Patents

Literature

39results about How to "Have installed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

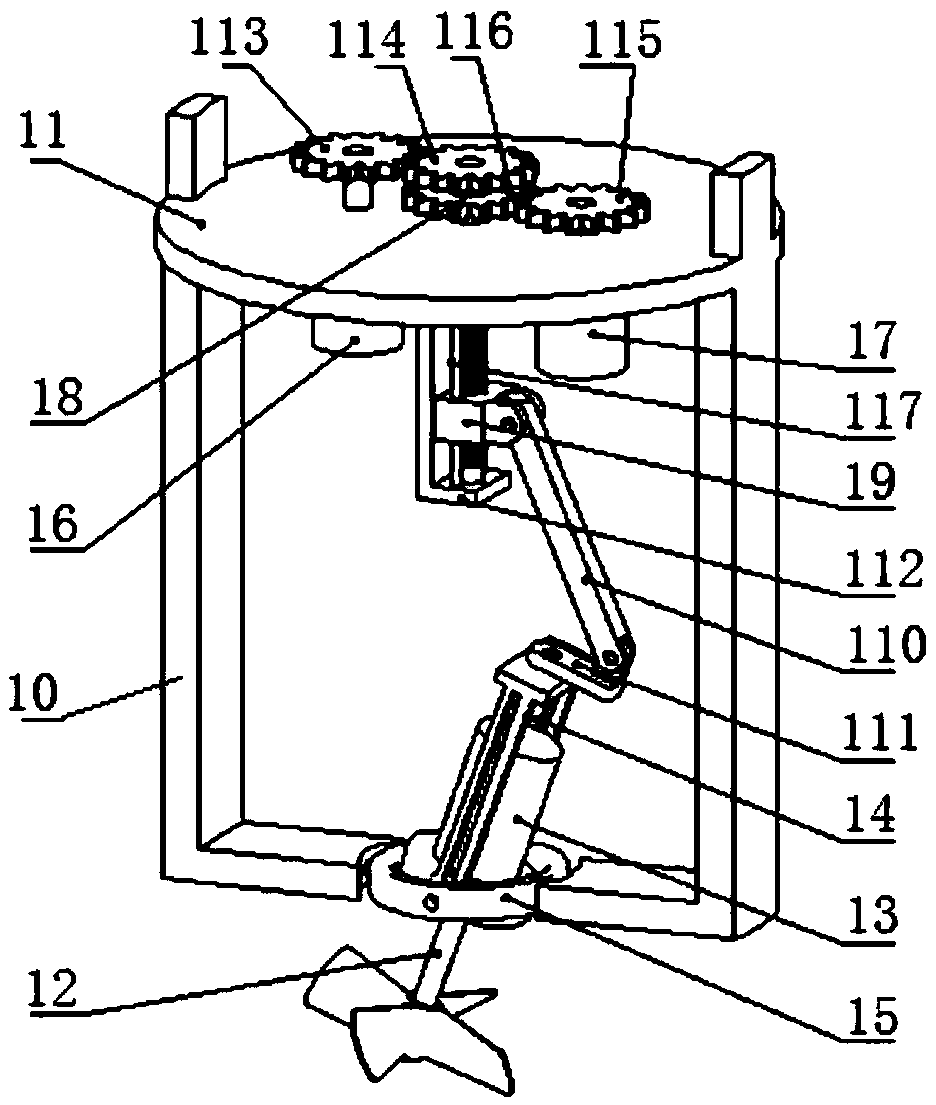

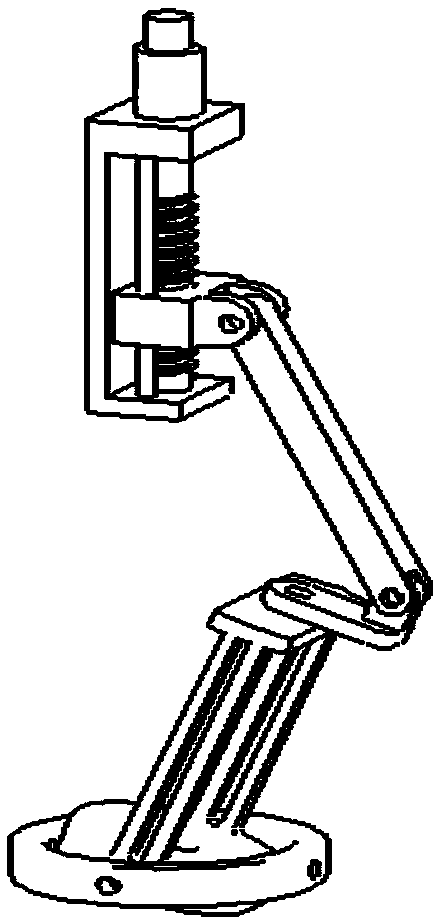

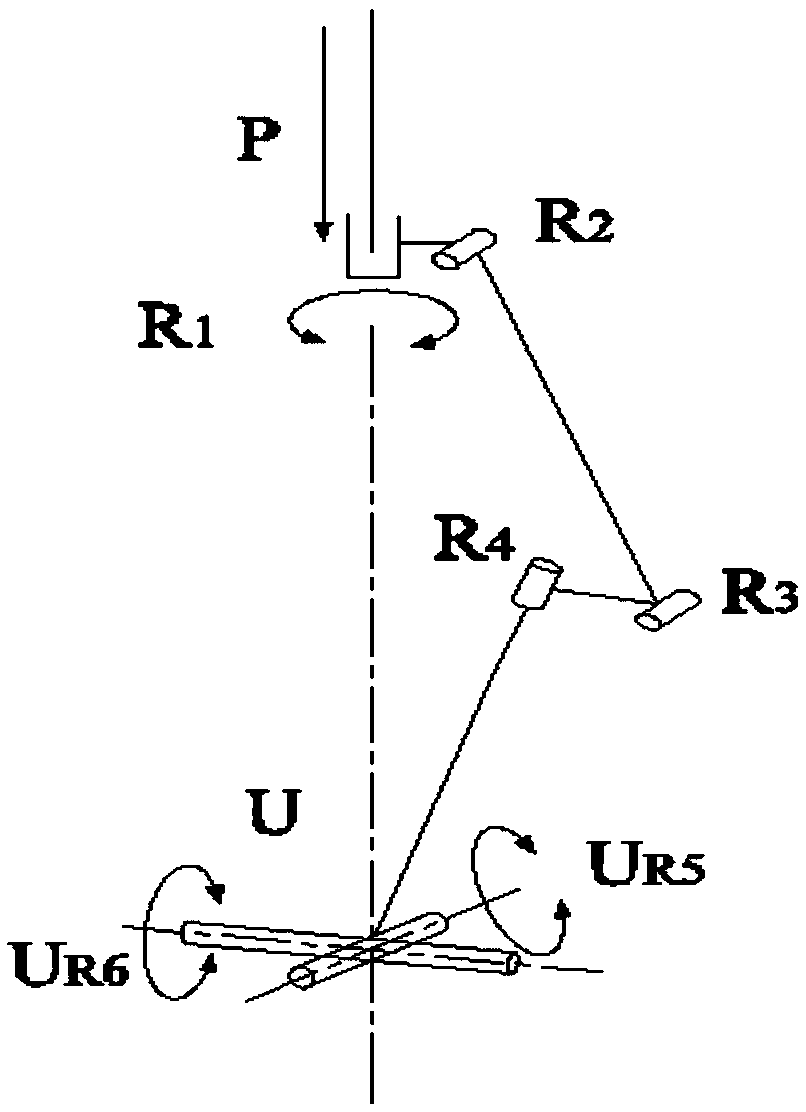

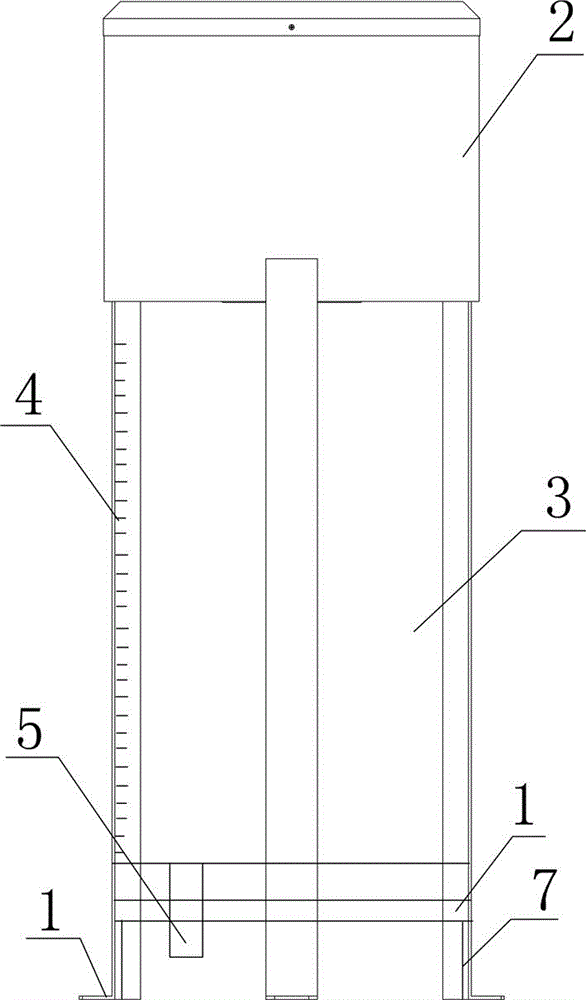

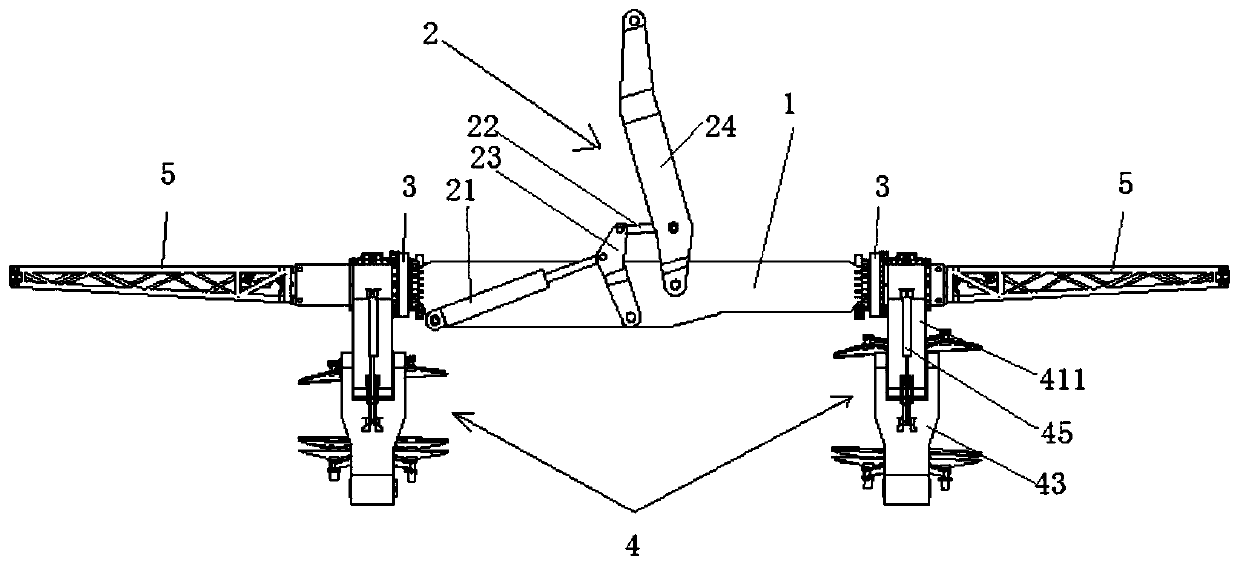

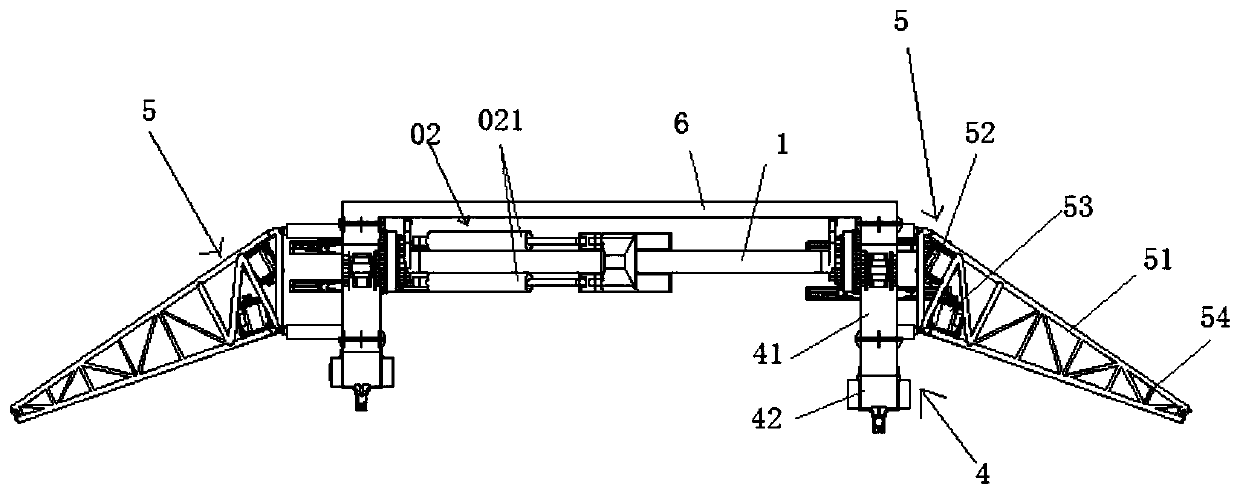

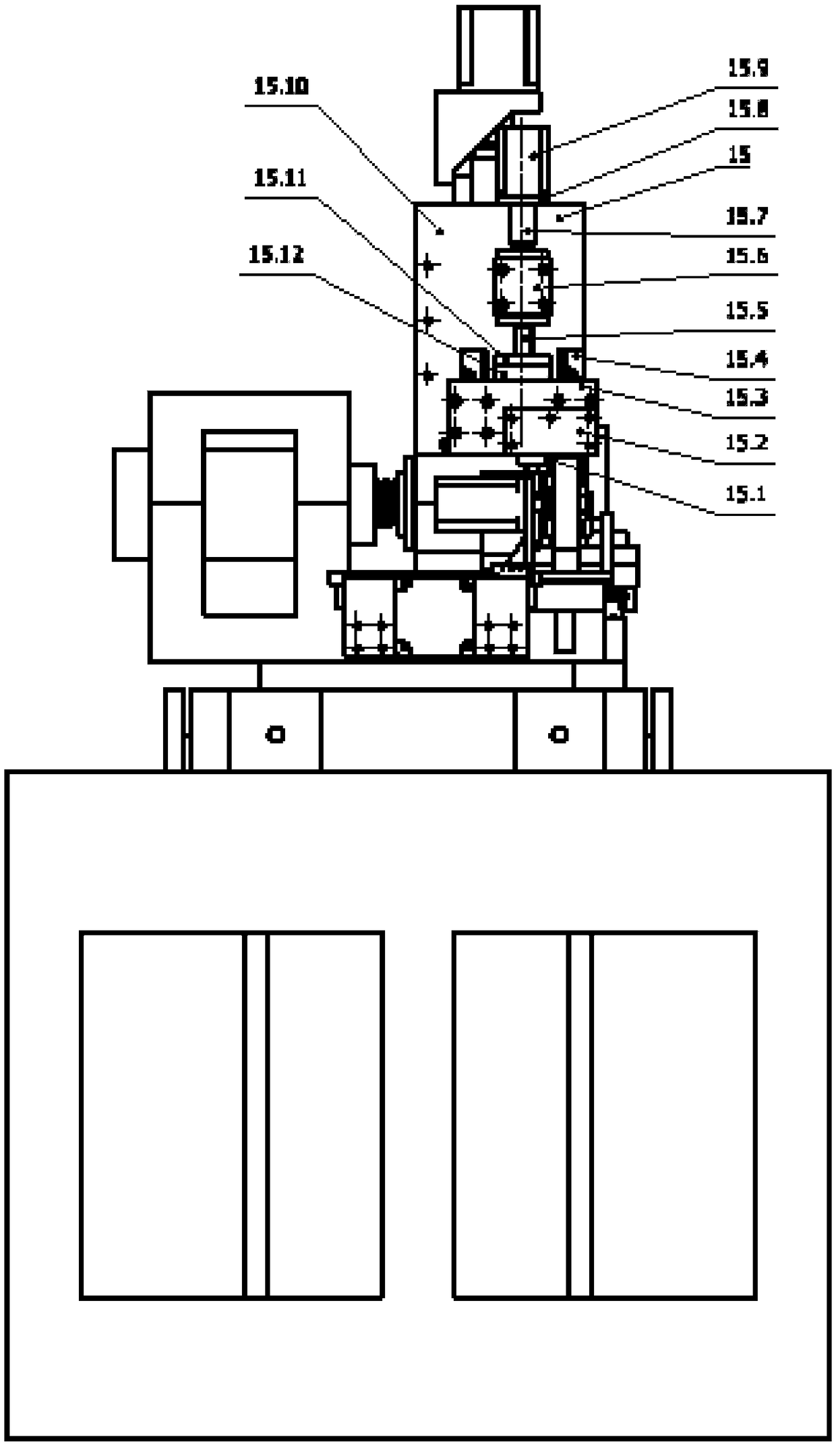

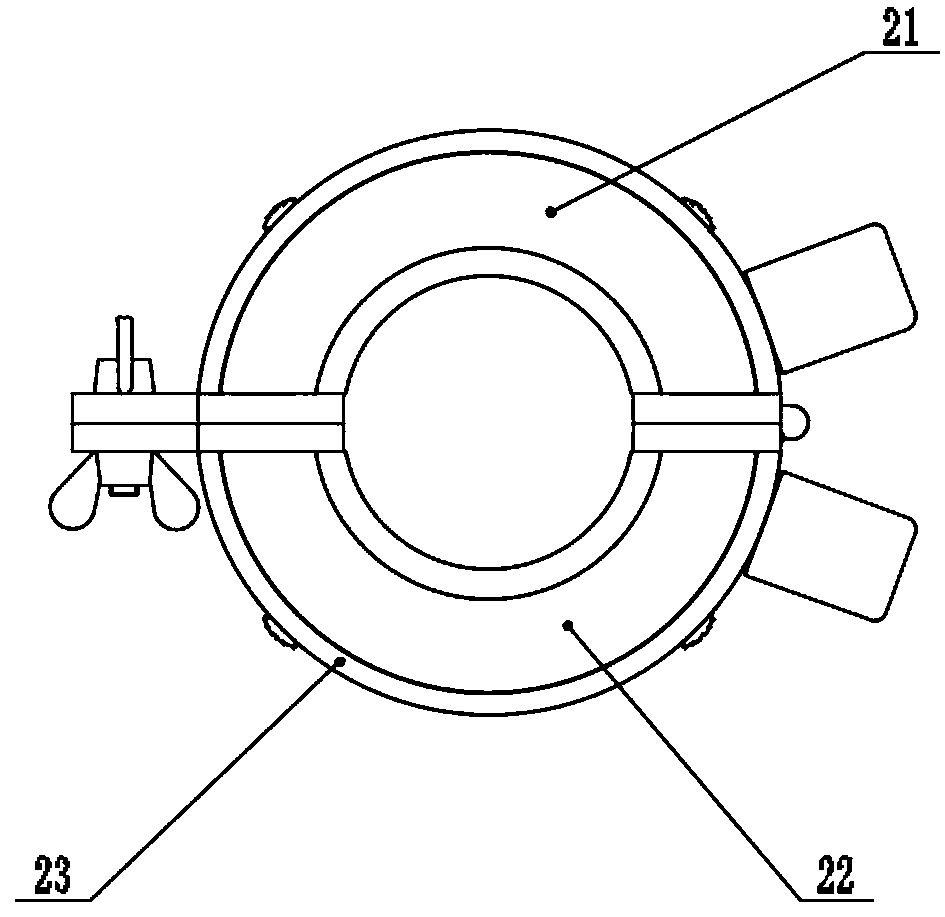

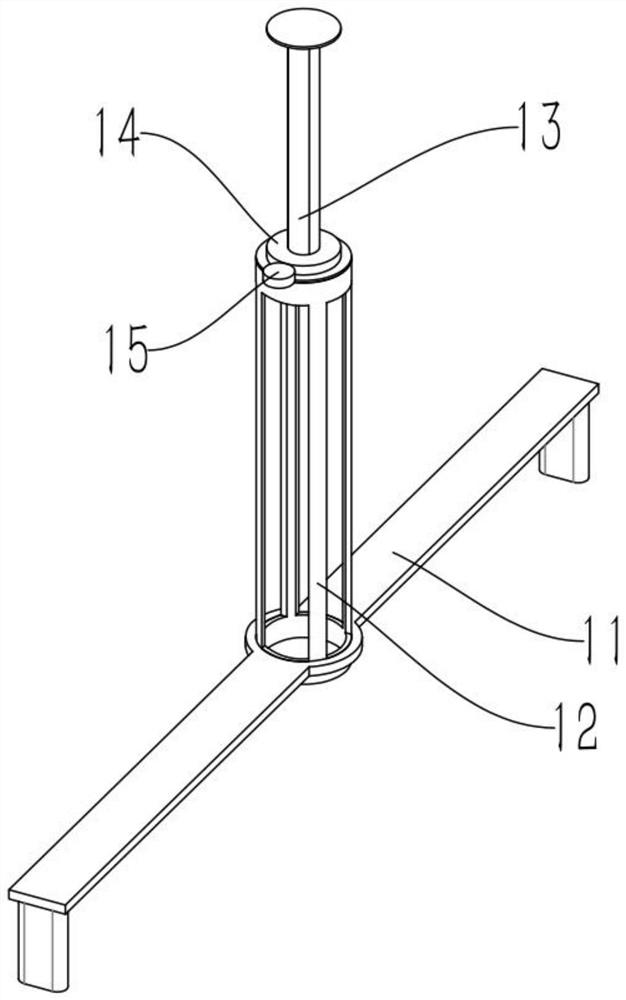

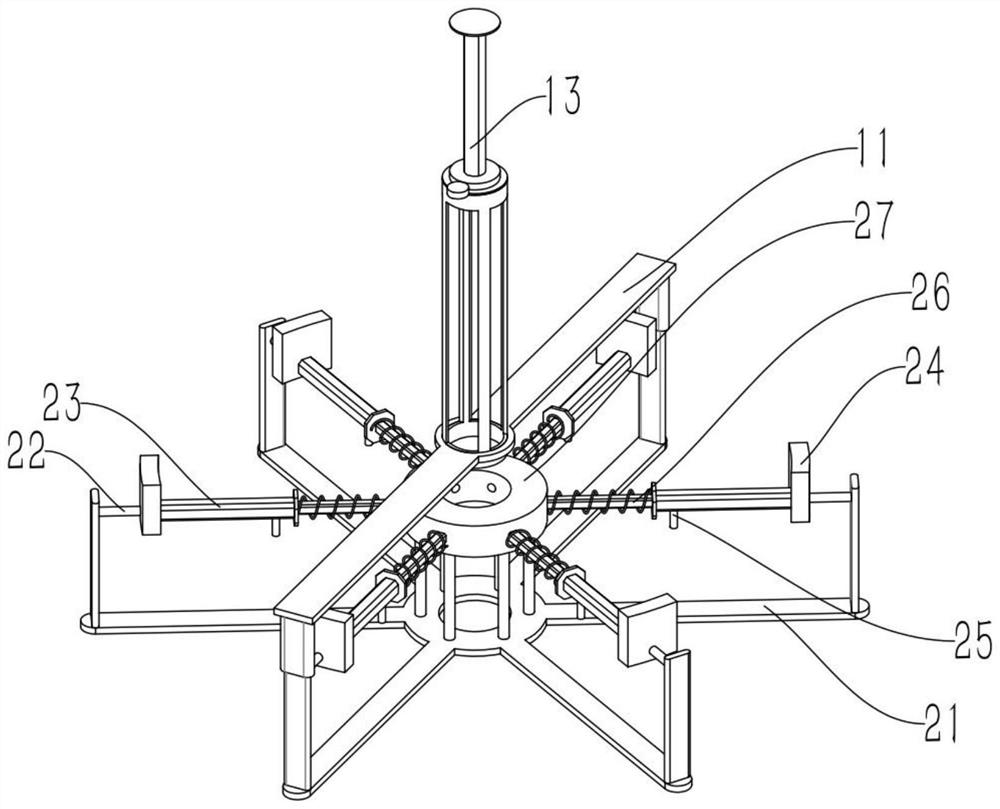

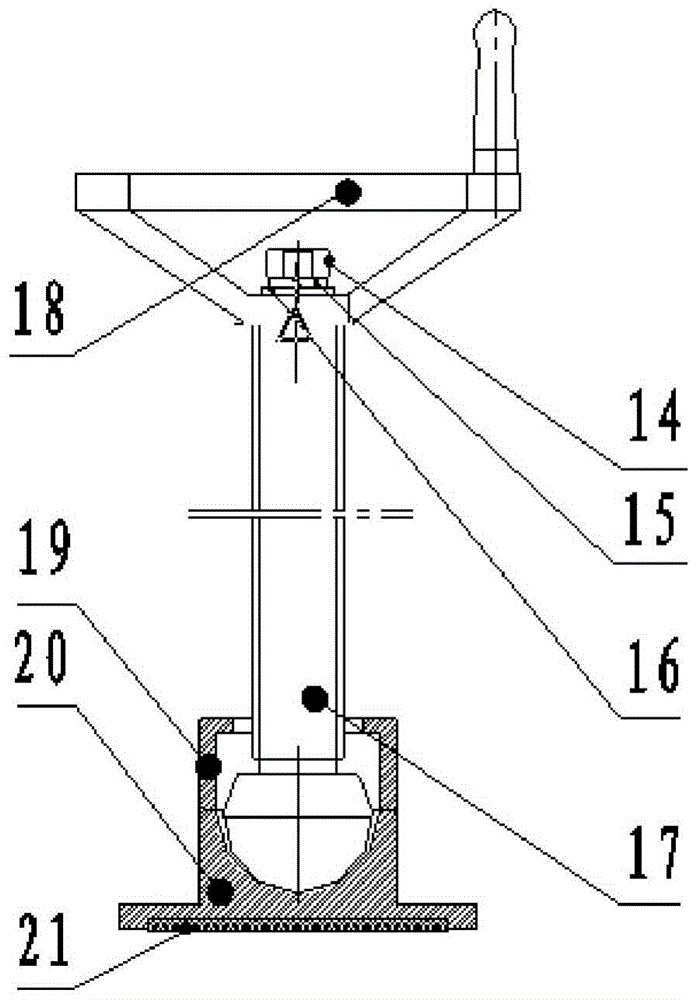

All deflection propeller vector boost mechanism and underwater navigation vehicle

