Oil and gas pipeline defect internal detector universal joint

An internal detector, oil and gas pipeline technology, used in special pipes, pipe components, couplings, etc., can solve the problems of fracture, low connection strength, easy breakage and fracture of cables, etc., to achieve fewer parts, good protection, and satisfaction Effects of use cases and conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

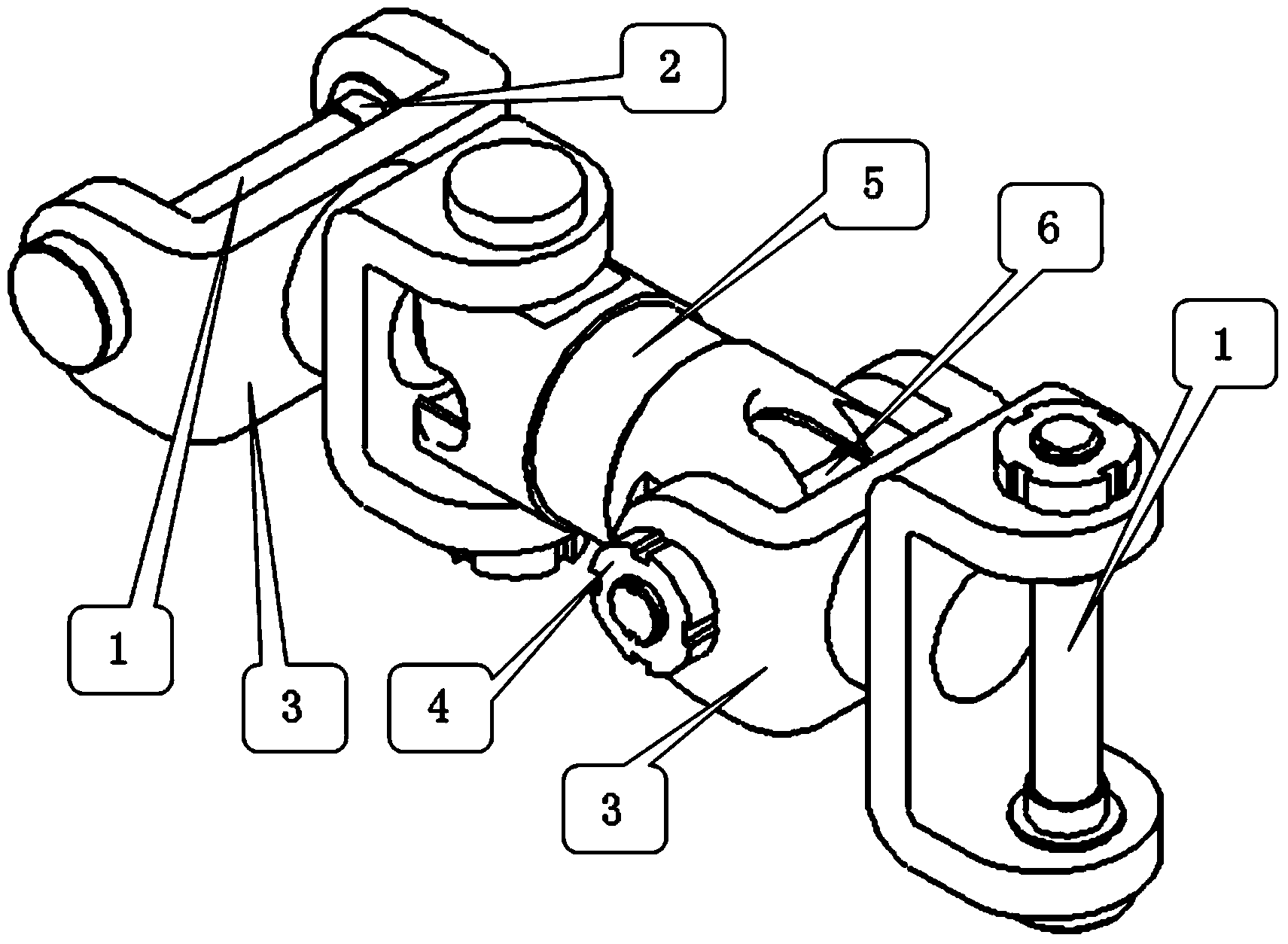

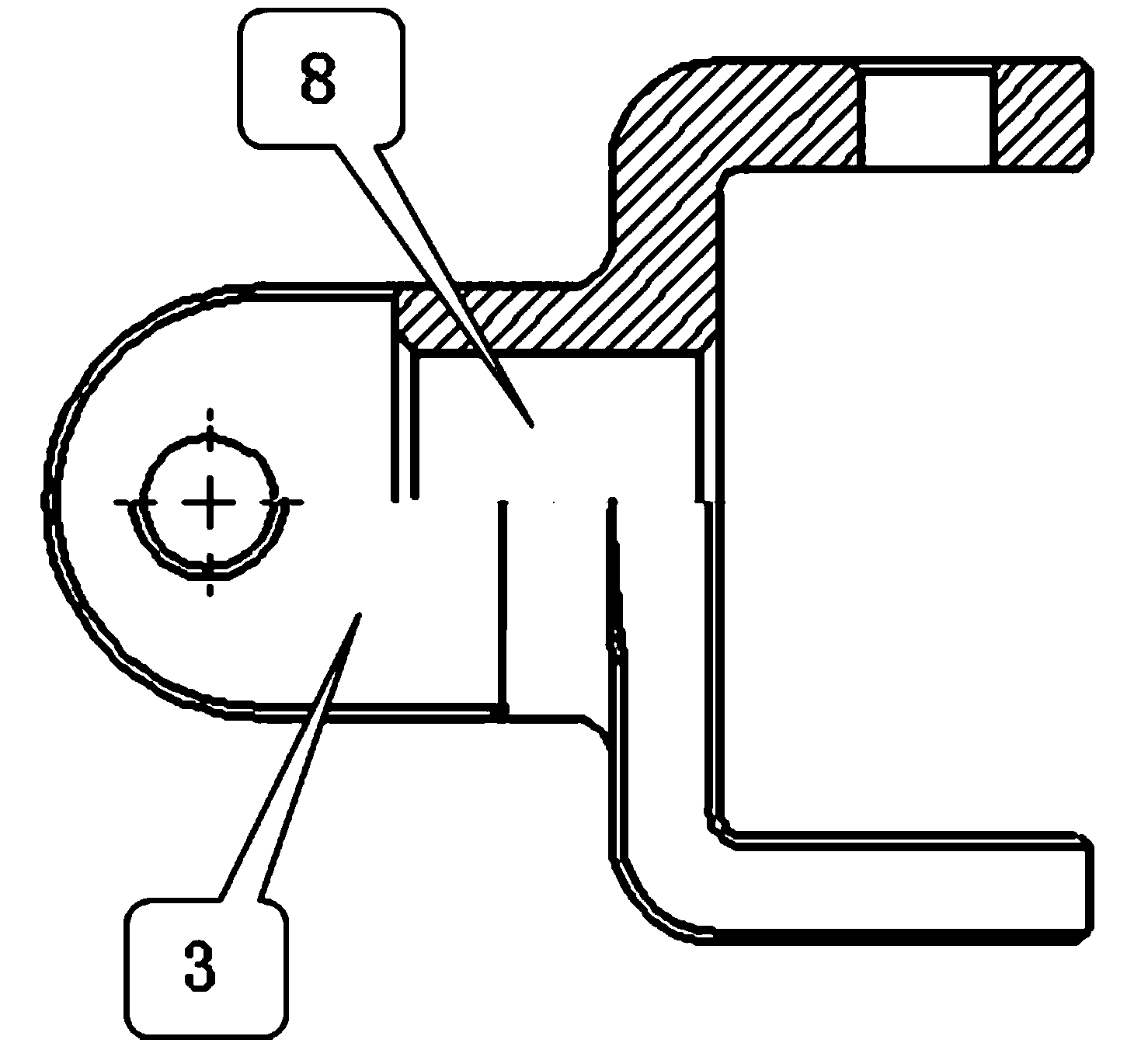

