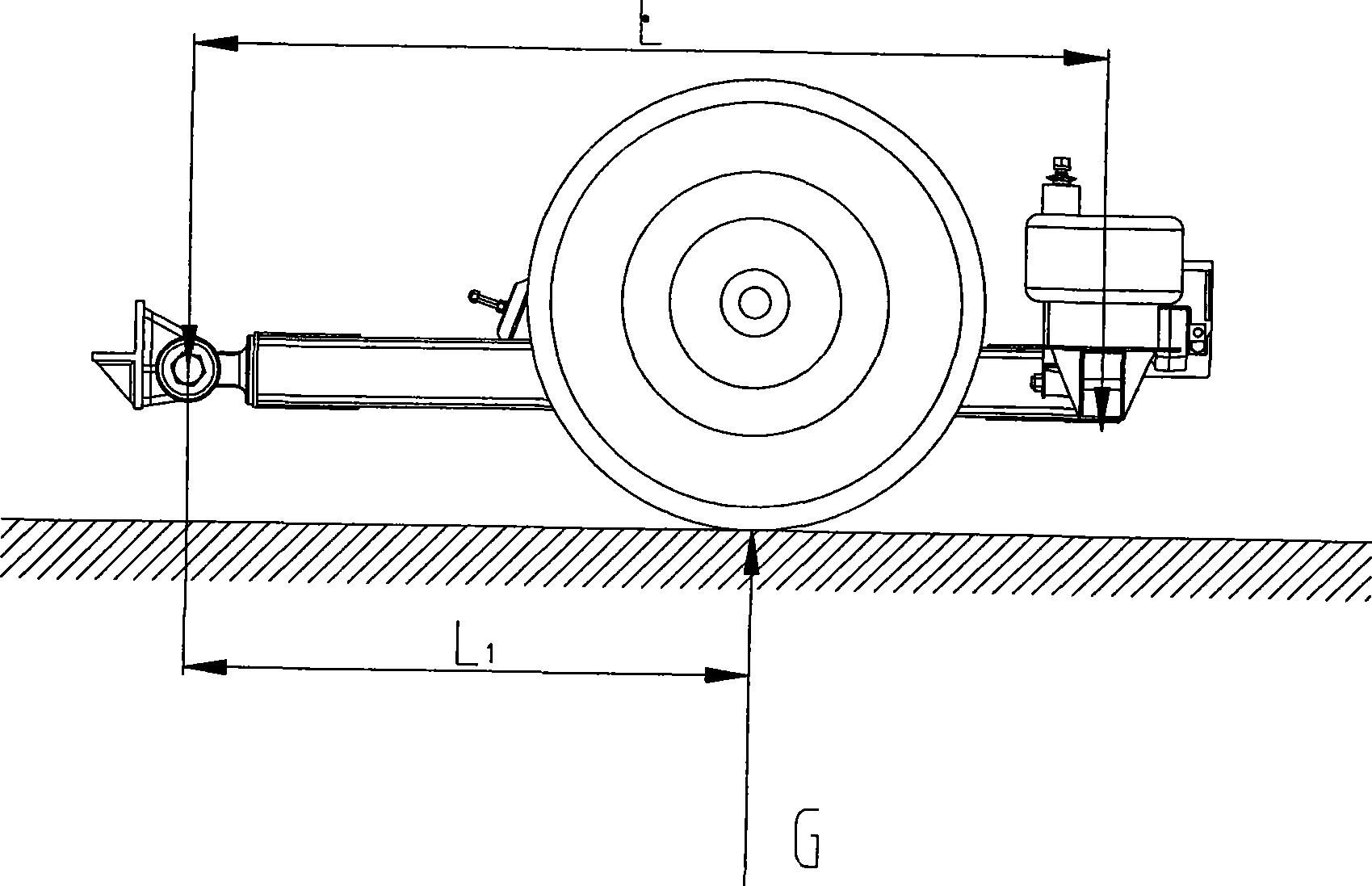

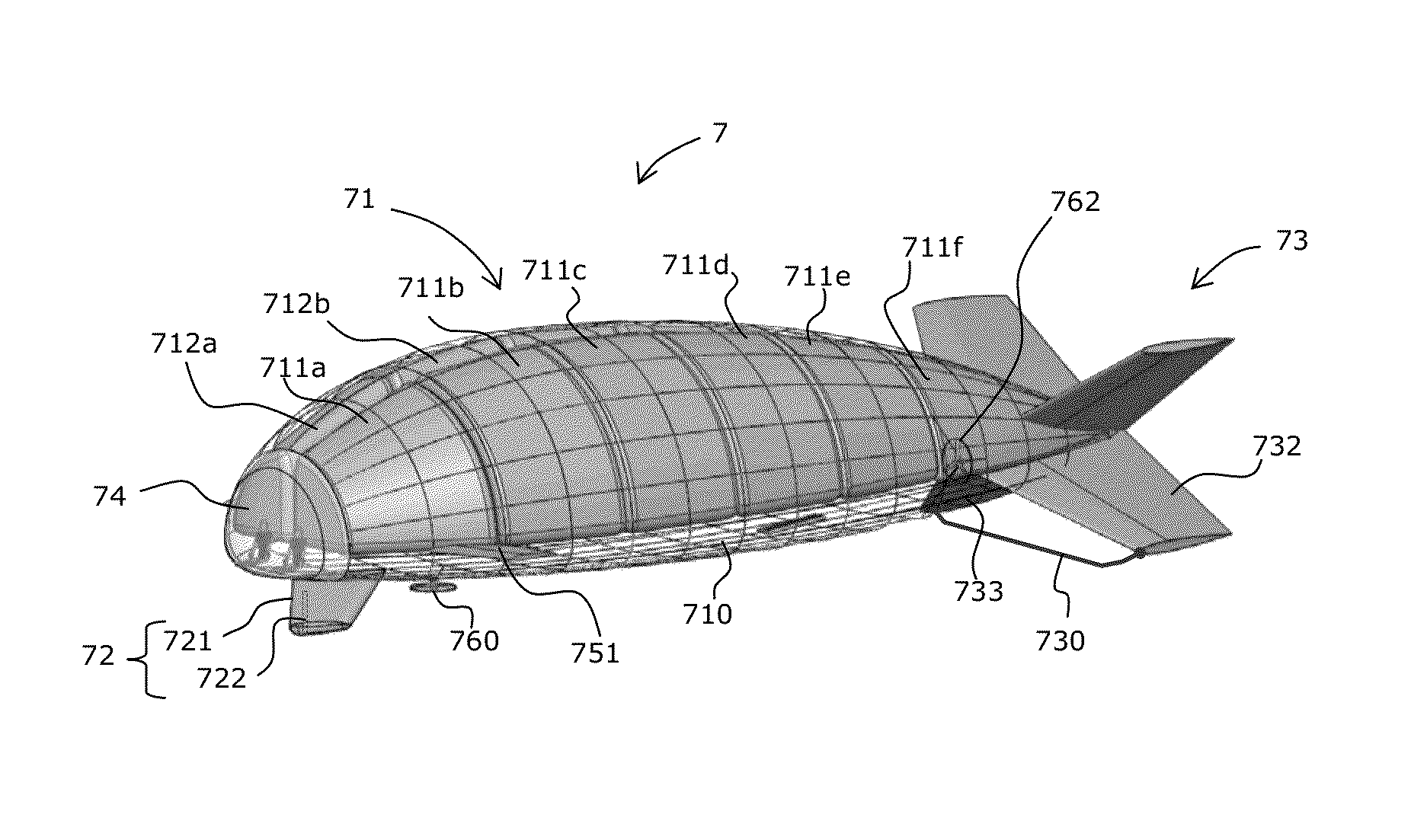

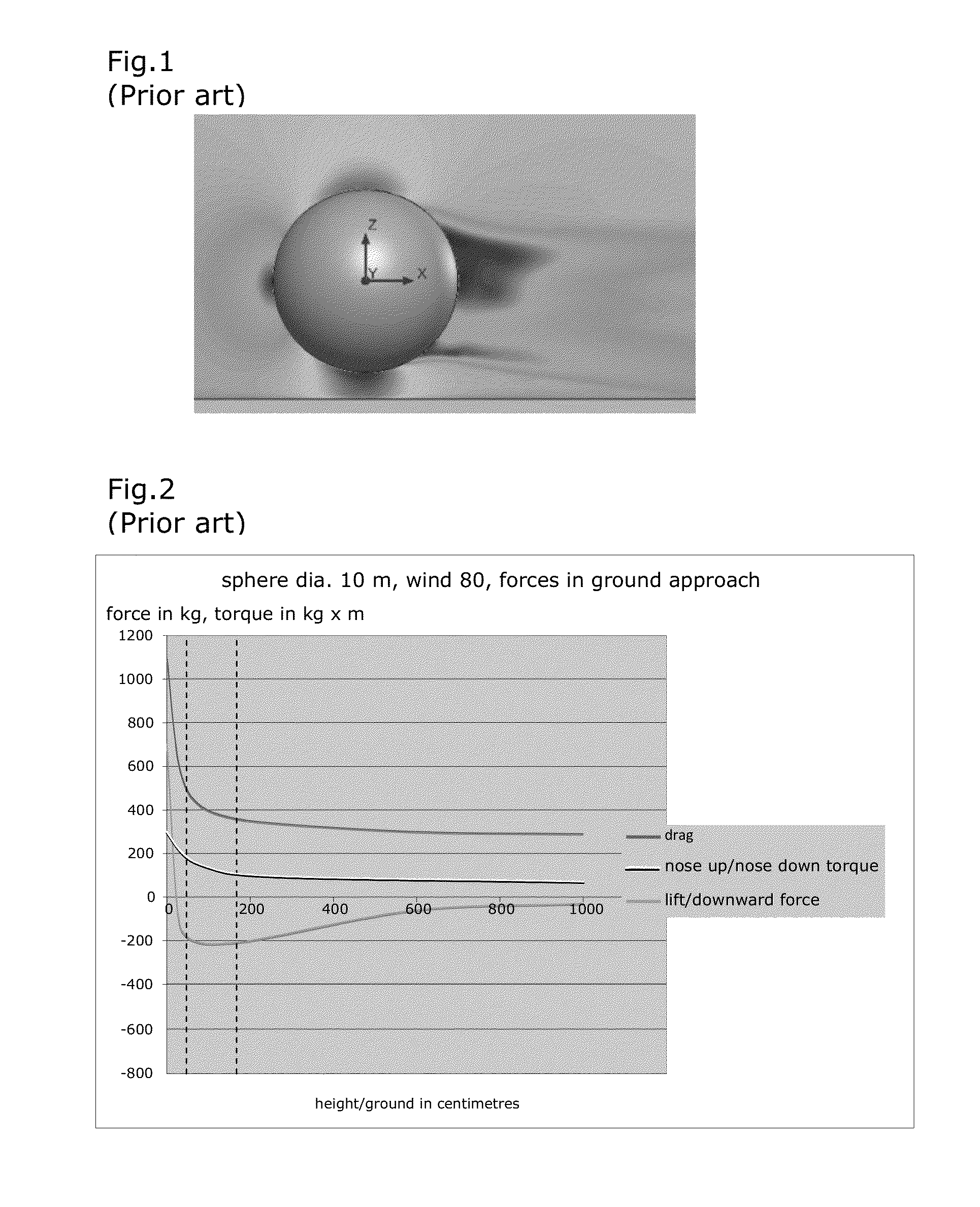

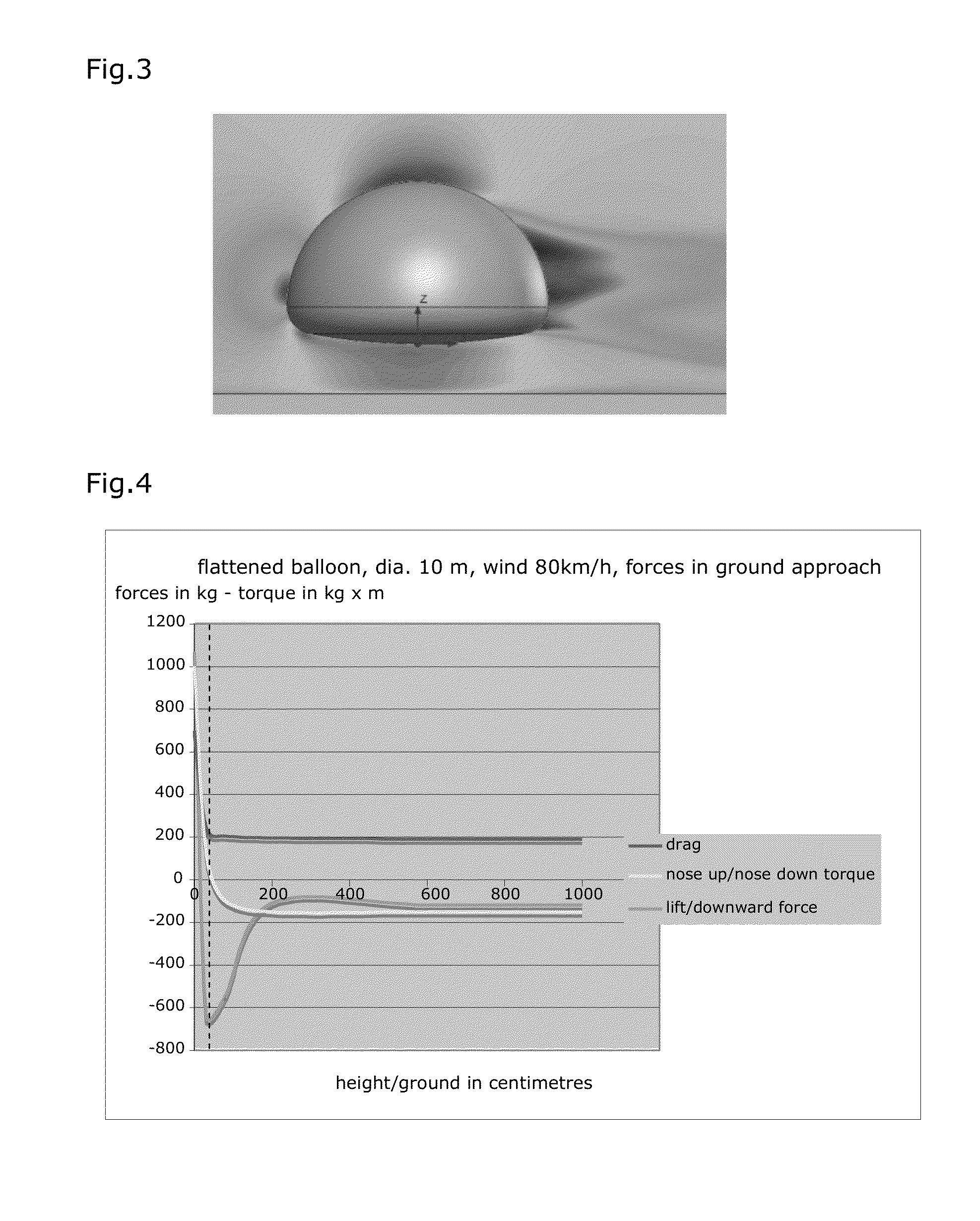

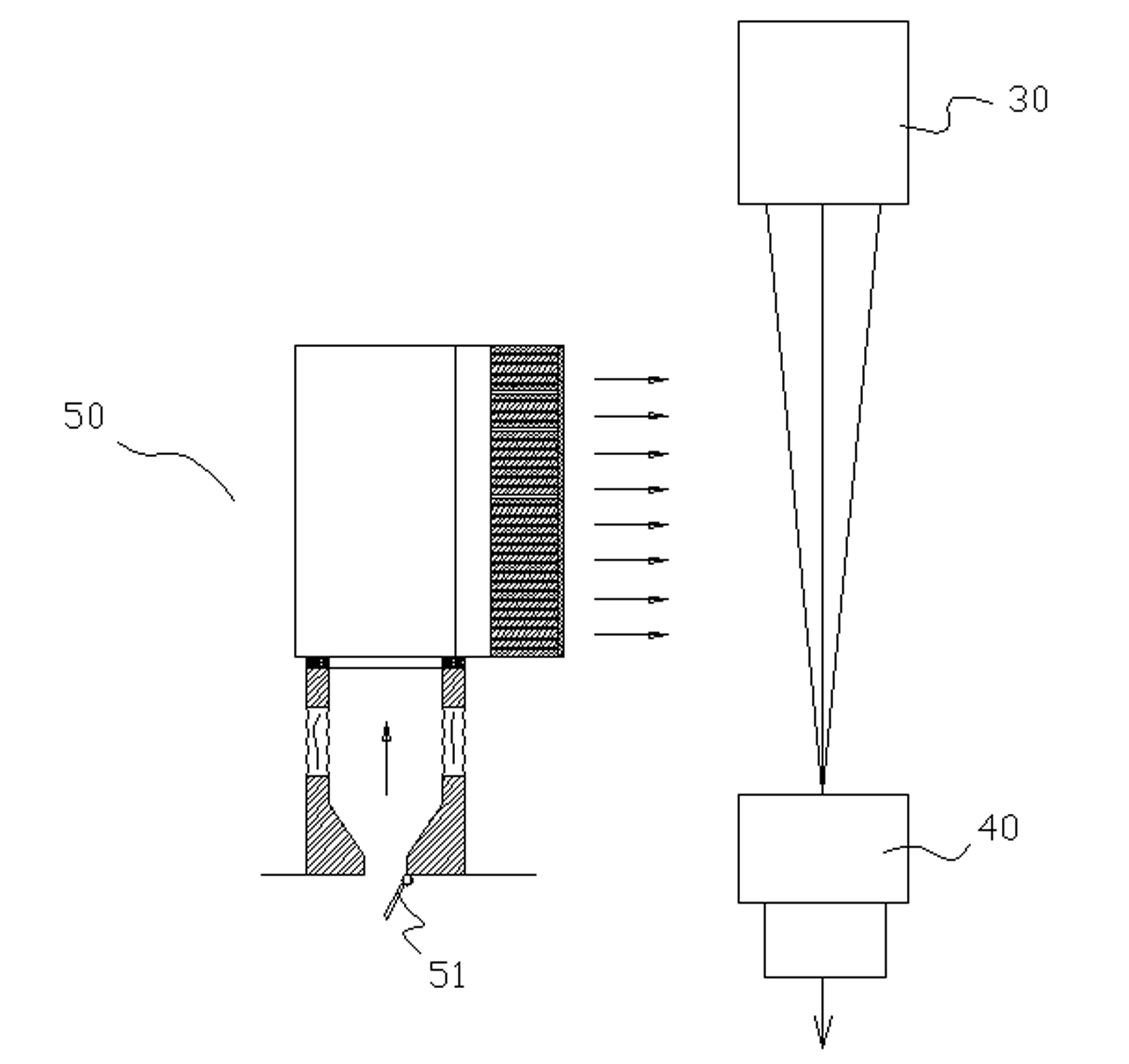

Airship, anchoring device, and landing and mooring method

ActiveUS20140158819A1Easy to liftProcess stabilityNon-rigid airshipsRigid airshipsEngineeringMechanical engineering

An air vehicle such as an airship is provided, having a rounded top portion, and the bottom portion of which has a substantially planar shape, including a region having a smaller inclination, which is referred to as a bottom surface, and the surface area of which is larger than that of an intermediate region having a greater inclination, referred to as an intermediate surface. The general shape produces, due to relative wind, a resulting overall downward force near the ground. The vehicle also includes a device for anchoring same to the ground, the anchoring device being stationary or controllable from the vehicle, located at the front portion of the vehicle, and projecting downward, in particular a ram including a portion which can be expanded by applying a bar against a translatably movable shoulder. Also included is a landing method implementing such a vehicle.

Owner:DIRISOLAR

Magnetoresistive element

InactiveUS9099188B2Reduced strengthReadily switched and reversedMagnetic-field-controlled resistorsSolid-state devicesMagnetic reluctanceSpin transfer

A STT-MRAM comprises apparatus, and method of operating a double-MTJ magnetoresistive memory and a plurality of magnetoresistive memory element having a first recording layer which has an interface interaction with an underneath dielectric functional layer and having a second recording layer which has no interface interaction with an underneath dielectric functional layer. The energy switch barrier of the first recording layer is reduced under an electric field applying along a perpendicular direction of the functional with a proper voltage on a digital line from a control circuitry; accordingly, the magnetization of the first recording layer is readily reversible in a low spin-transfer switching current while the magnetization of the second recording layer is readily reversible in a high spin-transfer switching current, enabling two separate bits recording in a double MTJ stack.