InactiveCN105501422AHave replacementPromote repairPropulsion power plantsPropulsive elementsIndependent motionCircular disc

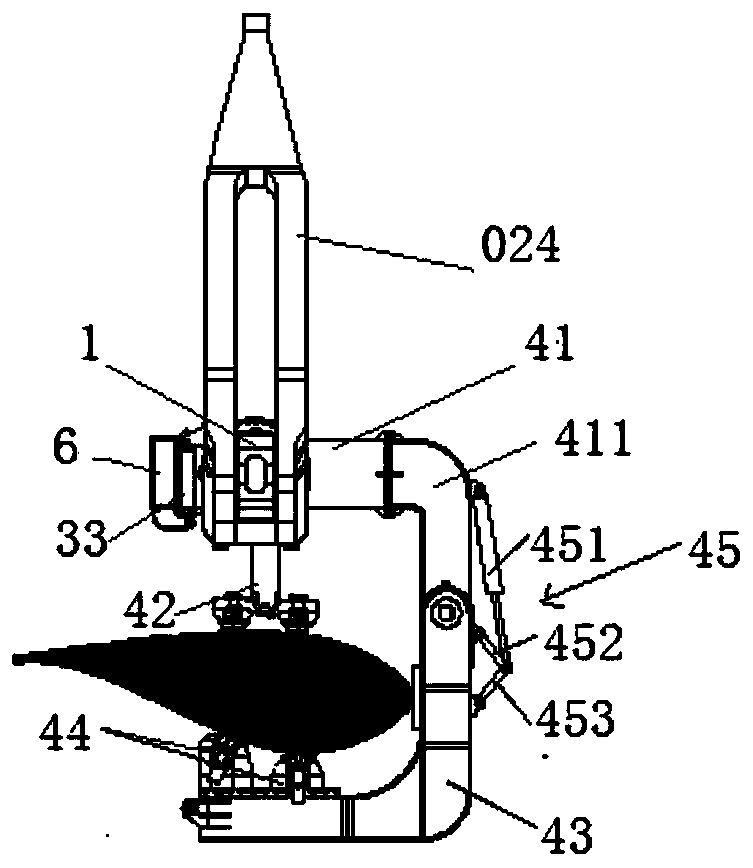

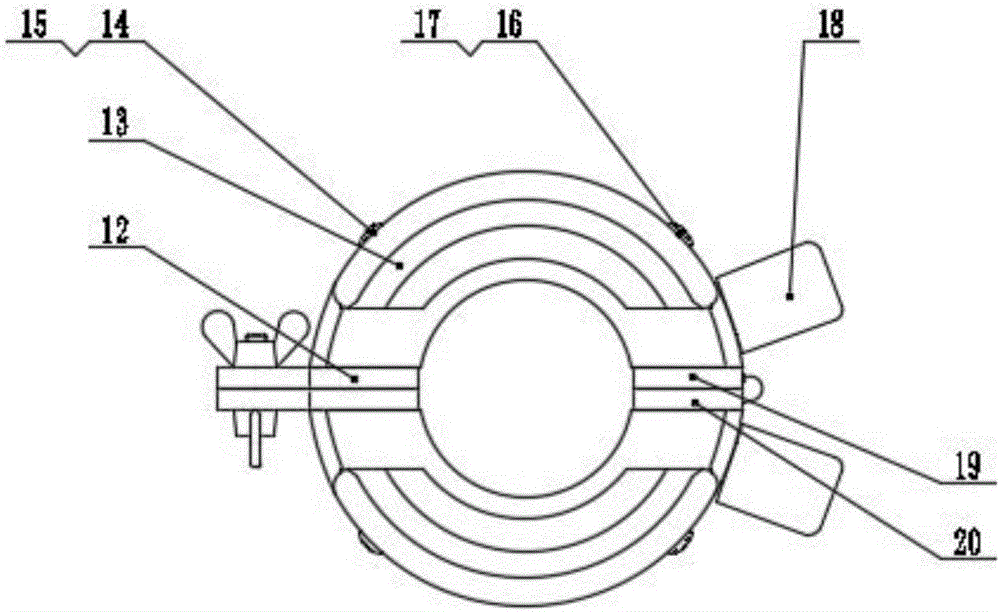

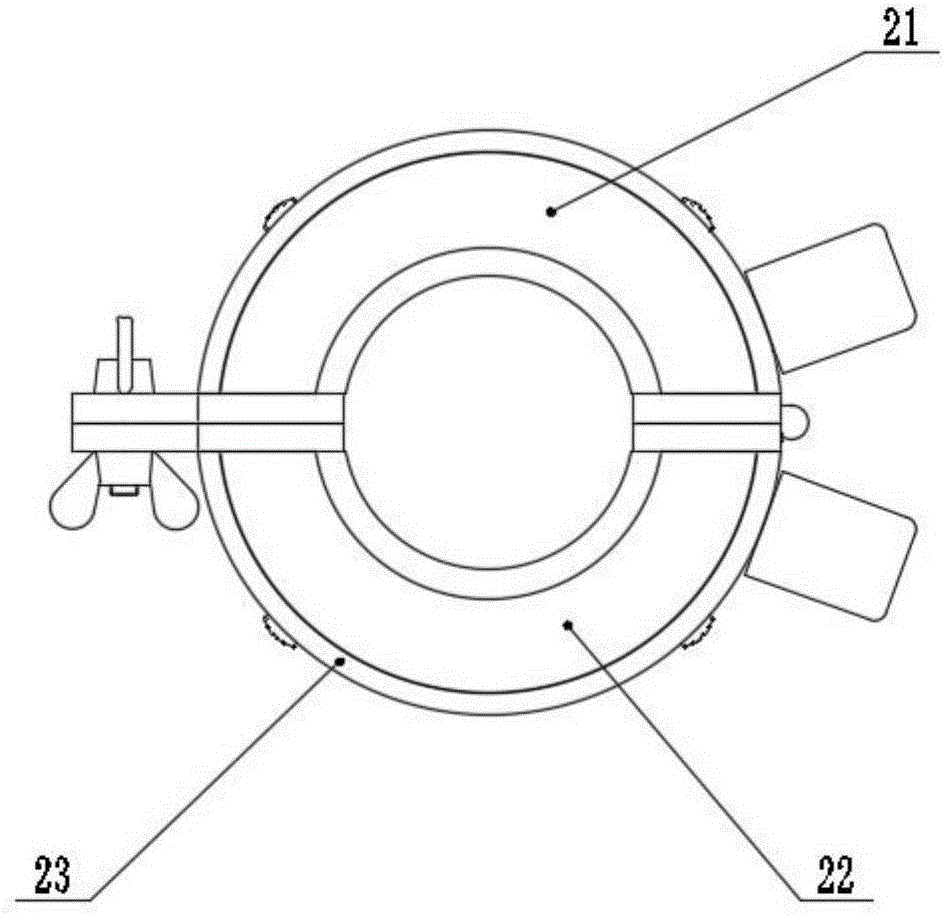

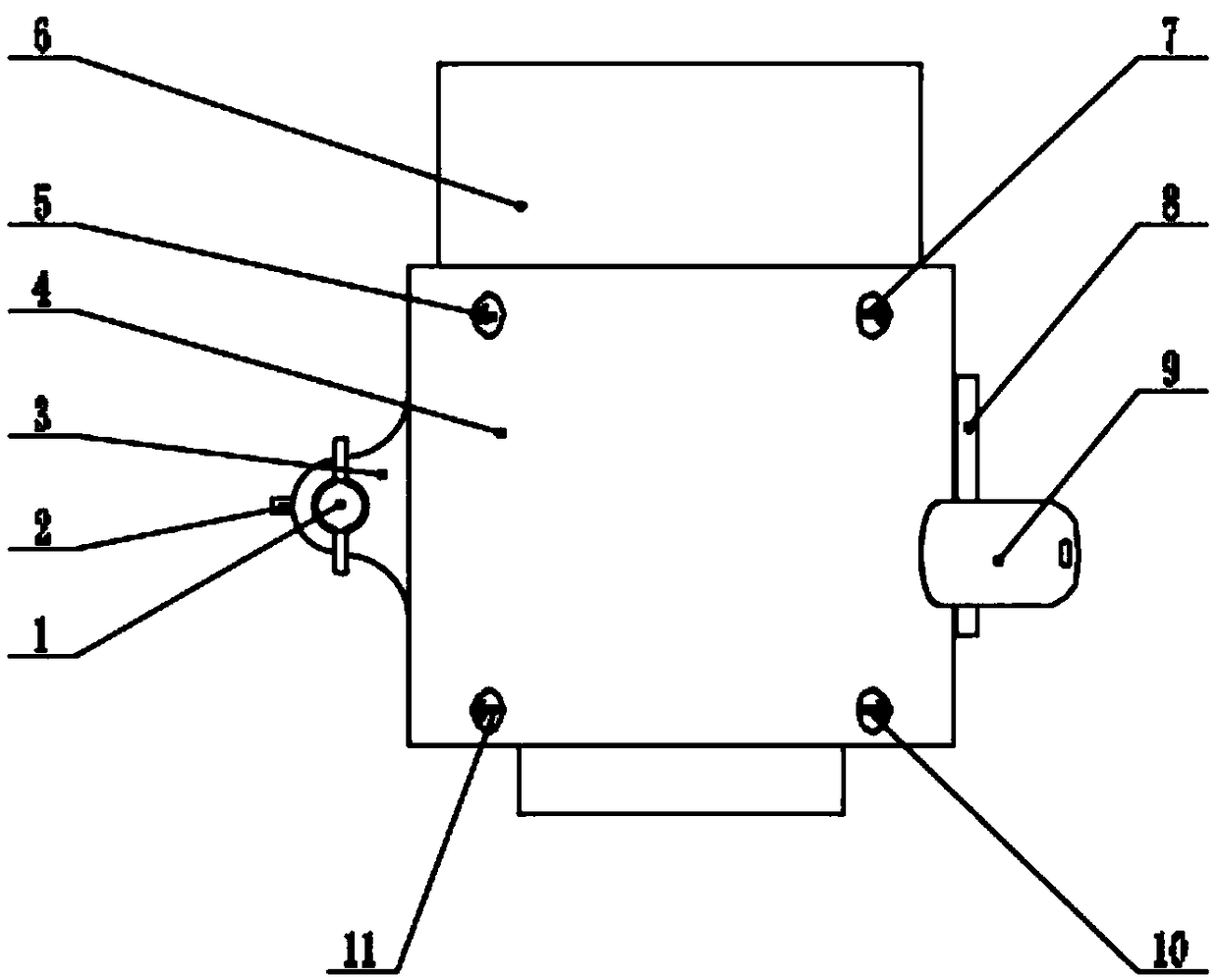

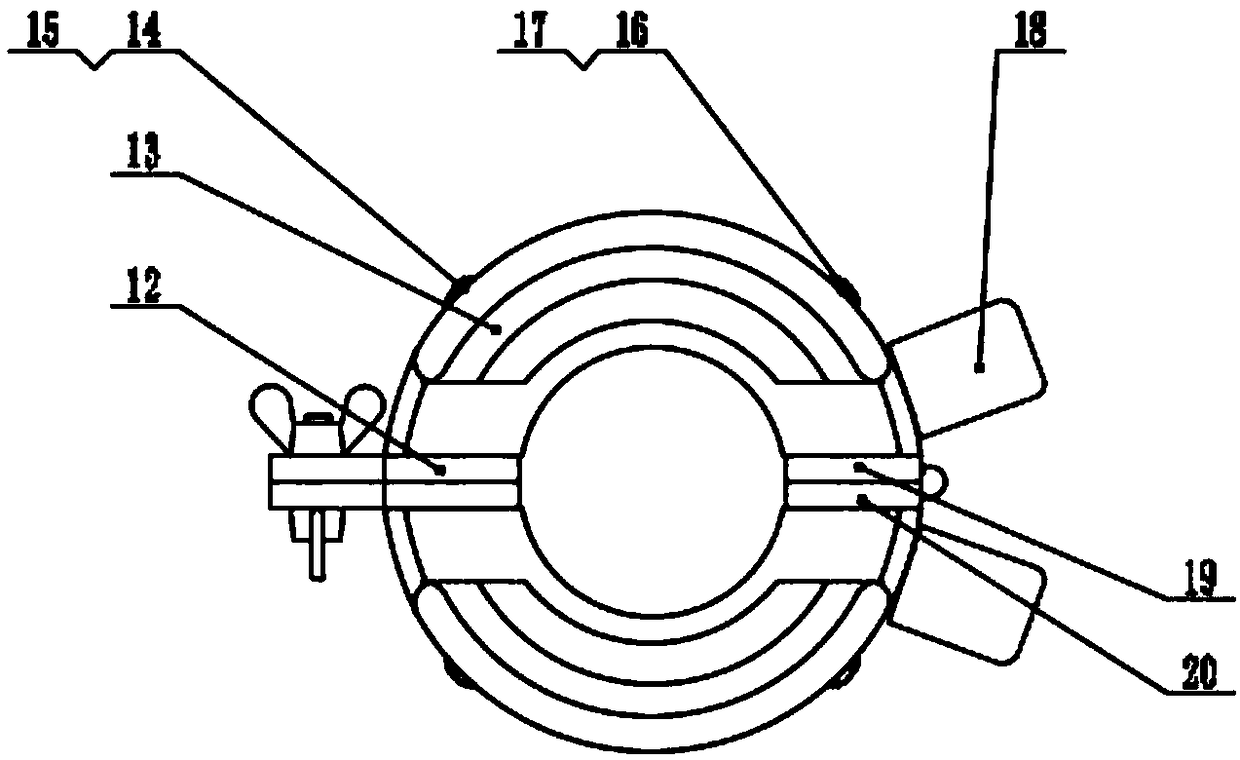

The invention discloses an all deflection propeller vector boost mechanism and an underwater navigation vehicle provided with the same and belongs to the technical field of underwater navigation vehicles. The all deflection propeller vector boost mechanism comprises a support, wherein a disk serving as a static platform is arranged above the support, and a cardan joint serving as a dynamic platform is arranged below the support; a propeller and a boost motor are arranged on the dynamic platform and connected to form a tail thruster; a deflecting mechanism and a slewing mechanism are arranged between the dynamic platform and the static platform. Through motion synthesis of two relatively or completely independent motion chains, namely the deflecting mechanism and the slewing mechanism, the tail thruster can rotate in all directions at any deflecting angle. The all deflection propeller vector boost mechanism has the advantages of being convenient to install and control, good in low-speed steering performance and the like.

Owner:SHANDONG UNIV

Method of producing architectural decorative material and wall bady material using phosphogypsum

InactiveCN1651348AGood weather resistanceImprove corrosion resistanceSolid waste managementFoaming agentPolymer science

A process for preparing wall material or decorative material from ardealite includes washing with water, drying, calcining, grinding, proportionally mixing it with PVC resin and auxiliary, stirring to obtain powdered material, heating to become paste, adding foamer, extruding and vacuum foaming in mould to obtain wall material, or heating while extruding said powdered material to become particles, heating and moulding to become decorative material.

Owner:GUIYANG PENGHONG HIGH NEW TECH DECORATION MATERIAL

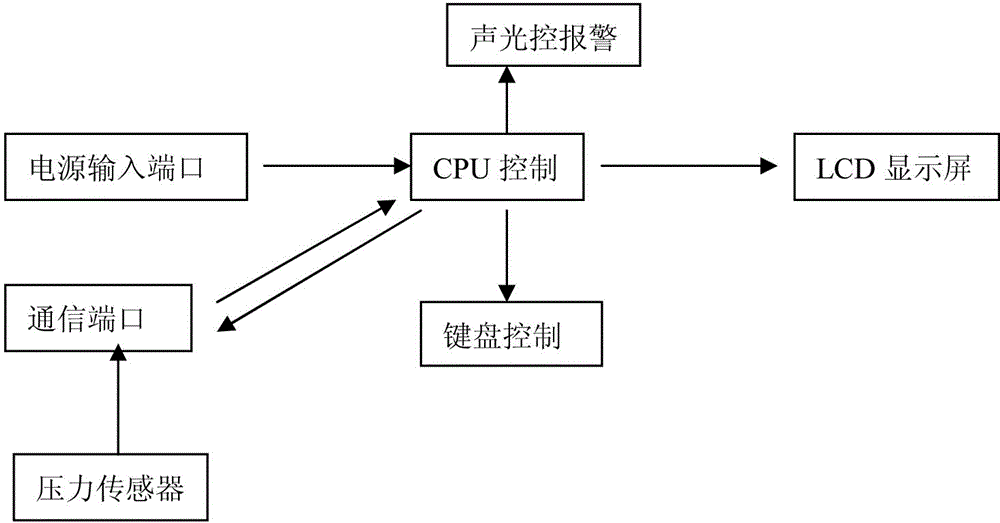

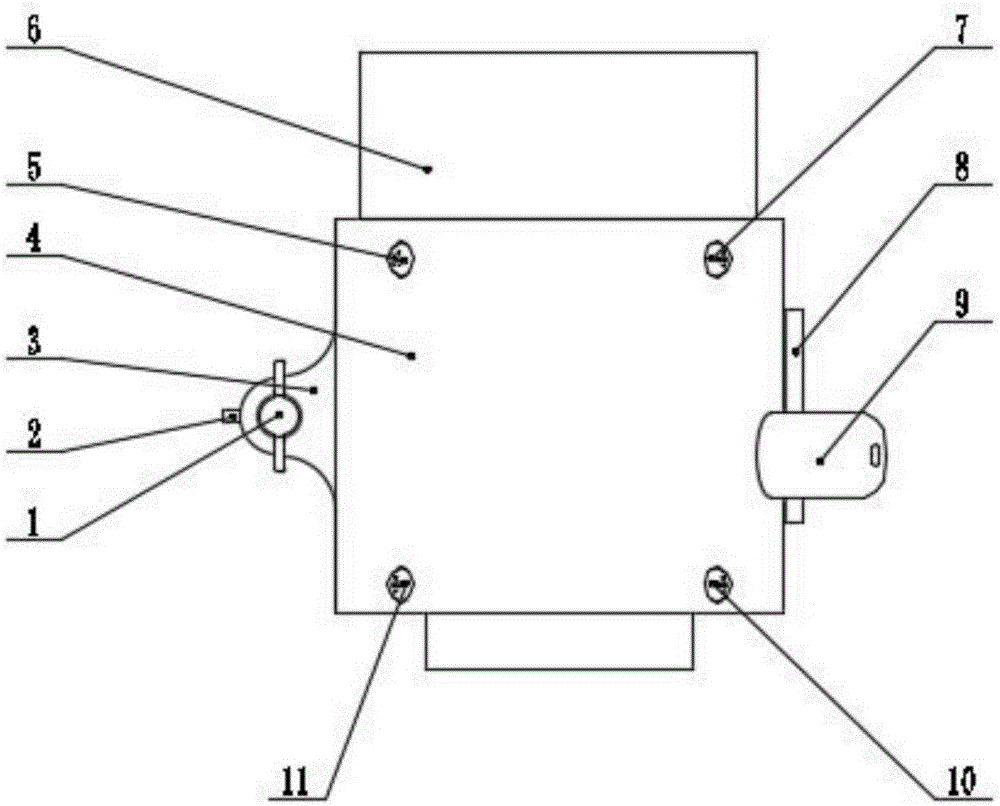

Intelligent alarm rain gauge

The invention relates to an intelligent alarm rain gauge, which comprises a rain gauge, an alerter and a measuring cylinder, wherein the lower part of the measuring cylinder is provided with a water drain valve and a pressure sensor; the pressure sensor is connected with the alerter and is installed on a fixed seat, and the pressure sensor is connected with the alerter through a cable; and the alerter comprises a case, an LED (Light-Emitting Diode) display screen installed on the case, and a control circuit installed in the case. The intelligent alarm rain gauge has the advantages of simple structure, small size, no pollution, light weight, long service life and low standby power consumption and can not be polluted or corroded by dust, greasy dirt, moisture, salt mist and the like. The intelligent alarm rain gauge has the characteristics of simplicity in installation, convenience in maintenance and more humanized operation, and the intelligent alerter can be externally connected with a simple rain gauge or tipping-bucket rain gauge. A communication mode adopts standard RS485 communication. The intelligent alarm rain gauge also has the advantages of stable running, high reliability, high compatibility, high accuracy of measured values, small temperature drift and small influence from environmental factors.