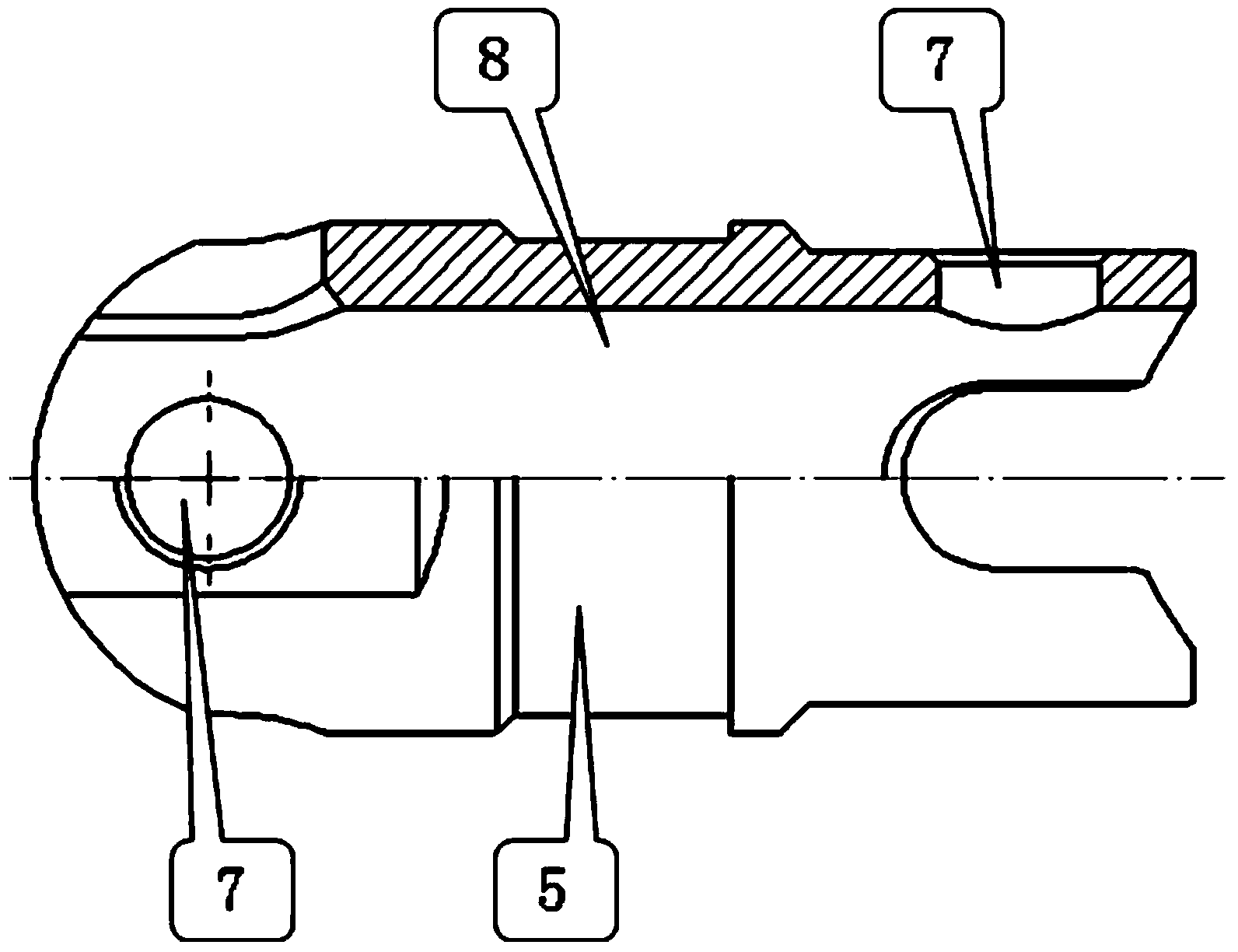

[0016] refer to figure 1 with figure 2 , the universal joint of the internal detector for oil and gas pipeline defects is composed of a hollow adapter shaft 5, a cross block 3, a rotating pin shaft 6, a flange connection pin shaft 1, a lock nut 4 and a sliding thrust copper sleeve 2; The front and rear end pin holes of the connecting shaft 5 are connected with the rear end shaft holes of the two hollow butterfly cross blocks 3 through the rotating pin shaft 6, and are locked with lock nuts 4, and the link pin holes at both ends of the hollow connecting shaft 5 are 7 are perpendicular to each other, and two hollow butterfly cross blocks 3 are symmetrically arranged. The front end of the butterfly cross block 3 is provided with a shaft hole, and the pin shaft 1 is connected to the flange on the functional joint of the internal defect detector of the oil and gas pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com