Medical paper-plastic composite blue film and preparation method thereof

A technology of paper-plastic composite and blue film, which is applied in the direction of chemical instruments and methods, adhesive types, adhesive additives, etc., can solve the problems of packaging that cannot be displayed intuitively, high cost of use, and the risk of large package breakage, and achieves excellent results. Freeze resistance, poor tear resistance, excellent gas barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

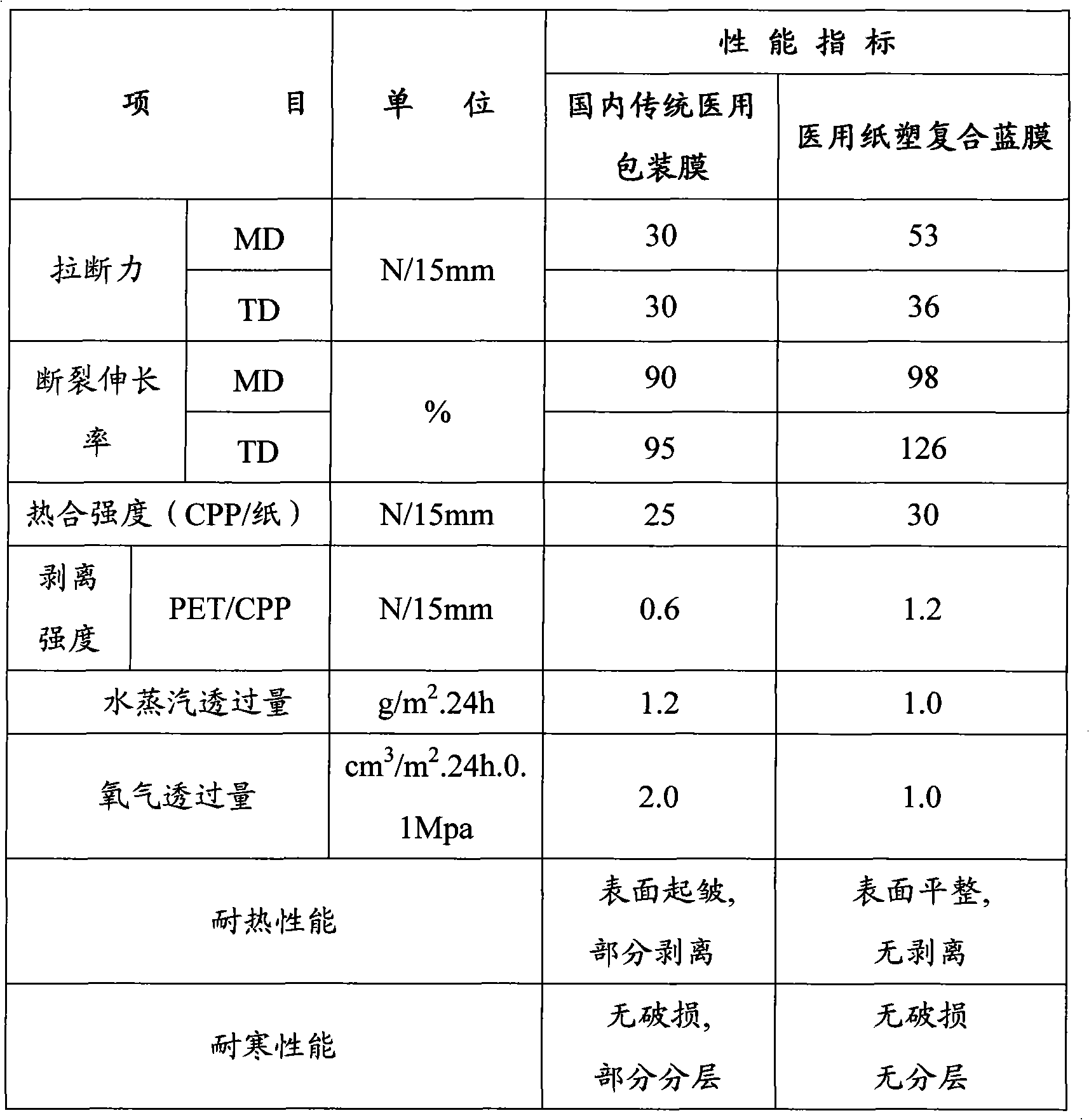

[0032] Medical paper-plastic composite blue film is composed of printed and coated biaxially stretched polyester film and cast polypropylene film. The cast polypropylene film is divided into corona layer, middle layer and heat seal layer. Three layers, the raw material component of the corona layer is additive-free binary copolymerized polypropylene resin RF401, and the raw material component of the middle layer is 85-95% binary random copolymerized polypropylene resin F800E and 5 -15% ethylene-butylene elastomer A-4085S, the raw material components of the heat-sealing layer are 85-90% binary copolymerized polypropylene resin RF402 containing anti-stick slip agent, 5-15% ethylene- Butylene elastomer A-4085S, 1-2% inorganic anti-sticking agent ABPP10S and 0.5-1.5% smooth modified masterbatch SE07PP.

[0033] Ethylene-butylene elastomer A-4085S is a grade of TAFMER series products produced by Mitsui Chemicals in Japan.

[0034] Preparation method of medical paper-plastic compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com