Owner:湖北亿立能科技股份有限公司

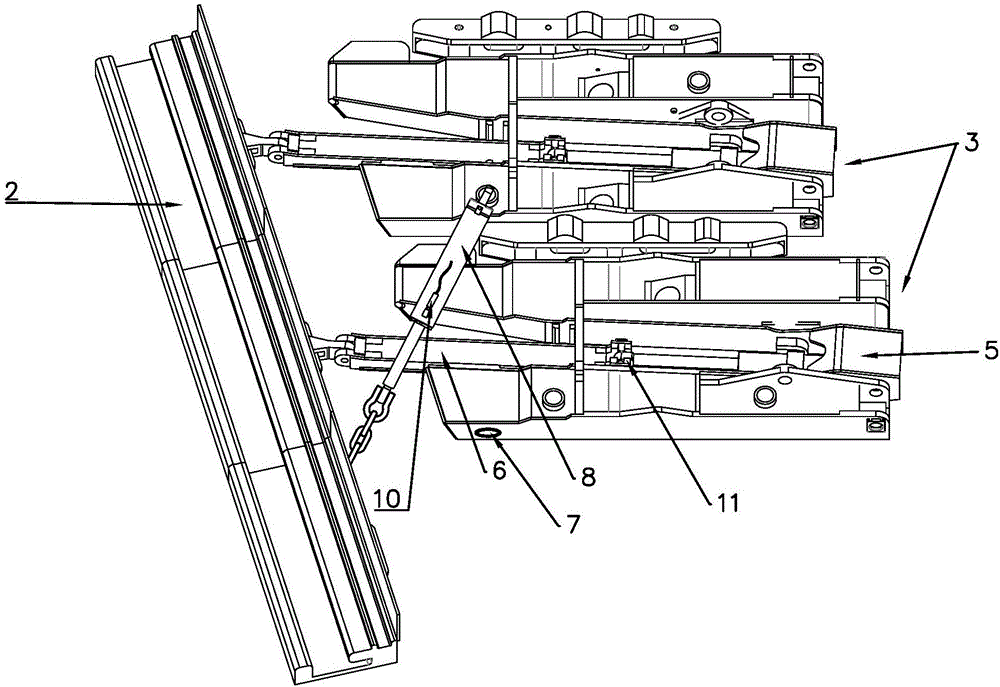

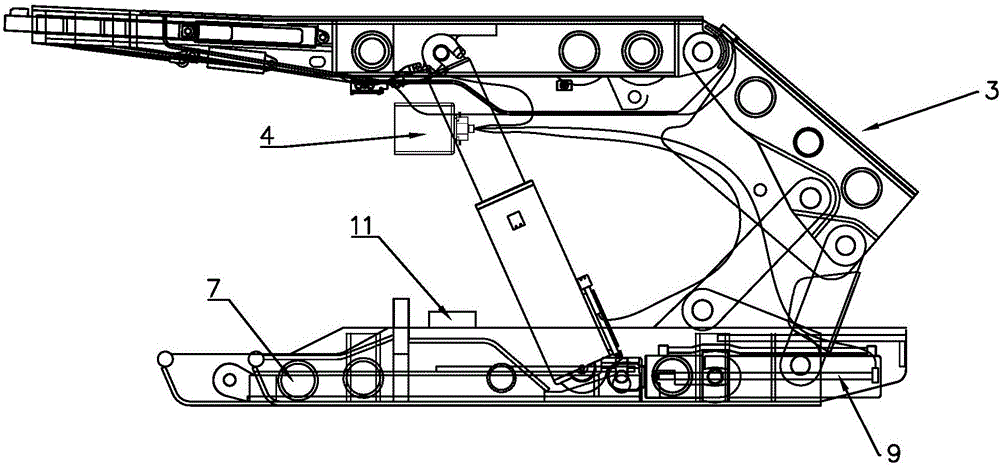

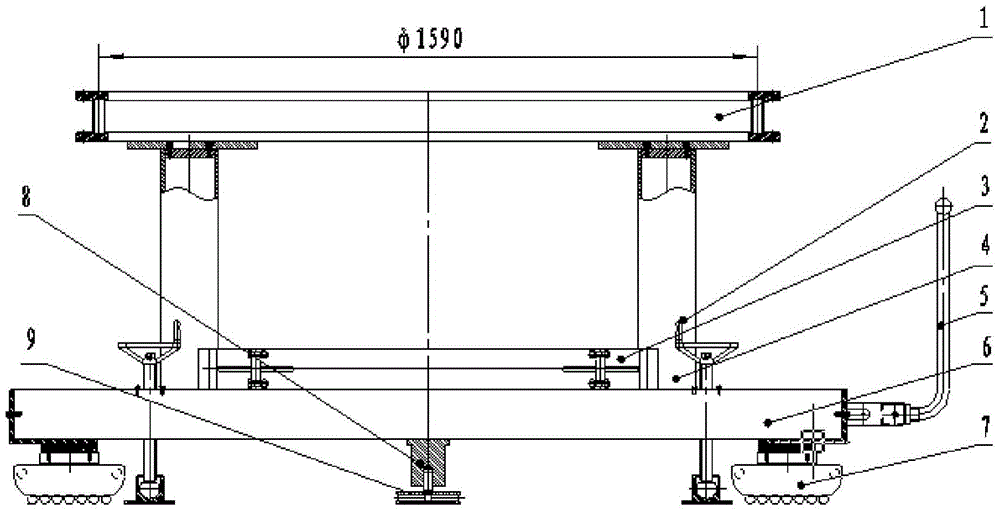

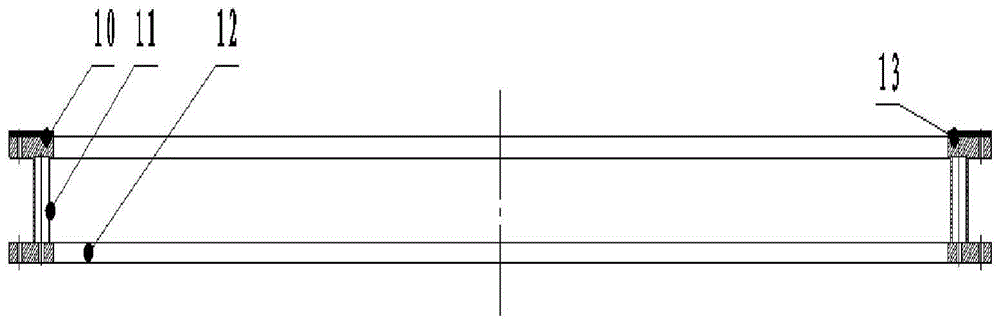

Single-blade mounting hanging tool for fan blade

The invention discloses a single-blade mounting hanging tool for a fan blade. The single-blade mounting hanging tool is characterized in that a longitudinal shaking mechanism is arranged on a main beam, two transverse shaking mechanisms are arranged at the two ends of the main beam in a sleeving mode correspondingly, each clamping mechanism is connected with the corresponding transverse shaking mechanism through an end transverse beam and comprises the end transverse beam, an upper supporting seat structure, a bottom beam, two lower supporting seat structures and a opening and closing device,one end of each end transverse beam is connected to the upper end of a vertical beam in an integrated mode, the upper end of each upper supporting seat structure is connected with the corresponding end transverse beam, and each bottom beam is of an L-shaped structure; and one end of each bottom beam is hinged to the lower end of the corresponding vertical beam, the lower ends of the two lower supporting seat structures are arranged on the corresponding bottom beam, each opening and closing device is arranged on the hinge joint side face of the corresponding end transverse beam and the corresponding bottom beam, and each cable wind mechanism is connected to the corresponding end transverse beam on the same side. According to the single-blade mounting hanging tool, each upper supporting seatstructure can be adjusted at an upper horizontal moving rail of the corresponding end transverse beam, each lower supporting seat structure can be adjusted at a lower horizontal moving rail of the corresponding bottom beam, the adaptive adjustment can be conducted according to the blades of different models, the whole machine control is convenient, and the maintenance is simple.

Owner:上海锡华机械工程有限公司

System for installing and adjusting adjustable reflection type optical object lens

InactiveCN101004555AHave installedFunctionalPhotomechanical exposure apparatusMicrolithography exposure apparatusMicrocontrollerTransducer

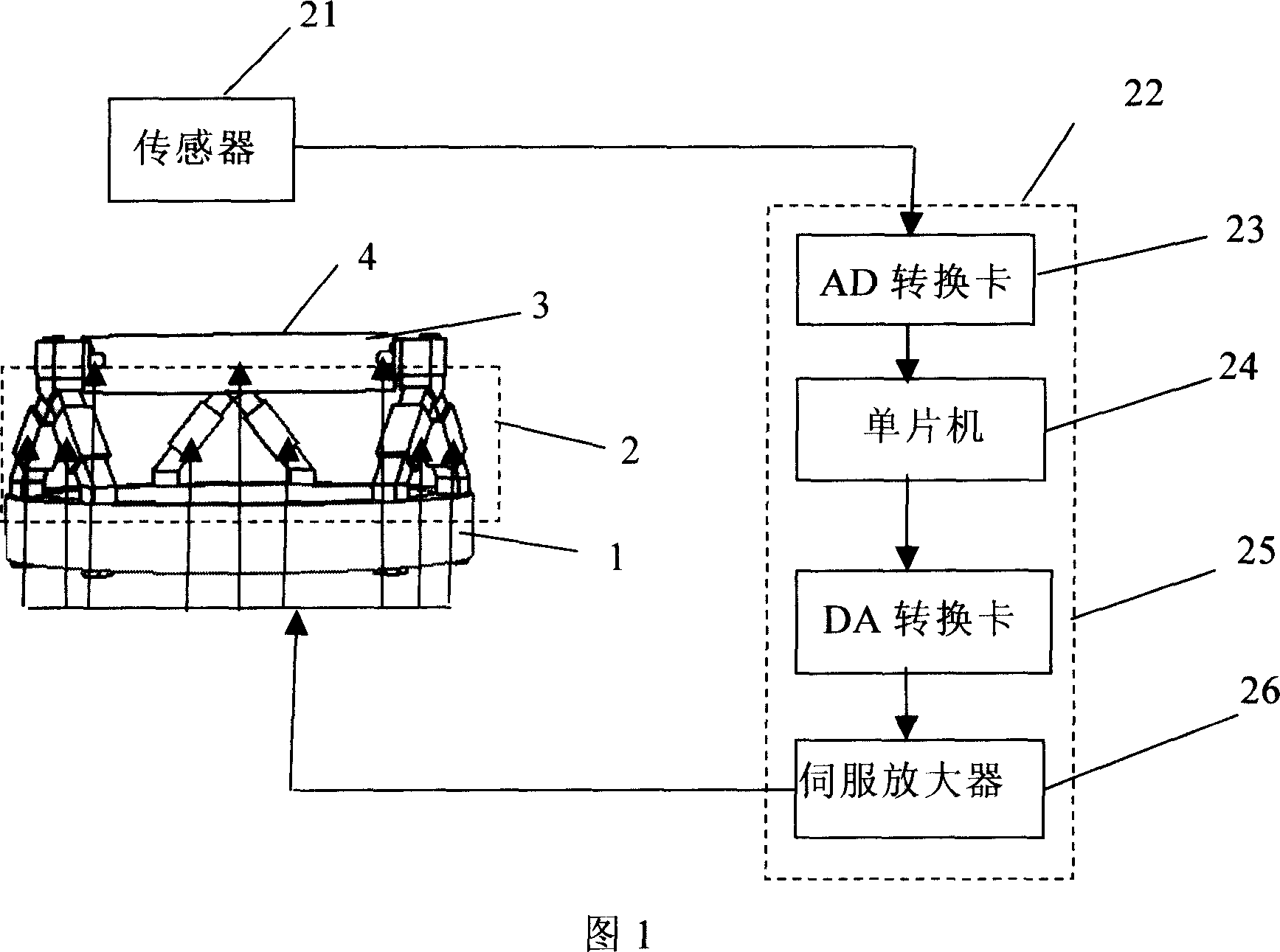

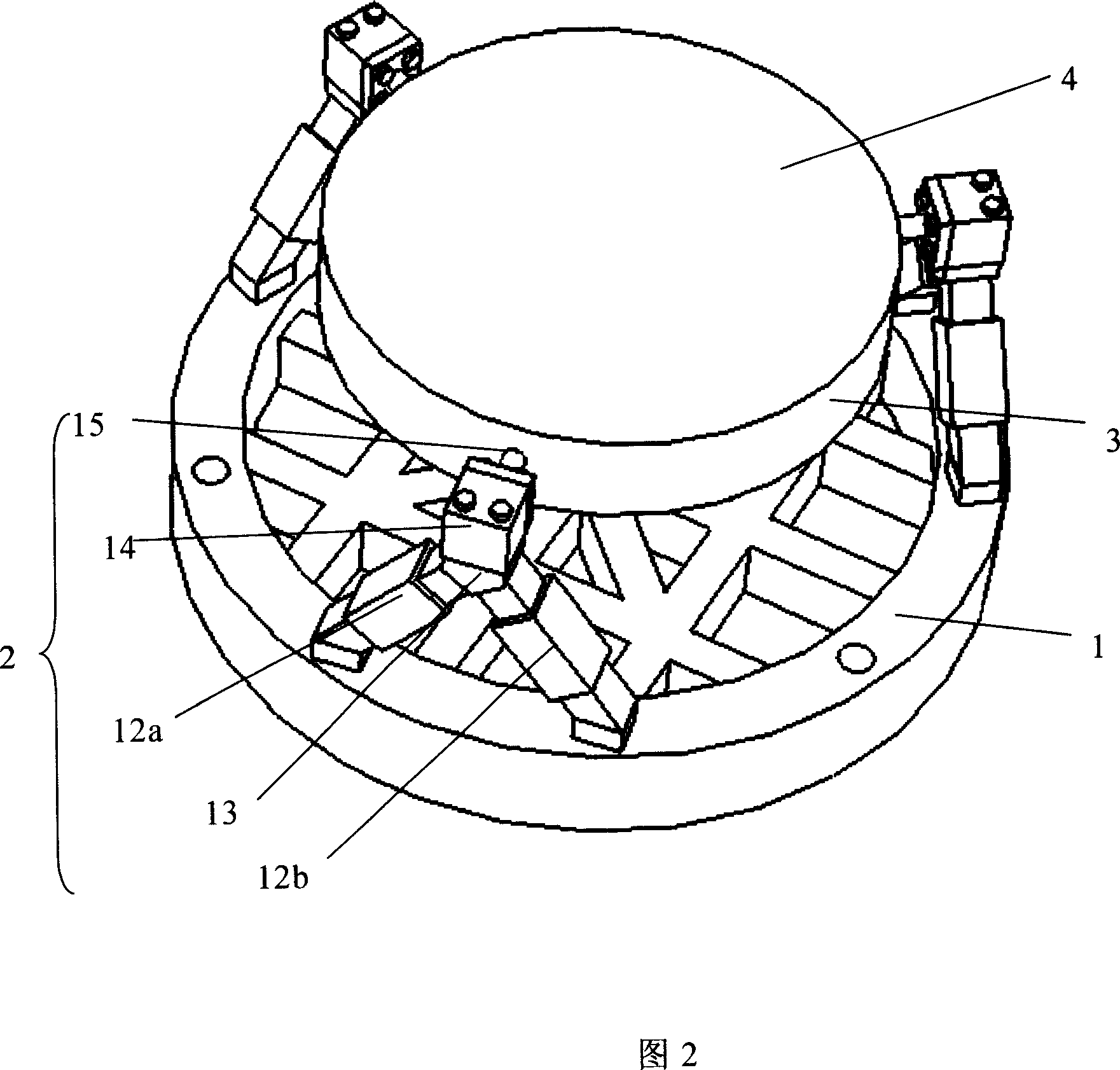

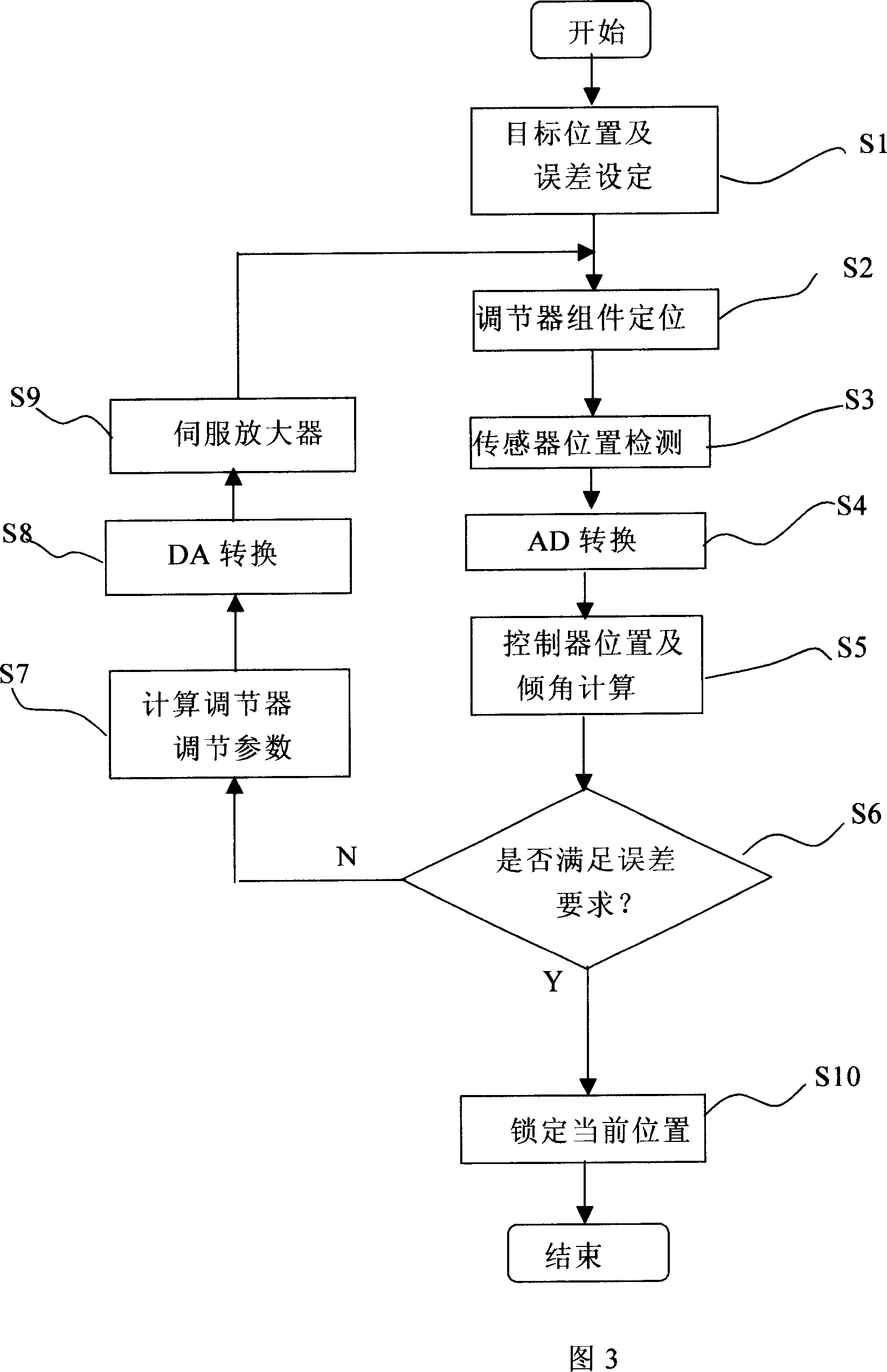

A regulation system of optical objective lens in adjustable reflection type is prepared for sending analog signal from transducer to A / D conversion card then to monolithic computer, calculating actual position and dip angle of objective lens by said computer, calculating out parameter to be regulated by regulation system component by comparing position and dip angle of objective lens with that of object, sending said parameter to servo amplifier then to regulation system component to make said component generate relevant linear movement to drive objective lens to required position.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