Owner:GUO YIMIN

Polymer gravel pile grouting method

Owner:HENAN POLYTECH INFRASTRUCTURE REHABILITATION

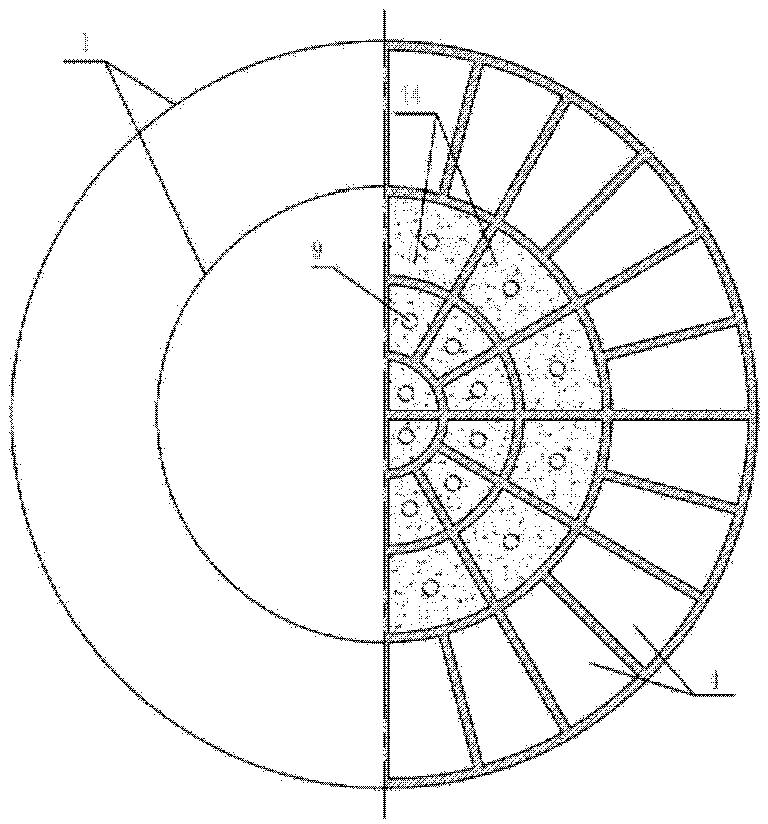

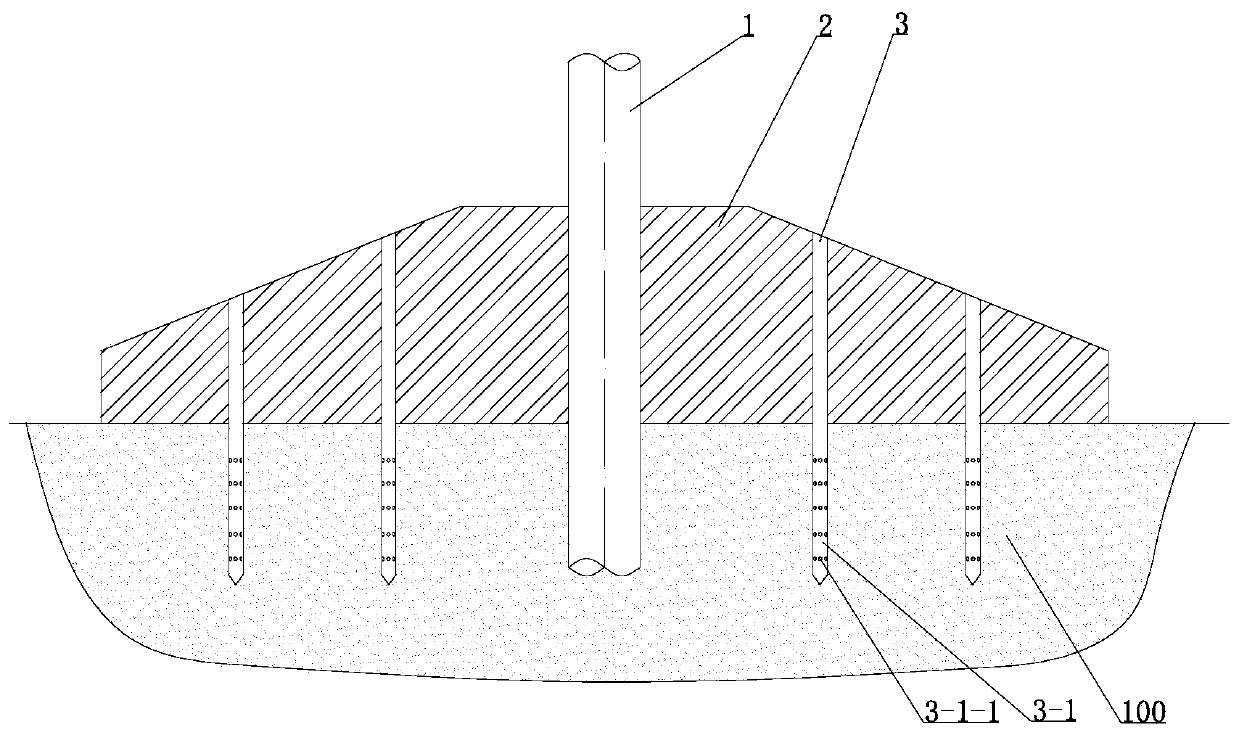

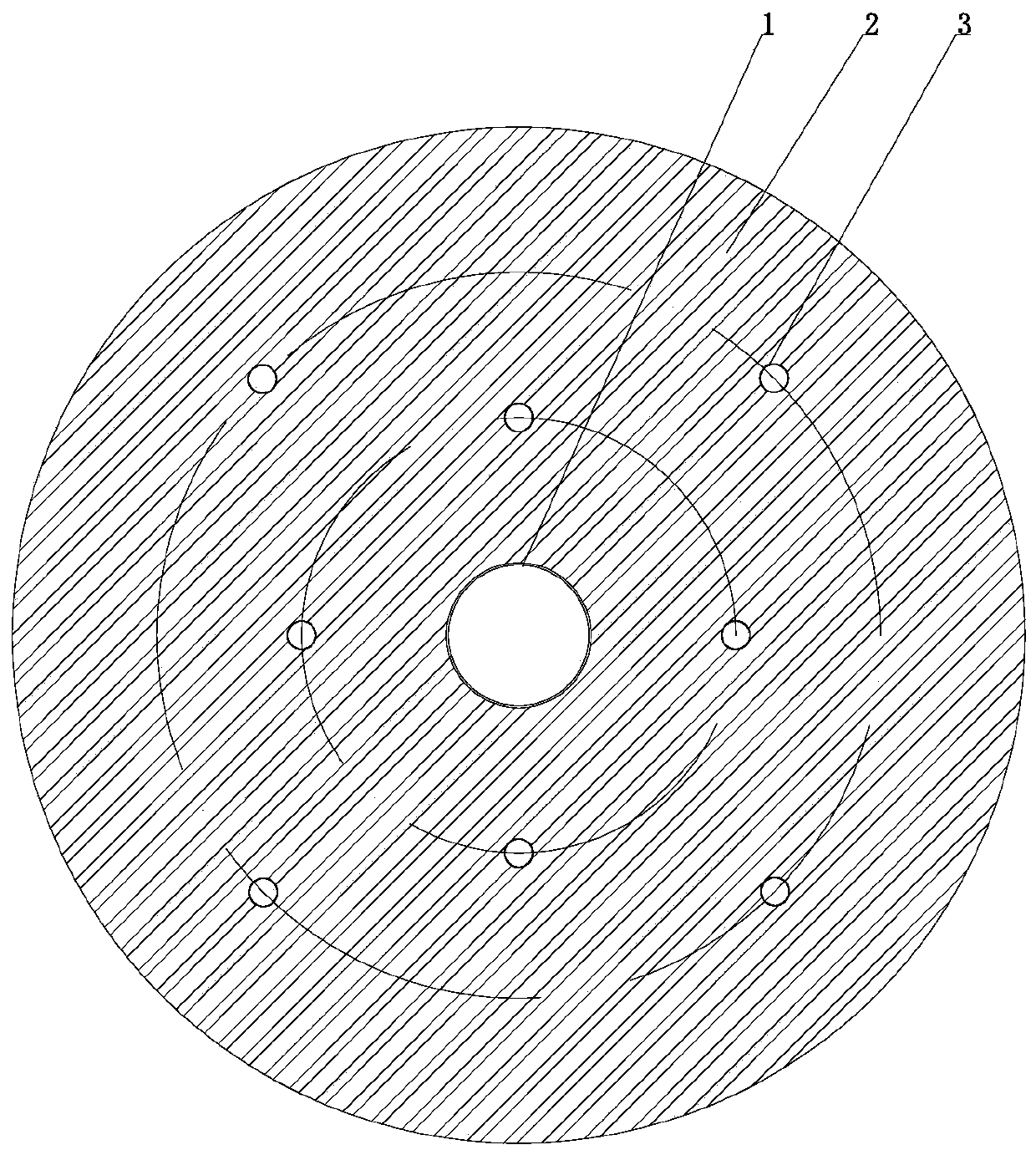

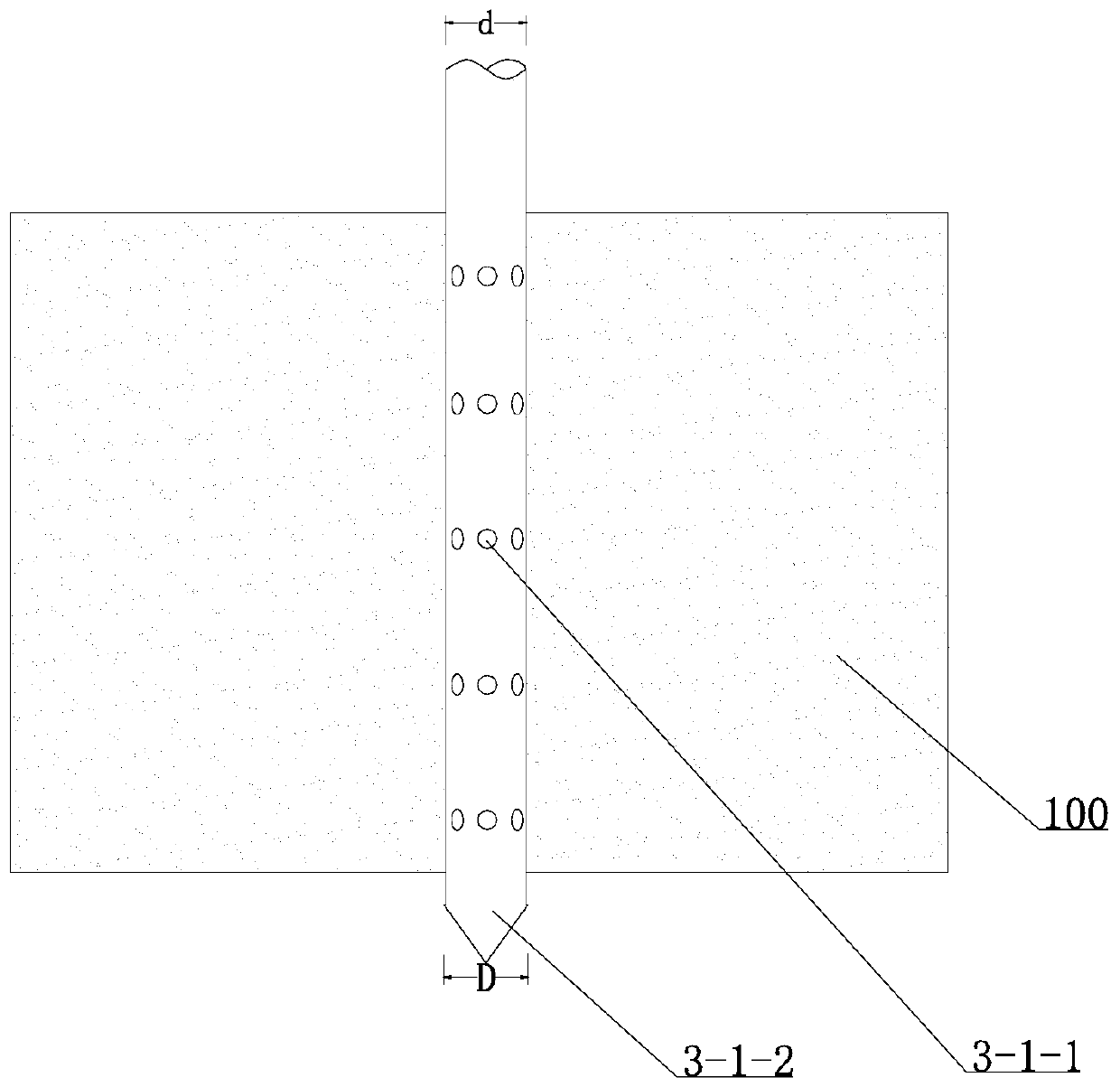

Offshore wind turbine composite foundation and foundation reinforcement construction method

ActiveCN111501814AIncrease contact areaImprove carrying capacityBulkheads/pilesSoil preservationRebarSteel tube

The invention relates to an offshore wind turbine composite foundation and a foundation reinforcement construction method. The composite foundation comprises a single-pile foundation body and a peripheral friction body, wherein the peripheral friction body is of a concrete integrated pouring structure with built-in steel bars and is in a circular truncated cone shape; the single-pile foundation body is sleeved with the peripheral friction body; the peripheral friction body makes contact with the upper end of a foundation soil body; vertical construction hole channels which communicate the upper end with the lower end and are used for achieving grouting are formed in the peripheral friction body; a plurality of