Heat-conducting type degaussing cable for ship

A technology for degaussing cables and ships, applied in the direction of insulating cables, cables, conductors, etc., can solve the problems of lowering the temperature resistance level of cables, cable bulging, and short service life, and achieve improved thermal conductivity, comprehensive performance, and high dielectric strength. constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

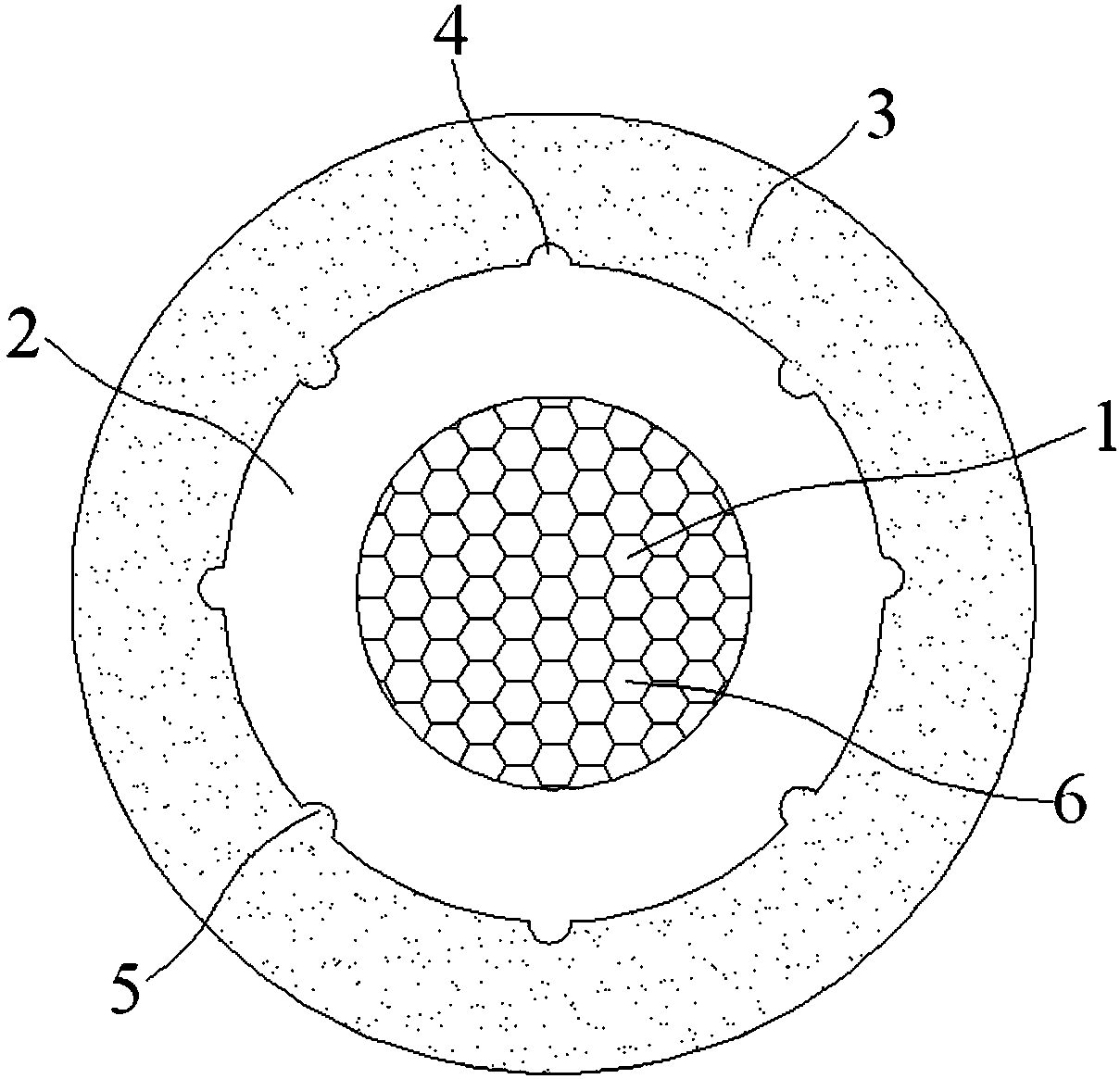

[0035] Embodiments 1 to 4: A heat-conducting degaussing cable for ships, including a copper conductor 1 located in the center, and the outer surface of the copper conductor 1 is covered with a heat-conducting ethylene-propylene rubber insulating layer 2, and the heat-conducting ethylene-propylene rubber insulation The outer surface of the layer 2 is covered with a chlorosulfonated polyethylene rubber sheath layer 3, and the outer surface of the thermally conductive ethylene-propylene rubber insulating layer 2 has several first semicircular protrusions 4, the first semicircular protrusions The starting part 4 is embedded in the chlorosulfonated polyethylene rubber sheath layer 3;

[0036] The inner surface of the chlorosulfonated polyethylene rubber sheath layer 3 has several second semicircular protrusions 5, and the second semicircular protrusions 5 are embedded in the thermally conductive ethylene-propylene rubber insulating layer 2;

[0037] The heat-conducting ethylene-pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com