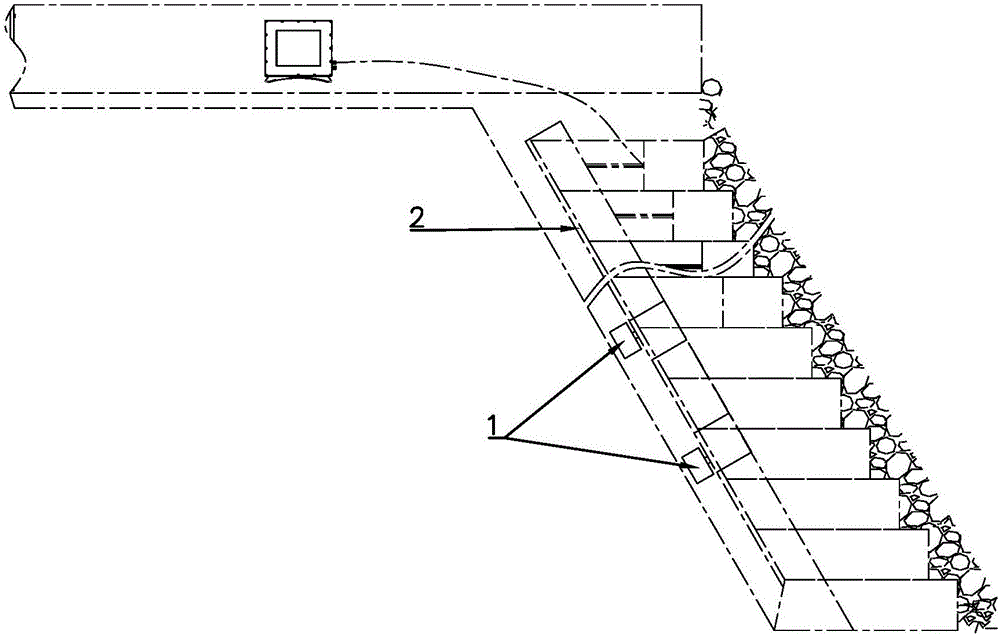

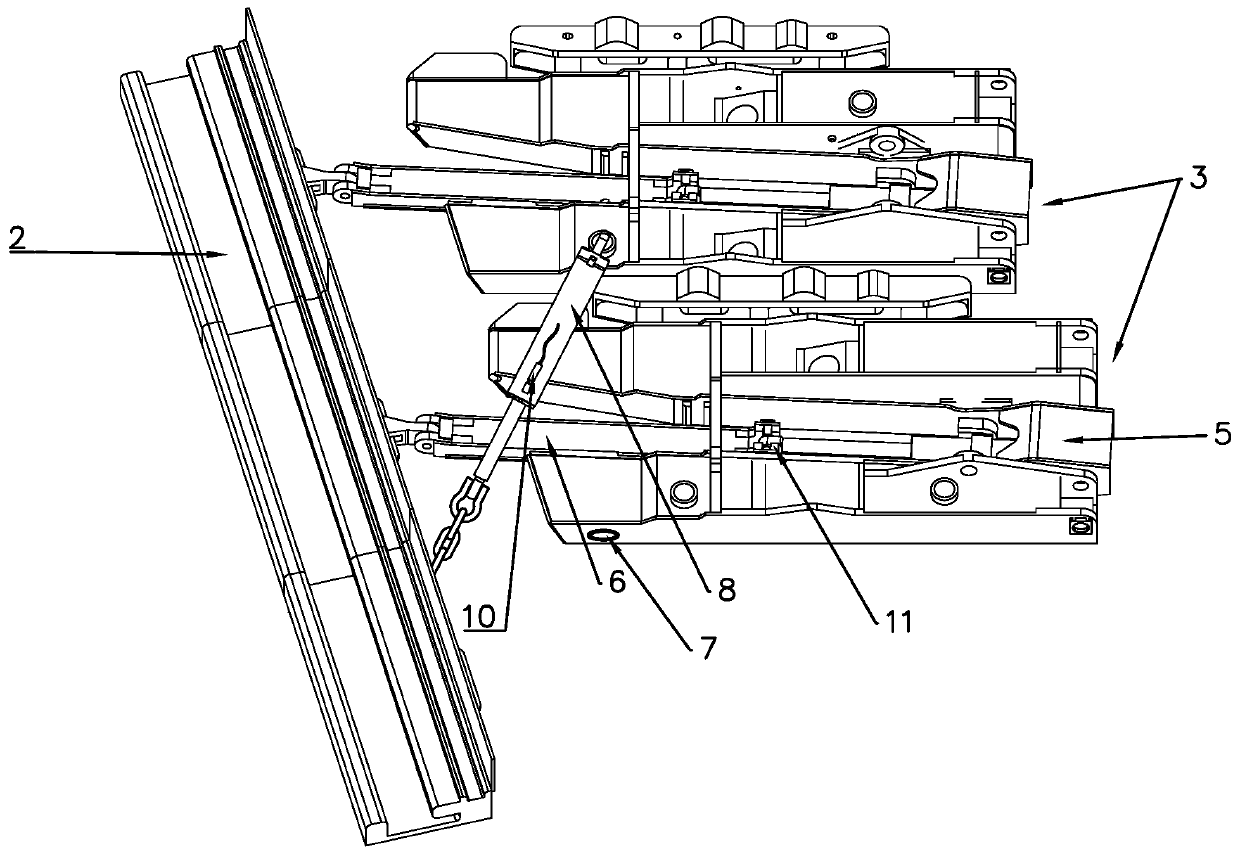

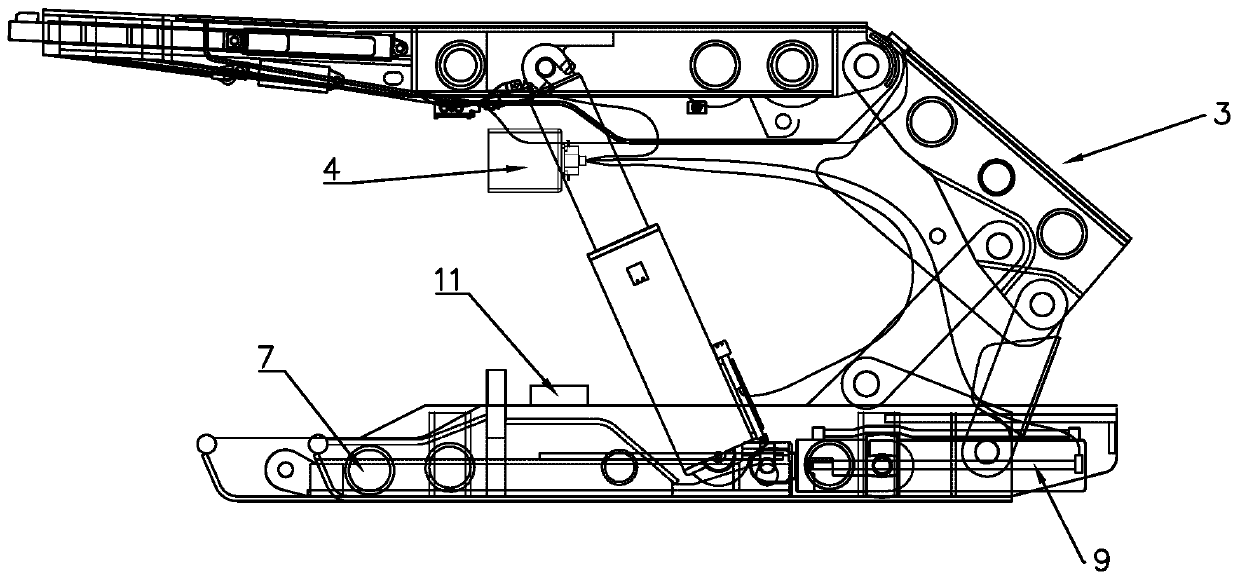

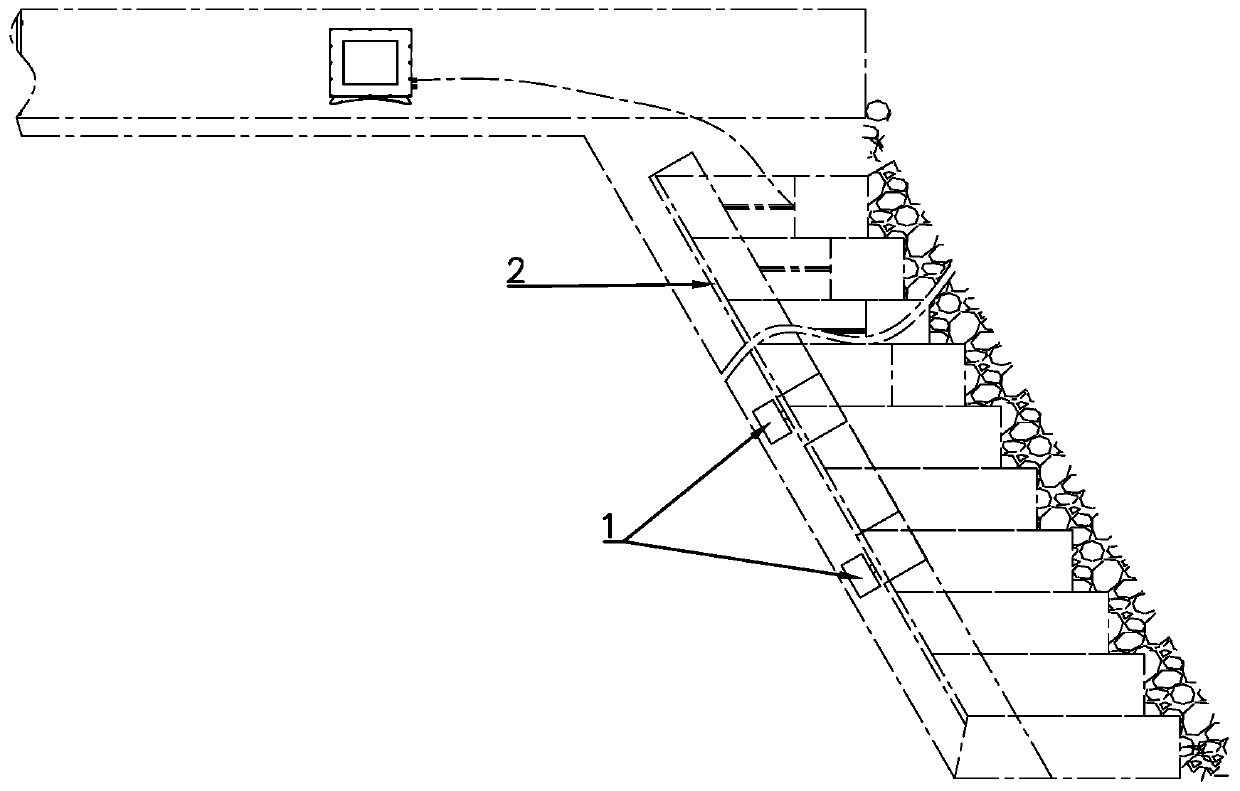

Scraper conveyor pushing structure for pitching oblique mining way of fully-mechanized coal mining face of sharp-inclined coal seam

ActiveCN106523012AOvercoming manual repeated up and down support operationsIncrease productivityMine roof supportsSupporting systemAutomatic control

The invention discloses a scraper conveyor pushing structure for a pitching oblique mining way of a fully-mechanized coal mining face of a sharp-inclined coal seam. The scraper conveyor pushing structure for the pitching oblique mining way of the fully-mechanized coal mining face of the sharp-inclined coal seam comprises a coal cutter arranged in the fully-mechanized coal mining face, a plurality of sections of guiding chutes which are connected in sequence, a plurality of hydraulic supports constituting a support system, and an electrohydraulic control system mounted on the hydraulic supports. Pushing oil cylinders and pushing rods are arranged in a base. An anti-slip oil cylinder is further arranged at the front end of the base. Cable-stayed oil cylinders are further arranged on the hydraulic supports. The electrohydraulic control system achieves automatic control over the scraper conveyor pushing process by the hydraulic supports through a control program. The scraper conveyor pushing structure has the advantages of being capable of achieving automatic control, simple in structure, high in precision, safe, reliable, convenient to mount, maintain and use and the like, and is worthy of popularization in the industry.

Owner:CHENGDU HANGTIAN PHOTOELECTRIC TECH +1

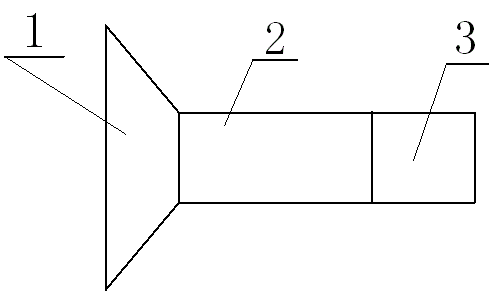

High-strength rivet and manufacturing method thereof

The invention relates to a high-strength rivet. The high-strength rivet is structurally divided into a rivet head, a high-strength end and a riveting end. The high-strength end is located between the rivet head and the riveting end. The high-strength end is a main stressed part. The riveting end is a riveting part. The high-strength rivet is manufactured in the steps that the rivet head is upset into shape, and a rod part is machined to a required length according to the requirements of different interlayer thicknesses; the whole rivet is subjected to thermal treatment and reinforcement first to make the tensile strength Sigma b reach more that 1100 MPa; the strength of the riveting end is reduced in a partial regression mode, and the regression length is determined according to the size of the rivet head; the rivet is subjected to annealing treatment in a high-frequency induction heating mode or a laser heating mode or a plasma arc heating mode to make the tensile strength Sigma b lower than 550 MPa, and then the finished high-strength rivet is obtained. Since the same rivet has different strengths through the special thermal treatment method, the riveting connection strength of the rivet is improved, and the rivet also has installation performance and riveting performance of common rivets.

Owner:GUIZHOU JINGLI HANGTAI TECH

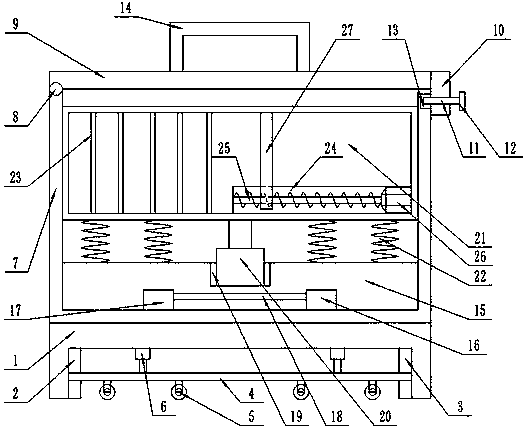

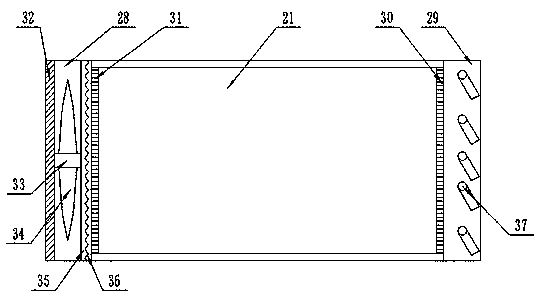

Pill lifting type storage box for cardiology department

InactiveCN108725961AEasy accessEasy to placeLiving organism packagingShock-sensitive articlesWindow shutterEngineering

The invention discloses a pill lifting type storage box for a cardiology department. The pill lifting type storage box comprises a storage box base, a left sliding rail, a right sliding rail, a sliding rod, sliding wheels, air pressure rods, a storage box body, a rotating shaft, a cover plate, a side cover plate, a pin shaft, a pull handle, a notch, a handle, a mounting base, a condenser, coolingfins, a communicating pipe and the like. According to the pill lifting type storage box for the cardiology department, the lifting and output function is provided, so that the pill for the cardiologydepartment is convenient to take, the air pressure rod lifts the sliding rod, so that the sliding wheel at the lower end of the sliding rod is released when moving, and the sliding wheel is stored when moving is not needed; the condenser is used for cooling and storing the medicines in the movable storage box through the cooling fins, fans blows heat emitted by s heater into the movable storage box, and the medicine is dehumidified and stored; waterproof shutters can effectively prevent water, a filter screen filters the incoming air, so that impurities are prevented from entering; and the driving motor drives a lead screw to rotate, movable partition plates on the lead screw can slide, the distance can be adjusted, and medicines with different specifications can be conveniently placed.

Owner:孙立民

Preparation method of lightweight sound-insulation wall-decoration artificial stone slab

The invention discloses a preparation method of a lightweight sound-insulation wall-decoration artificial stone slab. The mass ratio of methacrylic acid prepolymer resin to 325-mesh glass beads to 400-mesh glass powder to short-cut glass fiber with the length of 0.3 millimeter to color paste: a wetting dispersant to an antifoaming agent to a promoter to a curing agent is 25-60: 10-30: 15-35: 0.5-3: 0.05-2: 0.05-0.5: 0.001-0.01: 0.25-1: 0.25-1. The preparation method comprises the following steps: pouring the methacrylic acid prepolymer resin into an agitator and stirring; adding the color paste, the wetting dispersant, the antifoaming agent and the curing agent during the stirring process so as to prepare mixed resin; mixing the 325-mesh glass beads, the 400-mesh glass powder and the short-cut glass fiber with the length of 0.3 millimeter, and pouring the mixture into the mixed resin; adding the promoter during uniform stirring process; stirring continuously to prepare a mixed slurry after stirring; and introducing the mixed slurry into a plate-making mould for vacuum solidification, demoulding, and conducting dry brushing and water grinding so as to prepare the lightweight sound-insulation wall-decoration artificial stone slab. The method provided by the invention has advantages of simple process, low equipment requirement and low cost, and is easy for large-scale popularization. In addition, the prepared artificial stone slab has excellent comprehensive properties.

