High power LED ceramic packaging base

A ceramic packaging, high-power technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of affecting the life and luminous efficiency of high-power LEDs, weakening the overall heat dissipation performance of the packaging base, failing to achieve high power, long life, etc. problems, to achieve enhanced longitudinal and transverse heat transfer effects, strong resistance to high and low temperature impact performance, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] refer to Figure 4 to Figure 15 , the present invention is implemented like this:

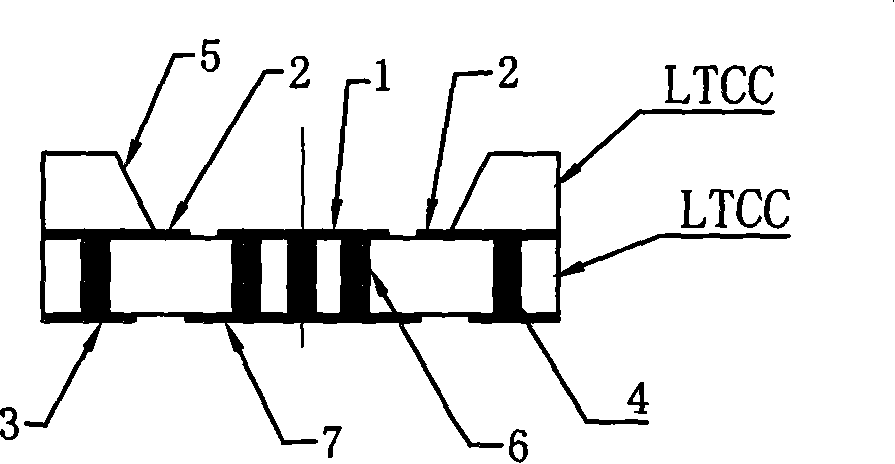

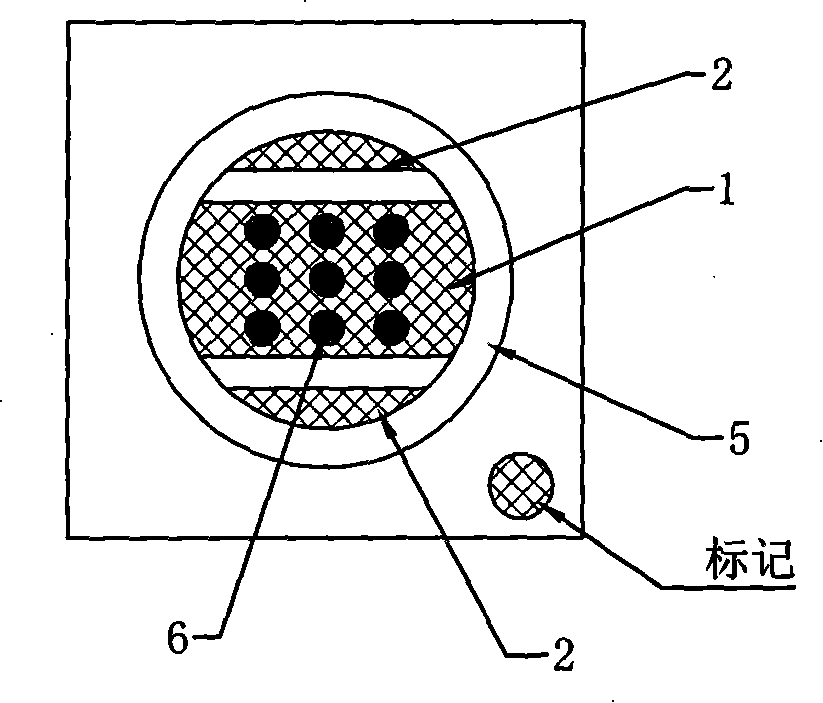

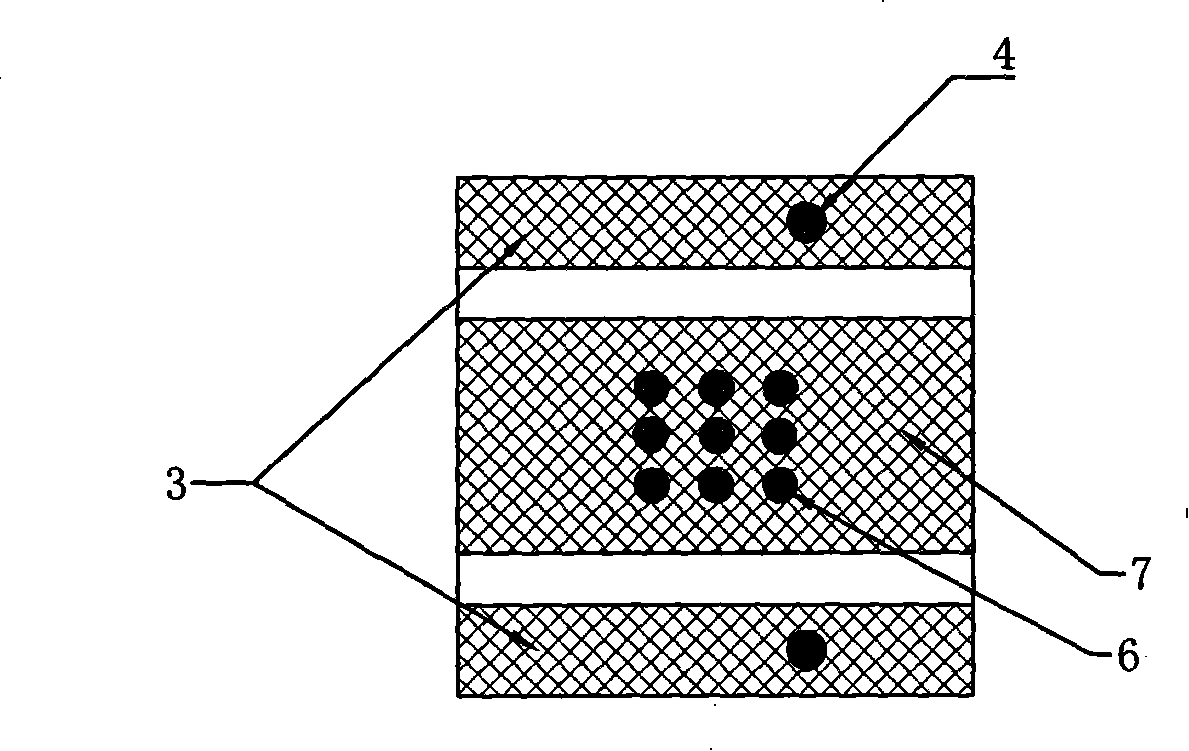

[0046]A high-power LED ceramic packaging base, the base is composed of an upper ceramic layer 10 and a lower ceramic layer 20, the upper ceramic layer 10 provides a reflective cup, the upper ceramic layer 10 is made of LTCC glass ceramic material, and the lower ceramic layer 20 is made of In order to install the chip and achieve electrical conduction with the bottom electrode, the upper side of the lower ceramic layer 20 is provided with a patch area 1 for installing the chip and a wire bonding area 2 for connecting the chip electrode through a welding wire, and the lower side of the lower ceramic layer 20 is provided with a pass through substrate. The metallized wiring on the base realizes the bottom pad 3 connected to the two electrodes of the chip, and the base is also provided with an electrical conduction hole 4 for connecting the upper and lower layers of metallized wiring to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com