Automatic braking trolley for construction site

An automatic braking and trolley technology, applied in the field of trolleys, can solve problems such as complex design, achieve the effects of light disassembly, saving construction costs, and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

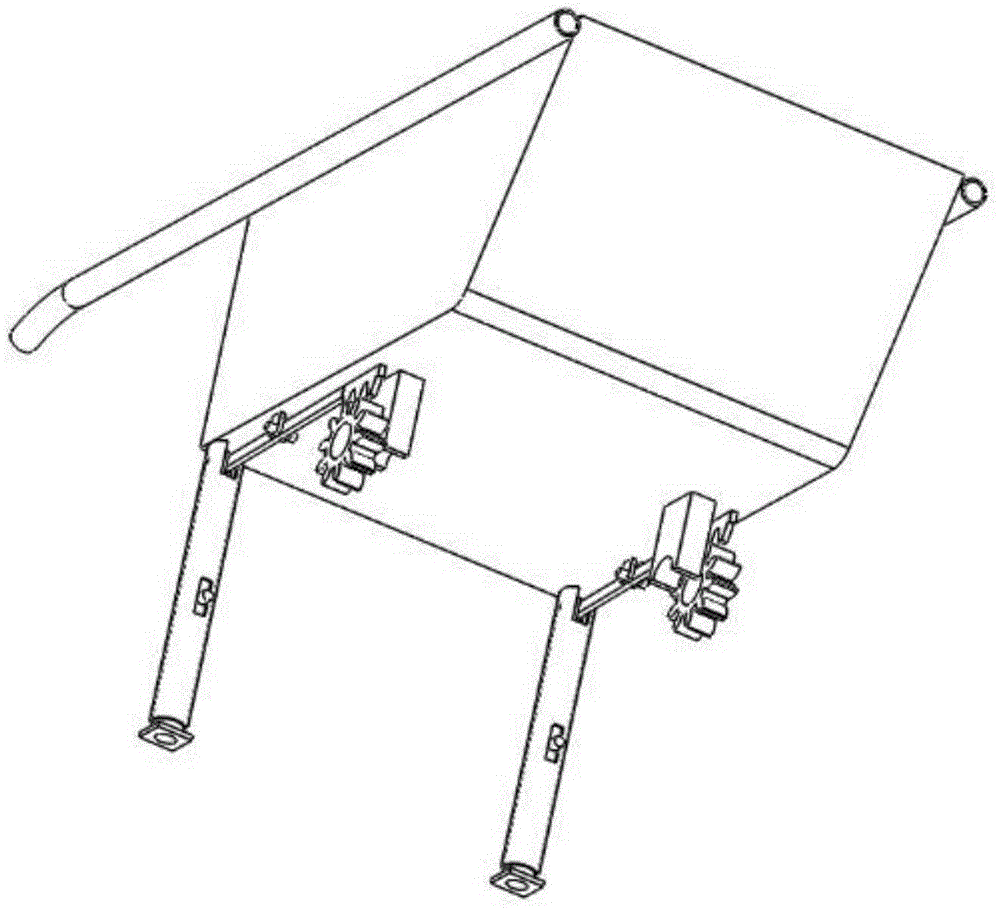

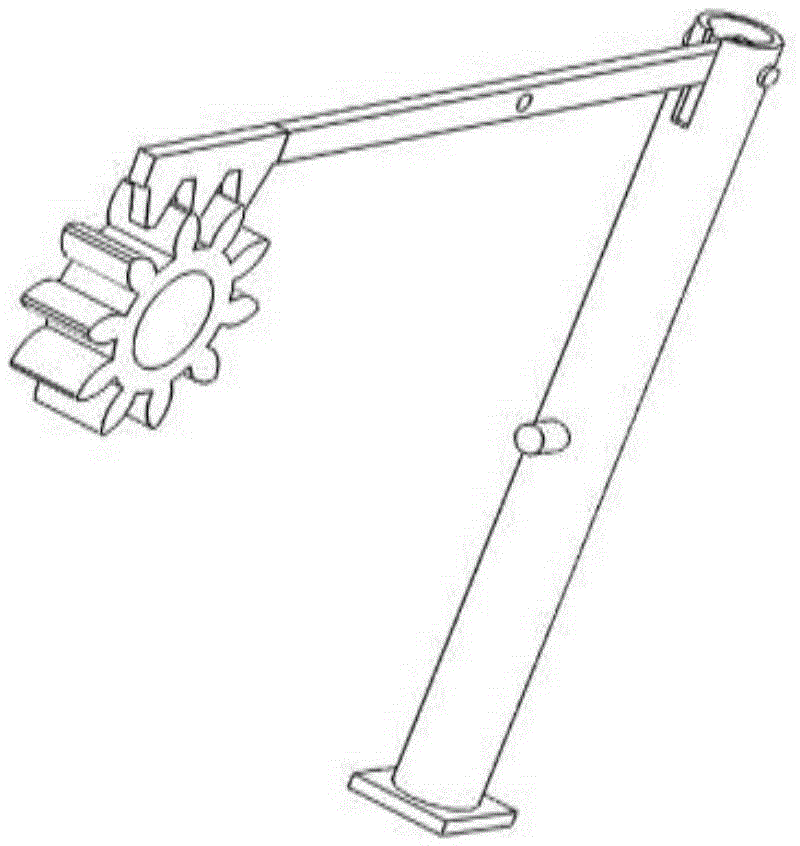

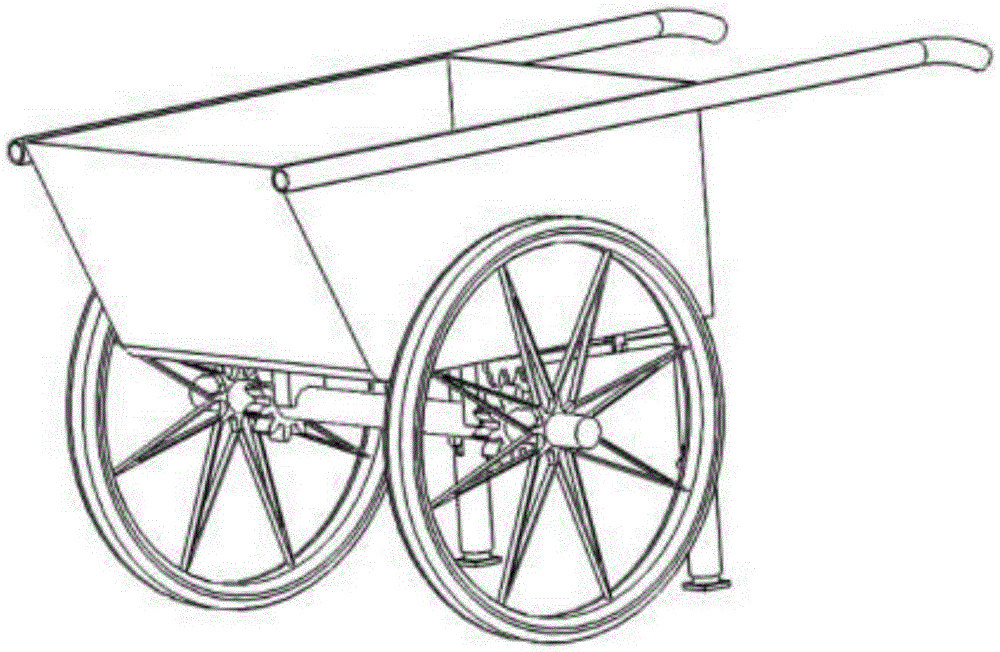

[0020] Combine below Figure 1-4 A specific embodiment of the present invention will be described in more detail with an example.

[0021] A construction site trolley capable of automatic braking, including a vehicle body and a braking device. The car body is a trolley for common construction sites, with wheels and supporting legs arranged at the bottom, and two handles at the end, the ends of which are bent. The braking device mainly includes a gear set and a lever transmission. The lever transmission device is mainly to add a steel hollow inner tube to the round tube of the ordinary trolley support leg, and slot the upper end of the outer tube so that the inner tube can be connected with the lever. The inner tube is directly inserted into the support round tube. In order to prevent the inner tube from slipping out of the support round tube, a bayonet pin is welded on the inner tube, and a slot is made in the middle of the outer tube to limit the movement of the bayonet pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com