Offshore wind turbine composite foundation and foundation reinforcement construction method

A composite foundation and offshore wind turbine technology, which is used in foundation structure engineering, soil protection, sheet pile walls, etc. The effect of foundation area, improving structural utilization, and improving vertical and lateral bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

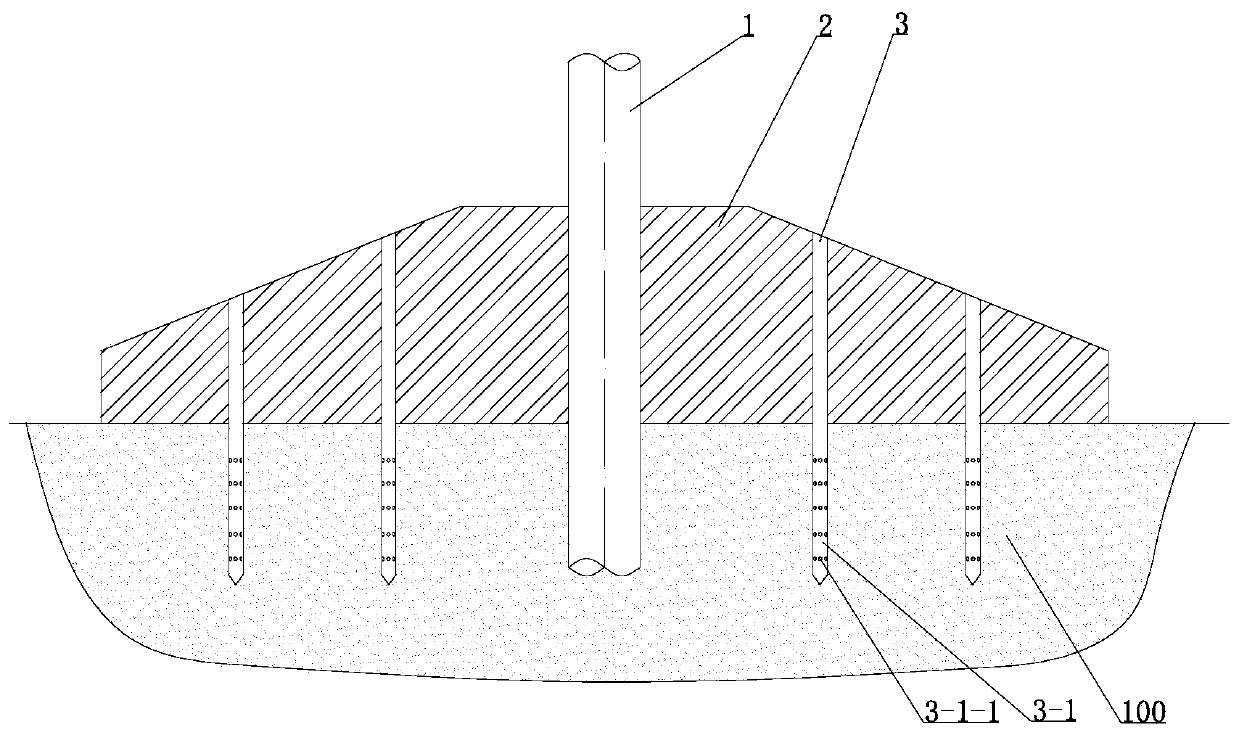

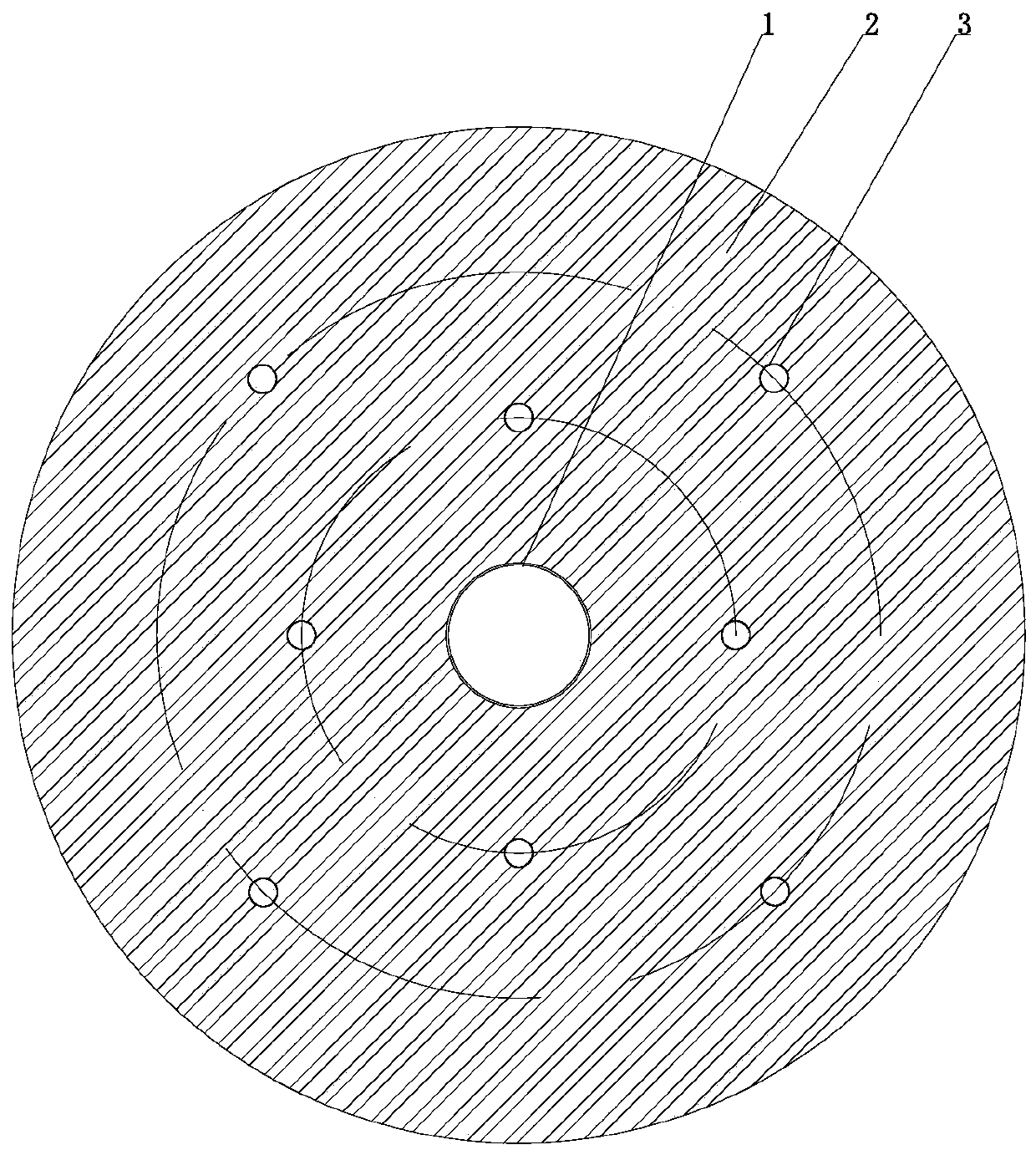

[0029] A composite foundation for offshore wind turbines, see Figure 1-3 , its invention point is:

[0030] Including the single pile foundation body 1, which is a hollow steel pipe pile, the lower section of the hollow steel pipe pile is inserted into the foundation soil, and the upper section is exposed above the foundation soil.