vertical construction hole channels are evenly distributed on one or more circles of circumference; and a steel pipe nail is connected into each vertical construction hole channel in a pouring mode or fixedly inserted into each vertical construction hole channel, the lower section of each steel pipe nail extends out of the lower end of the peripheral friction body and is inserted into the foundation soil body, and guniting holes are evenly distributed in the pipe wall of eachsteel pipe nail. According to the composite foundation, the contact area between the foundation and a subgrade is increased, grouting reinforcement treatment can be conducted on the soft soil foundation, thus the bearing capacity of the subgrade and the foundation can be improved, integrated construction is achieved, and seabed pretreatment is reduced.

Owner:HEBEI UNIV OF TECH

Flame-retardant aliphatic-aromatic copolyester and preparation method thereof

The invention discloses flame-retardant aliphatic-aromatic copolyester, which is prepared with aromatic dibasic acid, aliphatic dibasic acid, aliphatic dihydric alcohol and phosphorus-based flame retardant. The amount of the phosphorus-based flame retardant is 0.05-1.00 percent of the flame-retardant aliphatic-aromatic copolyester by weight. A preparation method comprises the steps of: a) preparing butanediol solution of phosphate; b) performing esterification to obtain a corresponding esterified compound; c) performing prepolymerization to obtain a corresponding prepolymer; and d) performing polycondensation reaction. The flame-retardant aliphatic-aromatic copolyester has the beneficial effects that a titanium chelate compound with hydrolysis resistance is adopted as a catalyst, the amount of the added catalyst is reduced, the titanium dioxide precipitate cannot be produced during production, and the maintenance / replacement cycle of production equipment can be extended; and the material has degrading properties and flame retardant properties, the scope of application of the biodegradable material can be broadened further, the effect of stabilizing the color of the copolyester can be achieved while the flame retardant properties of the material is realized, the structure of the copolyester can be controlled easily, no gel can be produced easily during reaction, and the produced membrane is free from crystallization points formed by gel.

