Modularized vehicle door with steel, aluminum and plastic mixed

A modular, door technology, applied in the direction of doors, vehicle parts, transportation and packaging, can solve the problems of long design cycle, complex process operation, low degree of modularization, etc., to improve product quality and production efficiency, simplify the process , good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will be combined with Figure 1-5 The technical solution of the present invention is described in detail.

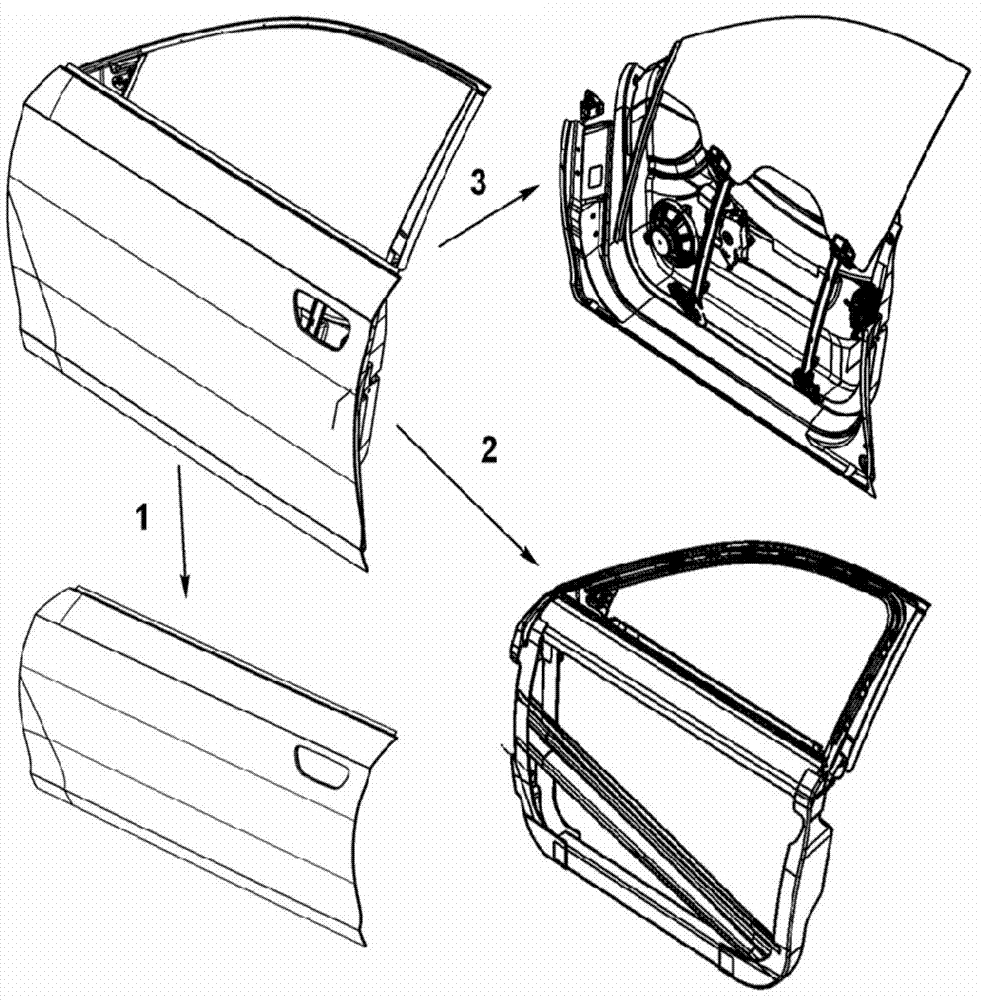

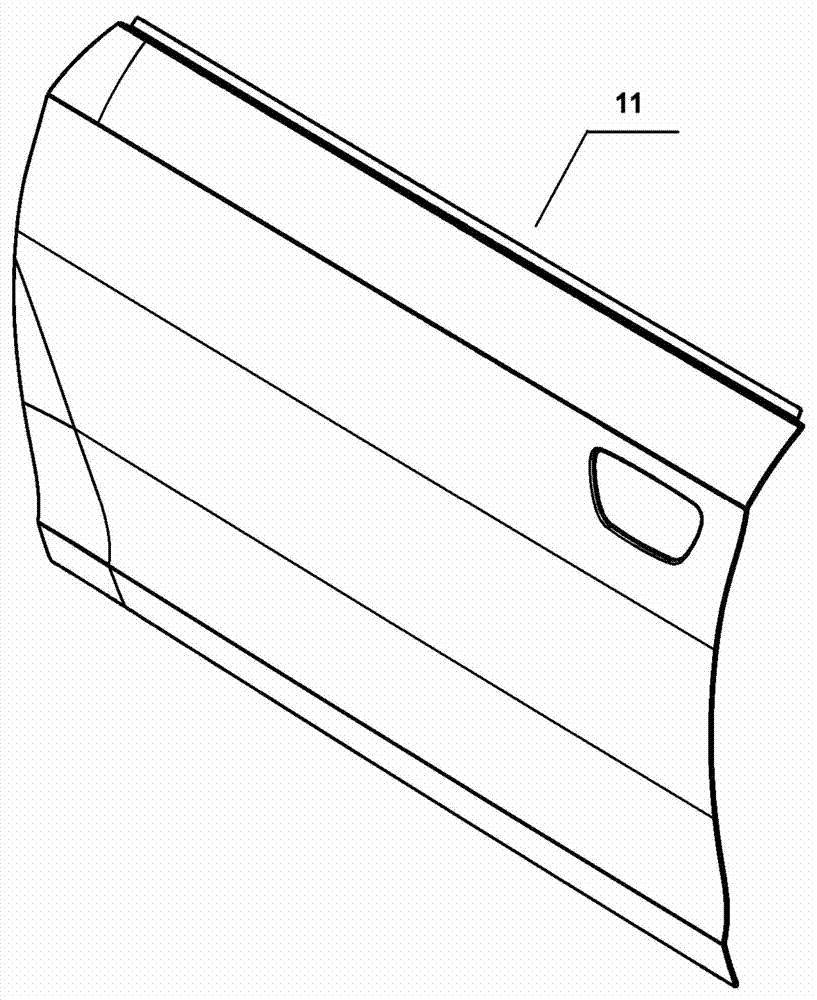

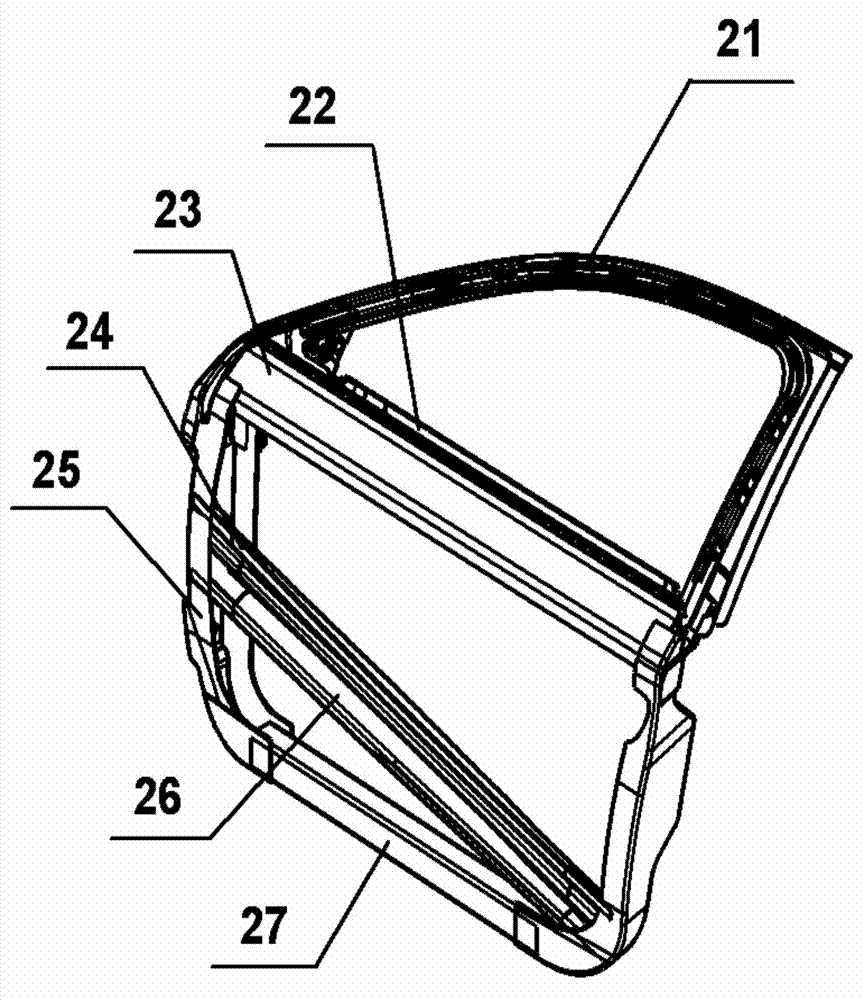

[0026] Such as Figure 1-3As shown, the modular structure car door of the present invention includes a car door outer panel assembly 1, a car door frame assembly 2, and a car door inner panel and accessory module assembly 3, wherein: the car door outer panel 1 assembly includes a car door outer panel 11, As a non-main load-bearing part of the door structure, it mainly meets the functional requirements of the exterior shape. The door frame assembly 2 includes a door window frame 21, an inner panel reinforcement 22, an outer panel reinforcement 23, a guide rail reinforcement 24, a hinge reinforcement 25, a reinforcement rib 26, and a door reinforcement beam 27. The door inner panel and accessory module assembly 3 includes a door glass 31, a guide rail 32, a door hinge 33, a door inner panel 34, a door lock 35, a loudspeaker 36, and a door glass lifte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com