Owner:江苏顺乾新型材料有限公司

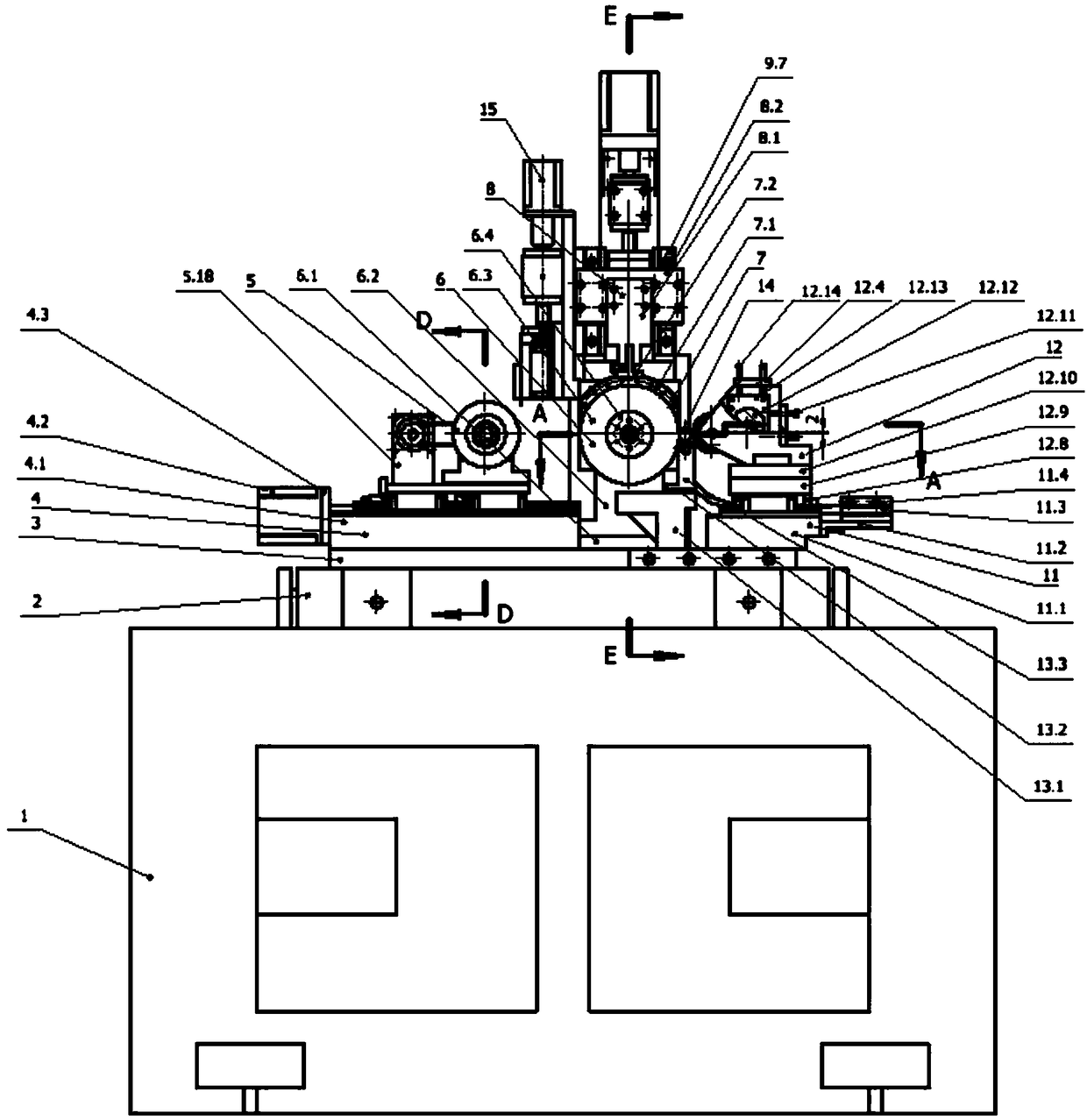

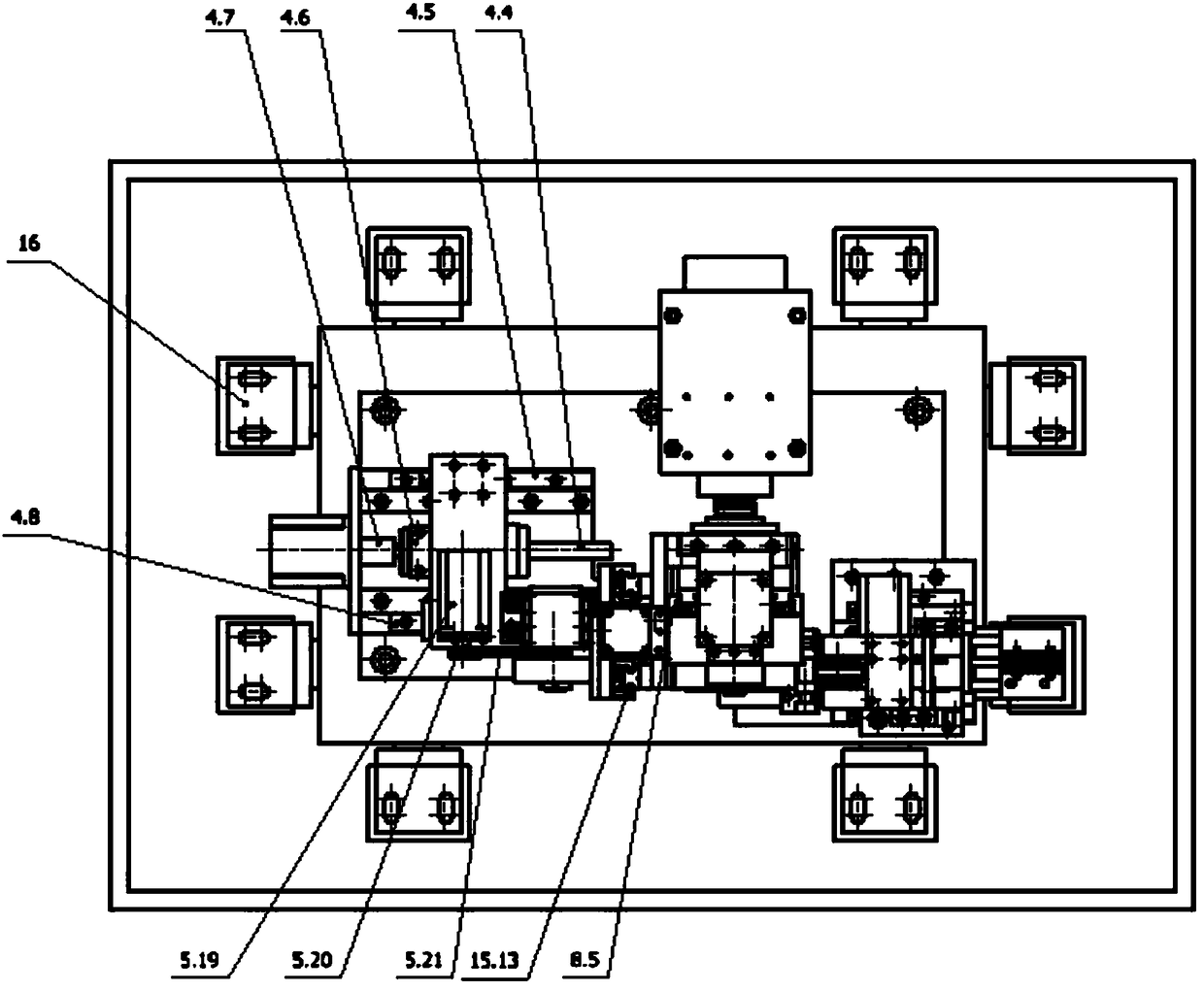

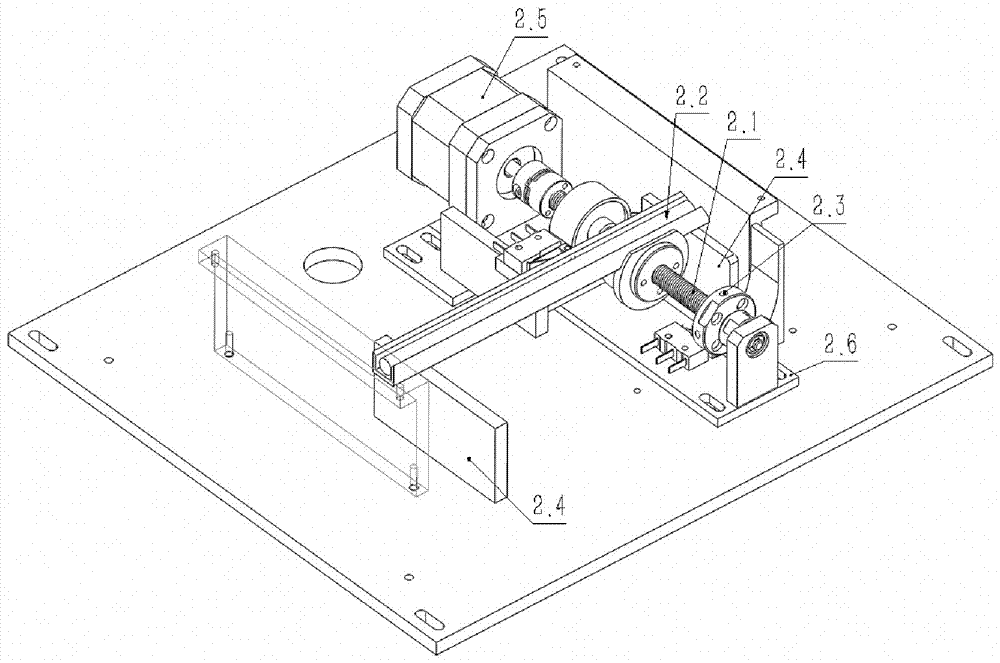

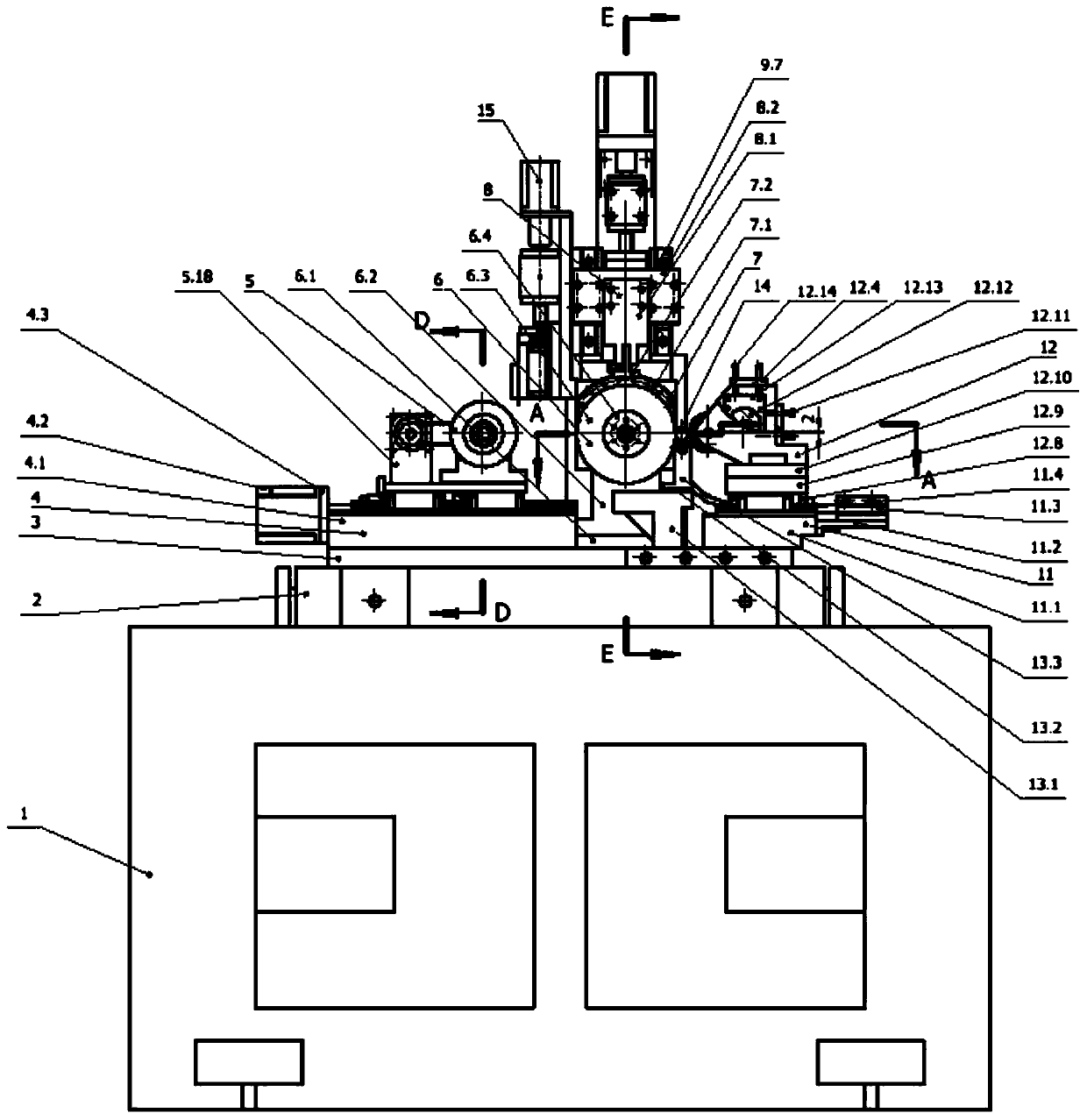

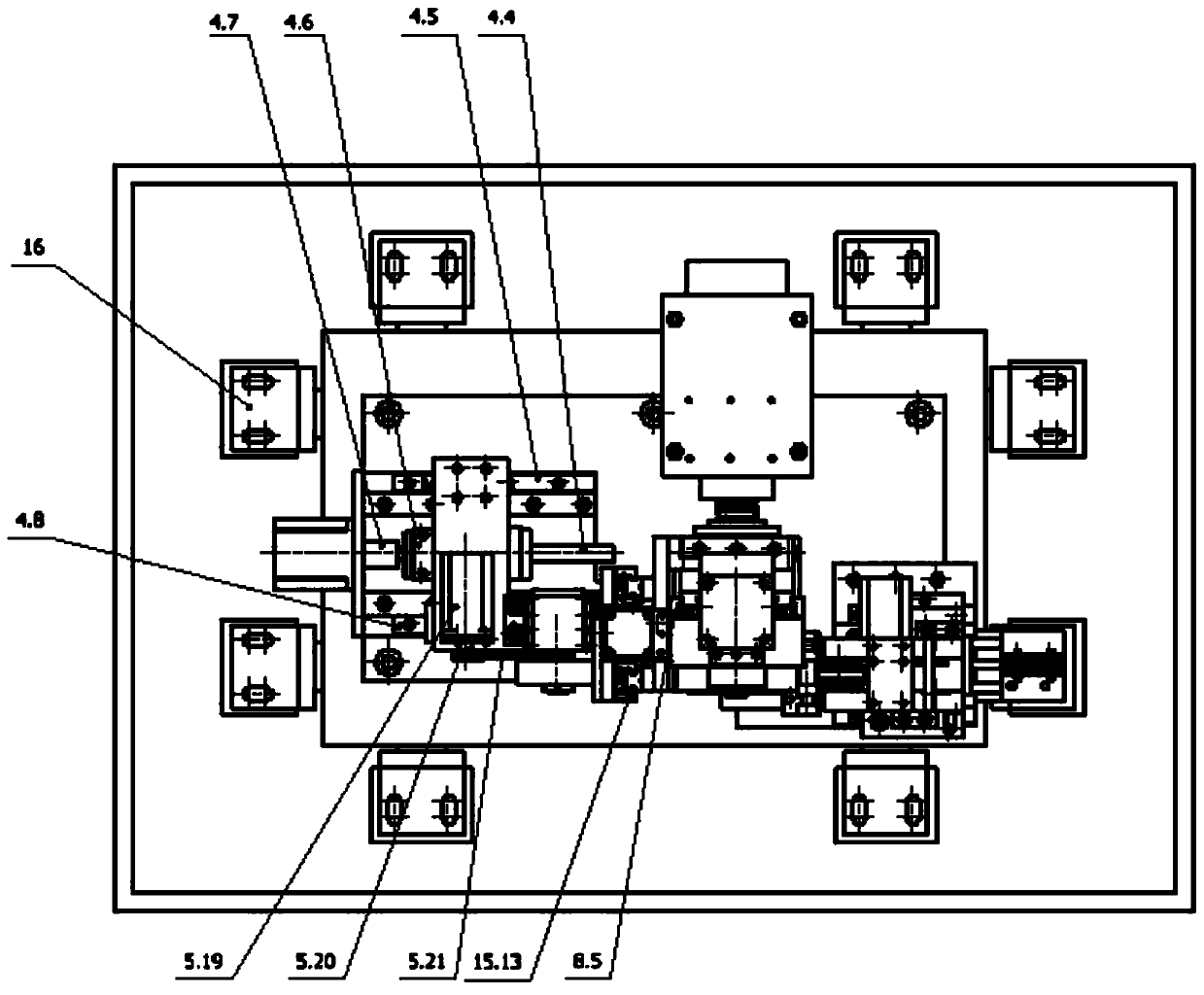

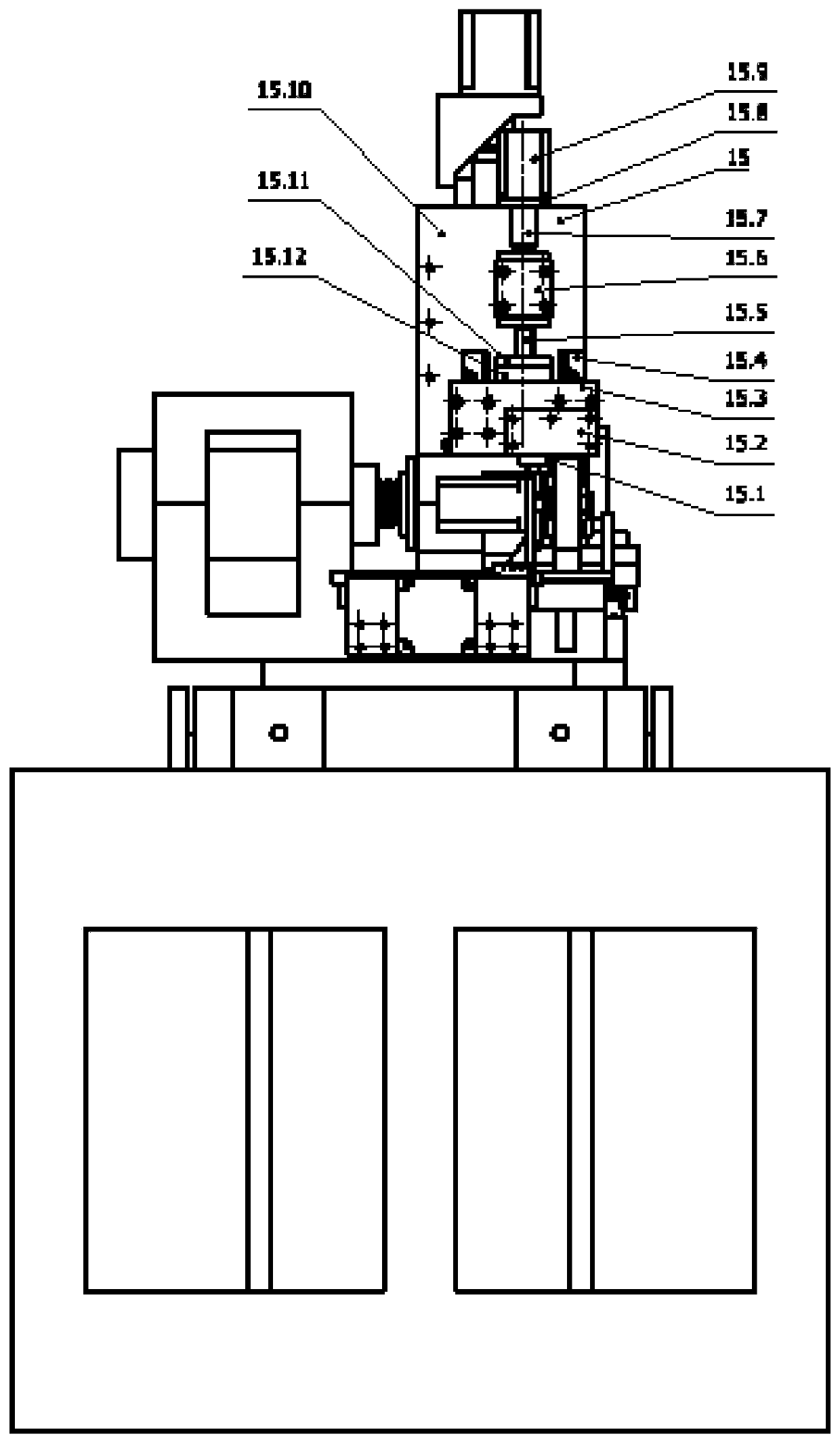

Application method of automatic grinding machine used for grinding small roller and provided with patching sharpening grinding wheel

ActiveCN108453626AHigh forming precisionImprove efficiencyAbrasive surface conditioning devicesRing deviceGraphite

The invention discloses an application method of an automatic grinding machine used for grinding a small roller and provided with a patching sharpening grinding wheel. The automatic grinding machine comprises a lathe bed, a marble table board, a bottom plate, a graphite wheel sliding plate drive device, a graphite wheel drive device, a grinding wheel device, a sharpening copper ring device, a vertical sharpening sliding plate device, a vertical sharpening drive device, an electric spindle device, a guide wheel transverse feed device, a guide wheel drive device, a supporting wheel device, the small roller, a graphite wheel sharpening device and angle plates. According to the automatic grinding machine, the small roller is subjected to grinding machining, meanwhile, the grinding wheel can becorrected online, the sharpening grinding wheel can be electrolyzed online, and therefore the grinding forming precision of the small roller is improved, the grinding efficiency is greatly improved,and cost is low; and due to the fact that the grinding size consistency of the small roller is good, the quality is stable and reliable, and the advantages that adjustment, mounting, maintaining and use are convenient are achieved.

Owner:LUOYANG LIBO NUMERICAL CONTROL TECH CO LTD

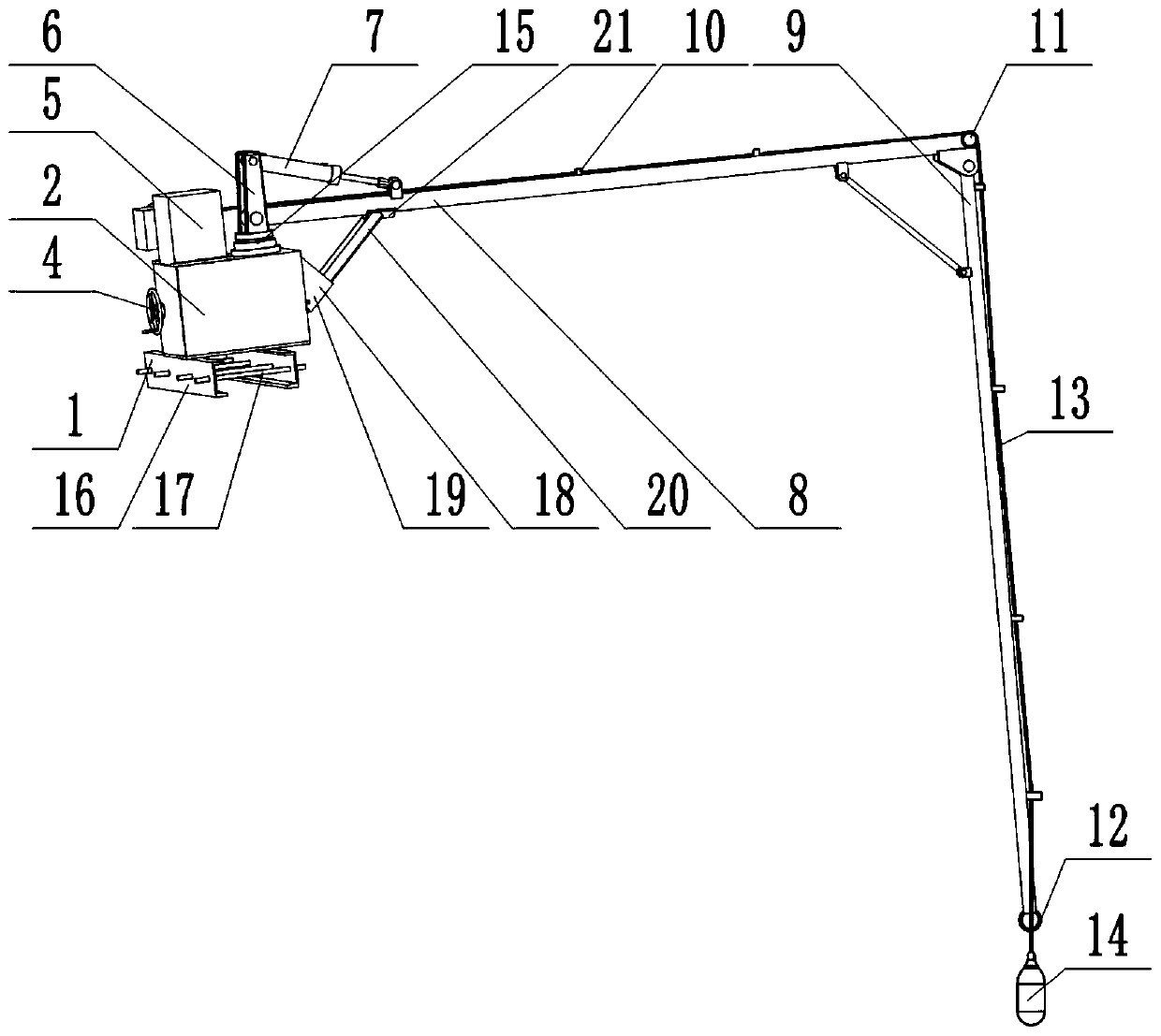

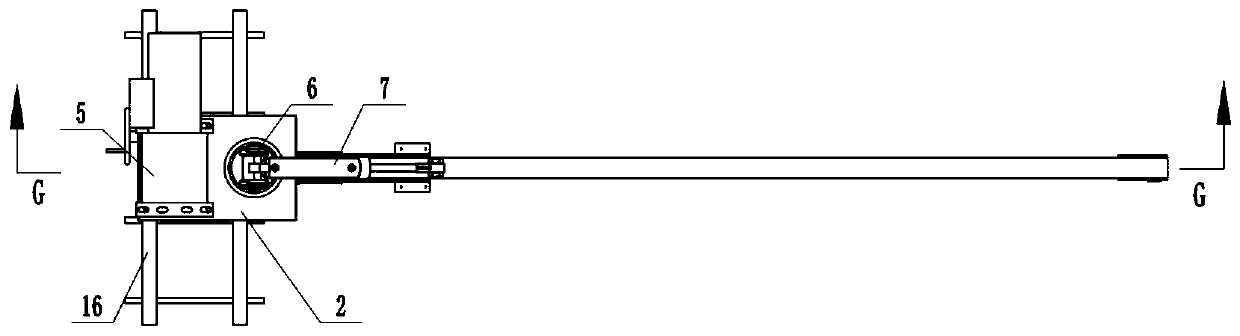

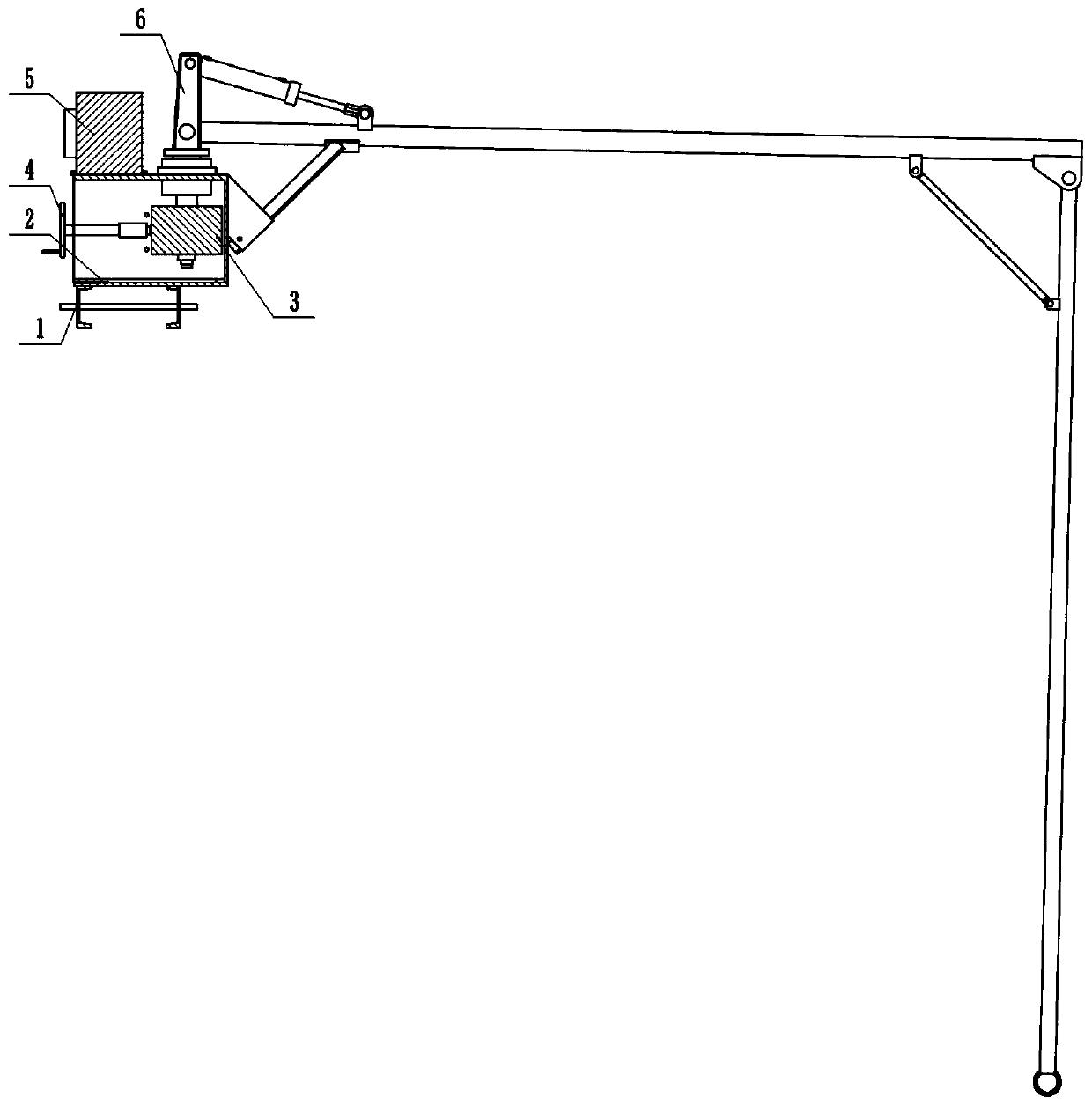

Portable electric side-scan sonar broadside support capable of reducing stress of cross bar

PendingCN111098975AReduced loading space requirementsReduce difficultyVessel partsAcoustic wave reradiationWire ropeWharf

The invention relates to a portable electric side-scan sonar broadside support capable of reducing the stress of a cross bar. The device comprises a fixing device, wherein the fixing device is fixed on a bollard on the ship side, a worm gear and a worm which are meshed together are arranged in a fixing box body, a motor-driven steel wire rope is wound on a take-up shaft on an output shaft of a hoisting motor, and the motor-driven steel wire rope passes through a positioning ring and a fixed pulley and then penetrates through a limiting ring to be connected with sonar. The device has functionsof portability, detachability and easiness in mounting, the requirement of the device on the loading space is reduced, and difficulty of achievement application is reduced, purposes of saving time andlabor and protecting personnel, instruments and equipment are achieved, the ship structure is fully utilized, and problems that the side space of a ship in the prior art is narrow, and side draggingsonar fish dragging is not easy to achieve are effectively solved, the function that a plurality of ships can berth and berth at a wharf side by side can be achieved without dismounting the broadsidesupport, in addition, the hoisting motor for hoisting the sonar is installed on the support, the stress condition of a cross rod can be reduced, and the service life is prolonged.

