Seal structure of oil-free vortex compressor

A scroll compressor and sealing structure technology, which is applied in the field of compressors, can solve the problems of increasing the processing accuracy requirements and high matching requirements of the scroll body, and achieve the effects of reliable sealing, reducing the elastic modulus and reducing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

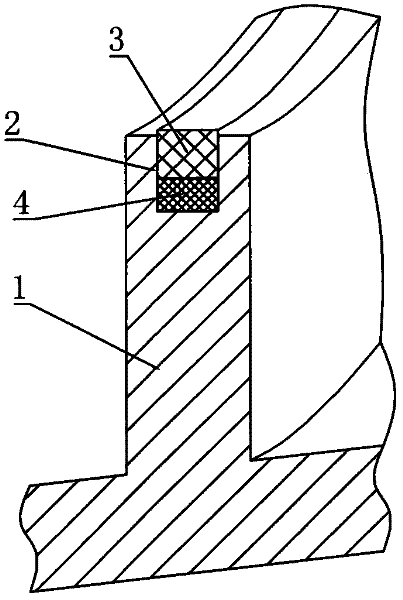

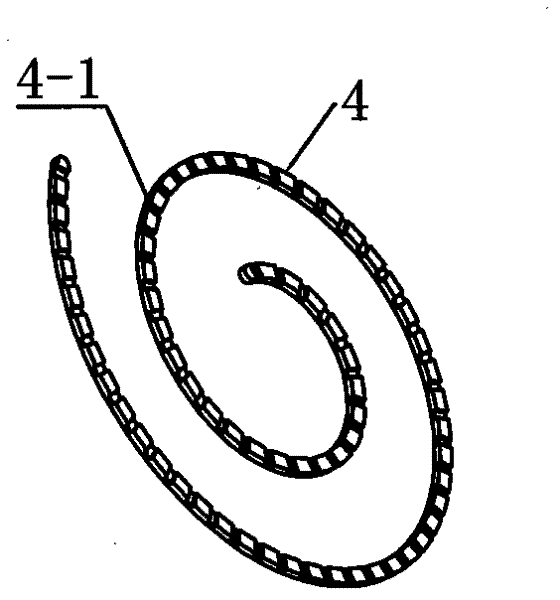

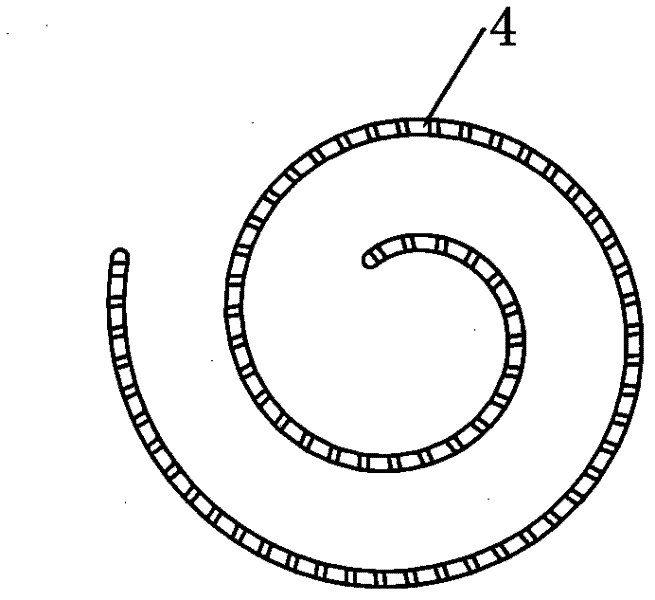

[0016] Such as Figure 1 ~ Figure 3 As shown, an oil-free scroll compressor sealing structure of the present invention includes a scroll body 1, a sealing groove 2 is provided on the top of the scroll body 1, and a sealing strip 3 and a sealing liner 4 are sequentially arranged in the sealing groove 2 from top to bottom. . The sealing lining is a soft material and needs to be fixed well to ensure that the sealing lining is partially deformed and detached after being stressed, such as using high-elastic silicone rubber. The sealing strip 3 is filled with polytetrafluoroethylene material with self-lubrication and high wear resistance. There is a groove 4-1 on one surface of the sealing liner 4, which is in a toothed structure. The flat surface of the sealing liner is connected with the scroll body downwards and glued together; the toothed surface is in contact with the sealing strip, and the toothed surface of the sealing liner The spacing between the teeth is evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com