A method of using an automatic grinding machine for grinding small rollers with a repairing and sharpening wheel

An automatic grinding machine and grinding wheel technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problem of unstable contact on the working surface of the pallet, which affects the improvement of processing accuracy and consistency, and errors And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention relates to a method for using an automatic grinding machine for grinding a small roller with a modified and sharpened grinding wheel. Through the automatic grinding machine, the grinding wheel can be corrected on-line while the small roller is being ground, and the grinding wheel can also be electrolytically sharpened on-line. In this way, the grinding precision of the small roller is improved, and the grinding efficiency is greatly improved and the cost is low. Due to the good consistency of the grinding size of the small roller, the quality is stable and reliable, and it has the characteristics of easy adjustment, installation, maintenance and use. .

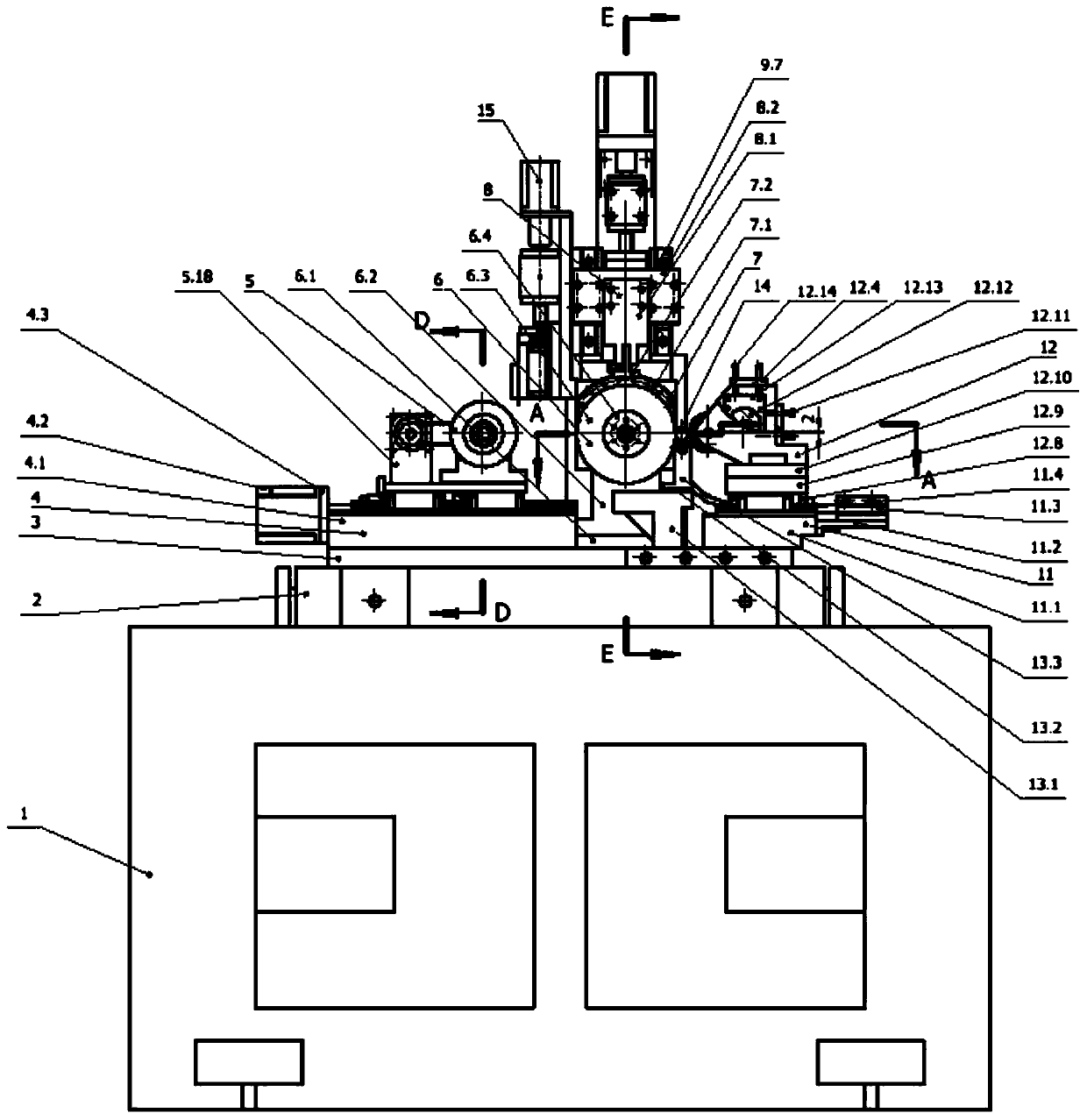

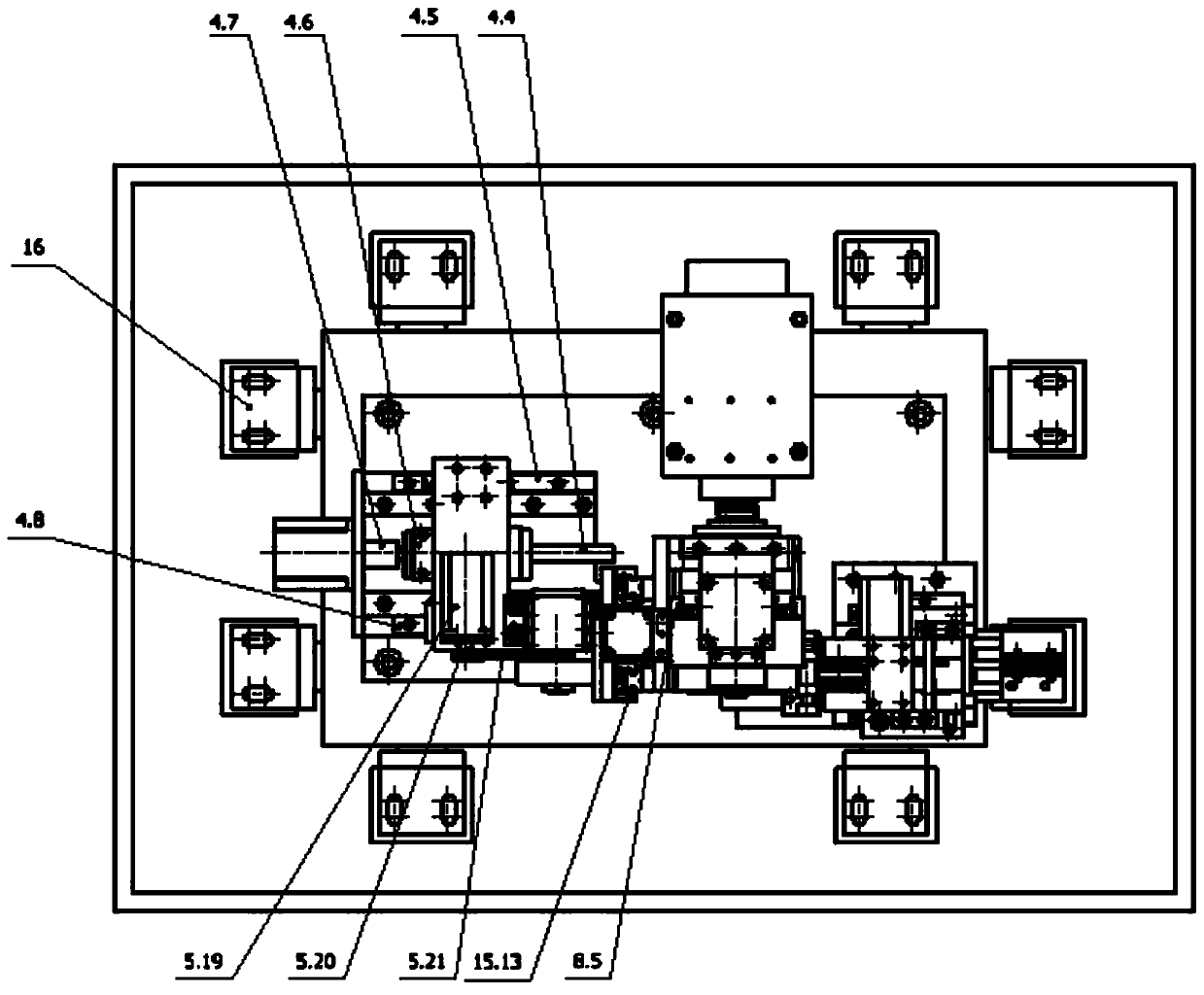

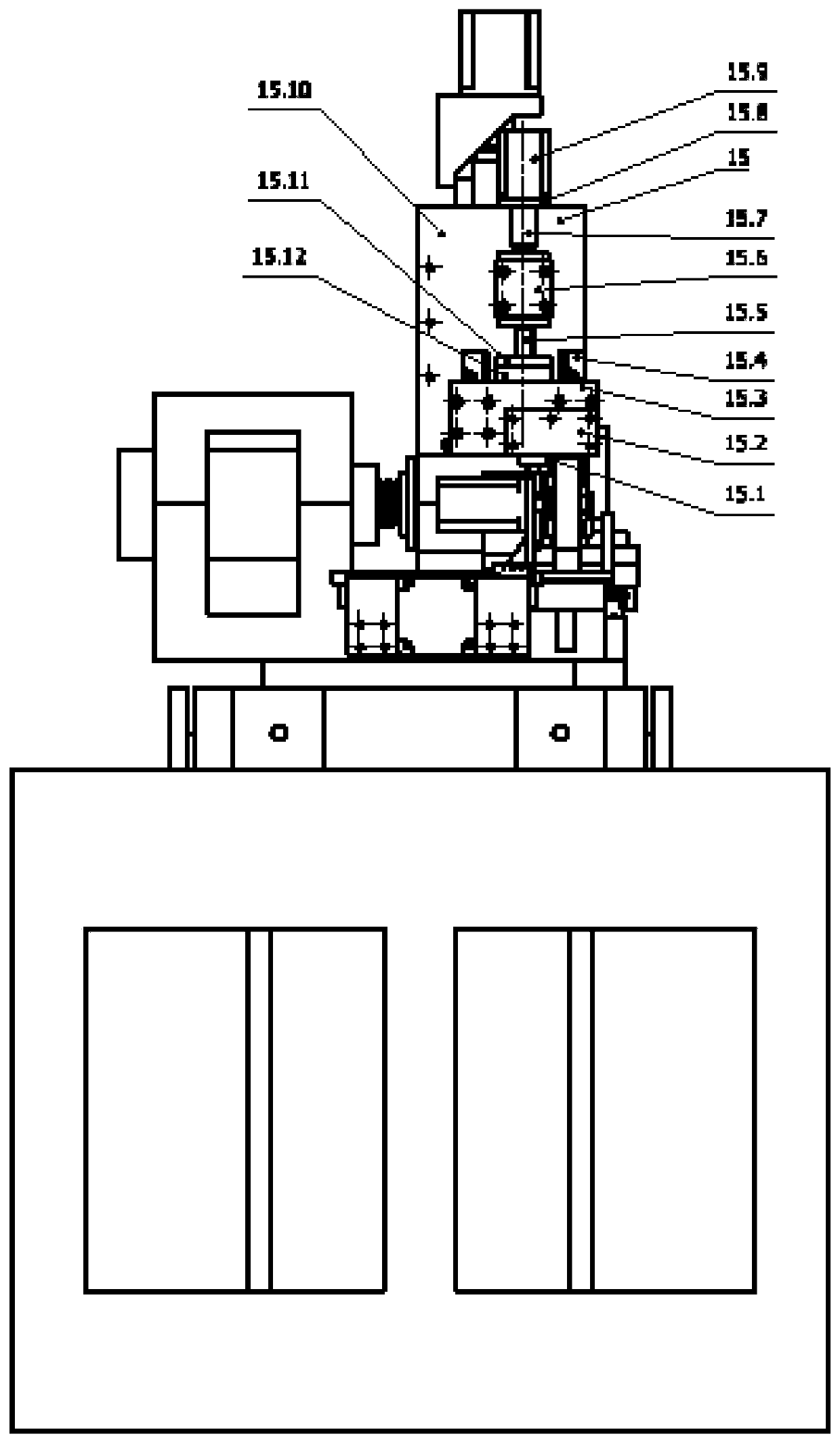

[0041] combine Figure 1-6 , The high-precision automatic grinding machine of the present invention includes a bed 1, a marble table top 2, a base plate 3, a graphite wheel skateboard drive device 4, a graphite wheel drive device 5, a grinding wheel device 6, a sharpening copper ring device 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com