Owner:交通运输部北海航海保障中心天津海事测绘中心

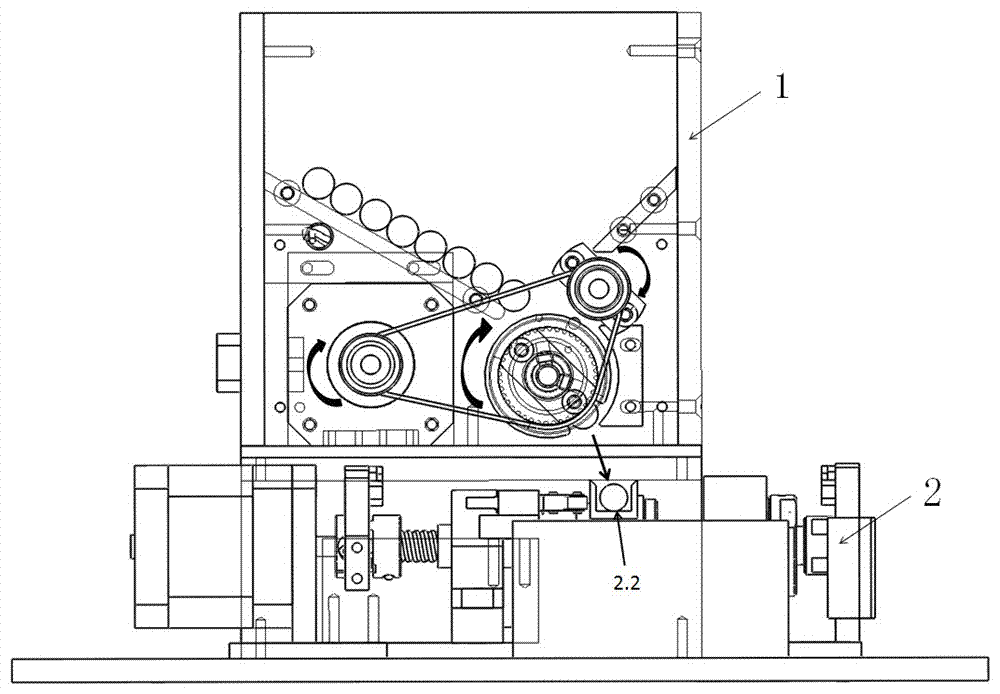

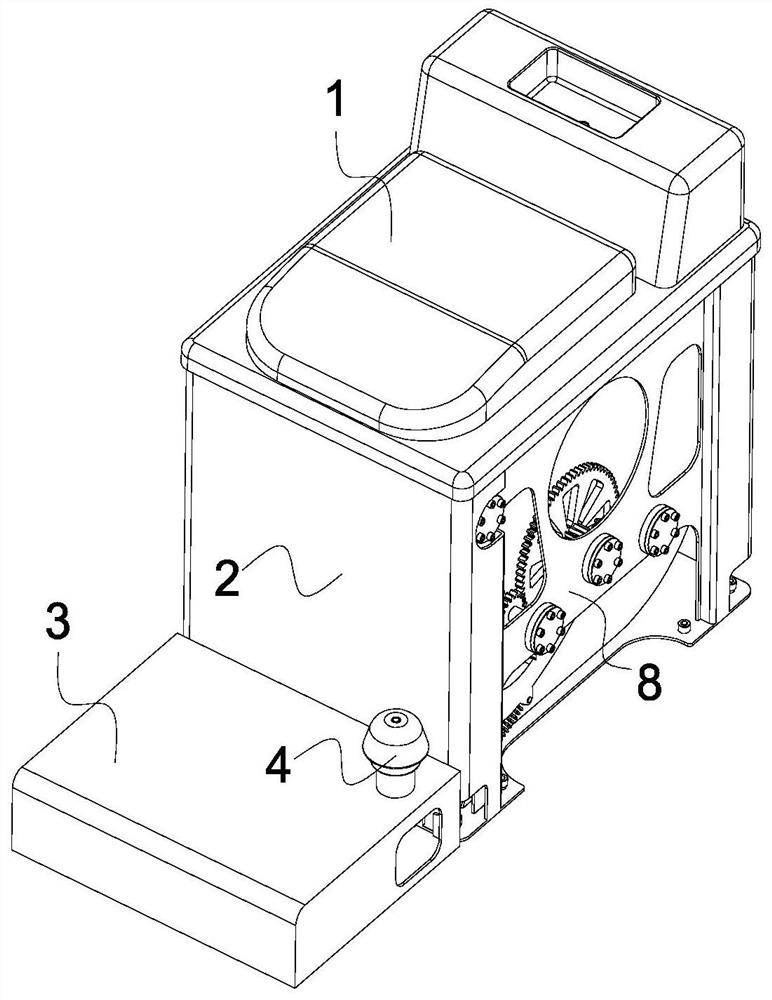

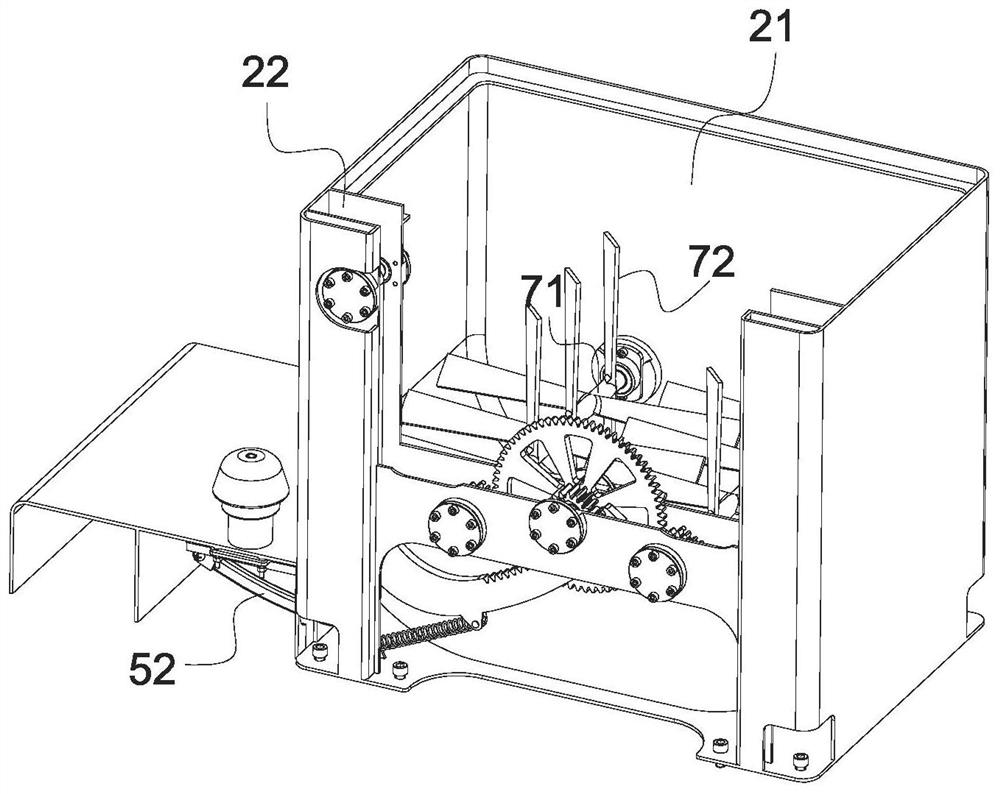

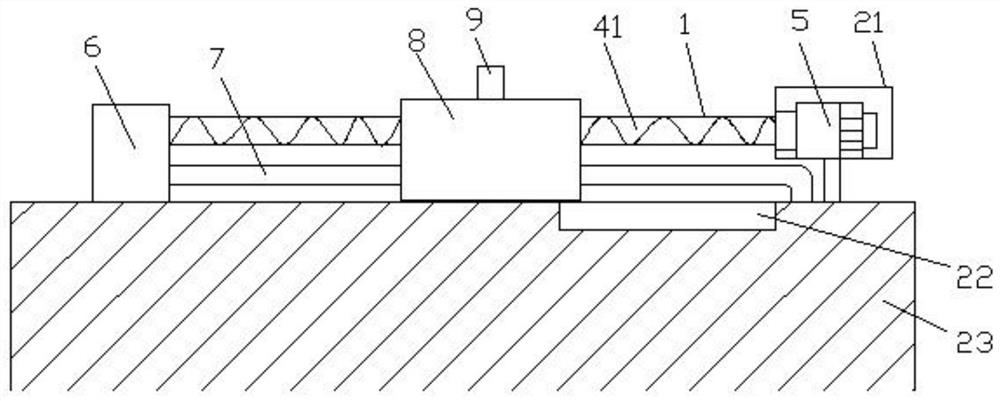

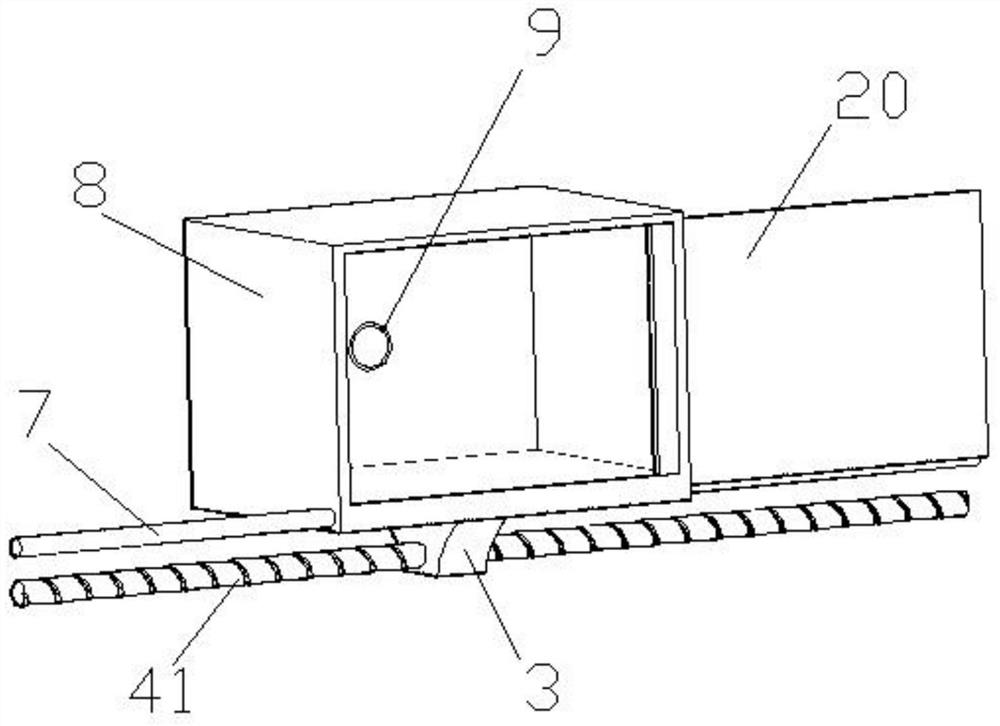

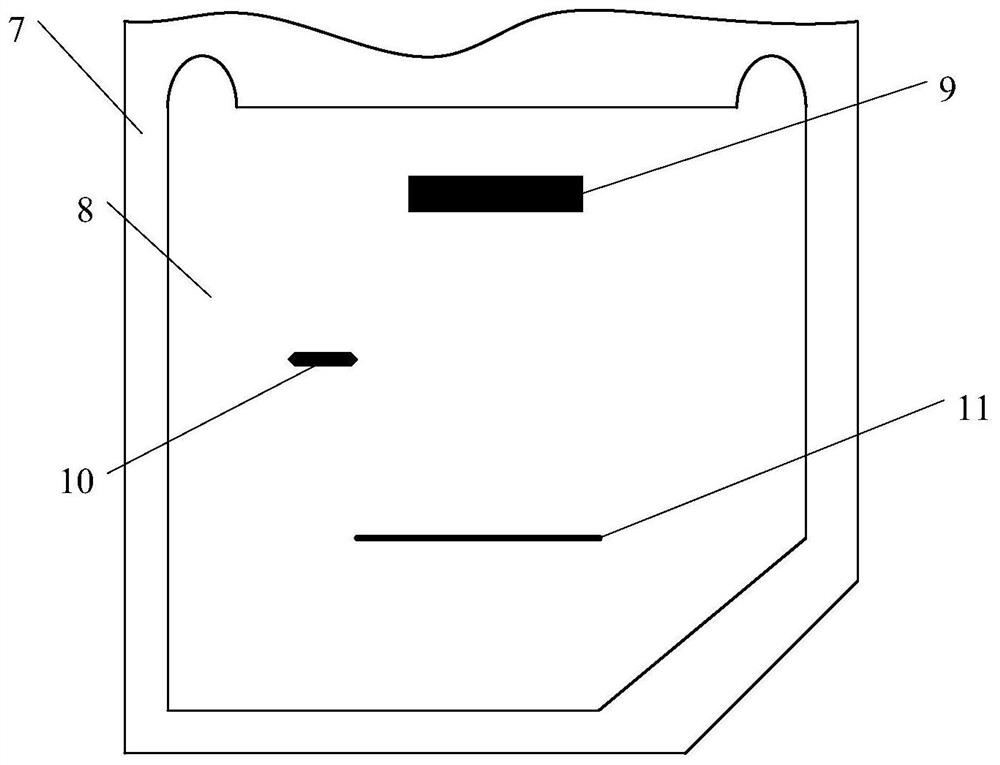

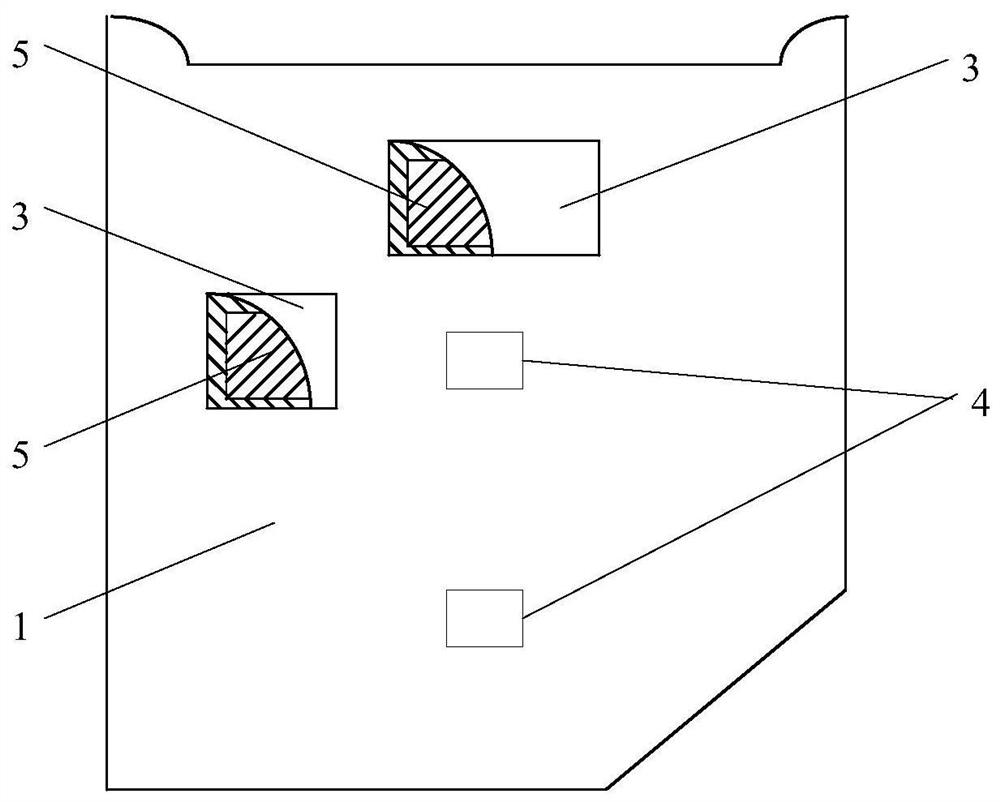

A method of using an automatic blanking device for round bar products

The invention discloses a round rod product automatic blanking apparatus and an application method thereof. The automatic blanking apparatus comprises a blanking supply mechanism and a rod material pushing rotary mechanism, the blanking supply mechanism is arranged right above the rod material pushing rotary mechanism, the blanking supply mechanism is mainly formed by a hopper, a material-taking rotary column, a material-taking blocking piece, a driving motor, and a synchronous belt, and the rod material pushing rotary mechanism is mainly formed by a screw rod, a material-receiving groove, and a motor. The automatic blanking apparatus is advantageous in that the structure is simple, the machining, installation, and debugging are convenient, the operation is stable and reliable, the structure is compact, the size is small, the apparatus can serve as the modular standard product, can be used with the cooperation of other machinery, and can be widely applied to automatic blanking occasions of other machinery, the automatic blanking apparatus is completely different from the blanking apparatus structures in the prior art in the market, the originality is provided, substantial characteristics are prominent, the progress is remarkable, the practical value is extremely high, the application mode is flexible, and the automatic blanking apparatus is more applicable to modular application.

Owner:SHANGHAI PUSHUO AUTOMATION

Efficient stirring mechanism, and environment-friendly pedestal pan using same

PendingCN111603969AExtend the mixing timeImprove mixing effectWater closetsTransportation and packagingElectric energyPower grid

Owner:四川升腾元创机电技术研究有限公司

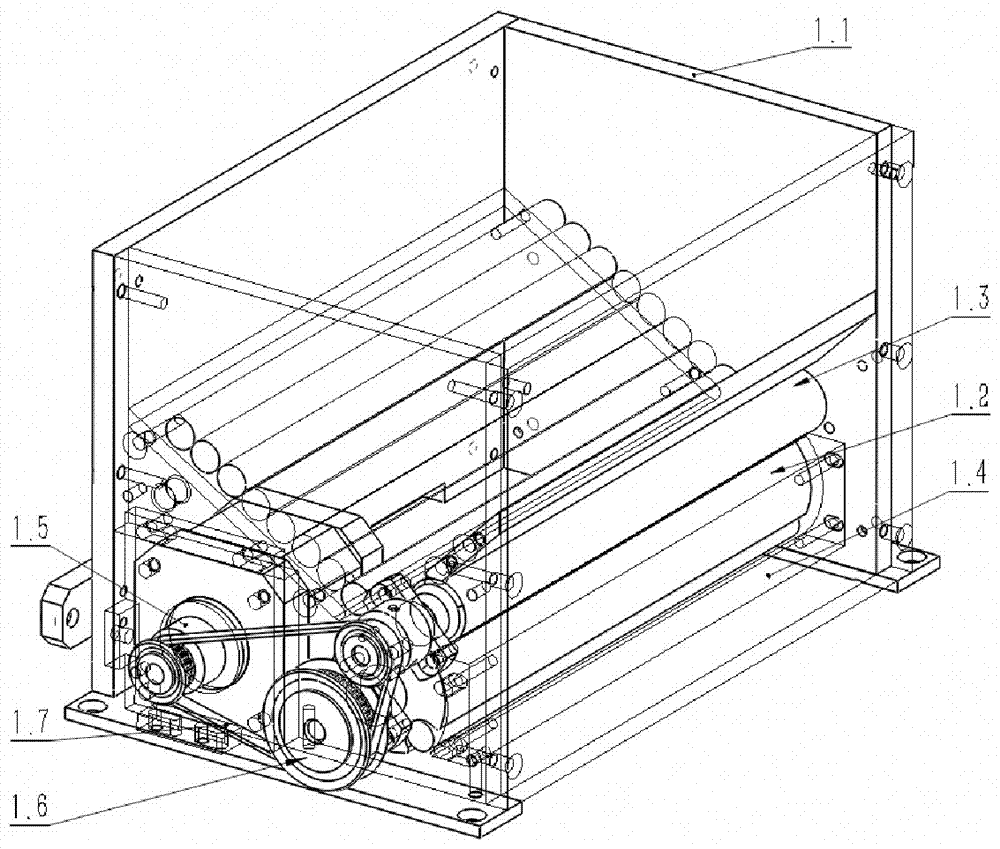

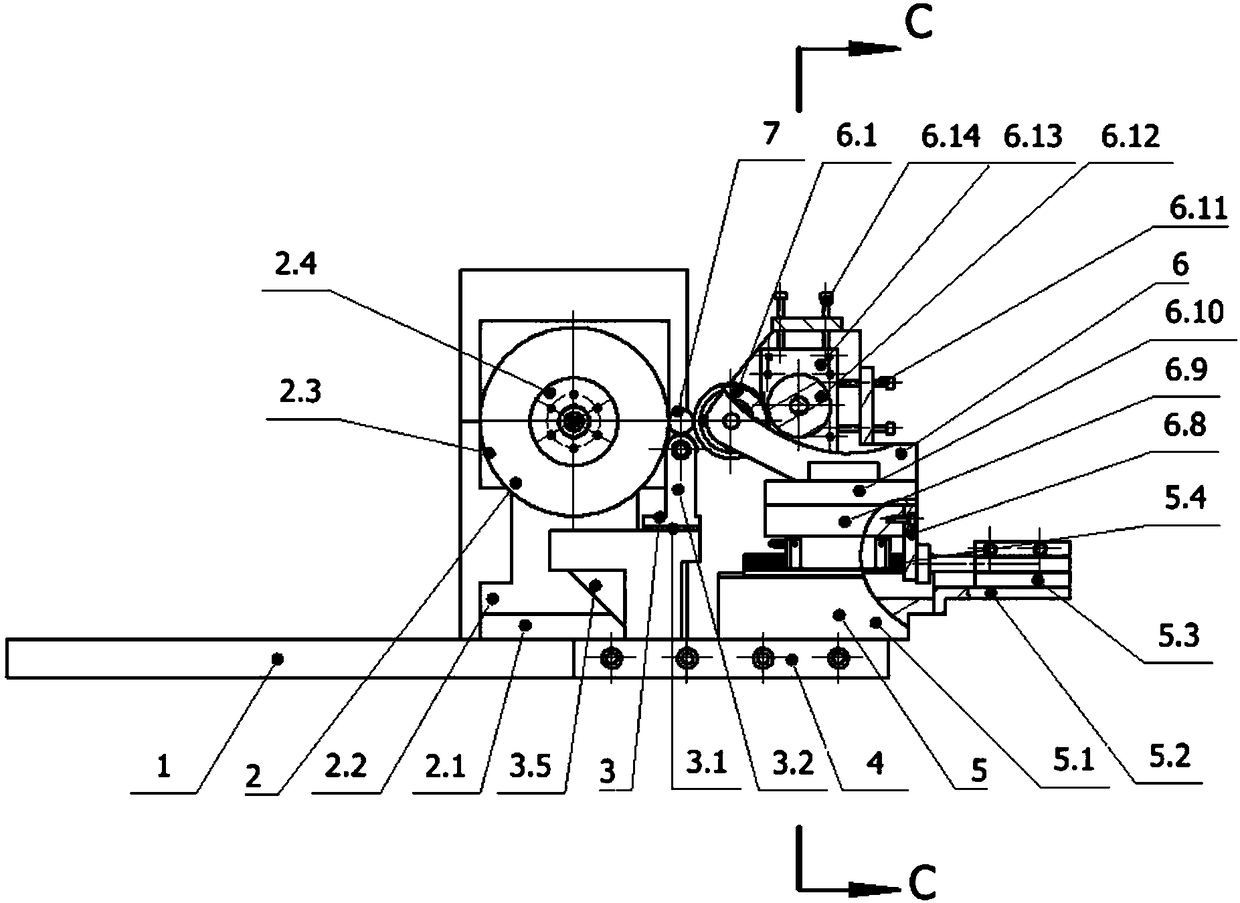

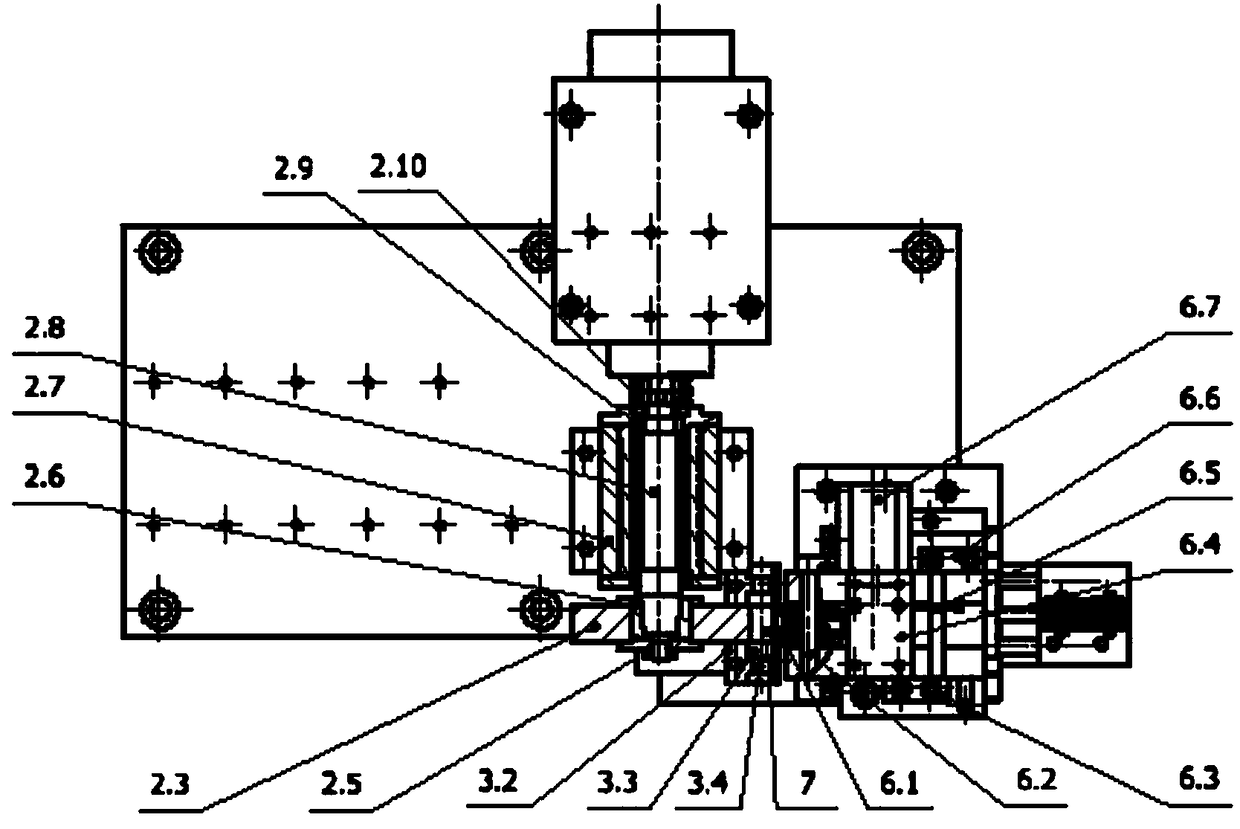

Method for precisely grinding small roller of bearing with automatic grinding device

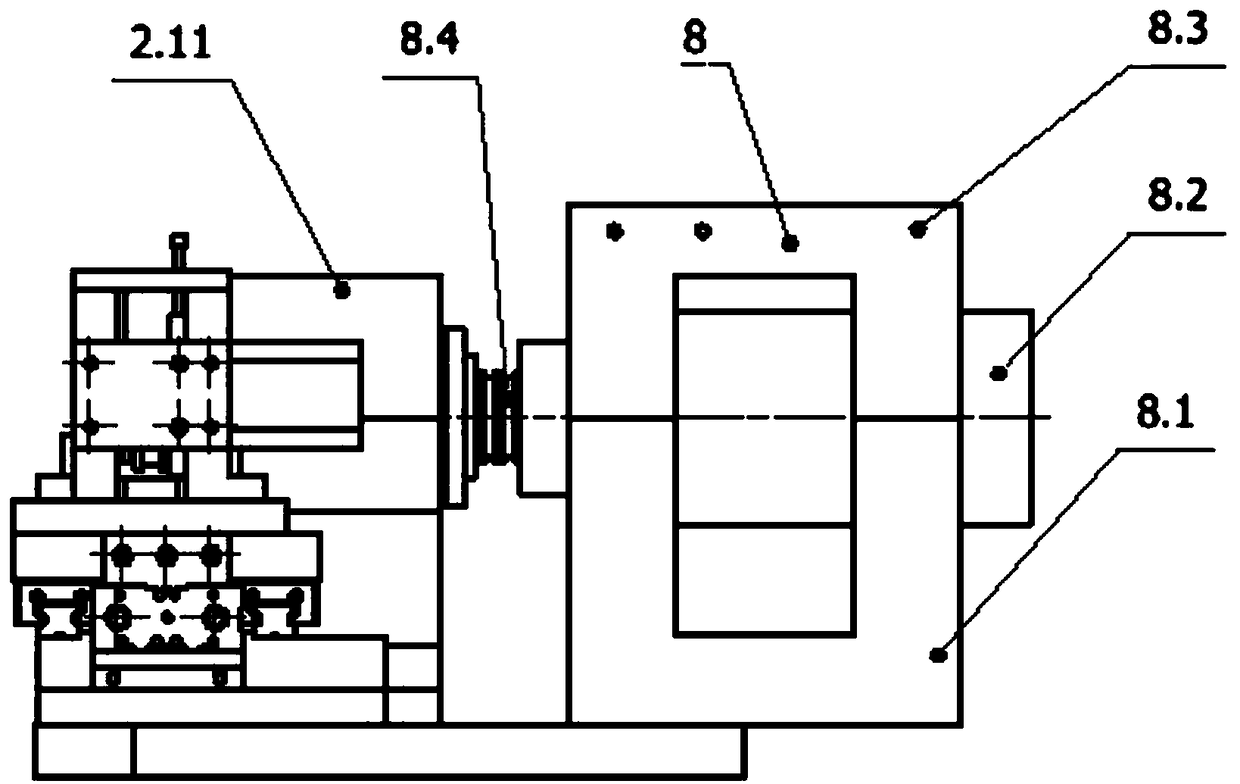

ActiveCN108436626AWith adjustmentHave installedGrinding carriagesRevolution surface grinding machinesEngineeringPerpendicular direction

The invention relates a method for precisely grinding a small roller of a bearing with an automatic grinding device. The automatic grinding device comprises a baseplate, a grinding wheel device, a supporting wheel device, a baseplate additional plate, a guide wheel transverse feed device, a guide wheel driving device and an electric spindle device; a small roller is placed on a supporting wheel between a grinding wheel and a guide wheel in the perpendicular direction during grinding, and the small roller does not need to be centered and supported by an ejector pin; the excircle of the ground small roller is regarded as the location datum, and the grinding wheel and the guide wheel are rotated in the same direction; the circumferential velocity of the guide wheel is very low, and is 20-30 m / min, and the circumferential velocity of the grinding wheel is 60-80 times the circumferential velocity of the guide wheel; the small roller is rotated under the effect of friction force between thegrinding wheel and the small roller as well as between the guide wheel and the small roller, and large linear velocity difference exists at the contact area between the small roller and the grinding wheel so that materials are removed; in order to ensure the excircle roundness of the small roller, the center height of the small roller is the same as the center height of the grinding wheel; and thecenter of the guide wheel is higher 2-3 nm than a line connecting the axis of the small roller with the axis of the grinding wheel.

