Polymer gravel pile grouting method

A technology of high polymer and gravel piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., to achieve strong anti-vibration and anti-crack performance, plump pile shape, and improved anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention will be further described.

[0037] A grouting method for polymer gravel piles, the specific implementation steps are as follows:

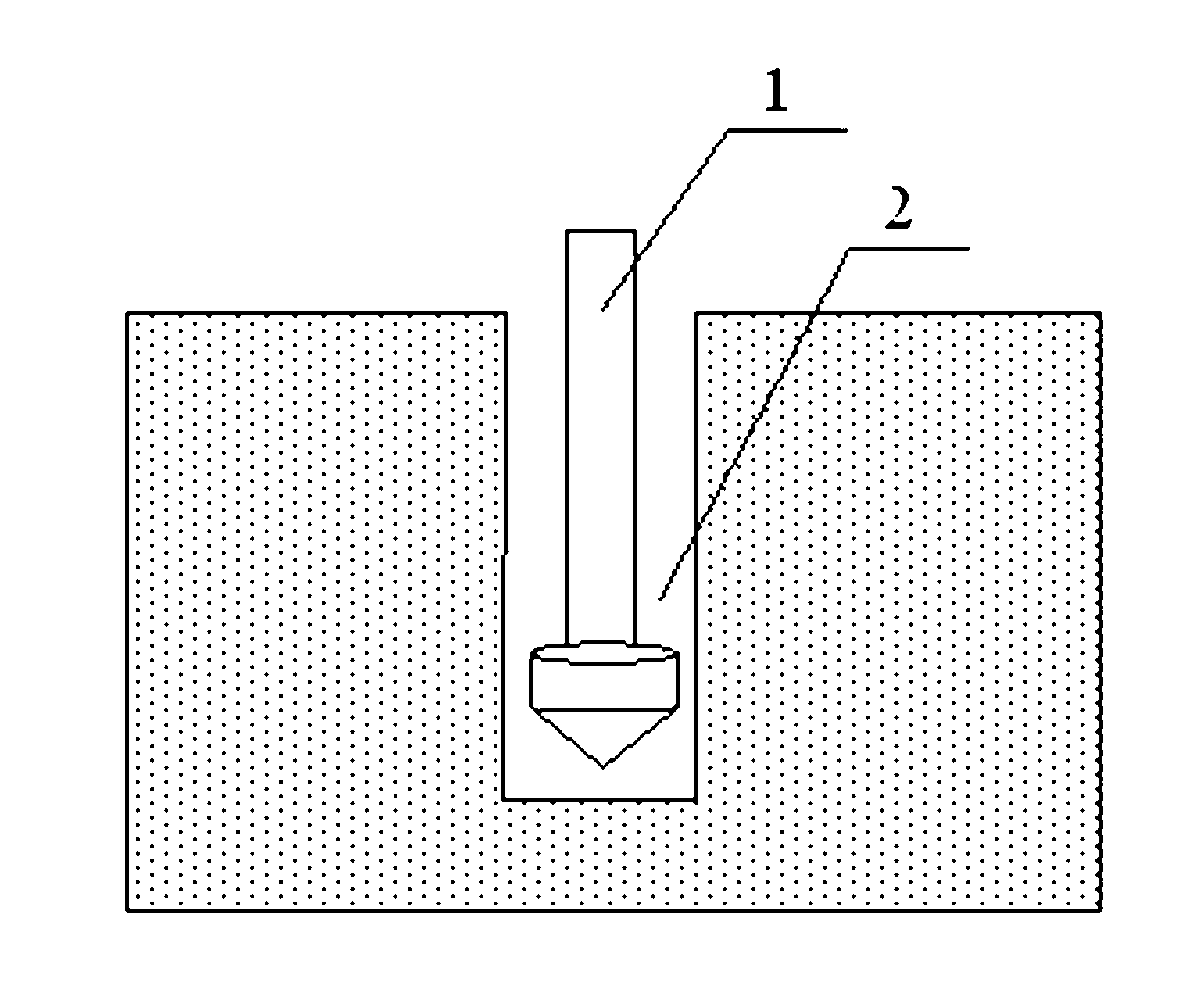

[0038] (1) Hole forming at the pile position: According to the design requirements, use the drilling tool 1 to construct the pile hole at the pile position, and the depth reaches the design depth, such asfigure 1 shown;