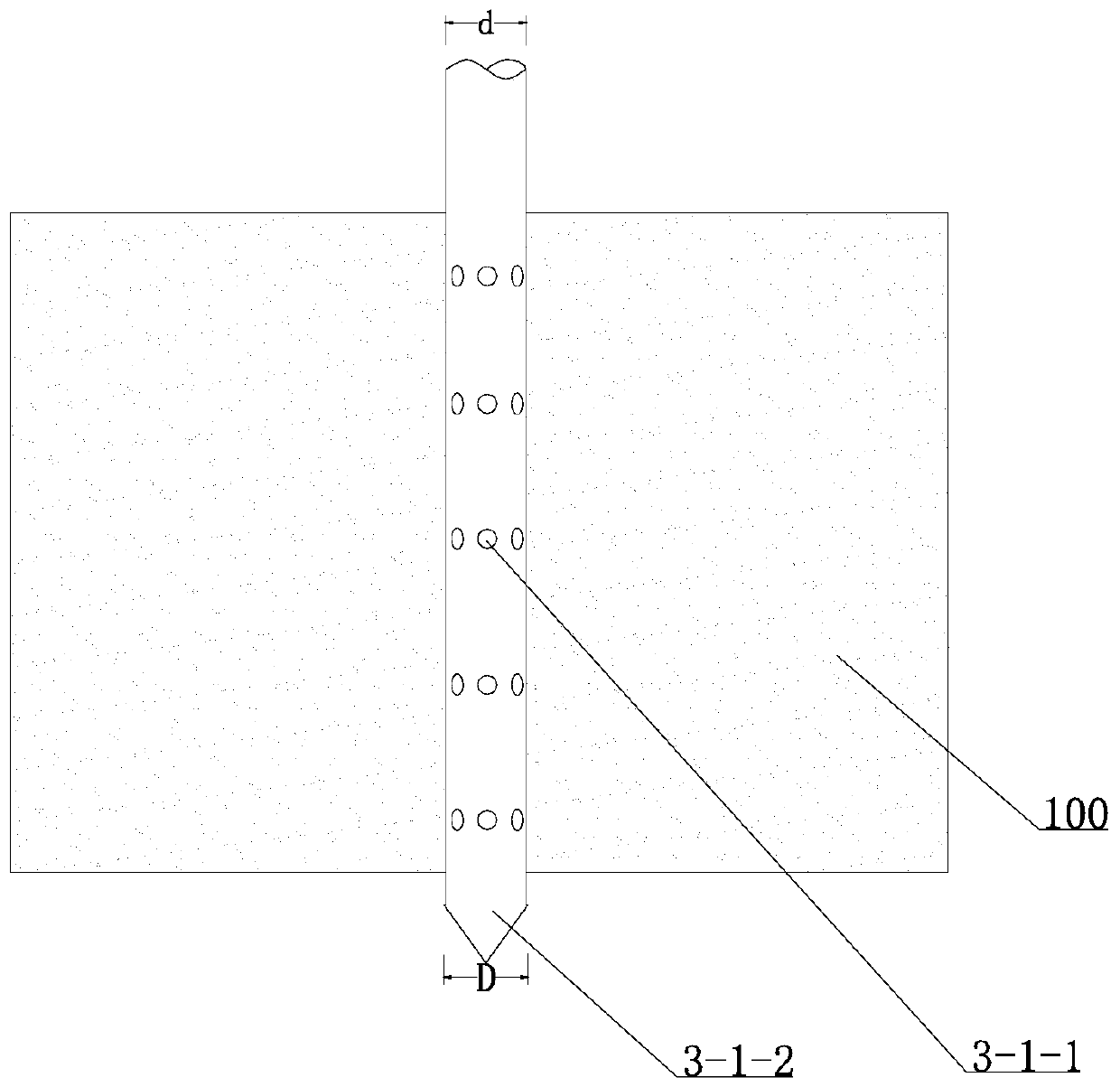

[0031] Including the peripheral friction body 2, which is an integrated concrete pouring structure with built-in steel bars. The upper and lower ends are used to realize the vertical construction tunnels for grouting. Multiple vertical construction tunnels are evenly distributed on one or more circles. Specifically, the diameter and position of the construction tunnels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com