Owner:LUOYANG LIBO NUMERICAL CONTROL TECH CO LTD

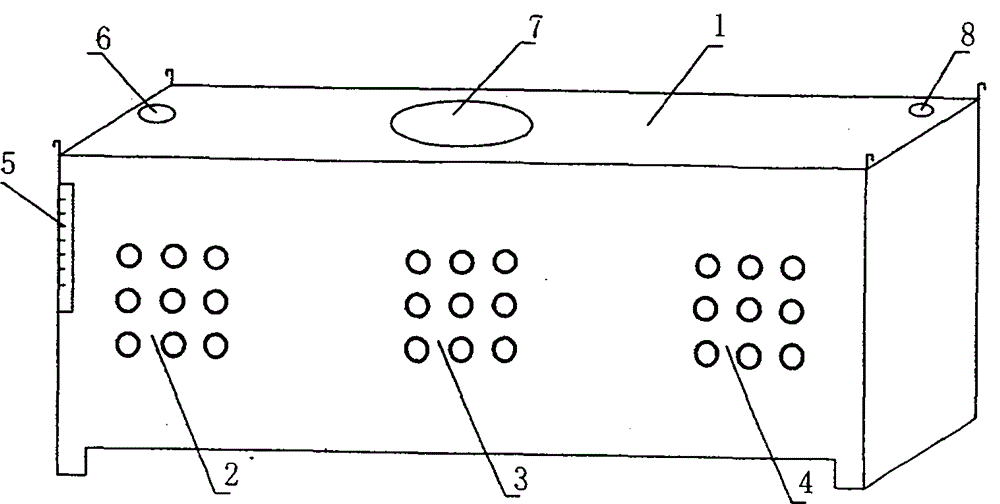

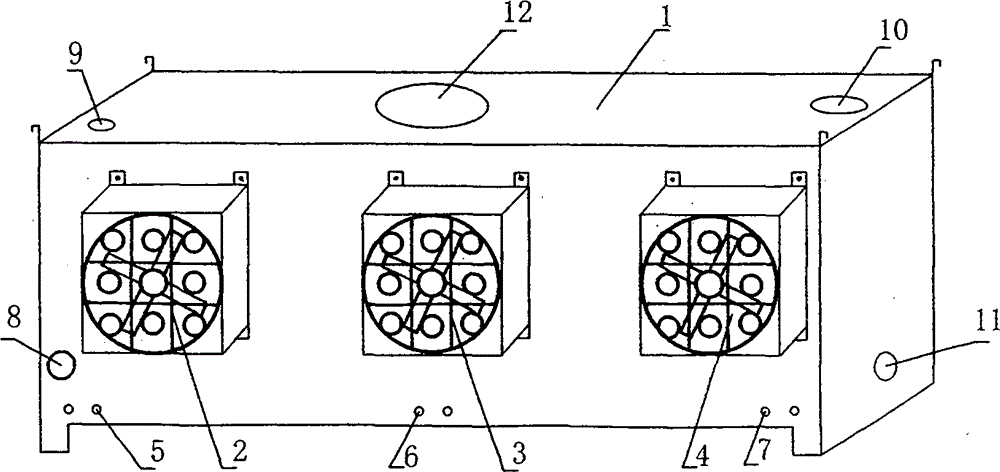

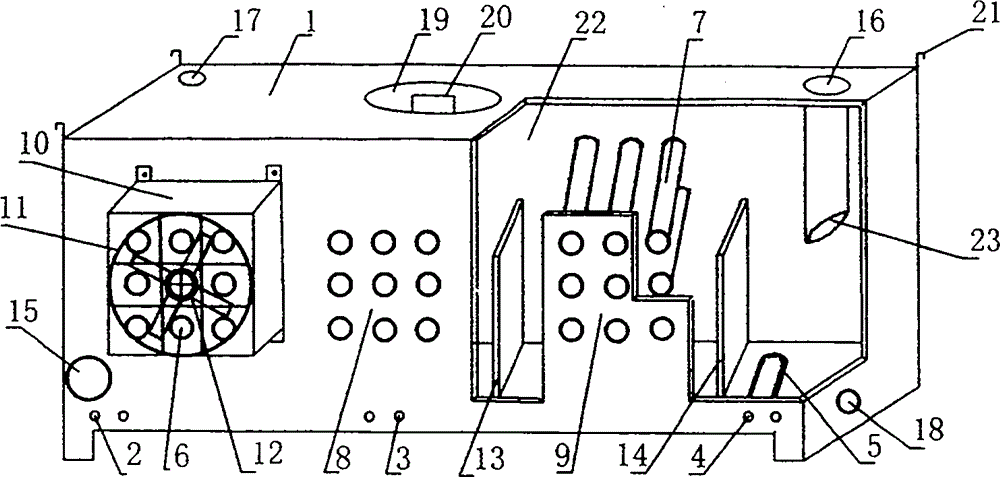

Hydraulic oil treatment device for hydraulic equipment

InactiveCN103953617AHave storageWith heatingFluid-pressure actuator componentsTemperature controlHydraulic equipment

The invention relates to a hydraulic oil treatment device for hydraulic equipment, and belongs to the hydraulic technical field. The hydraulic oil treatment device consists of a metal box body and accessories thereof, a heater, cooling pipe groups, an axial flow fan, an air flow guide cover and a safety protection net, wherein the box body is formed by welding iron plates or stainless steel plates; cooling pipes are arranged at corresponding positions on two non-adjacent box walls of the box body; two ends of the cooling pipes are welded together with the walls of the box body; multiple cooling pipes form a cooling pipe group; the axial flow fan is arranged at an air inlet in one side of each cooling pipe group; a bracket of the axial flow fan is fixed on the box body through screws; the air flow guide cover is arranged on the outer side of the axial flow fan; the safety protection net is arranged outside the air flow guide cover. The hydraulic oil treatment device has the advantages of energy conservation, environment friendliness, compact structure, complete functions, good oil liquid temperature control effect and safety and stability in running, and can be widely applied to hydraulic equipment industries and equipment for treating oil liquid temperature.

Owner:贾瑞勇

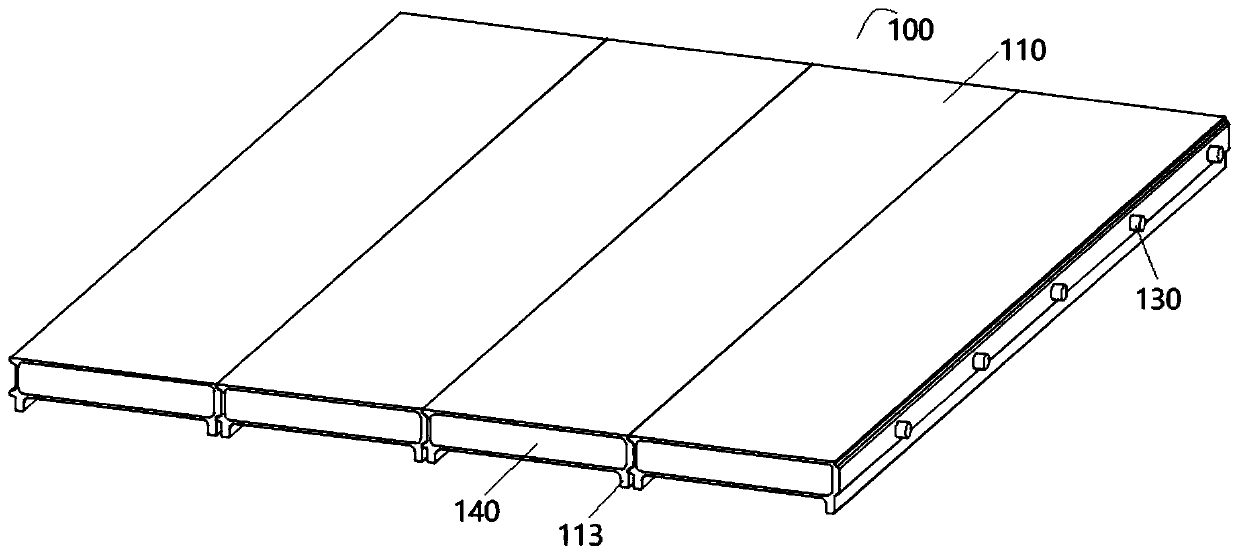

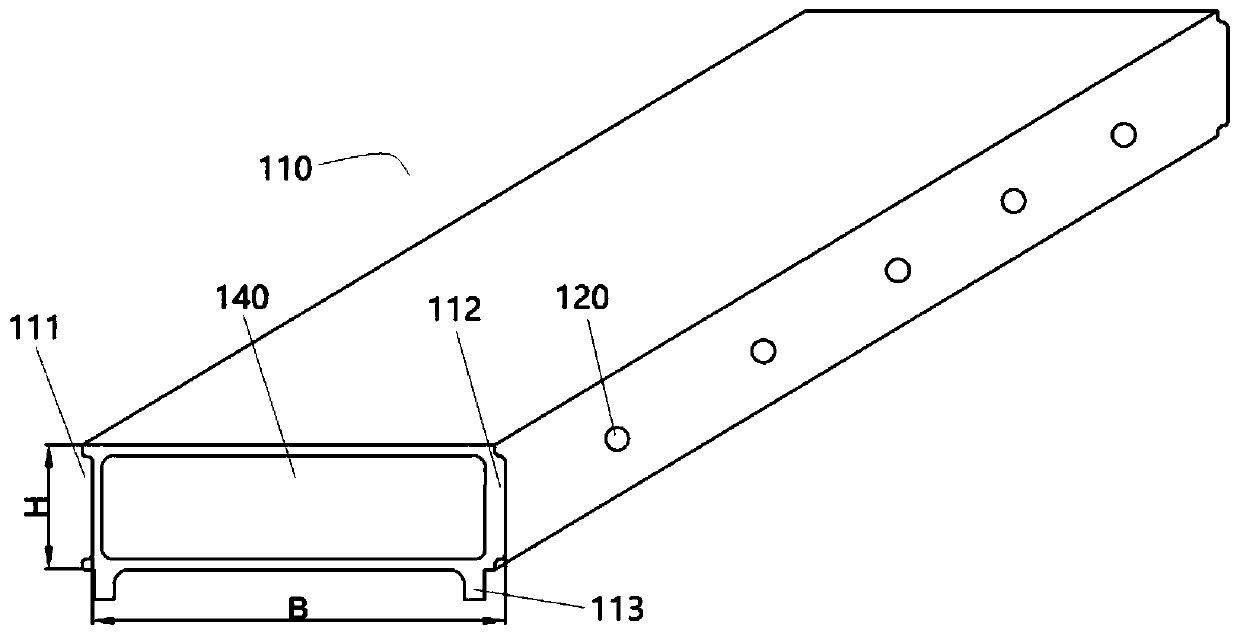

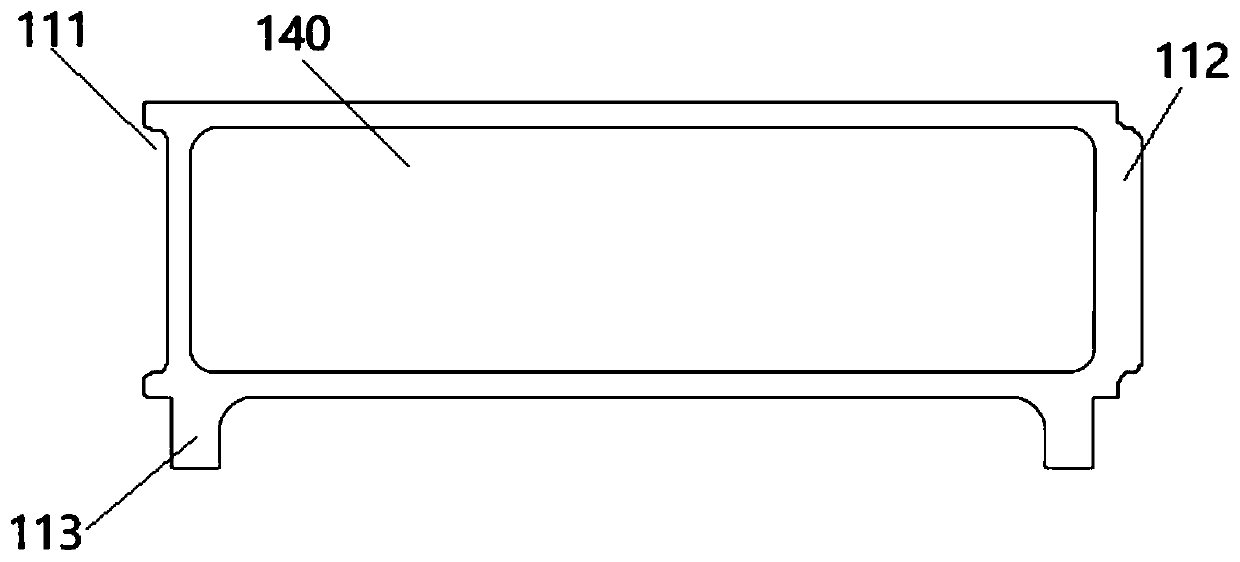

Platform pedal, preparation equipment, subway tunnel evacuation platform and preparation method of subway tunnel evacuation platform

PendingCN110439608AImprove the effect of fire protection and heat insulationReduce security risksSafety equipmentsEngineeringStructural engineering

Owner:北京玻钢院复合材料有限公司 +1

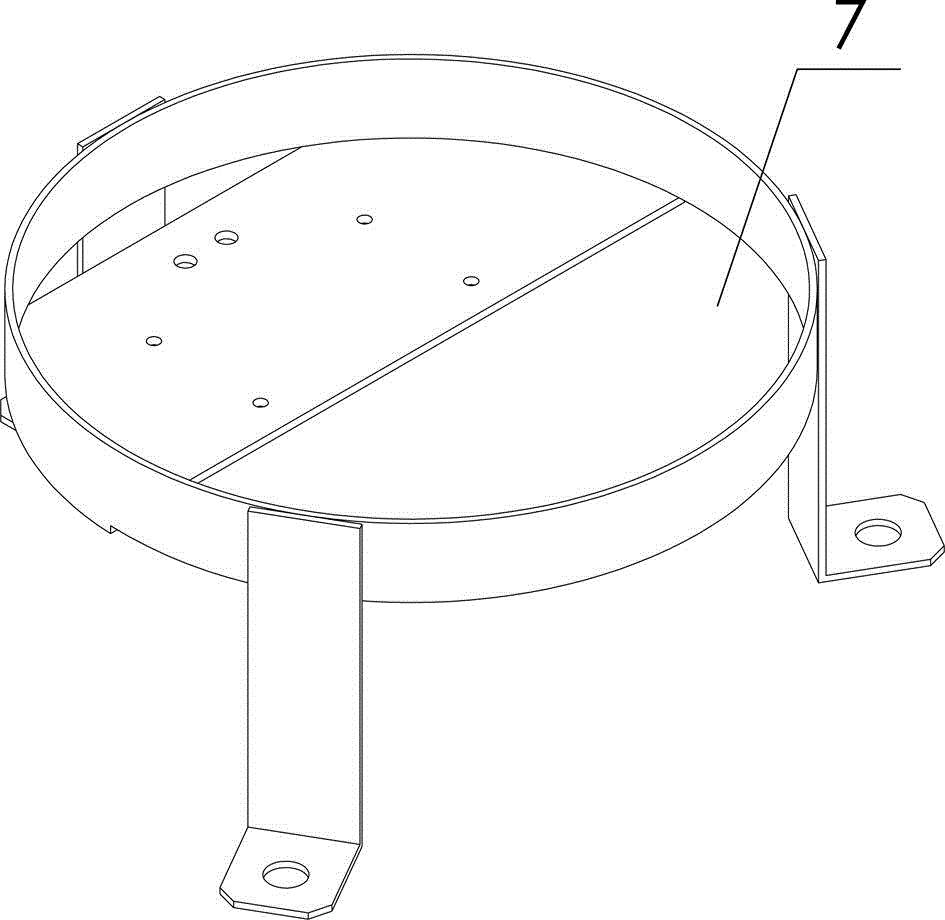

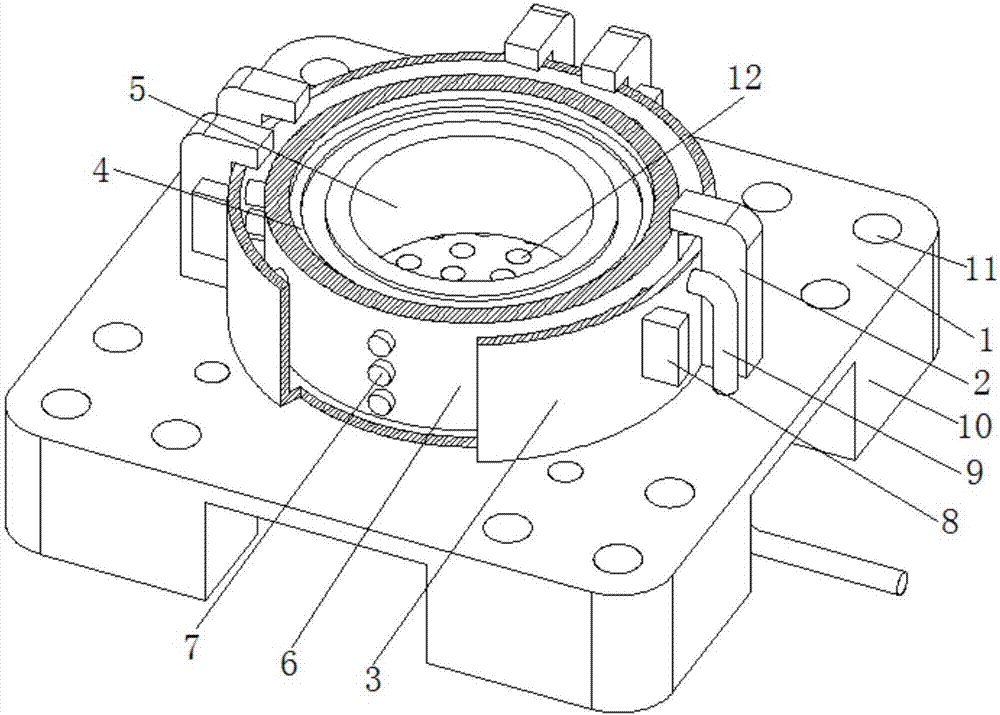

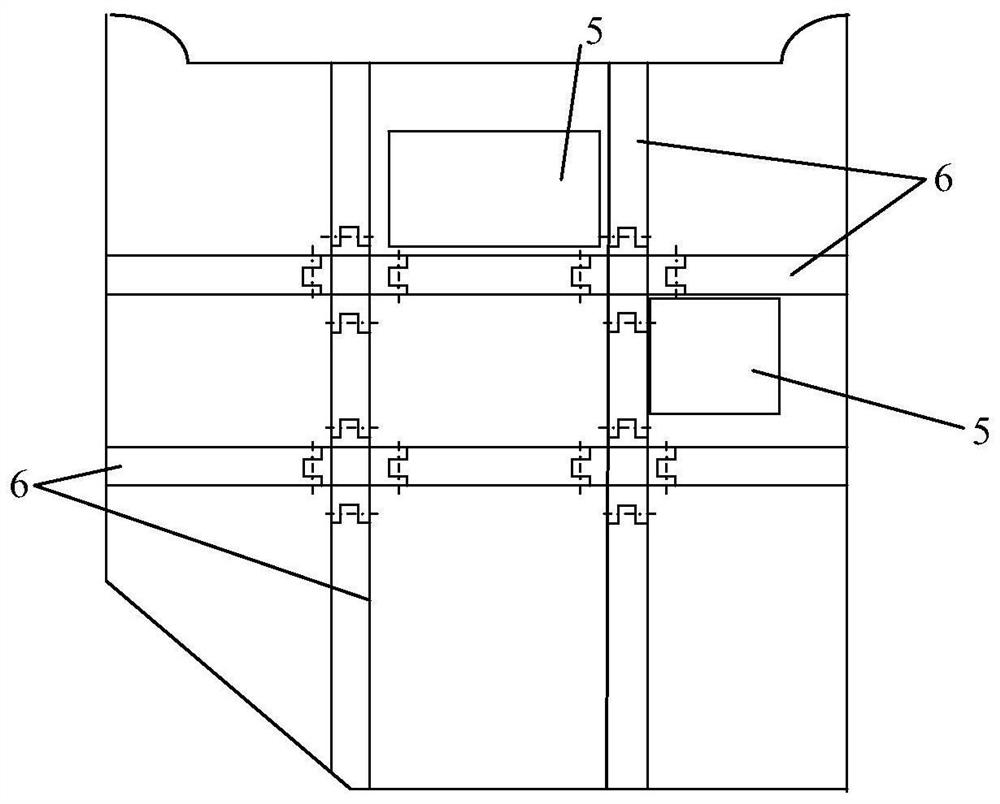

Detachable sleeve type force sensor used for bracket structure

ActiveCN105928642AImprove monitoring efficiency and reusabilitySmall sizeForce measurementAxial pressureWireless sensor network

The invention provides a detachable sleeve type force sensor used for a bracket structure, and belongs to the technical field of sensing. According to the detachable sleeve type force sensor used for the bracket structure, axial pressure of the vertical rod of the bracket structure can be monitored, and the detachable sleeve type force sensor can be detachably and repeatedly used so that the utilization rate and the use value of the sensor can be enhanced. With application of the developed detachable sleeve type force sensor used for the bracket structure, the developed senor is arranged at the field of the bracket structure in a distributed way with combination of a wireless sensor network technology so that force bearing of the vertical rod of the bracket structure can be monitored, the installed sensor can be detached anytime when the bracket structure is in the working state, the monitoring efficiency is high and the sensor has great application value and potential.

Owner:BEIJING UNIV OF TECH

A detachable sleeve-type force sensor for bracket structure

ActiveCN105928642BAvoid difficultiesImprove monitoring efficiencyForce measurementLine sensorAxial pressure

The invention provides a detachable sleeve type force sensor used for a bracket structure, and belongs to the technical field of sensing. According to the detachable sleeve type force sensor used for the bracket structure, axial pressure of the vertical rod of the bracket structure can be monitored, and the detachable sleeve type force sensor can be detachably and repeatedly used so that the utilization rate and the use value of the sensor can be enhanced. With application of the developed detachable sleeve type force sensor used for the bracket structure, the developed senor is arranged at the field of the bracket structure in a distributed way with combination of a wireless sensor network technology so that force bearing of the vertical rod of the bracket structure can be monitored, the installed sensor can be detached anytime when the bracket structure is in the working state, the monitoring efficiency is high and the sensor has great application value and potential.