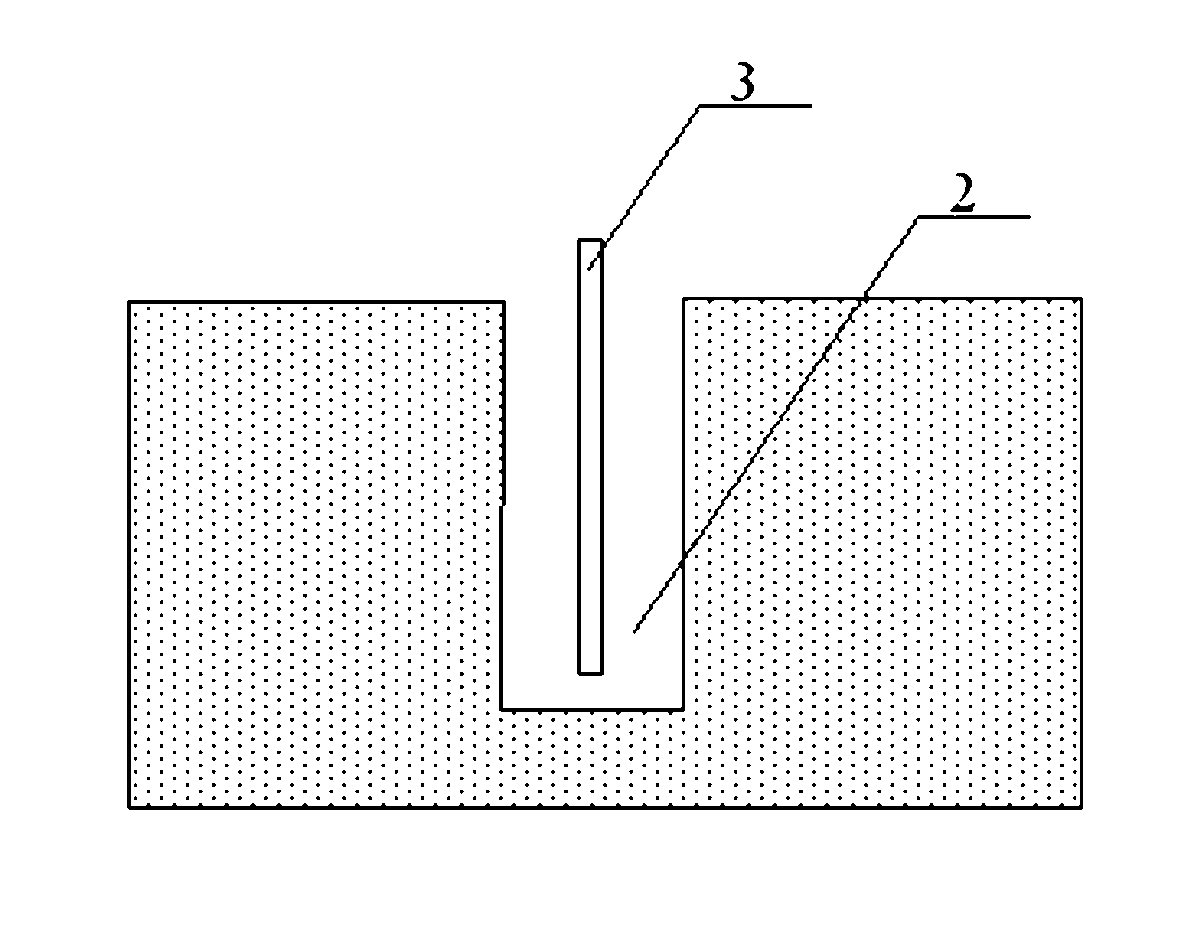

[0039] (2) Install the grouting pipe: install the grouting pipe 3 in the pile hole 2, the grouting pipe 3 is located in the center of the pile hole, and the outlet of the grouting pipe 3 goes deep into the bottom of the pile hole 2, such as figure 2 shown;

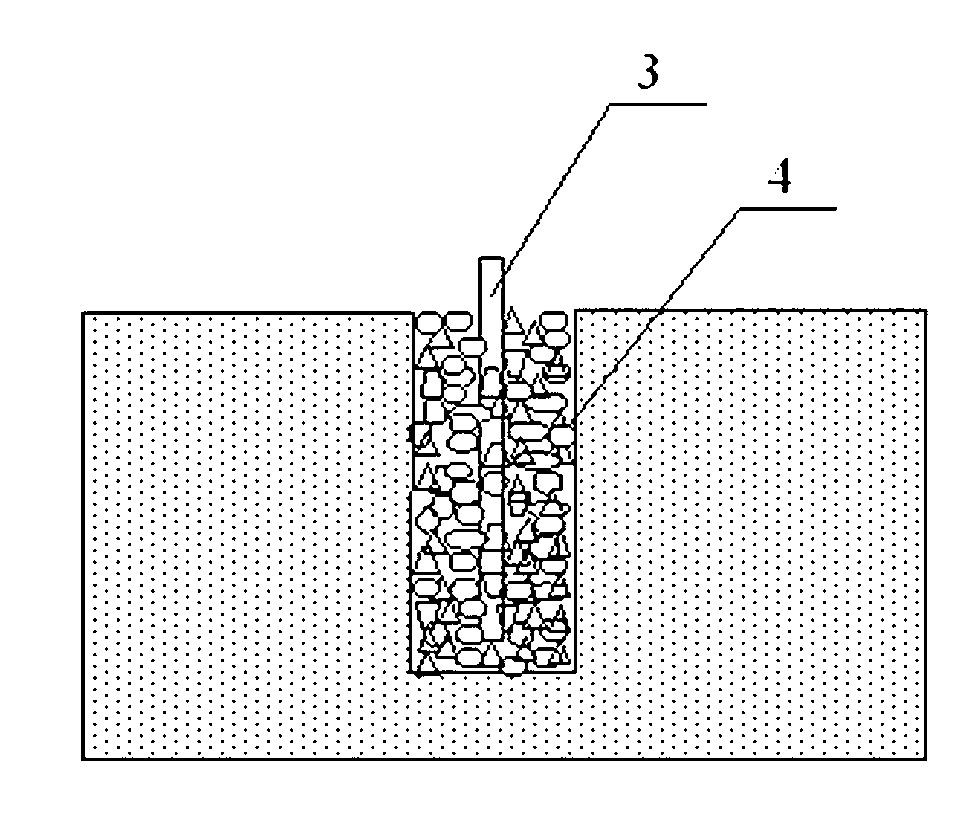

[0040] (3) Putting graded stone: According to different geological conditions, put graded stone 4 into the pile hole, such as image 3 shown;

[0041] (4) High polymer lifting grouting: place the high polymer lifting grouting control equipment 5 above the hole of the grouting pipe 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com