Exhaust silencing tube structure

A technology of muffler pipe and exhaust pipe, applied in the field of muffler pipe structure and exhaust muffler pipe structure, can solve the problems of large resistance, complex structure, easy blockage of small holes, etc. Good noise cancelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

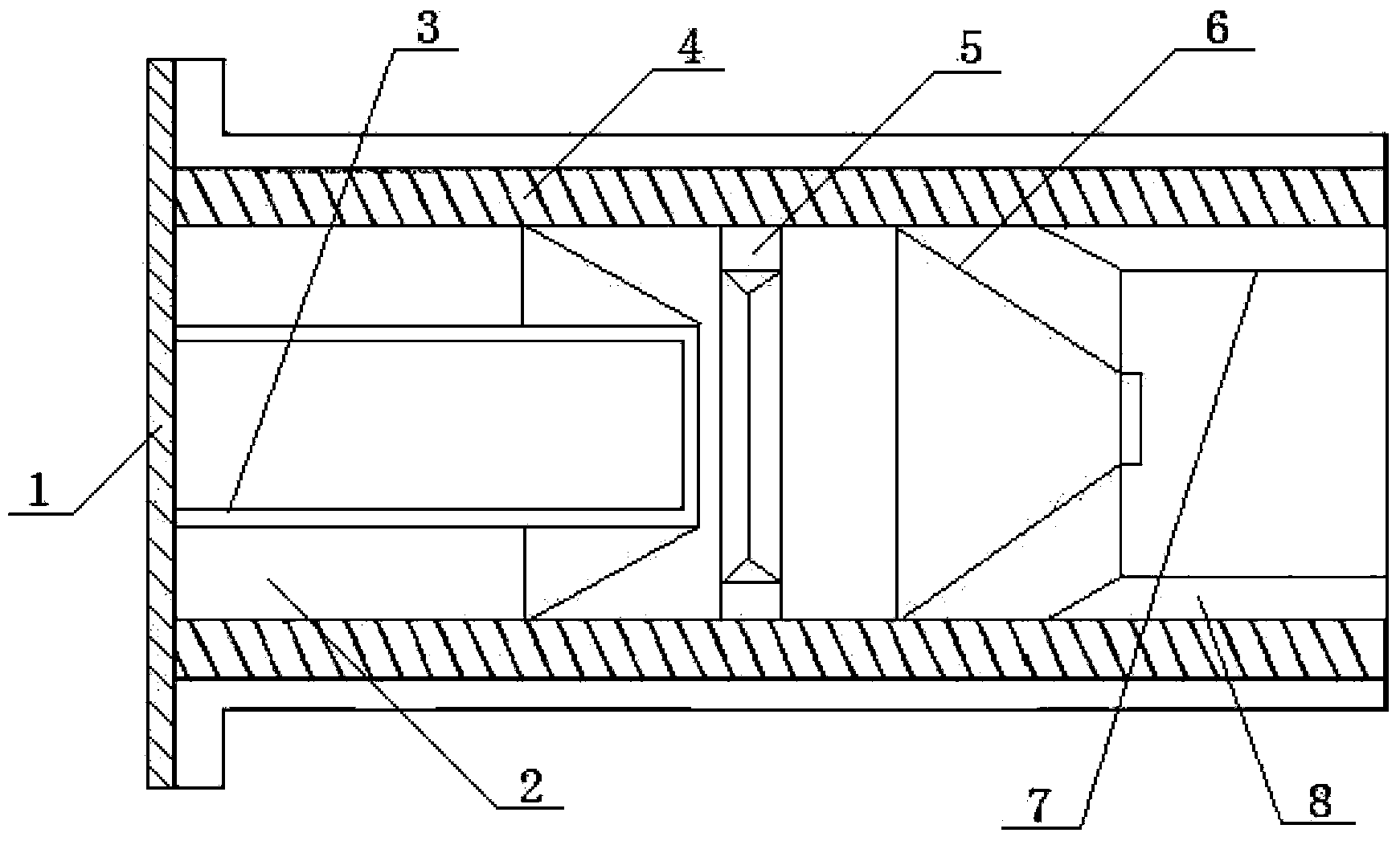

[0010] The exhaust muffler pipe structure has a cylinder body (2), a front resonance chamber (3) is arranged in the inner cavity of the cylinder body (2), and a noise reduction belt (5) is arranged on one side of the front resonance chamber (3). A spiral anechoic belt (6) is connected to one side of the anechoic belt (5), and a microporous plate (7) is installed on the helical anechoic belt (6), and a rear resonance cavity (8) is connected to the microporous plate (7), A throttling plate (4) is installed symmetrically up and down on the front resonance chamber (3), muffler band (5), spiral muffler band (6) and rear resonance chamber (8), and a throttling plate (4) is installed with a Exhaust pipe (1), fix the exhaust pipe (1) on the cylinder body (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com