Owner:BEIJING UNIV OF TECH

Nano abrasion-resistant high polymer material bearing cooling device

InactiveCN107477093AImprove cooling effectQuick fixShaftsRotary machine partsCooling effectEngineering

The invention discloses a bearing cooling device made of nanometer wear-resistant polymer material. A bearing seat (3) is placed in the middle of the upper surface of the fixed plate (1), and a clamp is arranged on the upper surface of the fixed plate (1). column (2), and the fixed plate (1) is fixedly connected with the bearing seat (3) through the card column (2), and the side of the bearing seat (3) corresponding to the card column (2) is provided with a positioning plate (8), the The side of the positioning plate (8) is in contact with the side of the clamping column (2), the inside of the bearing seat (3) is provided with an annular groove (6), and the inside of the bearing seat (3) is provided with a card slot (4) , and the bearing seat (3) is connected with the bearing (5) through the slot (4). The present invention can cool the bearing through air cooling and water cooling by arranging a fixed plate with ventilation holes, a bearing seat with an annular groove, a fan, a water inlet pipe and a water outlet pipe, thereby improving the cooling effect, and by providing the first screw hole The whole device can be quickly fixed, the installation is convenient, the operation is simple, and the use is convenient.

Owner:祝秀英

Road wheel for tracked vehicle

A loading wheel for a travel system relates to a loading wheel and aims at solving problems that the existing loading wheel for the travel system is complex in structure, apt to side slip when being used for traveling, large in noise, short in service life and not capable of being generally used on crawlers or wheeled vehicles. The loading wheel for the travel system comprises a hub, a rim, a tire and a side ring, wherein the section of the hub is shallow-U-shaped, and the big end of the hub is inserted onto the rim, the hub and the rim are integrally set. The side ring is composed of a clamp ring and a check ring which are integrally set. The clamp ring is arranged on one side surface of the rim, and the tire is inserted between the other side surface of the rim and the side ring. The solid tire comprises an outer layer, a middle layer and an inner layer, wherein the outer layer is made of cord fabric materials, the middle layer is made of carbon fiber adhesive materials, and the inner layer is made of natural rubber materials or synthetic rubber materials. The loading wheel can be used on the crawlers and the wheeled vehicles.

Owner:哈尔滨北方防务装备股份有限公司

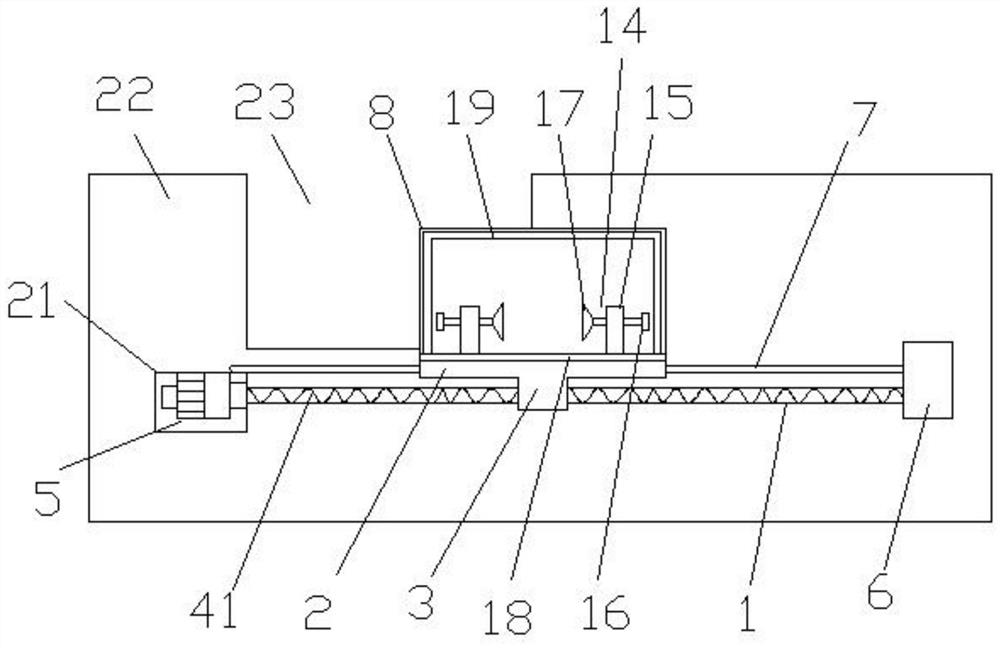

A central air-conditioning outdoor unit installation mechanism

ActiveCN109163389BHave installedEasy to installCondensate preventionLighting and heating apparatusBall screwElectric machinery

The invention discloses a central air-conditioning outdoor unit mounting mechanism. The central air-conditioning outdoor unit mounting mechanism comprises a transmission mechanism used for moving an outdoor unit. The transmission mechanism comprises a carrying platform. The bottom of the carrying platform is provided with a linkage block. The linkage block is provided with a ball screw. One end ofthe ball screw is connected with a transmission motor, and the other end of the ball screw is connected with a first locating block. A supporting sliding bar parallel to the ball screw further penetrates through the carrying platform. One end of the supporting sliding bar is fixedly connected to the first locating block. A polyurethane sound absorption shell used for noise reduction protection isarranged on the carrying platform. The polyurethane sound absorption shell is further provided with a noise wave reduction long pipe. The carrying platform is internally provided with a water collection tank. The water collection tank is internally provided with a flow guide pipe. The flow guide pipe extends out of the carrying platform. Through the central air-conditioning outdoor unit mountingmechanism, the large and heavy outdoor unit can be more convenient and safer to install, and the influence of noise and water dropping of the outdoor unit is reduced.

Owner:中筑科技股份有限公司

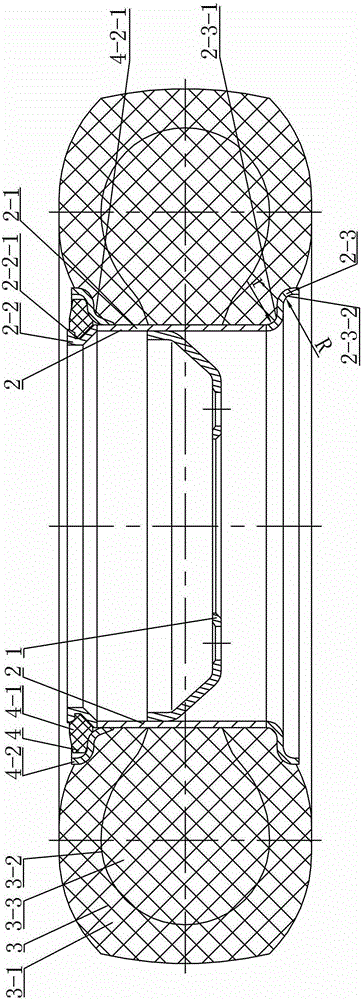

A door trim protection device based on a special vehicle

ActiveCN109278664BTough enoughImprove thermal protection performanceSuperstructure subunitsEngineeringMagnet

The invention discloses a door interior trim protection device based on a special vehicle and belongs to the field of vehicle protection. Problems of poor isolation and protection performance, loose adhesion, no protection for operation windows such as a door lock handle, poor durability, pollution and the like of an existing protection device are solved. The door interior trim protection device based on the special vehicle comprises a protection cover, a magnet filling bag and a magnet; the protection cover is of a cover-shaped structure; the shape and dimension of the cover-shaped structureare matched with those of a door interior trim; the magnet filling bag is arranged on the protection cover and used for placing the magnet; and the magnet protection cover is fixed on the surface of the door interior trim. According to the door interior trim protection device based on the special vehicle, the protection for the door interior trim during operation in a cab is realized.

Owner:BEIJING MECHANICAL EQUIP INST

A method of using an automatic grinding machine for grinding small rollers with a repairing and sharpening wheel

ActiveCN108453626BHigh forming precisionImprove efficiencyAbrasive surface conditioning devicesRing deviceEngineering

The invention discloses an application method of an automatic grinding machine used for grinding a small roller and provided with a patching sharpening grinding wheel. The automatic grinding machine comprises a lathe bed, a marble table board, a bottom plate, a graphite wheel sliding plate drive device, a graphite wheel drive device, a grinding wheel device, a sharpening copper ring device, a vertical sharpening sliding plate device, a vertical sharpening drive device, an electric spindle device, a guide wheel transverse feed device, a guide wheel drive device, a supporting wheel device, the small roller, a graphite wheel sharpening device and angle plates. According to the automatic grinding machine, the small roller is subjected to grinding machining, meanwhile, the grinding wheel can becorrected online, the sharpening grinding wheel can be electrolyzed online, and therefore the grinding forming precision of the small roller is improved, the grinding efficiency is greatly improved,and cost is low; and due to the fact that the grinding size consistency of the small roller is good, the quality is stable and reliable, and the advantages that adjustment, mounting, maintaining and use are convenient are achieved.

Owner:LUOYANG LIBO NUMERICAL CONTROL TECH CO LTD

A preparation method of light-weight sound-insulating wall decoration artificial stone plate

The invention discloses a preparation method of a light-weight sound-insulating wall decoration artificial stone plate. Methacrylic acid prepolymerized resin: 325 mesh glass beads: 400 mesh glass powder: 0.3 mm chopped glass fiber: color paste: wetting and dispersing agent: defoamer: accelerator: curing agent (mass ratio) = 25~ 60:10~30:15~35:0.5~3:0.05~2:0.05~0.5:0.001~0.01:0.25~1:0.25~1, pour the methacrylic acid type prepolymer resin into the mixing tank and stir, stir Add color paste, wetting and dispersing agent, defoamer and curing agent in the process to make mixed resin; 325 mesh glass beads, 400 mesh glass powder and 0.3 mm chopped glass fiber are mixed and then poured into the mixed resin. Add the accelerator in the uniform mixing project, continue to stir, and prepare the mixed slurry after the mixing is completed; introduce the mixed slurry into the plate making mold for vacuum curing, demoulding, dry brushing and water grinding, and then the light-weight sound-insulating wall decoration artificial stone slab. The method of the invention has the advantages of simple process, low equipment requirements, low cost, easy large-scale popularization, and the prepared artificial stone plate has excellent comprehensive performance.

Owner:江苏顺乾新型材料有限公司

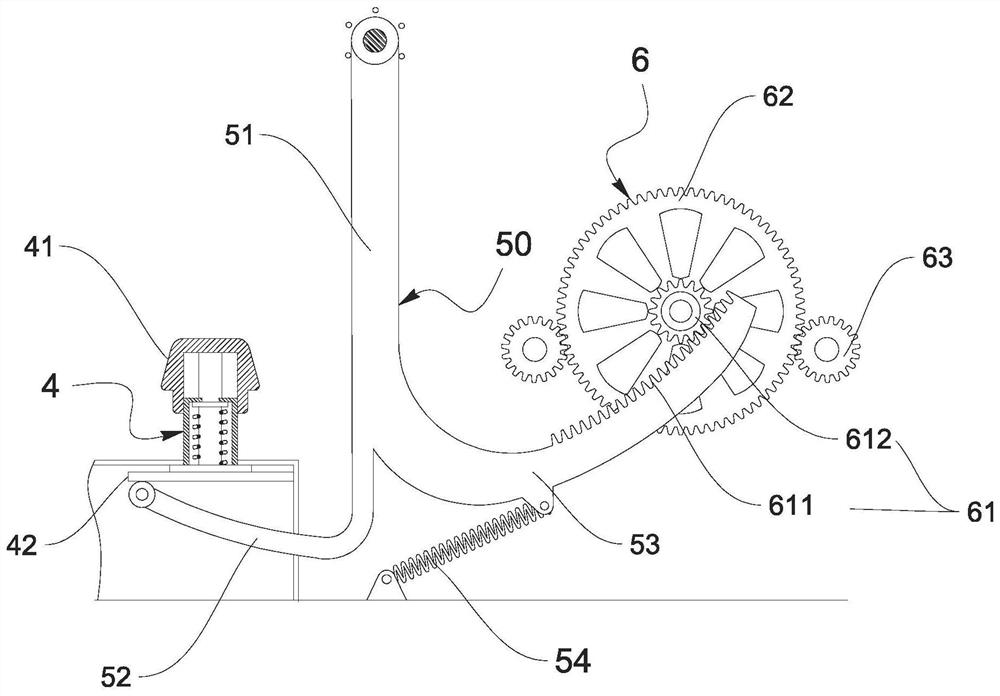

Winding machine capable of automatic measuring wire length

The present invention discloses a autometering wire length winding machine, it containing pedestal body part having wire length metering part and winding part, said metering wire length part set with standard wheel, pinch roller, counter and electromagnetic switch, wherein pinch roller use for clamping wire stock, fan-shaped loop set in standard wheel side, electromagnetic switch set on main panel standard wheel, counter and electromagnetic switch driven by external power supply. Said invention has simple principle of work, low cost, convenient making and installing.

Owner:SUPCON GRP +1

Method for producing architectural decoration material on basis of phosphogypsum

InactiveCN106186999AGood weather resistanceImprove corrosion resistanceWeather resistancePlasticizer

The invention discloses a method for producing an architectural decoration material on the basis of phosphogypsum. The method comprises the following steps: calcining and pulverizing phosphogypsum; heating a polyvinyl chloride resin to 90-100 DEG C, adding a plasticizer, a stabilizer and a surfactant, uniformly mixing by stirring for 1 minute, adding the phosphogypsum powder prepared in the previous step, continuing stirring and mixing uniformly, heating the powdery material to 160 DEG C, and extruding an extrusion-type granulator to obtain a granular material with the diameter of 5mm or so; and sending the granular material into an extruder to obtain the architectural decoration material. The architectural decoration material produced by the method has the advantages of favorable weather resistance, high corrosion resistance, smooth and beautiful appearance, low flammability, high strength, low cost, high installability and the like. The walling material produced by the method has the advantages of favorable weather resistance, high corrosion resistance, favorable heat insulation and sound insulation effects, low flammability, high strength, low cost and high installability, and is capable of reducing the total weight of the whole building and increasing the usable floor area of the building.

Owner:HEFEI GUANGJUCAI BUILDING DECORATION ENG CO LTD

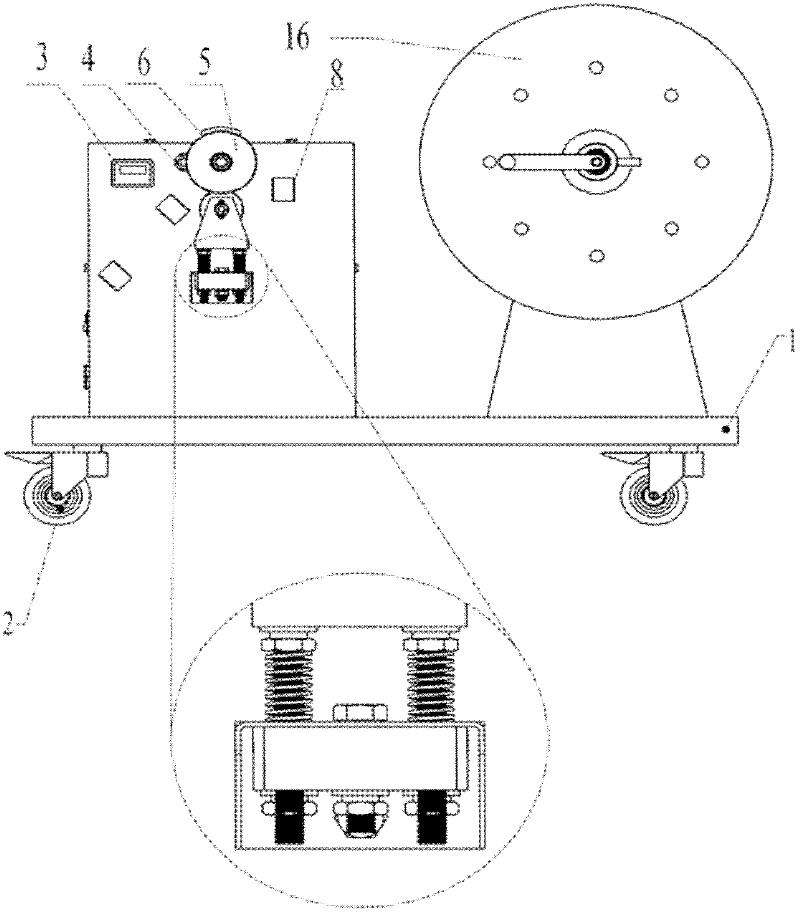

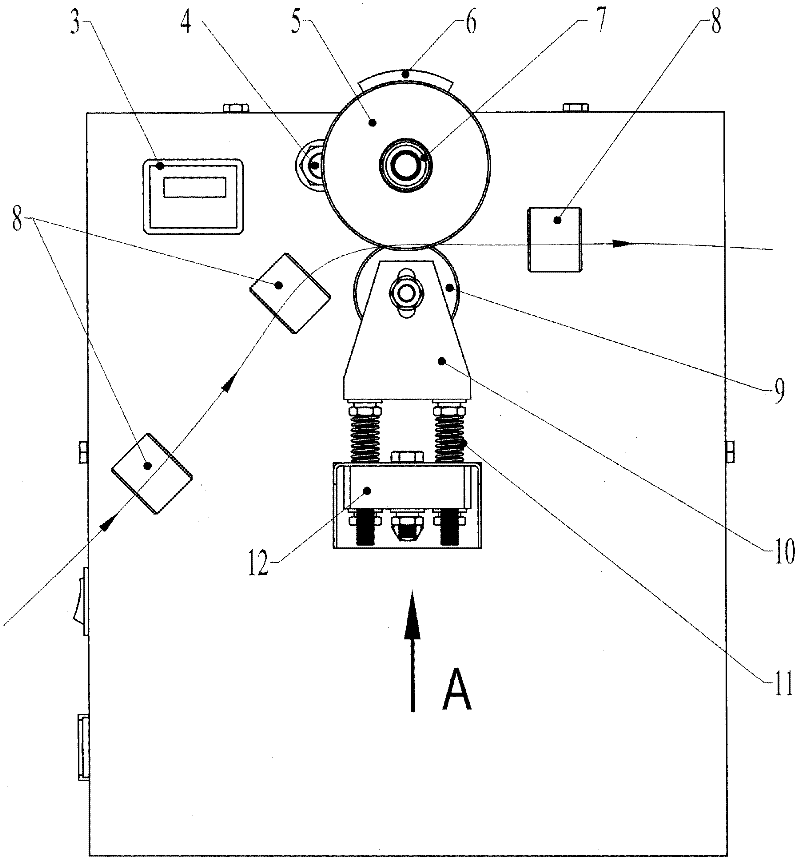

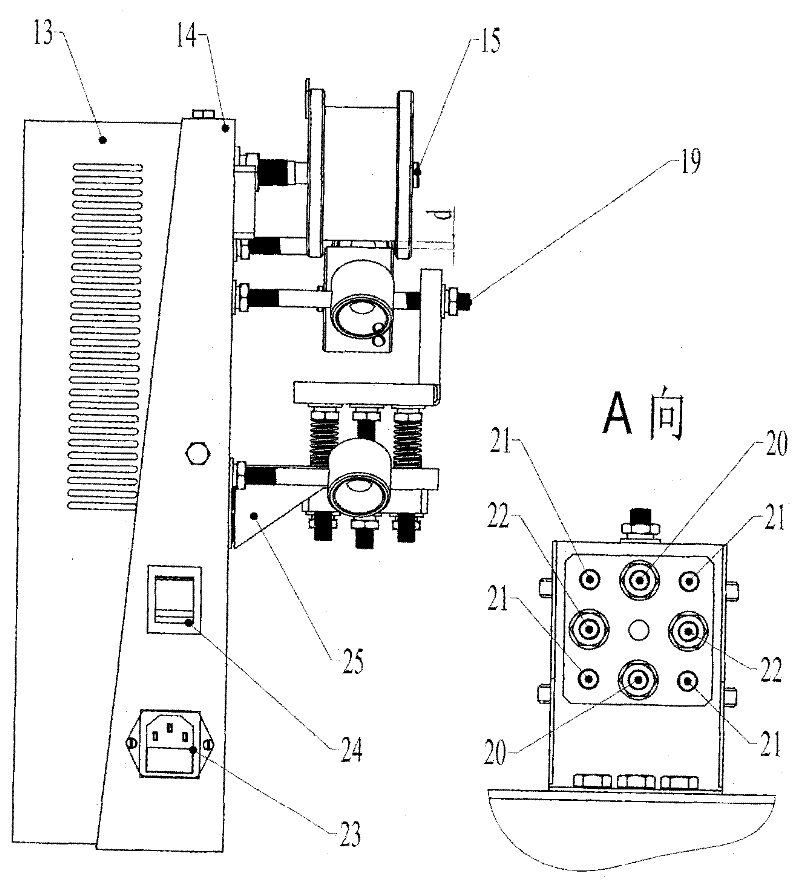

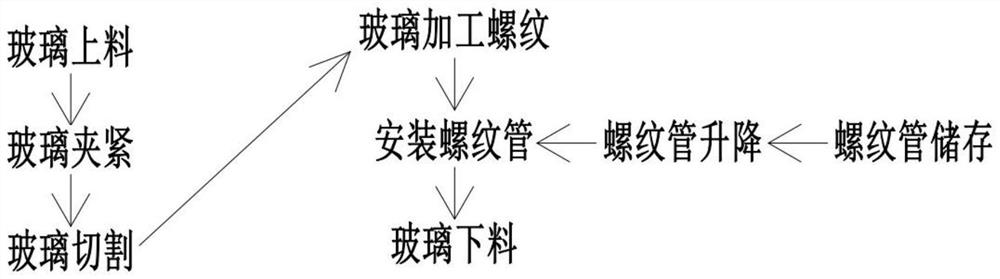

Glass manufacturing process

PendingCN114538763AHave installedWorking accessoriesGlass severing apparatusManufacturing technologyDrive wheel

The invention relates to the field of glass processing, in particular to a glass manufacturing process which comprises the following steps: step 1, cleaning glass and then clamping; 2, the clamped glass is cut, and the removed glass is knocked down; step 3, performing thread processing on the edge of the glass notch; and 4, the threaded pipe is installed at the machined threads, and the glass is taken down. The glass manufacturing process is realized by using a glass manufacturing device, the device comprises a positioning pipe, a waist-shaped rod, a threaded wheel and a driving wheel, the positioning pipe corresponds to the glass cut in the step 2 up and down and is used for loading a threaded pipe, the waist-shaped rod slides on the positioning pipe, the threaded wheel and the driving wheel rotate on the positioning pipe, and the threaded wheel and the driving wheel are in meshing transmission. The threaded wheel and the kidney-shaped rod are in transmission through threads. The threaded pipe can be installed at the center of the glass.

Owner:田宏元

Push-sliding structure used in fully mechanized coal mining face with steeply inclined coal seams

ActiveCN106523012BOvercoming manual repeated up and down support operationsIncrease productivityMine roof supportsAutomatic controlMining engineering

Owner:CHENGDU HANGTIAN PHOTOELECTRIC TECH +1

New Satellite Parking Device

ActiveCN104724299BImprove deformation resistanceImprove corrosion resistanceAircraft assemblyEngineeringParking brake

The invention provides a novel satellite parking device which comprises a rigid connecting ring, adjustable supporting feet, connecting rods, satellite parking connecting rods, a traction rod, a parking frame bottom board, heavy movable wheels, a supporting leg support and an adjusting screw. The rigid connecting ring is connected with the parking frame bottom board through the satellite parking connecting rods, the adjustable supporting feet are connected with the parking frame bottom board and adjacent to the satellite parking connecting rods, the connecting rods are connected with the satellite parking connecting rods, the traction rod is connected to the side face of the parking frame bottom board, the heavy movable wheels are arranged at the lower portion of the parking frame bottom board and connected with the parking frame bottom board, the supporting leg support is arranged in the middle position of the lower portion of the parking frame bottom board and connected with the parking frame bottom board, and the adjusting screw is connected with the supporting leg support. The novel satellite parking device has the advantages of being high in safety, convenient to adjust and high in universality.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Method of producing architectural decorative material and wall bady material using phosphogypsum

InactiveCN100424028CGood weather resistanceImprove corrosion resistanceSolid waste managementFoaming agentPolymer science

A process for preparing wall material or decorative material from ardealite includes washing with water, drying, calcining, grinding, proportionally mixing it with PVC resin and auxiliary, stirring to obtain powdered material, heating to become paste, adding foamer, extruding and vacuum foaming in mould to obtain wall material, or heating while extruding said powdered material to become particles, heating and moulding to become decorative material.

Owner:GUIYANG PENGHONG HIGH NEW TECH DECORATION MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com