Owner:KINGFA SCI & TECH CO LTD +2

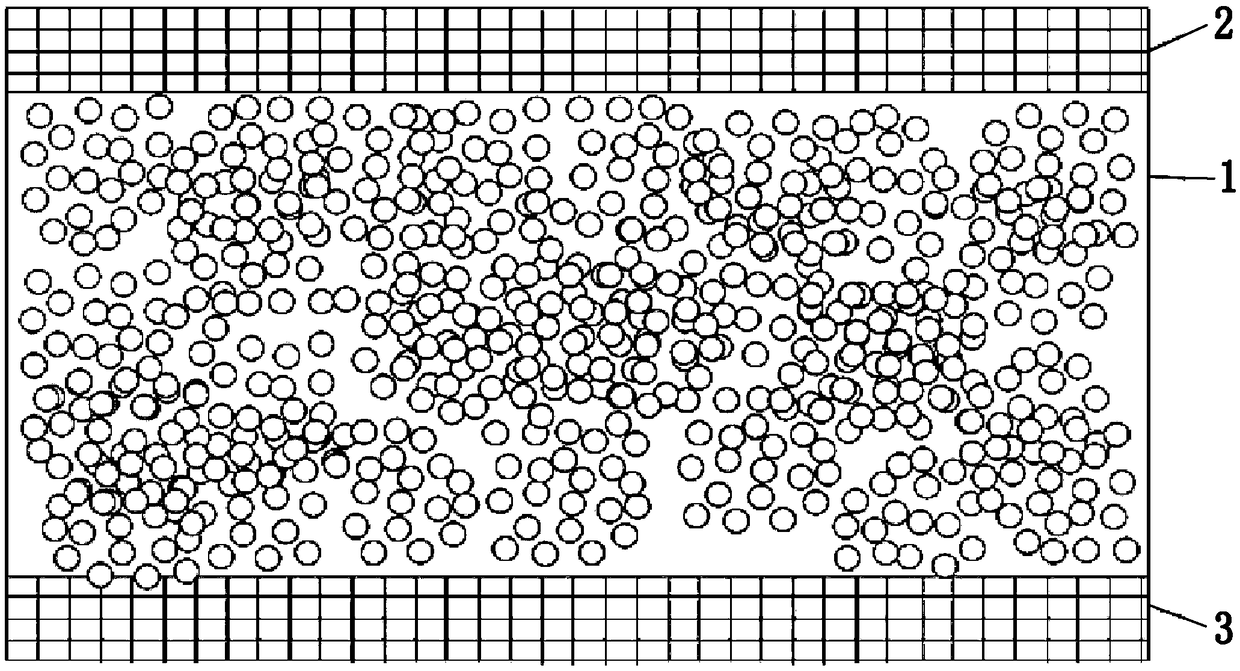

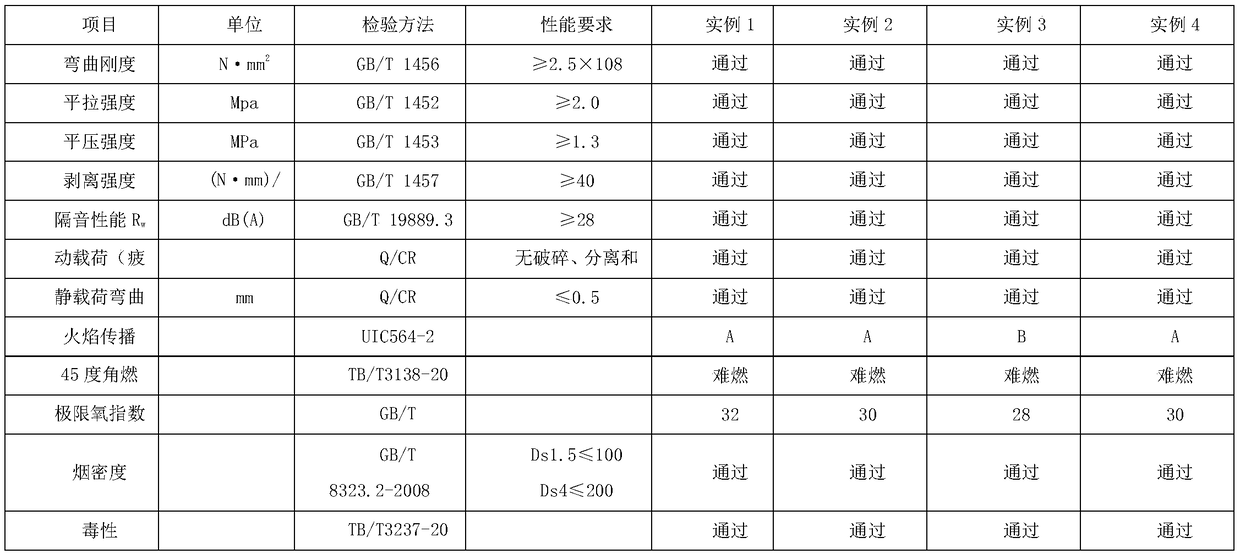

Method for preparing flame retardant rail transit vehicle interior floor based on foaming process

InactiveCN108943923AHigh vertical and horizontal performanceGood impact resistanceSynthetic resin layered productsLaminationEngineeringFiber

The invention relates to a method for preparing a flame retardant rail transit vehicle interior floor based on a foaming process. The interior floor comprises an upper surface layer, a core material and a lower surface layer arranged in sequence. The upper surface layer, the core material and the lower surface layer are compounded through heating and pressing to form the interior floor. The core material is a foam sheet. The upper surface layer and the lower surface layer are prepared from fabrics obtained by weaving multilayer unidirectional continuous glass fiber reinforced thermoplastic resin prepregs and / or glass fiber fabric-reinforced thermoplastic resin prepregs and / or glass fibers and thermoplastic resin co-extruded fibers. The polymer resin foams to form a lightweight foamed sheetas the core material through a physical or chemical foaming process. The lightweight composite core material has light weight and can absorb noise. The surface layers and the core layer are preparedfrom the same polymer. The base layer materials can be bonded through a direct practical hot pressing process and the base layer materials can be bonded with the surface layers directly through a hotpressing process without glue so that the glue spraying process is avoided. The floor materials can be recovered, is environmentally friendly and is easy to process.

Owner:嘉兴领科材料技术有限公司

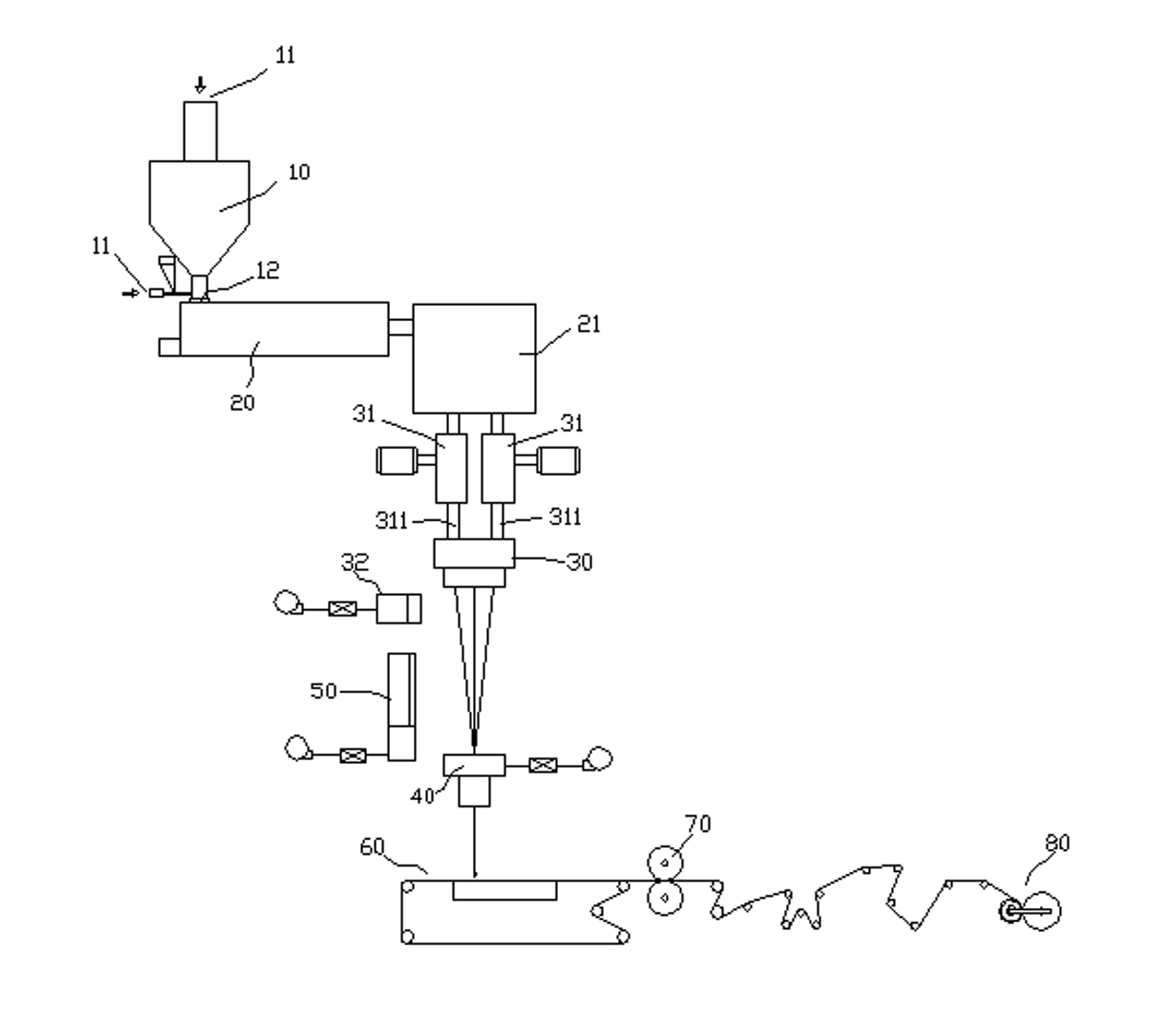

Automatic production equipment for 3.2-meter wide non-woven fabrics

ActiveCN101979744ASimple structureLow investment costNon-woven fabricsAir volumeProgrammable logic controller

The invention relates to the technical field of non-woven fabrics, in particular to manufacturing equipment for the non-woven fabrics. The equipment is controlled by the program of a programmable logic controller (PLC) and comprises a feeding unit, a screw extruder, an extension box body, an airflow drafting unit, a cooling side-blowing unit, a wet forming unit, a rolling mill and a winding unit,wherein the screw extruder is used for extruding raw materials by heating; a filter is arranged at the extrusion port of the screw extruder; the input end of the extension box body is connected to the filter through at least two counters which are connected in parallel; the airflow drafting unit is in vertical butt joint with the output end of the extension box body; a single body drawn by the extension box body is intertwined and staggered by the airflow drafting unit; the cooling side-blowing unit is arranged on the side of a single body drafting region between the extension box body and the airflow drafting unit; and a regulating valve capable of regulating air quantity is arranged on an air channel of the cooling side-blowing unit. The equipment can produce 3.2-meter wide non-woven fabrics, meets new state requirements of non-woven fabric industries and has a simple, scientific and reasonable structure.

Owner:东莞市威骏不织布有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com